High Breakdown Strength and Energy Storage Density in Aligned SrTiO3@SiO2 Core–Shell Platelets Incorporated Polymer Composites

Abstract

:1. Introduction

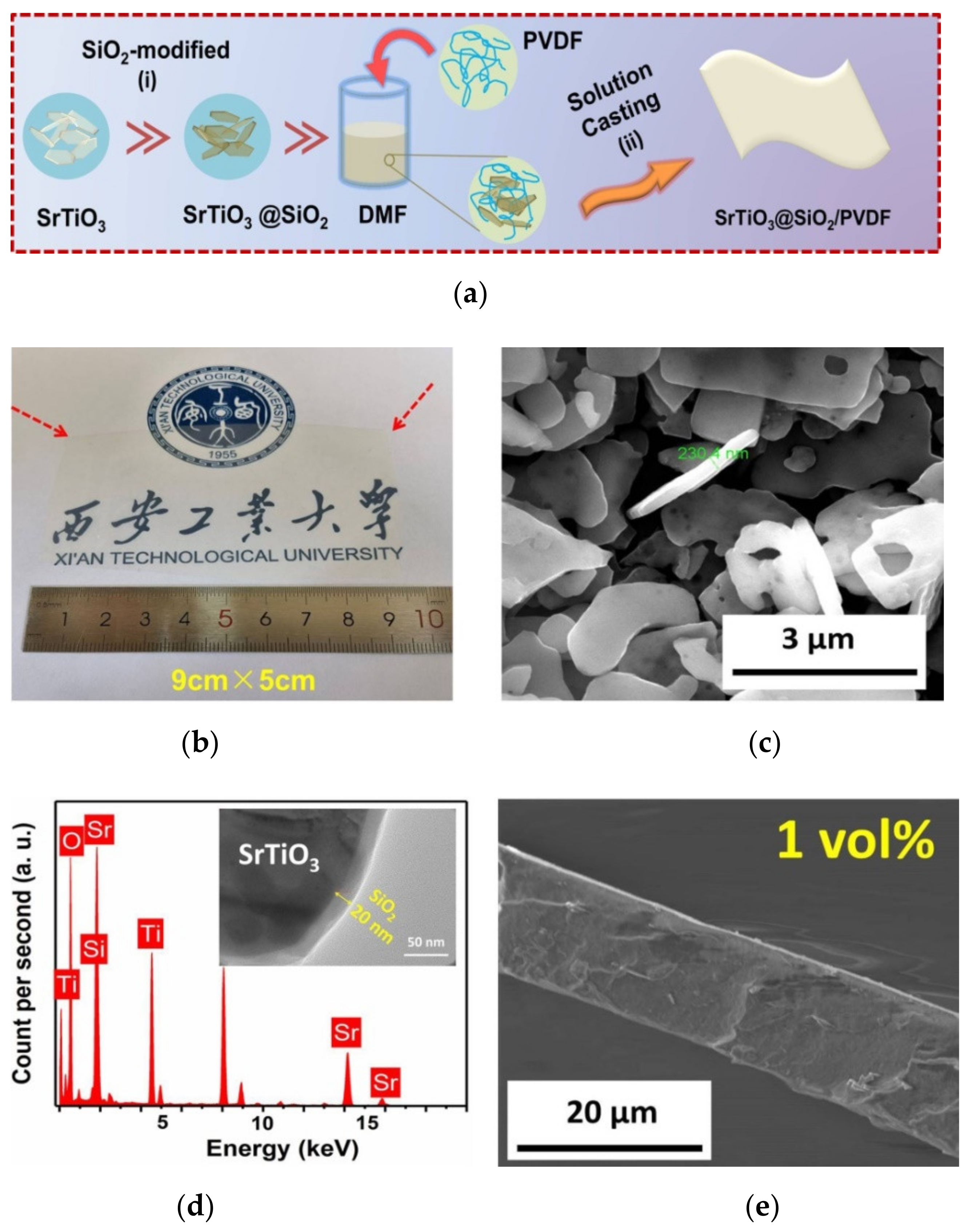

2. Materials and Methods

2.1. Synthesis of SrTiO3@SiO2 Platelets

