Abstract

This study evaluated the performance of a hybrid panel in an improved moveable weir after exposure to accelerated environmental climate conditions. When exposed to a river environment, corrosion problems on improved moveable weir steel panels can occur. To address this, a hybrid panel with structure layering glass fiber-reinforced polymer (GFRP) panels on both sides of the steel panel was used. The steel was, therefore, not exposed to the outside. However, this hybrid panel is a structure that uses a mixture of two materials with different properties and there is the possibility of performance degradation when the GFRP composite material, i.e., the structure that wraps around the bond interface, and the steel panel are exposed to a river environment. Thus, we evaluated the durability of the hybrid panels by repeated exposure to long-term high temperatures, dry–wet environmental cycling, long-term freezing, and freeze–thaw cycling in an accelerated climate deterioration environment. In the flexural tests, the surface processing of the steel panel was shown to be important, with sand-blasted test specimens showing higher flexural strength. For the control specimens, the flexural strength decreased as the thickness of the GFRP panels increased. However, for the sand-blasted specimens, the flexural strength increased as the thickness of the GFRP panels increased. After exposure to accelerated climate deterioration, the flexural strength tests showed that the residual strength increased with panel thickness and that the residual strengths were greater for specimens incorporating sand-blasted steel panels. The results of our testing show that hybrid panels incorporating sand-blasted steel were adequate for use in improved moveable weirs.

1. Introduction

A weir installed across a river must contain the river and secure water resources under normal circumstances, enabling sufficient water to pass over the cross-sectional area in times of flooding [1,2,3,4]. A fixed weir often causes overflow in the upper stream in times of flooding, which causes problems such as degraded river water flux due to soil accumulation. As a result, many existing concrete fixed weirs are no longer functional and are being demolished. The current trend is to re-install moveable weirs [1,5,6,7].

Representative forms of moveable weir installation technology include rubber weirs, hydraulic flip gates, open/close-type water gates, and hinge-type automatic water gates [1,8,9,10,11]. A moveable weir is valuable not only for the purpose of using and controlling a river, but also in other areas of water resource management [1,3,5,10]. A rubber weir is an air supply/discharge-type pneumatic moveable weir, but, while it is environmentally friendly with no sources of river contamination, it is weaker than steel gates [1,3,5,6,7,10]. Hydraulic steel flip gates have sufficient durability but the problem of possible river contamination from the hydraulic operating oil [1,3,5,6,7,10].

Improved moveable weirs boast the advantages of rubber weirs and flipping gates and have been in use since the 1980s [1,2,5,6,7,11,12,13]. Figure 1 shows an improved moveable weir [1,7]. It uses steel panels for all parts except the air bag, so there is concern regarding corrosion in a river environment as well as various other problems such as decreased durability with long-term use and possible river ecosystem damage due to the leakage of corrosive materials [1,5,6,7]. Figure 2 shows the corrosion of the steel panels [1,7].

Figure 1.

Improved moveable weir installed in a river.

Figure 2.

Corrosion of steel panels.

In a previous study, a hybrid panel with glass fiber-reinforced polymer (GFRP) panel layers on both sides of the steel panel was developed to replace the solely steel panel, thereby avoiding corrosion concerns [1,7]. In addition, the surface shape of the steel panel was changed to accommodate the characteristics of the GFRP panel [7]. The surface deformation of the steel improved the bond properties between the steel and the GFRP panels [1,7]. In addition, hybrid panels with outer GFRP layers or panels prevent the exposure of the steel to the ambient environment [1]. However, GFRP composite materials may exhibit performance degradation when exposed to various environments [1,14,15,16,17,18,19,20,21,22,23]. Especially in the case of a hybrid panel made by attaching steel and GFRP panels, there is the possibility of fracturing at the bond surface [1,24,25,26,27]. Previous studies have evaluated the performance of hybrid panels when exposed to chemically harsh environments, such as those containing high levels of sulfate and sea water [1]. However, these conditions are rarely encountered by the hybrid panels since they are most commonly used in rivers. Therefore, it is necessary to evaluate the performance of hybrid panels under relevant exposure conditions. Such conditions include exposure to winter and long-term freezing, repeated freeze–thaw cycles, summer heat and repeated dry–wet cycles, and long-term exposure to high temperatures. With repeated dry–wet cycles and long-term exposure to high temperatures, there is a high possibility of fracture at the bond interface because of the thermal expansion coefficient differences between the GFRP material and the steel panel. Furthermore, as moisture penetrates through the weir environment, there is the possibility of fracture via the corrosion of the steel panel. In the winter, with repeated freeze–thaw cycles and long-term freezing conditions, there is also a possibility of fracturing at the interface between the GFRP material and the steel panel with subsequent performance degradation of the GFRP composite.

Thus, this study provides a thorough performance evaluation that takes into account likely environmental conditions for the development of hybrid panels incorporating steel and GFRP material.

2. Materials and Manufacturing of Steel/GFRP Hybrid Panels

2.1. Materials

Steel panels and E-glass fibers were used to manufacture the hybrid panel; a vinyl ester resin was used to bond the two materials. Table 1 shows the characteristics of the components used in the hybrid steel/GFRP panels. The E-glass fiber and vinyl ester resin were mixed at a volume ratio of 4:6. The test specimens were manufactured with 3.2 mm steel panels and a total of 6 mm GFRP panels (3 mm each on the front and back sides of the steel panel).

