1. PV to Supply 24% Electricity by 2050

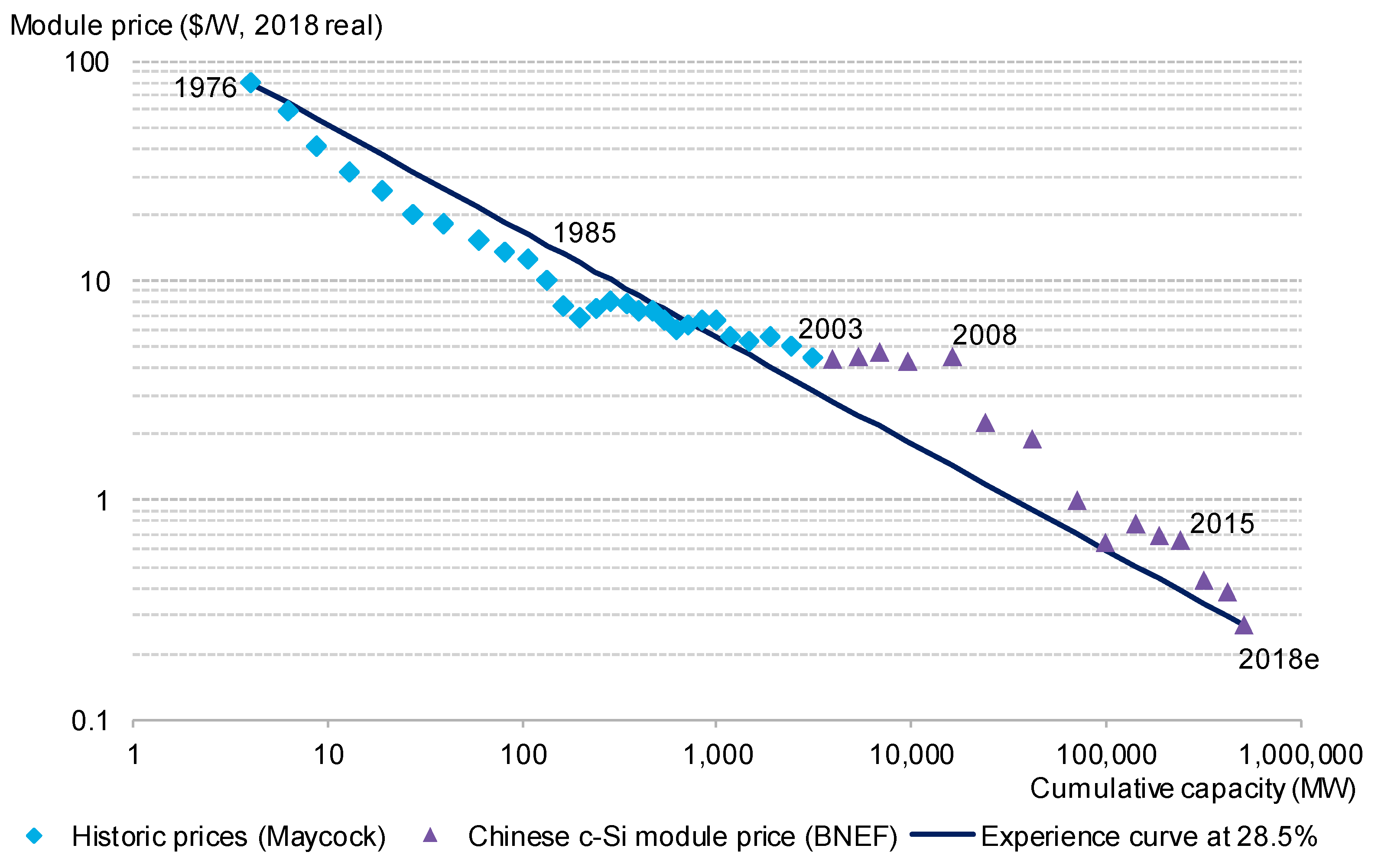

During the past 42 years (since 1976), PV module price dropped by 99.6% from

$79.3/W to

$0.3/W (both in 2018 USD), demonstrating a learning rate of 28.5% (

Figure 1, [

1]).

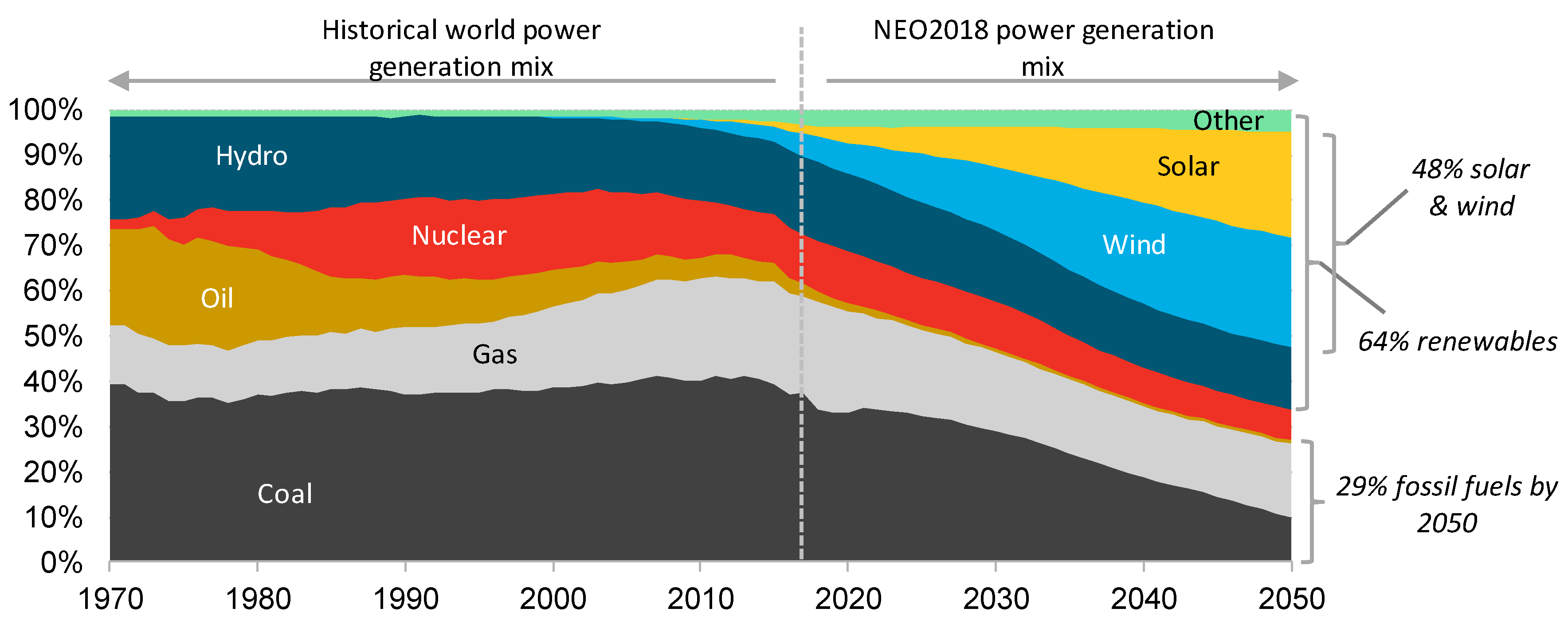

Along with the cost reduction of other components in PV systems, the economics of PV electricity has significantly improved. BloombergNEF expects 24% of worldwide electricity consumption will be supplied by PV by 2050, when a total of about 7TW PV will be installed (

Figure 2, [

2]).

