Improvement in EMI Shielding Properties of Silicone Rubber/POE Blends Containing ILs Modified with Carbon Black and MWCNTs

Abstract

:Featured Application

Abstract

1. Introduction

2. Experimental

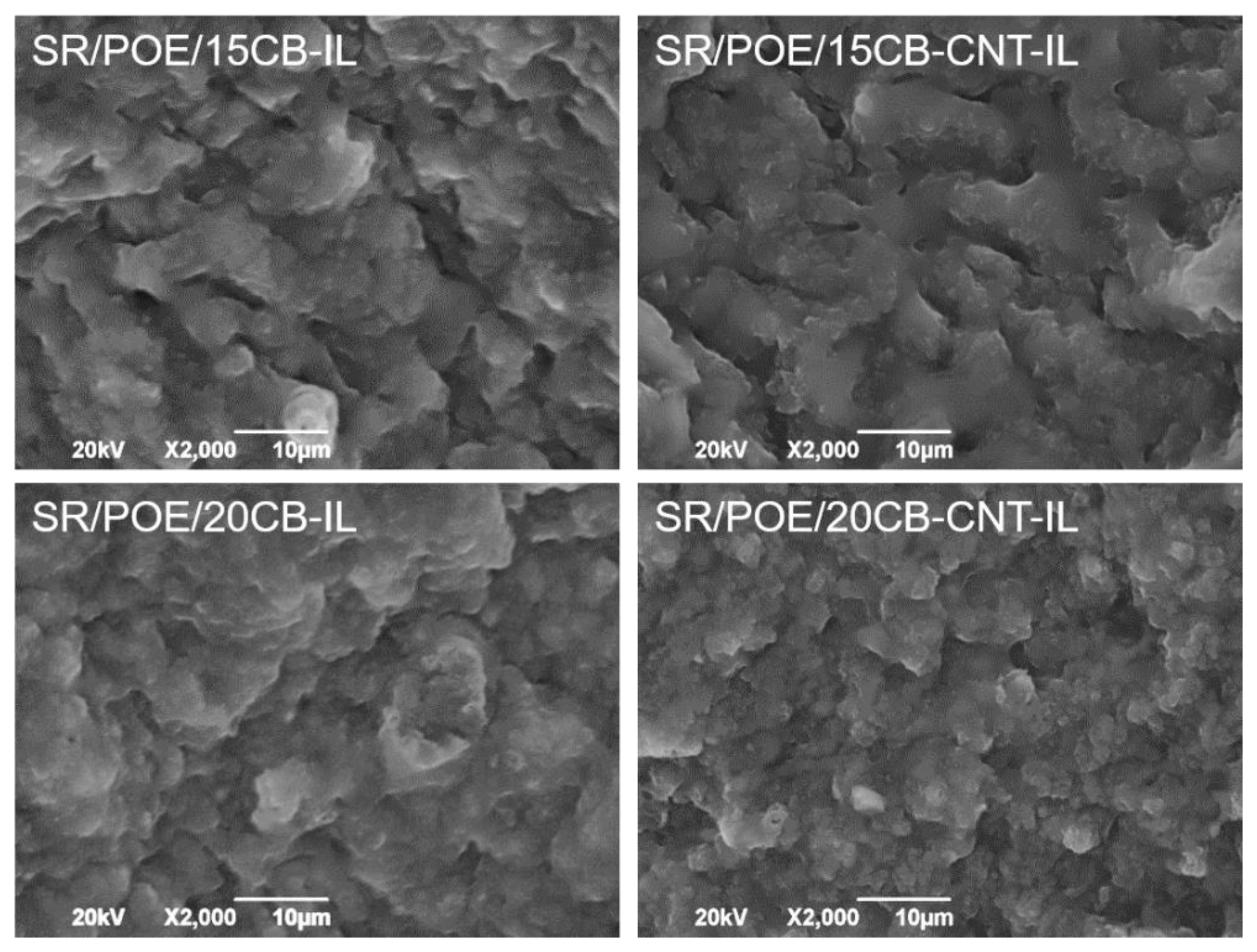

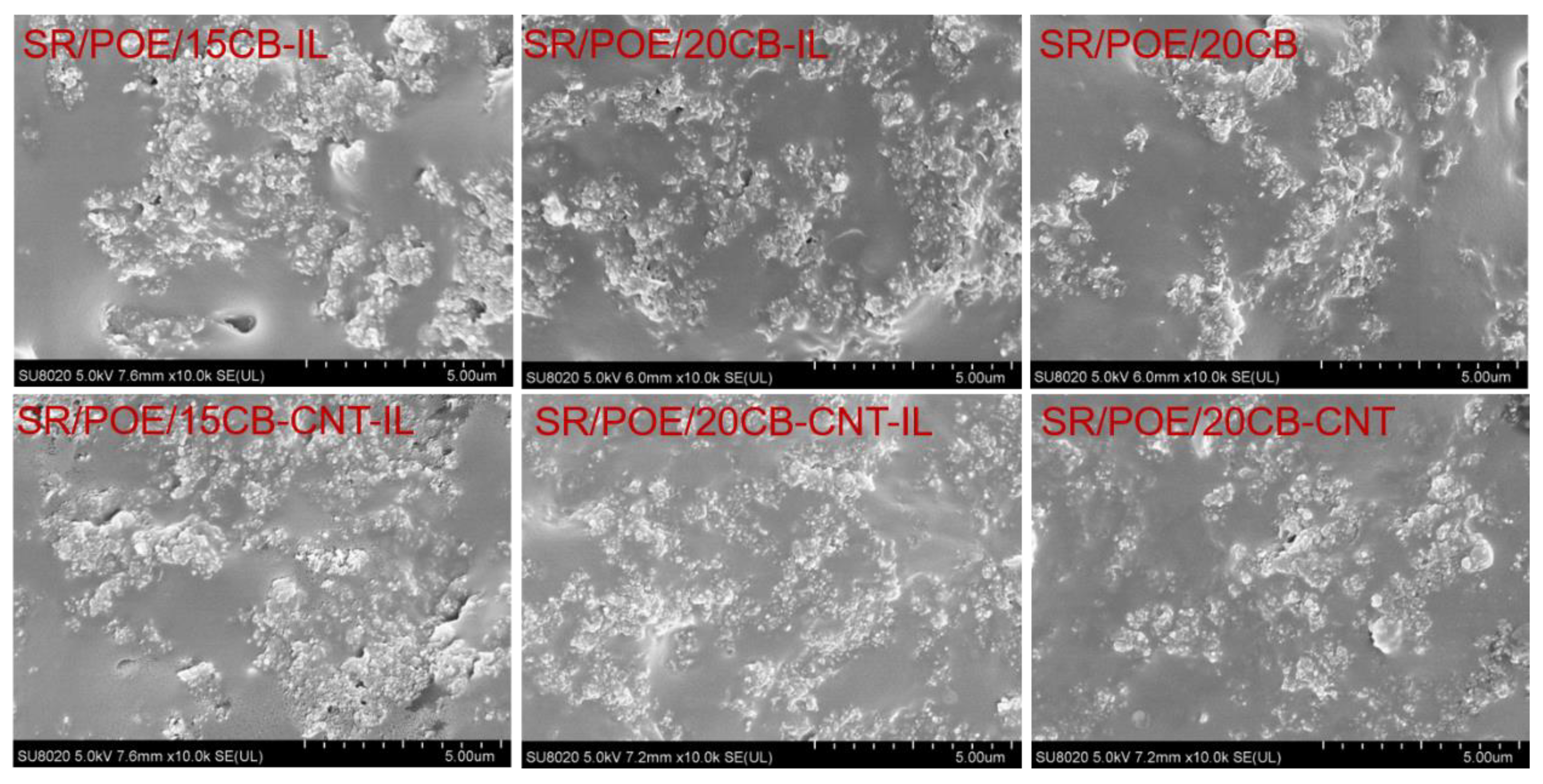

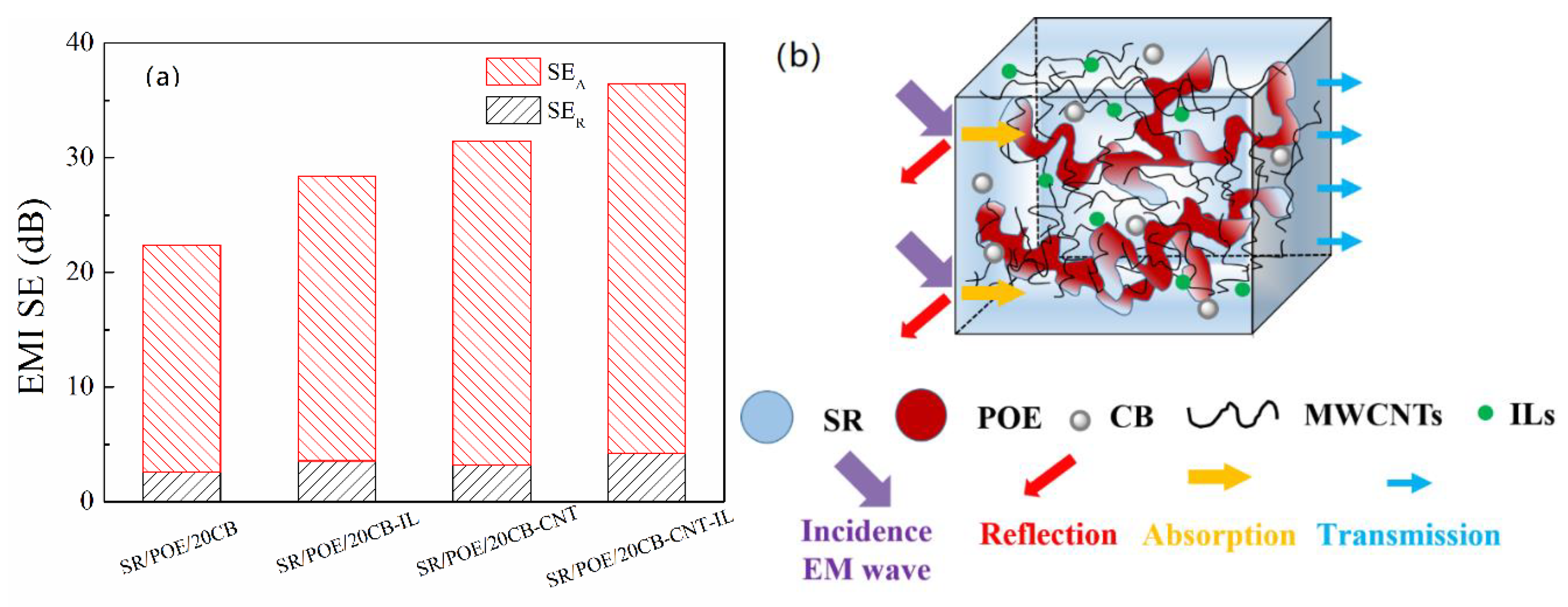

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, Y.L.; Li, M.J.; Pang, M.L.; Feng, S.Y.; Zhang, J.; Zhang, C.Q. Effects of multi-walled carbon nanotube structures on the electrical and mechanical properties of silicone rubber filled with multi-walled carbon nanotubes. J. Mater. Chem. C 2015, 3, 5573–5579. [Google Scholar] [CrossRef]

- Wang, H.B.; Teng, K.Y.; Chen, C.; Li, X.J.; Xu, Z.W.; Chen, L.; Fu, H.J.; Kuang, L.Y.; Ma, M.J.; Zhao, L.H. Conductivity and electromagnetic interference shielding of graphene-based architectures using MWCNTs as free radical scavenger in gamma-irradiation. Mater. Lett. 2017, 186, 78–81. [Google Scholar] [CrossRef]

- Wang, G.L.; Wang, L.; Mark, L.H.; Shaayegan, V.; Wang, G.Z.; Li, H.P.; Zhao, G.Q.; Park, C.B. Ultralow-threshold and lightweight biodegradable porous PLA/MWCNT with segregated conductive networks for high-performance thermal insulation and electromagnetic interference shielding applications. ACS Appl. Mater. Inter. 2018, 10, 1195–1203. [Google Scholar] [CrossRef] [PubMed]

