1. Introduction

In recent decades, novel materials were the subject of widespread research in order to reduce greenhouse emissions in civil engineering activities. Since its invention, geopolymer concrete (GPC) received considerable attention from researchers as an alternative for concrete using ordinary Portland cement (OPC) [

1]. Geopolymer binder is made from two main compounds: (i) rich alumino-silicate materials such as meta-kaolin, fly ash, silica fume, slag, or red mud, and (ii) an activator of alkaline solutions such as sodium or potassium hydroxide and sodium or potassium silicate. Manufacturing OPC generally uses raw materials and releases carbon dioxide, whereas geopolymer binder uses waste by-product materials. Therefore, such green materials are an excellent alternative for sustainable development. Many researchers pointed out the advantages of GPC, including chemical resistance or resistance to acid attack [

2], alkali–silica reactions [

3,

4], corrosion of steel reinforcement [

3,

5,

6], resistance to high temperatures and to fire [

7,

8], resistance to freeze–thawing [

9,

10], and efflorescence [

11,

12]. However, such works were applied to a limited alumino-silicate compound in GPC, for instance, fly ash, blast-furnace slags, or meta-kaolin. Many other admixtures could also be investigated and used, such as steel slag [

13].

Undeniably, slag from steel and iron plants is abundantly available as a waste product. This can be used as a cement additive, as well as in concrete admixtures [

13]. Indeed, the utilization of steel slag for production of cement or GPC is available in the literature. As an example, ground granulated blast-furnace slag (GGBFS) was blended with fly ash to fabricate GPC [

14]. Local steel slag was also used to replace natural crushed stone, as a substitute to coarse aggregate in GPC [

15]. The compressive strength of such GPC ranged from 40 to 54 MPa which is about 6% higher than that of natural crushed stone. In order to obtain the desired mechanical properties, researchers have to find an appropriate selection of ingredients and mixture design. Such a process requires an important number of laboratory experiments which consume substantial effort, time, and man power, thereby increasing the cost of production. Lloyd and Rangan [

16,

17,

18,

19] proposed a method in order to determine an optimum mix design of fly-ash-based GPC by identifying the effects of salient factors that affect the properties of GPC in the fresh and hardened states. Furthermore, Ferdous et al. [

20] proposed a flow chart methodology based on nine steps to determine mix proportions to obtain GPC with a targeted 45 MPa compressive strength at 28 days. These studies only considered a limited number of ingredients or mix proportions. Therefore, it is still required to find a more efficient, robust method to establish a direct relationship between these factors and the corresponding mechanical properties.

In recent years, artificial intelligence (AI)-based algorithms were widely used to solve very complex problems in engineering [

21,

22,

23]. Such algorithms were extended and applied to many civil engineering applications including building materials, concrete, or mortar [

24,

25]. Many works on the prediction of concrete properties were reported, including drying shrinkage [

26,

27], concrete durability [

28] or delivery [

29], concrete workability using meta-kaolin along with fly ash [

30], slump models [

31,

32], concrete at high temperatures [

33], concrete-based structures [

34,

35], concrete permeability [

36], and long-term effects of compounds on the mechanical behavior of GPC [

37]. Most of these works focused on the use of artificial neural network algorithms (ANN) or fuzzy logic (FL) to predict the mechanical properties of typical type of concrete, such as high-performance concrete (HPC) or self-consolidating concrete (SCC). Although these studies confirmed that the AI techniques are promising to predict the properties of concrete materials, there is still a need for the development of more efficient AI techniques that could handle more complex problems, such as the determination of properties of GPC with better predictive capability.

Compressive strength is an important parameter which is used to evaluate the quality of GPC. Therefore, the main objective of this study was to predict the compressive strength of fabricated GPC using novel hybrid AI approaches, namely a particle swarm optimization (PSO)-based adaptive network-based fuzzy inference system (PSOANFIS) and a genetic algorithm (GA)-based adaptive network based fuzzy inference system (GAANFIS), which were already applied effectively in solving other real-world problems, such as energy consumption prediction [

38] and landslide spatial prediction [

39], but are yet to be applied to predict the properties of GPC. PSOANFIS is a combination of an adaptive network-based fuzzy inference system (ANFIS) and particle swarm optimization (PSO), whereas the GAANFIS is a combination of ANFIS and the genetic algorithm (GA). A total number of 210 samples were fabricated using 100% waste slag aggregates, before they were tested to determine the input and output parameters for AI modeling. Finally, validation of the proposed models was done using root-mean-square error (RMSE), mean absolute error (MAE), and correlation coefficient (

R) methods.

2. Machine Learning Methods

2.1. Adaptive Neuro Fuzzy Inference System

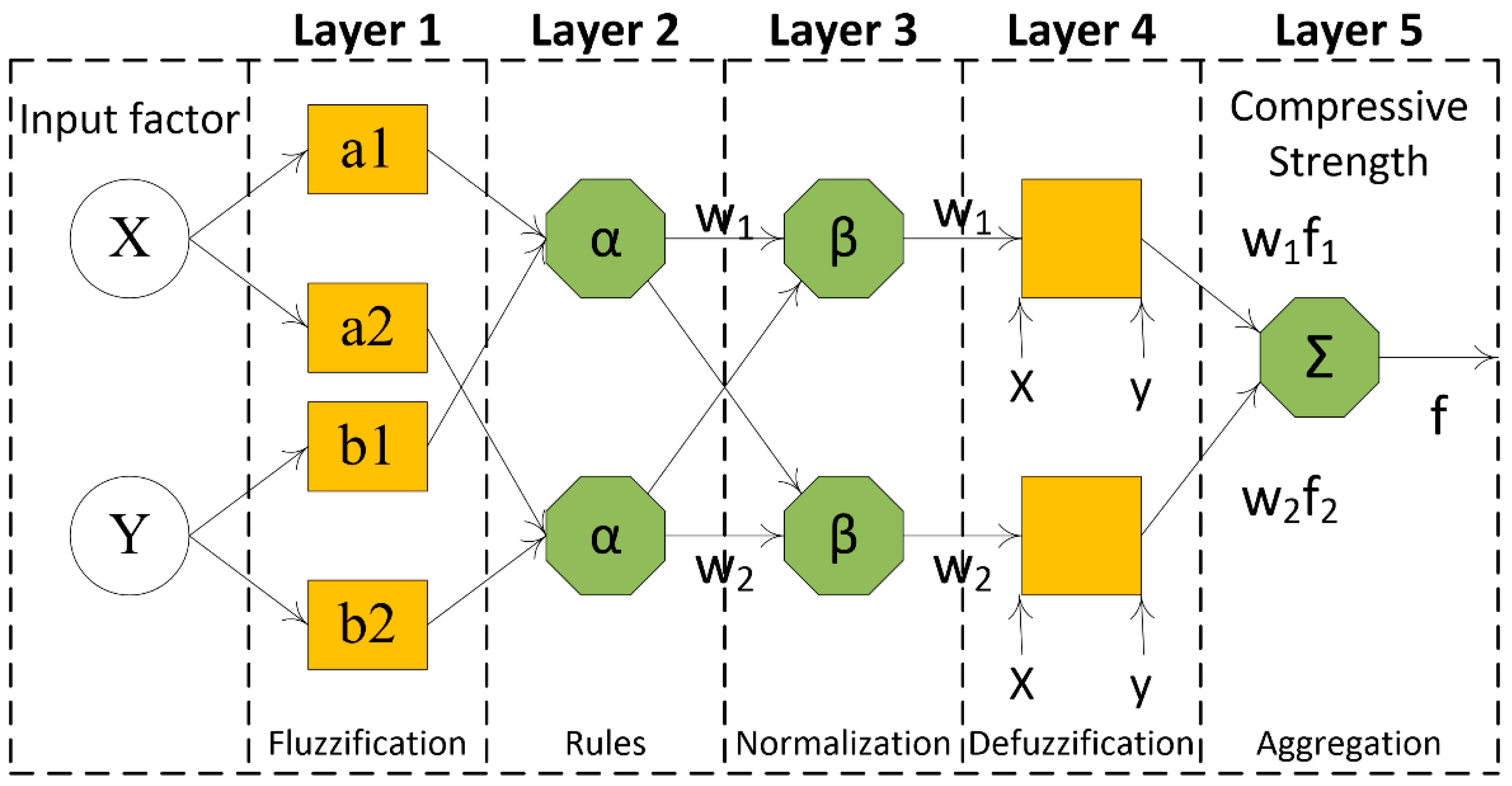

The adaptive neuro fuzzy inference system (ANFIS) is a typical model of a general fuzzy modeling structure described by two distinctive features including interpretation and accuracy. The ANFIS interpreting capability refers to the ability of the fuzzy model to represent the habits of its systems. The accuracy of ANFIS refers to the ability of the fuzzy model to honestly represent the modeling system [