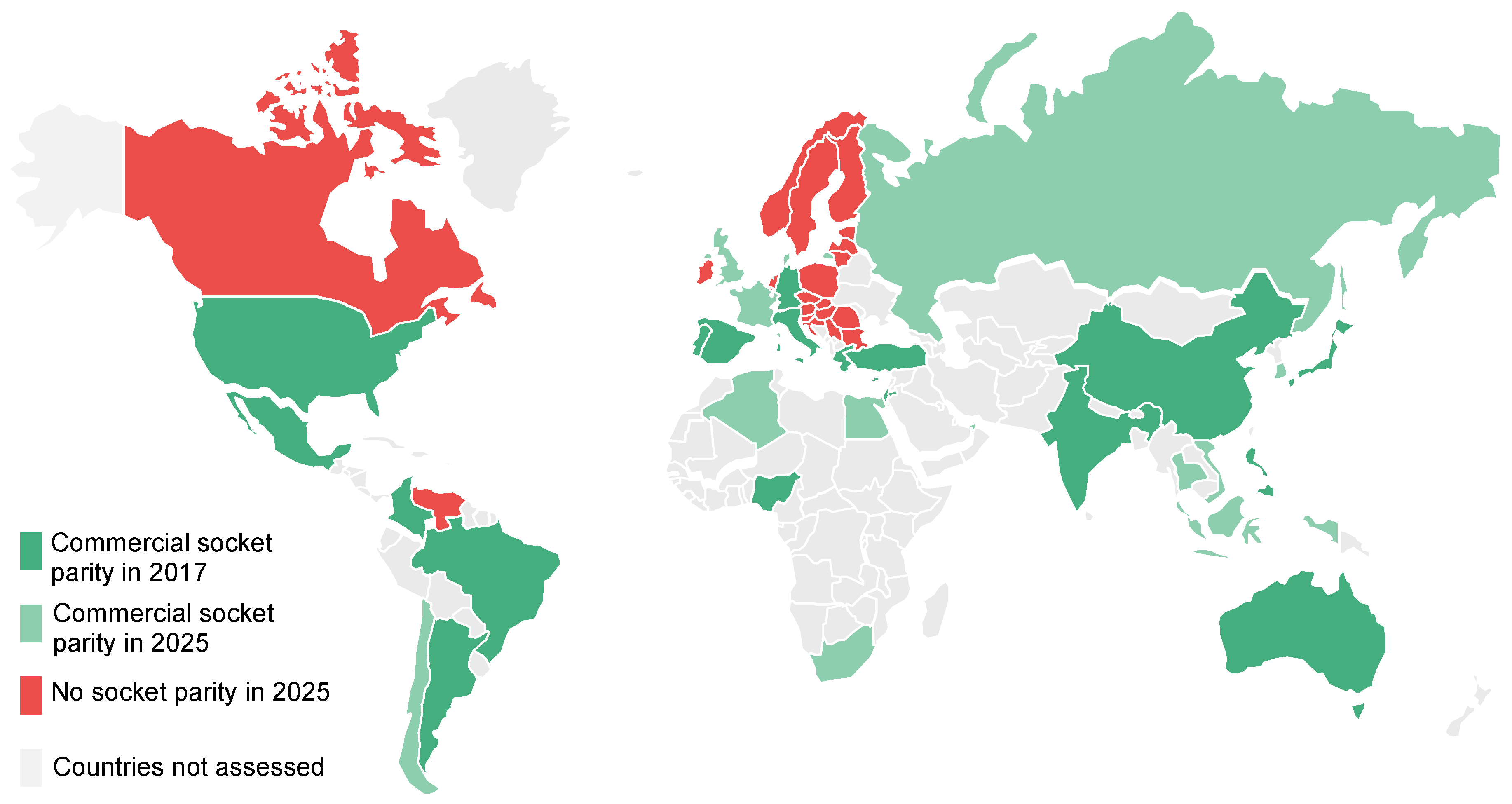

Despite the great potential of PV generation, continuous improvement is still needed before subsidies are eliminated. In industry, the ‘grid parity’ or ‘socket parity’ is defined by comparing the levelized cost of electricity (LCOE, to be defined) of PV generation and local retail price. For behind-the-meter applications—for example, commercial PV projects—the realized value of PV generation depends on the flow of the electricity, unless net metering policy is applied. This is because exported energy (uploaded to the grid) is usually valued at much lower rates than the retail rates.

Figure 3 shows the commercial socket parity achievement without generation-based subsidies by country in 2017 and expectation for 2025, assuming 75% on-site consumption ([

3]). Although socket parity will spread to more countries by 2025, there are still regions where subsidies are required to boost local market development. More analysis on residential socket parity can be found in the literature [

3,

4].

In addition to further efforts to lower the unit electricity cost, PV also needs to have its intermittency addressed in order to realize deeper penetration compared with the 2% contribution in power system in 2018 (

Figure 2). The coupling between PV and storage (PVS) is becoming an emerging market, thanks to cheaper lithium-ion batteries and the cost savings from synergy between PV and storage in the integrated system design. This point is mentioned here to provide a general and complete view of PV development. However, it is not the focus of this paper. More details about PVS can be found in the literature [

5,

6].

While there are still many challenges for PV to conquer before it can become a significant contributor to global electricity generation, we focus on one specific topic: how higher module efficiency can lower PV LCOE.

2. The Value of Module Efficiency Resides in Non-Module Costs

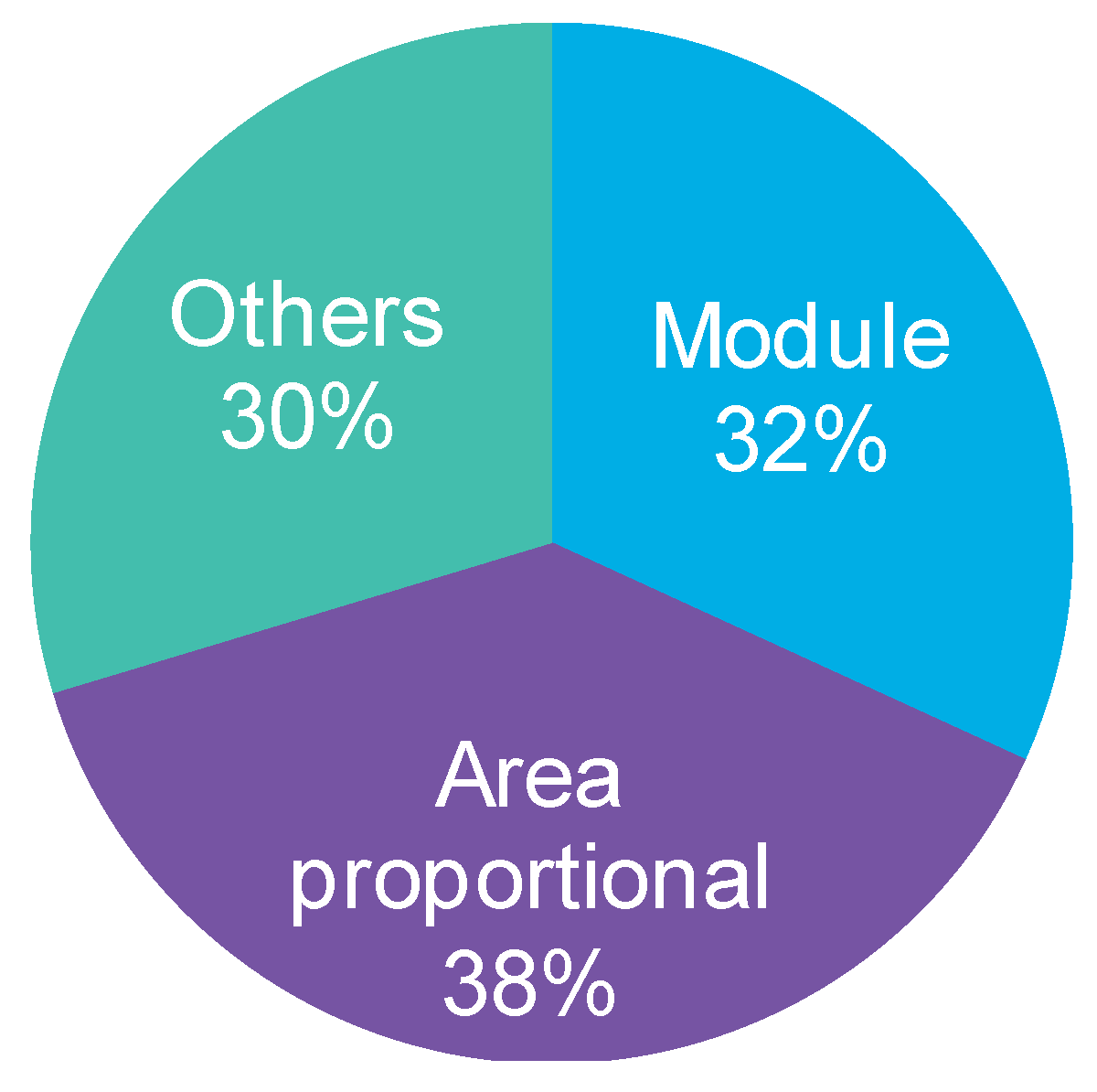

PV modules of higher efficiencies enjoy price premiums because they help lower the unit cost (per watt) of non-module components in a PV system. There are various ways of categorizing the costs of a PV project.

