Abstract

This paper investigated the machinability of a stone–plastic composite (SPC) via orthogonal cutting with diamond cutters. The objective was to determine the effect of cutting depth on its machinability, including cutting forces, heat, chip formation, and cutting quality. Increased cutting depth promoted an increase in both frictional and normal forces, and also had a strong influence on the change in normal force. The cutting temperatures of chips and tool edges showed an increasing trend as cutting depth increased. However, the cutting heat was primarily absorbed by chips, with the balance accumulating in the cutting edge. During chip formation, the highest von Mises strain was mainly found in SPC ahead of the cutting edge, and the SPC to be removed partially passed its elastic limit, eventually forming chips with different shapes. Furthermore, the average surface roughness and the mean peak-to-valley height of machined surfaces all positively correlated to an increase in cutting depth. Finally, with an increase in cutting depth, the chip shape changed from tubular, to ribbon, to arc, to segmental, and finally, to helical chips. This evolution in chip shape reduced the fluctuation in cutting force, improving cutting stability and cutting quality.

1. Introduction

In the flooring market, there is a tendency to use composite materials as flooring material instead of traditional materials, like high-density fiberboard and solid wood [1]. Among those advanced materials, the stone–plastic composite (SPC) has become one of the popular choices in flooring material, because it is stain-resistant, waterproof, environmentally friendly, durable, and easy to install [2].

SPC is made from calcium carbonate powder (CaCO3) and polyvinyl chloride (PVC). After their combination in a specific ratio, the mixture is formed into panels in a hot press [3]. However, PVC has a poor heat stability. This can be a problem during SPC production, as PVC is easily degraded in the type of high-temperature environment that can occur during cutting, potentially affecting the integrity of the machined surface [4]. Furthermore, since CaCO3 has a high hardness, it increases the wear rate of cutters, increasing costs and limiting productivity [5].

In the face of this difficult-to-cut material, diamond cutting tools appear to be the best choice [6]. Compared with other common cutter materials, such as cemented carbide [7] and ceramics [8], diamond cutting tools offer outstanding advantages. These include their low thermal expansion coefficient [9], high hardness [10], low friction coefficient [11], and high thermal conductivity [12].

Interest in the study of diamond cutting tools has recently increased [9]. When examining the state of research on material machinability with diamond cutting tools, it can be found that cutting forces, cutting heat, chip deformation, and cutting quality are important research objects in material processing theories. Those factors have a direction influence on tool design, energy consumption, machining methods, and production quality [13].

Cutting forces are affected by many factors, especially the cutting parameters. A series of experiments by Belmonte et al. [14] involved diamond turning of hard metal. Their results indicated that the increase of cutting speed, feed rate, and cutting depth promoted an increase in cutting forces. In related cutting forces research, Wang et al. [15] used diamond cutting tools to turn an aluminum alloy. They found that with increasing cutting depth and feed rate, there is a decrease in their effect on both thrust cutting force and principal cutting force.

Power consumed in materials machining is mainly converted into cutting heat, which directly or indirectly causes machining problems, such as tool wear and a loss of machining precision [16]. An experimental study of diamond milling of silicon carbide was designed by Iqbal et al. [17]; they found that cutting temperature decreases with an increase in cutting depth at a higher feed rate, but increases at low feed rates. They also stated that an increased cutting speed raises the cutting temperature at a high cutting depth, but decreases it at a low cutting speed. Wang et al. [18] determined the effect of cutting depth and cutting speed on heat generation in diamond milling of aluminum alloys. They found that the cutting temperature initially increases and then decreases with an increase in cutting depth, but the cutting temperature increases steadily with an increase in cutting speed.

Controlling chip deformation and motion is often important, as these factors can lead to superficial damage to the machined surface and reduce the service life of machining tools [19]. Based on their study of chip formation during cutting with diamond cutting tools, Jared and Dow [19] illustrated that cutting parameters and tool geometries have a great effect on chip deformation and motion. A chip deformation experiment of rock machined by a diamond cutter was performed by Che et al. [20]; they showed that cutting depth has a great effect on the chip shape, and chip size is directly proportional to the cutting depth.

Cutting quality is the basic guarantee of production quality, which is generally evaluated by the mean peak-to-valley height and average deviation of surface roughness [21]. Wu et al. studied the effect of cutting depth on cutting quality when turning a micro-prism array with diamond tools and showed that cutting depth affects surface defects; cutting depths greater than 4 μm further degraded the quality of the machined surface [22].

Although numerous researchers have focused on the machinability of different materials with diamond cutting tools, there is still a dearth of scientific data about SPC machinability. As mentioned above, SPC belongs to a group of difficult-to-cut materials with specific properties. Therefore, it is essential to pay attention to the adjustment of cutting parameters, especially cutting depth, one of the most important parameters affecting the machinability [23].

The objective of this paper was to provide more data on the machinability of difficult-to-cut materials like SPC. The machinability of SPC was investigated via an orthogonal cutting experiment in which SPC workpieces were planed by a diamond cutter and produced chips. The variables in question were the influence of cutting depth on cutting forces, cutting heat, chip deformation, material strain, and cutting quality. The experimental results are intended to facilitate a scientific selection of cutting parameters in SPC manufacturing processes.

