Structural and Barrier Properties of Compatibilized PE/PA6 Multinanolayer Films

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

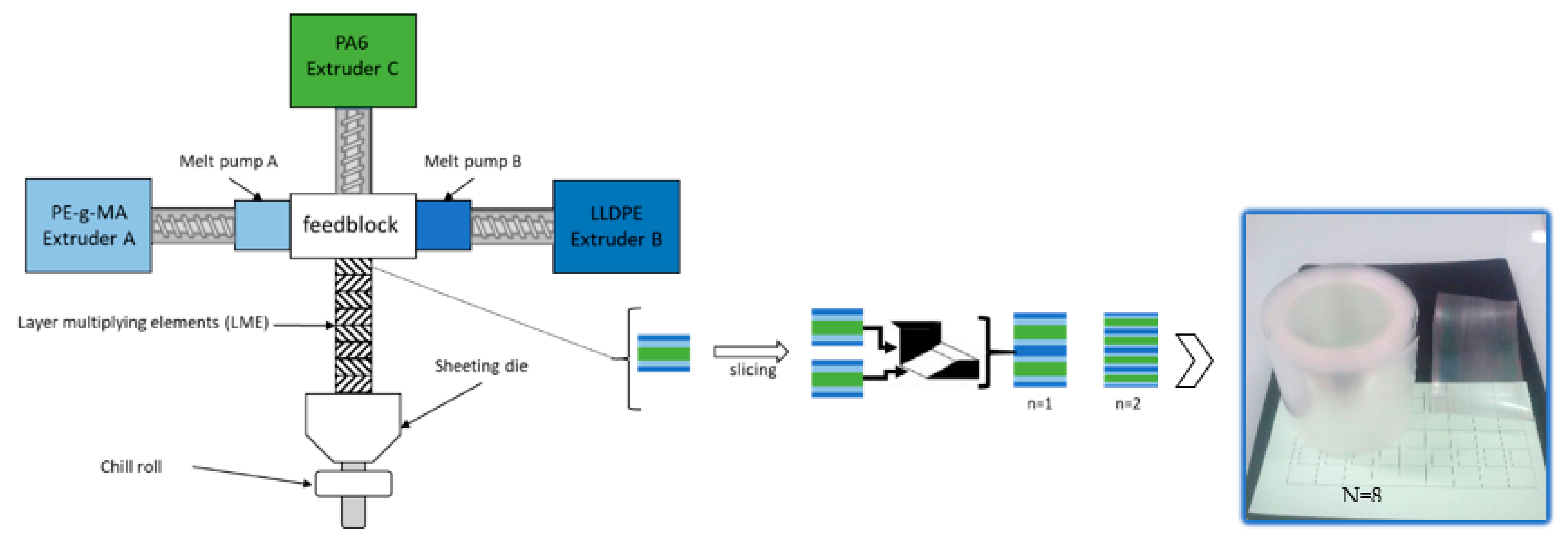

2.2. Coextrusion Process

2.3. Morphological Characterization

2.4. Structural Characterization

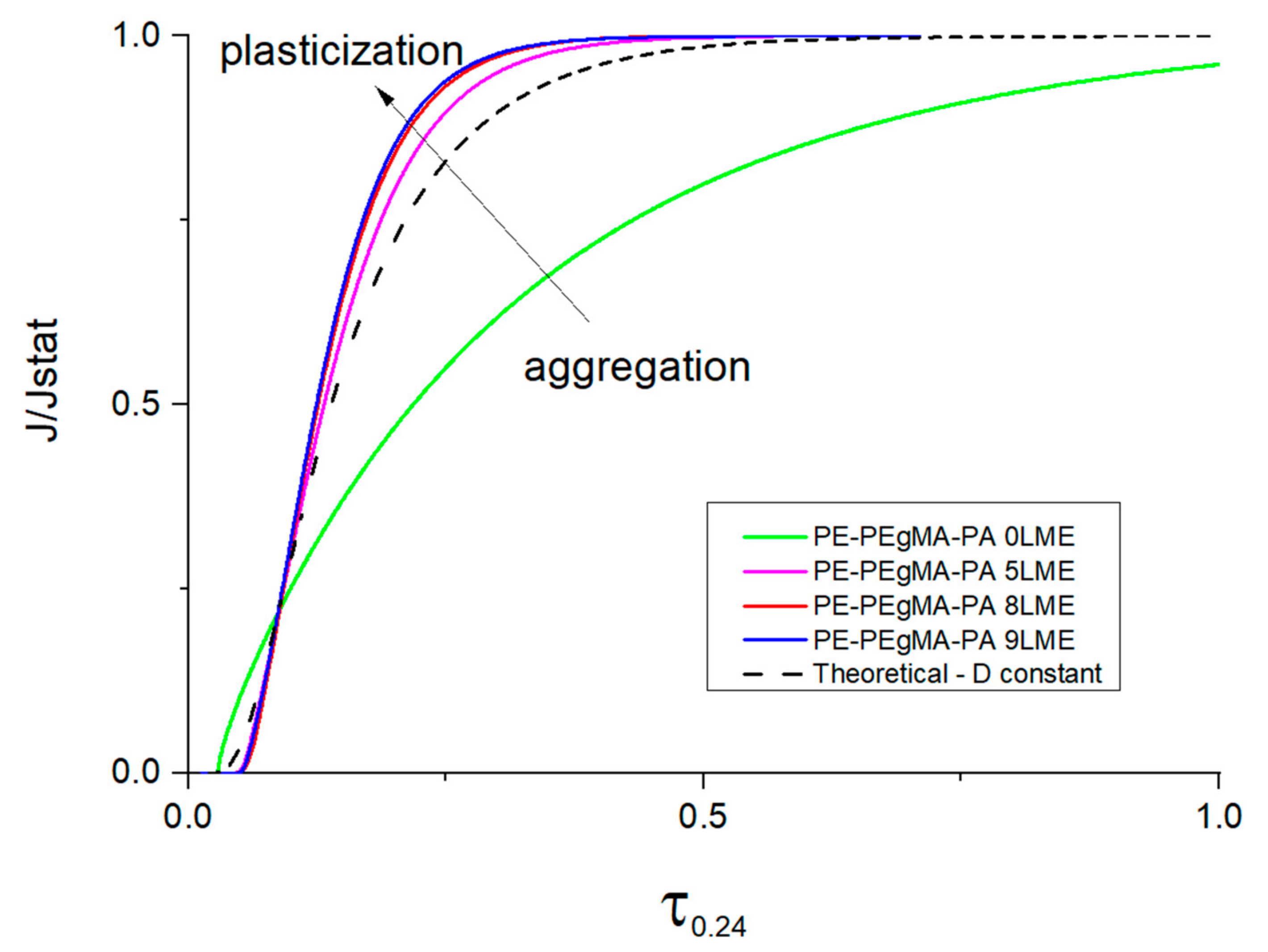

2.5. Transport Properties

2.5.1. Gas Permeation

2.5.2. Water Permeation

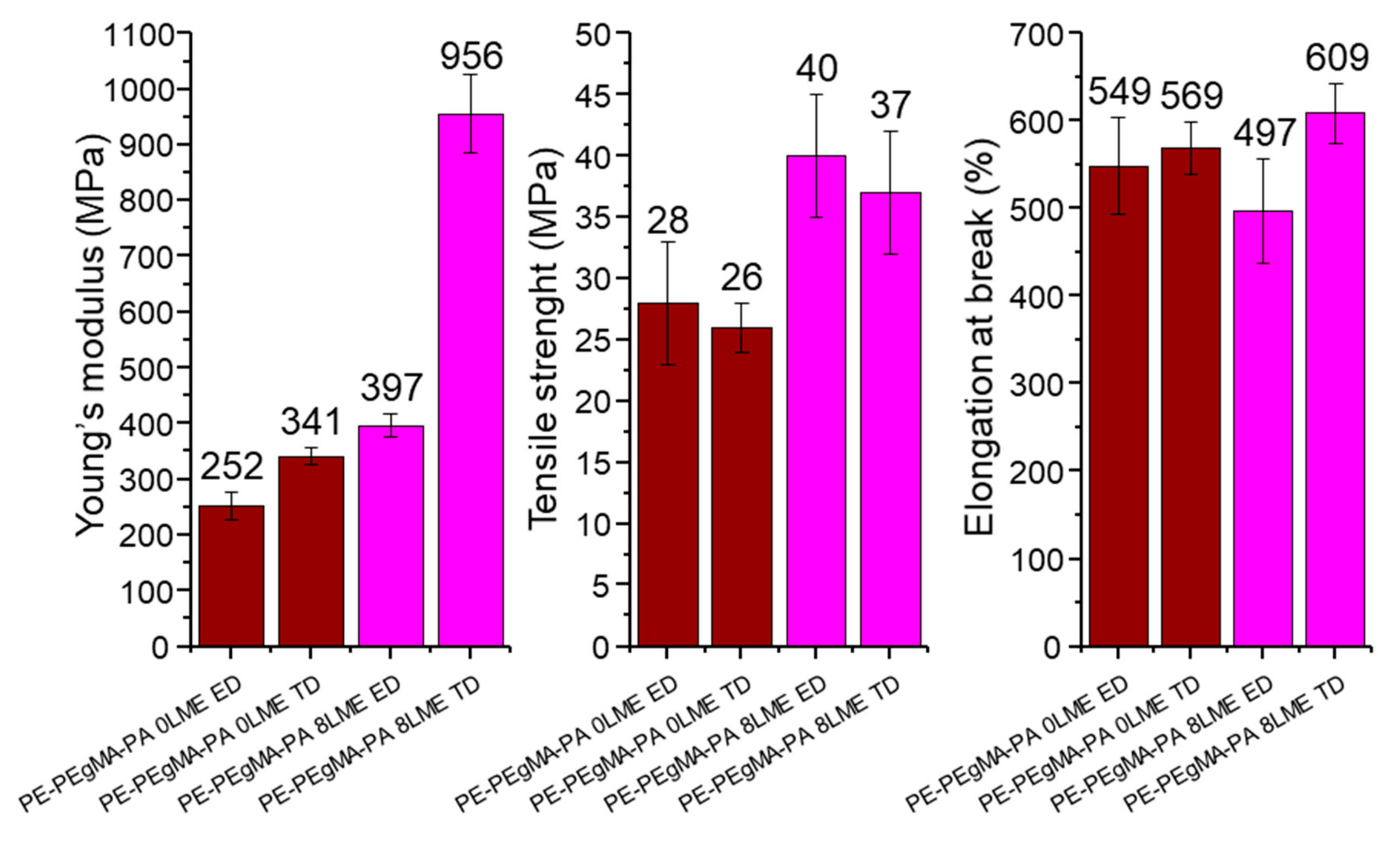

2.6. Mechanical Properties

3. Results and Discussion

3.1. Structural Characterization