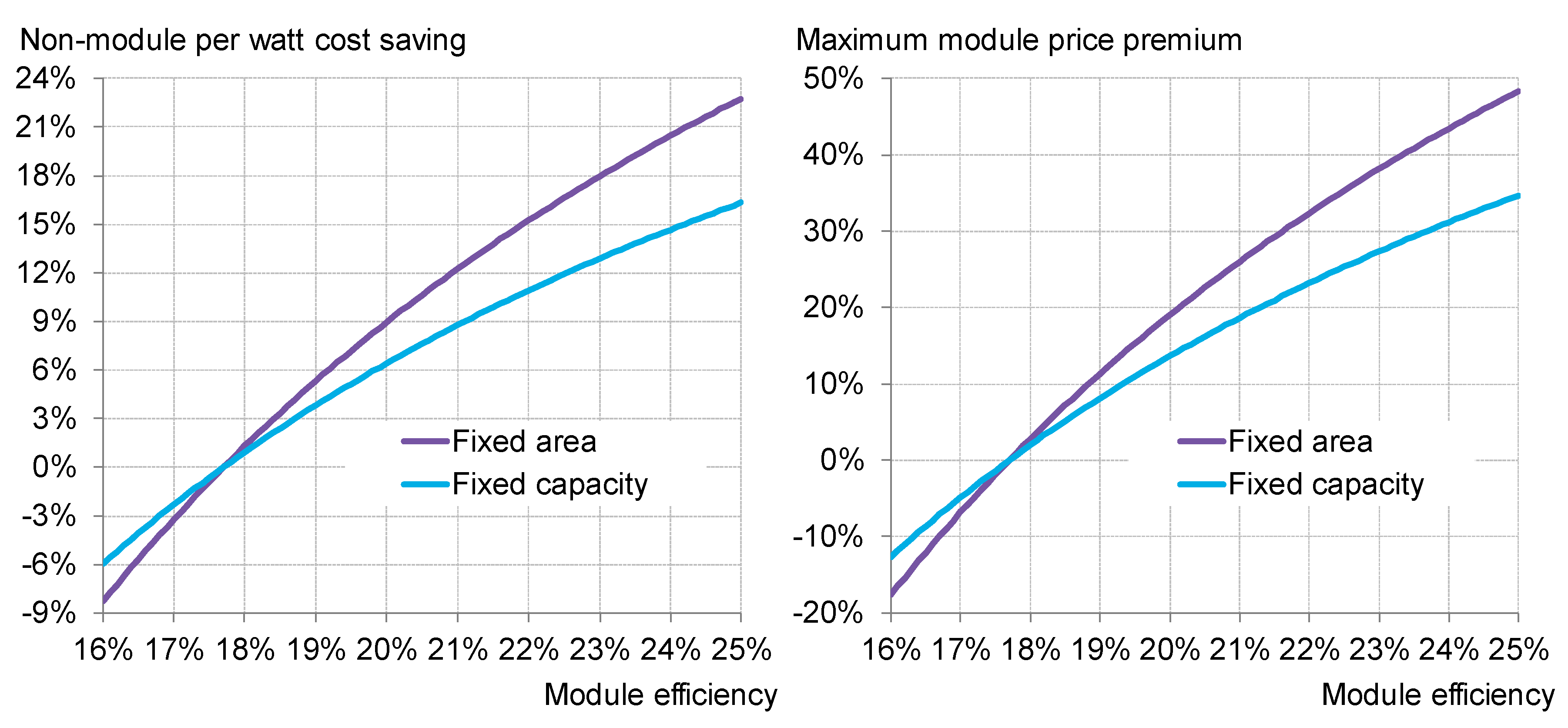

Figure 4 shows a simple structure of a utility PV project’s cost to illustrate the value of module efficiency. The category referred to as ‘area-proportional’ includes spending on racking, land, construction, transportation, etc. ‘Others’ refers to costs of electronic components that are quoted in terms of power rather than area, and soft costs related to administration, due diligence, etc.

In a case with a restricted grid interconnection capacity or a defined project power capacity, when modules of a higher efficiency are adopted, the required number of modules, land area, and ‘area-proportional’ costs are all reduced linearly. Therefore, the per-watt spending on area-related items is inversely proportional to module efficiency. In a case with a defined land area, when modules of a higher efficiency are adopted, all area-proportional costs are averaged over more power, so their per-watt value is reduced proportionally. Additionally, some soft costs categorized as ‘others’ remain the same or increase only marginally. Depending on the specific correlation between a certain cost item in ‘others’ and the system power, the impact of module efficiency on ‘others’ varies. For illustration purpose, we set a simplified assumption that half of the ‘others’, or 15% of the system cost, is of a fixed value. The left-hand chart in

Figure 5 shows the sensitivity of the non-module unit cost to module efficiency for the two scenarios. The impact of module efficiency is stronger when land area is restricted. Therefore, the maximum module price premium allowed is higher in such a case, as shown in the right-hand chart in

Figure 5. The maximum allowed module price premium is derived, assuming the system unit capex is the same as the reference point, which corresponds to 17.7% module efficiency.

3. The Value of Module Efficiency Depends on System Cost Structure

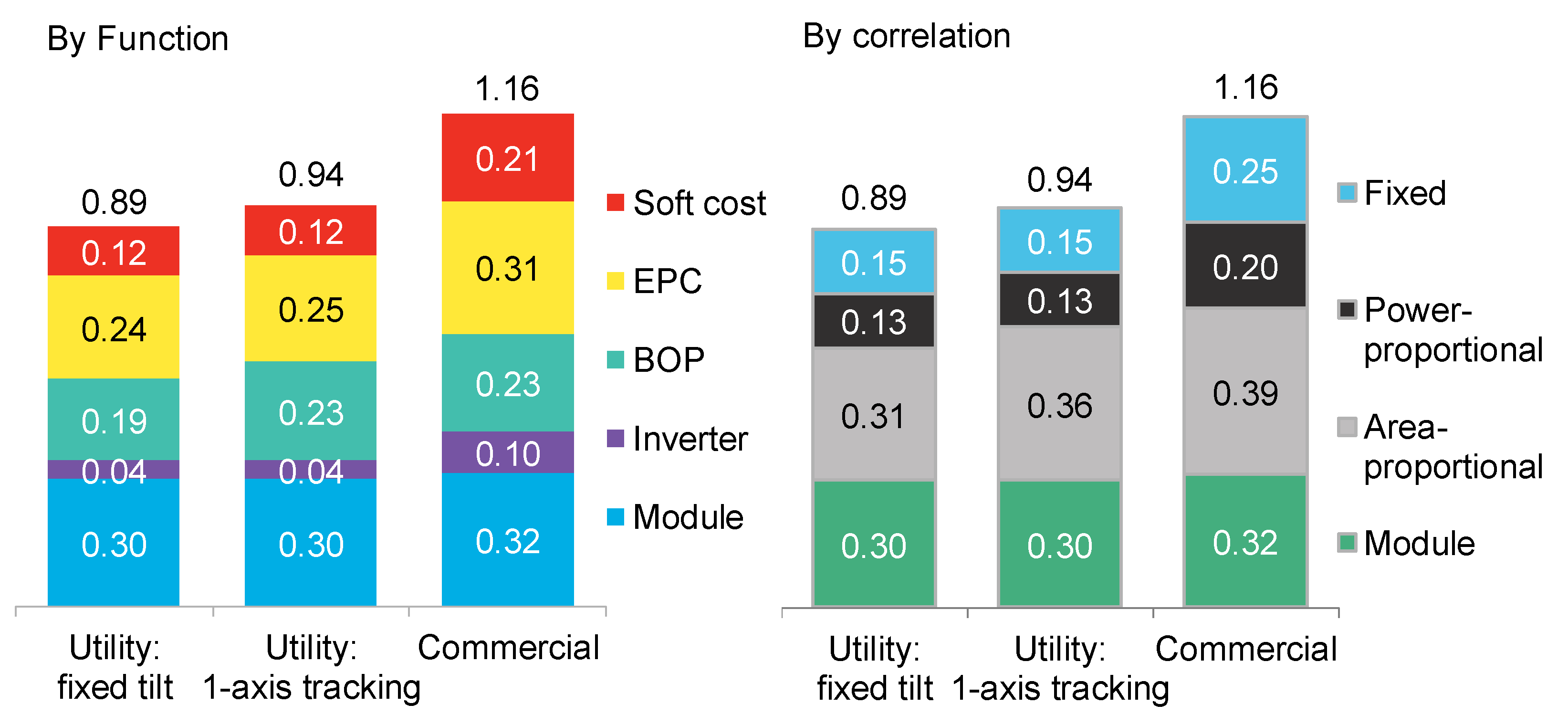

The quantitative conclusion in the previous section is only valid for the cost structure shown in

Figure 4. The value of module efficiency depends on the percentage of area-proportional non-module costs, and that of the fixed costs insensitive to project area or capacity. With the benchmark system costs in 2018 categorized by function, defined by BloombergNEF [

7], we re-group them based on the correlation to area and power. Note that each project has a different cost dependence, and the values shown in

Figure 6 are estimated for illustrative analysis purposes. (Prior to this paper, the same authors published one piece eight years ago, also to explore the value of module efficiency, with the benchmark system cost structure derived based on the market at that time [

8].)

Different electricity generation technologies have diverse patterns for both expenditure and yield over time. A well-recognized metric to quantify the economics of a certain technology is levelized cost of electricity (LCOE), which is “the cost that, if assigned to every unit of energy produced (or saved) by the system over the analysis period, will equal the total life-cycle cost (TLCC) when discounted back to the base year” [

9]. LCOE can be calculated using the following formula:

where

Cn is the cost for year

n,

Qn is the energy output for the year

n,

d is the discount rate, and

N is the analysis period. The parameters for all equations in this paper are summarized in

Appendix A.

