Commercial Pressure Retarded Osmosis Systems for Seawater Desalination Plants

Abstract

1. Introduction

2. Results and Discussion

2.1. State-of-the-Art Technological Trends

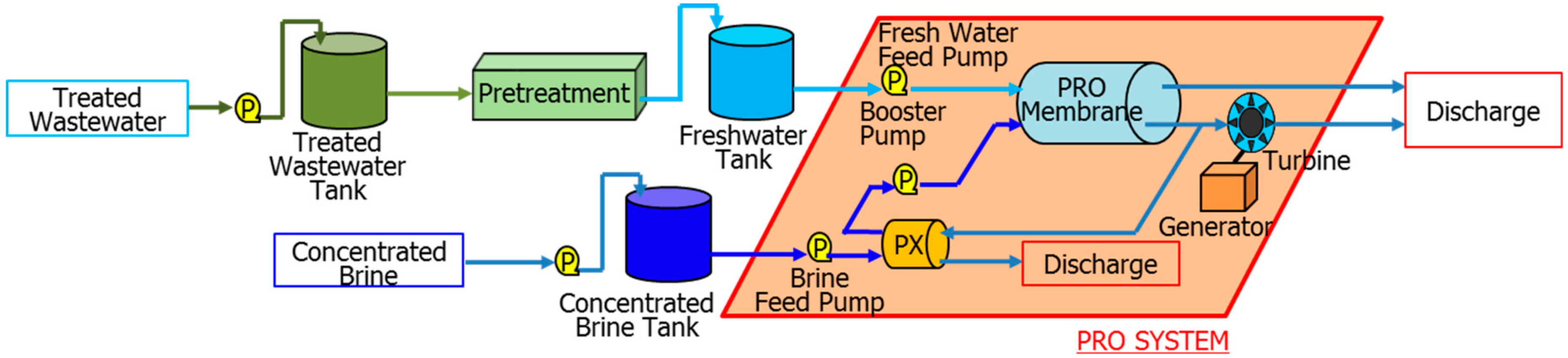

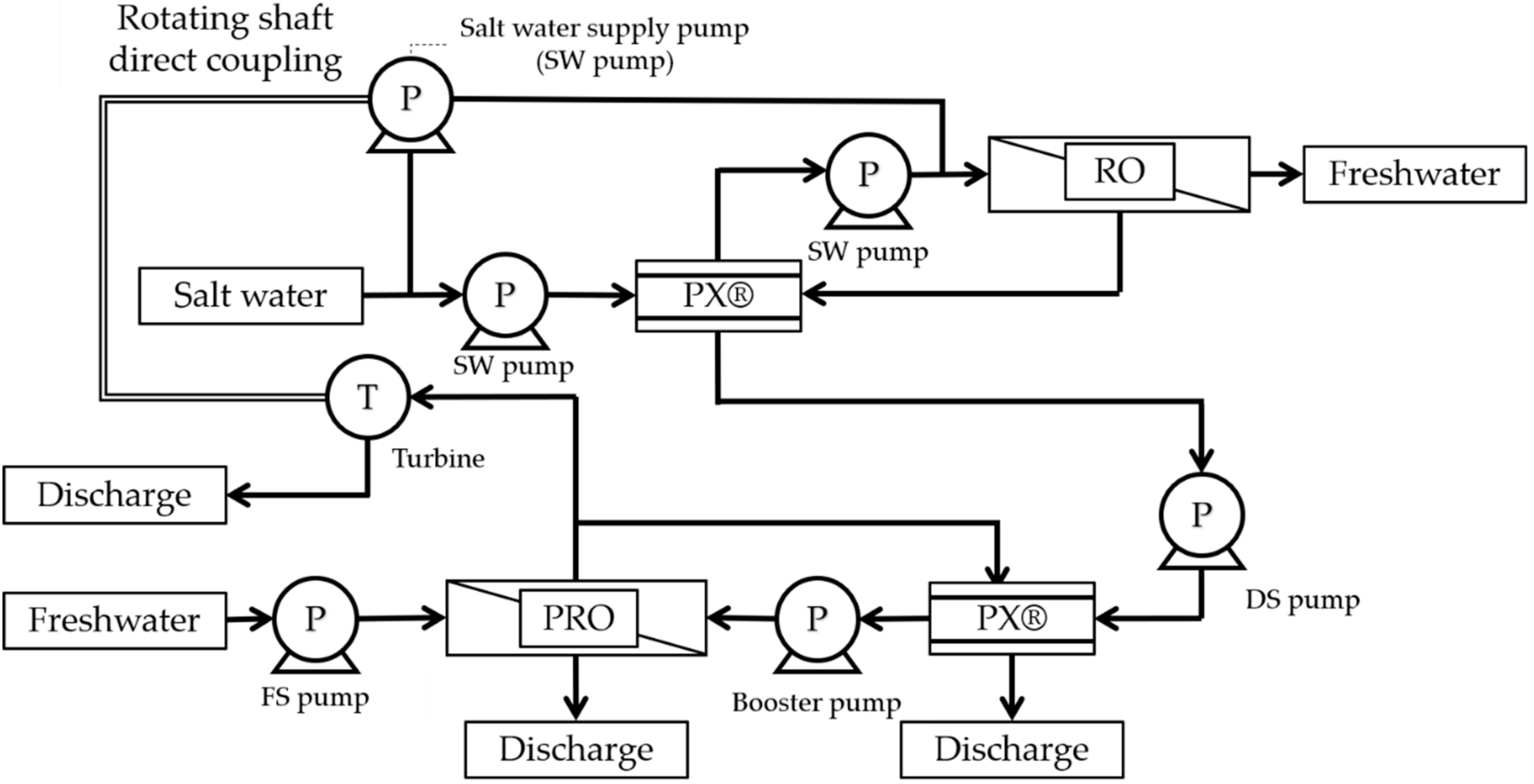

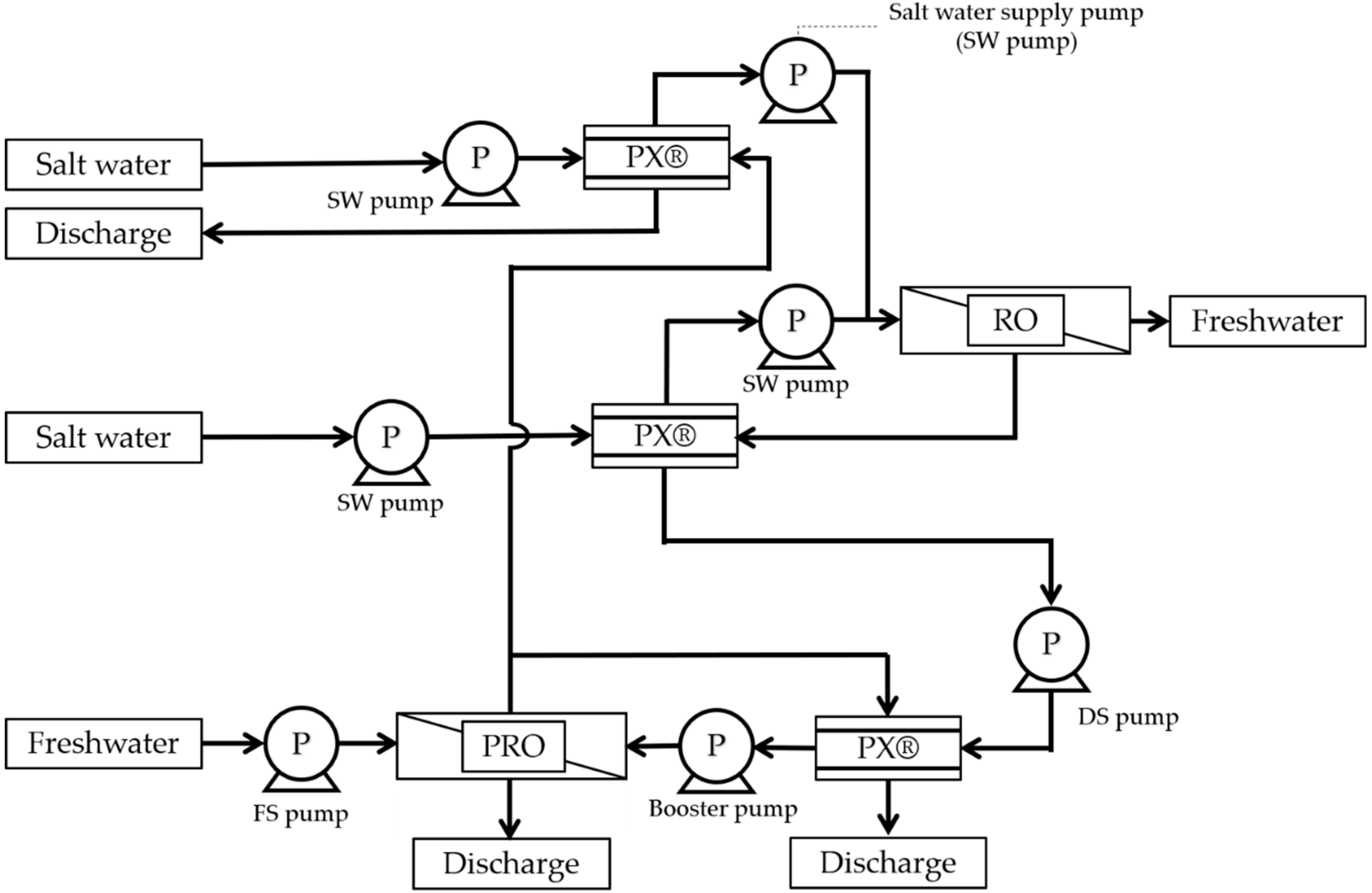