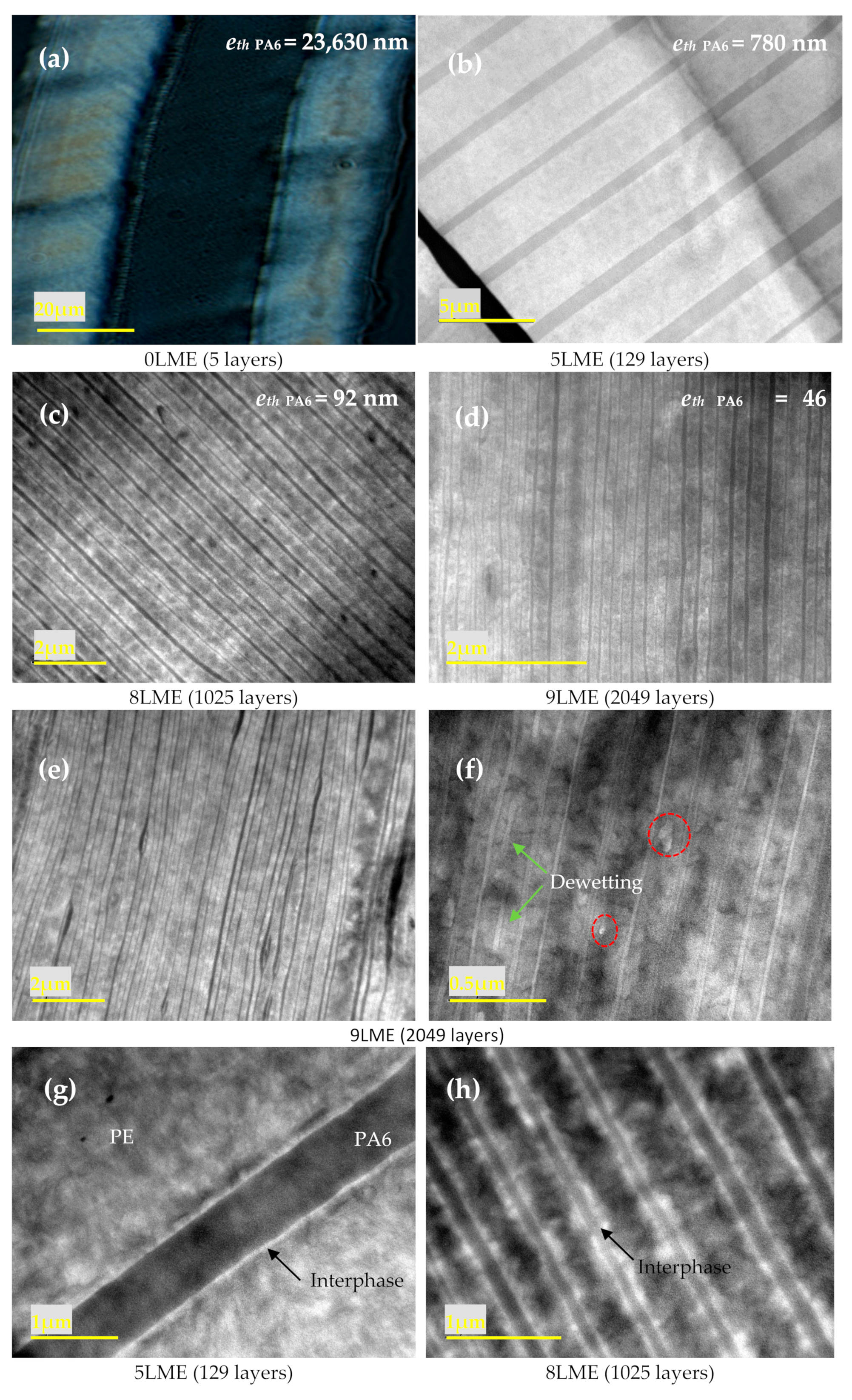

3.1.1. Morphology

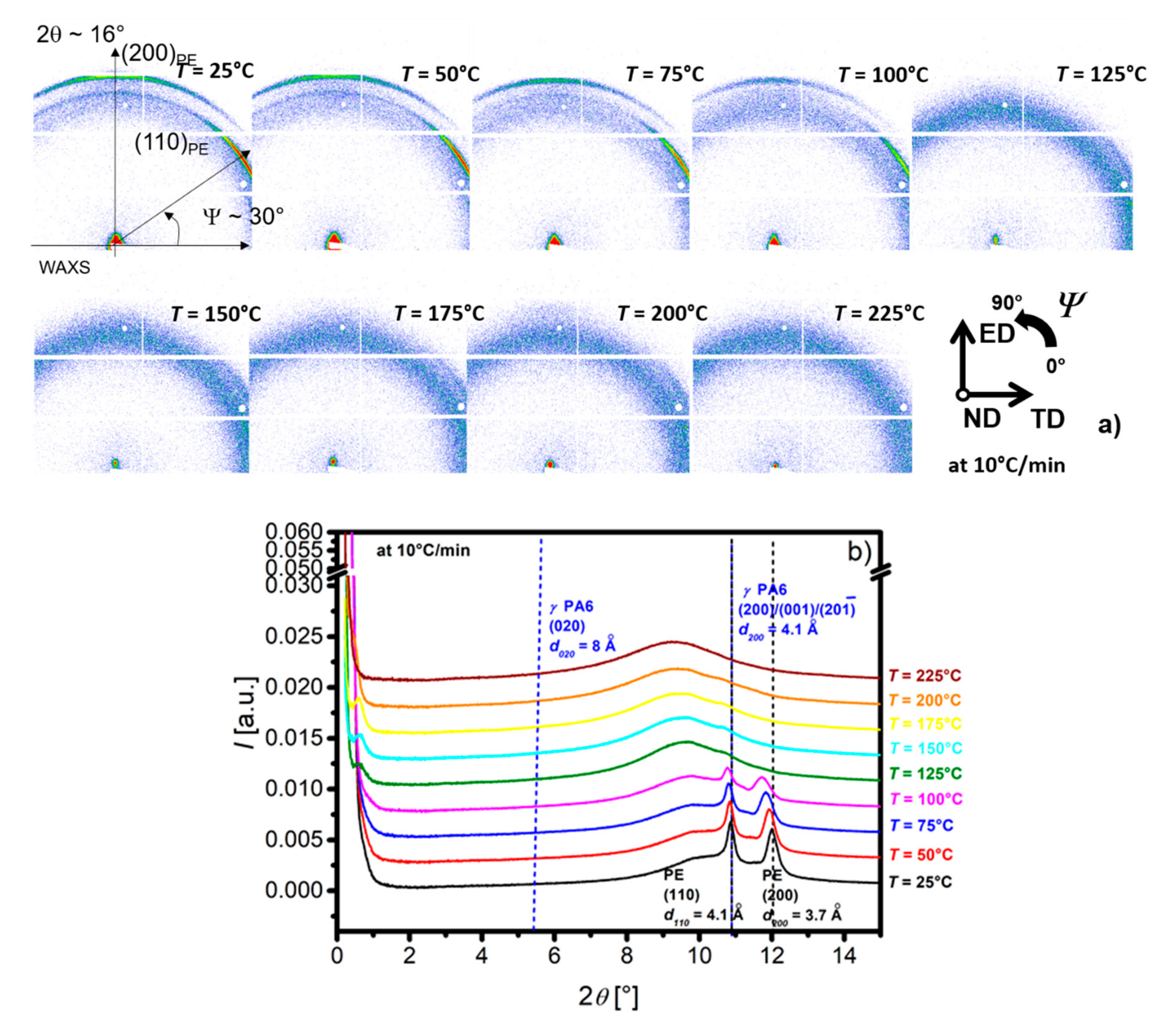

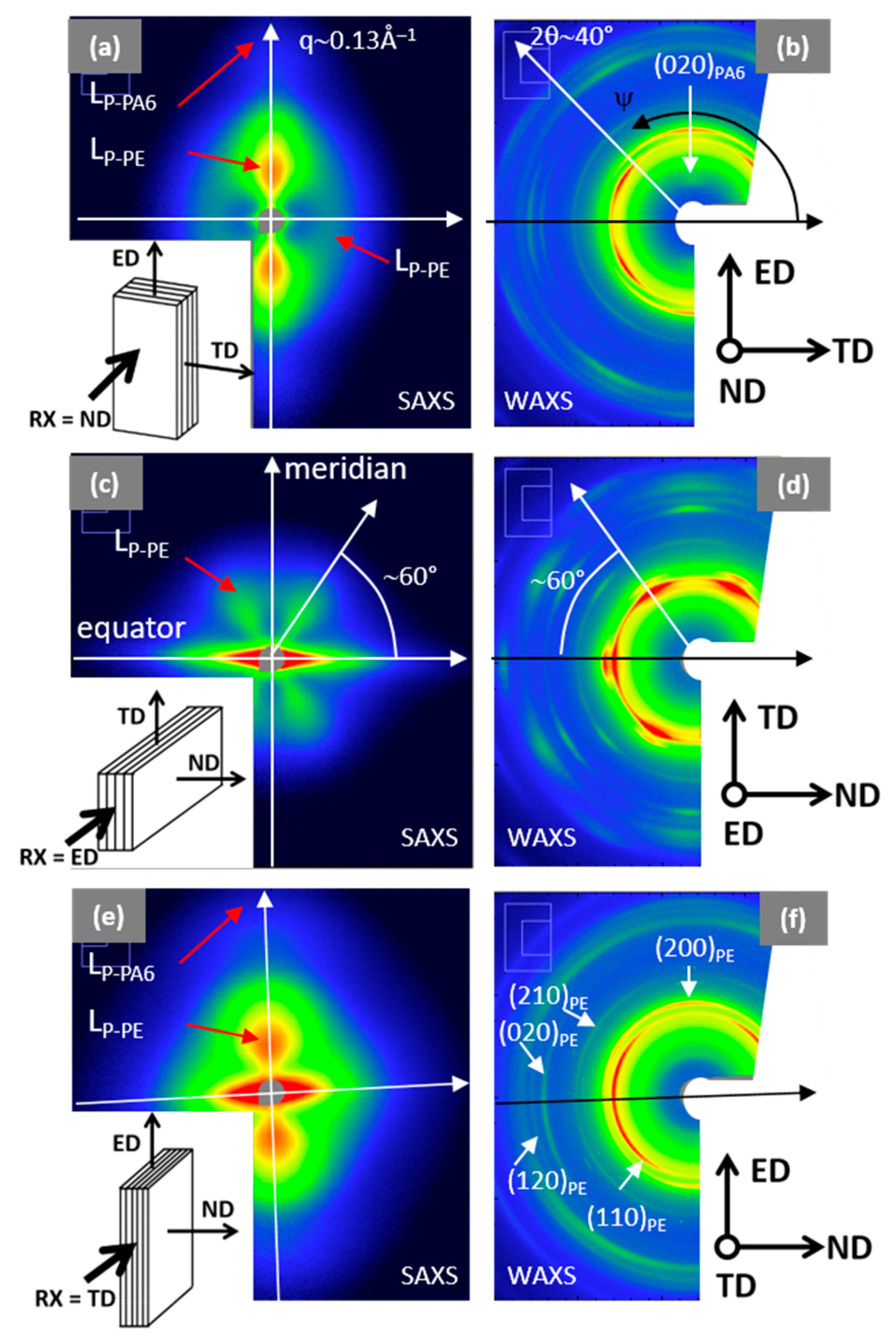

3.1.2. Crystallization

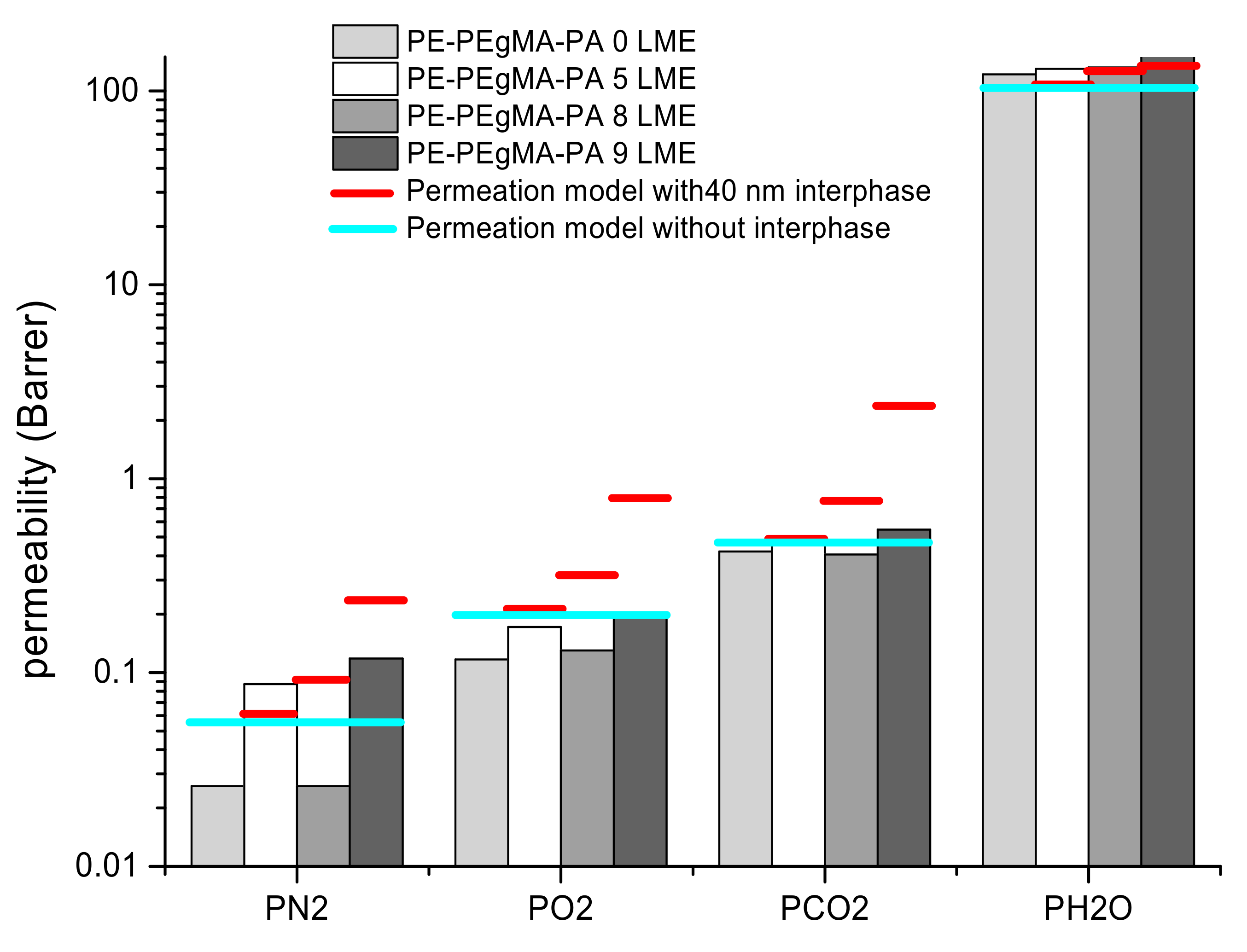

3.2. Transport Properties

3.3. Mechanical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Utracki, L.A. Commercial Polymer Blends; Chapmann and Hall: London, UK, 1998; p. 680. [Google Scholar]

- Anukiruthika, T.; Sethupathy, P.; Wilson, A.; Kashampur, K.; Moses, J.A.; Anandharamakrishnan, C. Multilayer