The Antioxidant Potential of Resveratrol from Red Vine Leaves Delivered in an Electrospun Nanofiber System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material

2.2. Chemicals and Reagents

2.3. Extraction Process for the Red Vine Leaf Extract and Investigation of Its Biological Activity

2.4. Obtaining Electrospun Nanofibers Containing Red Vine Leaf Extract

2.5. Characterization Studies of the Electrospun Nanofibers

2.5.1. Scanning Electron Microscopy (SEM)

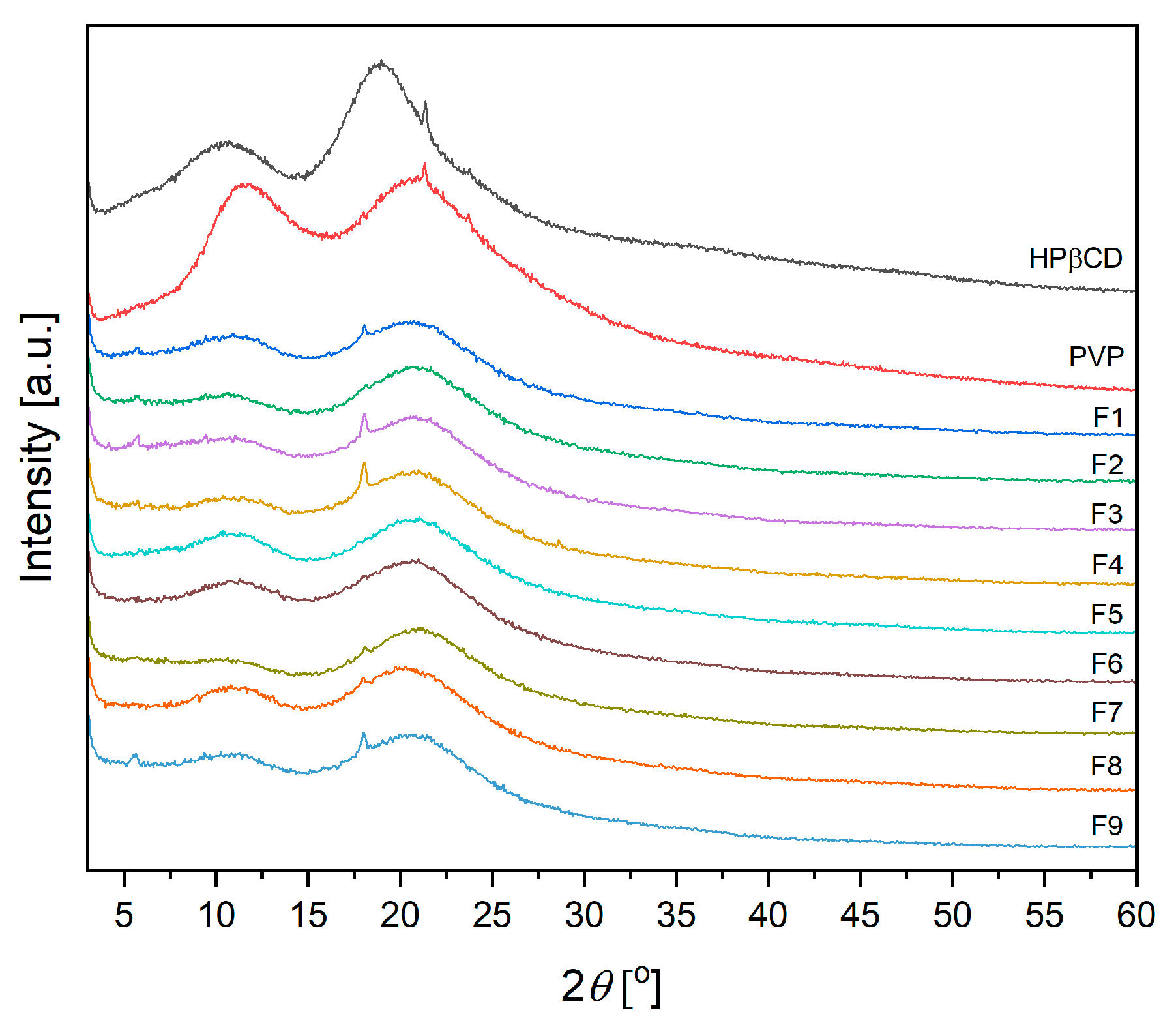

2.5.2. X-ray Diffraction (XRPD)

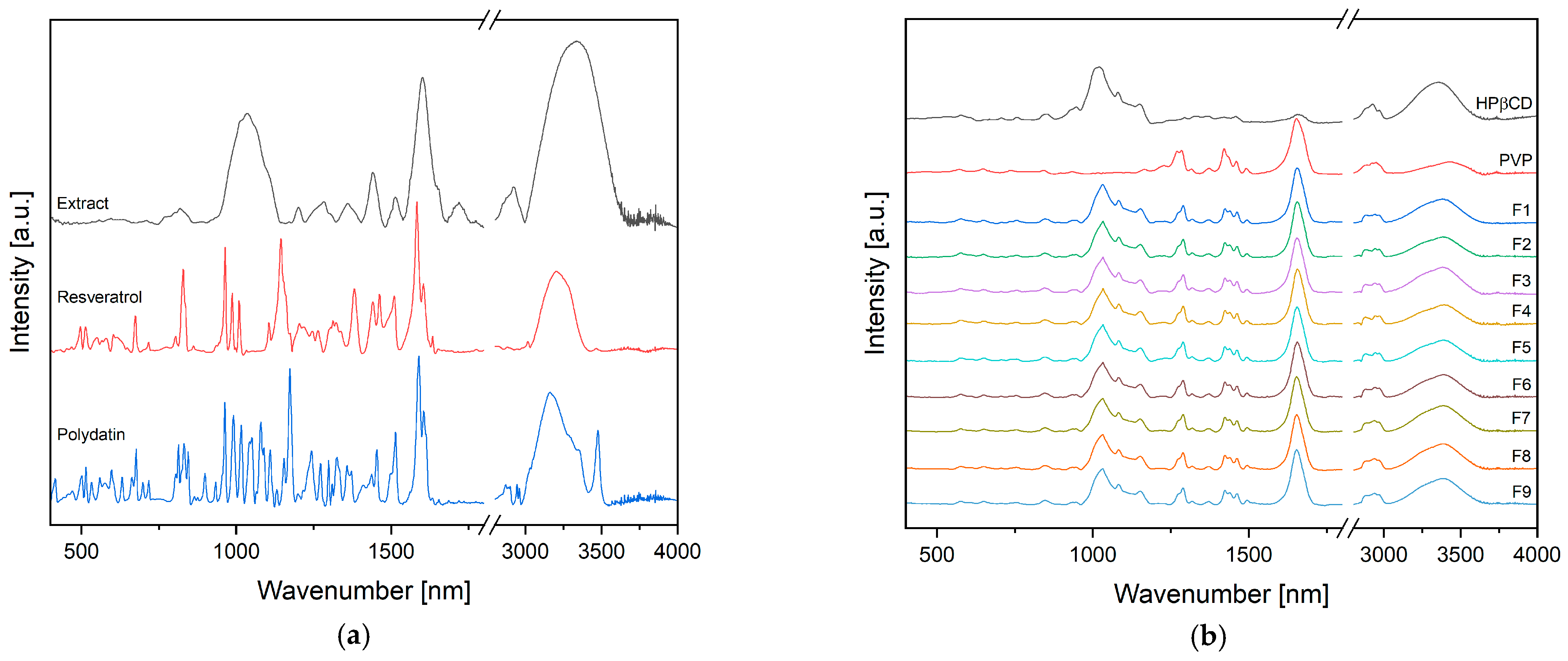

2.5.3. Fourier Transform Infrared Spectroscopy with Attenuated Total Reflectance (FTIR-ATR)

2.6. Characterization of Electrospun Nanofiber’s Functionality