- Engels, S.; Schneider, N.L.; Lefeldt, N.; Hein, C.M.; Zapka, M.; Michalik, A.; Elbers, D.; Kittel, A.; Hore, P.J.; Mouritsen, H. Anthropogenic electromagnetic noise disrupts magnetic compass orientation in a migratory bird. Nature 2014, 509, 353–356. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Yang, H.; Wang, J.L.; Li, F.X. The electromagnetic interference shielding of silicone rubber filled with nickel coated carbon fiber. Polym. Test. 2014, 38, 53–56. [Google Scholar] [CrossRef]

- Sudha, J.D.; Sivakala, S.; Kamlesh, P.; Nair, P.R. Development of electromagnetic shielding materials from the conductive blends of polystyrene polyaniline-clay nanocomposite. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1647–1652. [Google Scholar] [CrossRef]

- Das, N.C.; Khastgir, D.; Chaki, T.K.; Chakraborty, A. Electromagnetic interference shielding effectiveness of carbon black and carbon fibre filled EVA and NR based composites. Compos. Part A Appl. Sci. Manuf. 2000, 31, 1069–1081. [Google Scholar] [CrossRef]

- Zeng, Z.H.; Jin, H.; Chen, M.J.; Li, W.W.; Zhou, L.C.; Zhang, Z. Lightweight and anisotropic porous MWCNT/WPU composites for ultrahigh performance electromagnetic interference shielding. Adv. Funct. Mater. 2016, 26, 303–310. [Google Scholar] [CrossRef]

- Wang, G.L.; Zhao, G.Q.; Wang, S.; Zhang, L.; Park, C.B. Injection-molded microcellular PLA/graphite nanocomposites with dramatically enhanced mechanical and electrical properties for ultra-efficient EMI shielding applications. J. Mater. Chem. C 2018, 6, 6847–6859. [Google Scholar] [CrossRef]

- Jin, L.; Zhao, X.M.; Xu, J.F.; Luo, Y.Y.; Chen, D.Q.; Chen, G.H. The synergistic effect of a graphene nanoplate/Fe3O4@BaTiO3 hybrid and MWCNTs on enhancing broadband electromagnetic interference shielding performance. RSC Adv. 2018, 8, 2065. [Google Scholar] [CrossRef]

- Poothanari, M.A.; Abraham, J.; Kalarikkal, N.; Thomas, S. Excellent electromagnetic interference shielding and high electrical conductivity of compatibilized polycarbonate/polypropylene carbon nanotube blend nanocomposites. Ind. Eng. Chem. Res. 2018, 57, 4287–4297. [Google Scholar] [CrossRef]

- Kowsari, E.; Mohammadi, M. Synthesis of reduced and functional graphene oxide with magnetic ionic liquid and its application as an electromagnetic-absorbing coating. Compos. Sci. Technol. 2016, 126, 106–114. [Google Scholar] [CrossRef]

- Abraham, J.; Arif, M.P.; Kailas, L.; Kalarikkal, N.; George, S.C.; Thomas, S. Developing highly conducting and mechanically durable styrene butadiene rubber composites with tailored microstructural properties by a green approach using ionic liquid modified MWCNTs. RSC Adv. 2016, 6, 32493. [Google Scholar] [CrossRef]

- Abraham, J.; Arif, M.P.; Xavier, P.; Bose, S.; George, S.C.; Kalarikkal, N.; Thomas, S. Investigation into dielectric behaviour and electromagnetic interference shielding effectiveness of conducting styrene butadiene rubber composites containing ionic liquid modified MWCNT. Polymer 2017, 112, 102–115. [Google Scholar] [CrossRef]

- Li, Q.L.; Chen, L.; Ding, J.J.; Zhang, J.J.; Li, X.H.; Zheng, K.; Zhang, X.; Tian, X.Y. Open-cell phenolic carbon foam and electromagnetic interference shielding properties. Carbon 2016, 104, 90–105. [Google Scholar] [CrossRef]

