Nondestructive Testing with 3MA—An Overview of Principles and Applications

Abstract

:1. Introduction

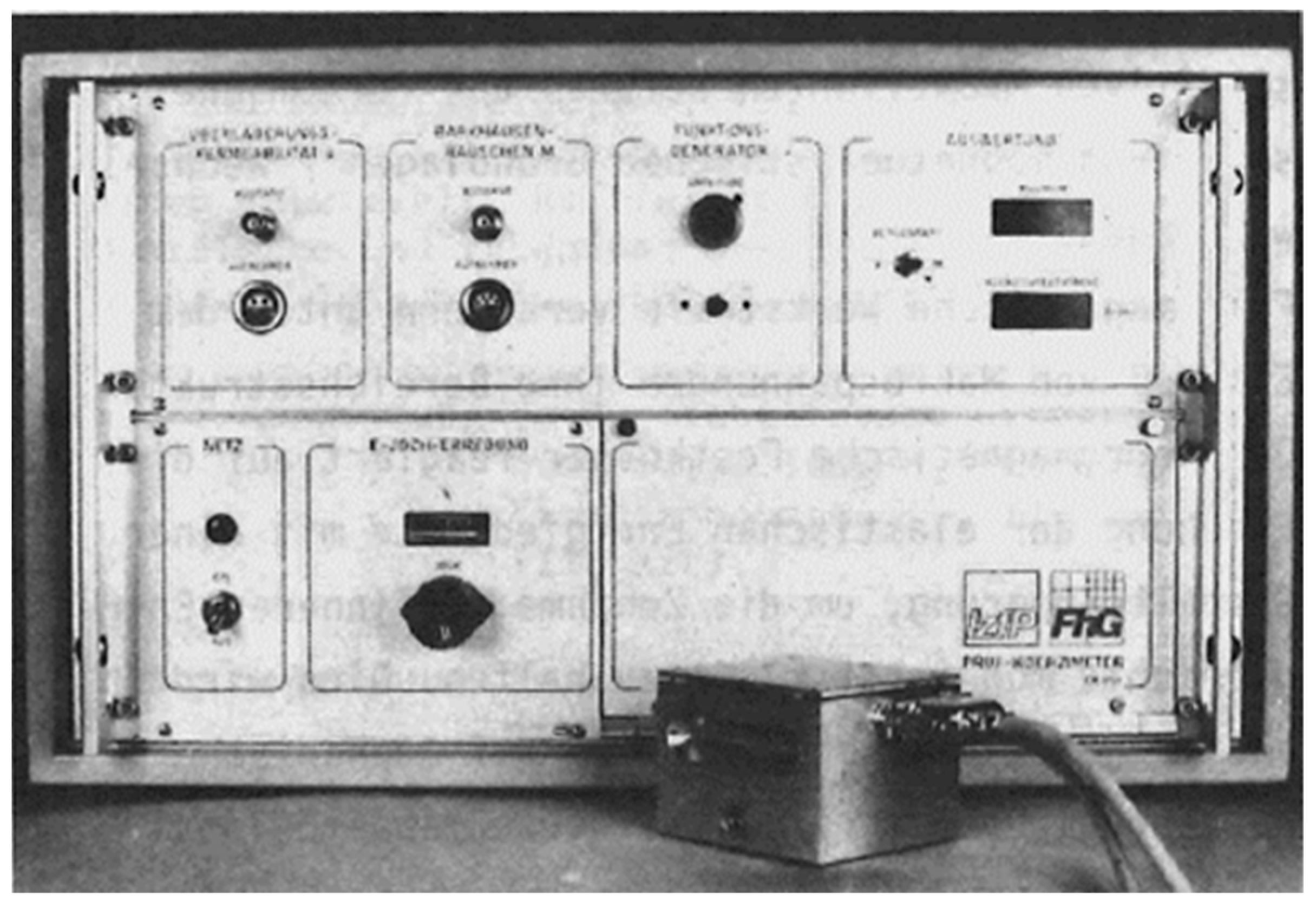