packaging: Advances in preparation techniques and emerging food applications. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1156–1186. [Google Scholar] [CrossRef]

- Wagner, J.R., Jr. Multilayer Flexible Packaging, 2nd ed.; William Andrew: Oxford, UK, 2016. [Google Scholar]

- Pongmuksuwan, P.; Harnnarongchai, W. In Situ Assembly of LDPE/PA6 Multilayer Structure by Stirring. Int. Polym. Process. 2020, 35, 58–69. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, G.; MacInnis, K.; Li, Z.; Olah, A.; Baer, E. Effect of compatibilizer on morphology and properties of HDPE/Nylon 6 blends. J. Polym. Sci. Part B Polym. Phys. 2019, 57, 281–290. [Google Scholar] [CrossRef]

- Wagner, J.R., Jr.; Mount, E.M.; Giles, H.F., Jr. Extrusion: The Definitive Processing Guide and Handbook, Plastics Design Library, 2nd ed.; William Andrew: Oxford, UK, 2014; pp. 449–466. [Google Scholar]

- Turner, A.; Schrenk, W. Multilayer Coextrusion Process for Producing Selective Reflectivity. U.S. Patent 4,094,947, 13 June 1978. [Google Scholar]

- Schrenk, W.J. Multilayer plastic articles. U.S. Patent 3,647,612, 7 March 1972. [Google Scholar]

- Ponting, M.; Hiltner, A.; Baer, E. Polymer Nanostructures by Forced Assembly: Process, Structure, and Properties. Macromol. Symp. 2010, 294, 19–32. [Google Scholar] [CrossRef]

- Bironeau, A.; Salez, T.; Miquelard-Garnier, G.; Sollogoub, C. Existence of a Critical Layer Thickness in PS/PMMA Nanolayered Films. Macromolecules 2017, 50, 4064–4073. [Google Scholar] [CrossRef]