- Cao, M.; Shu, J.J.; Chen, P.; Xia, R.; Yang, B.; Miao, J.B.; Qian, J.S. Orientation of boron nitride nanosheets in CM/EPDM co-continuous blends and their thermal conductive properties. Polym. Test. 2018, 69, 208–213. [Google Scholar] [CrossRef]

- Wang, P.; Xu, P.; Zhou, Y.Y.; Yang, Y.W.; Ding, Y.S. Effect of MWCNTs and P[MMA-IL] on the crystallization and dielectric behavior of PVDF composites. Eur. Polym. J. 2018, 99, 58–64. [Google Scholar] [CrossRef]

- Al-Saleh, M.H. Influence of conductive network structure on the EMI shielding and electrical percolation of carbon nanotube/polymer nanocomposites. Synth. Met. 2015, 205, 78–84. [Google Scholar] [CrossRef]

- Sang, G.L.; Dong, J.W.; He, X.T.; Jiang, J.C.; Li, J.B.; Xu, P.; Ding, Y.S. Electromagnetic interference shielding performance of polyurethane composites: A comparative study of GNs-IL/Fe3O4 and MWCNTs-IL/Fe3O4 hybrid fillers. Compos. Part B Eng. 2019, 164, 467–475. [Google Scholar] [CrossRef]

- Huang, H.D.; Liu, C.Y.; Zhou, D.; Jiang, X.; Zhong, G.J.; Yan, D.X.; Li, Z.M. Cellulose composite aerogel for highly efficient electromagnetic interference shielding. J. Mater. Chem. A 2015, 3, 4983–4991. [Google Scholar] [CrossRef]

| Sample | SR | POE | CB | MWCNTs | ILs | EVA | DBPH |

|---|---|---|---|---|---|---|---|

| SR/POE | 60 | 40 | - | - | - | 5 | 2 |

| SR/POE/5CB-IL | 60 | 40 | 5 | - | 1 | 5 | 2 |

| SR/POE/10CB-IL | 60 | 40 | 10 | - | 2 | 5 | 2 |

| SR/POE/15CB-IL | 60 | 40 | 15 | - | 3 | 5 | 2 |

| SR/POE/20CB | 60 | 40 | 20 | - | - | 5 | 2 |

| SR/POE/20CB-IL | 60 | 40 | 20 | - | 4 | 5 | 2 |

| SR/POE/15CB-CNT-IL | 60 | 40 | 10 | 5 | 3 | 5 | 2 |

| SR/POE/20CB-CNT | 60 | 40 | 15 | 5 | - | 5 | 2 |

| SR/POE/20CB-CNT-IL | 60 | 40 | 15 | 5 | 4 | 5 | 2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Yu, C.; Sang, G.; Xu, P.; Ding, Y. Improvement in EMI Shielding Properties of Silicone Rubber/POE Blends Containing ILs Modified with Carbon Black and MWCNTs. Appl. Sci. 2019, 9, 1774. https://doi.org/10.3390/app9091774

Liu C, Yu C, Sang G, Xu P, Ding Y. Improvement in EMI Shielding Properties of Silicone Rubber/POE Blends Containing ILs Modified with Carbon Black and MWCNTs. Applied Sciences. 2019; 9(9):1774. https://doi.org/10.3390/app9091774

Chicago/Turabian StyleLiu, Chao, Chuyang Yu, Guolong Sang, Pei Xu, and Yunsheng Ding. 2019. "Improvement in EMI Shielding Properties of Silicone Rubber/POE Blends Containing ILs Modified with Carbon Black and MWCNTs" Applied Sciences 9, no. 9: 1774. https://doi.org/10.3390/app9091774

APA StyleLiu, C., Yu, C., Sang, G., Xu, P., & Ding, Y. (2019). Improvement in EMI Shielding Properties of Silicone Rubber/POE Blends Containing ILs Modified with Carbon Black and MWCNTs. Applied Sciences, 9(9), 1774. https://doi.org/10.3390/app9091774