An Inverter Topology for Wireless Power Transfer System with Multiple Transmitter Coils

Abstract

1. Introduction

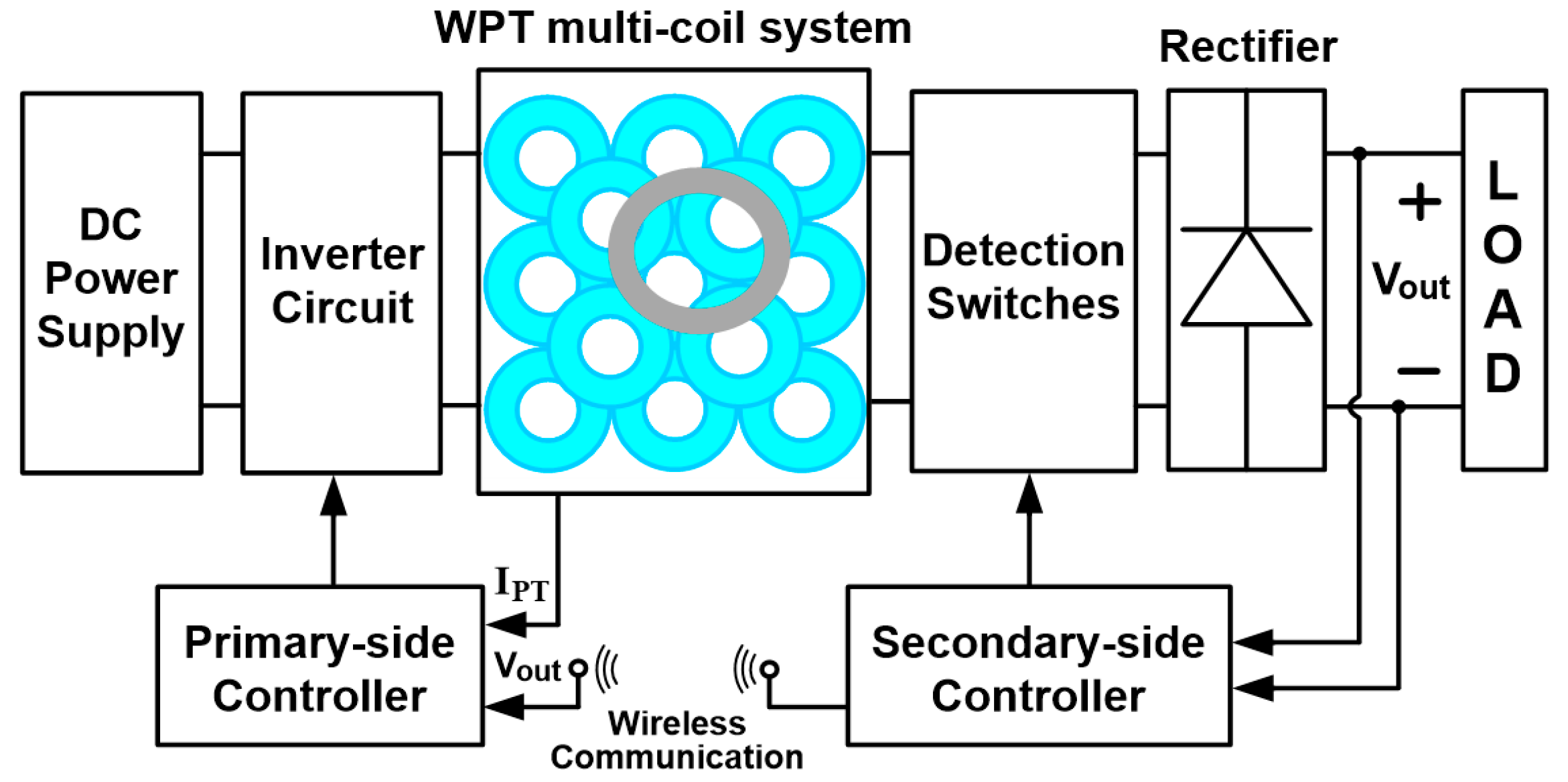

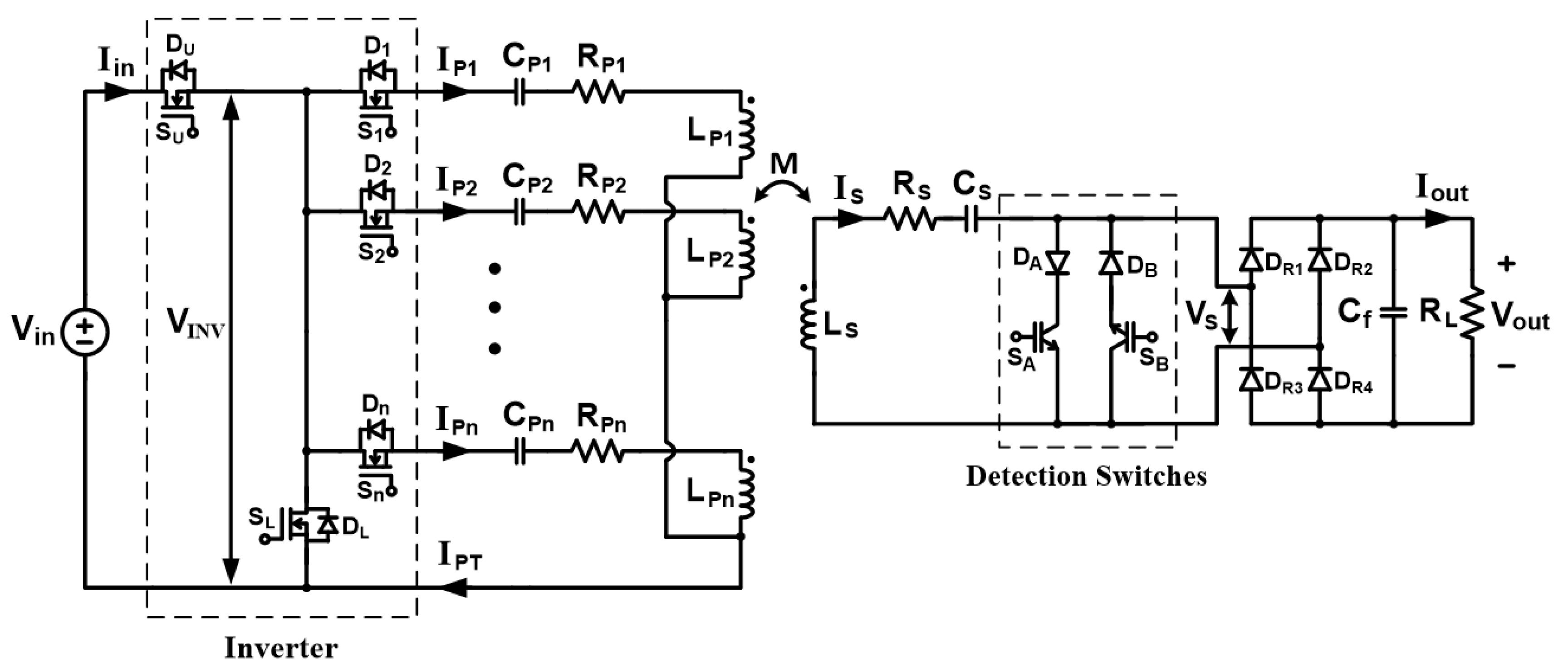

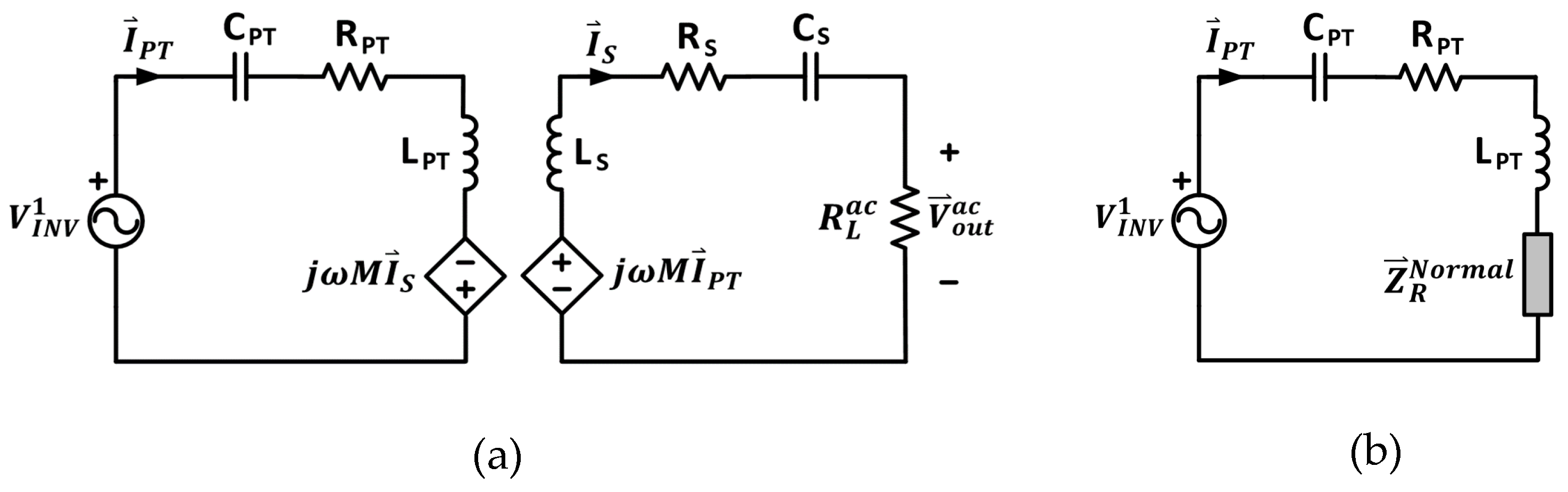

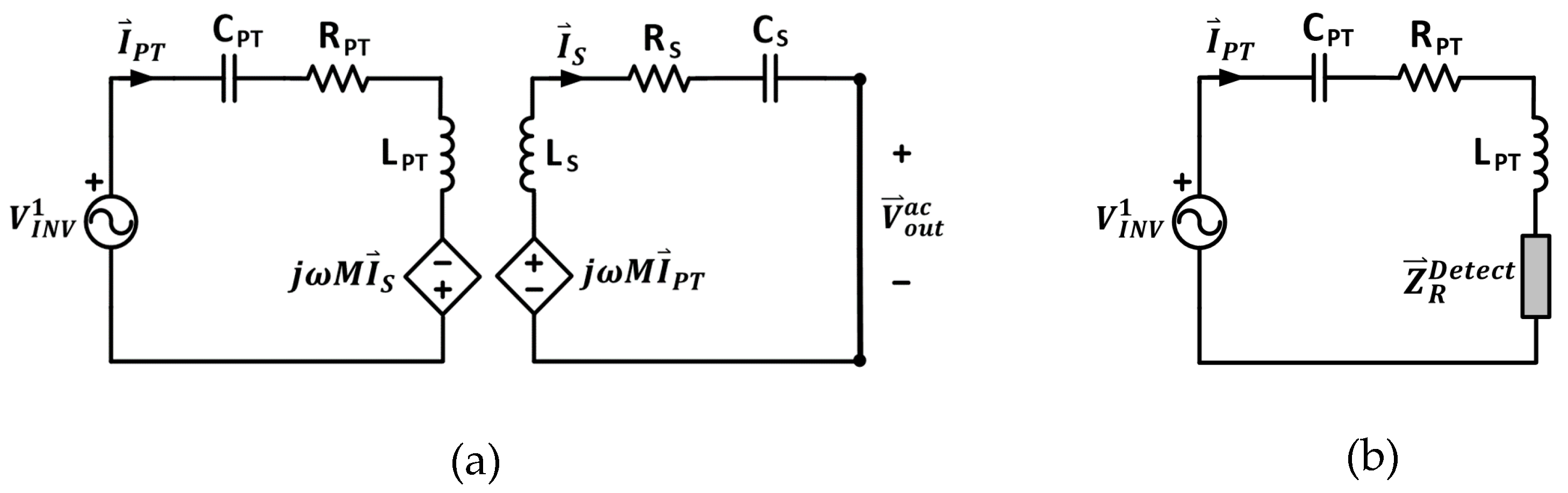

2. System Description and Operation

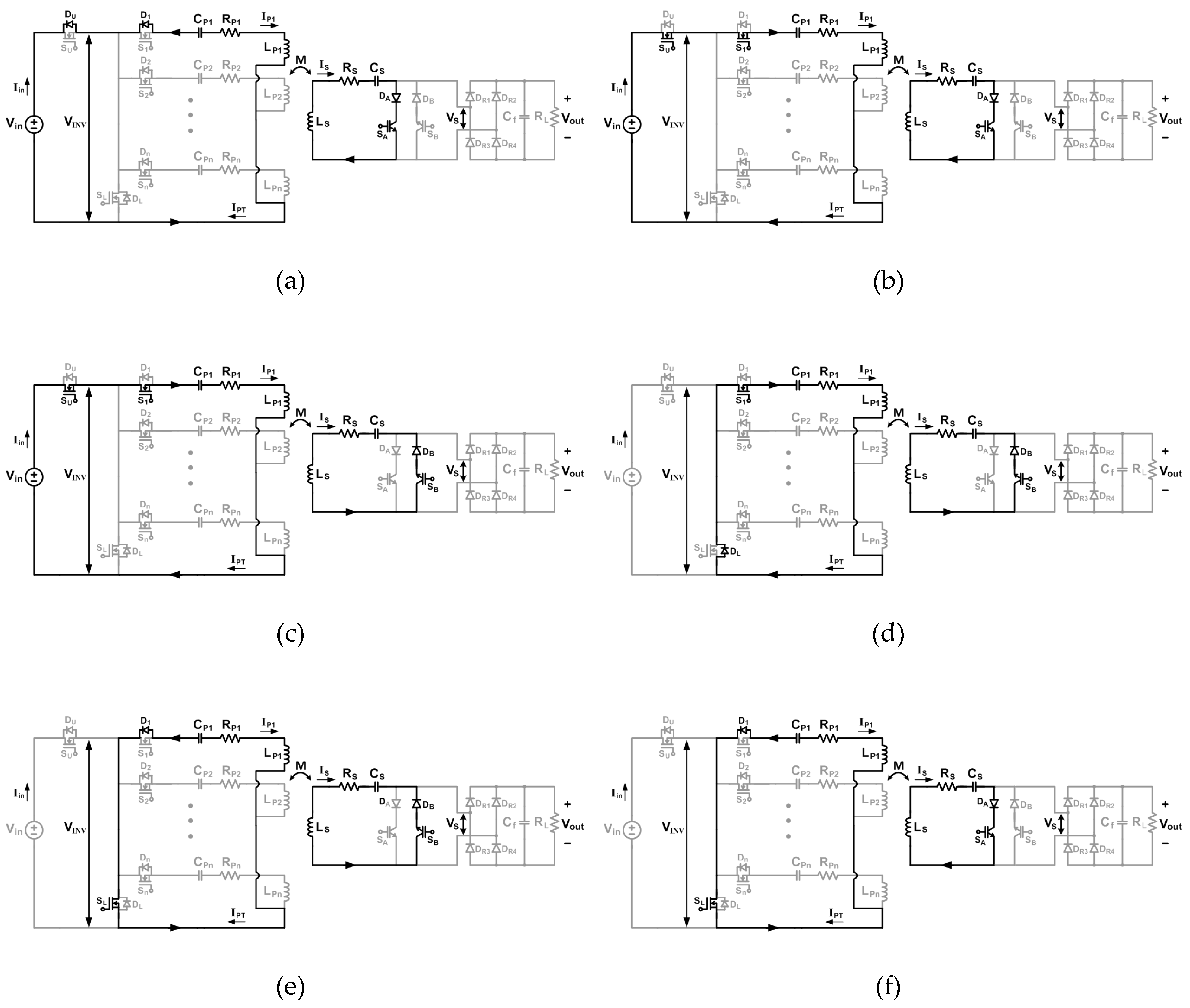

2.1. Circuit Configuration

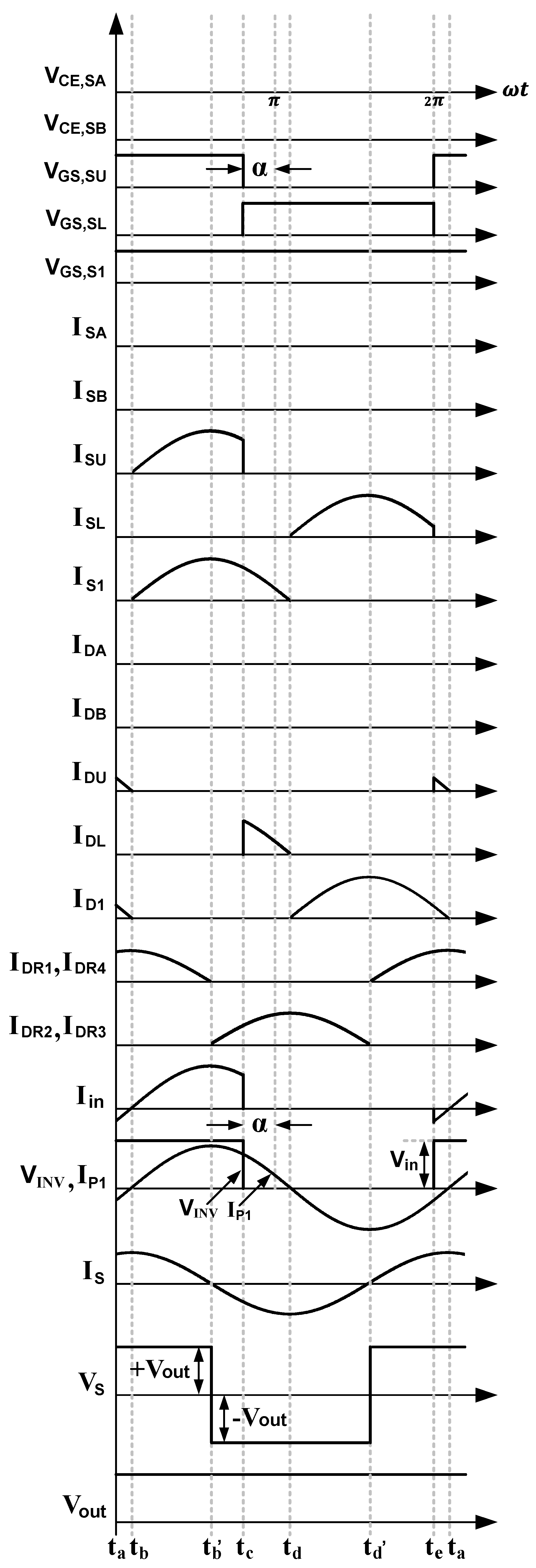