40]. The ANFIS establishes a set of fuzzy if–then rules with suitable membership functions to create the stipulated input–output sets. The ANFIS utilizes neural systems and fuzzy deduction systems. The task of fuzzy if–then rules is to simulate expert knowledge, whereas the task of the neural network is to optimize the membership capacities to reduce the mistake rate in the output. An ANFIS comprises five layers, and each layer is composed of some nodes and node functions [

41]. There are two sorts of nodes: adaptive nodes and fixed nodes. Adaptive nodes are stamped by squares that serve as parameter sets, which can be altered. Fixed nodes are stamped by circles, and their parameter sets are settled in the system (

Figure 1) [

41].

2.2. Particle Swarm Optimization

Particle swarm optimization (PSO) introduced by Kennedy et al. [

42] is one of the most commonly used evolutionary algorithms in optimizing the parameters of a classification model [

43]. The principle of the PSO algorithm is based on the social and biological behavior of animals when seeking food. In a PSO, each particle represents a potential answer to the problem. Each particle randomly moves along the search space where it can get disrupted as a result of its own knowledge and that of its neighbors [

39,

44]. Therefore, particle searches can be influenced by other particles in the swarm. This means that the particles learn and acquire knowledge from each other in a group and forward the same to their best neighbors [

39,

44]. Thus, in the PSO, each individual can adjust its position at the best location within the search space in comparison to its adjacent neighbors. The combined model of the regression model and the PSO optimization technique is considered very promising in classification and forecasting problems [

39,

44].

2.3. Genetic Algorithm

The genetic algorithm (GA) is an algorithm similar to natural evolution, whereby a population of specific species adapt to environmental conditions [

45]. In this process, a population is designed and created to grow in a controlled environment. The algorithmic nature of the structure is such that each individual is considered to be a solution to the problem. In the population, an individual is called a chromosome, which consists of different problem variables that act as genes in the algorithm. The search process includes developing a random chromosome population. The next generation of the population is created through the three following operators [

46,

47]:

Selection operator: The best chromosomes of the society are determined by calculating the fitness function of each chromosome, and they are then used as parents to produce offspring. Subsequently, new baby chromosomes then create the next-generation chromosomes.

Cross operators: New baby chromosomes born from two parent chromosomes have a better function than their parents. This is due to cross operator method which determines the structure and rate of the chromosome of a child in comparison to the parent chromosome.

Mutation operator: This operator searches new areas in available space. The local optimization result may not be accepted as the best solution. To realize this target, it is necessary to randomly change some genes inside the chromosome.

New child chromosomes created through these three operators form next-generation parents [

45]. The process is continued until the termination condition applied by the researcher is achieved [

45]. The GA, which is used to solve optimization problems, has the most important advantage due to its ability to use the information accumulated in the initial unspecified search space to move subsequent searches into useful spaces [

46,

47].

2.4. Quality Assessment

In this study, various methods, i.e., mean absolute error (MAE), root-mean-square error (RMSE), and correlation coefficient (

R), were selected for validation of the proposed models. MAE is a metric which is used for assessment and summary of the quality of a soft computing model. It measures the difference between the predicted and actual values. RMSE refers to the square root of the average of squared differences between the actual and predicted values [

48].

R is a statistic measurement which is used to measure the degree of relationship between the predicted and actual values [

49]. In prediction problems, MAE, RMSE, and

R are popular statistical validation methods for machine learning models [

50]. Lower RMSE and MAE values indicate better performance of the models [

48]. In contrast, higher

R values indicate better performance of the models [

49]. Formulas of these indexes are listed below.

where

n is the number of the samples,

and

are predicted and mean predicted values, and

and

are measures and mean values of the compressive strength, respectively.

3. Preparation of Samples and Data Used

3.1. Materials and Mix Proportion

Geopolymer concrete (GPC) was designed for a specified compressive strength grade (f’c = 25, 30, 35 MPa) based on the ACI 211-91 standard. For the preparation of GPC, fly ash, steel slag, sodium silicate, and sodium hydroxide were used. Fly ash (ASTM C618-03 Class F) was obtained from Pha Lai Thermal Power Plant (Hai Duong - Viet Nam). The typical chemical composition and the fineness of fly ash are shown in

Table 1 and

Table 2, respectively. Anhydrous NaOH (purity, P = 98.5%; density, D = 2.1 g/cm

3) and Na

2SiO

3 water glass solution (relative density, RD = 1.42; 39–40.03 wt.% Na

2SiO

3) were purchased from Viet Tri Chemical Factory. The activated alkaline solution was prepared by (i) dissolving NaOH powder in water to obtain NaOH solutions with different molar mass (M), and (ii) mixing with Na

2SiO

3 solution in different concentrations. The dissolution and the mixing process are exothermic reactions (temperature ≈ 70 °C). In order to correctly activate fly ash, the solutions were prepared at least one day before mixing into GPC.

Steel slag, served as both fine and coarse aggregates, was achieved from Thai Nguyen Iron and Steel Industrial Park (Thai Nguyen - Viet Nam). Prior to the preparation of samples, steel slag was crushed into different particle sizes and dried under vacuum, whereas excess metal was recovered by electromechanical equipment. The mixture of steel slag coarse aggregates (nominal maximum aggregate size, D

max = 19 mm) was sieved following the ASTMC 136 standard and was mixed together to satisfy the ASTMC33 standard. Steel slag aggregates were then divided into two groups: (i) particle size of 4.75–19 mm, acting as coarse aggregates, and (ii) particle size in a 0.15–4.75 mm range, serving as fine aggregates. It is noteworthy that the purchased steel slag aggregates do not naturally satisfy the ASTMC33 standard. The sieved aggregates at 9.5 mm feature 65.83 wt.%, which is out of the range of the ASTMC33 standard (i.e., 20–55%). Therefore, coarse aggregates need to be partially removed from each sieve range, then blended again in order to redistribute the raw material to satisfy such a standard. The aggregate distribution size before and after the mixing process is highlighted in

Figure 2 and

Figure 3.

