A Poly-D-Mannose Synthesized by a One-Pot Method Exhibits Anti-Biofilm, Antioxidant, and Anti-Inflammatory Properties In Vitro

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Poly-D-Mannose

2.3. SEM Observation

2.4. FT-IR Analysis

2.5. Molecular Weight Determination

2.6. Total Sugar Content Determination

2.7. Monosaccharide Composition Determination

2.8. Determination of Branching Degree

2.9. NMR Spectroscopy

2.10. In Vitro Evaluation of Poly-D-Mannose Safety

2.10.1. Cell Cytotoxicity Assay

2.10.2. Hemolysis Capacity

2.11. Biological Activity of Poly-D-Mannose

2.11.1. Anti-Biofilm Activity Assay

2.11.2. Antioxidant Activity Assay

DPPH Radical Scavenging Activity

Hydroxyl Radical Scavenging Activity

Superoxide Anion Scavenging Activity

ABTS Scavenging Activity

2.11.3. Anti-Inflammatory Activity

Culture of RAW264.7 Macrophages

Cell Proliferation, NO, and Cytokine (IL-6 and TNF-α) Determination

ROS Determination

2.12. Statistical Analysis

3. Results

3.1. Characterization of Poly-D-Mannose

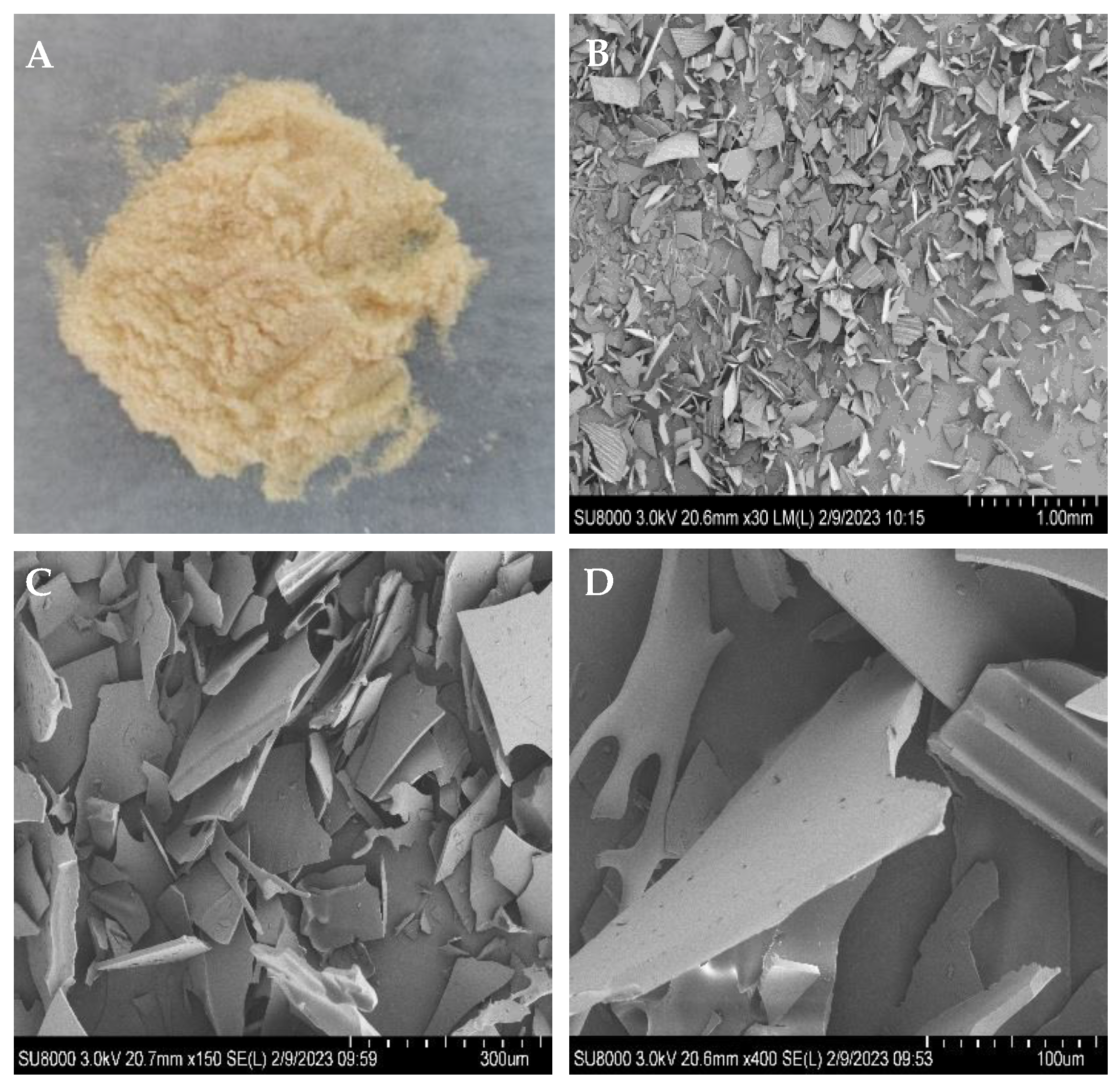

3.1.1. SEM Observation

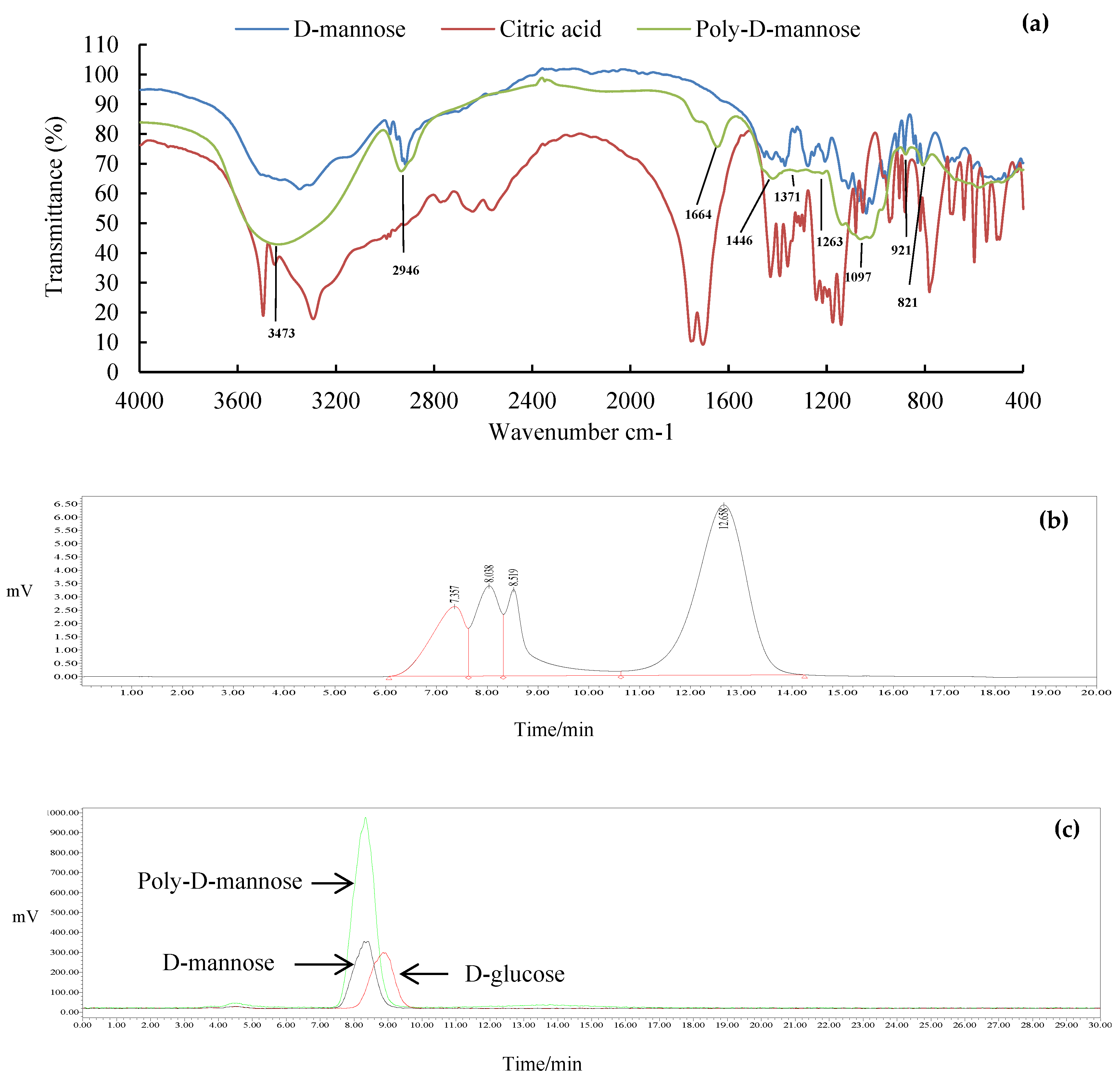

3.1.2. FT-IR

3.1.3. Molecular Weight

3.1.4. Total Sugar Content and Monosaccharide Composition

3.1.5. Degree of Branching

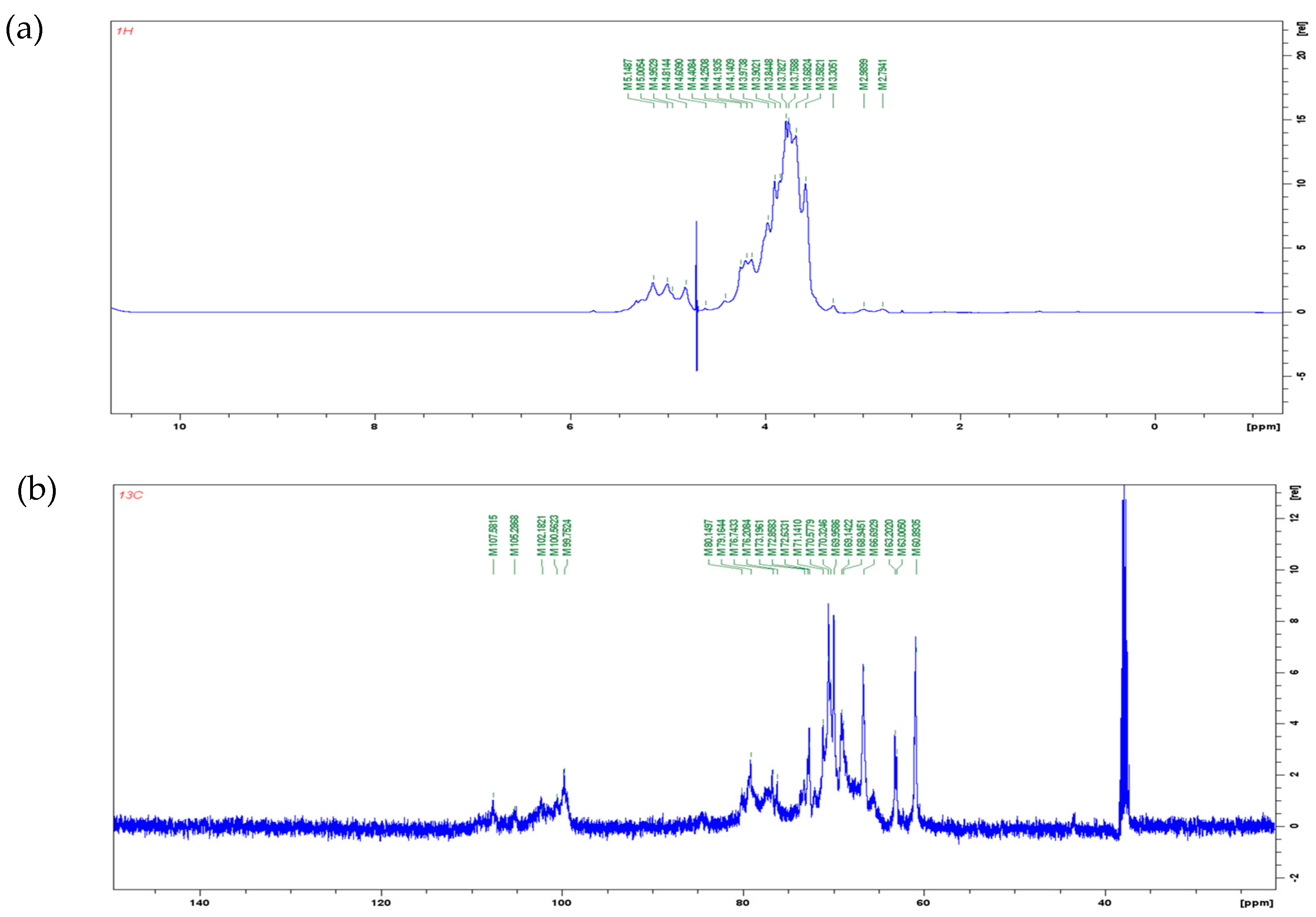

3.1.6. NMR Analysis

3.2. Safety Profile

3.2.1. Cytotoxicity

3.2.2. Hemolysis