2.2. Fabrication of the Composites

2.3. Characterization

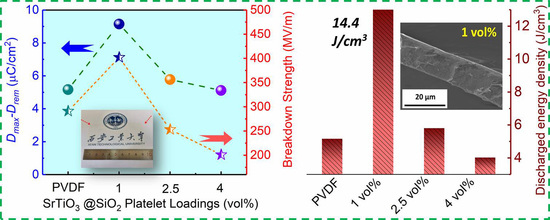

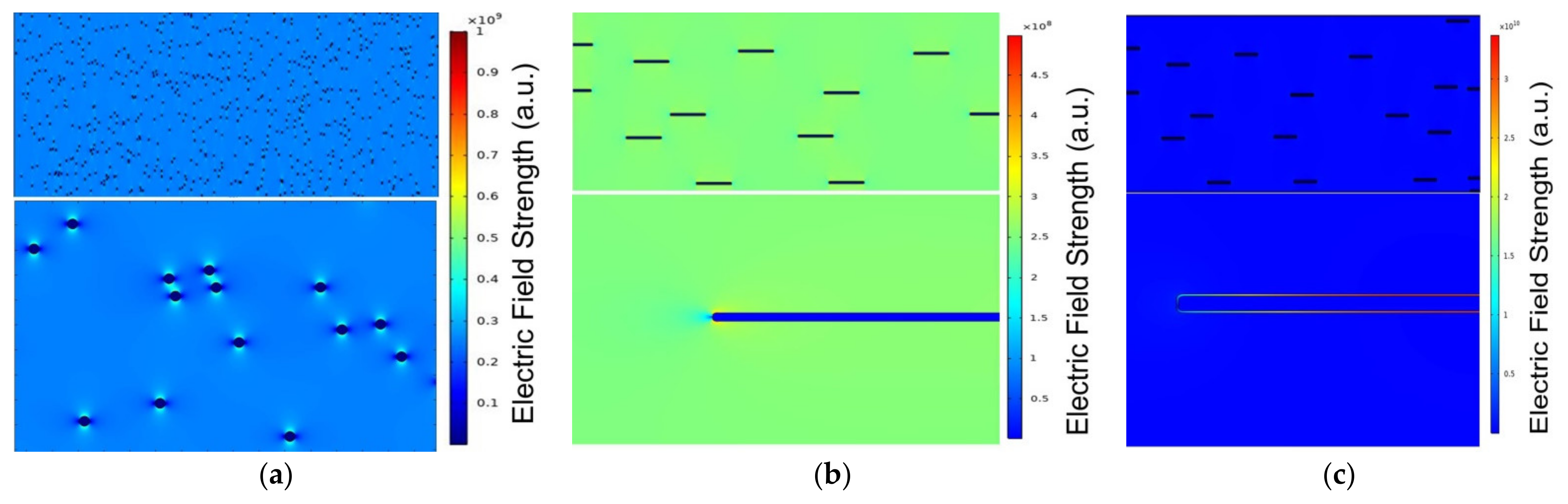

3. Results and Discussion

3.1. Structural and Morphology Characterization

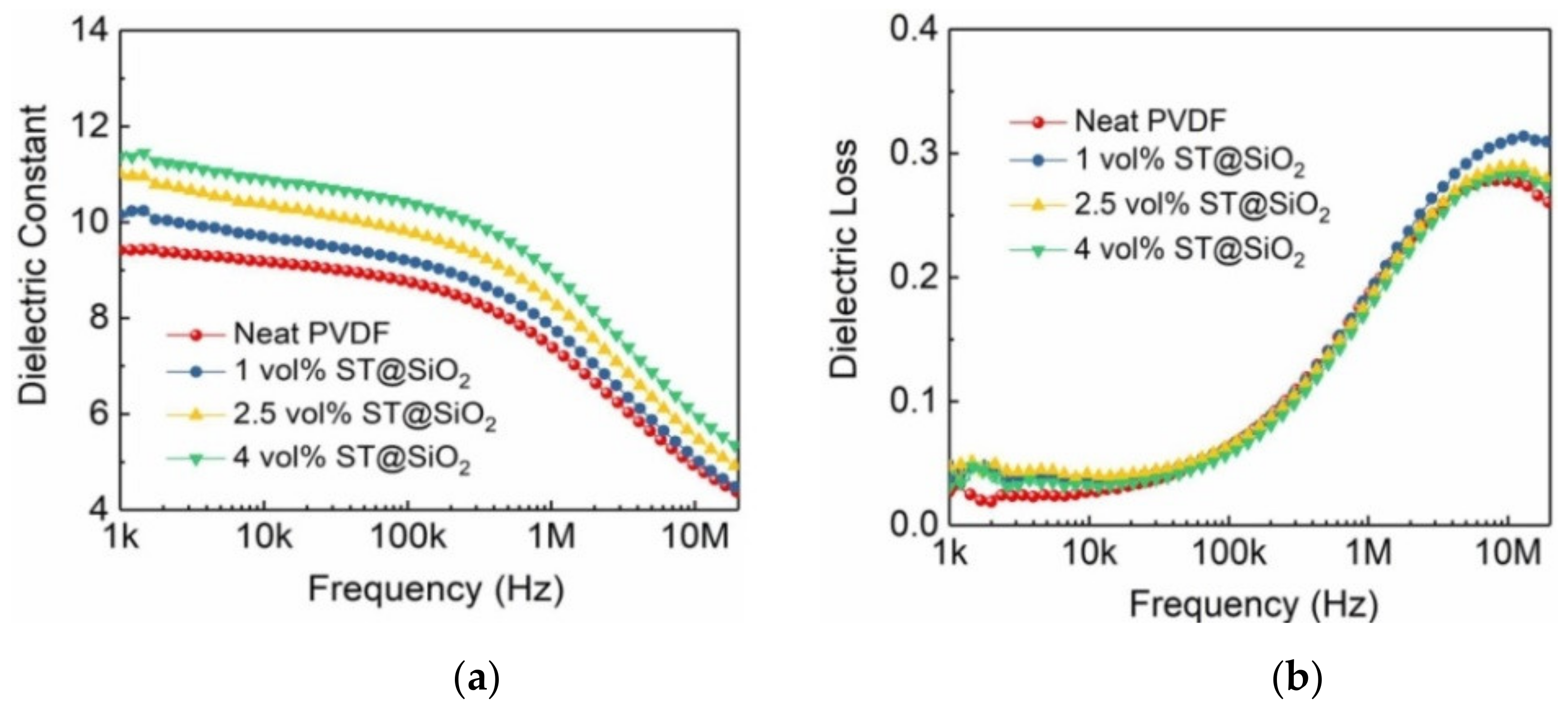