Table 1.

Mechanical properties of glass fiber and matrix resin [1].

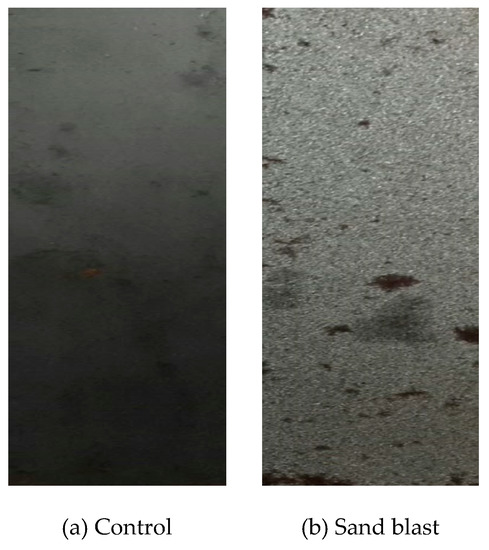

2.2. Surface Deformation of Steel Panels

The bond strength between the steel panel and the GFRP panels is an important factor in determining the bond characteristics and durability of a hybrid panel [1,7]. Several methods have been used to increase the adhesive force by pre-processing the surface of the steel panel [1,7]. A common strategy is the use of a high strength resin combined with mechanical deformation and/or adhesion-enhancing treatment of the steel surface [28,29,30,31,32]. Previous surface modifications have included scratching the steel surface, drilling holes through the steel layer, and the application of a silica sand coating [1]. The highest bond strength was obtained with the silica sand coating. Therefore, this study makes use of a similar coating to enhance the mechanical adhesion and a high-strength vinyl ester resin to enhance the chemical adhesion between the hybrid layers.

Figure 3a shows specimens with no surface processing (control) and Figure 3b shows specimens in which the steel surface was sand-blasted with silica particles [1,7].

Figure 3.

Surface deformation of steel panels.

2.3. Manufacturing of Steel/GFRP Hybrid Panels

When glass fiber is arranged in one direction, fractures may occur by splitting. Therefore, test specimens were made by layering glass fiber sheets with alternating fiber orientations. Vinyl ester resin was sprayed onto each sheet during the layering process [1,7]. When the first glass fiber panel was complete, the steel plate was placed in the middle and the glass fiber sheets were layered on top to make a hybrid structured panel.

GFRP composites have been extensively studied as a means of increasing the interlaminar strength between fibers and composite resins. Studies using polycaprolactone nanofibers showed that fiber-reinforced polymer composites exhibited high resistance to dynamic loads such as impact and vibration. Evaluations of the dynamic behavior and delamination resistance of GFRP composites using nylon nanofibers showed improved damping ratios and enhanced inter-laminar shear strength, due to the binding of the nanofibers. [33,34,35].

In this study, we did not attach the GFRP panel to the steel panel with adhesive. Instead, the hybrid panels were fabricated by repeating the layered design described above, in which the vinyl ester resin that was used to bond the glass fiber sheets also served as the interlaminar adhesive in the final hybrid panel.

2.4. Thickness of Steel/GFRP Hybrid Panels

The thickness of the GFRP panels was optimized for maximum flexural strength of the steel/GFRP hybrid panels. The performance of the hybrid panels was evaluated as a function of GFRP panel thickness, which varied from 6 to 12 mm. The steel panel thickness was fixed at 3.2 mm. Table 2 shows the test parameters used to evaluate the GFRP panel thickness.

Table 2.

Test parameters of steel and GFRP panels.

3. Accelerated Environmental Conditions and Test Methods

3.1. Repeated Wetting and Drying Cycles

Hybrid panels react sensitively to moisture conditions. In particular, along with environmental conditions involving continuous contact with moisture, the possibility of fracture in a hybrid panel surface increases when the panel is exposed to repeated wet and dry cycles. Therefore, the influence of the hybrid panel’s exposure to an environment of repeated dry-wet cycles was evaluated. Each cycle consisted of drying in an oven at 60 °C for 24 h and then immersing in water at 60 °C for 24 h. The panels were tested for 25 cycles over 50 days. Exposure temperatures were based on the results of a previous study in which the durability of FRP composites was evaluated at various environmental temperatures to accelerate deterioration [36,37,38]. In the current study, the exposure temperature of 60 °C corresponds to an artificially harsh environment and serves to accelerate the deterioration processes that would occur naturally in a modified movable weir.

3.2. Long-Term Freezing

A hybrid panel may freeze in winter, making it more susceptible to fracture in response to an applied load. We therefore evaluated the mechanical characteristics of hybrid panels after freezing at −5 °C for 50 days.

3.3. Long-Term Oven Drying

Differential thermal expansion coefficients of composite materials, such as those used in hybrid panels, can result in fracture at high temperatures. There are likely to be multiple cases of long-term high temperature exposure during summer, therefore, accelerated deterioration under these conditions should be considered. The exposure temperature used herein was 60 °C, which is more severe than would be encountered in real environments and represent an accelerated condition. Thus, our hybrid panels were held at 60 °C in a thermo-hygrostat for 50 days and their mechanical characteristics were evaluated thereafter.