- Ji, S.Z.; Yin, K.Z.; Mackey, M.; Brister, A.; Ponting, M.; Baer, E. Polymeric nanolayered gradient refractive index lenses: Technology review and introduction of spherical gradient refractive index ball lenses. Opt. Eng. 2013, 52, 1–13. [Google Scholar] [CrossRef]

- Burt, T.M.; Jordan, A.M.; Korley, L.T.J. Toward Anisotropic Materials via Forced Assembly Coextrusion. ACS Appl. Mater. Interfaces 2012, 4, 5155–5161. [Google Scholar] [CrossRef]

- Montana, J.-S.; Roland, S.; Richaud, E.; Miquelard-Garnier, G. Nanostructuration effect on the mechanical properties of PMMA toughened by a triblock acrylate copolymer using multilayer coextrusion. Polymer 2018, 149, 124–133. [Google Scholar] [CrossRef]

- Messin, T.; Follain, N.; Guinault, A.; Sollogoub, C.; Gaucher, V.; Delpouve, N.; Marais, S. Structure and Barrier Properties of Multinanolayered Biodegradable PLA/PBSA Films: Confinement Effect via Forced Assembly Coextrusion. ACS Appl. Mater. Interfaces 2017, 9, 29101–29112. [Google Scholar] [CrossRef]

- Boufarguine, M.; Guinault, A.; Miquelard-Garnier, G.; Sollogoub, C. PLA/PHBV Films with Improved Mechanical and Gas Barrier Properties. Macromol. Mater. Eng. 2012, 298, 1065–1073. [Google Scholar] [CrossRef]

- Michell, R.M.; Müller, A.J. Confined crystallization of polymeric materials. Prog. Polym. Sci. 2016, 183–213. [Google Scholar] [CrossRef]

- Zhang, G.; Lee, P.C.; Jenkins, S.; Dooley, J.; Baer, E. The effect of confined spherulite morphology of high-density polyethylene and polypropylene on their gas barrier properties in multilayered film systems. Polymer 2014, 55, 4521–4530. [Google Scholar] [CrossRef]

- Mackey, M.; Flandin, L.; Hiltner, A.; Baer, E. Confined crystallization of PVDF and a PVDF-TFE copolymer in nanolayered films. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1750–1761. [Google Scholar] [CrossRef]

- Messin, T.; Marais, S.; Follain, N.; Guinault, A.; Gaucher, V.; Delpouve, N.; Sollogoub, C. Biodegradable PLA/PBS multinanolayer membrane with enhanced barrier performances. J. Membr. Sci. 2020, 598, 117777. [Google Scholar] [CrossRef]

- Nassar, S.F.; Delpouve, N.; Sollogoub, C.; Guinault, A.; Stoclet, G.; Régnier, G.; Domenek, S. Impact of Nanoconfinement on Polylactide Crystallization and Gas Barrier Properties. ACS Appl. Mater. Interfaces 2020, 12, 9953–9965. [Google Scholar] [CrossRef]

- Sha, H.; Harrison, I.R. CO2 permeability and amorphous fractional free-volume in uniaxially drawn HDPE. J. Polym. Sci. Part B Polym. Phys. 1992, 30, 915–922. [Google Scholar] [CrossRef]

- Parodi, E.; Peters, G.; Govaert, L.E. Structure-Properties Relations for Polyamide 6, Part 1: Influence of the Thermal History during Compression Moulding on Deformation and Failure Kinetics. Polymer 2018, 10, 710. [Google Scholar] [CrossRef]

- Olivier, L.; Sabard, M.; Fulchiron, R.; Espuche, E.; David, L.; Guiu, A. Influence of a-ZrP fillers and process conditions on the morphology and the gas barrier properties of filled polyamide 6 films. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 1734–1746. [Google Scholar] [CrossRef]

- Lei, F.; Du, Q.; Li, T.; Li, J.; Guo, S. Effect of phase morphology and interfacial strength on barrier properties of high density polyethylene/polyamide 6 membranes. Polym. Eng. Sci. 2013, 53, 1996–2003. [Google Scholar] [CrossRef]

- Bironeau, A.; Dirrenberger, J.; Sollogoub, C.; Miquelard-Garnier, G.; Roland, S. Evaluation of morphological representative sample sizes for nanolayered polymer blends. J. Microsc. 2016, 264, 48–58. [Google Scholar] [CrossRef]

- Mathot, V.; Pijpers, M. Heat capacity, enthalpy and crystallinity of polymers from DSC measurements and determination of the DSC peak base line. Thermochim. Acta 1989, 151, 241–259. [Google Scholar] [CrossRef]

- Durmuş, A.; Woo, M.; Kaşgöz, A.; Macosko, C.W.; Tsapatsis, M. Intercalated linear low density polyethylene (LLDPE)/clay nanocomposites prepared with oxidized polyethylene as a new type compatibilizer: Structural, mechanical and barrier properties. Eur. Polym. J. 2007, 43, 3737–3749. [Google Scholar] [CrossRef]

- Illers, K.H. Polymorphie, kristallinität und schmelzwärme von poly(e-caprolactam) 2. Kalorimetrische untersuchungen. Die Makromol. Chem. 1978, 179, 497–507. [Google Scholar] [CrossRef]

- Tencé-Girault, S.; Lebreton, S.; Bunau, O.; Dang, P.; Bargain, F. Simultaneous SAXS-WAXS Experiments on Semi-Crystalline Polymers: Example of PA11 and Its Brill Transition. Crystals 2019, 9, 271. [Google Scholar] [CrossRef]

- Alexandre, B.; Colasse, L.; Langevin, D.; Médéric, P.; Aubry, T.; Chappey, C.; Marais, S. Transport Mechanisms of Small Molecules through Polyamide 12/Montmorillonite Nanocomposites. J. Phys. Chem. B 2010, 114, 8827–8837. [Google Scholar] [CrossRef] [PubMed]