In this paper, we analyze the impact of module efficiency on system LCOE for three system configurations, as shown in

Figure 6: utility with fixed tilt for modules, utility with one-axis tracking, and commercial projects with fixed tilt for modules. Assuming modules of different efficiencies will have the same per-watt yield, and operation cost is a fixed percentage of the system capital expenditure (capex), a PV project’s LCOE is proportional to the system unit capex. Applying the capex structure shown in

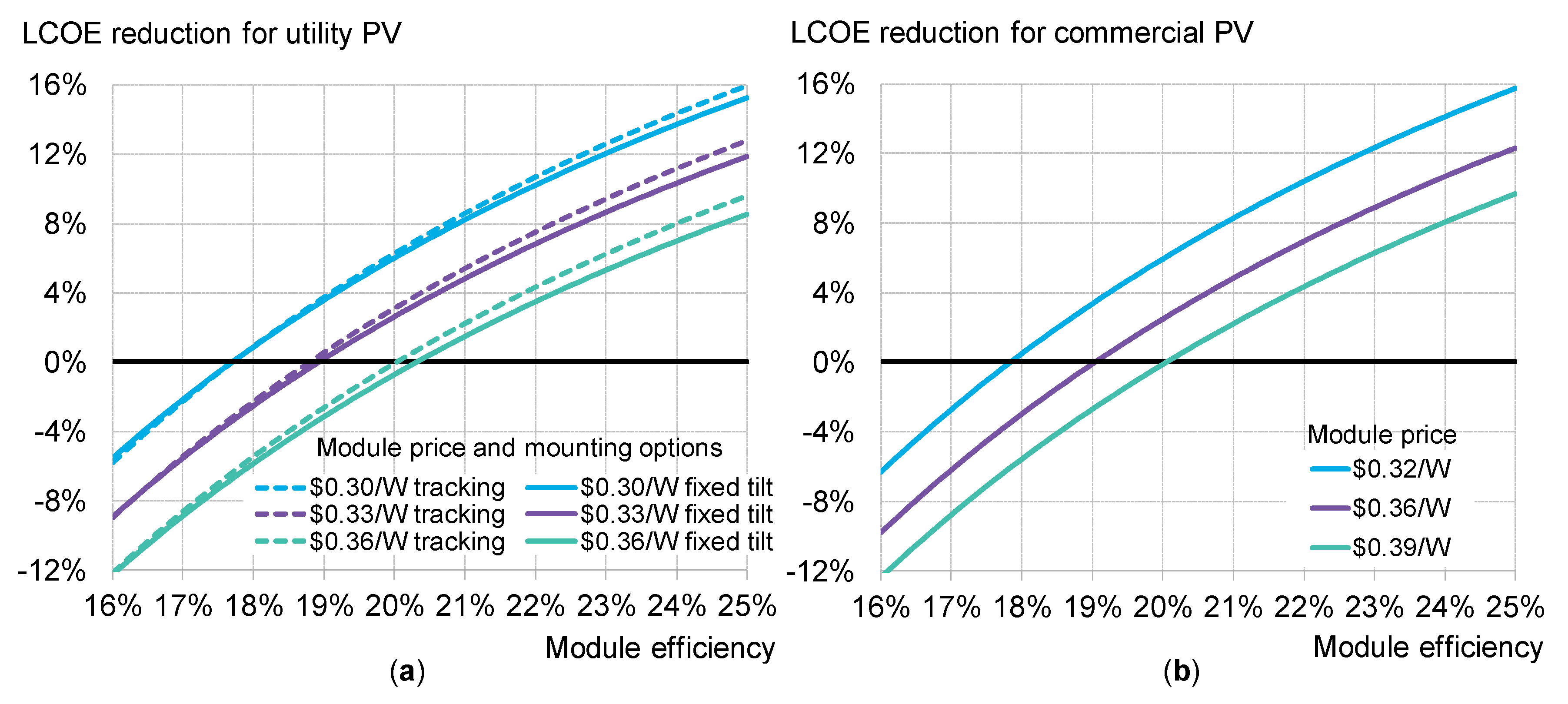

Figure 6, we derive the impact of module efficiency and price on PV LCOE for different applications, in the ‘fixed-area’ scenario. In

Figure 7, negative values on the

y-axis suggest that LCOE in a certain scenario is higher than that in the reference case. For utility PV, when trackers are introduced, the proportion of area-proportional costs is a higher percentage of the total system capex, so module efficiency can impose stronger leverage in reducing system LCOE. This is reflected in the higher position of the dashed lines than the solid lines in the left-hand chart of

Figure 7.

In commercial PV, due to restricted economies of scale, area-proportional and fixed non-module costs are higher than in utility PV. Module efficiency therefore holds more value in commercial PV. For instance, in a tracking utility PV, 20% efficient modules can ask for a price of

$0.36/W (the intersection between the dashed green line and the black line in

Figure 7a). In contrast, the same modules can push the quote up to

$0.39/W in commercial PV (the intersection between the green line and the black line in

Figure 7b).

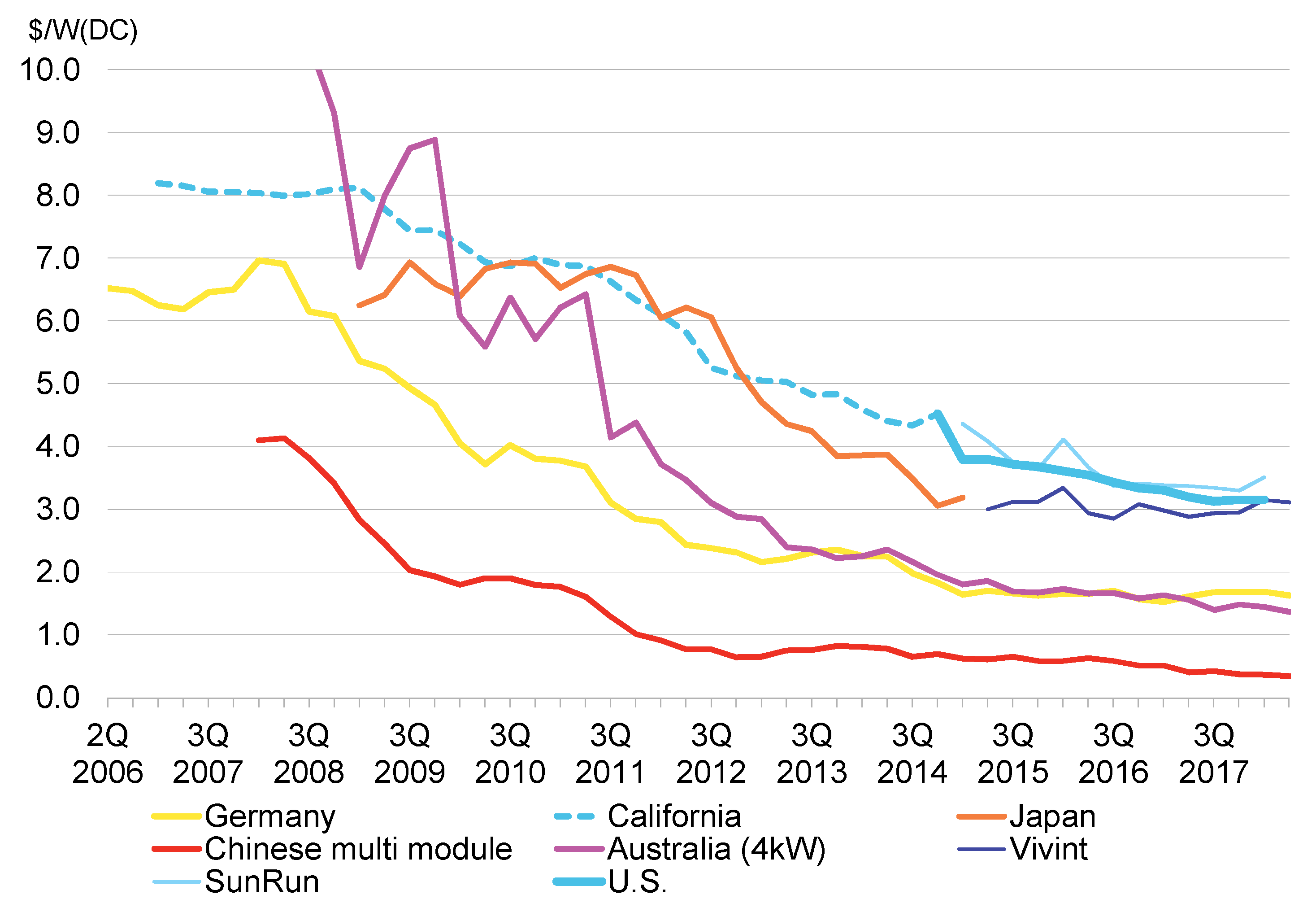

In general, the proportion of area-related and fixed costs in residential PV is greater than that in commercial PV, due to higher prices of equipment, labor, and process under the retail business model. However, the value heavily depends on the local market, as indicated by the wide range of residential system costs in

Figure 8 [

7]. The USA and Japan are the two most expensive residential PV markets, and the most popular markets for

n-type modules. In the fourth quarter of 2018,

p-type modules are quoted in the range of

$0.35–0.40/W to U.S. utility developers, including transportation and tariffs, while

n-type module suppliers sell for

$0.65–0.75/W to U.S. distributors, who add about additional 10% margins in the final sales to residential PV owners [

10].