2. Materials and Methods

2.1. Testing Material

SPC workpieces with dimensions of 3.3 mm thickness × 80 mm width × 250 mm length were used for testing. The SPC used in this work is a commercial product (Jiangsu Kentier Wood Co. Ltd., Nanjing, Jiangsu, China). The SPC panel production process fulfills the quality control standard GB/T4085-2015 and GB/T 11982.1-2005 [24,25]. Briefly, in its manufacture, PVC and CaCO3 (1:2.5 ratio by volume) are mixed for 15–20 min at 80 °C in a high-speed mixer. The resulting mixture is then passed through a melting machine and an extruder (approx. 15 min, 150–165 °C). The mixture is formed into panels for 45 min in a compression molding press at 140 °C and 6 MPa. The panel is then moved by two pressing rolls (4–17 MPa, 30–150 °C) as it is pressed to the desired thickness, and is transferred to a palletizing machine. When the temperature of panel decreases to 70 °C, the panel is transferred to a cooling machine at 10 MPa for fine-forming. When at room temperature, the resulting SPC is cut into sizes appropriate for the intended use. The material properties of the SPCs workpieces were measured prior to use: modulus of elasticity (8.10 GPa), tensile strength (16 MPa), modulus of rupture (27 MPa), moisture content (0.21%), and density (1.98 g·cm−3).

2.2. Cutting Tools

The blades consisted of polycrystalline diamond (PCD) fabricated by mixing diamond powder with metal binders and sintering. The angle geometries and the material properties of blades are displayed in Table 1.

Table 1.

Material parameters of the PCD (polycrystalline diamond) blades used in this work.

2.3. Experimental Procedure

As shown in Figure 1a, each SPC workpiece was planed by a diamond cutter on a shaping machine (B665, Dongtai machinery plant, Yancheng, China). The orthogonal cutting experiments were carried out at five cutting depths—0.1 mm, 0.6 mm, 1.1 mm, 1.6 mm, and 2.1 mm—while the cutting speed and the cutting length were kept constant, at 15.4 m/min and 250 mm, respectively. For each combination of cutting parameters, the cutting forces, heat, chip formation, and machined surface were measured for five samples.

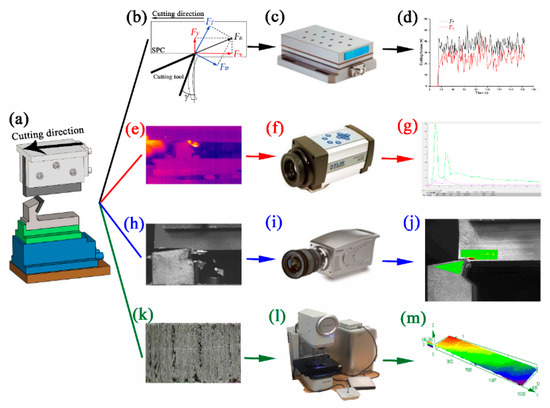

Figure 1.

Experimental system: (a) Planing, (b–d) measurement of forces, (e–g) cutting heat, (h–i) chip formation, and (k–m) machined surface.

The essential cutting forces were defined as the force components parallel and perpendicular to the cutting direction, namely Fx and Fy (Figure 1b–d). They were detected using a dynamometric system equipped with a three-dimensional piezoelectric dynamometer (Kistler 9257B, Winterthur, Switzerland), an amplifier (5070A, Winterthur, Switzerland), and processing software (Dynoware V2.6.5.16, Winterthur, Switzerland). Because the inclination angle of the cutter was 0°, the lateral force, Fz, was neglected. However, the values of frictional force, Ff, normal force, Fn, resultant force, Fr, difference between frictional and normal forces, FΔ, and standard deviation of force, Fσ, were calculated using Equations (1)–(4) [26]:

where Fn was defined as the component force normal to rake face, Ff was the component force parallel to rake face, γ was the rake angle, Fσ was the fluctuation of force, Fi was the dynamic force, and Fav was the average force.

Cutting heat generated during machining was measured by an infrared imaging camera (A20-M, Thermo Fisher Co. Ltd., Sheffield Village, OH, USA). It received the infrared radiation energy of samples with a refresh rate of 50 Hz and then generated thermal images with a resolution of 160 × 120 pixels (Figure 1e–g).

To examine chip formation processes (Figure 1h–j), a high-speed imaging camera system (Ispeed 3, Olympus, Co. Ltd., Tokyo, Japan) with a field-of-view image resolution of 1280 × 1024 pixels and a 1.3 MP sensor with an 8-bit dynamic range (one pixel in the images corresponds to approximately 0.07 mm) was used to record the machining processes at different cutting conditions.

Digital image correlation (DIC) analysis was performed on the recorded images, using ARAMIS 2017 professional software (GOM GmbH, Braunschweig, Germany) for determining and analyzing full-field mechanics. Further information on the different methods for evaluating and extracting constitutive parameters from full-field data can be found in Avril et al. [27], while He et al. [28] offers further information on the evaluation of the full-field stress-strain behavior of composites.

Grayscale image evaluation was performed on a region of interest (ROI) of the cutting tool and of the SPC workpiece. A grayscale uncertainty investigation was based on ten images obtained during experimental testing. The ten images used were captured before the workpiece reached the cutting edge. Grayscale values for the ROI in these images had a mean of 84.54 and a standard deviation (SD) of 23.56; the mean noise for the full image set was 0.23, with an SD of 0.07.