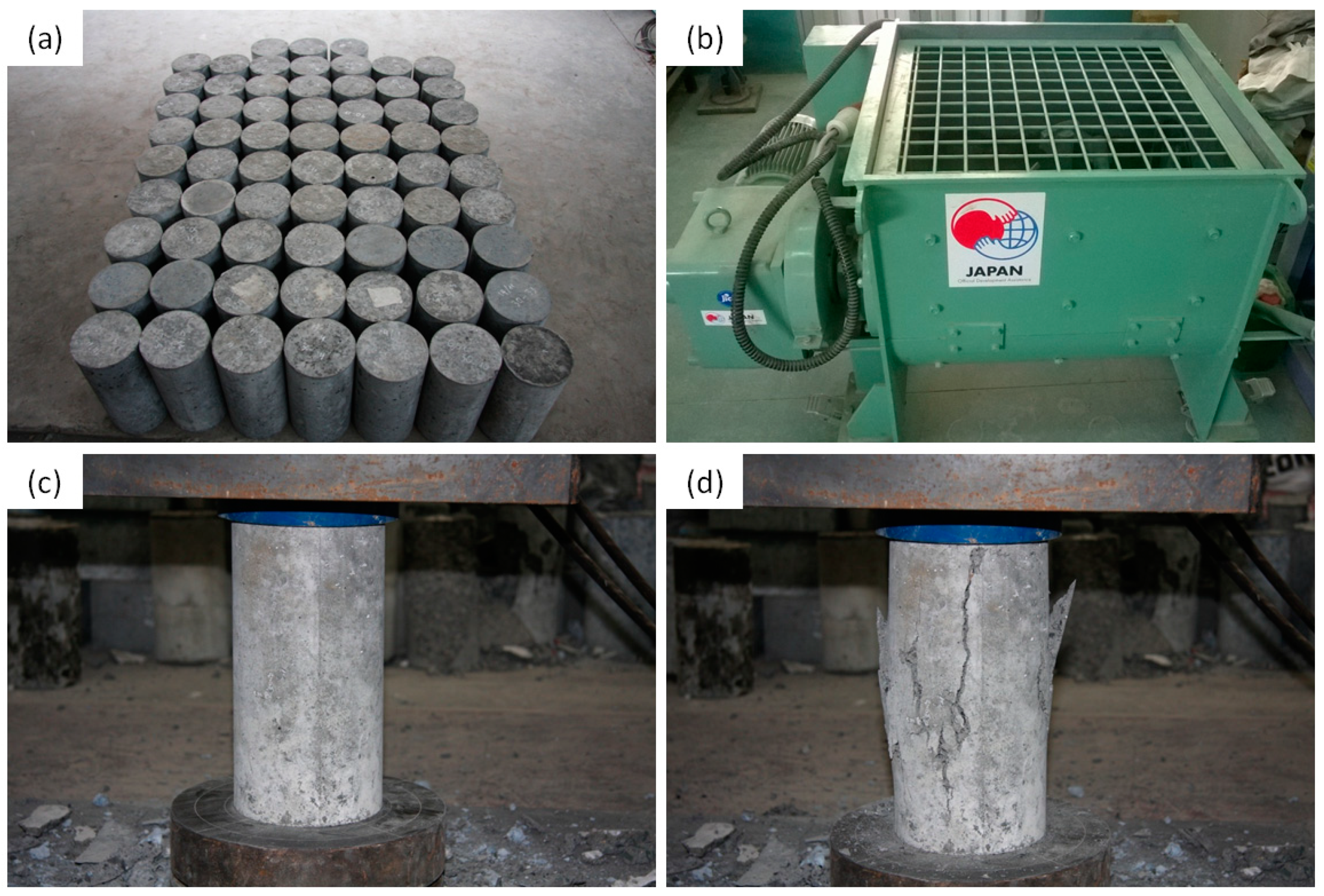

The mixing process was carried out with a forced mixing concrete mixer with 60-L capacity, supplied by Daiwa Kenko Co., LTD, Tokyo, Japan. The mixture was mixed following the ASTM C192 standard with a dry mixing time of 3 min and a wet mixing time of 5 min. After mixing, the slump of the mixture was measured, and then casted for the testing procedures. The mixture was added into the cylindrical mold and compacted on a vibrating table for about 1.5 min, which is two times longer than the process for traditional concrete. The sample surface was then covered by glossy paper to avoid evaporation. After 48 h, samples were removed from the mold and stored in the laboratory at a temperature T = 22 ± 4 °C and a humidity w = 60 ± 20% (

Figure 4).

3.2. Data Used for Modeling

In GPC, silica and aluminum oxides in fly ash react with activated alkaline solutions to form a binder in order to bond aggregate particles. Therefore, physical and mechanical properties of GPC highly depend on correlation factors including silicon, aluminum, alkali, and water content. Similar to cement concrete, the aggregates contain about 75–80% of the total weight of GPC. The compressive strength of GPC is affected by the ratio and properties of the ingredients that form the geopolymer binder. In this study, three main factors (concentration of NaOH solution, mass ratio of alkali activating solution to fly ash, and mass ratio of Na2SiO3 solution to NaOH solution) were used to predict the compressive strength of the GPC.

3.2.1. Concentration of NaOH Solution (X1)

A strong alkaline solution, such as NaOH or KOH, is necessary for the geopolymerization process in GPC. Previous studies on GPC using natural aggregates showed that increasing the molar concentration of alkaline solution will generate higher solubility of the material [

51,

52,

53]. Fernández-Jimenez [

54] concluded that GPC using 12.5 M NaOH gave higher compressive strength than that while using 8 M NaOH. However, a high concentration of alkaline solution is also suggested to reduce compressive strength of GPC. In the work of Palomo et al., the authors concluded that the geopolymer mortars produced with 12 M KOH had a faster activation rate and a higher compressive strength than those produced with 18 M KOH [

55]. In this study, the molar concentrations of NaOH were selected as 10 M, 12 M, and 14 M).

3.2.2. Mass Ratio of Alkali Activating Solution to Fly Ash (X2)

The activated alkaline mass in the mixture might also affect the compressive strength of GPC. As an example, Xie and Xi [

56] showed that higher compressive strength could be achieved by decreasing the mass ratio of alkali activated solution to fly ash (AAS/FA). In another work, Rangan [

18] suggested that the AAS/FA ratio should be in the range of 0.30–0.45 (

Table 3). In this work, the ratios of ASS/FA were selected as 0.4, 0.45, and 0.5.

3.2.3. Mass Ratio of the Sodium Silicate to the Sodium Hydroxide Solutions (X3)

Any strong alkaline hydroxide solution can be used as a component of the alkaline activating solution to form GPC. Palomo et al. demonstrated that, when the alkaline solutions contained sodium silicate solution (Na

2SiO

3) or potassium silicate (K

2SiO

3), the geopolymerization reaction occurred at a higher rate than when using only alkaline hydroxide [

57]. Fernández-Jimenez also showed that the presence of a silicate solution in the alkaline solutions resulted in a significant improvement in the compressive strength of GPC [

54]. In fact, NaOH or KOH solutions combined with Na

2SiO

3 or K

2SiO

3 are the most commonly alkaline activated solutions. The mass ratio of the sodium silicate to the sodium hydroxide solutions (SS/SH) generally determines the properties of the activated alkaline solution. According to the work of Rangan et al., GPC with conventional aggregates could be obtained with the SS/SH ratio of 2.5. When SS/SH increases, there is no significant change in terms of the obtained compressive strength [

58]. As there are no previous studies on GPC using steel slag aggregates, such ratios were selected as 2, 2.5, and 3, in order to avoid unexpected situations due to differences in chemical compositions or mechanical properties between steel slag and natural aggregates.

3.2.4. Compressive Strength (Y)

Compressive strength is one of the most important factors that reflect the quality of the GPC materials. In this study, the compressive strength was an output variable for the prediction problem. In order to prepare the data, laboratory experiments were carried out according to the ASTM C39 standard. The test samples were conducted on a 2000-kN universal testing machine. The applied force was in the range of 0 to 2000 kN with the speed of compressing ranging from 0.15 to 0.35 MPa/s. The cylindrical samples (150 × 300 mm) were tested at the age of 28 days in ambient conditions (temperature T = 22 ± 4 °C, humidity w = 60 ± 20%). The results were collected and are shown in

Table 4.

4. Modeling Methodology

Modeling methodology of this study was carried out with the following main steps (

Figure 5): (1) dataset preparation, (2) initiation and model generation, (3) metaheuristic optimization, (4) fitness evaluation, (5) stopping condition, and (6) construction of the final models. A detailed description of each step is given below.

(1) Dataset preparation: In this step, the data generated from the laboratory tests, which included 210 sets of parameters (concentration of NaOH solution, mass ratio of alkali activating solution to fly ash, mass ratio of solution Na2SiO3 to solution NaOH, and compressive strength), were divided into two parts. The first part included 70% of the data which were then used to construct the models. The second part consisted of 30% of the remaining data which were then used to validate the models.

(2) Initiation model generation: In this step, the initial ANFIS model was created using the training dataset where the Gaussian membership function was used to derived fuzzy sets and fuzzy membership values, and the fuzzy c-means clustering algorithm was used to distil natural groups from the training dataset for better training of the ANFIS.