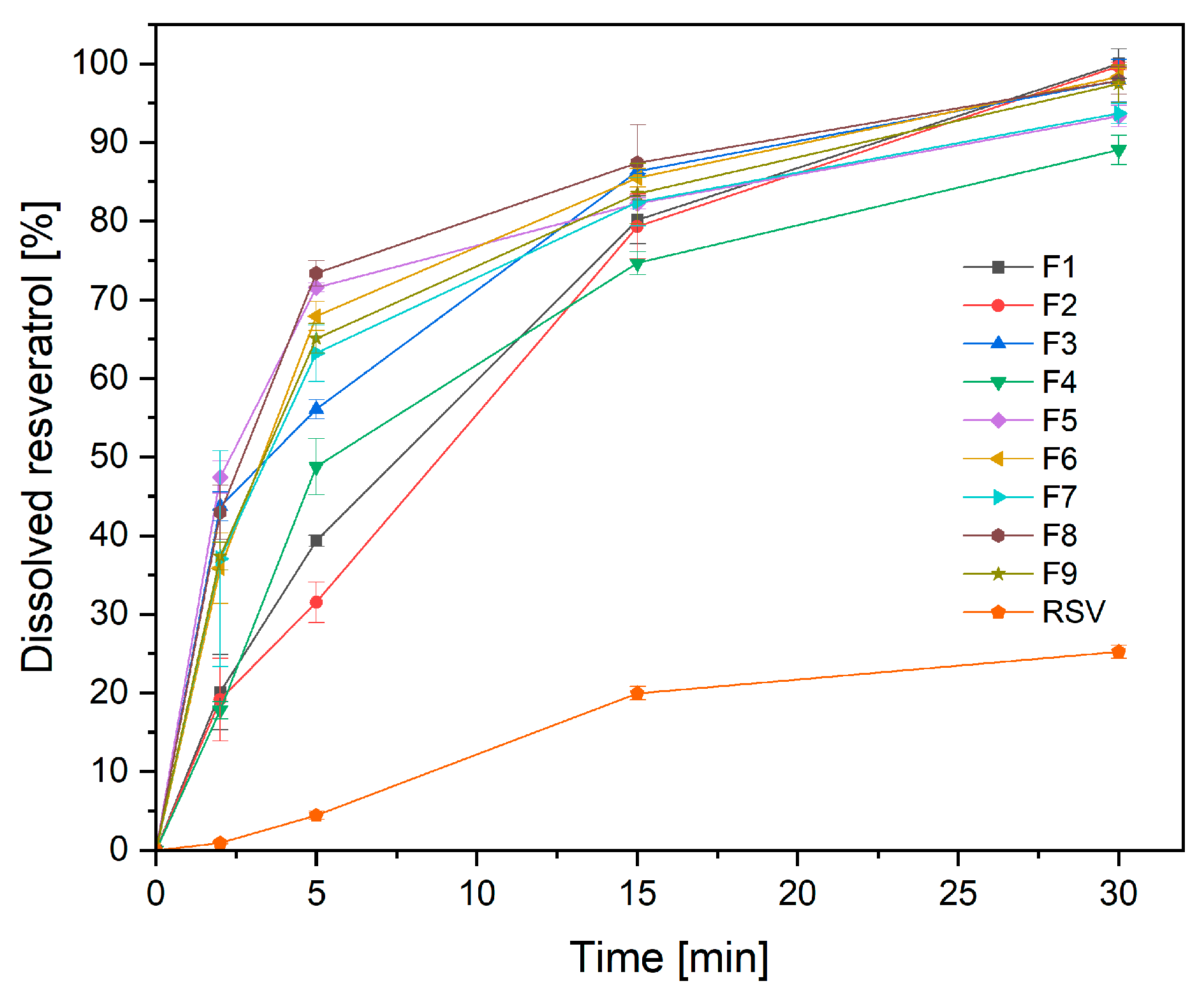

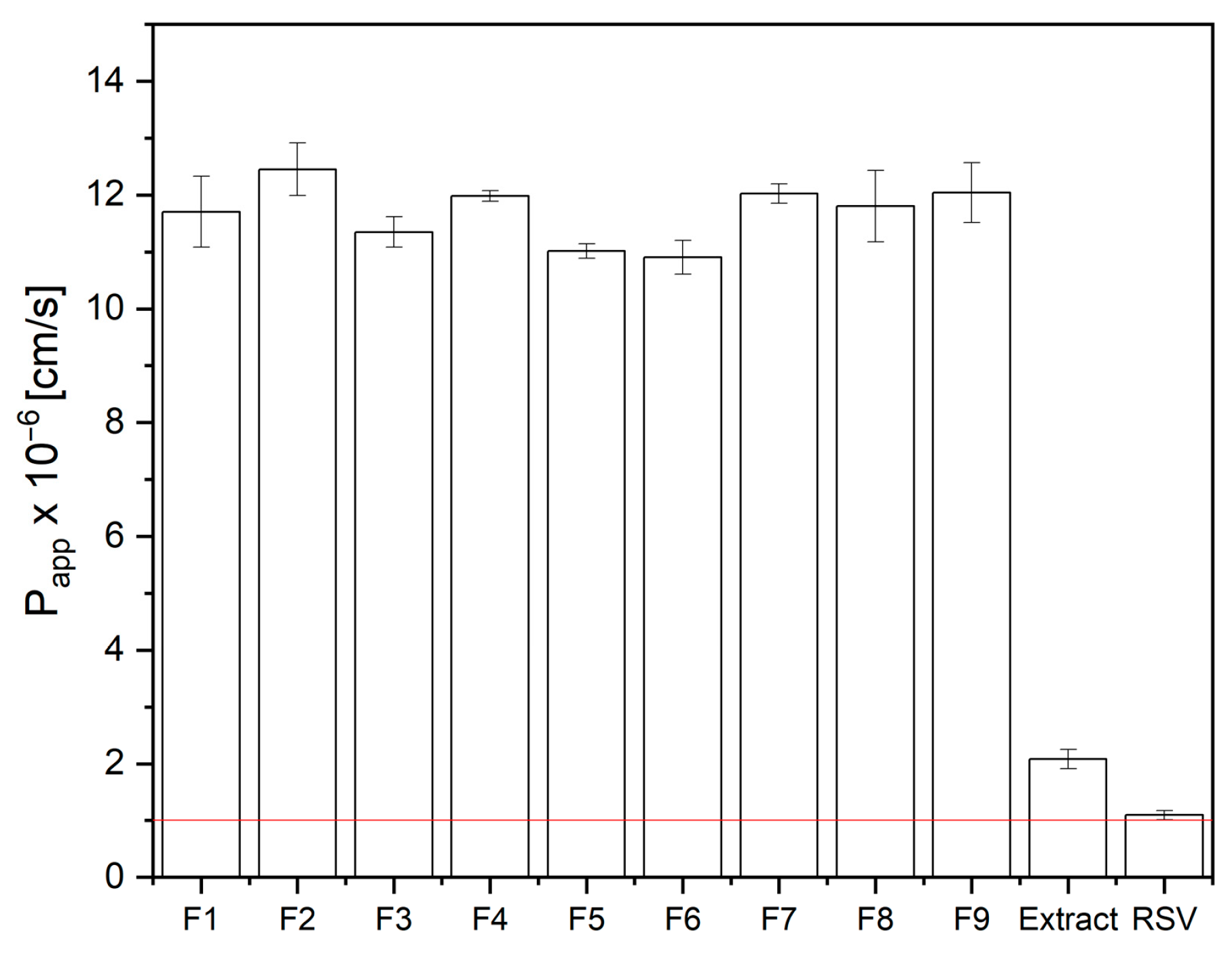

2.6.1. Resveratrol Release and Permeability Assays

2.6.2. Nanofibers’ Activity

2.6.3. Mucoadhesive Properties

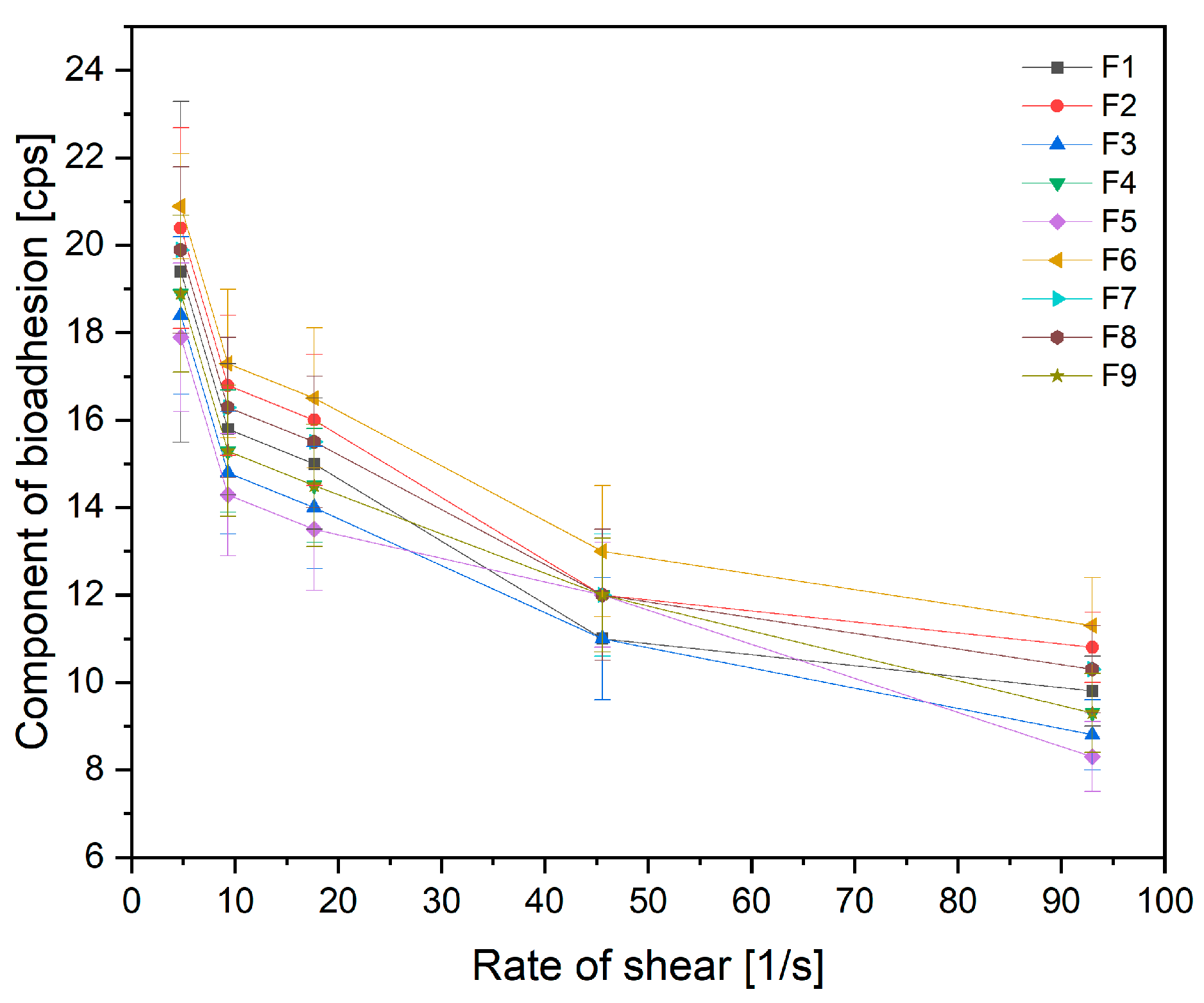

2.7. Statistical Analysis

3. Results and Discussion

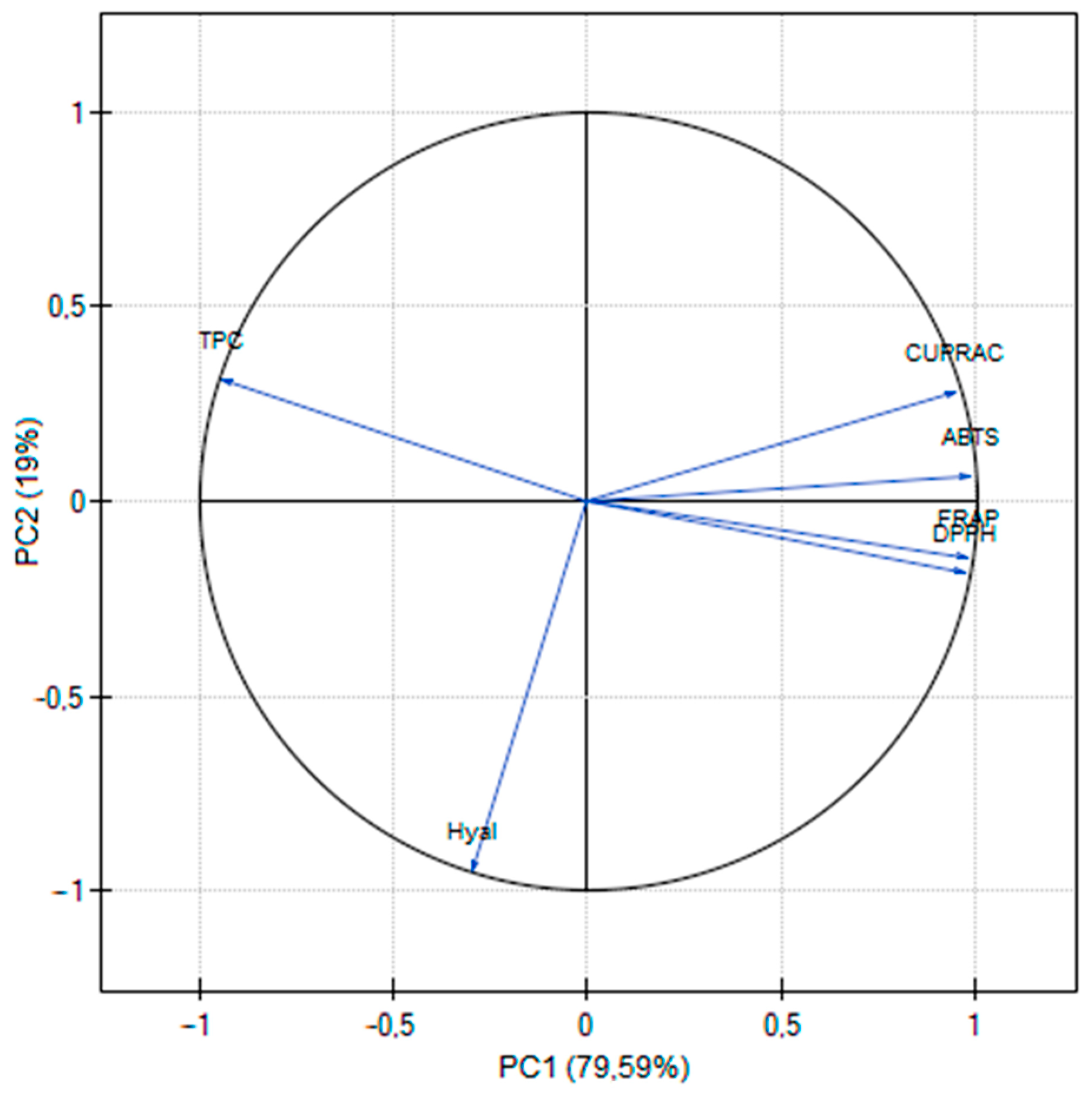

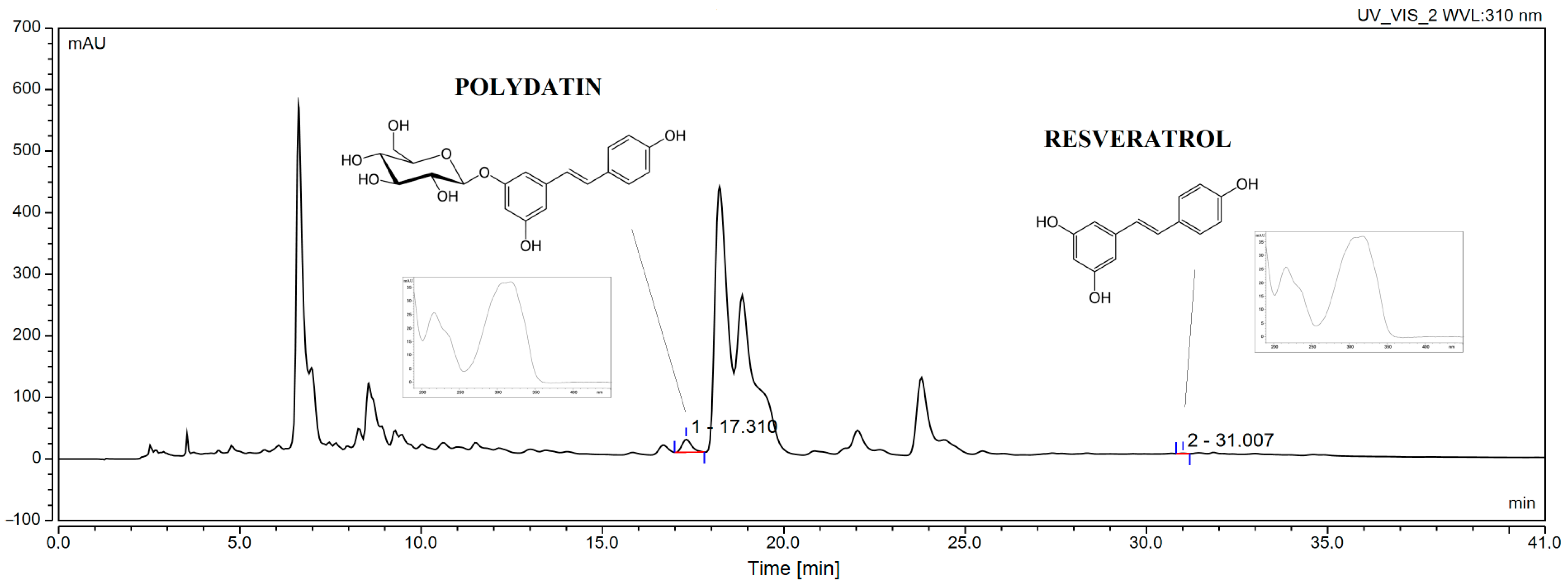

3.1. Obtaining and Characterization of Biological Activity of Red Vine Leaf Extract

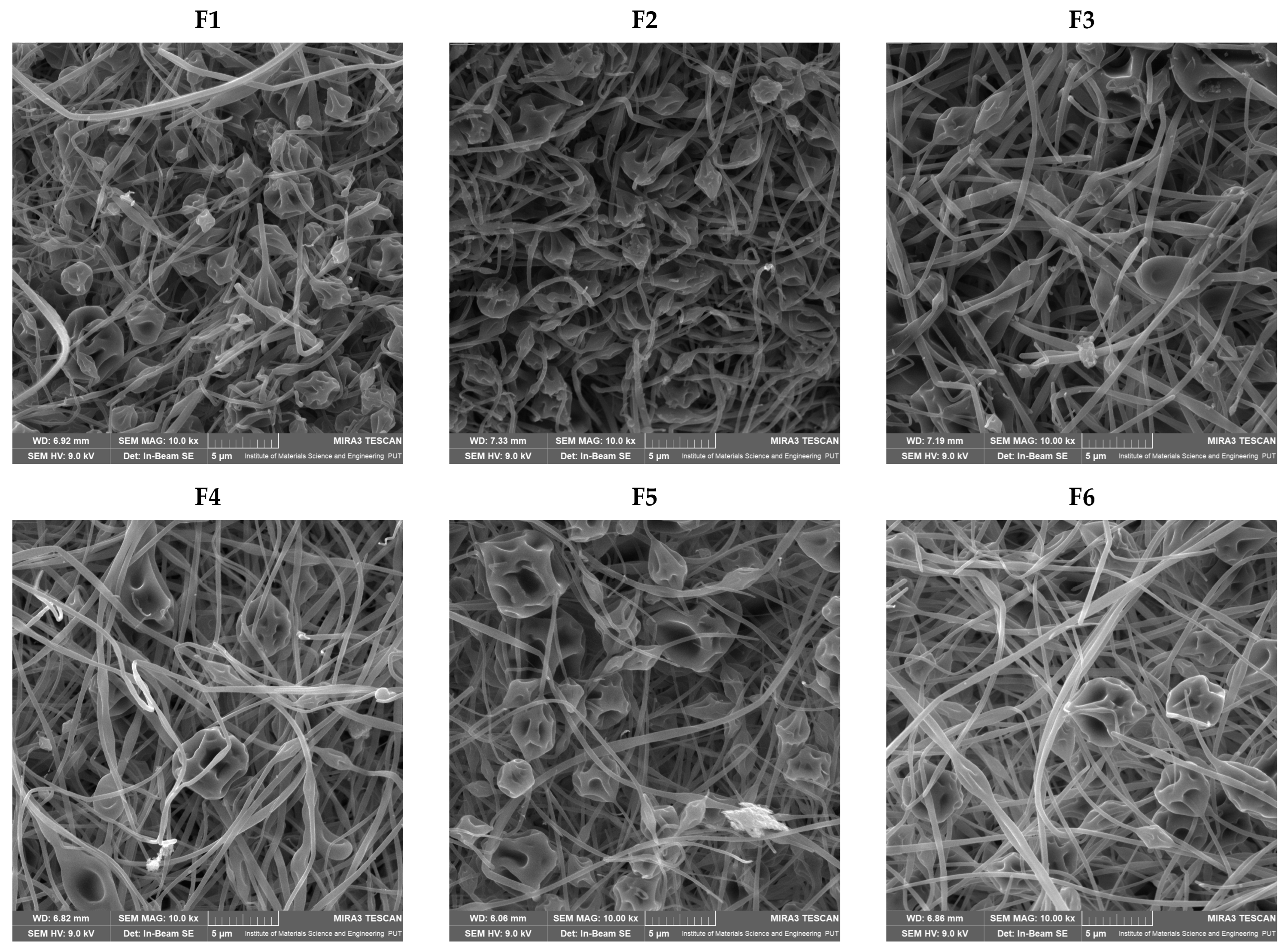

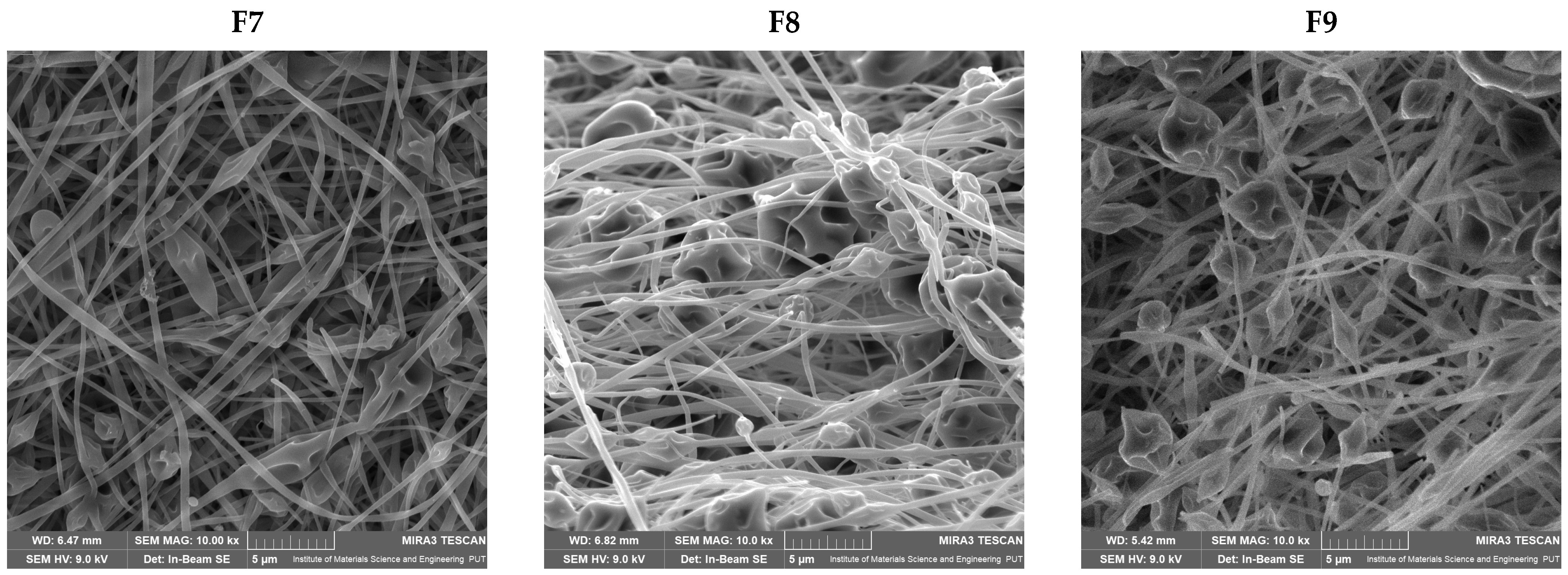

3.2. Obtaining of Electrospun Nanofibers Containing Red Vine Leaf Extract and Identification of Their Structure

3.3. Characterization of Electrospun Nanofibers’ Functionality