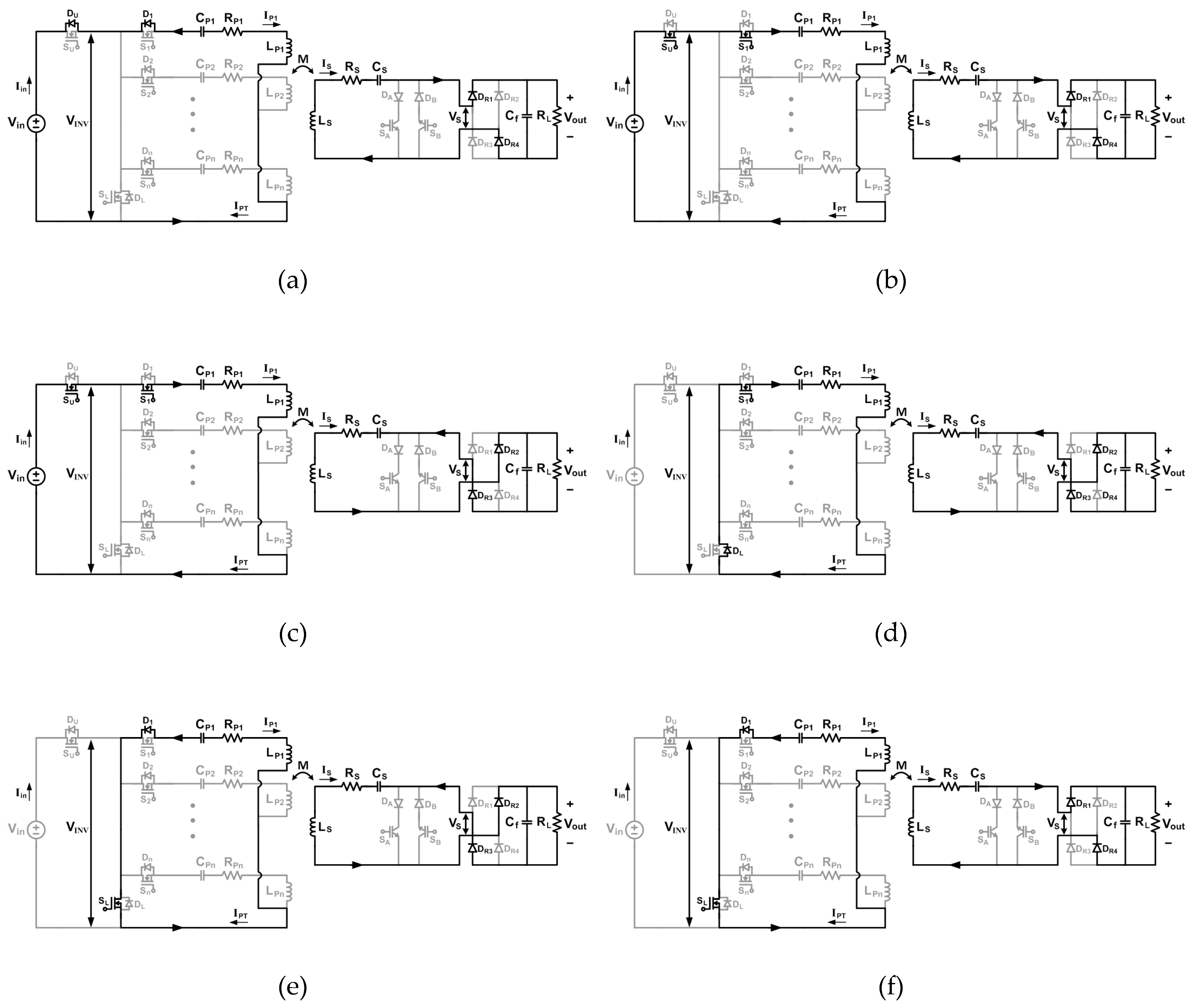

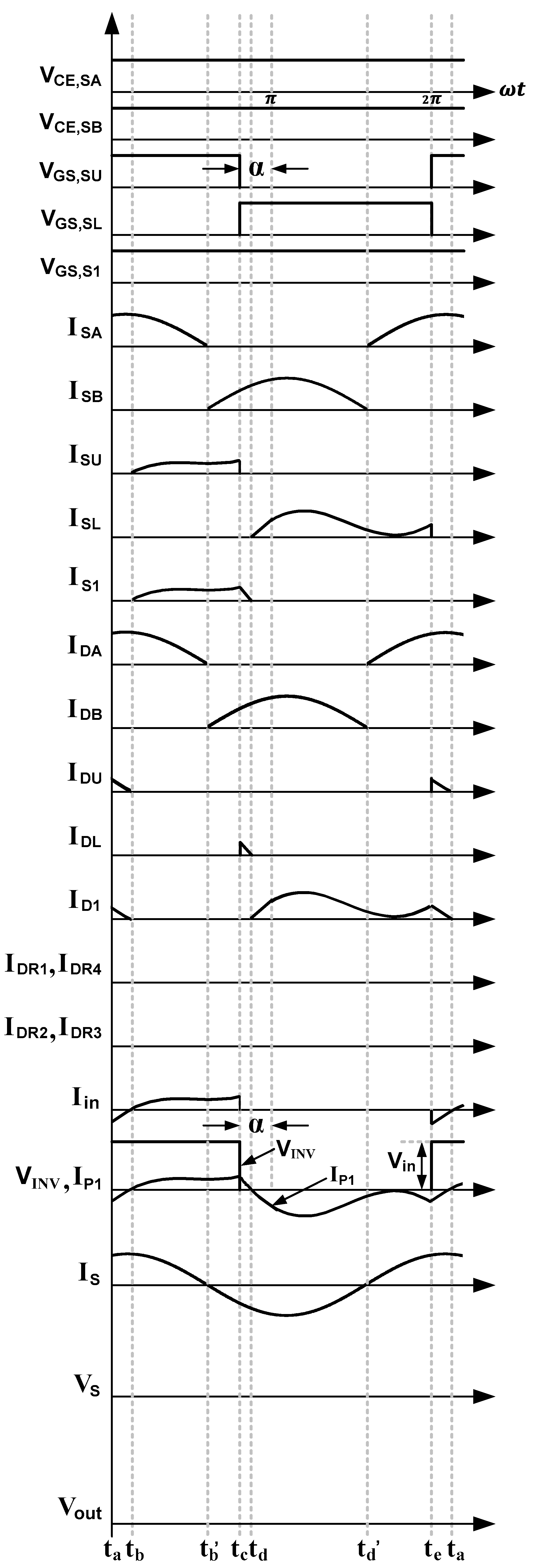

2.2. Mode of Operation

2.2.1. Normal Mode Operation

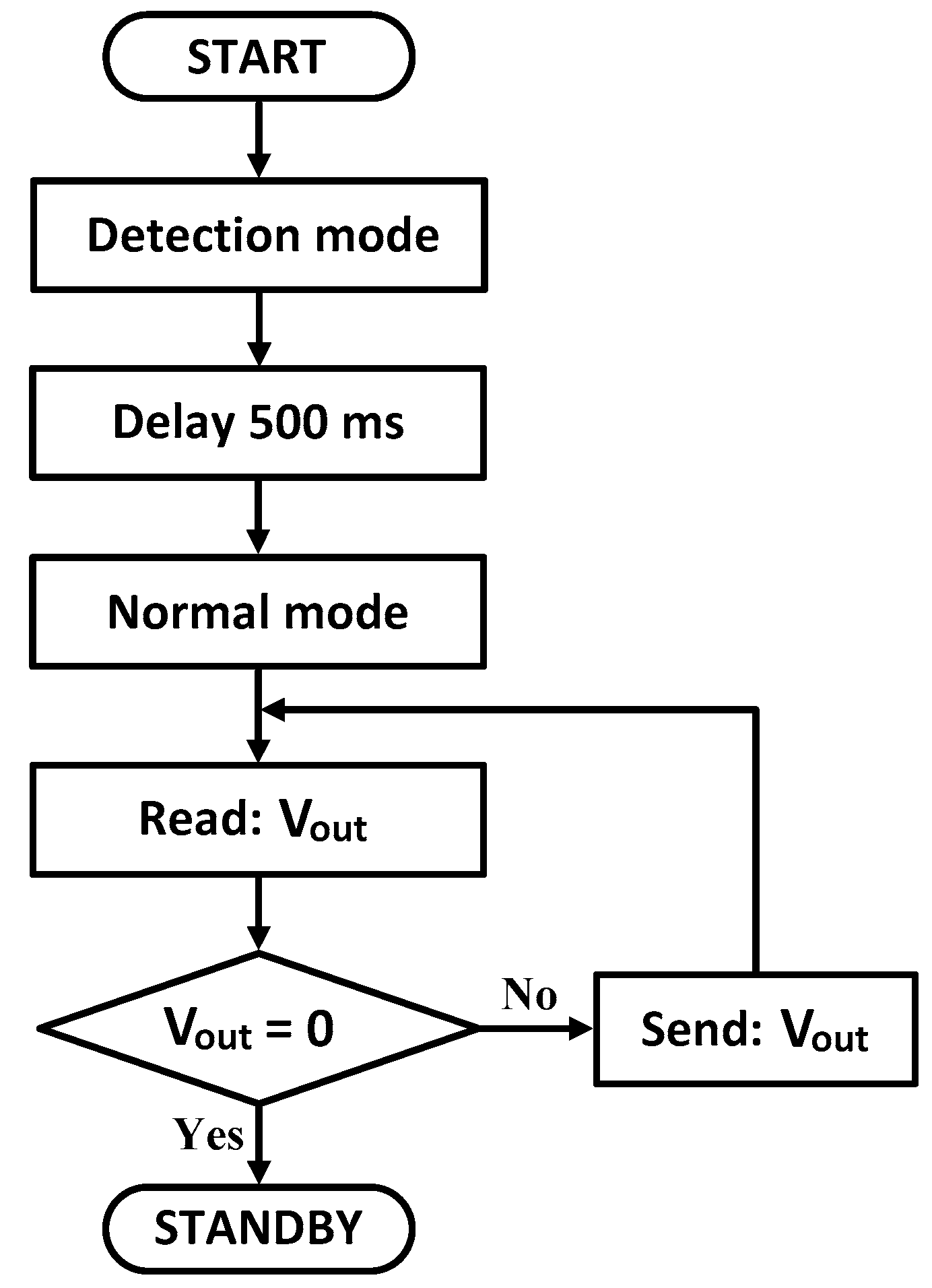

2.2.2. Detection Mode

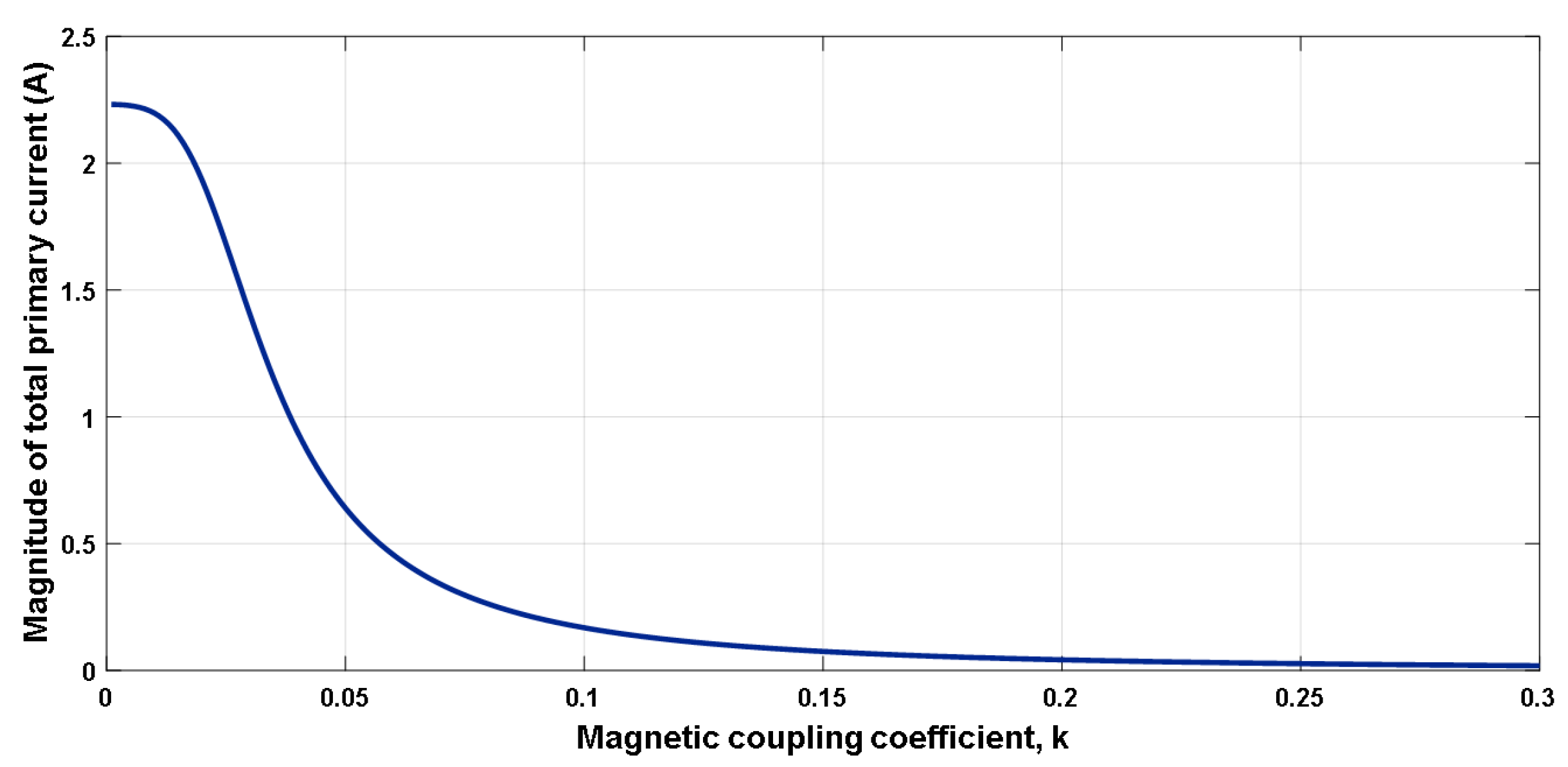

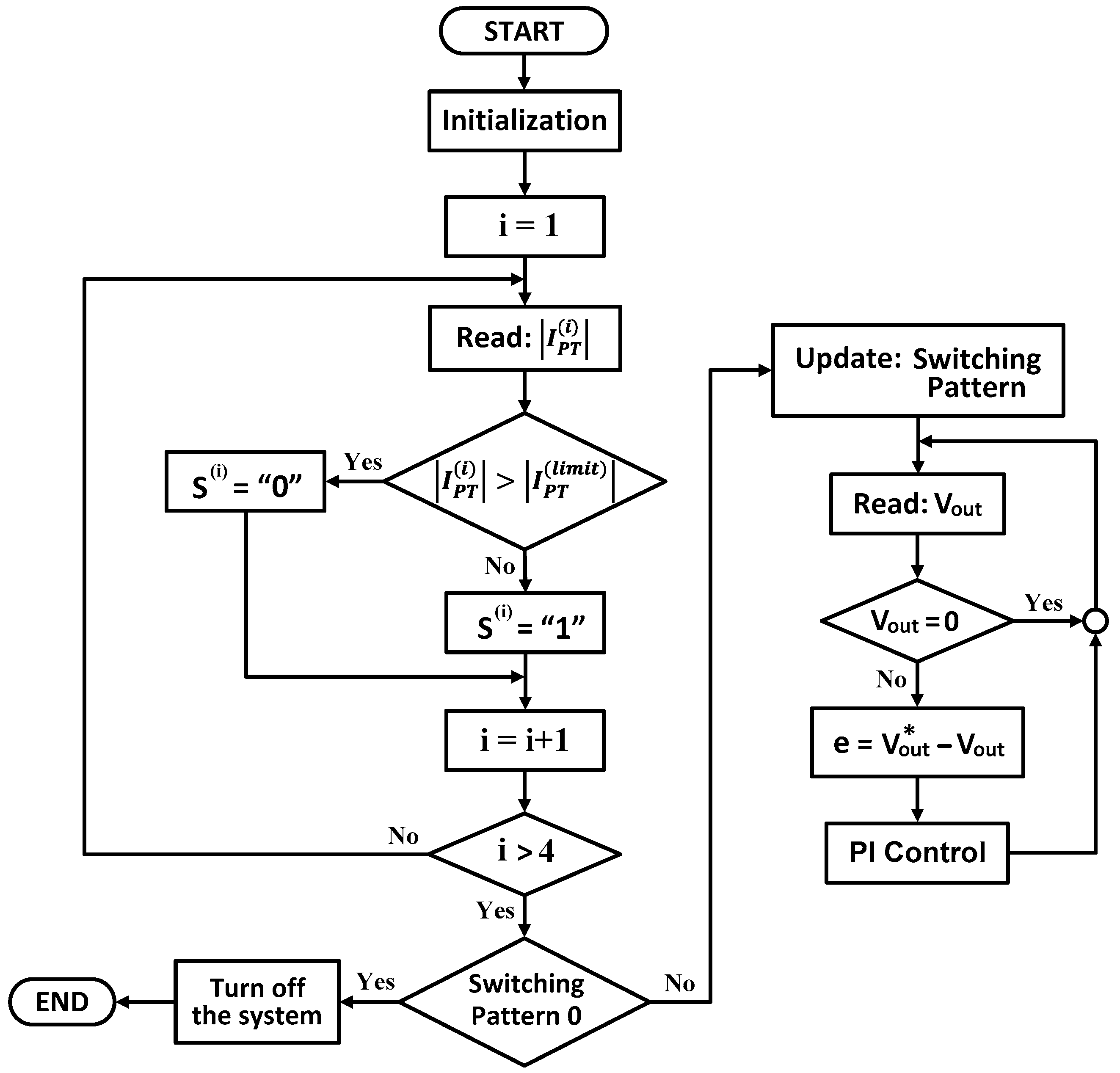

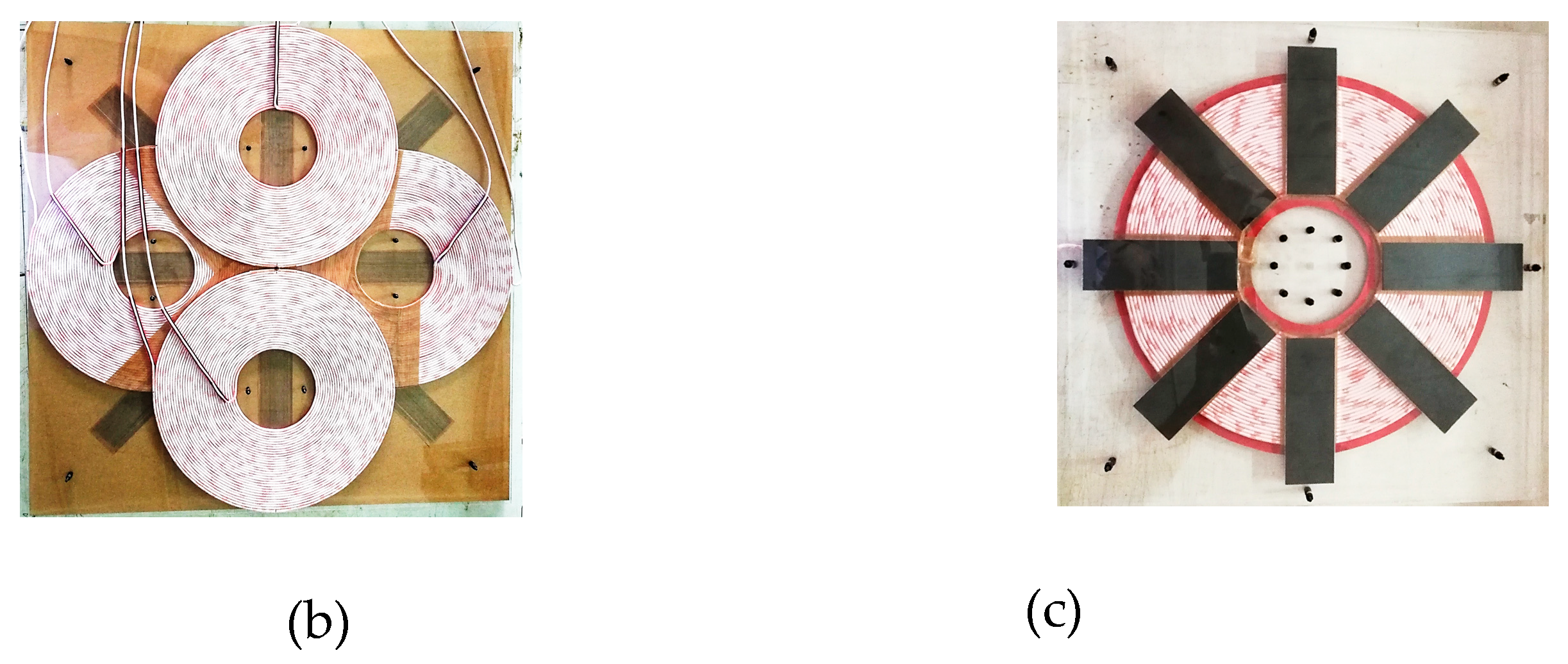

3. Transmitter Coil Excitation

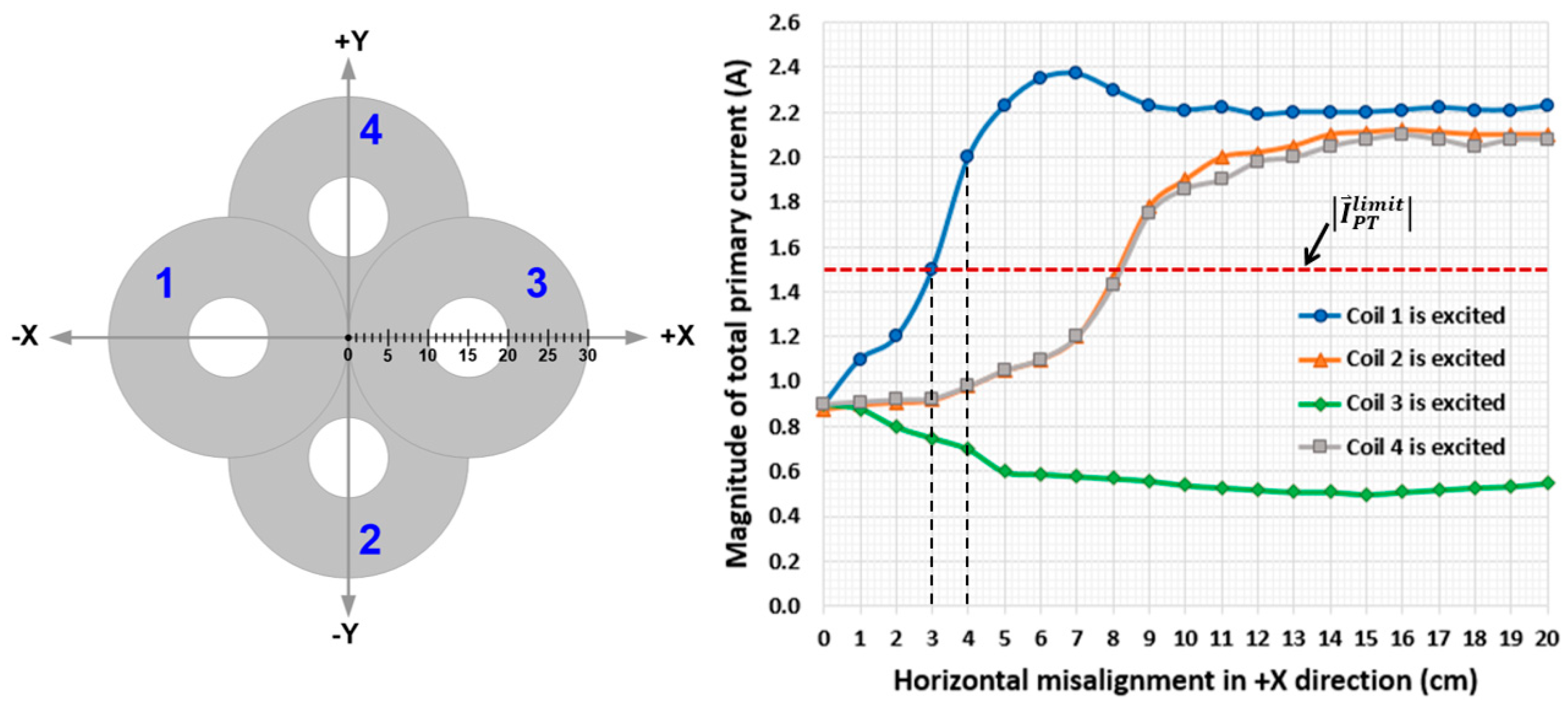

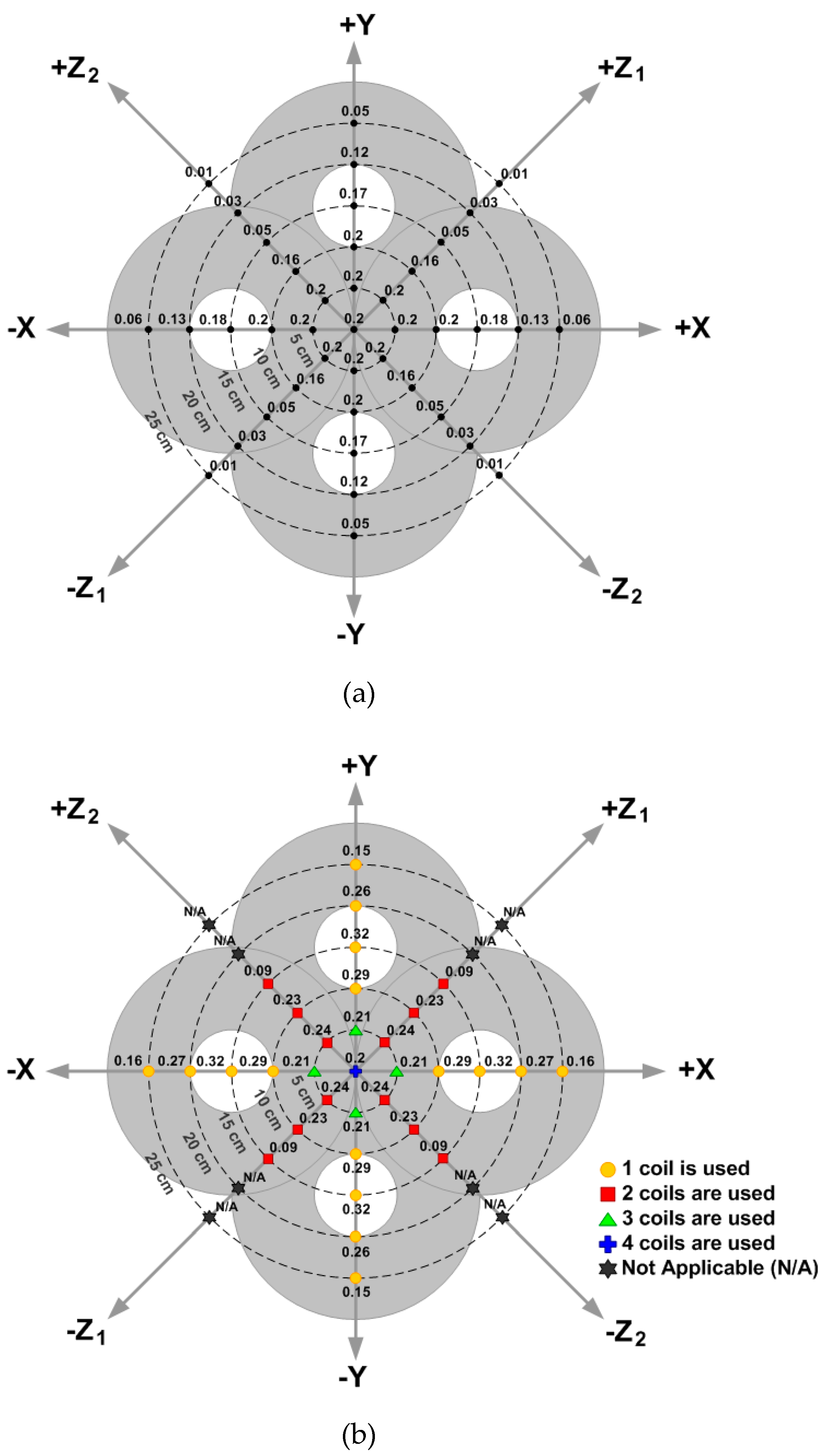