(3) Metaheuristic optimization: In this step, the PSO and GA optimization methods were used to find the optimal consequent and antecedent parameters of the ANFIS. To get the best optimization, a trial-and-error test was done to determine the best numbers of particles and individuals in PSO and GA. In the case of the PSO, the best number of particles was determined as “40”. With the GA, the best number of individuals was determined as “30”. In addition, other modeling parameters of the GA, the crossover rate and mutation rate, were set as 0.4 and 0.6, respectively, as suggested by Saker et al. [

59] and Bui et al. [

60], and another modeling parameter of the PSO, the inertia weight, was set as 0.9, as suggested by Bui et al. [

60].

(4) Fitness evaluation: The RMSE function was used in this step to validate the performance of the ANFIS. In the meantime, the various combinations of consequent and antecedent parameters were explored by the PSO and GA, whereby the PSO updated the positions of particles on the basis of RMSE values to look for the best position of the swarm, and the GA generated and checked the chromosomes for the best chromosome population based on the best RMSE values.

(5) Stopping condition: The optimization process was carried out until the maximum number of generations was set. In this study, a maximum of 1000 generations were set, and the best swarm position (PSO) and chromosomes (GA) were finally selected and compared to derive the optimal consequent and antecedent parameters.

(6) Construction of the final models: the final PSOANFIS and GAANFIS models were built using the optimal consequent and antecedent parameters in this step. Validation of the final models was also done using several methods (RMSE, MAE, and R).

5. Results and Discussion

In order to reduce greenhouse emissions in civil engineering activities, many novel construction materials were developed in recent decades [

61]. Unlike the fabrication process of OPC using compounds that release carbon dioxide, GPC uses waste by-product materials which are environment friendly [

62], and can be defined as green materials. Mechanical properties of GPC proved that this material can work as effectively as traditional OPC-based materials.

In this study, two hybrid AI models (PSOANFIS and GAANFIS) are proposed for predicting the compressive strength of the GPC using entirely waste-sourced steel slag as fine and coarse aggregates. Basically, the AI algorithm can predict the results which are only in good agreement with the target data, but not better regarding quality and quantity. However, for concrete composite materials, the influence of the variables can be better understood if they are set as ratios; thus, we used three parameters, namely X1 (molar mass of the NaOH solution), X2 (mass ratio between alkaline activated solution and fly ash), and X3 (mass ratio between the sodium silicate and the sodium hydroxide solutions), as input variables. The corresponding compressive strength of samples was used as the target variable (Y) for the prediction modeling, and they were determined from a compressive strength test of 210 GPC samples.

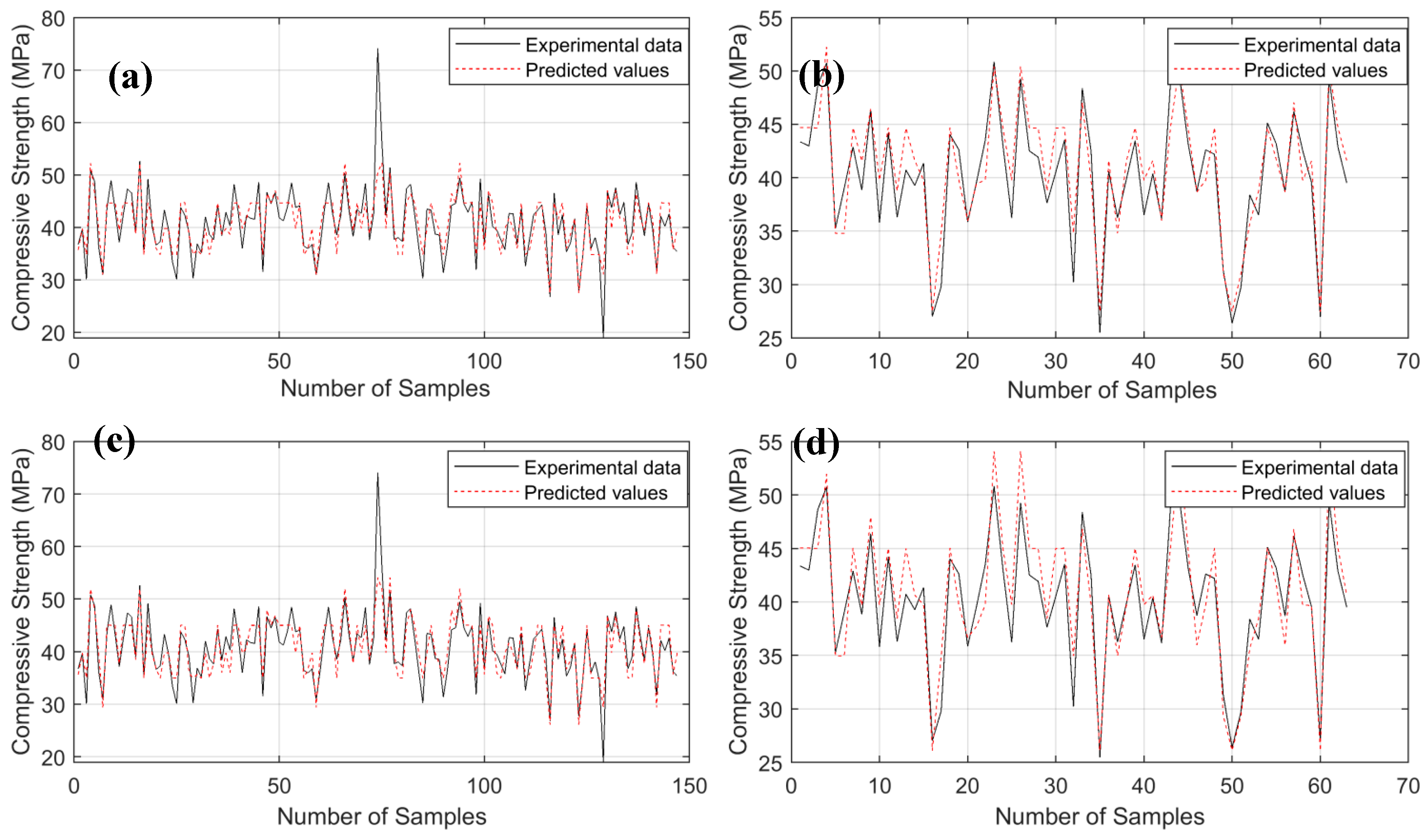

Validation of the models was done as shown in

Figure 6,

Figure 7,

Figure 8 and

Figure 9. It can be clearly observed from

Figure 6 that the experimental data (black, continuous line) and the predicted values (red, discontinuous) obtained from the training and the testing data of the PSOANFIS and the GAANFIS algorithms are strongly correlated with the experimental values. Such an assumption was validated with the training part (147 samples) of the data, as well as with the validation part (63 data), for the PSOANFIS and GAANFIS optimized algorithms. Indeed, it was universally concluded that both methods had the same effectiveness and a similar rate of success in finding optimal solutions. However, it can be observed that the PSOANFIS model was slightly better than GAANFIS, as the PSO optimization algorithm was a better candidate in terms of computational efficiency [

63]. In this work, the authors did not focus on such information, but rather performed the predictions with the same iteration criterion (i.e., 1000 iterations) on the PSO and the GA.