Note that the cost structure presented in

Figure 6 is considered representative of mature markets and no penalty tariffs on imported PV equipment are considered. The U.S. National Renewable Energy Laboratory (NREL) has updated the benchmark cost structure in 2018 for the domestic market, including antidumping tariffs and other impacts from various trade barriers [

11].

In this paper, we address the impact of module efficiency on mainstream PV applications, which adopt crystalline silicon (c-Si) modules and either fixed-tilt or one-axis (more specifically, one-axis horizontal) tracking configurations. Additional discussion of other types of modules and tracking options is given in the last section of this paper. Other researchers have provided overviews of the value of various modules [

12,

13].

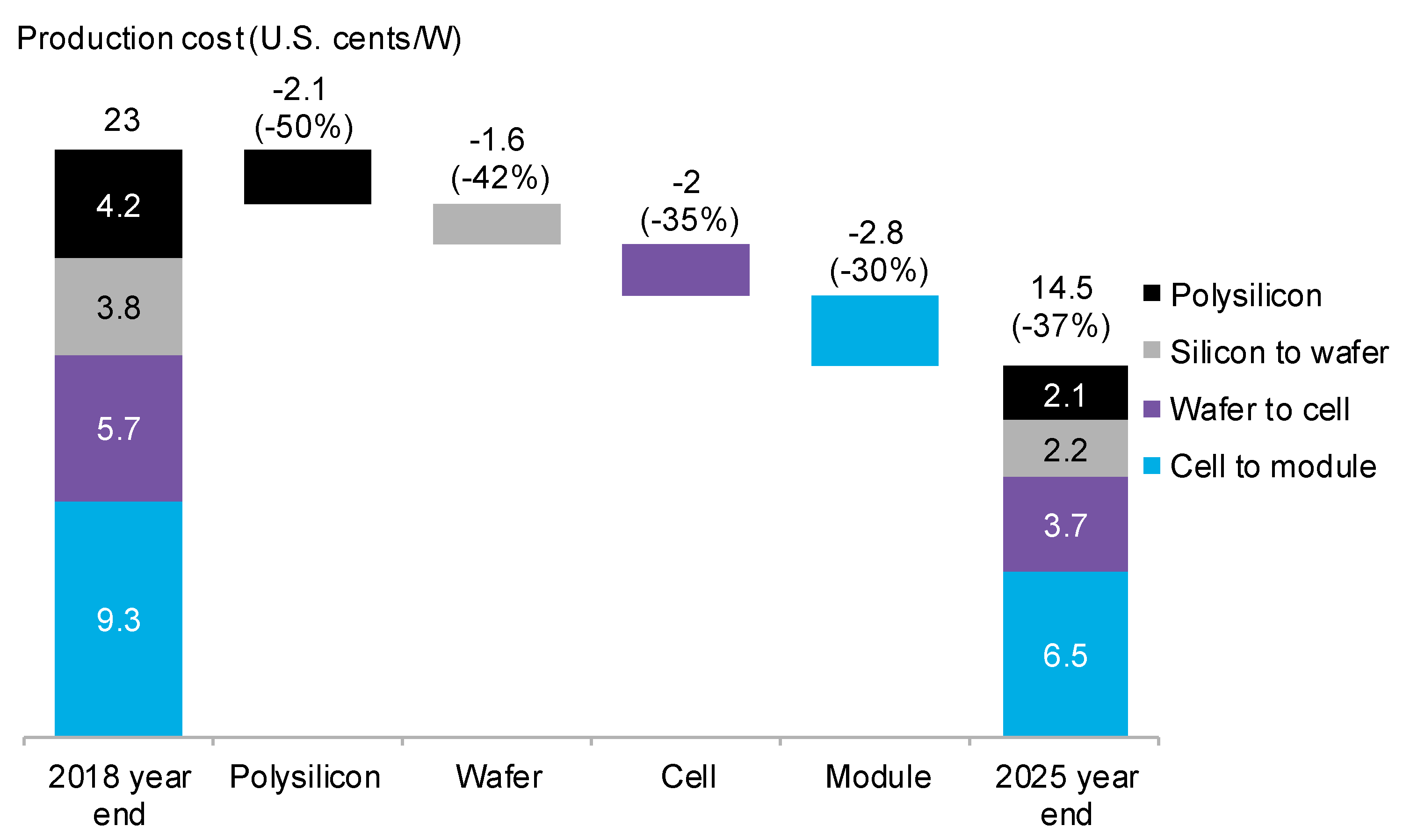

4. The Evolving Value of Module Efficiency

Module price will drop much faster than other system components in the coming years, due to sustainable technology innovation, continuous oversupply, and the choice of polysilicon makers to move to regions with low electricity rates [

14]. Based on the forecast made by BloombergNEF, the best-case integrated module production cost will fall from

$0.23/W at the end of 2018 to

$0.145/W by 2025 [

1], as shown in

Figure 9.

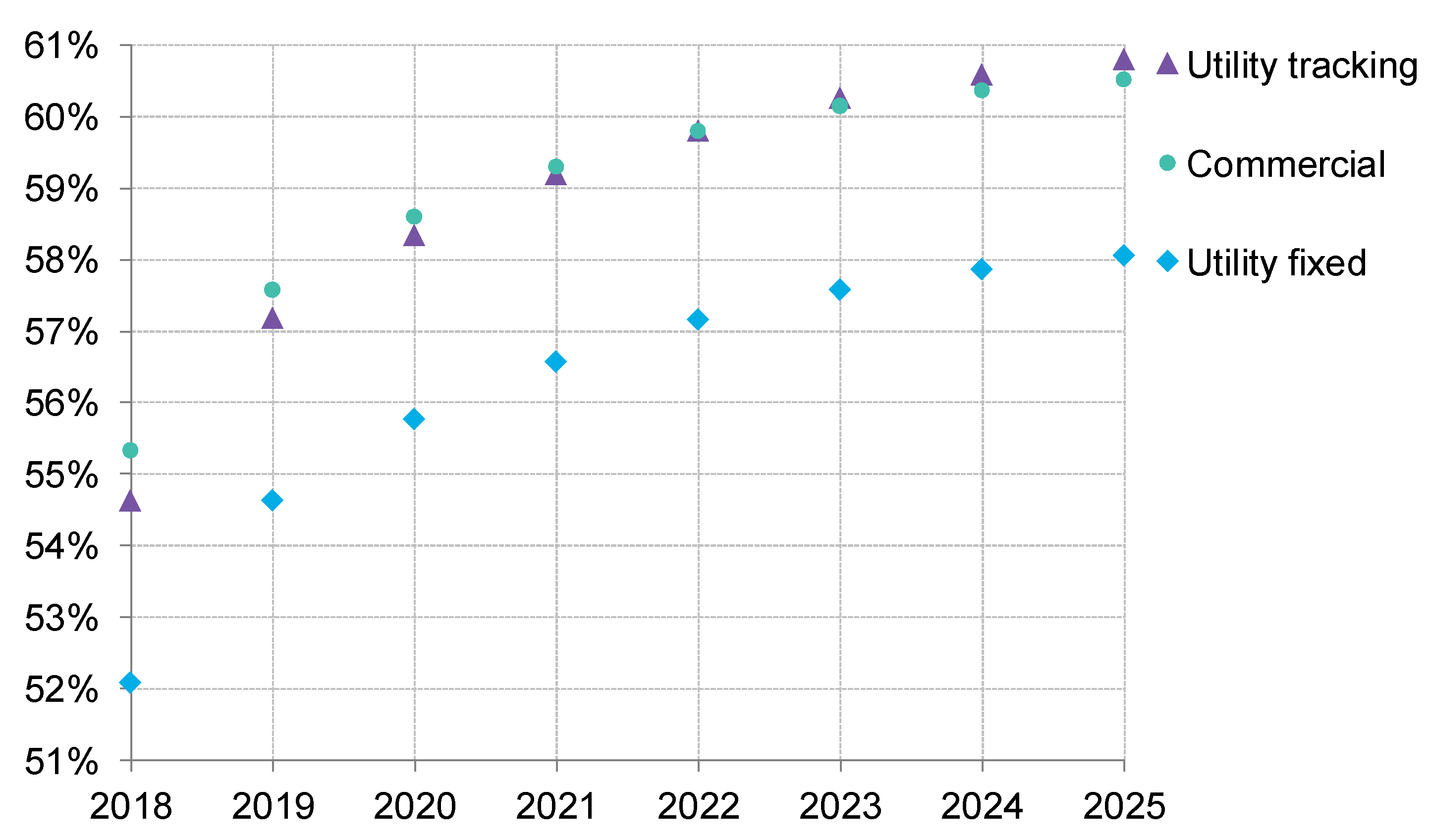

While the module price fall will continue following a learning rate of 28.5%, we expect the industry average module efficiency to rise by 2.5% relatively, on an annual average basis. For utility PV projects with fixed tilt, BloombergNEF expects that the per DC watt system capex will drop by 33% by 2025, compared with 2018 [

7]. The rate is 32% for commercial PV. We estimated the correlation between different cost components and area or power, and regrouped the spending, based on which the percentages of area-proportional costs and fixed costs are derived, as shown in

Figure 10.