3.3. Biological Activity Analysis

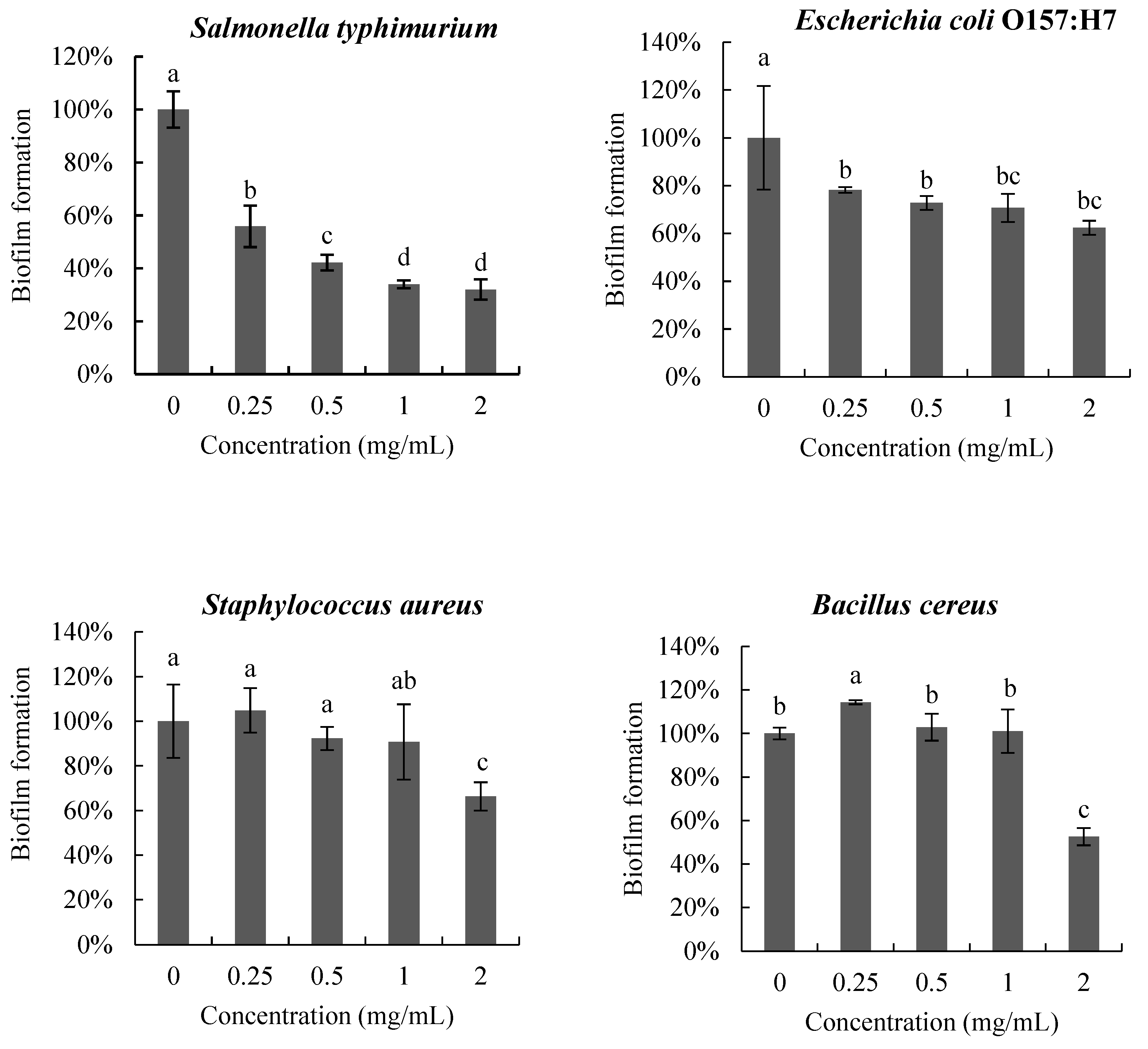

3.3.1. Anti-Biofilm Activity

3.3.2. Antioxidant Activity

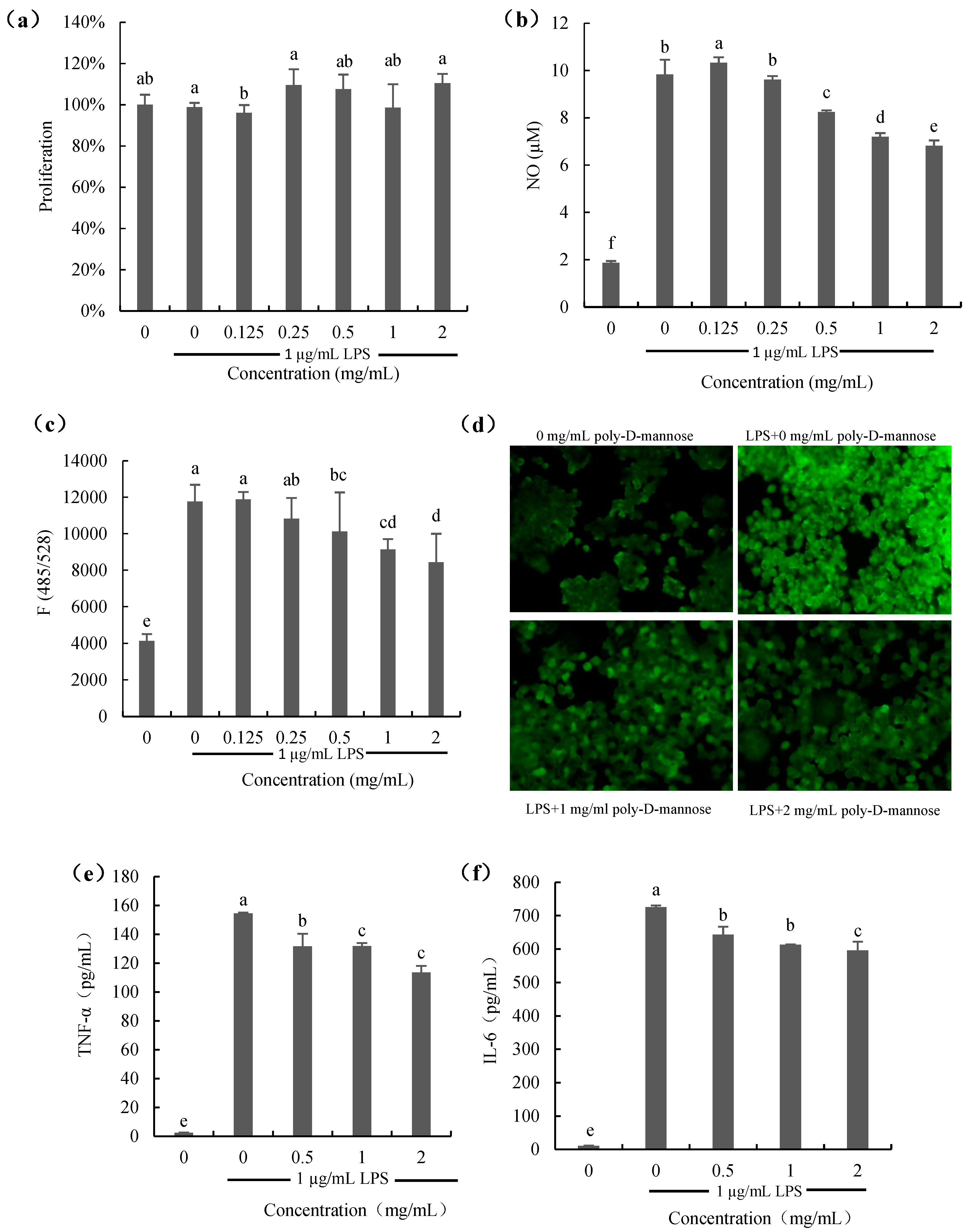

3.3.3. Anti-Inflammatory Result

- Proliferation and NO production

- 2.

- ROS production

- 3.

- The production of IL-6 and TNF-α

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moreira, L.R.S.; Filho, E.X.F. An overview of mannan structure and mannan-degrading enzyme systems. Appl. Microbiol. Biotechnol. 2008, 79, 165–178. [Google Scholar] [CrossRef] [PubMed]

- Liepman, A.H.; Nairn, C.J.; Willats, W.G.; Sørensen, I.; Roberts, A.W.; Keegstra, K. Functional Genomic Analysis Supports Conservation of Function Among Cellulose Synthase-like A Gene Family Members and Suggests Diverse Roles of Mannans in Plants. Plant Physiol. 2007, 143, 1881–1893. [Google Scholar] [CrossRef] [PubMed]

- Olaniyi, O.O.; Igbe, F.O.; Ekundayo, T.C. Optimization studies on mannanase production by Trichosporonoides oedocephalis in submerged state fermentation. J. Biotechnol. Pharm. Res. 2013, 4, 110–116. [Google Scholar]

- Bacon, J.S.; Farmer, V.C.; Jones, D.; Taylor, I.F. The glucan components of the cell wall of baker’s yeast (Saccharomyces cerevisiae) considered in relation to its ultrastructure. Biochem. J. 1969, 114, 557–567. [Google Scholar] [CrossRef] [PubMed]