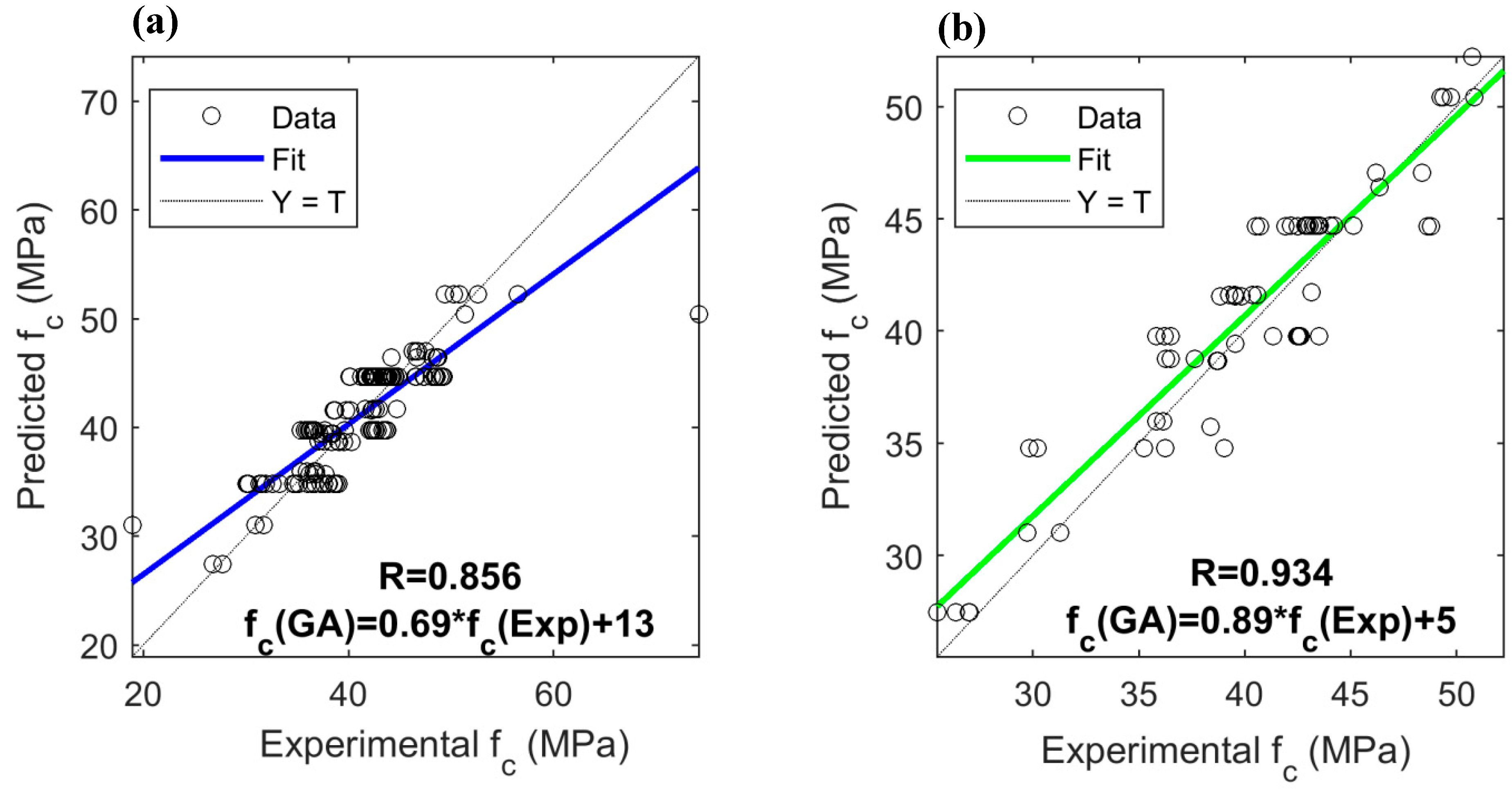

Validation results of the linear fit line, its equations, and the

R values are given in

Figure 7 for the training and testing in the PSOANFIS and GAANFIS models. Performance of the models in predicting the compressive strength values of the training and testing data was satisfactory with

R = 0.856,

R = 0.934 for the PSOANFIS algorithm, and

R = 0.869,

R = 0.927 for the GAANFIS algorithm, respectively. Absolute errors in predicting the compressive strength values in the training and testing of the PSOANFIS and GAANFIS models are plotted in

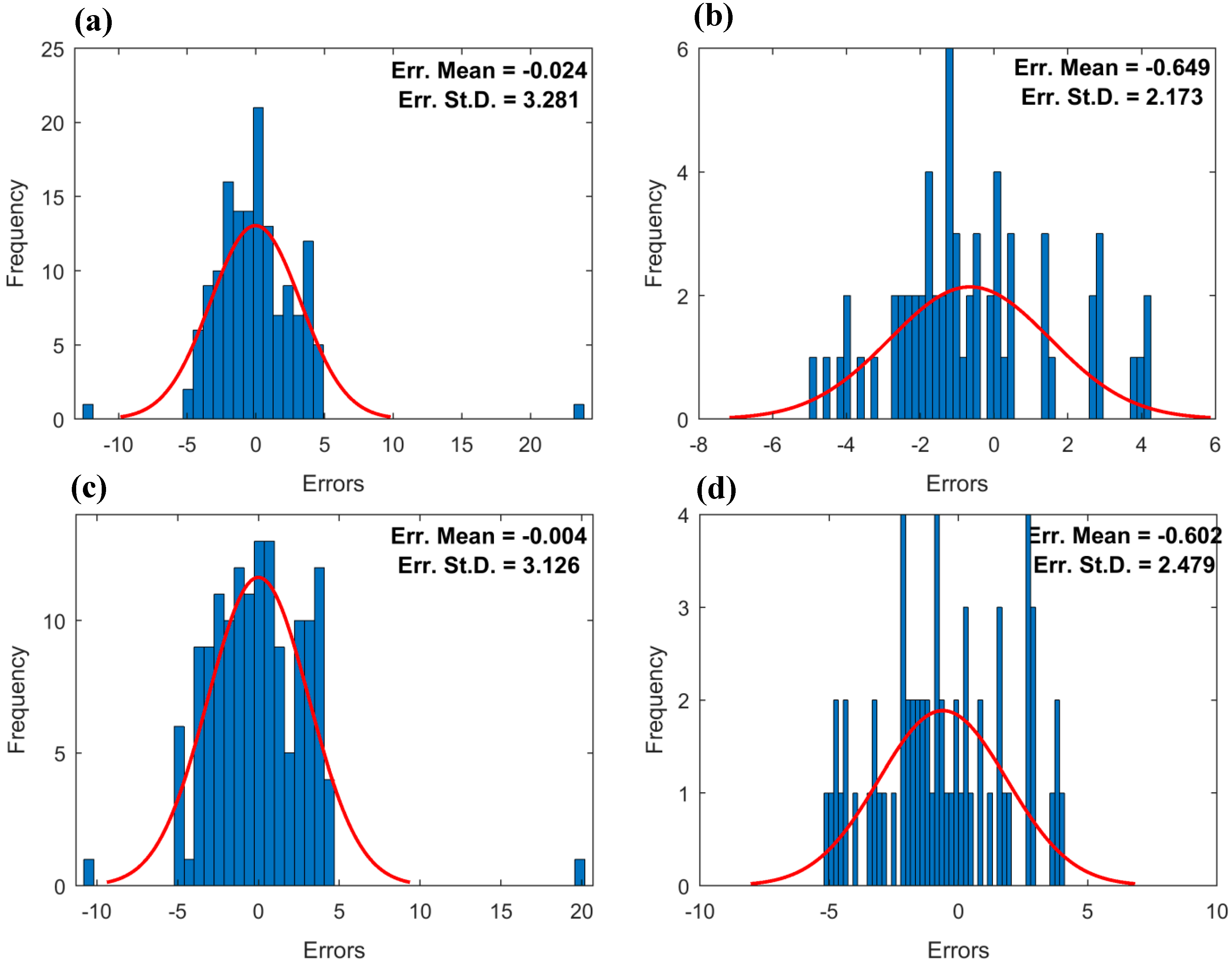

Figure 8. The maximum and minimum absolute errors were found as 23.70 and 20.02 for training of the PSOANFIS and GAANFIS models, respectively, whereas they were 4.79 and 5.13 for testing of the PSOANFIS and GAANFIS models, respectively. In addition, the statistical values for compressive strength values found from training and testing in PSOANFIS and GAANFIS models (RMSE, MAE, mean error, and standard deviation (SD)) are also given in

Figure 8 and

Figure 9 and

Table 5. While the statistical values of RMSE and MAE from training in the PSOANFIS model were found as 3.269 and 2.236, respectively, these values were found in testing as 2.251 and 1.847, respectively. Similarly, while the statistical values RMSE and MAE from training in the GAANFIS model were found as 3.115 and 2.293, respectively, these values were found in testing as 2.531 and 2.115, respectively. A small perceptible deviation was observed for the calculated values (

Figure 9). This result demonstrates that the proposed PSOANFIS and GAANFIS models are suitable and can predict the compressive strength values, which were very close to experimental values.