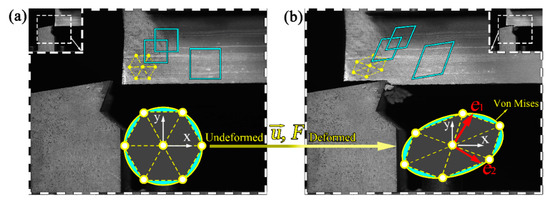

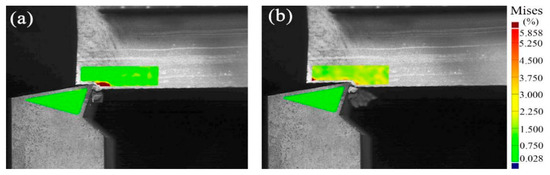

The DIC reference-stage grayscale image was based on the mean from combining the set of ten images. This procedure is advantageous because it can improve the spatial resolution for differentiating between smaller details and also reduce random system noise. This reference, with a natural stochastic surface ROI, was correlated with the first stages when the SPC workpiece reached the cutting tool (Figure 2).

Figure 2.

Graphical representation of the decomposition of deformation at cutting depth of 1.1 mm: (a) Before cutting edge reach SPC; (b) after cutting edge cut into SPC.

The quantity of interest (QOI) was strain representation: technical strain with dimension-equivalent von Mises strain. For DIC, a high-accuracy computation mode was used, with bicubic subpixel interpolation, a maximum residual of 20, a maximum intersection deviation of 0.1 pixels, and a minimum pattern quality of 1.1 pixels. No spatial or temporal filters and no tolerance sources were used. Subset matching was conducted against the first reference stage, with automatic subset starts, a strain tensor neighborhood of 1, and an interpolation size of 0.

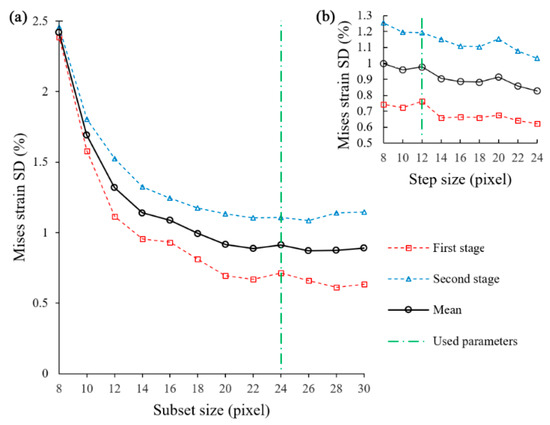

The full-field strain representation with the corresponding GOM continuous legend was three-sigma-scaled in the last stage. The former stage was scaled to the same legend range for a comparison of stages. An optimization study was performed to determine a suitable subset size (Figure 3a) and step size (Figure 3b) as the basis for the DIC mesh. For the subset size study, 50% subset overlap was initially used, and for the following study optimizing the step size, a subset size of 24 × 24 pixels was used. The final selected subset size for material analysis was 24 × 24 pixels at a step size of 12 pixels.

Figure 3.

DIC parameter study of (a) subset size and (b) step size for mesh optimization.

Von Mises strain noise-floor evaluation was based on correlating the reference stage to ten stages before the work piece reached the cutting tool. The same set of ten images used for grayscale evaluation from ROI was evaluated. Systematic error and SD were measured for the noise-floor. The system evaluation was based on ten stages. The mean value of von Mises strain was 0.09 (Equation (5)) and the SD of the mean was 0.05; the mean SD of von Mises strain was 0.08, and the SD was 0.04. In Equation (5), φM stands for the equivalent strain with the von Mises strain.

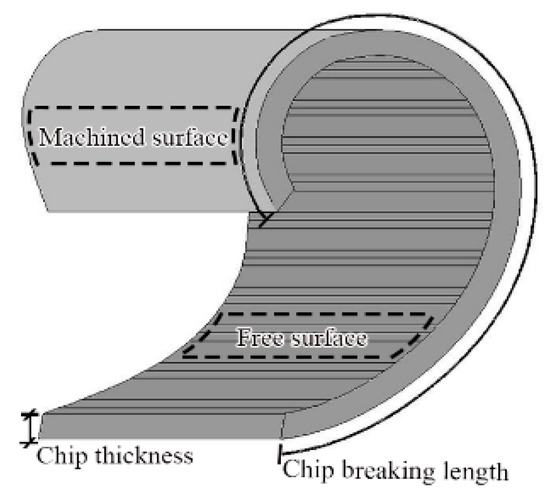

Meanwhile, chips formed under different cutting conditions were observed by an optical microscope (SZX16, Olympus Co. Ltd., Tokyo, Japan). Special attention was given to the machined surface, free surface, and degree of chip formation (Figure 4). Based on the chip-breaking length, cutting depth, and chip thickness, the compression ratio of chip thickness was obtained using Equation (6) [26], which was used to evaluate the degree of chip formation:

where ea is the compression ratio of chip thickness, ach is the chip thickness, and ac is the cutting depth.

Figure 4.

Chip parameters including machined surface, free surface, chip breaking length, and chip thickness.