- Fleet, G.H.; Manners, D.J. Isolation and Composition of an Alkali-soluble Glucan from the Cell Walls of Saccharomyces cerevisiae. Microbiology 1976, 94, 180–192. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Zhong, D.; Sun, R.; Zhang, Y.; Pegg, R.B.; Zhong, G. Prevention of loperamide induced constipation in mice by KGM and the mechanisms of different gastrointestinal tract microbiota regulation. Carbohydr. Polym. 2021, 256, 117418. [Google Scholar] [CrossRef] [PubMed]

- Abbott, D.W.; Martens, E.C.; Gilbert, H.J.; Cuskin, F.; Lowe, E.C. Coevolution of yeast mannan digestion: Convergence of the civilized human diet, distal gut microbiome, and host immunity. Gut Microbes 2015, 6, 334–339. [Google Scholar] [CrossRef]

- Singh, S.; Singh, G.; Arya, S.K. Mannans: An overview of properties and application in food products. Int. J. Biol. Macromol. 2018, 119, 79–95. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wu, Q.; Wu, X.; Algharib, S.A.; Gong, F.; Hu, J.; Luo, W.; Zhou, M.; Pan, Y.; Yan, Y.; et al. Structure, preparation, modification, and bioactivities of β-glucan and mannan from yeast cell wall: A review. Int. J. Biol. Macromol. 2021, 173, 445–456. [Google Scholar] [CrossRef]

- Patchaiyappan, A.; Prabakaran, M.; Sarangapany, S.; Kudungal, H.; Devipriya, S. Cytotoxic and antioxidant activity of the polysaccharide isolated from the seeds of Strychnos potatorum. Biocatal. Agric. Biotechnol. 2020, 25, 101586. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, G.; Lv, M. Extraction, characterization and antioxidant activities of mannan from yeast cell wall. Int. J. Biol. Macromol. 2018, 118, 952–956. [Google Scholar] [CrossRef]

- Tada, H.; Nemoto, E.; Shimauchi, H.; Watanabe, T.; Mikami, T.; Matsumoto, T.; Ohno, N.; Tamura, H.; Shibata, K.; Akashi, S.; et al. Saccharomyces cerevisiae- and Candida albicans-derived mannan induced production of tumor necrosis factor alpha by human monocytes in a CD14- and Toll-like receptor 4-dependent manner. Microbiol. Immunol. 2002, 46, 503–512. [Google Scholar] [CrossRef] [PubMed]

- Onishi, N.; Kawamoto, S.; Suzuki, H.; Santo, H.; Aki, T.; Shigeta, S.; Hashimoto, K.; Hide, M.; Ono, K. Dietary Pulverized Konjac Glucomannan Suppresses Scratching Behavior and Skin Inflammatory Immune Responses in NC/Nga Mice. Int. Arch. Allergy Immunol. 2007, 144, 95–104. [Google Scholar] [CrossRef]

- Smith, H.; Grant, S.; Parker, J.; Murphy, R. Yeast cell wall mannan rich fraction modulates bacterial cellular respiration potentiating antibiotic efficacy. Sci. Rep. 2020, 10, 21880. [Google Scholar] [CrossRef] [PubMed]

- Lakra, A.K.; Domdi, L.; Tilwani, Y.M.; Arul, V. Physicochemical and functional characterization of mannan exopolysaccharide from Weissella confusa MD1 with bioactivities. Int. J. Biol. Macromol. 2019, 143, 797–805. [Google Scholar] [CrossRef] [PubMed]