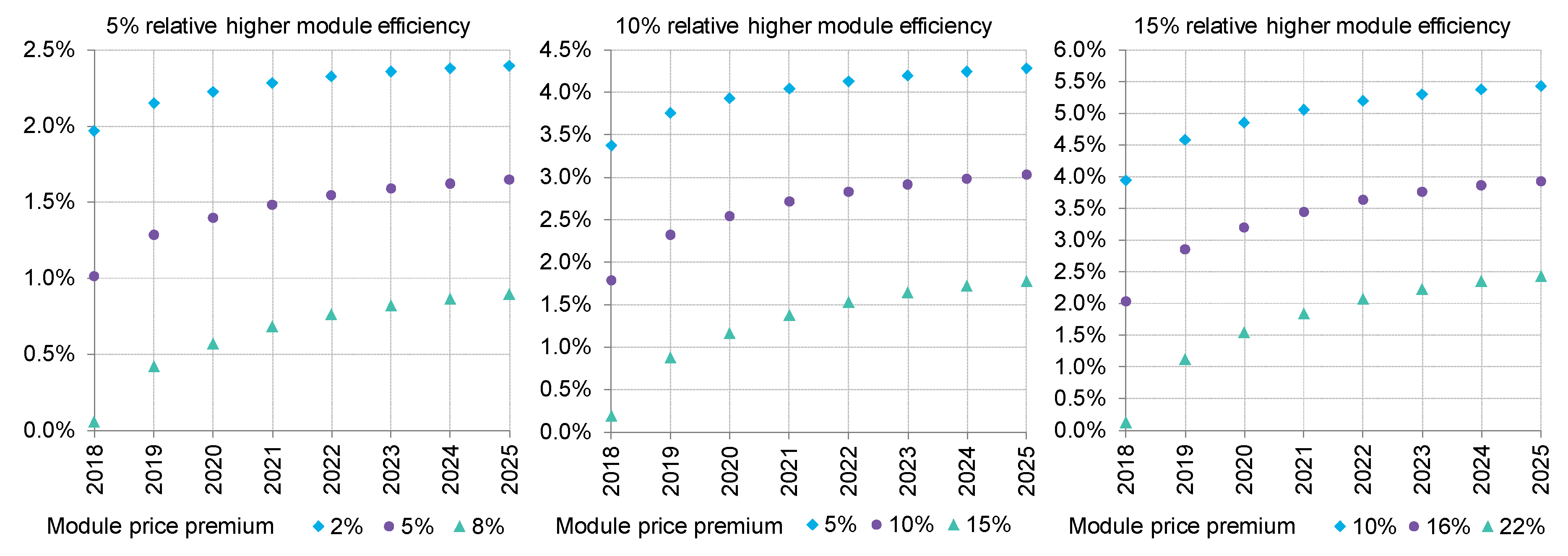

Module price reduction occurs faster than all other components in a PV system, resulting in a rising share of area-proportional and fixed non-module costs in the total system spending. As tracking is becoming a standard option for utility PV in sunny places [

15], and the percentage of area-proportional and fixed non-module costs is similar for tracking utility and commercial PV, here we use the tracking utility to illustrate the evolving value of module efficiency, as shown in

Figure 11. As time goes on, the value of module efficiency becomes greater, increasing the incentive to adopt high-efficiency technologies.

5. Bifacial Modules: Not a Simple Story about Higher Efficiency

By revising solar cells’ rear side electrical contact structure and replacing the opaque backsheet with glass, a PV module can convert light striking from the backside to electricity. This type of new products are referred as bifacial modules. A term ‘bifaciality’ describes how good the rear side efficiency is, compared with the front side, and is expressed as the ratio between the two:

The output from a bifacial module is expressed as the yield from both sides:

The bifacial yield gain compared with monofacial is the product of bifaciality and the ratio between input power from the rear side and that from the front side:

The second term in the above equation is referred to as the bifacial ratio, which is affected by many factors, including the reflectivity of the ground (or albedo), the angular distribution of light, orientation of the module, the height of the module, shading of the surrounding objects, etc. While some demonstration projects prove the bifacial gain can be higher than 20% [

18,

19], those achievements occurred with highly reflective ground and the projects are of small sales, so the gains are not considered representative. There is no standard bifacial ratio when measuring bifacial modules, although the National Renewable Energy Laboratory and Sandia National Laboratories suggested 130–140 W/m

2 as the representative irradiation for the rear side while maintaining 1000 W/m

2 for the front side [

20]. Applying a 13.5% bifacial ratio and 75% bifaciality, a 10% bifacial gain is derived. However, in the real market, developers are only accepting a 5% bifacial gain assumption in price negotiation, considering there are still uncertainties about the new technologies without enough field operation data.

Although the bifacial gain is caused by more input power, rather than higher conversion efficiency, the effect is the same. According to the left-hand chart in

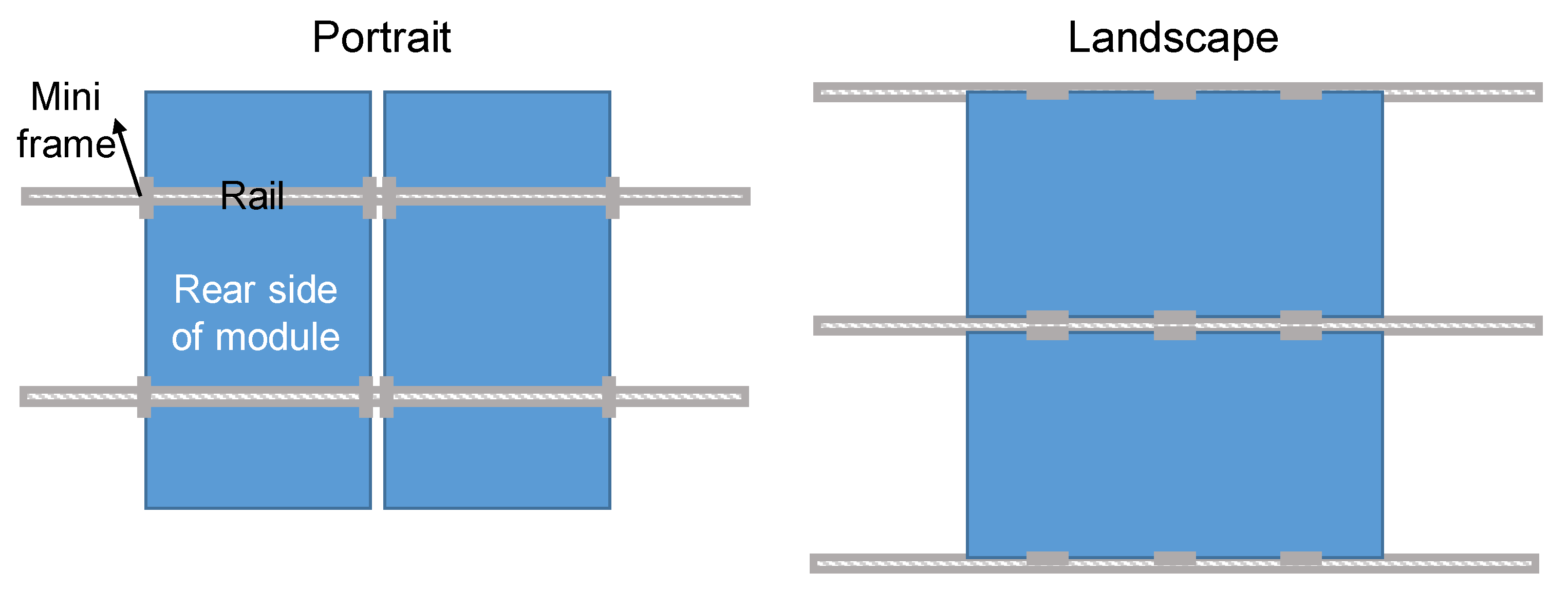

Figure 11, bifacial modules that can be considered 5% relatively more efficient can ask for a price premium of up to 8% in utility PV projects in 2018. However, extra costs will be introduced at the system level in order to avoid shading to the rear side.

Figure 12 shows the necessary changes for racking in a fixed-tilt scenario.

Figure 13 shows two trackers designed for bifacial modules. In both cases, the rails are positioned in the space between neighboring modules to avoid shading to the backside. In order to achieve the same mechanical stability, the metal consumption increases, resulting in an additional cost for trackers or fixed racking systems. Therefore, bifacial modules only receive a 3–4% price premium, with the power rating defined by the front-side yield. Even that value is sufficient to cover the extra cost. Therefore, we expect bifacial modules will see a rising market share, starting from 3GW global shipment, or a 3% share of total module shipment in 2018. BloombergNEF expects the global share to rise to 10% in 2020 and 40% in 2025 [

21].

6. Discussion

The above analysis addresses the value of module efficiency for the dominant equipment type (modules composed of cells made of p-type crystalline silicon wafers) and major system configurations (fixed-tilt and one-axis tracking). We expand the discussion to other scenarios for niche market applications.