3.2. Weak-Field Dielectric Characteristics

3.3. Weibull Breakdown Field Distribution

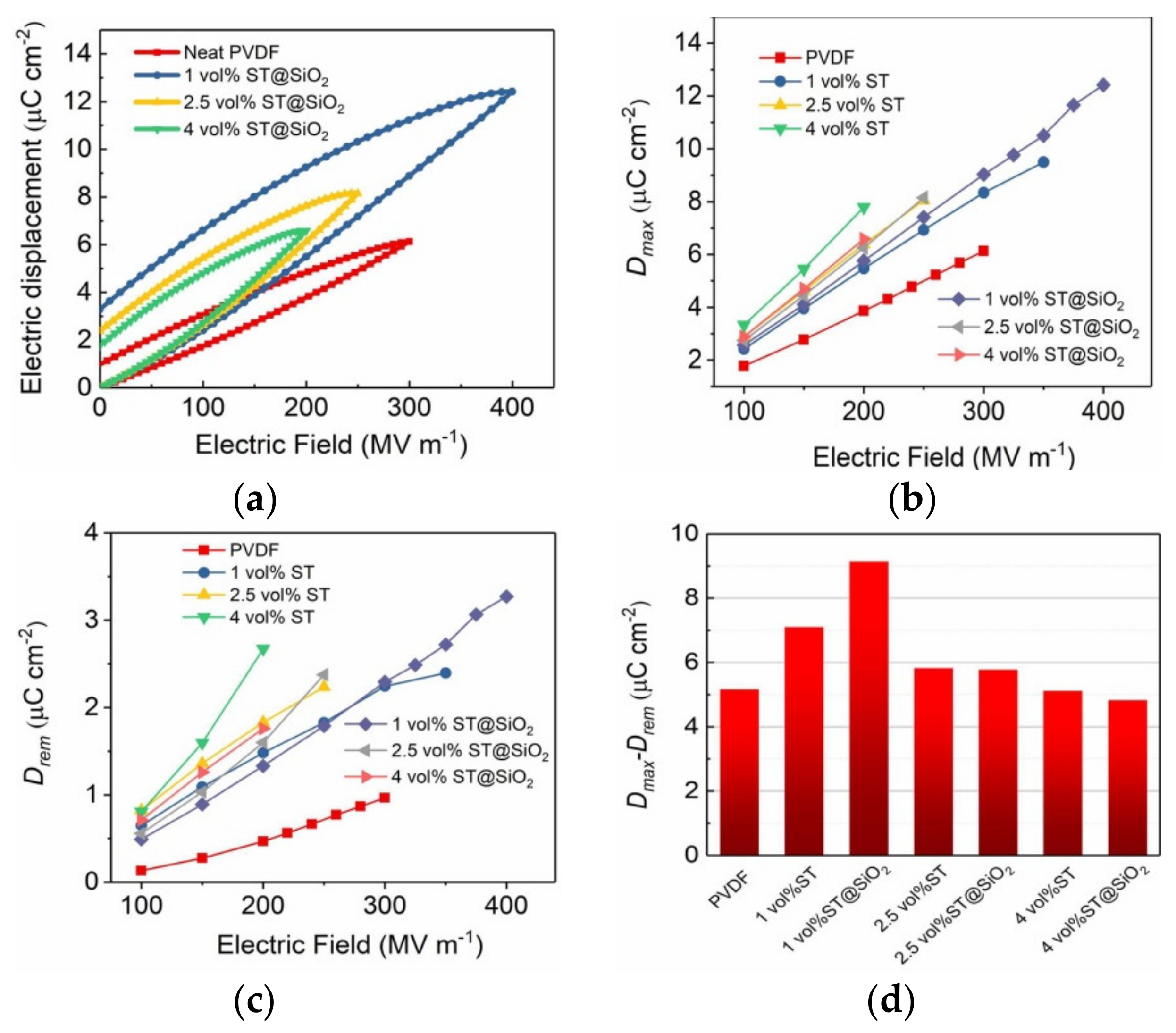

3.4. Electrical Displacement

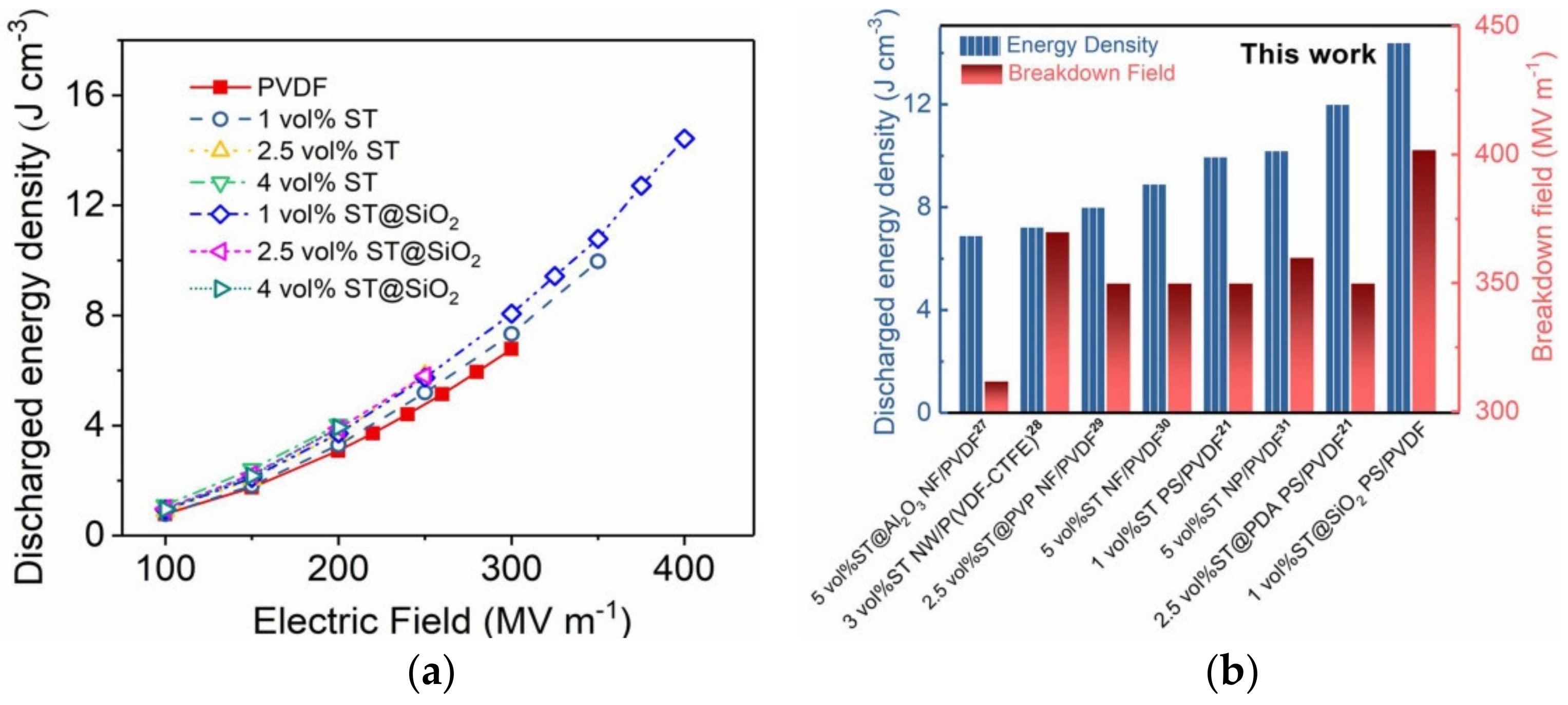

3.5. Capacitive Energy-Storage Capability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, H.; Gadinski, M.R.; Huang, Y.Q.; Ren, L.L.; Zhou, Y.; Ai, D.; Han, Z.B.; Yao, B.; Wang, Q. Crosslinked Fluoropolymers Exhibiting Superior High-Temperature Energy Density and Charge-Discharge Efficiency. Energy Environ. Sci. 2020, 13, 1279–1286. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Chen, L.; Gadinski, M.R.; Zhang, S.H.; Zhang, G.Z.; Li, H.Y.; Haque, A.; Chen, L.Q.; Jackson, T.; Wang, Q. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef]