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Frombaum, M.; Le Clanche, S.; Bonnefont-Rousselot, D.; Borderie, D. Antioxidant Effects of Resveratrol and Other Stilbene Derivatives on Oxidative Stress and *NO Bioavailability: Potential Benefits to Cardiovascular Diseases. Biochimie 2012, 94, 269–276. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.-X.; Li, C.-X.; Kakar, M.U.; Khan, M.S.; Wu, P.-F.; Amir, R.M.; Dai, D.-F.; Naveed, M.; Li, Q.-Y.; Saeed, M.; et al. Resveratrol (RV): A Pharmacological Review and Call for Further Research. Biomed. Pharmacother. 2021, 143, 112164. [Google Scholar] [CrossRef] [PubMed]

- Smoliga, J.M.; Blanchard, O. Enhancing the Delivery of Resveratrol in Humans: If Low Bioavailability Is the Problem, What Is the Solution? Molecules 2014, 19, 17154. [Google Scholar] [CrossRef] [PubMed]

- Zupančič, Š.; Baumgartner, S.; Lavrič, Z.; Petelin, M.; Kristl, J. Local Delivery of Resveratrol Using Polycaprolactone Nanofibers for Treatment of Periodontal Disease. J. Drug Deliv. Sci. Technol. 2015, 30, 408–416. [Google Scholar] [CrossRef]

- Karakucuk, A.; Tort, S. Preparation, Characterization and Antimicrobial Activity Evaluation of Electrospun PCL Nanofiber Composites of Resveratrol Nanocrystals. Pharm. Dev. Technol. 2020, 25, 1216–1225. [Google Scholar] [CrossRef]

- Xiang, S.; Tang, H.W.; Zhou, J.; Li1, X.Z. Electrospinning of Hydroxypropyl-Beta-Cyclodextrin/Polyvinylpyrrolidone Resveratrol-Loaded Nanofibers: Preparation and Characterization. Indian J. Pharm. Sci. 2019, 81, 618–625. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Hu, S.C.-S.; Huang, P.-H.; Lin, T.-C.; Yen, F.-L. Electrospun Resveratrol-Loaded Polyvinylpyrrolidone/Cyclodextrin Nanofibers and Their Biomedical Applications. Pharmaceutics 2020, 12, 552. [Google Scholar] [CrossRef] [PubMed]

- Maria Leena, M.; Yoha, K.S.; Moses, J.A.; Anandharamakrishnan, C. Edible Coating with Resveratrol Loaded Electrospun Zein Nanofibers with Enhanced Bioaccessibility. Food Biosci. 2020, 36, 100669. [Google Scholar] [CrossRef]

- Paczkowska-Walendowska, M.; Miklaszewski, A.; Cielecka-Piontek, J. Is It Possible to Improve the Bioavailability of Resveratrol and Polydatin Derived from Polygoni Cuspidati Radix as a Result of Preparing Electrospun Nanofibers Based on Polyvinylpyrrolidone/Cyclodextrin? Nutrients 2022, 14, 3897. [Google Scholar] [CrossRef] [PubMed]

- Rasoanaivo, P.; Wright, C.W.; Willcox, M.L.; Gilbert, B. Whole Plant Extracts versus Single Compounds for the Treatment of Malaria: Synergy and Positive Interactions. Malar. J. 2011, 10 (Suppl. S1), S4. [Google Scholar] [CrossRef]

- Tabeshpour, J.; Mehri, S.; Shaebani Behbahani, F.; Hosseinzadeh, H. Protective Effects of Vitis Vinifera (Grapes) and One of Its Biologically Active Constituents, Resveratrol, against Natural and Chemical Toxicities: A Comprehensive Review. Phytother. Res. 2018, 32, 2164–2190. [Google Scholar] [CrossRef] [PubMed]