- Métayer, M.; Labbé, M.; Marais, S.; Langevin, D.; Chappey, C.; Dreux, F.; Brainville, M.; Belliard, P. Diffusion of water through various polymer films: A new high performance method of characterization. Polym. Test. 1999, 18, 533–549. [Google Scholar] [CrossRef]

- Li, H.; Chiba, T.; Higashida, N.; Yang, Y.; Inoue, T. Polymer-polymer interface in polypropylene/polyamide blends by reactive processing. Polymer 1997, 38, 3921–3925. [Google Scholar] [CrossRef]

- Beuguel, Q.; Guinault, A.; Léger, L.; Restagno, F.; Sollogoub, C.; Miquelard-Garnier, G. Nanorheology with a Conventional Rheometer: Probing the Interfacial Properties in Compatibilized Multinanolayer Polymer Films. ACS Macro Lett. 2019, 8, 1309–1315. [Google Scholar] [CrossRef]

- Abu-Isa, I. α−γ transition in nylon 6. J. Polym. Sci. Part A-1 Polym. Chem. 1971, 9, 199–216. [Google Scholar] [CrossRef]

- Bunn, C.W. The crystal structure of long-chain normal paraffin hydrocarbons. The “shape” of the CH2 group. Trans. Faraday Soc. 1939, 35, 482–491. [Google Scholar] [CrossRef]

- Holmes, D.R.; Bunn, C.W.; Smith, D.J. The crystal structure of polycaproamide: Nylon 6. J. Polym. Sci. 1955, 17, 159–177. [Google Scholar] [CrossRef]

- Arimoto, H.; Ishibashi, M.; Hirai, M.; Chatani, Y. Crystal structure of the γ-form of nylon 6. J. Polym. Sci. Part A Gen. Pap. 1965, 3, 317–326. [Google Scholar] [CrossRef]

- Muratoǧlu, O.; Argon, A.; Cohen, R.; Muratoglu, O. Crystalline morphology of polyamide-6 near planar surfaces. Polymer 1995, 36, 2143–2152. [Google Scholar] [CrossRef]

- Zhong, L.-W.; Ren, X.-K.; Yang, S.; Chen, E.-Q.; Sun, C.-X.; Stroeks, A.; Yang, T.-Y. Lamellar orientation of polyamide 6 thin film crystallization on solid substrates. Polymer 2014, 55, 4332–4340. [Google Scholar] [CrossRef]

- Mohr, J.M.; Paul, D.R. Comparison of gas permeation in vinyl and vinyldiene polymers. J. Appl. Polym. Sci. 1991, 42, 1711–1720. [Google Scholar] [CrossRef]

- Devallencourt, C.; Marais, S.; Saiter, J.M.; Labbé, M.; Métayer, M. Study of transport af small molecules through ethylene-co-vinyl acetate copolymer films. Part A: Water molecules. Polym. Test. 2002, 21, 253–262. [Google Scholar] [CrossRef]

- Kim, Y.J.; Han, C.D.; Song, B.K.; Kouassi, E. Mechanical and transport properties of coextruded films. J. Appl. Polym. Sci. 1984, 29, 2359–2382. [Google Scholar] [CrossRef]

- Massey, K.L. Permeability Properties of Plastics and Elastomers: A Guide to Packaging and Barrier Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Alix, S.; Follain, N.; Tenn, N.; Alexandre, B.; Bourbigot, S.; Soulestin, J.; Marais, S. Effect of Highly Exfoliated and Oriented Organoclays on the Barrier Properties of Polyamide 6 Based Nanocomposites. J. Phys. Chem. C 2012, 116, 4937–4947. [Google Scholar] [CrossRef]

- Miri, V.; Persyn, O.; Lefebvre, J.-M.; Seguela, R. Effect of water absorption on the plastic deformation behavior of nylon 6. Eur. Polym. J. 2009, 45, 757–762. [Google Scholar] [CrossRef]

- Sabard, M.; Gouanvé, F.; Espuche, E.; Fulchiron, R.; Seytre, G.; Fillot, L.-A.; Trouillet-Fonti, L. Influence of montmorillonite and film processing conditions on the morphology of polyamide 6: Effect on ethanol and toluene barrier properties. J. Membr. Sci. 2014, 450, 487–498. [Google Scholar] [CrossRef]

- Liu, R.Y.F.; Bernal-Lara, T.E.; Hiltner, A.; Baer, E. Polymer interphase materials by forced assembly. Macromolecules 2005, 38, 4819–4827. [Google Scholar] [CrossRef]

- Marais, S.; Nguyen, Q.; Devallencourt, C.; Métayer, M.; Nguyen, T.U.; Schaetzel, P. Permeation of water through polar and nonpolar polymers and copolymers: Determination of the concentration-dependent diffusion coefficient. J. Polym. Sci. Part B Polym. Phys. 2000, 38, 1998–2008. [Google Scholar] [CrossRef]

- Lyu, S.-P.; Cernohous, J.J.; Bates, F.S.; Macosko, C.W. Interfacial Reaction Induced Roughening in Polymer Blends. Macromolecules 1999, 32, 106–110. [Google Scholar] [CrossRef]

- Orr, C.; Cernohous, J.J.; Guegan, P.; Jeon, H.K.; Macosko, C.W. Homogeneous reactive coupling of terminally functional polymers. Polymer 2001, 42, 8171–8178. [Google Scholar] [CrossRef]

- Hopfenberg, H.B.; Paul, D.R. Polymer Blends; Paul, D.R., Newman, S., Eds.; Academic Press Inc.: New York, NY, USA, 1978; p. 445. [Google Scholar]