After machining (Figure 1k–m), the mean peak-to-valley height (Rz) and average surface roughness (Ra) of the machined surface were measured using a surface profilometer (S-NEX001SD-12, Olympus, Co. Ltd., Japan). Meanwhile, a surface topography profilometer (DSX510, Olympus, Co. Ltd., Japan) was adopted to test the micrograph and three-dimensional surface topography of the machined surface.

3. Results and Discussion

3.1. Cutting Forces

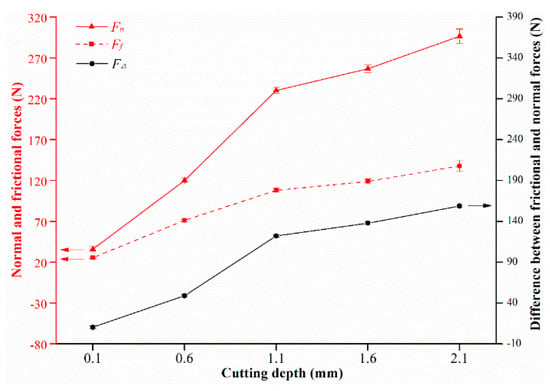

Changes in average cutting forces with an increase in cutting depth are shown in Figure 5. Both Ft and Fn increased with the increase of cutting depth. Machining is a removal process, during which the rake face separates unwanted material as chips. An increased cutting depth meant a higher machining quantity per unit time. Therefore, the force acting on the cutter increased due to the higher resistance of material deformation and friction at the cutter–workpiece interface.

Figure 5.

Influence of cutting depth on cutting forces; each point is the average of five observations, and the error bars of each data point represent one standard deviation.

Furthermore, FΔ showed an increasing trend as cutting depth increased, and it meant that the growth rate of Ft was higher than that of Fn. In other words, increasing cutting depth had a strong influence on Fn. Thus, during machining, with an increase of cutting depth, the forces acting on the cutter mainly resulted from resistance to material deformation, followed by friction at the cutter–chip interface.

3.2. Cutting Heat

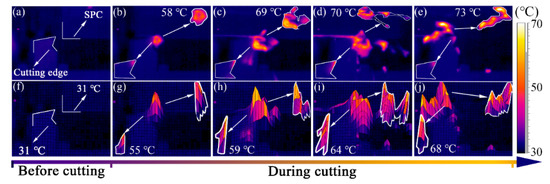

Figure 6 shows the cutting heat generation and distribution from the start to the end of machining. As cutting continued, the temperature of both the cutting edge and chips increased. During machining, the SPC was physically pulled apart by the cutting edge, and the unwanted material was then pushed out as chips by the rake face. Cutting heat was mainly generated in two ways: By friction at the chip–rake face and machined surface–flank face interfaces, and by SPC deformation in the shear zone ahead of the cutting edge. Meanwhile, based on comparing the different colors to each other, and the different peak heights to each other, it could be found that the temperature of the chip was higher than that of the cutting edge. Therefore, the cutting heat generated during machining was primarily taken off by chips, while the balance accumulated in the cutting edge.

Figure 6.

Heat distribution, and the max temperature of chips and cutting edge during SPC machining at cutting depth of 1.1 mm: (a–e) Infrared images, (f–j) three-dimensional heat maps.

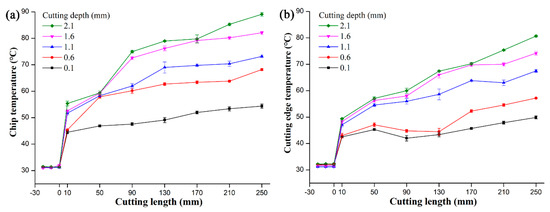

The effects of cutting depth on the max temperature of cutting edge and chips are shown in Figure 7. When the cutting edge cut into SPC, the temperatures of both the cutting edge and chip showed a sharp rise at all depths, and the temperatures were positively related to cutting depth. As mentioned above, increasing cutting depth meant a higher cutting quantity, leading to greater cutting forces, which translated to the generation of higher cutting heat the during cutting process.

Figure 7.

The maximum cutting temperature at varying cutting depths for the (a) cutting edge and (b) chips. Each point is the average of five measurements, and the error bars of each data point represent one standard deviation.

3.3. Chip Deformation

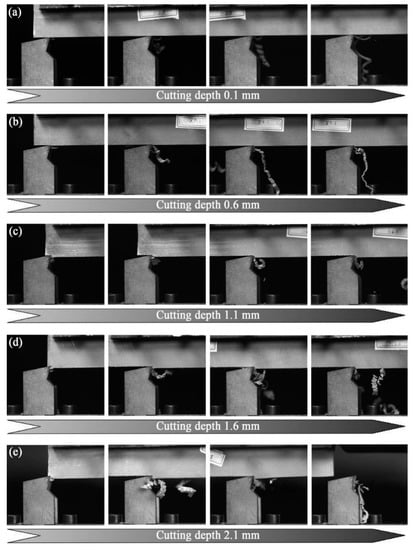

Machining is a material failure process. When the cutting edge bit into the workpiece, the unneeded SPC was separated and sheared along the cutting plane. Then, with further movement of the cutter, the rake face squeezed and accumulated the unneeded SPC. Finally, the unneeded material fell out and formed into chips with different shapes (Figure 8).

Figure 8.