3.4. Repeated Freeze/Thaw Cycles

The possibility of fracture by repeated freezing and thawing cycles should also be considered. Moveable weirs, in particular, are subject to freezing and thawing cycles throughout winter. Tests were carried out in accordance with ASTM C 666 (American Society for Testing and Materials C 666, Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing, ASTM International, 2015, West Conshohocken, PA, USA) to evaluate the resistance of our hybrid panels to repeated freezing and thawing cycles. These tests involved 300 repeated cycles between −18 and +4 °C.

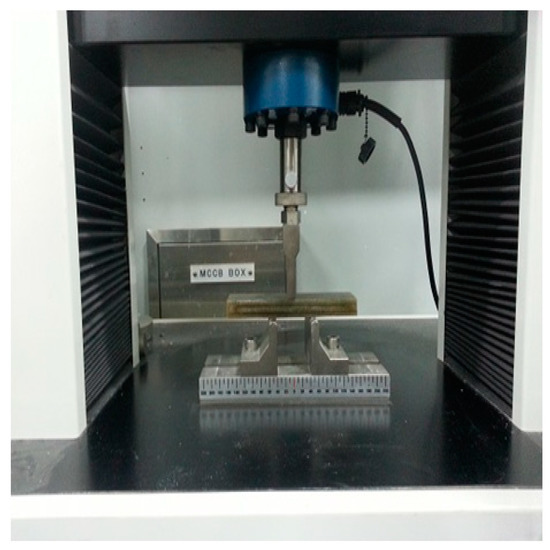

3.5. Flexural Test Methods

In this study, the performance of the hybrid panel of the improved moveable weir was evaluated. Improved moveable weirs is a structure receiving a water load. The load exposure condition is that of a structure subjected to a flexural load. Therefore, in this study, the flexural test was carried out considering the application conditions of the improved movable weir (Figure 4). The flexural strength of our hybrid panels was evaluated in accordance with ASTM D7264 (American Society for Testing and Materials D 7264, Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials, ASTM International, 2015, West Conshohocken, PA, USA). When a flexural load was applied to our hybrid panels the interface between the glass fiber and the resin and the adhesion interface between the GFRP panel and the steel panel were most affected. The ASTM D7264 was considered the most appropriate method for determining the mechanical limits of the glass fiber/resin and the GFRP/steel interfaces in our hybrid panels. The test specimens for these tests were prismatic in shape, with dimensions of 40 × 40 × 160 mm. The mechanical performance of the hybrid panels, in terms of residual strength after exposure to an accelerated deterioration environment, was also evaluated. The residual strength was calculated as shown in Equation (1).

Figure 4.

Flexural test set up.

Previous studies have specified a residual strength of 65% to analyze durability. While not directly applicable to this study, previous research results have shown that GFRP composite materials composed of glass fiber should retain ≥65% of their initial strength after environmental exposure if they are to be used as concrete-reinforcing materials [1,14,15]. In the current study, flexural tests were performed on six specimens under each environmental condition.

4. Results

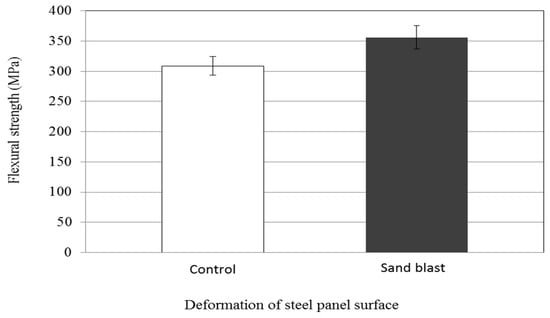

4.1. Test Results According to Surface Treatment Method

The flexural strength test results, as a function of surface processing, are shown in Figure 5. The flexural strengths of the control and sand-blasted specimens were 308.80 MPa and 355.91 MPa, respectively. The flexural strength of the sand-blasted specimens was higher than that of the control, indicating a higher bonding capacity for the GFRP panels. Generally, the fractures between the steel panels and the FRP composites occur in one or more of the following ways: (a) FRP and adhesive interface failure, (b) FRP delamination, (c) FRP rupture, and (d) steel yielding. In this study, the GFRP panel was manufactured using the same resin that was used to bond the steel panel to the GFRP [28,29,30,31,32]. Therefore, the only variable in our system was the shape and surface pre-treatment of the steel panel. The surface of our steel panel was roughened by sandblasting to reduce the occurrence of failure modes (a) and (c) [28]. Roughening the surface of the steel panel prevented interfacial failure and resulted in enhanced bending strength, relative to that of the control steel panel without any surface treatment.

Figure 5.

Flexural strength as a function of steel panel surface modification.

Figure 6 shows fracture deformation in specimens following long-span flexural tests. The control specimens exhibited fracture with interfacial delamination between the steel and GFRP panels prior to the occurrence of splitting cracks in the GFRP panel at the loading point (Figure 6a). In contrast, sand-blasted specimens (Figure 6b) did not exhibit interfacial delamination at the steel and GFRP bond interface, showing instead splitting fractures via cracking at the loading point. These data indicate that the specimens incorporating sand-blasted steel showed better performance than those incorporating unmodified steel panels.