2.1.1. PRO Systems

2.1.2. PRO Membranes

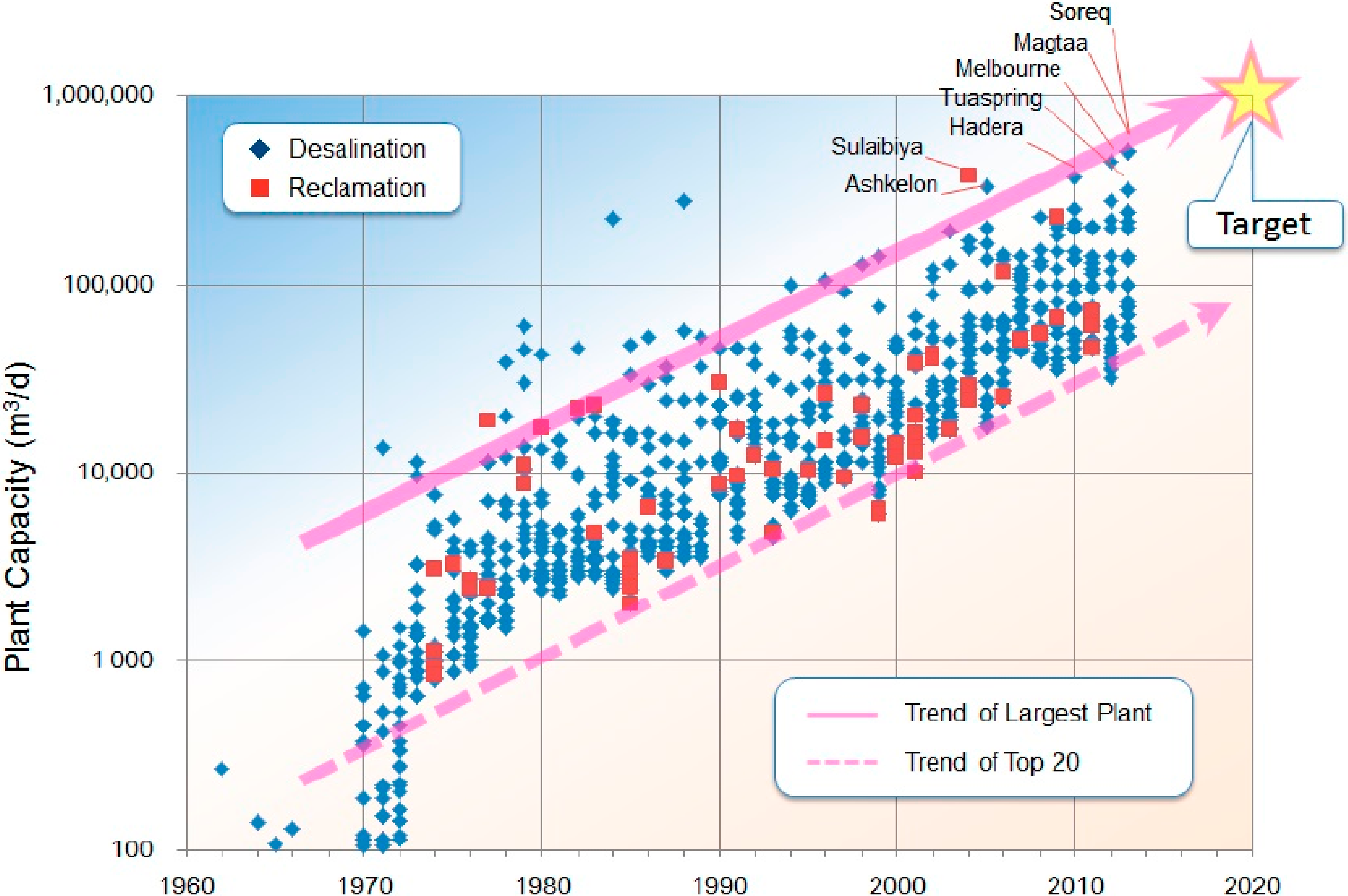

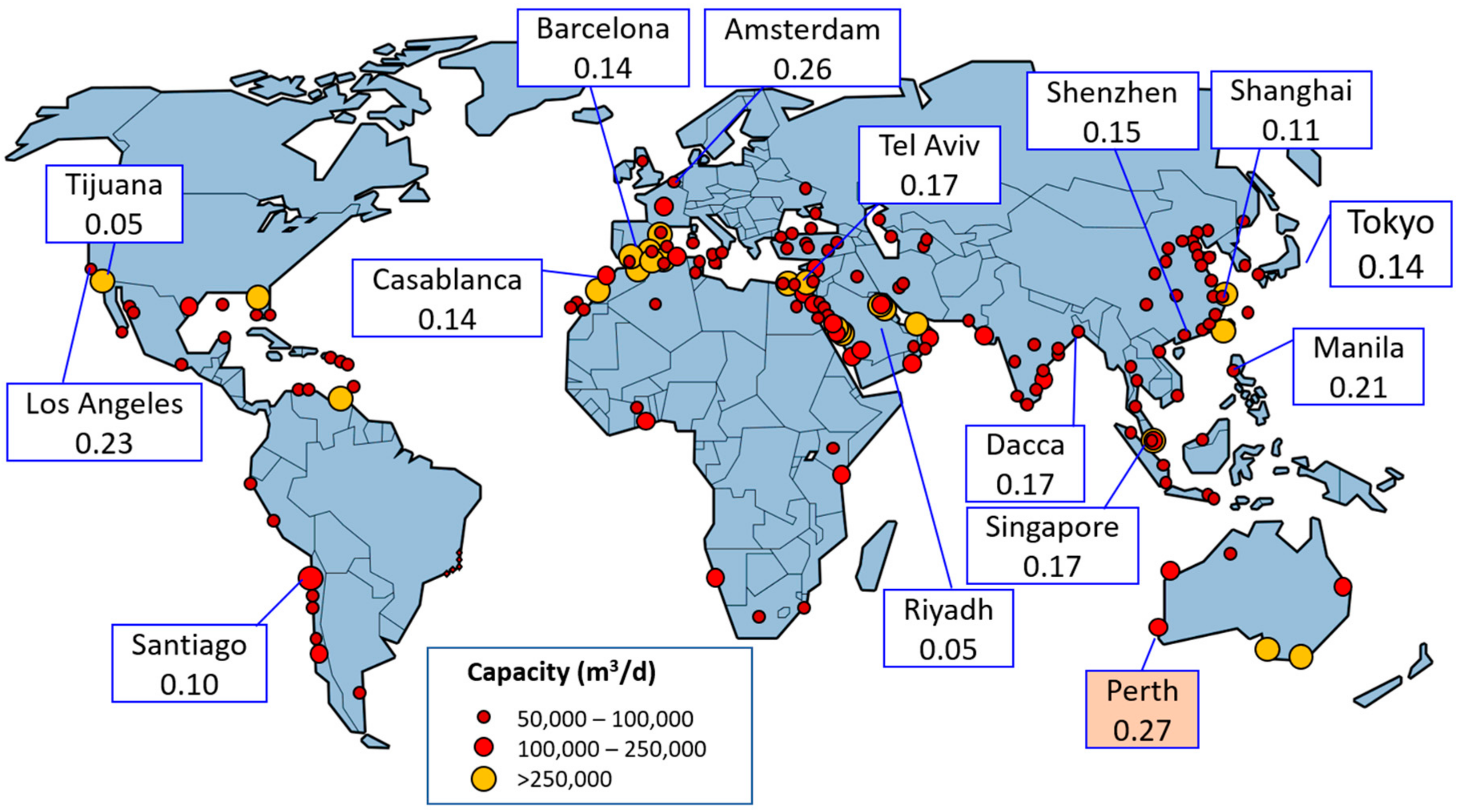

2.2. Current Status of Existing Seawater Desalination Plants

- 1.

- Directly discharged into the sea or rivers;

- 2.

- Discharged into the existing sewage system;

- 3.

- Discharged into the evaporation area (Evaporation Pond);

- 4.

- Discharged into deep wells;

- 5.

- Zero Liquid Discharge (ZLD).

2.3. Comparison of Current Power Generation Costs by PRO and Electricity Charges

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- UNDP. UNDP Support to the Implementation of Sustainable Development Goal 7: Affordable and Clean Energy; United Nations Development Programme: New York, NY, USA, 2016; Available online: https://www.undp.org/content/dam/undp/library/Climate%20and%20Disaster%20Resilience/7%20Clean%20Energy-Feb%202017.pdf (accessed on 17 December 2020).