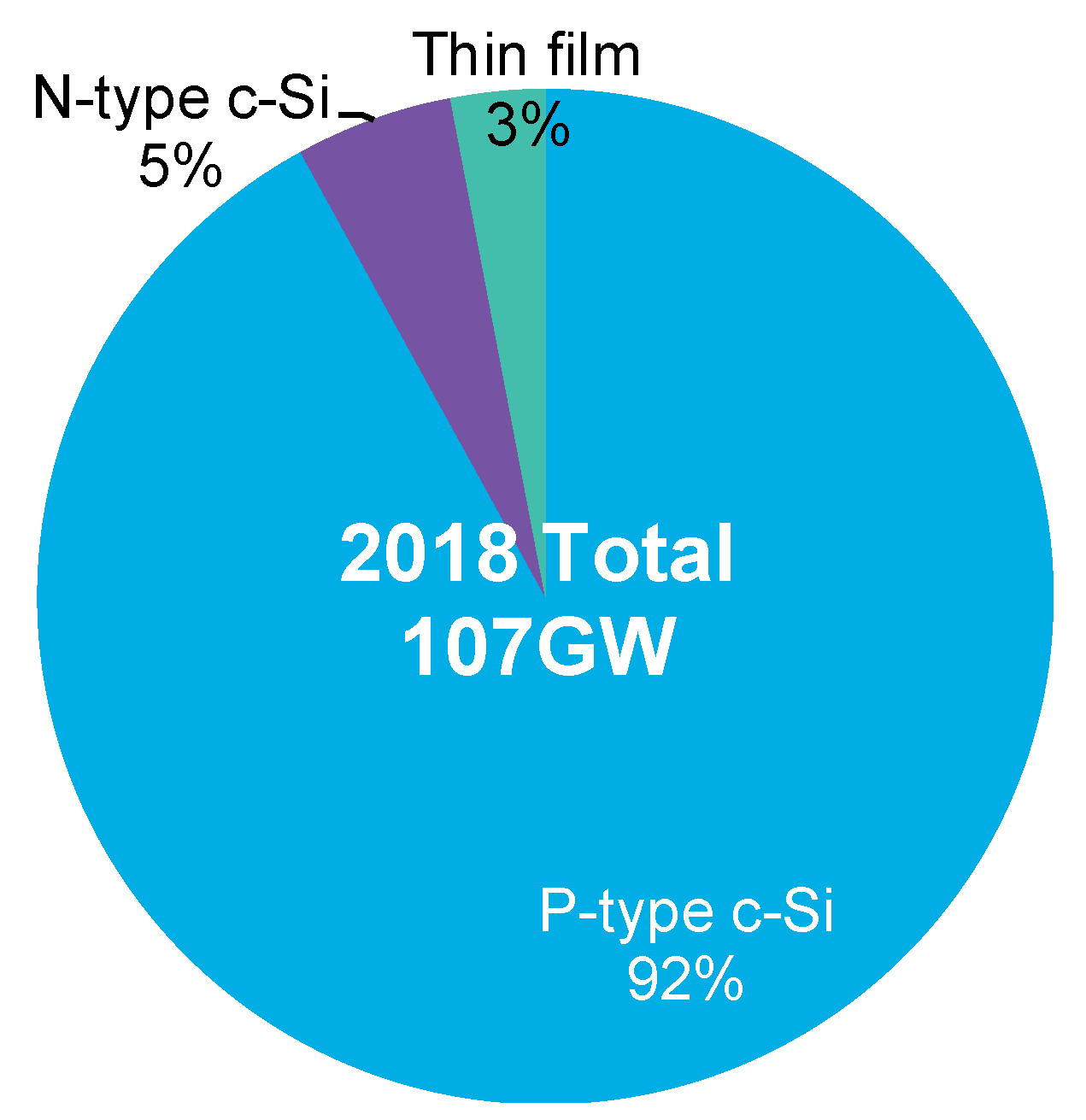

6.1. N-Type Crystalline Silicon Modules and Thin-Film Modules

2018 was the first year when the annual new PV build exceeded 100GW. Among all modules installed in 2018, 97% were of crystalline silicon types and only 3% were categorized as thin film modules, mainly supplied by First Solar (Tempe, AZ, USA) adopting cadmium telluride (CdTe) technologies and Solar Frontier (Tokyo, Japan) making copper indium selenium (CIS) products. While these thin-film modules have achieved efficiencies comparable to multicrystalline silicon products, their costs did not drop as rapidly as the c-Si peers. Considering the established advantages and sustainable approaches to even lower cost and higher efficiency for c-Si PV modules, it is unlikely for thin film to grow to a dominant share in the next 10 years.

Looking into the general category of crystalline silicon PV modules, it can be further separated into more sub-groups depending on the definition. The most popular sub-grouping is multi- vs. monocrystalline silicon PV, based on the crystalline structure quality of wafers. Alternatively, based on the doping materials in wafers, c-Si can be divided into negatively doped (with boron) and positively doped (with phosphorous), or simplified referred in industry as

n-type and

p-type c-Si PV.

N-type cells allow higher efficiencies, as the excited electrons in

n-type wafers can travel a longer distance before they return to the useless bonded status. However, they are more expensive to make. From the perspective of optimal economics at the system level, the industry showed more preference towards

p-type c-Si PV (

Figure 14).

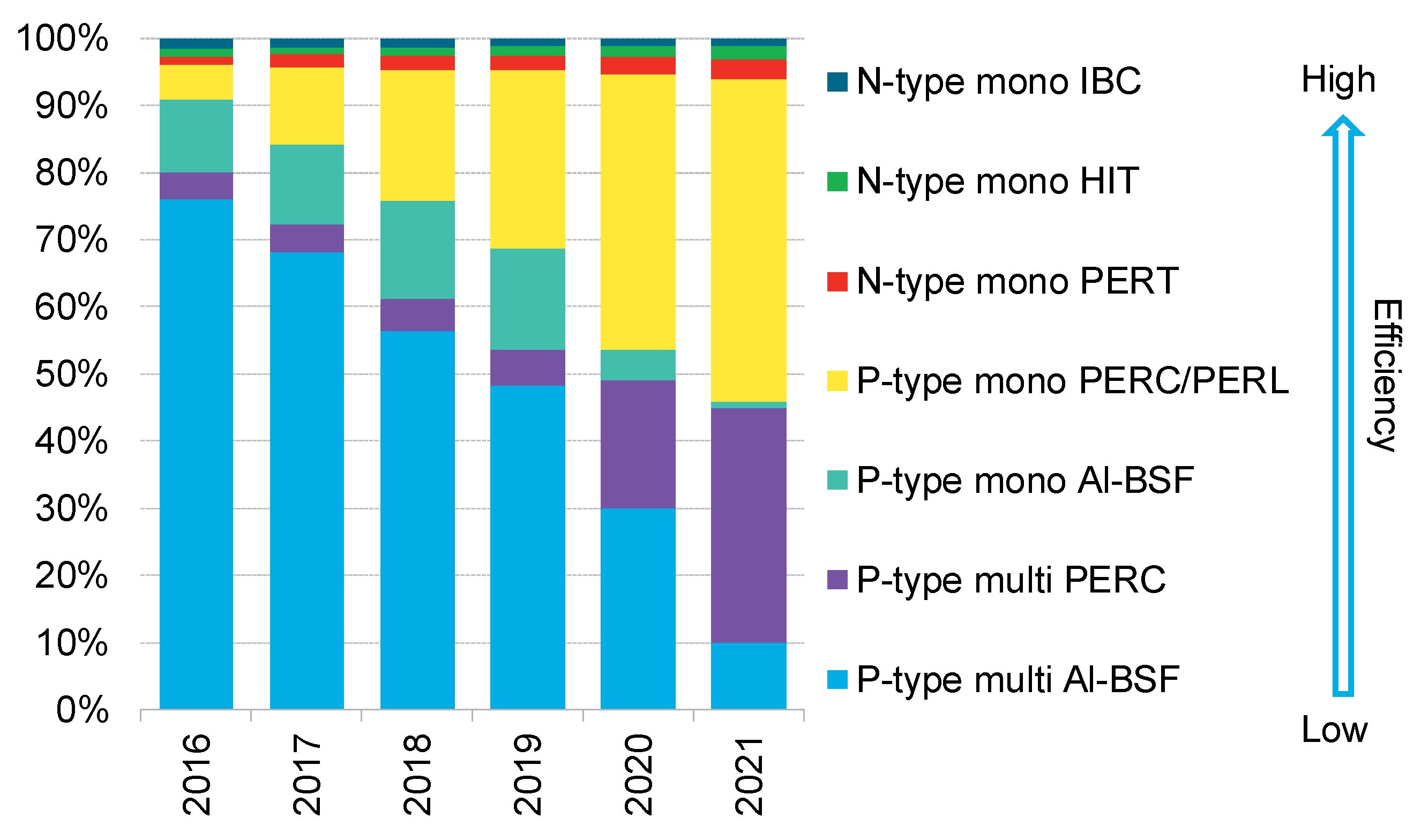

When cell structure is involved in categorizing PV modules, there are more options (

Figure 15). Note that not every combination of different metrics has commercial applications because some combinations have poor economic value. For instance, there are no

p-type IBC or HIT in the market, although theoretically such products can be made. Their absence from the market is because realizing these special cell structures necessitates higher production costs, but the

p-type wafers cannot allow the advanced cell structures to fully display their capabilities of boosting efficiency and therefore do not justify the commercial production of such cells or modules. BloombergNEF observed a rising market share of PV modules with higher efficiencies, and expects the same trend to continue. However,

p-type crystalline silicon PV modules are still likely to dominate in the near future, although monocrystalline silicon will win over its multi-peers soon.