Figure 6.

Fracture deformations of test specimens.

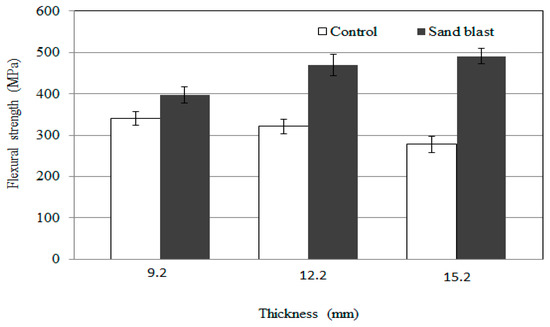

4.2. Test Results According to GFRP Panel Thickness

Flexural strength test results as a function of GFRP panel thickness are shown in Figure 7. The control specimens showed flexural strengths of 341.33, 321.26, and 287.11 MPa, respectively, as the GFRP panel increased in thickness from 9.2 to 12.2 to 15.2 mm. The flexural strengths of the sand-blasted specimens were 397.13, 470.21, and 491.11 MPa, respectively.

Figure 7.

Flexural strength as a function of GFRP panel thickness in hybrid panels.

In general, flexural strength increased with the thickness of the GFRP panel and the flexural strength of sand-blasted specimens was consistently higher than that of the control specimens. This shows that the sand-blasted specimens featured stronger adhesive forces than the control specimens. In addition, for sand-blasted specimens, the GFRP panel strength was greater than that of the steel panel, showing increased strength as a function of thickness. In contrast, the flexural strength of the control specimens decreased as a function of specimen thickness. This indicated that the control specimens were limited by weaker adhesive forces. As a result, the interfacial separation occurred before flexural failure.

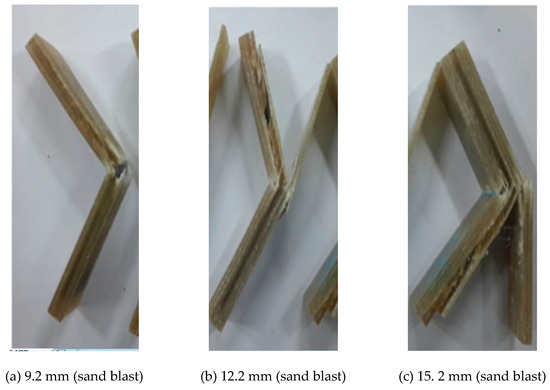

Specimen fracturing after the flexural tests is shown in Figure 8. The influence of GFRP panel thickness was not significant with the control specimens. The splitting fractures ultimately occurred at all interfaces regardless of GFRP panel thickness. With sand-blasted specimens, fracturing occurred at the interface between the steel and GFRP panels. Relative to the control, there was a significantly decreased tendency for interfacial delamination. Thus, fracture by interfacial delamination could be minimized or prevented by adjusting the thickness of the GFRP panel.

Figure 8.

Fracture deformation as a function of hybrid panel thickness.

In general, destruction of steel panels and FRP composites is due to delamination within the FRP composite, fiber delamination, the debonding of interfaces between steel panels and FRP composites, debonding between the steel panel and the adhesive, and the yielding of the steel panels [28,29,30,31,32]. In this study, the effects of steel panel surface modification and GFRP panel thickness on the overall strength of a hybrid panel were evaluated. The thickness of the steel panel was selected such that yielding of the steel panel would not cause failure. If the steel panel was too thin, it could fail before interfacial delamination occurred. In contrast, if the steel panel was too thick, it could lead to premature delamination at the GFRP/steel interface prior to the steel yielding [28]. Therefore, future studies should include an optimization of steel panel thickness. In addition, previous studies have shown that the arrangement of the fibers and matrix resin can have a significant effect on the mechanical properties and fracture behavior of FRP composites [28,29,30,31,32].

Generally, the strength decreased as the size of the FRP composite increased. However, this generality depended on the arrangement of fibers in the composite and the results were not always consistent [38,39,40,41]. This result was also obtained with FRP composite materials consisting of steel and GFRP panels. It is unlikely that size effects were significant in the current research, since fracturing tended to occur at the interface between the steel panel and the GFRP panel prior to destruction of the GFRP panel [38,39,40,41,42]. Further study considering the size effects in the adhesion failure of steel/GFRP hybrid panels is needed.