- Hu, H.L.; Zhang, F.; Lim, S.; Blanloeuil, P.; Yao, Y.; Guo, Y.; Wang, C.H. Surface functionalisation of carbon nanofiber and barium titanate by polydopamine to enhance the energy storage density of their nanocomposites. Compos. B. Eng. 2019, 178, 107459. [Google Scholar] [CrossRef]

- Wang, Y.F.; Li, Z.Z.; Wu, C.; Cao, Y. High-Temperature Dielectric Polymer Nanocomposites with Interposed Montmorillonite Nanosheets. Chem. Eng. J. 2020, 401, 126093. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, X.; Ren, G.K.; Jiang, J.J.; Dan, Z.K.; Zhang, Q.H.; Zhang, X.; Nan, C.W.; Shen, Y. Non-intuitive concomitant enhancement of dielectric permittivity, breakdown strength and energy density in percolative polymer nanocomposites by trace Ag nanodots. J. Mater. Chem. A 2019, 7, 15198–15206. [Google Scholar] [CrossRef]

- Ai, D.; Li, H.; Zhou, Y.; Ren, L.L.; Han, Z.B.; Yao, B.; Zhou, W.; Zhao, L.; Xu, J.M.; Wang, Q. Tuning Nanofillers in In Situ Prepared Polyimide Nanocomposites for High-Temperature Capacitive Energy Storage. Adv. Energy. Mater. 2020, 10, 1903881. [Google Scholar] [CrossRef]

- Dong, J.F.; Hu, R.C.; Xu, X.W.; Chen, J.; Niu, Y.J.; Wang, F.; Hao, J.Y.; Wu, K.; Wang, Q.; Wang, H. A facile in situ surface-functionalization approach to scalable laminated high-temperature polymer dielectrics with ultrahigh capacitive performance. Adv. Funct. Mater. 2021, 31, 2102644. [Google Scholar] [CrossRef]

- Li, W.J.; Meng, Q.J.; Zheng, Y.S.; Zhang, Z.C.; Xia, W.M.; Xu, Z. Electric energy storage properties of poly(vinylidene fluoride). Appl. Phys. Lett. 2010, 96, 192905. [Google Scholar]

- Wang, Y.; Yao, M.G.; Ma, R.; Yuan, Q.B.; Yang, D.S.; Cui, B.; Ma, C.R.; Liu, M.; Hu, D.W. Design strategy of barium titanate/polyvinylidene fluoride-based nanocomposite films for high energy storage. J. Mater. Chem. A 2020, 8, 884–917. [Google Scholar] [CrossRef]

- Li, L.; Cheng, J.S.; Cheng, Y.Y.; Han, T.; Liu, Y.; Zhou, Y.; Zhao, G.H.; Zhao, Y.; Xiong, C.X.; Dong, L.J.; et al. Significant Improvements in Dielectric Constant and Energy Density of Ferroelectric Polymer Nanocomposites Enabled by Ultralow Contents of Nanofillers. Adv. Energy. Mater. 2021, 33, 2102392. [Google Scholar]

- Zhu, L. Exploring Strategies for High Dielectric Constant and Low Loss Polymer Dielectrics. J. Phys. Chem. Lett. 2014, 21, 3677–3687. [Google Scholar] [CrossRef]

- Li, H.; Ren, L.L.; Zhou, Y.; Yao, B.; Wang, Q. Recent progress in polymer dielectrics containing boron nitride nanosheets for high energy density capacitors. High Voltage 2020, 5, 365–376. [Google Scholar] [CrossRef]

- Song, S.X.; Xia, S.; Liu, Y.; Lv, X.; Sun, S.L. Effect of Na+ MMT-ionic liquid synergy on electroactive, mechanical, dielectric and energy storage properties of transparent PVDF-based nanocomposites. Chem. Eng. J. 2019, 384, 123365. [Google Scholar] [CrossRef]