- Čížová, A.; Bystrický, P.; Bystrický, S. Ultrasonic and free-radical degradation of mannan from Candida albicans. Int. J. Biol. Macromol. 2015, 75, 32–36. [Google Scholar] [CrossRef]

- Mudgil, D.; Barak, S.; Khatkar, B.S. Effect of partially hydrolyzed guar gum on pasting, thermo-mechanical and rheological properties of wheat dough. Int. J. Biol. Macromol. 2016, 93, 131–135. [Google Scholar] [CrossRef]

- Jin, P.; Liang, Z.; Li, H.; Chen, C.; Xue, Y.; Du, Q. Biosynthesis of low-molecular-weight mannan using metabolically engineered Bacillus subtilis 168. Carbohydr. Polym. 2021, 251, 117115. [Google Scholar] [CrossRef]

- Grimaud, F.; Pizzut-Serin, S.; Tarquis, L.; Ladevèze, S.; Morel, S.; Putaux, J.L.; Potocki-Veronese, G. In Vitro Synthesis and Crystallization of β-1,4-Mannan. Biomacromolecules 2019, 20, 846–853. [Google Scholar] [CrossRef]

- Blibech, M.; Chaari, F.; Bhiri, F.; Dammak, I.; Ghorbel, R.E.; Chaabouni, S.E. Production of manno-oligosaccharides from locust bean gum using immobilized Penicillium occitanis mannanase. J. Mol. Catal. B Enzym. 2011, 73, 111–115. [Google Scholar] [CrossRef]

- Kadokawa, J.-I.; Tagaya, H. Architecture of polysaccharides with specific structures: Synthesis of hyperbranched polysaccharides. Polym. Adv. Technol. 2000, 11, 122–126. [Google Scholar] [CrossRef]

- Satoh, T.; Kakuchi, T. Synthesis of Hyperbranched Carbohydrate Polymers by Ring-Opening Multibranching Polymerization of Anhydro Sugar. Macromol. Biosci. 2007, 7, 999–1009. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Shen, B.; Qiao, M.; Linhardt, R.J.; Zhang, X. Recent advances on the one-pot synthesis to assemble size-controlled glycans and glycoconjugates and polysaccharides. Carbohydr. Polym. 2021, 258, 117672. [Google Scholar] [CrossRef] [PubMed]

- Allingham, R.P. Polydextrose—A new food ingredient: Technical Aspects. In Chemistry of Foods and Beverages: Recent Developments; Charalambous, G., Inglett, G., Eds.; Academic Press Inc.: New York, NY, USA, 1982; pp. 293–303. [Google Scholar]

- EFSA Panel on Food Additives and Flavourings (FAF); Younes, M.; Aquilina, G.; Castle, L.; Engel, K.H.; Fowler, P.; Fürst, P.; Gürtler, R.; Gundert-Remy, U.; Husøy, T. Re-evaluation of polydextrose (E 1200) as a food additive. EFSA J. 2021, 19, e06363. [Google Scholar]

- Zhou, C.; Huang, Y.; Chen, J.; Chen, H.; Wu, Q.; Zhang, K.; Li, D.; Li, Y.; Chen, Y. Effects of high-pressure homogenization extraction on the physicochemical properties and antioxidant activity of large-leaf yellow tea polysaccharide conjugates. Process. Biochem. 2022, 122, 87–94. [Google Scholar] [CrossRef]

- Ma, Y.; Xiu, W.; Wang, X.; Yu, S.; Luo, Y.; Gu, X. Structural characterization and in vitro antioxidant and hypoglycemic activities of degraded polysaccharides from sweet corncob. J. Cereal Sci. 2022, 108, 103579. [Google Scholar] [CrossRef]

- Xu, X.; Peng, Q.; Zhang, Y.; Tian, D.; Zhang, P.; Huang, Y.; Ma, L.; Dia, V.P.; Qiao, Y.; Shi, B. Antibacterial potential of a novel Lactobacillus casei strain isolated from Chinese northeast sauerkraut and the antibiofilm activity of its exopolysaccharides. Food Funct. 2020, 11, 4697–4706. [Google Scholar] [CrossRef]

- Wang, H.; Zainabu, M.; Zheng, R. Characterization of microwave-synthesized polydextrose and its radical-scavenging activity. J. Carbohydr. Chem. 2018, 37, 44–56. [Google Scholar] [CrossRef]

- Hawker, C.J.; Lee, R.; Frechet, J.M.J. One-step synthesis of hyperbranched dendritic polyesters. J. Am. Chem. Soc. 1991, 113, 4583–4588. [Google Scholar] [CrossRef]

- Rubini, D.; Hari, B.N.V.; Nithyanand, P. Chitosan coated catheters alleviates mixed species biofilms of Staphylococcus epidermidis and Candida albicans. Carbohydr. Polym. 2020, 252, 117192. [Google Scholar] [CrossRef]

- Upadhyay, J.; Kumar, A.; Gogoi, B.; Buragohain, A.K. Antibacterial and hemolysis activity of polypyrrole nanotubes decorated with silver nanoparticles by an in-situ reduction process. Mater. Sci. Eng. C 2015, 54, 8–13. [Google Scholar] [CrossRef]

- Xie, J.H.; Du, M.X.; Shen, M.Y.; Wu, T.; Lin, L.H. Physico-chemical properties, antioxidant activities and angiotensin-I converting enzyme inhibitory of protein hydrolysates from Mung bean (Vigna radiate). Food Chem. 2019, 270, 243–250. [Google Scholar] [CrossRef]

- Wu, S.M.; Liu, G.; Jin, W.H.; Xiu, P.Y.; Sun, C.M. Antibiofilm and Anti-infection of a Marine Bacterial Exopolysaccharide Against Pseudomonas aeruginasa. Front Microbiol. 2016, 7, 102. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Liu, L.; Su, Y.; Li, H.; Sun, Q.; Liang, X.; Lv, J. Antioxidative activity of lactic acid bacteria in yogurt. Afr. J. Microbiol. Res. 2011, 5, 5194–5201. [Google Scholar] [CrossRef]

- Gu, J.; Zhang, H.; Yao, H.; Zhou, J.; Duan, Y.; Ma, H. Comparison of characterization, antioxidant and immunological activities of three polysaccharides from Sagittaria sagittifolia L. Carbohydr. Polym. 2020, 235, 115939. [Google Scholar] [CrossRef]