4.3. Test Results under Accelerated Environmental Conditions

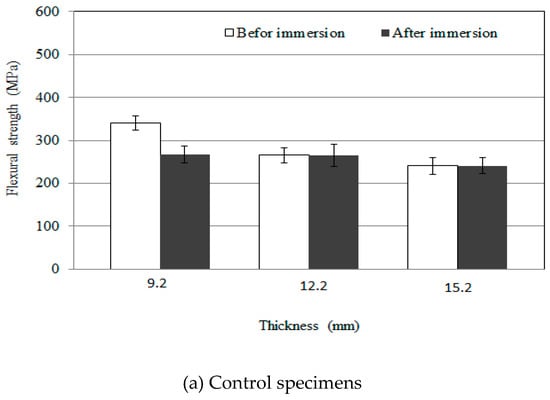

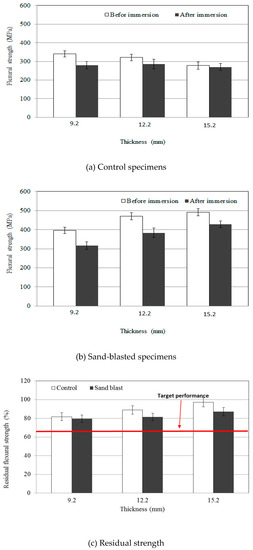

The results of long-term freezing tests are shown in Figure 9. The flexural strengths of the control specimens were 267.46, 265.25, and 240.80 MPa as the panel was thickness increased from 9.2 to 12.2 to 15.2 mm, respectively. The flexural strengths of the sand-blasted specimens were 355.57, 438.25, and 461.31 MPa, respectively. All of the evaluated specimens satisfied the residual strength goal of ≥65% (Figure 9b). As panel thickness increased from 9.2 to 12.2 to 15.2 mm, the residual strengths of the control and sand-blasted specimens were 78.34%, 82.57%, and 86.58%, respectively, and 89.54%, 93.20%, and 93.93%. The sand-blasted specimens showed higher residual strengths. In addition, interfacial delamination was suppressed at the surface, indicative of higher bond strength. Moisture penetration into the bond interface between the steel and GFRP panels accelerated fracturing, due to the expansion of water as it freezes. The sand-blasted specimens exhibited higher bond strength with a smaller degree of interfacial delamination via moisture penetration and subsequent freezing and expansion. As a result, both the initial and residual flexural strengths were enhanced.

Figure 9.

Flexural strength of hybrid panels following long-term freezing tests.

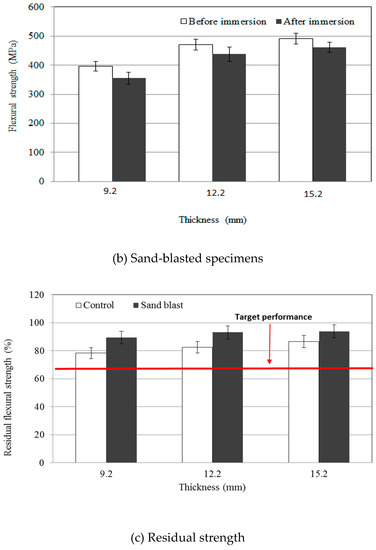

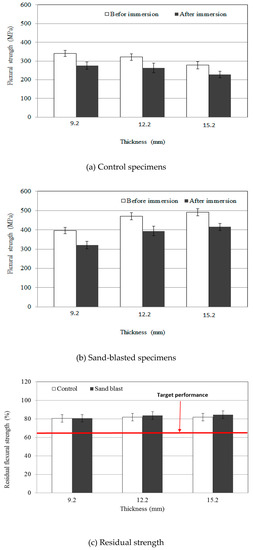

The results of the repeated dry-wet environment exposure are shown in Figure 10. As panel thickness increased from 9.2 to 12.2 to 15.2 mm, the control specimens showed flexural strengths of 279.35, 285.81, and 270.29 MPa, respectively. The sand-blasted specimens exhibited the significantly greater values of 316.69, 383.60, and 428.22 MPa, respectively. The flexural strength of the control specimens increased for panel thicknesses, up to 12.2 mm, but then decreased at 15.2 mm. This result shows that the flexural strength of the control specimens was limited by the bond strength between the steel and GFRP panels. After testing, fractures were evident at the bond interface before fracturing of the GFRP panel occurred. In contrast, the bond strength of the sand-blasted specimens was higher such that interfacial failure was determined primarily by the strength of the GFRP panel. In terms of residual strength, all of the panels satisfied the goal of this study (≥65%; Figure 10b). As the thickness of the hybrid panel increased from 9.2 to 12.2 to 15.2 mm, the control specimens showed residual strengths of 81.84%, 88.96%, and 97.19%, respectively, while those of the sand-blasted specimens were 79.74%, 81.58%, and 87.19%.

Figure 10.

Flexural strength of hybrid panels after repeated wetting and drying cycles.