- Paul, D.R.; Bucknall, C.B. Polymer Blends; Wiley: New York, NY, USA, 2000; Volume 1–2. [Google Scholar]

| PE/PEgMA/PA6 | Tmmax (°C) | ΔH (J/g) | Xc (%) | |||

|---|---|---|---|---|---|---|

| PE | PA6 | PE | PA6 | PE | PA6 | |

| 5 layers (0LME) | 124 | 220 | 726 | 162 | 38 ± 5 | 30 ± 5 |

| 129 layers (5LME) | 124 | 220 | 719 | 131 | 38 ± 5 | 24 ± 5 |

| 1025 layers (8LME) | 124 | 219 | 735 | 207 | 39 ± 5 | 38 ± 5 |

| 2049 layers (9LME) | 123 | 218 | 617 | 96 | 40 ± 5 | 22 ± 5 |

| Permeability Coefficients (Barrer *) | ||||||

|---|---|---|---|---|---|---|

| N2 | O2 | CO2 | H2O | |||

| PE 0LME (5 Layers) | 1.78 | 5.55 | 23.9 | 91 | ||

| PE 8LME (1025 Layers) | 1.73 | 5.42 | 22.7 | 91 | ||

| PEgMA 0LME (5 Layers) | 1.2 | 3.77 | 16.6 | 81 | ||

| PEgMA 8LME (1025 Layers) | 1.54 | 4.92 | 20.2 | 83 | ||

| PA6 0LME (5 Layers) | 0.015 | 0.038 | 0.089 | 4128 | ||

| PA6 8LME (1025 Layers) | 0.013 | 0.035 | 0.08 | 6653 | ||

| PEm/PA6 interphase (predicted) | 0.12 | 0.41 | 1.42 | 430 | ||

| PEm = mixed PE/PEgMA (predicted) | 1.46 | 4.57 | 19.9 | 89 | ||

| PE/PEgMA/PA6 multilayers | ||||||

| 0LME (5 Layers) | Experimental | 0.028 ± 0.001 | 0.117 ± 0.006 | 0.421 ± 0.020 | 122 ± 38 | |

| Predicted (Equation (4)) | 0.056 | 0.199 | 0.462 | 112 | ||

| Predicted (Equation (5)) | 0.056 | 0.200 | 0.463 | 113 | ||

| BIF ** (%) | 50 ± 2 50 ± 2 | 41 ± 3 41 ± 3 | 9 ± 4 9 ± 4 | −9 ± 34 −8 ± 34 | ||

| 5LME (129 Layers) | Experimental | 0.087 ± 0.014 | 0.172 ± 0.040 | 0.466 ± 0.080 | 130 ± 46 | |

| Predicted (Equation (4)) | 0.056 | 0.199 | 0.462 | 112 | ||

| Predicted (Equation (5)) | 0.059 | 0.209 | 0.487 | 114 | ||

| BIF ** (%) | −55 ± 25 −47 ± 23 | 14 ± 20 18 ± 19 | −1 ± 17 4 ± 16 | −16 ± 41 −14 ± 40 | ||

| 8LME (1025 Layers) | Experimental | 0.032 ± 0.010 | 0.130 ± 0.040 | 0.407 ± 0.100 | 132 ± 54 | |

| Predicted (Equation (4)) | 0.056 | 0.199 | 0.462 | 112 | ||

| Predicted (Equation (5)) | 0.091 | 0.319 | 0.775 | 123 | ||

| BIF ** (%) | 43 ± 18 65 ± 11 | 35 ± 20 59 ± 13 | 12 ± 22 48 ± 13 | −18 ± 48 −7 ± 44 | ||

| 9LME (2049 Layers) | Experimental | 0.118 ± 0.010 | 0.196 ± 0.020 | 0.546 ± 0.060 | 163 ± 32 | |

| Predicted (Equation (4)) | 0.056 | 0.199 | 0.462 | 112 | ||

| Predicted (Equation (5)) | 0.236 | 0.790 | 2.394 | 134 | ||

| BIF ** (%) | −110 ± 18 50 ± 4 | 2 ± 10 75 ± 2 | −18 ± 13 77 ± 3 | −46 ± 29 −22 ± 20 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lozay, Q.; Beuguel, Q.; Follain, N.; Lebrun, L.; Guinault, A.; Miquelard-Garnier, G.; Tencé-Girault, S.; Sollogoub, C.; Dargent, E.; Marais, S. Structural and Barrier Properties of Compatibilized PE/PA6 Multinanolayer Films. Membranes 2021, 11, 75. https://doi.org/10.3390/membranes11020075

Lozay Q, Beuguel Q, Follain N, Lebrun L, Guinault A, Miquelard-Garnier G, Tencé-Girault S, Sollogoub C, Dargent E, Marais S. Structural and Barrier Properties of Compatibilized PE/PA6 Multinanolayer Films. Membranes. 2021; 11(2):75. https://doi.org/10.3390/membranes11020075

Chicago/Turabian StyleLozay, Quentin, Quentin Beuguel, Nadège Follain, Laurent Lebrun, Alain Guinault, Guillaume Miquelard-Garnier, Sylvie Tencé-Girault, Cyrille Sollogoub, Eric Dargent, and Stéphane Marais. 2021. "Structural and Barrier Properties of Compatibilized PE/PA6 Multinanolayer Films" Membranes 11, no. 2: 75. https://doi.org/10.3390/membranes11020075

APA StyleLozay, Q., Beuguel, Q., Follain, N., Lebrun, L., Guinault, A., Miquelard-Garnier, G., Tencé-Girault, S., Sollogoub, C., Dargent, E., & Marais, S. (2021). Structural and Barrier Properties of Compatibilized PE/PA6 Multinanolayer Films. Membranes, 11(2), 75. https://doi.org/10.3390/membranes11020075