In general, the compressive strength of GPC containing waste steel slag could be predicted using PSOANFIS and GAANFIS without conducting too many experiments. Therefore, it can be reasonably stated that the PSOANFIS and GAANFIS algorithms are very promising AI tools for the prediction of compressive strength of GPC using entirely waste-sourced steel slag. These tools could provide useful information that could help engineers save time and costs, and increase work effectiveness.

6. Conclusions

GPC is an eco-environmentally friendly material which can be used as a replacement for cement concrete in civil engineering construction. The compressive strength is an important parameter for evaluation of the quality of this material. In this study, novel hybrid AI approaches named PSOANFIS and GAANFIS were proposed for quick prediction of the compressive strength of GPC using steel slag as both fine and coarse aggregates. A total of 210 samples were generated and tested in the laboratory to determine the parameters for modeling, such as the compressive strength as the output variable, and concentration of NaOH solution (10 M, 12 M, and 14 M), mass ratio of alkali activating solution to fly ash (AAS/FA) (0.4, 0.45, and 0.5), and mass ratio of solution Na2SiO3 to solution NaOH (SS/SH) (2, 2.5, and 3) as the input parameters. Validation and comparison of the models was done using various error determination criteria, including MAE, RSME, and R. The results show that the proposed models performed well for the prediction of the compressive strength of GPC, but the PSOANFIS model (MAE = 1.847 MPa, RMSE = 2.251 MPa, and R = 0.934) outperformed the GAANFIS model (MAE = 2.115 MPa, RMSE = 2.531 MPa, and R = 0.927). Thus, it can be reasonably concluded that the proposed hybrid AI approach of PSOANFIS is a promising method for the prediction of the compressive strength of GPC. This study would help in reducing the time and cost of construction, as well as in the improvement of the environment. However, a limitation of this study is that we considered only ingredients that combine to form geopolymer binders in predicting the compressive strength of GPC, and we did not consider the quality, quantity, or properties of aggregates which might affect the compressive strength of GPC. Thus, this is proposed to carry out a study of these factors in future modeling. In addition, a sensitivity analysis of different combinations of input data may also be carried out to test the importance of each input parameter for better modeling of the compressive strength of GPC.

Author Contributions

Conceptualization, D.V.D., H.-B.L. and B.T.P.; Methodology, D.V.D., H.-B.L. and B.T.P.; Software, B.T.P., H.-B.L.; Validation, D.V.D., S.H.T., and H.-B.L.; Formal Analysis, D.V.D. and S.H.T.; Investigation, D.V.D. and S.H.T.; Resources, D.V.D., S.H.T., H.-B.L. and B.T.P.; Data Curation, D.V.D. and S.H.T.; Writing—Original Draft Preparation, D.V.D., S.H.T., H.-B.L. and B.T.P.; Writing—Review & Editing, D.V.D., H.-B.L. and B.T.P.; Visualization, D.V.D., S.H.T., H.-B.L. and B.T.P.; Supervision, D.V.D.; Project Administration, D.V.D.; Funding Acquisition, D.V.D.

Funding

This research received no external funding.

Acknowledgments

The authors thank the University of Transport Technology (Hanoi, Vietnam) for providing the facility to carry out this research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Shi, C.; Stegemann, J.A. Acid corrosion resistance of different cementing materials. Cem. Concr. Res. 2000, 30, 803–808. [Google Scholar] [CrossRef]

- Puertas, F.; Palacios, M.; Gil-Maroto, A.; Vázquez, T. Alkali-aggregate behaviour of alkali-activated slag mortars: Effect of aggregate type. Cem. Concr. Compos. 2009, 31, 277–284. [Google Scholar] [CrossRef]

- García-Lodeiro, I.; Palomo, A.; Fernández-Jiménez, A. Alkali–aggregate reaction in activated fly ash systems. Cem. Concr. Res. 2007, 37, 175–183. [Google Scholar] [CrossRef]

- Roy, D.M.; Jiang, W.; Silsbee, M.R. Chloride diffusion in ordinary, blended, and alkali-activated cement pastes and its relation to other properties. Cem. Concr. Res. 2000, 30, 1879–1884. [Google Scholar] [CrossRef]

- Saraswathy, V.; Muralidharan, S.; Thangavel, K.; Srinivasan, S. Influence of activated fly ash on corrosion-resistance and strength of concrete. Cem. Concr. Compos. 2003, 25, 673–680. [Google Scholar] [CrossRef]

- Temuujin, J.; Rickard, W.; Lee, M.; van Riessen, A. Preparation and thermal properties of fire resistant metakaolin-based geopolymer-type coatings. J. Non-Cryst. Solids 2011, 357, 1399–1404. [Google Scholar] [CrossRef]

- Kong, D.L.; Sanjayan, J.G.; Sagoe-Crentsil, K. Factors affecting the performance of metakaolin geopolymers exposed to elevated temperatures. J. Mater. Sci. 2008, 43, 824–831. [Google Scholar] [CrossRef]

- Brooks, R.; Bahadory, M.; Tovia, F.; Rostami, H. Properties of alkali-activated fly ash: High performance to lightweight. Int. J. Sustain. Eng. 2010, 3, 211–218. [Google Scholar] [CrossRef]

- Slavik, R.; Bednarik, V.; Vondruska, M.; Nemec, A. Preparation of geopolymer from fluidized bed combustion bottom ash. J. Mater. Process. Technol. 2008, 200, 265–270. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Influence of sodium carbonate addition on the thermal reactivity of tungsten mine waste mud based binders. Constr. Build. Mater. 2010, 24, 56–60. [Google Scholar] [CrossRef]

- Škvára, F.; Kopeckỳ, L.; Šmilauer, V.; Bittnar, Z. Material and structural characterization of alkali activated low-calcium brown coal fly ash. J. Hazard. Mater. 2009, 168, 711–720. [Google Scholar] [CrossRef] [PubMed]

- Yi, H.; Xu, G.; Cheng, H.; Wang, J.; Wan, Y.; Chen, H. An Overview of Utilization of Steel Slag. Procedia Environ. Sci. 2012, 16, 791–801. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P.K. Drying Shrinkage of Slag Blended Fly Ash Geopolymer Concrete Cured at Room Temperature. Procedia Eng. 2015, 125, 594–600. [Google Scholar] [CrossRef]

- Omar, O.M.; Heniegal, A.M.; Elhameed, G.A.; Mohamadien, H.A. Effect of Local Steel Slag as a Coarse Aggregate on Properties of Fly Ash Based-Geopolymer Concrete. Egypt World Acad. Sci. Eng. Technol. 2015, 9, 508–516. [Google Scholar]

- Lloyd, N.; Rangan, V. Geopolymer concrete with fly ash. In Proceedings of the Second International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28 June 2010; UWM Center for By-Products Utilization: Milwaukee, WI, USA, 2010; pp. 1493–1504. [Google Scholar]

- Lloyd, N.A.; Rangan, B.V. Geopolymer concrete: A review of development and opportunities. In Proceedings of the 35th Conference on Our World in Concrete & Structures, Singapore, 25–27 August 2010. [Google Scholar]

- Rangan, B.V. Fly Ash-Based Geopolymer Concrete; Curtin University of Technology: Perth, Australia, 2008. [Google Scholar]

- Rangan, B.V. Design and manufacture of flyash-based geopolymer concrete. Concr. Aust. 2008, 34, 37–43. [Google Scholar]