- UNDP. UNDP Support to the Implementation of Sustainable Development Goal 14: Ocean Governanceu; United Nations Development Programme: New York, NY, USA, 2016; Available online: https://www.undp.org/content/dam/undp/library/Sustainable%20Development/14_Oceans_Jan15_digital.pdf (accessed on 17 December 2020).

- Ratnam, K.S.; Palanisamy, K.; Yang, G. Future low-inertia power systems: Requirements, issues, and solutions—A review. Renew. Sustain. Energy Rev. 2020, 124, 109773. [Google Scholar] [CrossRef]

- Jahangiri, M.; Haghani, A.; Mostafaeipour, A.; Khosravi, A.; Raeisi, H.A. Assessment of Solar-Wind Power Plants in Afghanistan: A Review. Renew. Sustain. Energy Rev. 2019, 99, 169–190. [Google Scholar] [CrossRef]

- Loeb, S. Production of energy from concentrated brines by pressure-retarded osmosis. J. Membr. Sci. 1976, 1, 49–63. [Google Scholar] [CrossRef]

- Lee, C.; Chae, S.H.; Yang, E.; Kim, S.; Kim, J.H.; Kim, I.S. A comprehensive review of the feasibility of pressure retarded osmosis: Recent technological advances and industrial efforts towards commercialization. Desalination 2020, 491, 114501. [Google Scholar] [CrossRef]

- Matsuyama, K.; Makabe, R.; Ueyama, T.; Sakai, H.; Saito, K.; Okumura, T.; Hayashi, H.; Tanioka, A. Power Generation System Based on Pressure Retarded Osmosis with a Commercially Available Hollow Fiber PRO Membrane Module Using Seawater and Freshwater. Desalination 2021, 499, 114805. [Google Scholar] [CrossRef]

- Aseffa, H.T.; Gautam, D.K.; Subbiah, S. Optimization of pressure retarded osmosis process and estimation of Indian blue energy capacity. Desalination 2021, 498, 114752. [Google Scholar] [CrossRef]

- Skilhagen, S.E.; Dugstad, J.E.; Aaberg, R.J. Osmotic power—power production based on the osmotic pressure difference between waters with varying salt gradients. Desalination 2008, 220, 476–482. [Google Scholar] [CrossRef]

- Ahmed, F.E.; Hashaikeh, R.; Hilal, N. Hybrid technologies: The future of energy efficient desalination—A review. Desalination 2020, 495, 114659. [Google Scholar] [CrossRef]

- Kohout, F.A. Reorientation of Our Saline Water Resources Thinking. Water Resour. Res. 1970, 6, 1442–1448. [Google Scholar] [CrossRef]

- El-Ghonemy, A.M.K. Performance test of a sea water multi-stage flash distillation plant: Case study. Alex. Eng. J. 2018, 57, 2401–2413. [Google Scholar] [CrossRef]

- Guo, Y.; Bao, M.; Gong, L.; Shen, S. Effects of preheater arrangement on performance of MED desalination system. Desalination 2020, 496, 114702. [Google Scholar] [CrossRef]

- Esfahani, I.J.; Ataei, A.; Shetty, V.; Oh, T.; Park, J.H.; Yoo, C. Modeling and Genetic Algorithm-Based Multi-Objective Optimization of the MED-TVC Desalination System. Desalination 2012, 292, 87–104. [Google Scholar] [CrossRef]

- Pontié, M.; Awad, S.; Tazerout, M.; Chaouachi, O.; Chaouachi, B. Recycling and Energy Recovery Solutions of End-of-Life Reverse Osmosis (RO) Membrane Materials: A Sustainable Approach. Desalination 2017, 423, 30–40. [Google Scholar] [CrossRef]

- Mustakeem, M.; Qamar, A.; Alpatova, A.; Ghaffour, N. Dead-End Membrane Distillation with Localized Interfacial Heating for Sustainable and Energy-Efficient Desalination. Water Res. 2020, 189, 116584. [Google Scholar] [CrossRef]

- Elimelech, M.; Phillip, W.A. The Future of Seawater Desalination: Energy, Technology, and the Environment. Science 2011, 333, 712–717. [Google Scholar] [CrossRef]

- Kaminski, W.; Marszalek, J.; Tomczak, E. Water Desalination by Pervaporation—Comparison of Energy Consumption. Desalination 2018, 433, 89–93. [Google Scholar] [CrossRef]