- Shen, Z.H.; Wang, J.J.; Jiang, J.Y.; Huang, S.X.; Lin, Y.H.; Nan, C.W.; Chen, L.Q.; Shen, Y. Phase-field modeling and machine learning of electric-thermal-mechanical breakdown of polymer-based dielectrics. Nat. Commun. 2019, 10, 1843. [Google Scholar] [CrossRef]

- Bao, Z.W.; Hou, C.M.; Shen, Z.H.; Sun, H.Y.; Zhang, G.Q.; Luo, Z.; Dai, Z.Z.; Wang, C.M.; Chen, X.W.; Li, L.B.; et al. Negatively Charged Nanosheets Significantly Enhance the Energy-Storage Capability of Polymer-Based Nanocomposites. Adv. Mater. 2020, 32, 1907227. [Google Scholar] [CrossRef]

- Shen, Z.H.; Wang, J.J.; Lin, Y.H.; Nan, C.W.; Chen, L.Q.; Shen, Y. High-Throughput Phase-Field Design of High-Energy-Density Polymer Nanocomposites. Adv. Mater. 2018, 30, 1704380. [Google Scholar] [CrossRef]

- Zhou, L.; Zhou, Y.F.; Shi, Y.C.; Chen, T.W.; Zou, T.G.; Zhou, D.X.; Fu, Q.Y. Enhancing thermal stability of P(VDF-HFP) based nanocomposites with core-shell fillers for energy storage applications. Compos. Sci. Technol. 2020, 186, 107934. [Google Scholar] [CrossRef]

- Li, H.; Ai, D.; Ren, L.L.; Yao, B.; Han, Z.B.; Shen, Z.H.; Wang, J.J.; Chen, L.Q.; Wang, Q. Scalable Polymer Nanocomposites with Record High-Temperature Capacitive Performance Enabled by Rationally Designed Nanostructured Inorganic Fillers. Adv. Mater. 2019, 31, 1900875. [Google Scholar] [CrossRef]

- Chen, G.L.; Zhang, P.; Pan, L.L.; Qi, L.; Yu, F.C.; Gao, C.X. Flexible nonvolatile resistive memory devices based on SrTiO3 nanosheets and polyvinylpyrrolidone composites. J. Mater. Chem. C 2017, 5, 9799. [Google Scholar] [CrossRef]

- Chen, J.W.; Ye, D.G.; Wu, X.W.; Zhu, W.B.; Wang, X.C.; Xiao, P.; Duan, Z.K.; Yu, X.M. Large enhancement of discharge energy density of polymer nanocomposites filled with one-dimension core-shell structured NaNbO3@SiO2 nanowires. Composites Part A 2020, 133, 105832. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.F.; Chen, W.X. Superior capacitive energy storage capability in polymer composites induced by polydopamine coated paraelectric platelets. J. Mater. Sci. 2021, 56, 9395–9407. [Google Scholar] [CrossRef]

- Wang, Y.F.; Wang, L.X.; Yuan, Q.B.; Niu, Y.J.; Chen, J.; Wang, Q.; Wang, H. Ultrahigh electric displacement and energy density in gradient layer-structured BaTiO3/PVDF nanocomposites with an interfacial barrier effect. J. Mater. Chem. A 2017, 5, 10849–10855. [Google Scholar] [CrossRef]

- Wang, Y.F.; Cui, J.; Wang, L.X.; Yuan, Q.B.; Niu, Y.J.; Chen, J.; Wang, Q.; Wang, H. Compositional tailoring effect on electric field distribution for significantly enhanced breakdown strength and restrained conductive loss in sandwich-structured ceramic/polymer nanocomposites. J. Mater. Chem. A 2017, 5, 4710–4718. [Google Scholar] [CrossRef]

- Zhang, M.; Li, B.; Wang, J.J.; Huang, H.B.; Zhang, L.; Chen, L.Q. Polymer Dielectrics with Simultaneous Ultrahigh Energy Density and Low Loss. Adv. Mater. 2021, 33, 2008198. [Google Scholar] [CrossRef]