- Cui, Y.; Liu, X.; Li, S.; Hao, L.; Du, J.; Gao, D.; Kang, Q.; Lu, J. Extraction, characterization and biological activity of sulfated polysaccharides from seaweed Dictyopteris divaricate. Int. J. Biol. Macromol. 2018, 117, 256–263. [Google Scholar] [CrossRef]

- Jia, R.B.; Li, Z.R.; Wu, J.; Ou, Z.R.; Zhu, Q.; Sun, B.; Lin, L.; Zhao, M. Physicochemical properties of polysaccharide fractions from Sargassum fusiforme and their hypoglycemic and hypolipidemic activities in type 2 diabetic rats. Int. J. Biol. Macromol. 2020, 147, 428–438. [Google Scholar] [CrossRef]

- Yan, J.-K.; Wu, L.-X.; Qiao, Z.-R.; Cai, W.-D.; Ma, H. Effect of different drying methods on the product quality and bioactive polysaccharides of bitter gourd (Momordica charantia L.) slices. Food Chem. 2019, 271, 588–596. [Google Scholar] [CrossRef]

- Dai, Y.-L.; Jiang, Y.-F.; Lee, H.G.; Jeon, Y.-J.; Kang, M.-C. Characterization and screening of anti-tumor activity of fucoidan from acid-processed hijiki (Hizikia fusiforme). Int. J. Biol. Macromol. 2019, 139, 170–180. [Google Scholar] [CrossRef]

- Zhang, W.N.; Gong, L.L.; Zhou, Z.B.; Sun, M.; Li, Y.Y.; Sun, J.W.; Chen, Y. Structural characterization and immunomodulatory activity of a mannan from Helvella leucopus. Int. J. Biol. Macromol. 2022, 212, 495–507. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Liu, J.; Tang, N.; Deng, J.; Liu, C.; Kan, H.; Zhao, P.; Zhang, X.; Shi, Z.; Liu, Y. Sequential extraction, structural characterization, and antioxidant activity of polysaccharides from Dendrocalamus brandisii bamboo shoot shell. Food Chem. X 2023, 17, 100621. [Google Scholar] [CrossRef] [PubMed]

- Schröder, R.; Atkinson, R.G.; Redgwell, R.J. Re-interpreting the role of endo-β-mannanases as mannan endotransglycosylase/hydrolases in the plant cell wall. Ann. Bot. 2009, 104, 197–204. [Google Scholar] [CrossRef] [PubMed]

- Nakanishi-Shindo, Y.; Nakayama, K.I.; Tanaka, A.; Toda, Y.; Jigami, Y. Structure of the N-linked oligosaccharides that show the complete loss of alpha-1, 6-polymannose outer chain from och1, och1 mnn1, and och1 mnn1alg3 mutants of Saccharomyces cerevisiae. J. Biol. Chem. 1993, 268, 26338–26345. [Google Scholar] [CrossRef]

- Young, M.; Davies, M.J.; Bailey, D.; Gradwell, M.J.; Smestad-Paulsen, B.; Wold, J.K.; Barnes, R.M.; Hounsell, E.F. Characterization of oligosaccharides from an antigenic mannan of Saccharomyces cerevisiae. Glycoconj. J. 1998, 15, 815–822. [Google Scholar] [CrossRef] [PubMed]

- Voit, B.I.; Lederer, A. Hyperbranched and Highly Branched Polymer Architectures—Synthetic Strategies and Major Characterization Aspects. Chem. Rev. 2009, 109, 5924–5973. [Google Scholar] [CrossRef]

- Costerton, J.W.; Cheng, K.J.; Geesey, G.G.; Ladd, T.I.; Nickel, J.C.; Dasgupta, M.; Marrie, T.J. Bacterial Biofilms in Nature and Disease. Annu. Rev. Microbiol. 1987, 41, 435–464. [Google Scholar] [CrossRef]

- Jiang, P.; Li, J.; Han, F.; Duan, G.; Lu, X.; Gu, Y.; Yu, W. Antibiofilm Activity of an Exopolysaccharide from Marine Bacterium Vibrio sp. QY101. PLoS ONE 2011, 6, e18514. [Google Scholar] [CrossRef]

- Zammuto, V.; Rizzo, M.G.; Spanò, A.; Spagnuolo, D.; Di Martino, A.; Morabito, M.; Manghisi, A.; Genovese, G.; Guglielmino, S.; Calabrese, G.; et al. Effects of crude polysaccharides from marine macroalgae on the adhesion and biofilm formation of Pseudomonas aeruginosa and Staphylococcus aureus. Algal Res. 2022, 63, 102646. [Google Scholar] [CrossRef]

- Jiang, H.; Luan, Z.; Fan, Z.; Wu, X.; Xu, Z.; Zhou, T.; Wang, H. Antibacterial, Antibiofilm, and Antioxidant Activity of Polysaccharides Obtained from Fresh Sarcotesta of Ginkgo biloba: Bioactive Polysaccharide that Can Be Exploited as a Novel Biocontrol Agent. Evidence Based Complement. Altern. Med. 2021, 2021, 5518403. [Google Scholar] [CrossRef]

- Kim, Y.; Oh, S.; Kim, S.H. Released exopolysaccharide (r-EPS) produced from probiotic bacteria reduce biofilm formation of enterohemorrhagic Escherichia coli O157:H7. Biochem. Biophys. Res. Commun. 2009, 379, 324–329. [Google Scholar] [CrossRef]

- Wittschier, N.; Lengsfeld, C.; Vorthems, S.; Stratmann, U.; Ernst, J.F.; Verspohl, E.J.; Hensel, A. Large molecules as anti-adhesive compounds against pathogens. J. Pharm. Pharmacol. 2007, 59, 777–786. [Google Scholar] [CrossRef]

- Rehman, T.; Yin, L.; Latif, M.B.; Chen, J.; Wang, K.; Geng, Y.; Huang, X.; Abaidullah, M.; Guo, H.; Ouyang, P. Adhesive mechanism of different Salmonella fimbrial adhesins. Microb. Pathog. 2019, 137, 103748. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Cheng, F. Antioxidant activity of bioactive polysaccharides isolated from natural sources. J. Anim. Sci. Biotechno. 2011, 2, 230–238. [Google Scholar]

