Wine Lees as a Source of Antioxidant Compounds

Abstract

:1. Introduction

2. Wine Lees

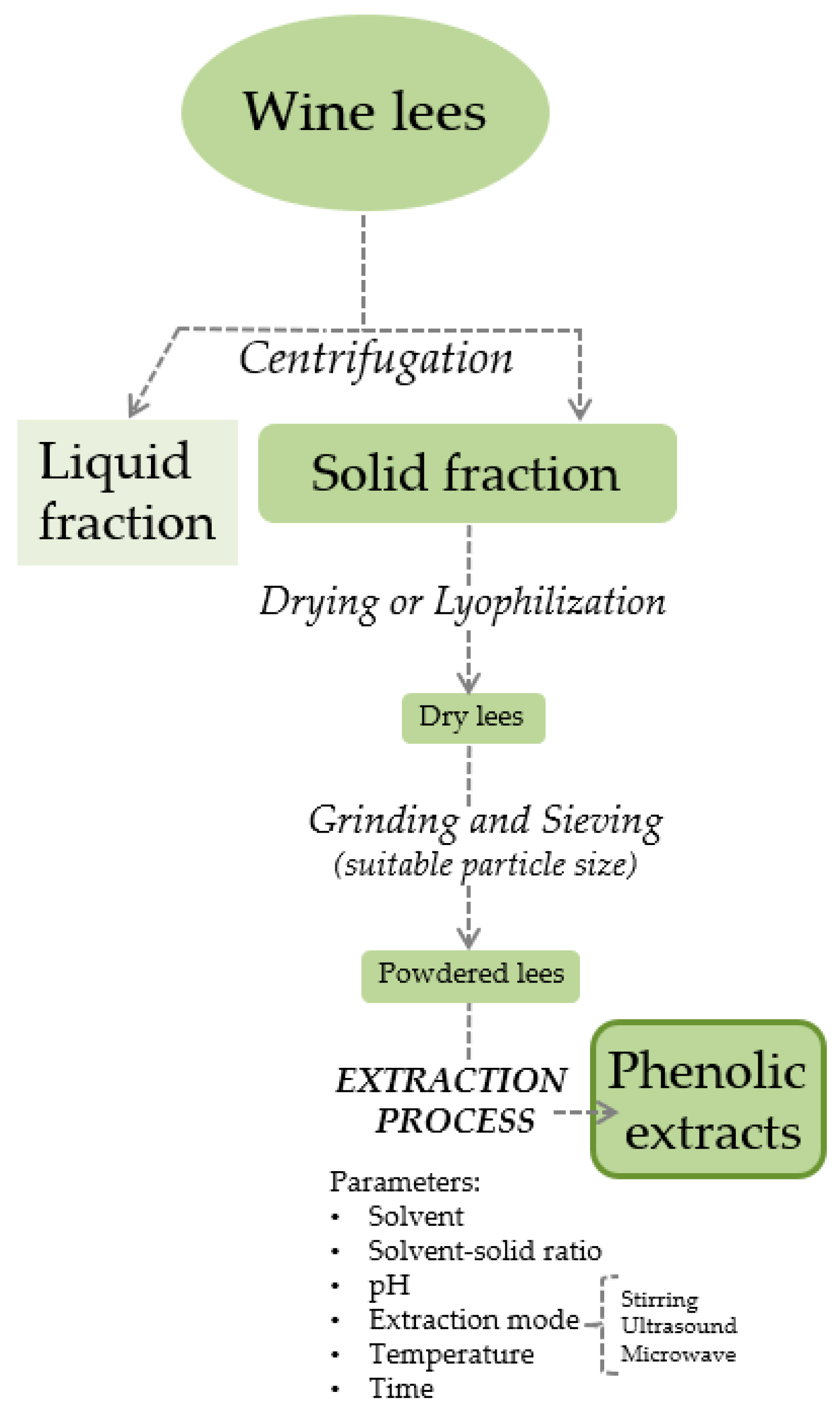

3. Phenolic Extraction from Solid Fraction of Wine Lees

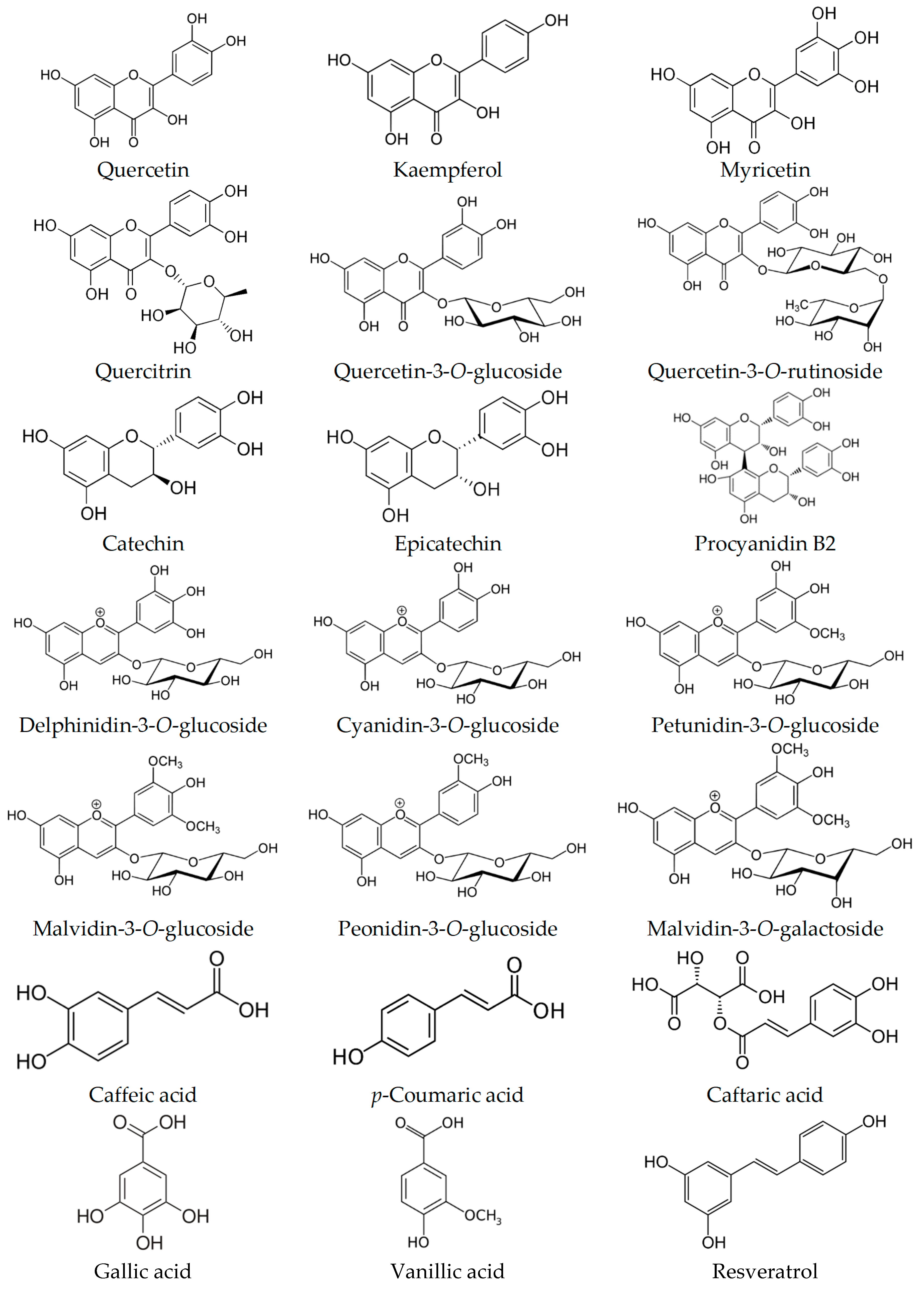

4. Phenolic Compounds in Wine Lees

5. Antioxidant Activity

6. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ABTS | 3-ethylbenzothiazoline-6-sulfonic acid |

| DL | dry lees |

| DM | dry matter |

| DPPH | 1,1-diphenyl-2-picrylhydrazyl |

| FRAP | cupric reducing antioxidant capacity |

| GAE | gallic acid equivalents |

| HORAC | hydroxyl radical averting capacity |

| HOSC | hydroxyl radical scavenging capacity |

| NADES | natural deep eutectic solvents |

| ORAC | oxygen radical absorbance capacity |

| TE | Trolox equivalents |

| TPTZ | 2,4,6-tripyridyl-s-trizin |

References

- OIV: Organisation Internationale de la vigne et du vin. Global Economic Vitiviniculture Data. 2017. Available online: http://www.oiv.int/public/medias/5681/en-communiqu-depresse-octobre-2017.pdf (accessed on 10 January 2019).