- Koutsou, C.P.; Kritikos, E.; Karabelas, A.J.; Kostoglou, M. Analysis of Temperature Effects on the Specific Energy Consumption in Reverse Osmosis Desalination Processes. Desalination 2020, 476, 114213. [Google Scholar] [CrossRef]

- Villa Sallangos, O.L. Operating Experience of the Dhekelia Seawater Desalination Plant Using an Innovative Energy Recovery System. Desalination 2005, 173, 91–102. [Google Scholar] [CrossRef]

- Lee, S.; Choi, J.; Park, Y.-G.; Shon, H.; Ahn, C.H.; Kim, S.-H. Hybrid Desalination Processes for Beneficial Use of Reverse Osmosis Brine: Current Status and Future Prospects. Desalination 2019, 454, 104–111. [Google Scholar] [CrossRef]

- Liyanaarachchi, S.; Jegatheesan, V.; Muthukumaran, S.; Gray, S.; Shu, L. Mass Balance for a Novel RO/FO Hybrid System in Seawater Desalination. J. Membr. Sci. 2016, 501, 199–208. [Google Scholar] [CrossRef]

- Saito, K.; Irie, M.; Zaitsu, S.; Sakai, H.; Hayashi, H.; Tanioka, A. Power Generation with Salinity Gradient by Pressure Retarded Osmosis Using Concentrated Brine from SWRO System and Treated Sewage as Pure Water. Desalin. Water Treat. 2012, 41, 114–121. [Google Scholar] [CrossRef]

- Sakai, H.; Ueyama, T.; Irie, M.; Matsuyama, K.; Tanioka, A.; Saito, K.; Kumano, A. Energy Recovery by PRO in Sea Water Desalination Plant. Desalination 2016, 389, 52–57. [Google Scholar] [CrossRef]

- Hayashi, H.; Okumura, T.; Sakai, H.; Irie, M. Hollow Fiber Forward Osmosis Membrane. European Patent EP2586518A4, 24 June 2011. [Google Scholar]

- Sakai, H.; Irie, M.; Tanioka, A. Salt Water Desalination Device. Australia Patent AU2014247832B2, 24 March 2016. [Google Scholar]

- Sakai, H.; Irie, M.; Zaitsu, S. Controller for Energy Generation System. Australia Patent AU2016310895A1, 11 October 2018. [Google Scholar]

- Panagopoulos, A.; Haralambous, K.J. Environmental Impacts of Desalination and Brine Treatment—Challenges and Mitigation Measures. Mar. Pollut. Bull. 2020, 161, 111773. [Google Scholar] [CrossRef] [PubMed]

- Skilhagen, S.E. Osmotic Power—A New, Renewable Energy Source. Desalin. Water Treat. 2010, 15, 271–278. [Google Scholar] [CrossRef]

- Osmotic Power Opportunity—Statkraft. Available online: https://www.statkraft.com/globalassets/old-contains-the-old-folder-structure/documents/osmotic-power-at-ida-event-huntington-beach-usa-02112010_tcm9-19286.pdf (accessed on 17 December 2020).

- Mehta, G.D.; Loeb, S. Internal Polarization in the Porous Substructure of a Semipermeable Membrane Under Pressure-Retarded Osmosis. J. Membr. Sci. 1978, 4, 261–265. [Google Scholar] [CrossRef]

- Ju, J.; Choi, Y.; Lee, S.; Park, Y.G. Comparison of Different Pretreatment Methods for Pressure Retarded Osmosis (PRO) Membrane in Bench-Scale and Pilot-Scale Systems. Desalination 2020, 496, 114528. [Google Scholar] [CrossRef]

- Wan, C.F.; Jin, S.; Chung, T.S. Mitigation of Inorganic Fouling on Pressure Retarded Osmosis (PRO) Membranes by Coagulation Pretreatment of the Wastewater Concentrate Feed. J. Membr. Sci. 2019, 572, 658–667. [Google Scholar] [CrossRef]

- Liu, X.; Foo, L.-X.; Li, Y.; Lee, J.-Y.; Cao, B.; Tang, C.Y. Fabrication and Characterization of Nanocomposite Pressure Retarded Osmosis (PRO) Membranes with Excellent Anti-Biofouling Property and Enhanced Water Permeability. Desalination 2016, 389, 137–148. [Google Scholar] [CrossRef]

- Zhang, S.; Sukitpaneenit, P.; Chung, T.-S. Design of Robust Hollow Fiber Membranes with High Power Density for Osmotic Energy Production. Chem. Eng. J. 2014, 241, 457–465. [Google Scholar] [CrossRef]