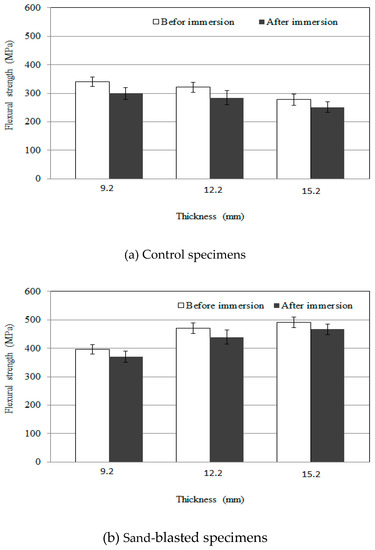

The results of the repeated freeze-thaw cycling are shown in Figure 11. As the thickness of the hybrid panel increased from 9.2 to 12.2 to 15.2 mm, the control specimens showed flexural strengths of 279.30, 265.21, and 228.23 MPa, respectively, while those of sand-blasted specimens were 320.819, 394.24, and 415.18 MPa. Generally, repeated freeze-thaw cycles allow moisture to penetrate GFRP composite materials, resulting in fracture of fibers and resin by subsequent expansion during freezing. In a similar fashion, moisture penetration into the bond interface between the steel and GFRP panels may cause fractures in the bond interface. In such cases, the degree of fracture is determined by the strength of the bond interface. In this study, sand-blasted specimens exhibited higher bond strengths and a greater resistance to moisture penetration in repeated freeze–thaw cycles. As a result, the residual flexural strength remained high after testing. In terms of residual strength, all of our panels satisfied the goal of this study (≥ 65%; Figure 11b). As the thickness of the hybrid panel increased from 9.2 to 12.2 to 15.2 mm, the control specimens exhibited residual strengths of 80.65%, 81.93%, and 82.06%, respectively, while those of sand-blasted specimens were 80.78%, 83.84%, and 84.54%.

Figure 11.

The flexural strength of hybrid panels after repeated freezing and thawing cycles.

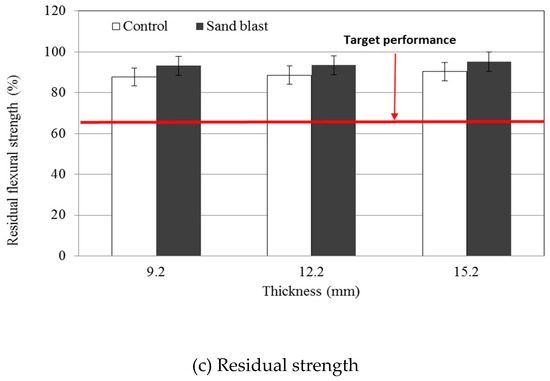

The results of long-term high-temperature environment exposure are shown in Figure 12. As the thickness of the hybrid panel increased from 9.2 to 12.2 to 15.2 mm, the flexural strengths of the control specimens were 299.36, 284.78, and 251.29 MPa, respectively, while those of sand-blasted specimens were 370.21, 439.68, and 467.21 MPa. Fracturing of the GFRP composite materials by heat occurs due to differences in the thermal expansion coefficients of the different materials, especially the glass fiber and the polymer resin. At high temperatures, the glass transition temperature of the polymer resin becomes an important factor in determining the strength of the hybrid panel. In addition, the possibility of fracture between the steel and GFRP panels is also high. Flexural strength decreased as the thickness of the panel increased. The reason for this was the combined influence of differences in the thermal expansion coefficients of the steel and GFRP panel and the glass transition temperature of the polymer resin. The reason for decreasing flexural strength as a function of increasing panel thickness was the influence of the resin glass transition temperature on the mechanical integrity of the GFRP panel. In addition, unmodified steel control panels were significantly weaker than sand-blasted panels due to fracturing at the steel/GFRP interface and the greater interfacial bond strength of the sand-blasted specimens. Regarding the residual strength, all of the tested panels satisfied the goal of this study (≥ 65%; Figure 12b). As the thickness of the hybrid panel increased from 9.2 to 12.2 to 15.2 mm, the control specimens showed residual strengths of 87.70%, 88.64%, and 90.35%, respectively, while those of sand-blasted specimens were 83.22%, 93.51%, and 95.13%. Thus, sand-blasted specimens exhibited higher residual strength because of their higher interfacial bond strengths. Interfacial delamination was also suppressed despite the significant differences in the thermal expansion coefficient.

Figure 12.

Flexural strength of hybrid panels after long-term high-temperature exposure.

5. Conclusions

This study evaluated the performance of corrosion-resistant hybrid panels, i.e., composite steel and GFRP panels, for use in improved moveable weirs as a function of accelerated environmental exposure. The results can be summarized as follows.

- Regarding the modification of the steel surface, the flexural strength of the specimens incorporating sand-blasted steel panels was higher than that of the specimens incorporating unmodified steel panels. The sand-blasted specimens exhibited greater bond strengths with the GFRP panel.

- Flexural strength increased with the thickness of the GFRP panel.

- Both flexural strength and residual strength increased as a function of panel thickness after exposure to accelerated environmental conditions. Higher residual strengths were obtained with sand-blasted specimens.

- The residual strength of all specimens was at least 78% following all environmental tests. This satisfied the study goal of ≥65%, indicating that the durability of these hybrid panels may not be a major problem.

Author Contributions

S.-Y.Y. conceived and designed the experiments; J.-H.L. performed the experiments; H.-J.S. reviewed the references and provided useful comments; C.-G.P. analyzed the data and wrote the paper. All authors have read and approved the final manuscript.