- Teixeira Barcia, M.; Becker Pertuzatti, P.; Gómez-Alonso, S.; Teixeira Godoy, H.; Hermosín-Gutiérrez, I. Phenolic composition of grape and winemaking by-products of Brazilian hybrid cultivars BRS Violeta and BRS Lorena. Food Chem. 2014, 159, 95–105. [Google Scholar] [CrossRef] [PubMed]

- Jara-Palacios, M.J.; Hernanz, D.; Escudero-Gilete, M.L.; Heredia, F.J. The use of grape seed byproducts rich in flavonoids to improve the antioxidant potential of red wines. Molecules 2016, 21, 1526. [Google Scholar] [CrossRef] [PubMed]

- Jara-Palacios, M.J.; Goncalves, S.; Hernanz, D.; Heredia, F.J.; Romano, A. Effects of In Vitro Gastrointestinal Digestion on Phenolic Compounds and Antioxidant Activity of Different White Winemaking Byproducts Extracts. Food Res. Int. 2018, 109, 433–439. [Google Scholar] [CrossRef] [PubMed]

- Fontana, A.R.; Antoniolli, A.; Bottini, R. Grape pomace as a sustainable source of bioactive compounds: Extraction, characterization, and biotechnological applications of phenolics. J. Agric. Food Chem. 2013, 61, 8987–9003. [Google Scholar] [CrossRef] [PubMed]

- Beres, C.; Costa, G.N.S.; Cabezudo, I.; da Silva-James, N.K.; Teles, A.S.C.; Cruz, A.P.G.; Mellinger-Silva, C.; Tonon, R.V.; Cabral, L.M.C.; Freitas, S.P. Towards integral utilization of grape pomace from winemaking process: A review. Waste Manag. 2017, 68, 581–594. [Google Scholar] [CrossRef] [PubMed]

- Peixoto, C.M.; Diasa, M.I.; Alves, M.J.; Calhelha, R.C.; Barros, L.; Pinho, S.P.; Ferreira, I.C.F.R. Grape pomace as a source of phenolic compounds and diverse bioactive properties. Food Chem. 2018, 253, 132–138. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Serradilla, J.A.; Luque de Castro, M.D. Role of lees in wine production: A review. Food Chem. 2008, 111, 447–456. [Google Scholar] [CrossRef] [PubMed]

- Romero-Díez, R.; Rodríguez-Rojo, S.; Cocero, M.J.; Duarte, C.M.M.; Matias, A.A.; Bronze, M.R. Phenolic characterization of aging wine lees: Correlation with antioxidant activities. Food Chem. 2018, 259, 188–195. [Google Scholar] [CrossRef]

- García Martín, J.F.; Guillemet, L.; Feng, C.; Sun, D.-W. Cell viability and proteins release during ultrasound-assisted yeast lysis of light lees in model wine. Food Chem. 2013, 141, 934–939. [Google Scholar] [CrossRef]

- Delteil, D. Working with lees: Key elements to wine maturing. Aust. Grapegrow. Winemak. 2002, 461, 104–108. [Google Scholar]

- Bustamante, M.A.; Moral, R.; Paredes, C.; Pérez-Espinosa, A.; Moreno-Caselles, J.; Pérez-Murcia, M.D. Agrochemical characterisation of the solid byproducts and residues from the winery and distillery industry. Waste Manag. 2008, 28, 372–380. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Bibbins, B.; Torrado-Agrasar, A.; Salgado, J.M.; Pinheiro de Souza Oliveira, R.; Domínguez, J.M. Potential of lees from wine, beer and cider manufacturing as a source of economic nutrients: An overview. Waste Manag. 2015, 40, 72–81. [Google Scholar] [CrossRef] [PubMed]