Chip formation at different cutting depths: (a) 0.1 mm, (b) 0.6 mm, (c) 1.1 mm, (d) 1.6 mm, and (e) 2.1 mm.

For more details of the cutting process, the full-field related mechanics of SPC machining were analyzed, and the von Mises strain was examined at the interface of the SPC and the cutting tool based on DIC analysis. As displayed in Figure 9a, when the cutting edge cut into the SPC, the highest von Mises strain response was in the SPC along the cutting tool edge, primarily in the cutting direction at the area oriented along the edge and into the SPC. Due to the considerably lower stiffness of the SPC compared to the cutting tool, the measurable strain was determined in the SPC.

Figure 9.

Full-field mechanics of SPC machining at moderate cutting depth of 1.1 mm: (a) The first captured stage; (b) the following capture stage.

The strain localization at the edge in front of the cutting tool differs between the DIC stages, as shown in Figure 9a,b. This is related to the SPC material elasticity limit; thus, it is an explanation for the systematic discontinuity of the chip formation shape for arc chips at this moderate cutting depth of 1.1 mm. The strain gradually builds up until it reaches the material’s elasticity limit, at which point a new strain localization connection forms and creates an arc chip.

It can be concluded based on the von Mises strain that the cutting tool is influencing the SPC even at a considerable distance from the cutting tool. It influences not only the cutting surface, but also material below the surface. Measurement of von Mises strain indicates that the machined material partially passed its elastic limit, as it did not fully recover after the tool left the area (Figure 9b). This indicates that the material below the machined surface of the SPC reached its plastic yield point, and eventually, the unneeded SPC was removed by the rake face and then deformed into chips.

Regarding the uncertainty quantification, values larger than the von Mises strain noise-floor mean of 0.09 with an SD of 0.05, indicate the experimentally tested material’s actual mechanical response (Figure 9).

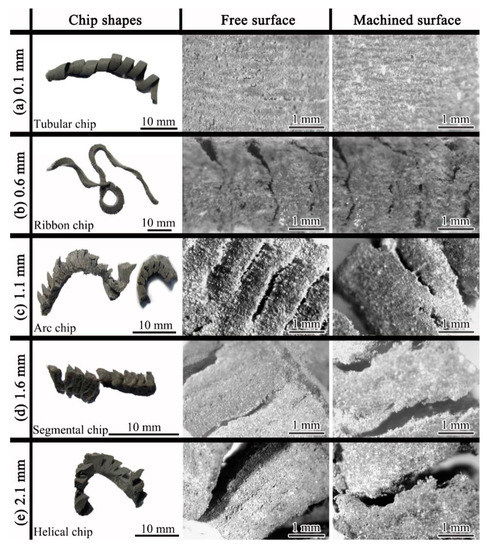

Based on the observation of their shapes, the SPC chips were divided into five categories: tubular, ribbon, arc, segmental, and helical chips. Figure 10 reveals the chip shapes produced when SPC was machined with different cutting depths. SPC consists of PVC and stone; while the chip shapes produced during its machining are more similar to the chip shapes of PVC materials than of the stone material [29].

Figure 10.

Chip formation at different cutting depths, where the free and machined surfaces are the noncontact and contact surfaces of chip and rake face, respectively: (a) 0.1 mm, (b) 0.6 mm, (c) 1.1 mm, (d) 1.6 mm, and (e) 2.1 mm.

Tubular chips had a cylindrical shape with a chip-breaking length of 188–248 mm. They were mainly produced at a cutting depth of 0.1 mm. The machined surface was smoother than the free surface of the tubular chip; some irregular pits could be found on the free surface of tubular chips.

Ribbon chips were flake-like, with the chip-breaking length ranging from 114–124 mm. They were primarily generated with a cutting depth of 0.6 mm. Cracks were observed on both the free and machined surfaces of ribbon chips.

Arc chips had a C-shape, with a chip-breaking length of 13–35 mm. They were mainly observed with a cutting depth of 1.1 mm. Some clear serrated borders could be observed on both the machined and free surfaces of arc chips.

Segmental chips were a discontinuous chip, formed at a cutting depth of 1.6 mm. Segmental chips had low strength, with a breaking-chip length varying from 6–11 mm. They were loosely connected by particle chips, which were easily broken into the chips with different sizes. Both the free surface and machined surfaces of helical chips had sawteeth and obvious cracks.

Helical chips, with a chip-breaking length of about 27–39 mm, were mainly generated at a cutting depth of 2.1 mm. Their chip structure was similar to that of segmental chips. Helical chips were also connected with particle chips and had a low strength. Both the free and machined surfaces of helical chips had obvious cracks and serrated borders.