- Fan, J.; Feng, H.; Yu, Y.; Sun, M.; Liu, Y.; Li, T.; Sun, X.; Liu, S.; Sun, M. Antioxidant activities of the polysaccharides of Chuanminshen violaceum. Carbohydr. Polym. 2017, 157, 629–636. [Google Scholar] [CrossRef] [PubMed]

- Machová, E.; Bystrický, S. Antioxidant capacities of mannans and glucans are related to their susceptibility of free radical degradation. Int. J. Biol. Macromol. 2013, 61, 308–311. [Google Scholar] [CrossRef] [PubMed]

- Faustino, M.; Pereira, C.F.; Durão, J.; Oliveira, A.S.; Pereira, J.O.; Ferreira, C.; Pintado, M.E.; Carvalho, A.P. Effect of drying technology in Saccharomyces cerevisiae mannans: Structural, physicochemical, and functional properties. Food Chem. 2023, 412, 135545. [Google Scholar] [CrossRef]

- Yang, B.; Jiang, Y.; Zhao, M.; Chen, F.; Wang, R.; Chen, Y.; Zhang, D. Structural characterisation of polysaccharides purified from longan (Dimocarpus longan Lour.) fruit pericarp. Food Chem. 2009, 115, 609–614. [Google Scholar] [CrossRef]

- Fujiwara, N.; Kobayashi, K. Macrophages in inflammation. Curr. Drug Targets Inflamm. Allergy 2005, 4, 281–286. [Google Scholar] [CrossRef]

- Jayawardena, T.U.; Kim, H.S.; Sanjeewa, K.A.; Kim, S.Y.; Rho, J.R.; Jee, Y.; Ahn, G.; Jeon, Y.J. Sargassum horneri and isolated 6-hydroxy-4, 4, 7a-trimethyl-5,6,7,7a-tetrahydrobenzofuran-2(4H)-one (HTT); LPS-induced inflammation attenuation via suppressing NF-κB, MAPK and oxidative stress through Nrf2/HO-1 pathways in RAW 264.7 macrophages. Algal Res. 2019, 40, 101513. [Google Scholar] [CrossRef]

- Palladino, M.A.; Bahjat, F.R.; Theodorakis, E.A.; Moldawer, L.L. Anti-TNF-α therapies: The next generation. Nat. Rev. Drug Discov. 2003, 2, 736–746. [Google Scholar] [CrossRef]

- Pu, H.-L.; Chiang, W.-L.; Maiti, B.; Liao, Z.-X.; Ho, Y.-C.; Shim, M.S.; Chuang, E.-Y.; Xia, Y.; Sung, H.-W. Nanoparticles with Dual Responses to Oxidative Stress and Reduced pH for Drug Release and Anti-inflammatory Applications. ACS Nano 2014, 8, 1213–1221. [Google Scholar] [CrossRef]

- Wang, Y.H.; Zeng, K.W. Natural products as a crucial source of anti-inflammatory drugs: Recent trends and advancements. Tradit. Med. Res. 2019, 4, 257–268. [Google Scholar] [CrossRef]

- Sarkar, D.; Saha, P.; Gamre, S.; Bhattacharjee, S.; Hariharan, C.; Ganguly, S.; Sen, R.; Mandal, G.; Chattopadhyay, S.; Majumdar, S.; et al. Anti-inflammatory effect of allylpyrocatechol in LPS-induced macrophages is mediated by suppression of iNOS and COX-2 via the NF-κB pathway. Int. Immunopharmacol. 2008, 8, 1264–1271. [Google Scholar] [CrossRef]

- Pugh, T.J.; Sartor, C.I.; O’Neil, B.; Raben, D. Biologics and Their Interactions with Radiation. In Clinical Radiation Oncology; Elsevier: Amsterdam, The Netherlands, 2012; pp. 83–94. [Google Scholar]

- Yu, Q.; Nie, S.-P.; Wang, J.-Q.; Yin, P.-F.; Huang, D.-F.; Li, W.-J.; Xie, M.-Y. Toll-like receptor 4-mediated ROS signaling pathway involved in Ganoderma atrum polysaccharide-induced tumor necrosis factor-α secretion during macrophage activation. Food Chem. Toxicol. 2014, 66, 14–22. [Google Scholar] [CrossRef] [PubMed]

- Freeman, B.A.; Crapo, J.D. Biology of disease: Free radicals and tissue injury. Lab. Investig. 1982, 47, 412–426. [Google Scholar] [PubMed]

- Hou, C.; Chen, L.; Yang, L.; Ji, X. An insight into anti-inflammatory effects of natural polysaccharides. Int. J. Biol. Macromol. 2020, 153, 248–255. [Google Scholar] [CrossRef]

- Nian, M.; Lee, P.; Khaper, N.; Liu, P. Inflammatory Cytokines and Postmyocardial Infarction Remodeling. Circ. Res. 2004, 94, 1543–1553. [Google Scholar] [CrossRef]

- Pan, M.H.; Maresz, K.; Lee, P.S.; Wu, J.C.; Ho, C.T.; Popko, J.; Mehta, D.S.; Stohs, S.J.; Badmaev, V. Inhibition of TNF-α, IL-1α, and IL-1β by pretreatment of human monocytederived macrophages with Menaquinone-7 and cell activation with TLR agonists in vitro. J. Med. Food. 2016, 19, 663–669. [Google Scholar] [CrossRef]

- Yang, Y.; Xing, R.; Liu, S.; Qin, Y.; Li, K.; Yu, H.; Li, P. Immunostimulatory effects of sulfated chitosans on RAW 264.7 mouse macrophages via the activation of PI3K/Akt signaling pathway. Int. J. Biol. Macromol. 2018, 108, 1310–1321. [Google Scholar] [CrossRef] [PubMed]

- Levy-Ontman, O.; Huleihel, M.; Hamias, R.; Wolak, T.; Paran, E. An anti-inflammatory effect of red microalga polysaccharides in coronary artery endothelial cells. Atherosclerosis 2017, 264, 11–18. [Google Scholar] [CrossRef]

- Sanjeewa, K.K.A.; Fernando, I.P.S.; Kim, S.Y.; Kim, H.S.; Ahn, G.; Jee, Y.; Jeon, Y.J. In vitro and in vivo anti-inflammatory activities of high molecular weight sulfated polysaccharide; containing fucose separated from Sargassum horneri: Short communication. Int. J. Biol. Macromol. 2018, 107, 803–807. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Gu, X.; Tong, Y.; Wang, X.; Wu, J.; Chang, C. Protective effects of mannan/β-glucans from yeast cell wall on the deoxyniyalenol-induced oxidative stress and autophagy in IPEC-J2 cells. Int. J. Biol. Macromol. 2019, 135, 619–629. [Google Scholar] [CrossRef] [PubMed]