3.1. Detection of Receiver Coil Position

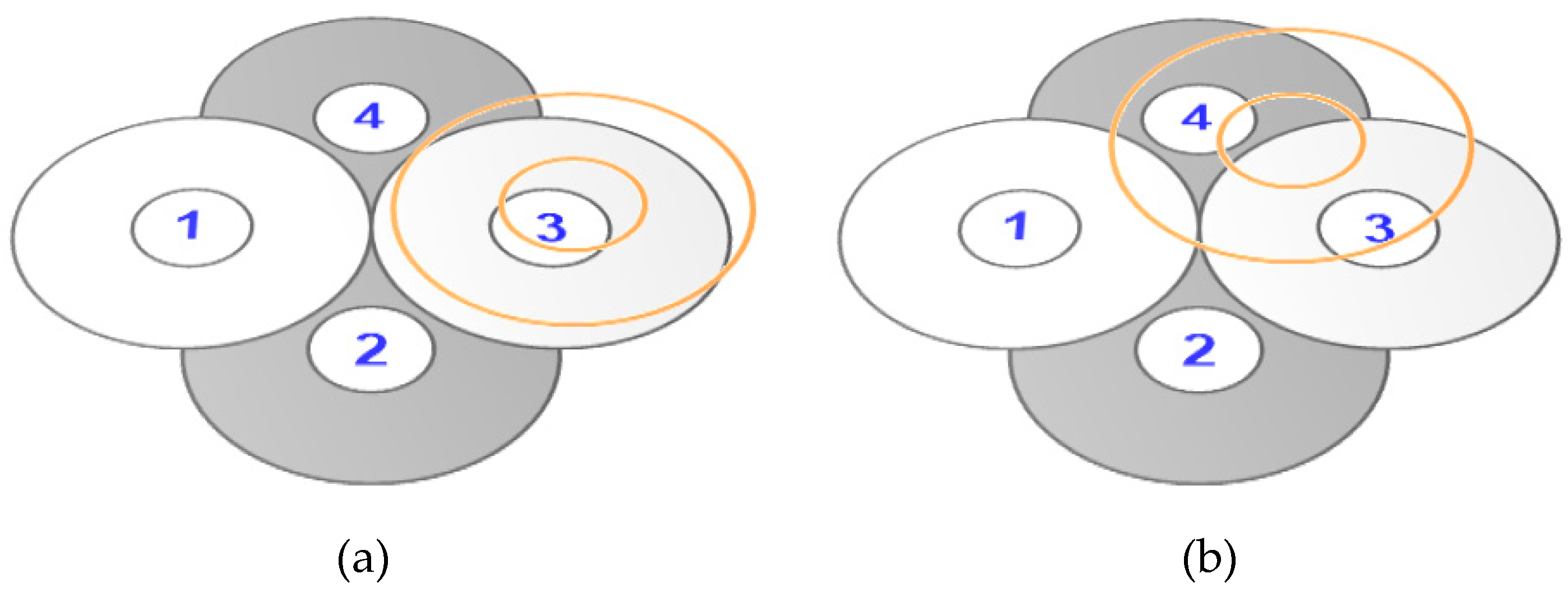

3.2. Transmitter Coil Pattern Selection

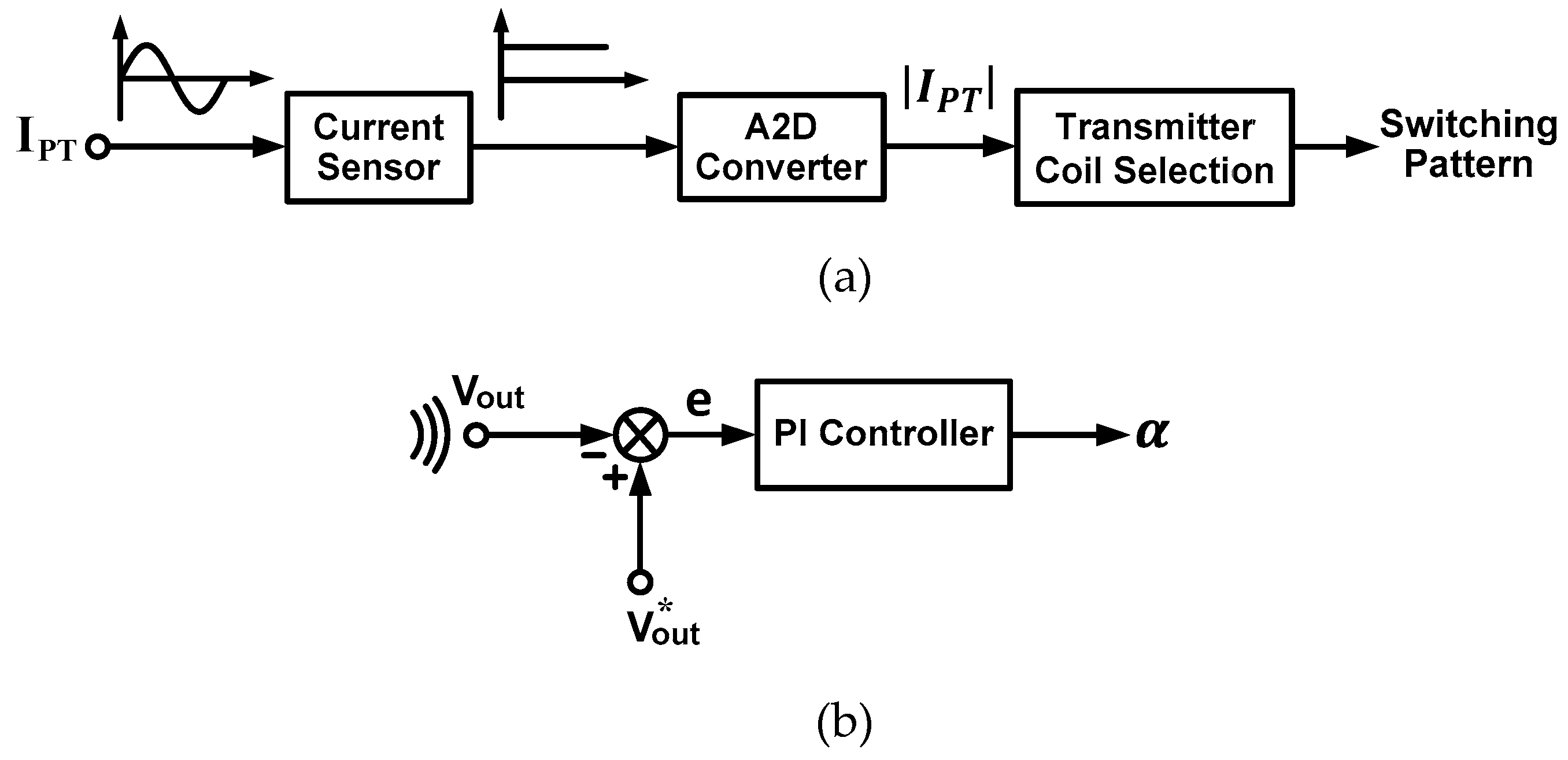

4. Proposed Controller

4.1. Secondary-Side Controller

4.2. Primary-Side Controller

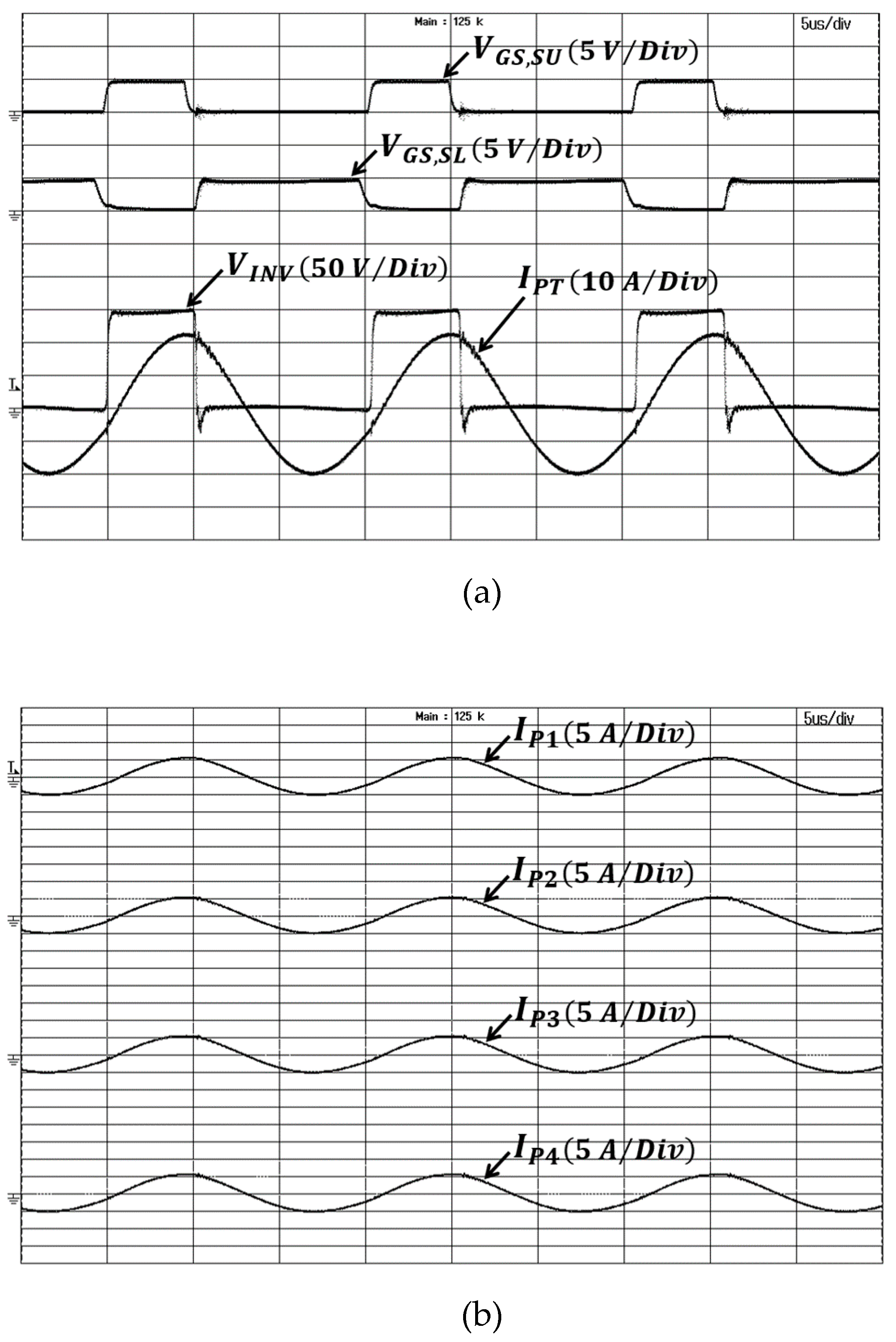

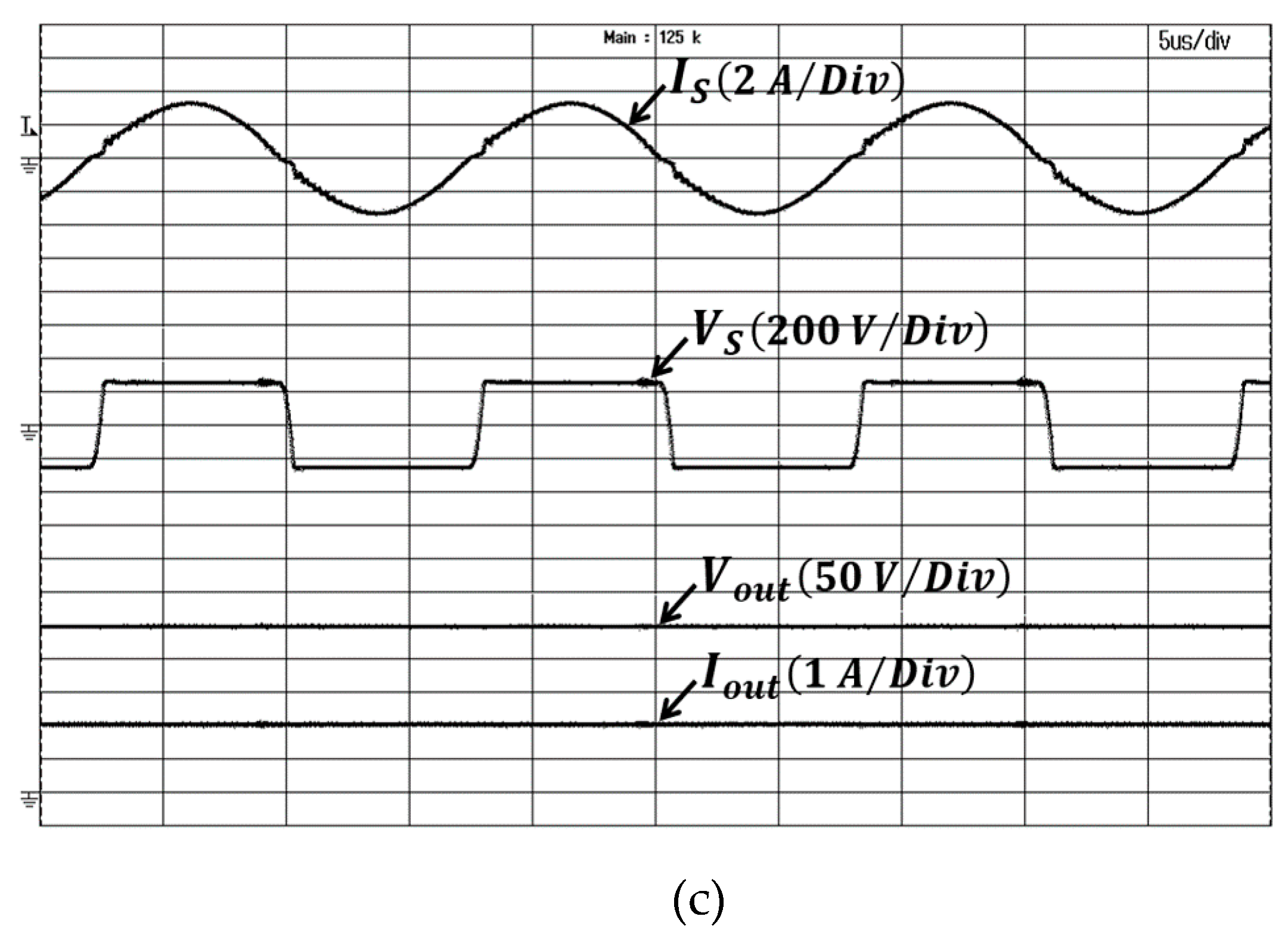

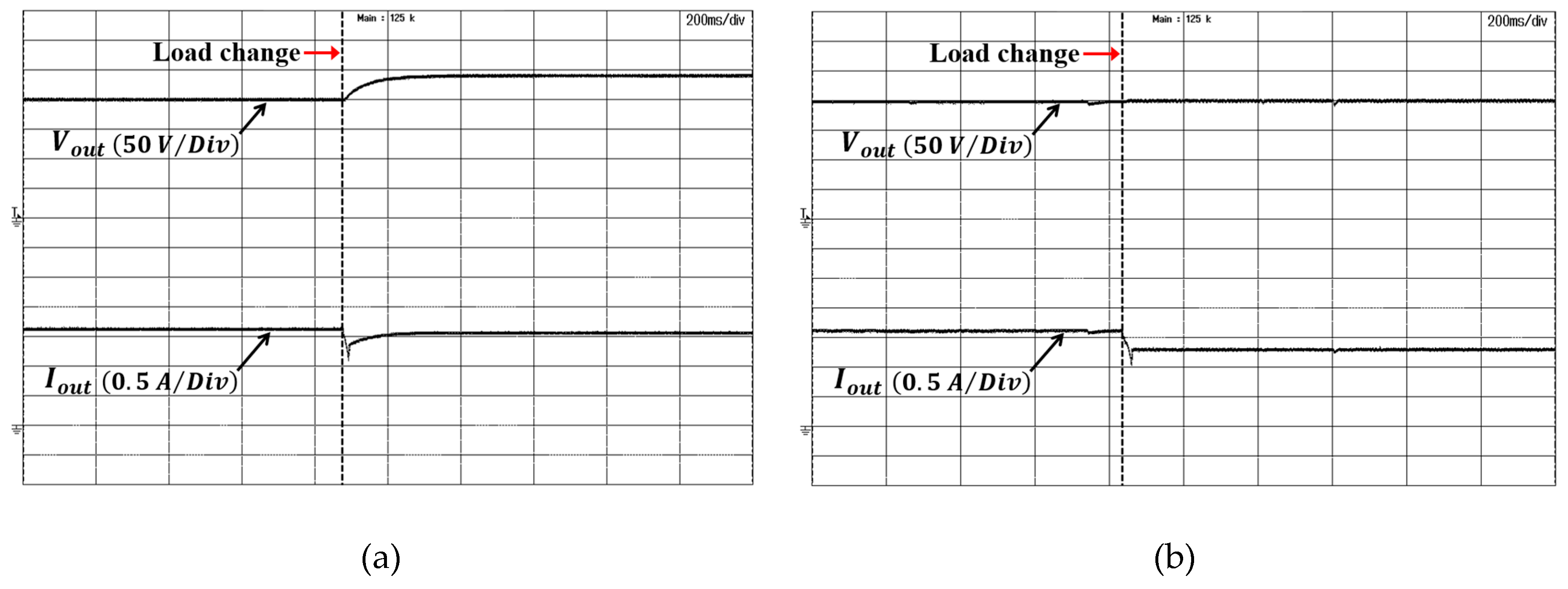

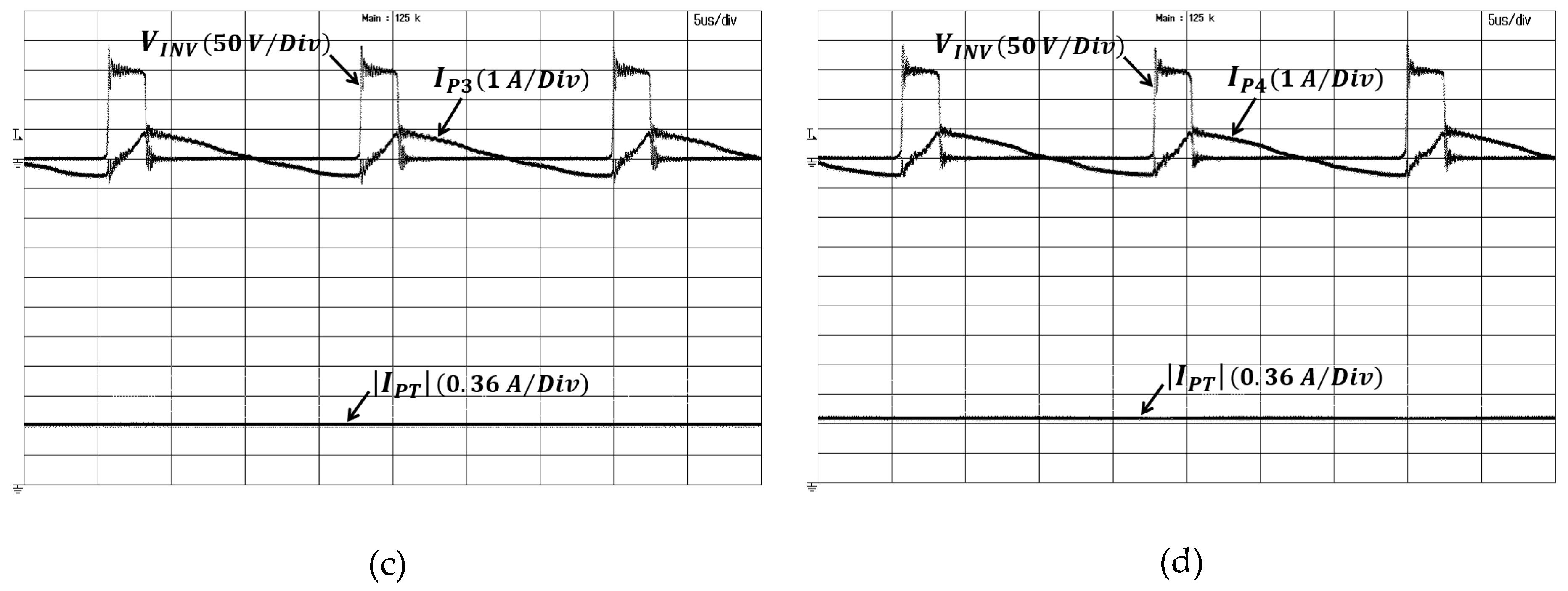