- Li, X.; Cai, T.; Chung, T.S. Anti-Fouling Behavior of Hyperbranched Polyglycerol-Grafted Poly(Ether Sulfone) Hollow Fiber Membranes for Osmotic Power Generation. Environ. Sci. Technol. 2014, 48, 9898–9907. [Google Scholar] [CrossRef]

- Fan, X.; Liu, Y.; Quan, X. A Novel Reduced Graphene Oxide/Carbon Nanotube Hollow Fiber Membrane with High Forward Osmosis Performance. Desalination 2019, 451, 117–124. [Google Scholar] [CrossRef]

- Tang, Y.; Li, S.; Xu, J.; Gao, C. Thin Film Composite Forward Osmosis Membrane with Single-Walled Carbon Nanotubes Interlayer for Alleviating Internal Concentration Polarization. Polymers 2020, 12, 260. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Park, T.; Park, Y.-G.; Lee, W.; Kim, S.-H. Toward Scale-Up of Seawater Reverse Osmosis (SWRO)-Pressure Retarded Osmosis (PRO) Hybrid System: A Case Study of a 240 m3/Day Pilot Plant. Desalination 2020, 491, 114429. [Google Scholar] [CrossRef]

- Valladares Linares, R.V.; Li, Z.; Sarp, S.; Bucs, S.S.; Amy, G.; Vrouwenvelder, J.S. Forward Osmosis Niches in Seawater Desalination and Wastewater Reuse. Water Res. 2014, 66, 122–139. [Google Scholar] [CrossRef] [PubMed]

- Toyobo’s Hollow Fiber Forward Osmosis Membrane Adopted at Danish Osmotic Power Plant. Available online: https://www.toyobo-global.com/system/files/News_Release/201902/press20181217.pdf (accessed on 17 December 2020).

- Jones, E.; Qadir, M.; van Vliet, M.T.H.; Smakhtin, V.; Kang, S.M. The State of Desalination and Brine Production: A Global Outlook. Sci. Total Environ. 2019, 657, 1343–1356. [Google Scholar] [CrossRef]

- Kurihara, M.; Takeuchi, H.; Ito, Y. A Reliable Seawater Desalination System Based on Membrane Technology and Biotechnology Considering Reduction of the Environmental Impact. Environments 2018, 5, 127. [Google Scholar] [CrossRef]

- Kurihara, M.; Ito, Y. Sustainable Seawater Reverse Osmosis Desalination as Green Desalination in the 21st Century. J. Membr. Sci. Res. 2020, 6, 20–29. [Google Scholar]

- Jenkins, S.; Paduan, J.; Roberts, P. (Chair), Daniel Schlenk, Judith Weis, Management of Brine Discharges to Coastal Waters Recommendations of a Science Advisory Panel; 2012 Technical Report 694; California Water Resources Control Board: Sacramento, CA, USA, 2012. [Google Scholar]

- Wang, H.; Jiang, X. Legal Measures to Reduce Marine Environmental Risks of Seawater Desalination in China. Nat. Resour. Forum 2020, 44, 129–143. [Google Scholar] [CrossRef]

- Ozair, G.; Al-Zahrany, S.A.; Al-Shubaili, A.A. MARAFIQ’s Quest to Minimizing the Impact of Desalination on the Marine Environment; IDA World Congress: Dubai, UAE, 2019. [Google Scholar]

- Kelaher, B.P.; Clark, G.F.; Johnston, E.L.; Coleman, M.A. Effect of Desalination Discharge on the Abundance and Diversity of Reef Fishes. Environ. Sci. Technol. 2020, 54, 735–744. [Google Scholar] [CrossRef]

- Oki, T.; Kanae, S. Global Hydrological Cycles and World Water Resources. Science 2006, 313, 1068–1072. [Google Scholar] [CrossRef]

| Item | Specification | Origin | |

|---|---|---|---|

| Raw water | Concentrated brine | 460 m3/d | Mamizu Pia (Desalination Plant) |

| Treated wastewater | 420 m3/d | Wajiro Wastewater Treatment Center | |

| Freshwater pretreatment | UF | RS50-S8 (8 inches) | NITTO (Reused membrane) |

| Low-pressure RO | ES20B-D8 (8 inches) | NITTO (Reused membrane) | |

| PRO membrane | Hollow fiber | 4 ports 10 inches × 8 | TOYOBO |

| Water-turbine generator | Pelton | Power 7.7 kW | Canada, Japan |

| Region/Authority | Salinity Limit | Compliance Point (Relative to Discharge) |

|---|---|---|

| US EPA | Increment ≤ 4 ppt | |

| Carlsbad, CA | Absolute ≤ 40 ppt | 1000 ft. |

| Huntington Beach, CA | Absolute ≤ 40 ppt salinity (expressed as discharge dilution ratio of 7.5:1) | 1000 ft. |