- Ferdous, M.W.; Kayali, O.; Khennane, A. A detailed procedure of mix design for fly ash based geopolymer concrete. In Proceedings of the Fourth Asia-Pacific Conference on FRP in Structures (APFIS 2013), Melbourne, Australia, 11–13 December 2013; pp. 11–13. [Google Scholar]

- Chou, J.-H.; Ghaboussi, J. Genetic algorithm in structural damage detection. Comput. Struct. 2001, 79, 1335–1353. [Google Scholar] [CrossRef]

- Lai, S.; Serra, M. Concrete strength prediction by means of neural network. Constr. Build. Mater. 1997, 11, 93–98. [Google Scholar] [CrossRef]

- Mansour, M.Y.; Dicleli, M.; Lee, J.-Y.; Zhang, J. Predicting the shear strength of reinforced concrete beams using artificial neural networks. Eng. Struct. 2004, 26, 781–799. [Google Scholar] [CrossRef]

- Prasad, B.K.R.; Eskandari, H.; Reddy, B.V.V. Prediction of compressive strength of SCC and HPC with high volume fly ash using ANN. Constr. Build. Mater. 2009, 23, 117–128. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Sarıdemir, M. Prediction of compressive strength of concrete containing fly ash using artificial neural networks and fuzzy logic. Comput. Mater. Sci. 2008, 41, 305–311. [Google Scholar] [CrossRef]

- Bal, L.; Buyle-Bodin, F. Artificial neural network for predicting drying shrinkage of concrete. Constr. Build. Mater. 2013, 38, 248–254. [Google Scholar] [CrossRef]

- Karthikeyan, J.; Upadhyay, A.; Bhandari, N.M. Artificial neural network for predicting creep and shrinkage of high performance concrete. J. Adv. Concr. Technol. 2008, 6, 135–142. [Google Scholar] [CrossRef]

- Bilim, C.; Atiş, C.D.; Tanyildizi, H.; Karahan, O. Predicting the compressive strength of ground granulated blast furnace slag concrete using artificial neural network. Adv. Eng. Softw. 2009, 40, 334–340. [Google Scholar] [CrossRef]

- Yu, J.-B.; Yu, Y.; Wang, L.-N.; Yuan, Z.; Ji, X. The knowledge modeling system of ready-mixed concrete enterprise and artificial intelligence with ANN-GA for manufacturing production. J. Intell. Manuf. 2016, 27, 905–914. [Google Scholar] [CrossRef]

- Bai, J.; Wild, S.; Ware, J.A.; Sabir, B.B. Using neural networks to predict workability of concrete incorporating metakaolin and fly ash. Adv. Eng. Softw. 2003, 34, 663–669. [Google Scholar] [CrossRef]

- Chine, W.-H.; Chen, L.; Hsu, H.-H.; Wang, T.-S.; Chiu, C.-H. Modeling slump of concrete using the artificial neural networks. In Proceedings of the 2010 International Conference on Artificial Intelligence and Computational Intelligence (AICI), Sanya, China, 23–24 October 2010; Volume 3, pp. 236–239. [Google Scholar]

- Chandwani, V.; Agrawal, V.; Nagar, R. Modeling slump of ready mix concrete using genetic algorithms assisted training of Artificial Neural Networks. Expert Syst. Appl. 2015, 42, 885–893. [Google Scholar] [CrossRef]

- Mukherjee, A.; Biswas, S.N. Artificial neural networks in prediction of mechanical behavior of concrete at high temperature. Nucl. Eng. Des. 1997, 178, 1–11. [Google Scholar] [CrossRef]

- Ince, R. Prediction of fracture parameters of concrete by artificial neural networks. Eng. Fract. Mech. 2004, 71, 2143–2159. [Google Scholar] [CrossRef]

- Perera, R.; Arteaga, A.; De Diego, A. Artificial intelligence techniques for prediction of the capacity of RC beams strengthened in shear with external FRP reinforcement. Compos. Struct. 2010, 92, 1169–1175. [Google Scholar] [CrossRef]

- Tarefder, R.A.; White, L.; Zaman, M. Neural network model for asphalt concrete permeability. J. Mater. Civ. Eng. 2005, 17, 19–27. [Google Scholar] [CrossRef]

- Özcan, F.; Atiş, C.D.; Karahan, O.; Uncuoğlu, E.; Tanyildizi, H. Comparison of artificial neural network and fuzzy logic models for prediction of long-term compressive strength of silica fume concrete. Adv. Eng. Softw. 2009, 40, 856–863. [Google Scholar] [CrossRef]

- Barak, S.; Sadegh, S.S. Forecasting energy consumption using ensemble ARIMA–ANFIS hybrid algorithm. Int. J. Electr. Power Energy Syst. 2016, 82, 92–104. [Google Scholar] [CrossRef]

- Chen, W.; Panahi, M.; Pourghasemi, H.R. Performance evaluation of GIS-based new ensemble data mining techniques of adaptive neuro-fuzzy inference system (ANFIS) with genetic algorithm (GA), differential evolution (DE), and particle swarm optimization (PSO) for landslide spatial modelling. Catena 2017, 157, 310–324. [Google Scholar] [CrossRef]

- Basser, H.; Karami, H.; Shamshirband, S.; Akib, S.; Amirmojahedi, M.; Ahmad, R.; Jahangirzadeh, A.; Javidnia, H. Hybrid ANFIS–PSO approach for predicting optimum parameters of a protective spur dike. Appl. Soft Comput. 2015, 30, 642–649. [Google Scholar] [CrossRef]

- Karaboga, D.; Kaya, E. Adaptive network based fuzzy inference system (ANFIS) training approaches: A comprehensive survey. Artif. Intell. Rev. 2018, 1–31. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle Swarm Optimization. In Proceedings of the IEEE International Conference on Neural Networks (ICNN’95), Perth, Australia, 27 November–1 December 1995. [Google Scholar]

- Heo, J.S.; Lee, K.Y.; Garduno-Ramirez, R. Multiobjective control of power plants using particle swarm optimization techniques. IEEE Trans. Energy Convers. 2006, 21, 552–561. [Google Scholar] [CrossRef]

- Sehgal, V.; Sahay, R.R.; Chatterjee, C. Effect of utilization of discrete wavelet components on flood forecasting performance of wavelet based ANFIS models. Water Resour. Manag. 2014, 28, 1733–1749. [Google Scholar] [CrossRef]

- Azadeh, A.; Ghaderi, S.F.; Tarverdian, S.; Saberi, M. Integration of artificial neural networks and genetic algorithm to predict electrical energy consumption. Appl. Math. Comput. 2007, 186, 1731–1741. [Google Scholar] [CrossRef]

- Metawa, N.; Hassan, M.K.; Elhoseny, M. Genetic algorithm based model for optimizing bank lending decisions. Expert Syst. Appl. 2017, 80, 75–82. [Google Scholar] [CrossRef]

- Sivanandam, S.N.; Deepa, S.N. Genetic algorithm optimization problems. In Introduction to Genetic Algorithms; Springer: New York, NY, USA, 2008; pp. 165–209. [Google Scholar]

- Willmott, C.J.; Matsuura, K. Advantages of the mean absolute error (MAE) over the root mean square error (RMSE) in assessing average model performance. Clim. Res. 2005, 30, 79–82. [Google Scholar] [CrossRef]

- Taylor, R. Interpretation of the correlation coefficient: A basic review. J. Diagn. Med. Sonogr. 1990, 6, 35–39. [Google Scholar] [CrossRef]

- Montavon, G.; Rupp, M.; Gobre, V.; Vazquez-Mayagoitia, A.; Hansen, K.; Tkatchenko, A.; Müller, K.-R.; Von Lilienfeld, O.A. Machine learning of molecular electronic properties in chemical compound space. New J. Phys. 2013, 15, 095003. [Google Scholar] [CrossRef]

- Phair, J.W.; Van Deventer, J.S.J. Effect of silicate activator pH on the leaching and material characteristics of waste-based inorganic polymers. Miner. Eng. 2001, 14, 289–304. [Google Scholar] [CrossRef]