- Dimou, C.; Kopsahelis, N.; Papadaki, A.; Papanikolaou, S.; Kookos, I.K.; Mandala, I.; Koutinas, A.A. Wine lees valorization: Biorefinery development including production of a generic fermentation feedstock employed for poly(3-hydroxybutyrate) synthesis. Food Res. Int. 2015, 73, 81–87. [Google Scholar]

- Tsukada, M.; Sheng, H.; Kamachi, T.; Niwano, Y. Microbicidal action of photoirradiated aqueous extracts from wine lees. J. Food Sci. Technol. 2016, 53, 3020–3027. [Google Scholar] [CrossRef]

- Rankine, B.C.; Fornachon, J.C.; Boehm, E.W.; Cellier, K.M. lnfluence of grape variety, climate and soil on grape composition and on the composition and quality of table wines. Vitis 1971, 10, 33–50. [Google Scholar]

- Del Fresno, J.M.; Loira, I.; Morata, A.; González, C.; Suárez-Lepe, J.A.; Cuerda, R. Application of ultrasound to improve lees ageing processes in red wines. Food Chem. 2018, 261, 157–163. [Google Scholar] [CrossRef] [PubMed]

- Salmon, J.-M.; Fornairon-Bonnefond, C.; Mazauric, J.-P.; Moutounet, M. Oxygen consumption by wine lees: Impact on lees integrity during wine ageing. Food Chem. 2000, 71, 519–528. [Google Scholar] [CrossRef]

- Tao, Y.; Wu, D.; Zhang, Q.-A.; Sun, D.-W. Ultrasound-assisted extraction of phenolics from wine lees: Modeling, optimization and stability of extracts during storage. Ultrason. Sonochem. 2014, 21, 706–715. [Google Scholar] [CrossRef]

- Fornairon-Bonnefond, C.; Camarasa, C.; Moutounet, M.; Salmon, J. New trends on yeast autolysis and wine ageing on lees: A bibliographic review. OENO One 2002, 36, 49–59. [Google Scholar] [CrossRef]

- Tao, Y.; Garcia, J.M.; Sun, D.-W. Advances in wine aging technologies for enhancing wine quality and accelerating the aging process. Crit. Rev. Food Sci. Nutr. 2014, 54, 817–835. [Google Scholar] [CrossRef]

- Mena, P.; Ascacio-Valdes, J.A.; Girones-Vilaplana, A.; Del Rio, D.; Moreno, D.A.; Garcia-Viguera, C. Assessment of pomegranate wine lees as a valuable source for the recovery of (poly)phenolic compounds. Food Chem. 2014, 145, 327–334. [Google Scholar] [CrossRef] [PubMed]

- Carmona-Jiménez, Y.; García-Moreno, M.V.; Igartuburu, J.M.; Garcia Barroso, C. Simplification of the DPPH assay for estimating the antioxidant activity of wine and wine by-products. Food Chem. 2014, 165, 198–204. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Serradilla, J.A.; Luque de Castro, M.D. Microwave-assisted extraction of phenolic compounds from wine lees and spray-drying of the extract. Food Chem. 2011, 124, 1652–1659. [Google Scholar] [CrossRef]

- Delgado de la Torre, M.P.; Priego-Capote, F.; Luque de Castro, M.D. Characterization and comparison of wine lees by liquid chromatography-mass spectrometry in high resolution mode. J. Agric. Food Chem. 2015, 63, 1116–1125. [Google Scholar] [CrossRef] [PubMed]

- Bosiljkov, T.; Dujmić, F.; Cvjetko Bubalo, M.; Hribar, J.; Vidrih, R.; Brnčić, M.; Zlatic, E.; Radojčić Redovniković, I.; Jokić, S. Natural deep eutectic solvents and ultrasound assisted extraction: Green approaches for extraction of wine lees anthocyanins. Food Bioprod. Process. 2017, 102, 195–203. [Google Scholar] [CrossRef]

- Martín Bueno, J.; Sáez-Plaza, P.; Ramos-Escudero, F.; Jiménez, A.M.; Fett, R.; Asuero, A.G. Analysis and Antioxidant Capacity of Anthocyanin Pigments. Part II: Chemical Structure, Color, and Intake of Anthocyanins. Crit. Rev. Anal. Chem. 2012, 42, 126–151. [Google Scholar] [CrossRef]