| Western Australia guidelines | Increment < 5% | |

| Oakajee Port, Western Australia | Increment ≤ 1 ppt | |

| Perth, Australia/Western AustraliaEPA | Increment ≤ 1.2 ppt at 50 m and ≤ 0.8 ppt at 1000 m | 50 and 1000 m |

| Sydney, Australia | Increment ≤ 1 ppt | 50–75 m |

| Gold Coast, Australia | Increment ≤ 2 ppt | 120 m |

| Okinawa, Japan | Increment ≤ 1 ppt | Mixing zone boundary |

| Abu Dhabi | Increment ≤ 5% | Mixing zone boundary |

| Oman | Increment ≤ 2 ppt | 300 m |

| PRO System Size | Mega-Ton Water PRO System Size | Mega-Ton Water PRO System Size (Future Price of the PRO Membrane) | |

|---|---|---|---|

| Draw side | Brine (Concentration 7%) | ||

| Concentrated brine (CMD) | 100,000 | 1,000,000 | 1,000,000 |

| PRO membrane cost (USD/module) | 4100 | 3200 | 550 * |

| Pump efficiency (%) | 85 | ||

| Turbine efficiency (%) | 88 | 92 ** | 92 ** |

| Power density (W/m2) | 12 | ||

| Net output power (kW) | 1100 | 12,000 | 12,000 |

| Facility redemption (USD/kWh) | 0.17 | 0.11 | 0.06 |

| Running cost (USD/kWh) | 0.11 | 0.08 | 0.03 |

| Generation cost (USD/kWh) | 0.28 | 0.19 | 0.09 |

| RO | MSF | MED | ED | Other | Total | ||

|---|---|---|---|---|---|---|---|

| Seawater desalination plant capacity [42] | 64 | 18 | 8.5 | 2.5 | 2.37 | 95.4 | million m3/d |

| Recovery [42] | 42 | 22 | 25 | 86 | 4 | % | |

| Brine capacity | 88 | 64 | 26 | 0.4 | 3.6 | 182 | million m3/d |

| Brine concentration | 6.03 | 4.5 | 4.7 | 25 | 5.8 | w/w % | |

| Osmotic pressure | 5.1 | 3.8 | 4.0 | 21 | 4.9 | MPa | |

| PRO DS pressure | 2.5 | 1.8 | 1.9 | 6 * | 2.4 | MPa | |

| Permeation rate | 65 | % | |||||

| Power generation | 0.57 | 0.32 | 0.14 | 0.007 | 0.03 | 1.03 | TWh/year |

| 1.6 | 0.9 | 0.4 | 0.019 | 0.08 | 3 | GW | |

| Net Output Power | 0.35 | 0.16 | 0.07 | 0.006 | 0.02 | 0.57 | TWh/year |

| 1.0 | 0.4 | 0.2 | 0.016 | 0.05 | 1.7 | GW | |

| Total Sustainable Water Defined as Discharge | 124,600 | Million m3/d |

|---|---|---|

| Seawater concentration | 3.5 | w/w % |

| Osmotic pressure | 3.0 | MPa |

| PRO DS pressure | 1.5 | MPa |

| Permeation rate | 70 | % |

| Power generation | 650 | TWh/year |

| 1781 | GW | |

| Net output power | 320 | TWh/year |

| 877 | GW |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makabe, R.; Ueyama, T.; Sakai, H.; Tanioka, A. Commercial Pressure Retarded Osmosis Systems for Seawater Desalination Plants. Membranes 2021, 11, 69. https://doi.org/10.3390/membranes11010069

Makabe R, Ueyama T, Sakai H, Tanioka A. Commercial Pressure Retarded Osmosis Systems for Seawater Desalination Plants. Membranes. 2021; 11(1):69. https://doi.org/10.3390/membranes11010069

Chicago/Turabian StyleMakabe, Ryo, Tetsuro Ueyama, Hideyuki Sakai, and Akihiko Tanioka. 2021. "Commercial Pressure Retarded Osmosis Systems for Seawater Desalination Plants" Membranes 11, no. 1: 69. https://doi.org/10.3390/membranes11010069

APA StyleMakabe, R., Ueyama, T., Sakai, H., & Tanioka, A. (2021). Commercial Pressure Retarded Osmosis Systems for Seawater Desalination Plants. Membranes, 11(1), 69. https://doi.org/10.3390/membranes11010069