- Xu, H.; Van Deventer, J.S.J. The geopolymerisation of alumino-silicate minerals. Int. J. Miner. Process. 2000, 59, 247–266. [Google Scholar] [CrossRef]

- Xu, H.; Van Deventer, J.S.J.; Lukey, G.C. Effect of alkali metals on the preferential geopolymerization of stilbite/kaolinite mixtures. Ind. Eng. Chem. Res. 2001, 40, 3749–3756. [Google Scholar] [CrossRef]

- Fernandez-Jimenez, A.M.; Palomo, A.; Lopez-Hombrados, C. Engineering properties of alkali-activated fly ash concrete. ACI Mater. J. 2006, 103, 106. [Google Scholar]

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Xie, Z.; Xi, Y. Hardening mechanisms of an alkaline-activated class F fly ash. Cem. Concr. Res. 2001, 31, 1245–1249. [Google Scholar] [CrossRef]

- Palomo, A.; Blanco-Varela, M.T.; Granizo, M.L.; Puertas, F.; Vazquez, T.; Grutzeck, M.W. Chemical stability of cementitious materials based on metakaolin. Cem. Concr. Res. 1999, 29, 997–1004. [Google Scholar] [CrossRef]

- Hardjito, D.; Rangan, B.V. Development and Properties of Low-Calcium Fly Ash-Based Geopolymer Concrete; Curtin Research Publications: Perth, Australia, 2005. [Google Scholar]

- Sarker, R.A. Agent-Based Evolutionary Search; Springer: New York, NY, USA, 2018. [Google Scholar]

- Bui, D.T.; Pradhan, B.; Nampak, H.; Bui, Q.-T.; Tran, Q.-A.; Nguyen, Q.-P. Hybrid artificial intelligence approach based on neural fuzzy inference model and metaheuristic optimization for flood susceptibilitgy modeling in a high-frequency tropical cyclone area using GIS. J. Hydrol. 2016, 540, 317–330. [Google Scholar]

- Pires, E.F.C.; de Azevedo, C.M.C.; Pimenta, A.R.; da Silva, F.J.; Darwish, F.A.I. Fracture Properties of Geopolymer Concrete Based on Metakaolin, Fly Ash and Rice Rusk Ash. Mater. Res. 2017, 20, 630–636. [Google Scholar] [CrossRef]

- Chiang, S.-W.; Chao-Chen, H.S.U.; Chien, K.-L.; Lin, K.-M.; Chung, J.-C. Environmentally Friendly Cement and Production Method Thereof. U.S. Patent US 2,0170,260,090A1, 26 September 2017. [Google Scholar]

- Hassan, R.; Cohanim, B.; De Weck, O.; Venter, G. A comparison of particle swarm optimization and the genetic algorithm. In Proceedings of the 46th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Austin, TX, USA, 18–21 April 2005; p. 1897. [Google Scholar]

Figure 1.

The structure of the adaptive neuro fuzzy inference system (ANFIS) algorithm.

Figure 1.

The structure of the adaptive neuro fuzzy inference system (ANFIS) algorithm.

Figure 2.

Gradation curves of fine aggregate.

Figure 2.

Gradation curves of fine aggregate.

Figure 3.

Gradation curves of coarse aggregate.

Figure 3.

Gradation curves of coarse aggregate.

Figure 4.

(a) Samples of geopolymer concrete (GPC) using steel slag aggregate; (b) forced mixing concrete mixer; (c) compressive strength test of the specimen; (d) fracture mode.

Figure 4.

(a) Samples of geopolymer concrete (GPC) using steel slag aggregate; (b) forced mixing concrete mixer; (c) compressive strength test of the specimen; (d) fracture mode.

Figure 5.

Modeling methodology flow chart of this study.

Figure 5.

Modeling methodology flow chart of this study.

Figure 6.

Experimental and predicted values of compressive strength with different models: (a) training particle swarm optimization (PSO)-based ANFIS (PSOANFIS), (b) testing PSOANFIS, (c) training genetic algorithm (GA)-based ANFIS (GAANFIS), and (d) testing GAANFIS.

Figure 6.

Experimental and predicted values of compressive strength with different models: (a) training particle swarm optimization (PSO)-based ANFIS (PSOANFIS), (b) testing PSOANFIS, (c) training genetic algorithm (GA)-based ANFIS (GAANFIS), and (d) testing GAANFIS.

Figure 7.

Correlation coefficients of different models: (a) training PSOANFIS, (b) testing PSOANFIS, (c) training GAANFIS, and (d) testing GAANFIS.

Figure 7.

Correlation coefficients of different models: (a) training PSOANFIS, (b) testing PSOANFIS, (c) training GAANFIS, and (d) testing GAANFIS.

Figure 8.

Error distribution of different models: (a) training PSOANFIS, (b) testing PSOANFIS, (c) training GAANFIS, and (d) testing GAANFIS.

Figure 8.

Error distribution of different models: (a) training PSOANFIS, (b) testing PSOANFIS, (c) training GAANFIS, and (d) testing GAANFIS.

Figure 9.

Mean errors and standard deviations of different models: (a) training PSOANFIS, (b) testing PSOANFIS, (c) training GAANFIS, and (d) testing GAANFIS.

Figure 9.

Mean errors and standard deviations of different models: (a) training PSOANFIS, (b) testing PSOANFIS, (c) training GAANFIS, and (d) testing GAANFIS.

Table 1.

Main chemical compositions of fly ash (wt.%).

Table 1.

Main chemical compositions of fly ash (wt.%).

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | TiO2 | SO3 | LOI * |

|---|

| 51.74 | 24.53 | 5.59 | 0.81 | 1.95 | 4.42 | 0.11 | 0.76 | 0.31 | 8.98 |

Table 2.

Particle size distribution of fly ash.

Table 2.

Particle size distribution of fly ash.

| Size range (μm) | 30 | 20 | 10 | 5 |

| Passing Sieved volume (wt.%) | 95 | 51.67 | 33.06 | 16.77 |

Table 3.

Experimental results determining the effect of alkali activated solution to fly ash (AAS/FA) ratio.

Table 3.

Experimental results determining the effect of alkali activated solution to fly ash (AAS/FA) ratio.

| AAS/FA | Workability | Compressive Strength (MPa) |

|---|

| 0.30 | Hard | 58 |

| 0.35 | Moderate | 45 |

| 0.40 | Moderate | 37 |

| 0.45 | High slump | 32 |

Table 4.

Mix proportions and compressive strength results of GPC using steel slag aggregate.

Table 4.

Mix proportions and compressive strength results of GPC using steel slag aggregate.

| Mixture No. | X1 (M) | X2 | X3 | Y (MPa) |

|---|

| GPC 01 | 10 | 0.4 | 2 | 40.17 |

| GPC 02 | 14 | 0.4 | 2 | 49.43 |

| GPC 03 | 10 | 0.5 | 2 | 29.73 |

| GPC 04 | 14 | 0.5 | 2 | 43.17 |

| … | … | … | … | … |

| … | … | … | … | … |

| … | … | … | … | … |

| GPC 206 | 12 | 0.45 | 3 | 35.33 |

| GPC 207 | 12 | 0.45 | 2.5 | 42.47 |

| GPC 208 | 14 | 0.40 | 3 | 48.59 |

| GPC 209 | 14 | 0.5 | 3 | 36.28 |

| GPC 210 | 14 | 0.45 | 2.5 | 49.39 |

Table 5.

Validation results of the two proposed models.

Table 5.

Validation results of the two proposed models.

| Statistical Parameters | PSOANFIS | GAANFIS |

|---|

| Training Set | Testing Set | Training Set | Testing Set |

|---|

| RMSE | 3.269 | 2.251 | 3.115 | 2.531 |

| R | 0.856 | 0.934 | 0.869 | 0.927 |

| MAE | 2.236 | 1.847 | 2.293 | 2.115 |

| Mean error | −0.024 | −0.649 | −0.004 | −0.602 |

| SD | 3.281 | 2.173 | 3.126 | 2.479 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).