- Song, M.; Fan, Y.; Su, H.; Ye, J.; Liu, F.; Zhu, X.; Wang, L.; Gao, P.; Shu, G.; Wang, Z.; et al. Effects of Actigen, a second-generation mannan rich fraction, in antibiotics-free diets on growth performance, intestinal barrier functions and inflammation in weaned piglets. Livest. Sci. 2019, 229, 4–12. [Google Scholar] [CrossRef]

- Wang, W.; Li, Z.; Han, Q.; Guo, Y.; Zhang, B.; D’inca, R. Dietary live yeast and mannan-oligosaccharide supplementation attenuate intestinal inflammation and barrier dysfunction induced by Escherichia coli in broilers. Br. J. Nutr. 2016, 116, 1878–1888. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.-J.; Huang, X.-J.; Shi, X.-D.; Chen, H.-H.; Cui, S.W.; Nie, S.-P. Protective effect of three glucomannans from different plants against DSS induced colitis in female BALB/c mice. Food Funct. 2019, 10, 1928–1939. [Google Scholar] [CrossRef]

- Meng, L.-Z.; Feng, K.; Wang, L.-Y.; Cheong, K.-L.; Nie, H.; Zhao, J.; Li, S.-P. Activation of mouse macrophages and dendritic cells induced by polysaccharides from a novel Cordyceps sinensis fungus UM01. J. Funct. Foods 2014, 9, 242–253. [Google Scholar] [CrossRef]

- Park, B.S.; Lee, J.-O. Recognition of lipopolysaccharide pattern by TLR4 complexes. Exp. Mol. Med. 2013, 45, e66. [Google Scholar] [CrossRef]

- Zhang, X.; Qi, C.; Guo, Y.; Zhou, W.; Zhang, Y. Toll-like receptor 4-related immunostimulatory polysaccharides: Primary structure, activity relationships, and possible interaction models. Carbohydr. Polym. 2016, 149, 186–206. [Google Scholar] [CrossRef]

| Peak Number | Derivatives | Linkage | Relative Molar Percentage | |

|---|---|---|---|---|

| Terminal residues | 1 | 2,3,4,6-Me4-Man | T-Manp-(1→ | 29.39 |

| Linear residues | 2 | 3,4,6-Me3-Man | →2)-Manp-(1→ | 6.34 |

| 3 | 2,3,6-Me3-Man | →4)-Manp-(1→ | 11.24 | |

| 4 | 2,3,4-Me3-Man | →6)-Manp-(1→ | 22.72 | |

| 5 | 2,3,5-Me3-Man | →6)-Manf-(1→ | 6.60 | |

| Branch residues | 6 | 2,3-Me2-Man | →4,6)-Manp-(1→ | 10.95 |

| 7 | 3,4-Me2-Man | →2,6)-Manp-(1→ | 4.15 | |

| 8 | 6-Me-Man | →2,3,4)-Manp-(1→ | 0.91 | |

| 9 | 2,4-Me2-Man | →3,6)-Manp-(1→ | 1.95 | |

| 10 | 2-Me-Man | →3,4,6)-Manp-(1→ | 1.92 | |

| 11 | 3-Me-Man | →2,4,6)-Manp-(1→ | 3.83 |

| Hemolysis Rate of Different Concentrations of Poly-D-Mannose (mg/mL) | ||||||||

|---|---|---|---|---|---|---|---|---|

| 0.125 | 0.25 | 0.5 | 1 | 2 | 4 | 8 | ||

| 4 h | Pos1-H2O | 0.00 ± 0.00% | 0.00 ± 0.19% | −0.13 ± 0.11% | 0.19 ± 0.00% | 0.38 ± 0.19% | 0.19 ± 0.19% | 0.50 ± 0.22% |

| Pos2-TritonX-100 | 0.00 ± 0.00% | 0.00 ± 0.19% | −0.13 ± 0.11% | 0.19 ± 0.00% | 0.38 ± 0.19% | 0.19 ± 0.19% | 0.50 ± 0.22% | |

| 20 h | Pos1-H2O | 0.06 ± 0.44% | −0.13 ± 0.11% | −0.26 ± 0.11% | −0.13 ± 0.11% | −0.06 ± 0.11% | −0.06 ± 0.11% | 0.26 ± 0.11% |

| Pos2-TritonX-100 | 0.07 ± 0.49% | 0.14 ± 0.12% | 0.28 ± 0.12% | 0.14 ± 0.12% | 0.07 ± 0.12% | 0.07 ± 0.12% | 0.28 ± 0.12% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, D.; Qiao, Y.; Peng, Q.; Zhang, Y.; Gong, Y.; Shi, L.; Xiong, X.; He, M.; Xu, X.; Shi, B. A Poly-D-Mannose Synthesized by a One-Pot Method Exhibits Anti-Biofilm, Antioxidant, and Anti-Inflammatory Properties In Vitro. Antioxidants 2023, 12, 1579. https://doi.org/10.3390/antiox12081579

Tian D, Qiao Y, Peng Q, Zhang Y, Gong Y, Shi L, Xiong X, He M, Xu X, Shi B. A Poly-D-Mannose Synthesized by a One-Pot Method Exhibits Anti-Biofilm, Antioxidant, and Anti-Inflammatory Properties In Vitro. Antioxidants. 2023; 12(8):1579. https://doi.org/10.3390/antiox12081579

Chicago/Turabian StyleTian, Dandan, Yu Qiao, Qing Peng, Yuwei Zhang, Yuxin Gong, Linbo Shi, Xiaoyan Xiong, Mengxin He, Xiaoqing Xu, and Bo Shi. 2023. "A Poly-D-Mannose Synthesized by a One-Pot Method Exhibits Anti-Biofilm, Antioxidant, and Anti-Inflammatory Properties In Vitro" Antioxidants 12, no. 8: 1579. https://doi.org/10.3390/antiox12081579

APA StyleTian, D., Qiao, Y., Peng, Q., Zhang, Y., Gong, Y., Shi, L., Xiong, X., He, M., Xu, X., & Shi, B. (2023). A Poly-D-Mannose Synthesized by a One-Pot Method Exhibits Anti-Biofilm, Antioxidant, and Anti-Inflammatory Properties In Vitro. Antioxidants, 12(8), 1579. https://doi.org/10.3390/antiox12081579