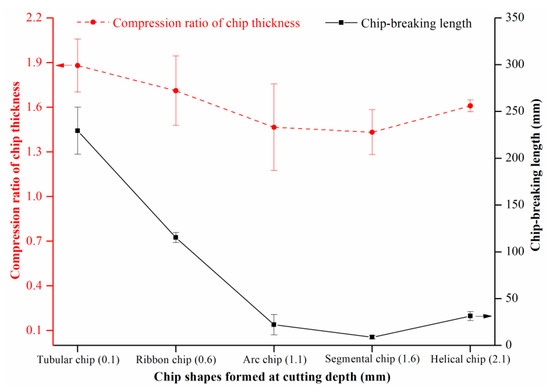

As shown in Figure 11, with an increase in cutting depth, the chip shapes changed from tubular, to ribbon, to arc, to segmental, and eventually to helical chips. According to classic cutting theory [24], the chip compression ratio declines with an increase of cutting depth. However, in this paper, the chip compression ratio first increased and then decreased, which is a trend similar to the trend in chip-breaking length. This phenomenon resulted from the special properties of the workpiece. As previously mentioned, the PVC contained in SPC has a poor heat stability. Cutting temperature was observed to increase with cutting depth. Thus, the high cutting temperature generated with a cutting depth of 2.1 mm reduced the stability of SPC in the cutting layer and increased the chip compression ratio.

Figure 11.

Average values of chip compression ratios and chip-breaking length for different chip shapes; each point is the average of five observations, and the error bars represent one standard deviation.

3.4. Cutting Quality

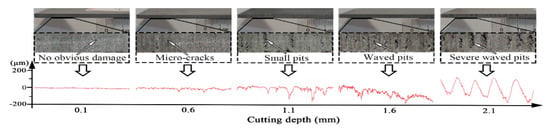

The quality of the local surface of workpieces varied with cutting depth. With a cutting depth of 0.1 mm, the machined surfaces were very smooth, and did not show obvious damage. However, with an increased cutting depth, the damage morphology of machined surfaces changed from micro-cracks, to small pits, to waved pits, and finally to obvious waved pits. Furthermore, two-dimensional topography of each machined surface revealed that as the cutting depth increased, the range of the topographical curve had more fluctuations, and it developed from almost linear, to slight lines, to standing waves. Therefore, it can be conducted that the increasing cutting depth led to a rougher surface (Figure 12).

Figure 12.

Machined surface of workpiece planed at different cutting depths.

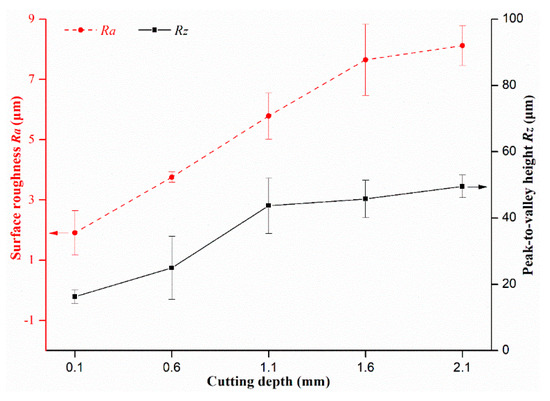

For further evaluating the effect of cutting depth on cutting quality, the peak-to-valley height and the surface roughness of the whole machined surface were measured (Figure 13). The values of Ra and Rz positively correlate to an increase in cutting depth because the increasing cutting depth raised the cutting quantity per time, and it led to more resistance for the cutting edge. That is to say, the difficulty of removing unneeded material by the rake face increased with increasing cutting depth, resulting in a poorer cutting quality with larger cutting depths.

Figure 13.

Surface roughness, Ra and peak-to-valley height, Rz of surfaces machined at different cutting depths; each point is the average of five observations, and the error bars of each data point represent one standard deviation.

3.5. Relation Between Cutting Depth and Machinability of SPC

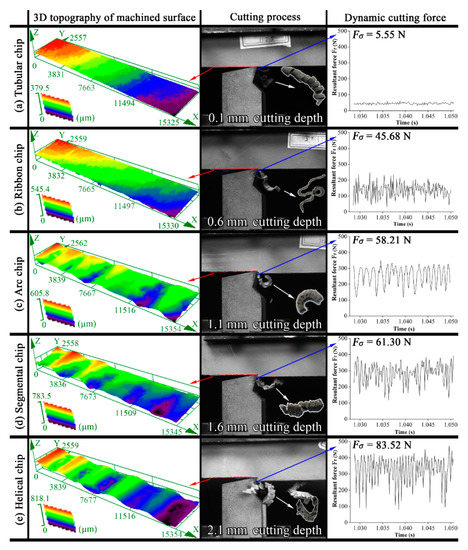

Figure 14 reveals the relation between cutting quality, cutting force, and chip formation during different cutting depths, mainly the three-dimensional topography of the machined surface, dynamic resultant force, and chip shape.

Figure 14.

Relation between machined surface, resultant force, and chip shapes during machining at different cutting depths.

First, when the chips were tubular, the machined surface was smooth with a fair surface, and the Fσ was low, with a value of 5.55 N. Then, when ribbon chips were produced, the machined surface was slightly uneven, and the Fσ was larger, with a value of 45.68 N. Thirdly, when arc chips emerged, some waved surfaces were found on the workpiece, and the Fσ became even bigger, with a value of 58.21 N. Fourthly, when segmental chips started to appear, the machined surface became rougher, and the Fσ continued to grow to 61.30 N. Finally, when generating helical chips, clear waved surfaces were observed on the machined surface, and the Fσ increased to its highest value, 83.52 N.

As chip shapes changed from tubular, to ribbon, to arc, to segmental, and finally to helical chips, the fluctuation in cutting force became greater, and the flatness of the final machined surface increased. All in all, with the increase of cutting depth, the chip shapes evolved, and the cutting stability decreased, leading to a rougher machined surface.