- Reis, G.M.; Faccin, H.; Viana, C.; da Rosa, M.B.; de Carvalho, L.M. Vitis vinífera L. cv Pinot noir pomace less as potential sources of bioactive compounds. Int. J. Food Sci. Nut. 2016, 67, 789–796. [Google Scholar] [CrossRef]

- Tao, Y.; Sun, D.-W. Enhancement of food processes by ultrasound: A review. Crit. Rev. Food Sci. Nutr. 2015, 55, 570–594. [Google Scholar] [CrossRef]

- Morata, A.; Gómez-Cordovés, M.C.; Colomo, B.; Suárez, J.A. Cell Wall anthocyanin adsorption by different Saccharomyces strains during the fermentation of Vitis vinifera L. cv Graciano grapes. Eur. Food Res. Technol. 2005, 220, 341–346. [Google Scholar] [CrossRef]

- Landeka Jurčević, I.; Dora, M.; Guberović, I.; Petras, M.; Rimac, S.; Đikić, D. Polyphenols from wine lees as a novel functional bioactive compound in the protection against oxidative stress and hyperlipidaemia. Food Technol. Biotechnol. 2017, 55, 109–116. [Google Scholar] [CrossRef]

- Caro, M.; Sansone, A.; Amézaga, J.; Navarro, V.; Ferreri, C.; Tueros, I. Wine lees modulate lipid metabolism and induce fatty acid remodelling in Zebrafish. Food Funct. 2017, 8, 1652–1659. [Google Scholar] [CrossRef]

- Romero-Díez, R.; Matos, M.; Rodrigues, L.; Bronze, M.R.; Rodríguez-Rojo, S.; Cocero, M.J.; Matias, A.A. Microwave and ultrasound pre-treatments to enhance anthocyanins extraction from different wine lees. Food Chem. 2019, 272, 258–266. [Google Scholar] [CrossRef]

- Alonso, A.M.; Guillén, D.A.; Barroso, C.; Puertas, B.; García, A. Determination of antioxidant activity of wine byproducts and its correlation with polyphenolic content. J. Agric. Food Chem. 2002, 50, 5832–5836. [Google Scholar] [CrossRef]

- Gallardo-Chacón, J.J.; Vichi, S.; Urpí, P.; López-Tamames, E.; Buxaderas, S. Antioxidant activity of lees cell surface during sparkling wine sur lie aging. Int. J. Food Microbiol. 2010, 143, 48–53. [Google Scholar] [CrossRef]

- Jara-Palacios, M.J.; Hernanz, D.; Gonzalez-Manzano, S.; Santos-Buelga, C.; Escudero-Gilete, M.L.; Heredia, F.J. Detailed phenolic composition of white grape by-products by RRLC/MS and measurement of the antioxidant activity. Talanta 2014, 125, 51–57. [Google Scholar] [CrossRef]

- Palomero, F.; Morata, A.; Benito, S.; Calderón, F.; Suárez-Lepe, J.A. New genera of yeasts for over-lees aging of red wine. Food Chem. 2009, 112, 432–441. [Google Scholar] [CrossRef]

- Naziri, E.; Glisic, S.B.; Mantzouridou, F.T.; Tsimidou, M.Z.; Nedovic, V.; Bugarski, B. Advantages of supercritical fluid extraction for recovery of squalene from wine lees. J. Supercrit. Fluids 2016, 107, 560–565. [Google Scholar] [CrossRef]

- Stefenon, C.A.; Bonesi, C.M.; Marzarotto, V.; Barnabé, D.; Spinelli, F.R.; Webber, V.; Vanderlinde, R. Phenolic composition and antioxidant activity in sparkling wines: Modulation by the ageing on lees. Food Chem. 2014, 145, 292–299. [Google Scholar] [CrossRef]

| Sample | Pre-Treatment | Solvents | Extraction Mode | Reference |

|---|---|---|---|---|

| Wine lees from red grapes (Vitis vinifera cv. Syrah). | Lees were centrifuged at 2100× g and the solid phase was dried at 40 °C for 48 h in an oven, milled, and sieved (particle size: 0.5 mm). | The lees were mixed with ethanol 75% (hydrochloric acid 1% in water) in a 1:10 (w/v) ratio. | (1) A microwave-assisted extraction at 200 W irradiation power for 17 min was applied. (2) The mixture was stirred at 40 °C for 24 h. | [24] |