5. Experimental Results

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hui, S.Y.R.; Zhong, C.W.; Lee, C.K. Critical Review of Recent Progress in Mid-Range Wireless Power Transfer. IEEE Trans. Power Electron. 2014, 29, 4500–4511. [Google Scholar] [CrossRef]

- Kim, H.J.; Hirayama, H.; Kim, S.; Han, K.J.; Zhang, R.; Choi, J.W. Review of Near-Field Wireless Power and Communication for Biomedical Applications. IEEE Access. 2017, 5, 21264–21285. [Google Scholar] [CrossRef]

- Yan, Z.; Siyao, K.; Zhu, Q.; Huang, L.; Hu, A.P. A Simple Brightness and Color Control Method for LED Lighting Based on Wireless Power Transfer. IEEE Access. 2018, 6, 51477–51483. [Google Scholar] [CrossRef]

- Nutwong, S.; Sangswang, A.; Naetiladdanon, S.; Mujjalinvimut, E. A Novel Output Power Control of Wireless Powering Kitchen Appliance System with Free-Positioning Feature. Energies 2018, 11, 1671. [Google Scholar] [CrossRef]

- Cai, C.; Wang, J.; Fang, Z.; Zhang, P.; Hu, M.; Zhang, J.; Li, L.; Lin, Z. Design and Optimization of Load-Independent Magnetic Resonant Wireless Charging System for Electric Vehicles. IEEE Access. 2018, 6, 17264–17274. [Google Scholar] [CrossRef]

- Wang, C.S.; Stielau, O.H.; Covic, G.A. Design Considerations for a Contactless Electric Vehicle Battery Charger. IEEE Trans. Ind. Electron. 2005, 52, 1308–1314. [Google Scholar] [CrossRef]

- Budhia, M.; Covic, G.A.; Boys, J.T. Design and Optimization of Circular Magnetic Structures for Lumped Inductive Power Transfer Systems. IEEE Trans. Power Electron. 2011, 26, 3096–3108. [Google Scholar] [CrossRef]

- Fotopoulo, K.; Flynn, B.W. Wireless Power Transfer in Loosely Coupled Links: Coil Misalignment Model. IEEE Trans. Magn. 2011, 47, 416–430. [Google Scholar] [CrossRef]