- Sangiovanni, E.; Lorenzo, C.D.; Colombo, E.; Colombo, F.; Fumagalli, M.; Frigerio, G.; Restani, P.; Dell’Agli, M. The Effect of in Vitro Gastrointestinal Digestion on the Anti-Inflammatory Activity of Vitis Vinifera L. Leaves. Food Funct. 2015, 6, 2453–2463. [Google Scholar] [CrossRef] [PubMed]

- Niculescu, V.-C.; Ionete, R.-E. An Overview on Management and Valorisation of Winery Wastes. Appl. Sci. 2023, 13, 5063. [Google Scholar] [CrossRef]

- Hübner, A.d.A.; de Aguiar, M.M.G.B.; Demarque, D.P.; Rosado, C.; Velasco, M.V.R.; Kikuchi, I.S.; Baby, A.R.; Pessoa, F.V.L.S. Technological Aspects and Potential Cutaneous Application of Wine Industry By-Products. Appl. Sci. 2023, 13, 9068. [Google Scholar] [CrossRef]

- Carotenuto, F.; Fiaschini, N.; Di Nardo, P.; Rinaldi, A. Towards a Material-by-Design Approach to Electrospun Scaffolds for Tissue Engineering Based on Statistical Design of Experiments (DOE). Materials 2023, 16, 1539. [Google Scholar] [CrossRef]

- Paczkowska-Walendowska, M.; Gościniak, A.; Szymanowska, D.; Szwajgier, D.; Baranowska-Wójcik, E.; Szulc, P.; Dreczka, D.; Simon, M.; Cielecka-Piontek, J. Blackberry Leaves as New Functional Food? Screening Antioxidant, Anti-Inflammatory and Microbiological Activities in Correlation with Phytochemical Analysis. Antioxidants 2021, 10, 1945. [Google Scholar] [CrossRef]

- Costa, P.; Sousa Lobo, J.M. Modeling and Comparison of Dissolution Profiles. Eur. J. Pharm. Sci. 2001, 13, 123–133. [Google Scholar] [CrossRef]

- Paczkowska-Walendowska, M.; Szymańska, E.; Winnicka, K.; Szwajgier, D.; Baranowska-Wójcik, E.; Ruchała, M.A.; Simon, M.; Cielecka-Piontek, J. Cyclodextrin as Functional Carrier in Development of Mucoadhesive Tablets Containing Polygoni Cuspidati Extract with Potential for Dental Applications. Pharmaceutics 2021, 13, 1916. [Google Scholar] [CrossRef]

- Floegel, A.; Kim, D.-O.; Chung, S.-J.; Koo, S.I.; Chun, O.K. Comparison of ABTS/DPPH Assays to Measure Antioxidant Capacity in Popular Antioxidant-Rich US Foods. J. Food Compos. Anal. 2011, 24, 1043–1048. [Google Scholar] [CrossRef]

- Suktham, T.; Jones, A.; Soliven, A.; Dennis, G.R.; Shalliker, R.A. A Comparison of the Performance of the Cupric Reducing Antioxidant Potential Assay and the Ferric Reducing Antioxidant Power Assay for the Analysis of Antioxidants Using Reaction Flow Chromatography. Microchem. J. 2019, 149, 104046. [Google Scholar] [CrossRef]

- Apak, R.; Güçlü, K.; Demirata, B.; Özyürek, M.; Çelik, S.E.; Bektaşoğlu, B.; Berker, K.I.; Özyurt, D. Comparative Evaluation of Various Total Antioxidant Capacity Assays Applied to Phenolic Compounds with the CUPRAC Assay. Molecules 2007, 12, 1496. [Google Scholar] [CrossRef] [PubMed]

- Tekos, F.; Makri, S.; Skaperda, Z.-V.; Patouna, A.; Terizi, K.; Kyriazis, I.D.; Kotseridis, Y.; Mikropoulou, E.V.; Papaefstathiou, G.; Halabalaki, M.; et al. Assessment of Antioxidant and Antimutagenic Properties of Red and White Wine Extracts In Vitro. Metabolites 2021, 11, 436. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Xu, M.; Liu, C.; Wang, J.; Xi, H.; Wu, B.; Loescher, W.; Duan, W.; Fan, P.; Li, S. Resveratrols in Grape Berry Skins and Leaves in Vitis Germplasm. PLoS ONE 2013, 8, e61642. [Google Scholar] [CrossRef] [PubMed]

- Nees, S.; Weiss, D.R.; Reichenbach-Klinke, E.; Rampp, F.; Heilmeier, B.; Kanbach, J.; Esperester, A. Protective Effects of Flavonoids Contained in the Red Vine Leaf on Venular Endothelium against the Attack of Activated Blood Components In Vitro. Arzneimittelforschung 2003, 53, 330–341. [Google Scholar] [CrossRef]

- Chinnappan, B.A.; Krishnaswamy, M.; Xu, H.; Hoque, M.E. Electrospinning of Biomedical Nanofibers/Nanomembranes: Effects of Process Parameters. Polymers 2022, 14, 3719. [Google Scholar] [CrossRef]

- Haider, A.; Haider, S.; Kang, I.-K. A Comprehensive Review Summarizing the Effect of Electrospinning Parameters and Potential Applications of Nanofibers in Biomedical and Biotechnology. Arab. J. Chem. 2018, 11, 1165–1188. [Google Scholar] [CrossRef]

- Paczkowska-Walendowska, M.; Dvořák, J.; Rosiak, N.; Tykarska, E.; Szymańska, E.; Winnicka, K.; Ruchała, M.A.; Cielecka-Piontek, J. Buccal Resveratrol Delivery System as a Potential New Concept for the Periodontitis Treatment. Pharmaceutics 2021, 13, 417. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, D.; Zhang, Z.; Pan, J.; Cui, Z.; Yu, D.-G.; Annie Bligh, S.-W. Testing of Fast Dissolution of Ibuprofen from Its Electrospun Hydrophilic Polymer Nanocomposites. Polym. Test. 2021, 93, 106872. [Google Scholar] [CrossRef]