| Wine lees from red grapes (Vitis labrusca hybrid varieties: BRS Violeta and BRS Lorena). | Lees were freeze-dried for 48 h. | A sample of 0.25 g was extracted with 50 mL of methanol/water/formic acid (50:48.5:1.5, v/v/v). | The mixture was placed in ultrasonic bath during 2 min and centrifuged at 5000× g at 5 °C for 5 min. | [2] |

| Wine lees from red grapes (mixture of Vitis vinifera cv. Cabernet Sauvignon 60%, Merlot 30%, and Cabernet Franc 10%). | Wine lees were dried in an oven at 40 °C for 48 h, and then milled and sieved (particle size: smaller than 0.6 mm). | Dried wine lees and 50 mL of aqueous ethanol solution were mixed. | (1) The mixture was placed in an ultrasonic bath system and centrifuged at 12,000 rpm for 10 min. (2) Conventional solvent extraction: maceration. | [19] |

| Wine lees from red grapes (variety not mentioned). | Lees were dried in a climate chamber at 40 °C, ground, and sieved (particle size: 100–300 µm). | A sample of 1 g was extracted with 25 mL ethanol/water (1:1). | The mixture was placed in an ultrasound bath. | [23] |

| Wine lees from red grapes (Vitis vinifera cv. Tempranillo, Merlot, Garnacha, Cabernet, and Mazuelo). | Lees were centrifuged at 855× g and the solid phase was dried at 40 °C for 48 h in an oven, milled, and sieved (particle size: 0.5 mm). | A sample of 6 g was mixed with 50 mL of 60:40 (v/v) ethanol-water (adjusted to pH 4 with formic acid). | The mixture was placed in a microwave-assisted digestor at 140 W irradiation power for 10 min. | [25] |

| Wine lees from white grapes (Vitis labrusca cv. Niagara). | Lees were freeze-dried. | A sample of 1 g was homogenized with 3 mL of pure water. | The mixture was agitated at 150 rpm overnight at room temperature. | [15] |

| Wine lees from red grapes (Vitis vinifera cv. Pinot noir). | Lees were dried in an air-circulation oven for 12 h at 50 °C and ground. | A sample of 20 g was homogenized with 150 mL of ethanol/water/formic acid (50:48.5:1.5, v/v). | The mixture was placed in a blender for 2 min and centrifuged at 2500× g for 15 min. | [28] |

| Wine lees from red grapes (Vitis vinifera cv. Merlot). | Lees were lyophilized. | (1) NADES: mixtures of choline chloride with a hydrogen donor. (2) Ethanol/water/formic acid (50:48.5:1.5, v/v/v) at pH 2.7. | The mixtures were placed in an ultrasonic bath system with different time and ultrasonic power depending on an experimental design. | [26] |

| Aging wine lees from red grapes (Vitis vinifera cv. Tempranillo). | Lees were centrifuged for 90 min at 10,000 rpm and were freeze-dried for 48 h. | A sample of 0.25 g was mixed in 10 mL of solvent: distilled water, ethanol, acetone, methanol and two mixtures of ethanol:water (50:50 and 75:25 v/v). | The mixture was stirred for 5 min at room temperature followed by 10 min of sonication in an Transsonic 700/H bath. | [9] |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jara-Palacios, M.J. Wine Lees as a Source of Antioxidant Compounds. Antioxidants 2019, 8, 45. https://doi.org/10.3390/antiox8020045

Jara-Palacios MJ. Wine Lees as a Source of Antioxidant Compounds. Antioxidants. 2019; 8(2):45. https://doi.org/10.3390/antiox8020045

Chicago/Turabian StyleJara-Palacios, María José. 2019. "Wine Lees as a Source of Antioxidant Compounds" Antioxidants 8, no. 2: 45. https://doi.org/10.3390/antiox8020045

APA StyleJara-Palacios, M. J. (2019). Wine Lees as a Source of Antioxidant Compounds. Antioxidants, 8(2), 45. https://doi.org/10.3390/antiox8020045