When comparing the economics of different types of modules, more metrics should be brought into consideration besides module efficiency. Two important ones are temperature coefficient and degradation rate. While the module efficiency is measured under standard testing conditions, the actual operation environment varies constantly, and modules with the same area and efficiency (and thus the same nameplate capacity) but different materials or cell structures could generate different yields. One reason is that their operating efficiency could respond to the temperature change with various sensitivities, which is measured with a temperature coefficient with a unit of %/°C. For instance, cells made on p-type wafers (multi and mono) have TC around −0.43%/°C. N-type cells’ TC is around −0.30%/°C. Assuming the average cell temperature in the field is 20 °C higher than the standard testing condition, n-type IBC PV modules have 2.6% more yield than p-type mono PERC products for the same nameplate power rating, and this gap cannot be captured by efficiency.

Another important metric that affects actual yield is degradation rate, which measures how fast module efficiency declines over time. For example, Jinko Solar’s mono PERC modules have a warranty for 3% degradation in the first year and 0.7% linear annual degradation in the following 24 years, suggesting the warranted module efficiency at the end of the 25th year will be 80.2% that of the original nameplate efficiency. First Solar’s CdTe thin film module power warranty includes a starting point of 2% degradation for the first year and a 0.5% annual drop afterwards until the 25th year, indicating that the warranted module efficiency at the end of the 25th year will be 86% of the original nameplate efficiency. In a simplified assumption, where the annual illumination is the same over the 25-year period, First Solar’s modules could generate 4% more electricity than Jinko Solar’s modules of the same nameplate capacity.

Note that the purpose of deploying the discussion above is to illustrate the limitation of relying solely on module efficiency when evaluating actual performance and LCOE, rather than to set up a complete model to compare different types of modules.

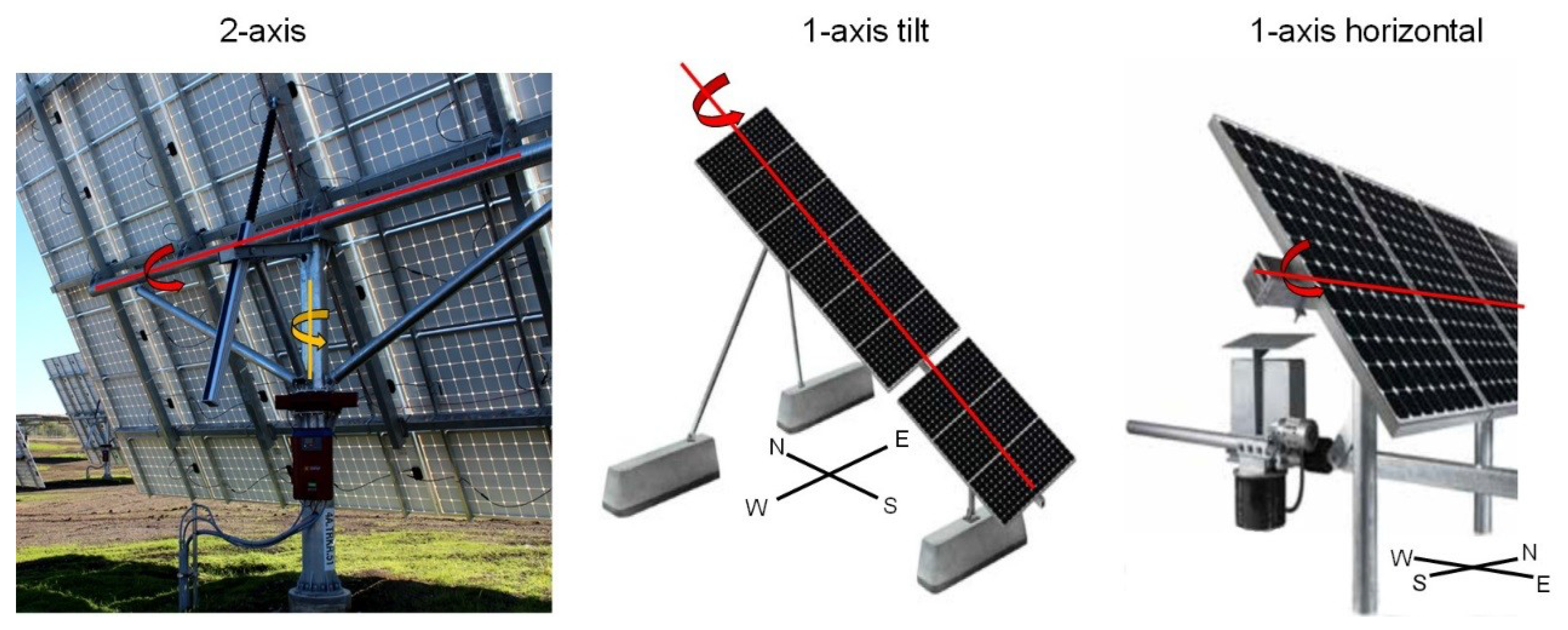

6.2. Different Tracking Options

As shown in

Figure 16, there are three types of trackers available for PV modules. When mounted on a two-axis tracker, a PV module can receive direct light perpendicularly. Alternatively, a one-axis tracker can track the more dominant sun movement along the east–west direction, while sacrificing the accuracy on the north–south dimension and saving on equipment. Depending on the relative angle between the rotation pivot and the ground, one-axis trackers have two options: horizontal and tilt (

Figure 16).

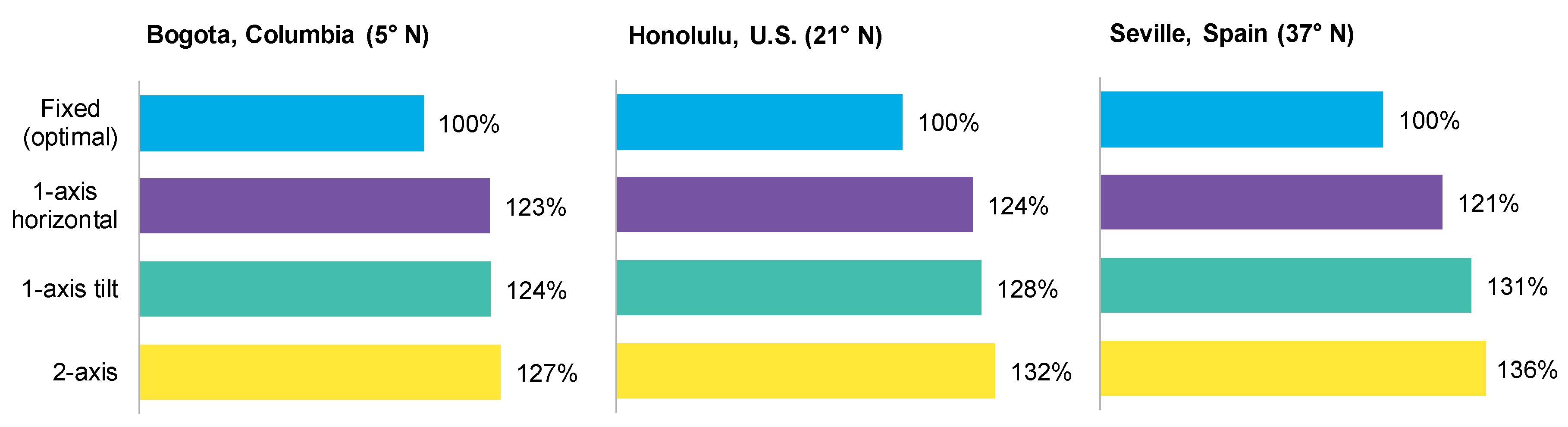

Although all three trackers have been commercialized at some point, one-axis horizontal is the only type that is still being applied in utility-scale PV projects. While the input power gain compared with the fixed tilt by different trackers varies depending on the latitude (

Figure 17), the general conclusion holds that the additional yield when choosing one-axis tilt tracker and two-axis trackers over one-axis horizontal trackers cannot justify the much greater capital costs and long-term maintenance fees [

15].

Therefore, we consider it less valuable to conduct a detailed analysis of the impact of module efficiency on system LCOE in configurations adopting one-axis tilt trackers or two-axis trackers. However, it is understandable that in those systems, area-related non-module costs account for a higher percentage of the total system spending, and a certain module efficiency rise can impose a stronger leverage in lowering system cost and therefore LCOE. In fact, most of the two-axis tracker shipments in history were for systems adopting concentrator PV (CPV) modules composed of multi-junction solar cells with module efficiencies up to 30%, although the module efficiency testing condition for CPV modules is different from that for flat-plate PV modules [

22].