- Sun, Q.Z.; Wang, J.P.; Zhang, L.X.; Mao, P.; Liu, S.J.; He, L.Q.; Kang, F.; Xue, R. Achieving high energy density and discharge efficiency in multi-layered PVDF–PMMA nanocomposites composed of 0D BaTiO3 and 1D NaNbO3@SiO2. J. Mater. Chem. C 2020, 8, 7211–7220. [Google Scholar] [CrossRef]

- Li, Y.S.; Zhou, Y.; Zhu, Y.J.; Cheng, S.; Yuan, C.; Hu, J.; He, J.L.; Li, Q. Polymer nanocomposites with high energy density and improved charge–discharge efficiency utilizing hierarchically-structured nanofillers. J. Mater. Chem. A 2020, 8, 6576–6585. [Google Scholar] [CrossRef]

- Pan, Z.B.; Yao, L.M.; Liu, J.J.; Liu, X.Y.; Pi, F.P.; Chen, J.W.; Shen, B.; Zhai, J.W. Superior discharge energy density and efficiency in polymer nanocomposites induced by linear dielectric core–shell nanofibers. J. Mater. Chem. C 2019, 7, 405–413. [Google Scholar] [CrossRef]

- Zhang, H.B.; Zhu, Y.W.; Li, Z.Y.; Fan, P.Y.; Ma, W.G.; Xie, B. High discharged energy density of polymer nanocomposites containing paraelectric SrTiO3 nanowires for flexible energy storage device. J. Alloys. Compd. 2018, 744, 116–123. [Google Scholar] [CrossRef]

- Liu, S.H.; Zhai, J.W. Improving the dielectric constant and energy density of poly(vinylidene fluoride) composites induced by surface-modified SrTiO3 nanofibers by polyvinylpyrrolidone. J. Mater. Chem. A 2015, 3, 1511–1517. [Google Scholar] [CrossRef]

- Yao, L.M.; Pan, Z.B.; Zhai, J.W.; Zhang, G.Z.; Liu, Z.Y.; Liu, Y.H. High-energy-density with polymer nanocomposites containing of SrTiO3 nanofibers for capacitor application. Composites Part A 2018, 109, 48–54. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.H.; Wang, J.Y.; Hao, H.S.; Zhao, L.M.; Zhai, J.W. Improving dielectric properties and energy storage performance of poly(vinylidene fluoride) nanocomposite by surface-modified SrTiO3 nanoparticles. J. Alloys Compd. 2017, 726, 587–592. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Zhang, X.; Yang, X.; Li, C.; Wang, Y.; Chen, W. High Breakdown Strength and Energy Storage Density in Aligned SrTiO3@SiO2 Core–Shell Platelets Incorporated Polymer Composites. Membranes 2021, 11, 756. https://doi.org/10.3390/membranes11100756

Chen J, Zhang X, Yang X, Li C, Wang Y, Chen W. High Breakdown Strength and Energy Storage Density in Aligned SrTiO3@SiO2 Core–Shell Platelets Incorporated Polymer Composites. Membranes. 2021; 11(10):756. https://doi.org/10.3390/membranes11100756

Chicago/Turabian StyleChen, Jie, Xiaoyong Zhang, Xiao Yang, Chuanyang Li, Yifei Wang, and Weixing Chen. 2021. "High Breakdown Strength and Energy Storage Density in Aligned SrTiO3@SiO2 Core–Shell Platelets Incorporated Polymer Composites" Membranes 11, no. 10: 756. https://doi.org/10.3390/membranes11100756

APA StyleChen, J., Zhang, X., Yang, X., Li, C., Wang, Y., & Chen, W. (2021). High Breakdown Strength and Energy Storage Density in Aligned SrTiO3@SiO2 Core–Shell Platelets Incorporated Polymer Composites. Membranes, 11(10), 756. https://doi.org/10.3390/membranes11100756