Funding

This research was supported by the basic science research program through the National Research Foundation of Korea (NRF) funded by Ministry of Education (NRF-2016R1D1A3A03918587) and this research was supported by a Grant (code-14TBIP-C073993-01-000000) from Technology Business Innovation Program (TBIP) funded by Ministry of Land, Infrastructure and Transport of Korean Government.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lee, S.-K.; Yoo, S.-Y.; Park, C.-G. Sulfate and Calcium Chloride Resistance of Steel/Glass Fiber-Reinforced Polymer Hybrid Panel for Improved Movable Weir Application. Int. J. Polym. Sci. 2017, 2017, 6895649. [Google Scholar] [CrossRef]

- Yeo, C.G.; Kim, Y.H.; Seo, G.S.; Song, J.W. The study for Hydraulic Influence by installing Movable Weir. In Proceedings of the Conference of the Korean Society of Civil Engineers in 2009, Tokyo, Japan, 16–19 April 2009; pp. 1452–1455. [Google Scholar]

- Park, H.J. Study on the Effect of Weir on Stream Flow. Master’s Thesis, Konkuk University, Seoul, Korea, 2010. [Google Scholar]

- Kim, P.S.; Kim, S.J.; Shin, J.H.; Park, H.J. The study of Flood Hazard Mitigation Effect for Movable Weir. In Proceedings of the Korea Water Resources Association Conference, Daejeon, Korea, 13–14 May 2010; pp. 808–812. [Google Scholar]

- Kim, J.K. The Variation of Flow Characteristics by Installing Improved Movable Weir in a River. Master’s Thesis, Inchon University, Inchon, Korea, 2006. [Google Scholar]

- Lee, J.W.; Park, C.G.; Kim, J.O.; Lee, S.K. Durability Characteristics of Glass Fiber Reinforced Polymer Composite Clapping Plates for Application of Rubber Dam. J. Agric. Eng. 2011, 53, 17–23. [Google Scholar]

- Kim, K.W.; Kwon, H.J.; Kim, P.S.; Park, C.G. Flexural and Interfacial Bond Properties of Hybrid Steel/Glass Fiber Reinforced Polymer Composites Panel Gate with Steel Gate Surface Deformation for Improved Movable Weir. J. Agric. Eng. 2015, 57, 57–66. [Google Scholar]

- Choi, J.W.; Joo, H.J.; Kim, J.M.; Lee, K.S.; Yoon, S.J. An Analytical Study on the Structural Performance Evaluation of the Multistage Overturning Movable Gate. J. Korean Soc. Steel Constr. 2013, 25, 613–622. [Google Scholar] [CrossRef]

- Choi, G.W.; Byeeon, S.J.; Kim, Y.K.; Cho, S.U. The Flow Characteristic Variation by Installing a Movable Weir having Water Drainage. J. Korean Soc. Hazard Mitig. 2008, 8, 117–122. [Google Scholar]

- Choi, B.J. A Study on the Effect of Weir on Stream Flow and Ground Water. Master’s Thesis, Seoul National University of Science and Technology, Seoul, Korea, 2011. [Google Scholar]

- Lee, K.S.; Jang, C.L.; Lee, N.J.; An, S.J. Analysis of Flow Characteristics of the Improved-Pneumatic-Movable Weir through the Laboratory Experiments. J. Korean Water Resour. Assoc. 2014, 47, 1007–1015. [Google Scholar] [CrossRef]

- Hwang, T.G.; Kim, J.G. Analysis of fluid-structure interaction for development of korean inflatable improved movable weirs for small hydropower. J. Korean Soc. Mar. Eng. 2008, 32, 1221–1230. [Google Scholar] [CrossRef]

- Kim, H.H.; Hwang, T.G. Analysis of fluid-structure interaction for development of inflatable improved movable weirs for small hydropower. J. Fluid Mach. 2008, 111, 86–92. [Google Scholar]

- Park, C.G.; Won, J.P.; Yoo, J.K. Long-term effect of chemical environments on FRP reinforcing bar for concrete reinforcement. J. Korean Concr. Inst. 2003, 15, 811–819. [Google Scholar] [CrossRef]

- Micelli, F.; Nanni, A. Mechanical Properties and Durability of FRP Rod; Report of CIES 00-22; Department of civil engineering, University of Missouri-Rolla: St, Rolla, MO, USA, 2001. [Google Scholar]

- ACI 440H. Guide for the Design and Construction of Concrete Reinforced with FRP Bars; American Concrete Institute Committee: Farmington Hills, MI, USA, 2000. [Google Scholar]

- Feng, P.; Wang, J.; Wang, Y.; Loughery, D.; Niu, D. Effects of corrosive environments on properties of pultruded GFRP plates. Compos. Part B Eng. 2014, 67, 427–433. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, X.; Chen, S. Durability and service life prediction of GFRP bars embedded in concrete under acid environment. Nucl. Eng. Des. 2011, 241, 4095–4102. [Google Scholar] [CrossRef]

- Sousa, J.M.; Correia, J.R.; Cabral-Fonseca, S.; Diogo, A.C. Effects of thermal cycles on the mechanical response of pultruded GFRP profiles used in civil engineering applications. Compos. Struct. 2014, 116, 720–731. [Google Scholar] [CrossRef]

- Park, C.G.; Won, J.P. Effect of accelerated aging on the tensile and bond properties of FRP rebar for concrete. J. Korean Soc. Agric. Eng. 2015, 47, 73–84. [Google Scholar]

- Aldajah, S.; Alawsi, G.; Rahmaan, S.A. Impact of sea and tap water exposure on the durability of GFRP laminates. Mater. Des. 2009, 30, 1835–1840. [Google Scholar] [CrossRef]