- Yan, K.; Le, Y.; Mengen, H.; Zhongbo, L.; Zhulin, H. Effect of Solution Miscibility on the Morphology of Coaxial Electrospun Cellulose Acetate Nanofibers. Polymers 2021, 13, 4419. [Google Scholar] [CrossRef]

| No. | % of Methanol in the Extraction Mixture | Temperature [°C] | Time [min] |

|---|---|---|---|

| E1 | 0 | 30 | 30 |

| E2 | 0 | 50 | 90 |

| E3 | 0 | 70 | 60 |

| E4 | 35 | 30 | 90 |

| E5 | 35 | 50 | 60 |

| E6 | 35 | 70 | 30 |

| E7 | 70 | 30 | 60 |

| E8 | 70 | 50 | 30 |

| E9 | 70 | 70 | 90 |

| No. | Mixing Time [min] | Flow Rate of Mixture [mL/h] | Rotation Speed of Collector [rpm] |

|---|---|---|---|

| F1 | 5 | 1 | 100 |

| F2 | 5 | 2 | 300 |

| F3 | 5 | 3 | 200 |

| F4 | 60 | 1 | 300 |

| F5 | 60 | 2 | 200 |

| F6 | 60 | 3 | 100 |

| F7 | 115 | 1 | 200 |

| F8 | 115 | 2 | 100 |

| F9 | 115 | 3 | 300 |

| No. | TPC [mg GAE/1 g Plant Material] | Antioxidant Activity | Anti-Inflammatory Activity | |||

|---|---|---|---|---|---|---|

| DPPH IC50 [µg/mL] | ABTS IC50 [µg/mL] | CUPRAC IC0.5 [µg/mL] | FRAP IC0.5 [µg/mL] | Inhibition of Hyaluronidase Activity IC50 [mg/mL] | ||

| E1 | 9.65 ± 0.23 | 124.61 ± 3.69 | 199.83 ± 15.37 | 508.09 ± 8.24 | 83.22 ± 7.92 | 4.73 ± 0.07 |

| E2 | 10.91 ± 0.23 | 108.75 ± 13.25 | 180.61 ± 10.97 | 421.45 ± 38.54 | 74.39 ± 5.52 | 4.08 ± 0.08 |

| E3 | 12.78 ± 0.36 | 94.47 ± 3.20 | 167.83 ± 10.02 | 312.97 ± 4.07 | 62.33 ± 4.18 | 3.63 ± 0.22 |

| E4 | 13.50 ± 0.26 | 86.93 ± 3.22 | 143.14 ± 10.93 | 89.09 ± 6.20 | 53.38 ± 6.16 | 5.66 ± 0.87 |

| E5 | 15.93 ± 0.41 | 67.89 ± 0.68 | 116.84 ± 26.53 | 75.69 ± 0.83 | 51.08 ± 4.25 | 5.51 ± 0.95 |

| E6 | 16.84 ± 0.29 | 60.78 ± 2.33 | 113.37 ± 7.15 | 66.60 ± 6.55 | 45.28 ± 3.21 | 4.58 ± 0.39 |

| E7 | 12.21 ± 0.63 | 95.47 ± 2.88 | 132.21 ± 25.28 | 69.88 ± 4.66 | 62.01 ± 2.70 | 9.12 ± 0.10 |

| E8 | 13.76 ± 0.36 | 76.07 ± 6.64 | 131.60 ± 30.61 | 60.28 ± 3.41 | 54.47 ± 4.34 | 8.03 ± 0.39 |

| E9 | 17.21 ± 0.65 | 62.79 ± 2.96 | 104.02 ± 22.23 | 48.00 ± 2.44 | 41.77 ± 3.44 | 5.17 ± 0.32 |

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 |

|---|---|---|---|---|---|---|---|---|

| % | ||||||||

| 62.42 | 63.58 | 50.92 | 60.76 | 61.81 | 58.35 | 62.45 | 61.93 | 51.98 |

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 |

|---|---|---|---|---|---|---|---|---|

| Fiber diameter [nm] | ||||||||

| 321.87 ± 8.97 | 339.51 ± 7.45 | 515.87 ± 17.86 | 489.42 ± 13.31 | 441.47 ± 14.14 | 445.33 ± 15.47 | 462.96 ± 23.31 | 365.96 ± 7.88 | 365.96 ± 12.20 |

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 |

|---|---|---|---|---|---|---|---|---|

| Content [µg] in 100 mg of nanofibers | ||||||||

| 0.306 ± 0.009 | 0.563 ± 0.042 | 0.338 ± 0.098 | 0.054 ± 0.001 | 0.751 ± 0.046 | 0.027 ± 0.001 | 0.387 ± 0.018 | 0.141 ± 0.011 | 0.190 ± 0.034 |

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 |

|---|---|---|---|---|---|---|---|---|

| Resveratrol dissolution in 5 min [%] | ||||||||

| 39.33 | 31.51 | 56.06 | 48.77 | 71.55 | 67.88 | 63.20 | 73.35 | 65.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paczkowska-Walendowska, M.; Miklaszewski, A.; Michniak-Kohn, B.; Cielecka-Piontek, J. The Antioxidant Potential of Resveratrol from Red Vine Leaves Delivered in an Electrospun Nanofiber System. Antioxidants 2023, 12, 1777. https://doi.org/10.3390/antiox12091777

Paczkowska-Walendowska M, Miklaszewski A, Michniak-Kohn B, Cielecka-Piontek J. The Antioxidant Potential of Resveratrol from Red Vine Leaves Delivered in an Electrospun Nanofiber System. Antioxidants. 2023; 12(9):1777. https://doi.org/10.3390/antiox12091777

Chicago/Turabian StylePaczkowska-Walendowska, Magdalena, Andrzej Miklaszewski, Bożena Michniak-Kohn, and Judyta Cielecka-Piontek. 2023. "The Antioxidant Potential of Resveratrol from Red Vine Leaves Delivered in an Electrospun Nanofiber System" Antioxidants 12, no. 9: 1777. https://doi.org/10.3390/antiox12091777

APA StylePaczkowska-Walendowska, M., Miklaszewski, A., Michniak-Kohn, B., & Cielecka-Piontek, J. (2023). The Antioxidant Potential of Resveratrol from Red Vine Leaves Delivered in an Electrospun Nanofiber System. Antioxidants, 12(9), 1777. https://doi.org/10.3390/antiox12091777