- Flynn, B.W.; Fotopoulo, K. Rectifying loose coils: Wireless power transfer in loosely coupled inductive links with lateral and angular misalignment. IEEE Microw. Mag. 2011, 14, 48–54. [Google Scholar] [CrossRef]

- Nguyen, M.Q.; Hughes, Z.; Woods, P.; Seo, Y.S.; Rao, S.; Chiao, L.C. Field Distribution Models of Spiral Coil for Misalignment Analysis in Wireless Power Transfer Systems. IEEE Trans. Microw. Theory Tech. 2014, 62, 920–933. [Google Scholar] [CrossRef]

- Xia, C.; Wang, W.; Ren, S.; Wu, X.; Sun, Y. Robust Control for Inductively Coupled Power Transfer Systems with Coil Misalignment. IEEE Trans. Power Electron. 2018, 33, 8110–8122. [Google Scholar] [CrossRef]

- Wijaya, F.P.; Shimotsu, T.; Saito, T.; Kondo, K. A Simple Active Power Control for a High-Power Wireless Power Transmission System Considering Coil Misalignment and Its Design Method. IEEE Trans. Power Electron. 2018, 33, 9989–10002. [Google Scholar] [CrossRef]

- Aldhaher, S.; Luk, P.C.K.; Whidborne, J.F. Electronic Tuning of Misaligned Coils in Wireless Power Transfer Systems. IEEE Trans. Power Electron. 2014, 29, 5975–5982. [Google Scholar] [CrossRef]

- Moghaddami, M.; Sundararajan, A.; Sarwat, A.I. A Power-Frequency Controller with Resonance Frequency Tracking Capability for Inductive Power Transfer Systems. IEEE Trans. Ind. Appl. 2018, 54, 1773–1783. [Google Scholar] [CrossRef]

- Budhia, M.; Boys, J.T.; Covic, G.A.; Huang, C.Y. Development of a Single-Sided Flux Magnetic Coupler for Electric Vehicle IPT Charging Systems. IEEE Trans. Ind. Electron. 2013, 60, 318–328. [Google Scholar] [CrossRef]

- Deng, J.; Li, W.; Nguyen, T.D.; Li, S.; Mi, C.C. Compact and Efficient Bipolar Coupler for Wireless Power Chargers: Design and Analysis. IEEE Trans. Power Electron. 2015, 30, 6130–6140. [Google Scholar] [CrossRef]

- Aditya, K.; Sood, V.K.; Williamson, S.S. Magnetic Characterization of Unsymmetrical Coil Pairs Using Archimedean Spirals for Wider Misalignment Tolerance in IPT Systems. IEEE Trans. Transp. Electrif. 2017, 3, 454–463. [Google Scholar] [CrossRef]

- Mohammad, M.; Choi, S.; Islam, M.Z.; Kwak, S.; Baek, J. Core Design and Optimization for Better Misalignment Tolerance and Higher Range of Wireless Charging of PHEV. IEEE Trans. Transp. Electrif. 2017, 3, 445–453. [Google Scholar] [CrossRef]

- Villa, J.L.; Sallán, J.; Osorio, J.F.S.; Llombart, A. High-Misalignment Tolerant Compensation Topology for ICPT Systems. IEEE Trans. Ind. Electron. 2012, 59, 945–951. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, B.; Kou, Z.; He, Z.; Cao, G.; Mai, R. Hybrid and Reconfigurable IPT Systems with High-Misalignment Tolerance for Constant-Current and Constant-Voltage Battery Charging. IEEE Trans. Power Electron. 2018, 33, 8259–8269. [Google Scholar] [CrossRef]

- Zhong, W.X.; Liu, X.; Hui, S.Y.R. A Novel Single-Layer Winding Array and Receiver Coil Structure for Contactless Battery Charging Systems with Free-Positioning and Localized Charging Features. IEEE Trans. Ind. Electron. 2011, 58, 4136–4144. [Google Scholar] [CrossRef]

- Zhao, B.; Kuo, N.C.; Niknejad, A.M. A Gain Boosting Array Technique for Weakly-Coupled Wireless Power Transfer. IEEE Trans. Power Electron. 2017, 32, 7130–7139. [Google Scholar] [CrossRef]

- Sritongon, C.; Wisestherrakul, P.; Hansupho, N.; Nutwong, S.; Sangswang, A.; Naetiladdanon, S.; Mujjalinvimut, E. Novel IPT Multi-Transmitter Coils with Increase Misalignment Tolerance and System Efficiency. In Proceedings of the 2018 IEEE International Symposium on Circuit and System, Florence, Italy, 27–30 May 2018. [Google Scholar]

- Kallel, B.; Kanoun, O.; Trabelsi, H. Large air gap misalignment tolerable multi-coil inductive power transfer for wireless sensors. IET Power Electron. 2016, 9, 1768–1774. [Google Scholar] [CrossRef]

- Jayathurathnage, P.; Vilathgamuwa, D.M.; Gregory, S.D.; Fraser, J.F.; Tran, N.T. Effects of Adjacent Transmitter Current for Multi-Transmitter Wireless Power Transfer. In Proceedings of the 2017 IEEE Southern Power Electronic Conference, Puerto Varas, Chile, 4–6 December 2017. [Google Scholar]

- Dai, X.; Jiang, J.; Li, Y.; Yang, T. A Phase-Shifted Control for Wireless Power Transfer System by Using Dual Excitation Units. Energies 2017, 10, 1000. [Google Scholar] [CrossRef]

- Sun, T.; Xie, X.; Li, G.; Gu, Y.; Deng, Y.; Wang, Z. A Two-Hop Wireless Power Transfer System with an Efficiency-Enhanced Power Receiver for Motion-Free Capsule Endoscopy Inspection. IEEE Trans. Biomed. Eng. 2012, 59, 3247–3254. [Google Scholar]

- Cortes, I.; Kim, W.J. Lateral Position Error Reduction Using Misalignment-Sensing Coils in Inductive Power Transfer Systems. IEEE Trans. Mechatron. 2018, 23, 875–882. [Google Scholar] [CrossRef]

- Liu, X.; Han, W.; Liu, C.; Pong, P.W.T. Marker-Free Coil-Misalignment Detection Approach Using TMR Sensor Array for Dynamic Wireless Charging of Electric Vehicles. IEEE Trans. Magn. 2018, 54, 4002305. [Google Scholar] [CrossRef]

- Guidi, G.; Suul, J.A. Minimizing Converter Requirements of Inductive Power Transfer Systems with Constant Voltage Load and Variable Coupling Conditions. IEEE Trans. Ind. Electron. 2016, 63, 6835–6844. [Google Scholar] [CrossRef]

- Nutwong, S.; Sangswang, A.; Naetiladdanon, S.; Mujjalinvimut, E. Comparative Study of IPT Multi-Transmitter Coils Single-Receiver Coil System Focusing on Misalignment Tolerance and System Efficiency. In Proceedings of the 2018 IEEE International Conference on Electrical Machines and Systems, Jeju, Korea, 7–10 October 2018. [Google Scholar]

| Switching Pattern | Switching Function | Activated Coil | |||

|---|---|---|---|---|---|

| S1 | S2 | S3 | S4 | ||

| 0 | 0 | 0 | 0 | 0 | None |

| 1 | 0 | 0 | 0 | 1 | Coil No.4 |

| 2 | 0 | 0 | 1 | 0 | Coil No.3 |

| 3 | 0 | 0 | 1 | 1 | Coil No.3, 4 |

| 4 | 0 | 1 | 0 | 0 | Coil No.2 |

| 5 | 0 | 1 | 0 | 1 | Coil No.2, 4 |

| 6 | 0 | 1 | 1 | 0 | Coil No.2, 3 |

| 7 | 0 | 1 | 1 | 1 | Coil No.2, 3, 4 |

| 8 | 1 | 0 | 0 | 0 | Coil No.1 |

| 9 | 1 | 0 | 0 | 1 | Coil No.1, 4 |

| 10 | 1 | 0 | 1 | 0 | Coil No.1, 3 |

| 11 | 1 | 0 | 1 | 1 | Coil No.1, 3, 4 |

| 12 | 1 | 1 | 0 | 0 | Coil No.1, 2 |

| 13 | 1 | 1 | 0 | 1 | Coil No.1, 2, 4 |

| 14 | 1 | 1 | 1 | 0 | Coil No.1, 2, 3 |

| 15 | 1 | 1 | 1 | 1 | Coil No.1, 2, 3, 4 |

| Parameters | Symbol | Value |

|---|---|---|

| Self-inductance of transmitter coil | LP1–LP4 | 280 µH |

| Self-inductance of receiver coil | LS | 1,370 µH |

| Winding resistance of transmitter coil | RP1–RP4 | 0.33 Ω |

| Winding resistance of receiver coil | RS | 2.03 Ω |

| Load resistance | RL | 123.2 Ω |

| Primary compensation capacitance | CP1–CP4 | 26.4 nF |

| Secondary compensation capacitance | CS | 5.4 nF |

| Filter capacitance | Cf | 560 µF |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nutwong, S.; Sangswang, A.; Naetiladdanon, S. An Inverter Topology for Wireless Power Transfer System with Multiple Transmitter Coils. Appl. Sci. 2019, 9, 1551. https://doi.org/10.3390/app9081551

Nutwong S, Sangswang A, Naetiladdanon S. An Inverter Topology for Wireless Power Transfer System with Multiple Transmitter Coils. Applied Sciences. 2019; 9(8):1551. https://doi.org/10.3390/app9081551

Chicago/Turabian StyleNutwong, Supapong, Anawach Sangswang, and Sumate Naetiladdanon. 2019. "An Inverter Topology for Wireless Power Transfer System with Multiple Transmitter Coils" Applied Sciences 9, no. 8: 1551. https://doi.org/10.3390/app9081551

APA StyleNutwong, S., Sangswang, A., & Naetiladdanon, S. (2019). An Inverter Topology for Wireless Power Transfer System with Multiple Transmitter Coils. Applied Sciences, 9(8), 1551. https://doi.org/10.3390/app9081551