4. Conclusions

In this work, a series of cutting experiments were carried out to determine the machinability of SPC planed by a diamond cutter. Firstly, as indicated by the experimental results, both frictional and normal forces increased with increasing cutting depth, and an increase cutting depth had a particularly notable influence on the increase in normal force. Secondly, the cutting heat generated during SPC machining was primarily contained within the chips, and so was removed from the workpiece, with most of the balance accumulated in the cutting edge. The cutting temperatures of both the chips and tool edge were positively correlated with an increase in cutting depth. Thirdly, during SPC machining, the highest von Mises strain was observed in the SPC ahead of the cutting edge, as the unneeded SPC material partially passed its elastic limit before finally being removed by the rake face and formed into chips. Meanwhile, chips formed during SPC machining could be divided into five categories based on their shapes: tubular, ribbon, arc, segmental, and helical chips. Fourthly, the average surface roughness and the mean peak-to-valley height of the machined surface increased with an increase in cutting depth. The damage morphology of machined surfaces changed from a smooth surface to micro-cracks, to small pits, to waved pits, and eventually to more prominent waved pits. Finally, as cutting depth increased, the chip shapes changed from tubular, to ribbon, to arc, to segmental, and eventually to helical chips, which led to a more stable cutting process and higher cutting quality.

This work focused solely on the machinability of SPC during planing. Thus, future studies may explore the machinability of SPC during milling, sawing, and drilling processes, which will offer more guidance for the SPC manufacturing industry. In this research, digital image correlation (DIC) was applied as a method for the analysis of full field-related mechanics, and further research via DIC could have the potential to provide novel insights.

Author Contributions

Conceptualization, P.C.; date curation: D.B., Z.Z.; formal analysis: D.B., Z.Z.; project administration: P.C., X.G.; resource: P.C., X.G.; supervision: M.E., P.C.; writing-original draft: Z.Z., D.B..

Acknowledgments

This work was supported by the [National Natural Science Foundation of China] grant number [31500480]; the [Doctorate Fellowship Foundation of Nanjing Forestry University]; and the [Priority Academic Program Development of Jiangsu Higher Education Institutions] grant number [PAPD]. The authors are also grateful for Leitz Tooling System Co. Ltd. for supplying the diamond cutting tools, and to Jiangsu Kentier Wood Co. Ltd., for supplying the samples of stone–plastic composite material used in this work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hutyrova, Z.; Harnicarova, M.; Zajac, J.; Valicek, J.; Mihok, J. Experimental Study of Surface Roughness of Wood Plastic Composites after Turning. Adv. Mater. Res. 2014, 856, 108–112. [Google Scholar] [CrossRef]

- Li, Y.Z. PVC Stone Based Material and Its Application. Patent Application No. CN101306927A, 19 November 2008. Available online: https://patents.google.com/patent/CN101306927A/zh (accessed on 25 December 2018).

- Huang, Z.G. Fast-Fixed Stone Plastic Clad Plate. Patent Application No. CN200999444Y, 2 January 2008. Available online: https://patents.google.com/patent/CN200999444Y/en (accessed on 17 December 2018).

- Barletta, M.; Tagliaferri, V.; Trovalusci, F.; Veniali, F.; Gisario, A. The Mechanisms of Material Removal in the Fluidized Bed Machining of Polyvinyl Chloride Substrates. J. Manuf. Sci. E 2013, 135, 11003. [Google Scholar] [CrossRef]

- Yousefi, R.; Gorjizadeh, A.; Mikaeil, R. The Effect of Machining Parameters on Force Signal and Tool Wear in Stone Cutting. Mater. Process. Technol. 2011, 1315, 961–966. [Google Scholar] [CrossRef]

- Kanda, K.; Takehana, S.; Yoshida, S.; Watanabe, R.; Takano, S.; Ando, H.; Shimakura, F. Application of Diamond-Coated Cutting Tools. Surf. Coat. Technol. 1995, 73, 115–120. [Google Scholar] [CrossRef]

- Guo, X.L.; Zhu, Z.L.; Ekevad, M.; Bao, X.; Cao, P.X. The Cutting Performance of Al2O3 and Si3N4 Ceramic Cutting Tools in the Milling Plywood. Adv. Appl. Ceram. 2018, 117, 16–22. [Google Scholar] [CrossRef]

- Zhu, Z.L.; Guo, X.L.; Ekevad, M.; Cao, P.X.; Na, B.; Zhu, N.F. The Effects of Cutting Parameters and Tool Geometry on Cutting Forces and Tool Wear in Milling High-Density Fiberboard with Ceramic Cutting Tools. Int. J. Adv. Manuf. Technol. 2017, 91, 4033–4041. [Google Scholar] [CrossRef]

- Giles, C.; Adriano, C.; Lubambo, A.F.; Cusatis, C.; Mazzaro, I.; Honnicke, M.G. Diamond Thermal Expansion Measurement Using Transmitted X-Ray Back-Diffraction. J. Synchrotron. Radiat. 2005, 12, 349–353. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, S.; Barra, E.D.; Laugier, M.T. Hardness Measurement of CVD Diamond Coatings on Sic Substrates. Surf. Coat. Technol. 2005, 193, 200–205. [Google Scholar] [CrossRef]