- Miyano, Y.; Nakada, M.; Sekine, N. Accelerated testing for long-term durability of GFRP laminates for marine use. Compos. Part B Eng. 2004, 35, 497–503. [Google Scholar] [CrossRef]

- Biscaia, H.C.; Silva, M.A.G.; Chastre, C. An experimental study of GFRP-to-concrete interfaces submitted to humidity cycles. Compos. Struct. 2014, 110, 354–368. [Google Scholar] [CrossRef]

- Giampaolia, M.; Terlizzia, V.; Rossib, M.; Chiappinib, G.; Munafòa, P. Mechanical performances of GFRP-steel specimens bonded with different epoxy adhesives, before and after the aging treatments. Compos. Struct. 2017, 171, 145–157. [Google Scholar] [CrossRef]

- Heshmati, M.; Haghani, R.; Al-Emrani, M. Durability of bonded FRP-to steel joints: Effects of moisture, de-icing salt solution, temperature and FRP type. Compos. Part B Eng. 2017, 119, 153–167. [Google Scholar] [CrossRef]

- Haghani, R.; Al-Emrani, M. A new design model for adhesive joints used to bond FRP laminates to steel beams—Part A: Background and theory. Constr. Build. Mater. 2012, 34, 486–493. [Google Scholar] [CrossRef]

- Heshmati, M.; Haghani, R.; Al-Emrani, M. Effects of moisture on the long-term performance of adhesively bonded FRP/steel joints used in bridges. Compos. Part B Eng. 2016, 92, 1–16. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, L. State-of-the-art review on FRP strengthened steel structures. Eng. Struct. 2007, 29, 1808–1823. [Google Scholar] [CrossRef]

- Yuan, H.; Teng, J.G.; Seracino, R.; Wu, Z.S.; Yao, J. Full-range behavior of FRP-to-Concrete bonded joints. Eng. Struct. 2004, 26, 553–564. [Google Scholar] [CrossRef]

- Lu, X.Z.; Teng, J.G.; Ye, L.P.; Jiang, J.J. Bond-slip models for FRP sheets/plates bonded to concrete. Eng. Struct. 2005, 27, 920–937. [Google Scholar] [CrossRef]

- Fawzia, S.; Al-Mahaidi, R.; Zhao, X.L.; Rizkalla, S. Strengthening of circular hollow steel tubular section using high modulus CFRP sheets. Constr. Build. Mater. 2007, 21, 839–845. [Google Scholar] [CrossRef]

- Fawzia, S.; Zhao, X.L.; Al-Mahaidi, R.; Rizkalla, S. Bond characteristics between CFRP and steel plates in double strap joints. Adv. Steel Constr. Int. J. 2005, 1, 17–28. [Google Scholar]

- Garcia, C.; Trendafilova, I.; Zucchelli, A. The Effect of Polycaprolactone Nanofibers on the Dynamic and Impact Behavior of Glass Fibre Reinforced Polymer Composites. J. Compos. Sci. 2018, 2, 43. [Google Scholar] [CrossRef]

- Garcia, C.; Trendafilova, I.; Zucchelli, A.; Contreras, J. The effect of nylon nanofibers on the dynamic behaviour and the delamination resistance of GFRP composites. In Proceedings of the MATEC Web Conference, International Conference on Engineering Vibration (ICoEV 2017), Sofia, Bulgaria, 4–7 September 2017. [Google Scholar]

- Okeil, A.M.; Ulger, T.; Babaizadeh, H. Effect of adhesive type on Strengthening-By-Stiffening for shear-deficient thin-walled steel structures. Int. J. Adhes. Adhes. 2015, 58, 80–87. [Google Scholar] [CrossRef]

- Micelli, F.; Nanni, A. Durability of FRP rods for concrete structures. Constr. Build. Mater. 2004, 18, 491–503. [Google Scholar] [CrossRef]

- Stewart, A.; Elliot, P.D. Accelerated Testing of Epoxy-FRP Composites for Civil Infrastructure Applications: Property Changes and Mechanisms of Degradation. J. Polym. Rev. 2012, 52, 115–141. [Google Scholar] [CrossRef]

- Robert, M.; Wang, P.; Cousin, P.; Benmokrane, B. Temperature as an Accelerating Factor for Long-Term Durability Testing of FRPs: Should There Be Any Limitations? J. Compos. Constr. 2010, 14, 361–367. [Google Scholar] [CrossRef]

- Batdorf, S.B.; Ghaffarian, R. Size Effect and Strength Variability of Unidirectional Composites. Int. J. Fract. 1984, 26, 113–123. [Google Scholar] [CrossRef]

- Kaminski, B.E. Effects of Specimen Geometry on the Strength of Composite Materials. In Analysis of the Test Methods for High Modulus Fibers and Composites; ASTM International: West Conshohocken, PA, USA, 1973; pp. 181–191. [Google Scholar]

- Okeil, A.M.; El-Tawil, S.; Shahawy, M. Short-term tensile strength of carbon fiber-reinforced polymer laminates for flexural strengthening of concrete girders. Struct. J. 2001, 98, 470–478. [Google Scholar]

- Sutherland, L.S.; Shenoi, R.A.; Lewis, S.M. Size and scale effects in composites: I. Literature review. Compos. Sci. Technol. 1999, 59, 209–220. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).