- Romanski, A.; Lachowski, J. Effect of Friction Coefficient on Diamond Retention Capabilities in Diamond Impregnated Tools. Arch. Metall. Mater. 2009, 54, 1112–1118. [Google Scholar]

- Che, J.; Cagin, T.; Deng, W.Q.; Goddard, W.A.; William, A. Thermal Conductivity of Diamond and Related Materials From Molecular Dynamics Simulations. J. Chem. Phys. 2000, 113, 6888–6900. [Google Scholar] [CrossRef]

- Uhlmann, E.; Worner, E.; Brücher, M. More Efficient Cutting Processes Due to the Heat-Spreading Effect of CVD Diamond. Ind. Diam. Rev. 2003, 63, 25–29. [Google Scholar]

- Belmonte, M.; Oliveira, F.J.; Sacramento, J.; Fernandes, A.J.S.; Silva, R.F. Cutting Forces Evolution with Tool Wear in Sintered Hardmetal Turning with CVD Diamond. Diam. Relat. Mater. 2004, 13, 843–847. [Google Scholar] [CrossRef]

- Wang, H.X.; Zong, W.J.; Li, D.; Dong, S. Feed Rate and Depth of Cut Influence on Cutting Forces in Diamond Turning Aluminium Alloy. Mater. Sci. Forum. 2004, 471–472, 634–639. [Google Scholar] [CrossRef]

- Shihab, S.K.; Khan, Z.A.; Mohammad, A.; Siddiquee, A.N. A Review of Turning of Hard Steels Used in Bearing And Automotive Applications. Prod. Manuf. Res. 2014, 2, 24–29. [Google Scholar] [CrossRef]

- Iqbal, M.; Konneh, M.; Ani, M.H.; Abdallah, K.A.; Binting, M.F. Cutting Temperature in High Speed Milling of Silicon Carbide Using Diamond Coated Tool. IIUM. Repos. 2015, 3, 62–66. [Google Scholar]

- Wang, S.J.; Chen, X.; To, S.; Ouyang, X.B.; Liu, Q.; Liu, J.W.; Lee, W.B. Effect of Cutting Parameters on Heat Generation in Ultra-Precision Milling of Aluminum Alloy 6061. Int. J. Adv. Manuf. Technol. 2015, 80, 1265–1275. [Google Scholar] [CrossRef]

- Jared, B.H.; Dow, T.A. Investigation of the Direction of Chip Motion in Diamond Turning. Precis. Eng. 2001, 25, 155–164. [Google Scholar] [CrossRef]

- Che, D.; Zhang, W.; Ehmann, K. Chip Formation and Force Responses in Linear Rock Cutting: An Experimental Study. J. Manuf. Sci. E 2017, 139, 011011. [Google Scholar] [CrossRef]

- Guo, X.L.; Ekevad, M.; Grönlund, A.; Marklund, B.; Cao, P.X. Tool Wear and Machined Surface Roughness During Wood Flour/Polyethylene Composite Peripheral Up milling Using Cemented Tungsten Carbide Tools. Bioresources 2014, 9, 3779–3791. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, P.; Wang, H.; Qiao, Z.; Wang, B. Effect of Cutting Parameters on Surface Quality During Diamond Turning of Micro-Prism Array. Proc. Inst. Mech. Eng. B-J. Eng. 2016, 231, 555–561. [Google Scholar] [CrossRef]

- Jamal, S.A.; Jaby, M. Optimization of Process Parameters in Diamond Abrasive Machining of Carbon Fiber-Reinforced Epoxy. Adv. Manuf. Process. 2014, 29, 1361–1366. [Google Scholar] [CrossRef]

- Wang, H.Y.; Tang, W.J.; Xu, R.Y.; Fang, Q.H.; Bao, J.H.; Yuan, S.F.; Li, Q.; Du, G.B. Effect of Thermo-treatment on Heating Dimensional Change Rate of Formed PVC Composite Wood Floor. Eng. Plast. Appl. 2014, 42, 55–58. [Google Scholar] [CrossRef]

- Zhao, Y.Y. Synthetic Stone–Plastic Flooring. Patent Application No. CN101003425A, 10 December 2007. Available online: http://www.google.com/patents/CN100441535C?cl=zh (accessed on 11 December 2018).

- Shaw, M.C.; Cookson, J.O. Metal Cutting Principles. Tribol. Int. 1985, 18, 55. [Google Scholar] [CrossRef]

- Avril, S.; Bonnet, M.; Bretelle, A.S.; Grédiac, M.; Hild, F.; Ienny, P.; Latourte, F.; Lemosse, D.; Pagano, S.; Pagnacco, E. Overview of Identification Methods of Mechanical Parameters Based on Full-Field Measurements. Exp. Mech. 2008, 48, 381–402. [Google Scholar] [CrossRef]

- He, T.; Liu, L.; Makeev, A.; Shonkwiler, B. Characterization of Stress–Strain Behavior of Composites Using Digital Image Correlation and Finite Element Analysis. Compos. Struct. 2016, 140, 84–93. [Google Scholar] [CrossRef]

- Guo, X.L.; Ekevad, M.; Marklund, B.; Li, R.R.; Cao, P.X.; Grönlund, A. Cutting Forces and Chip Morphology During Wood Plastic Composites Orthogonal Cutting. Bioresources 2014, 9, 2090–2106. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).