2. Historical Development

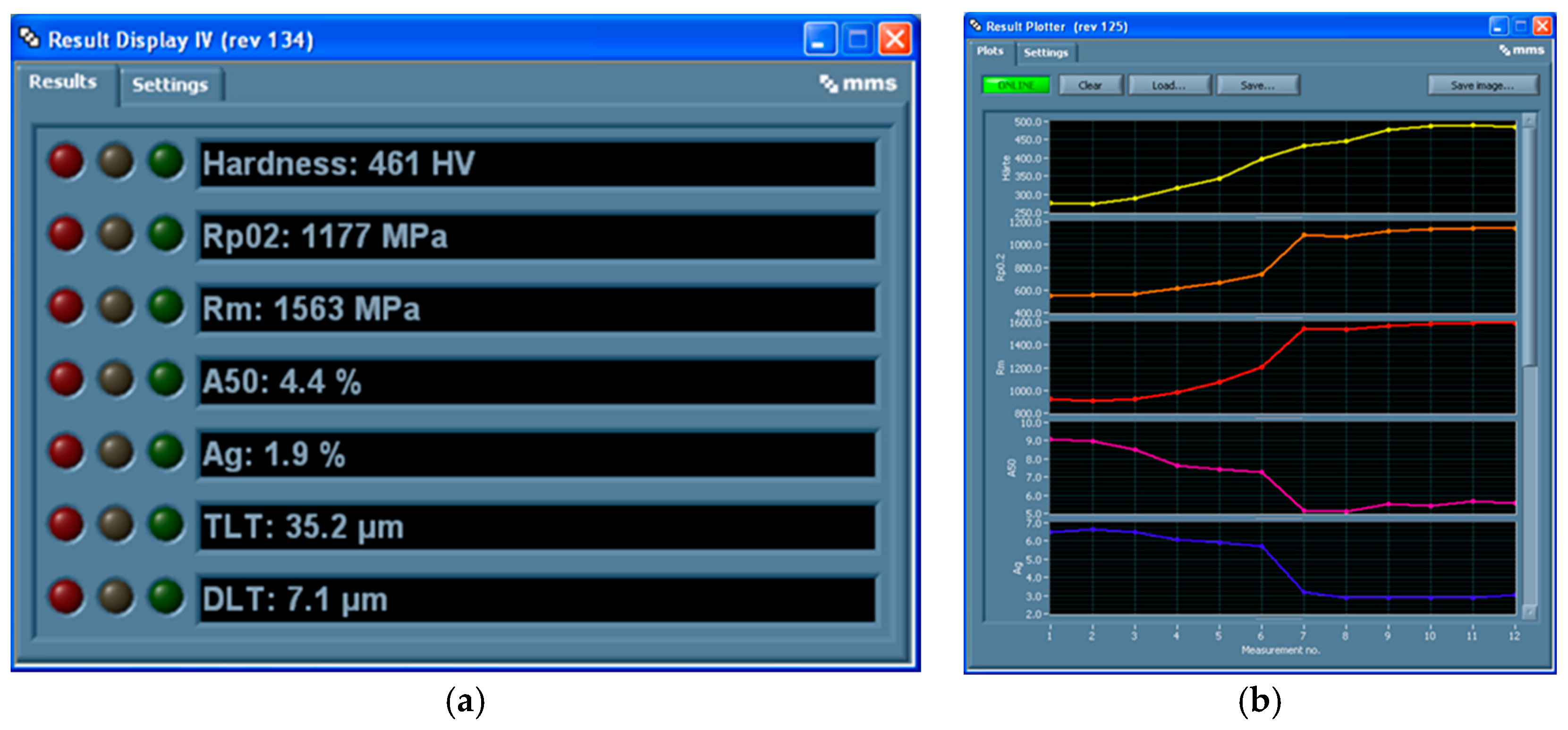

3. Basic Principles of 3MA

3.1. Harmonic Analysis (HA) Method

3.2. Eddy Current (EC) Method

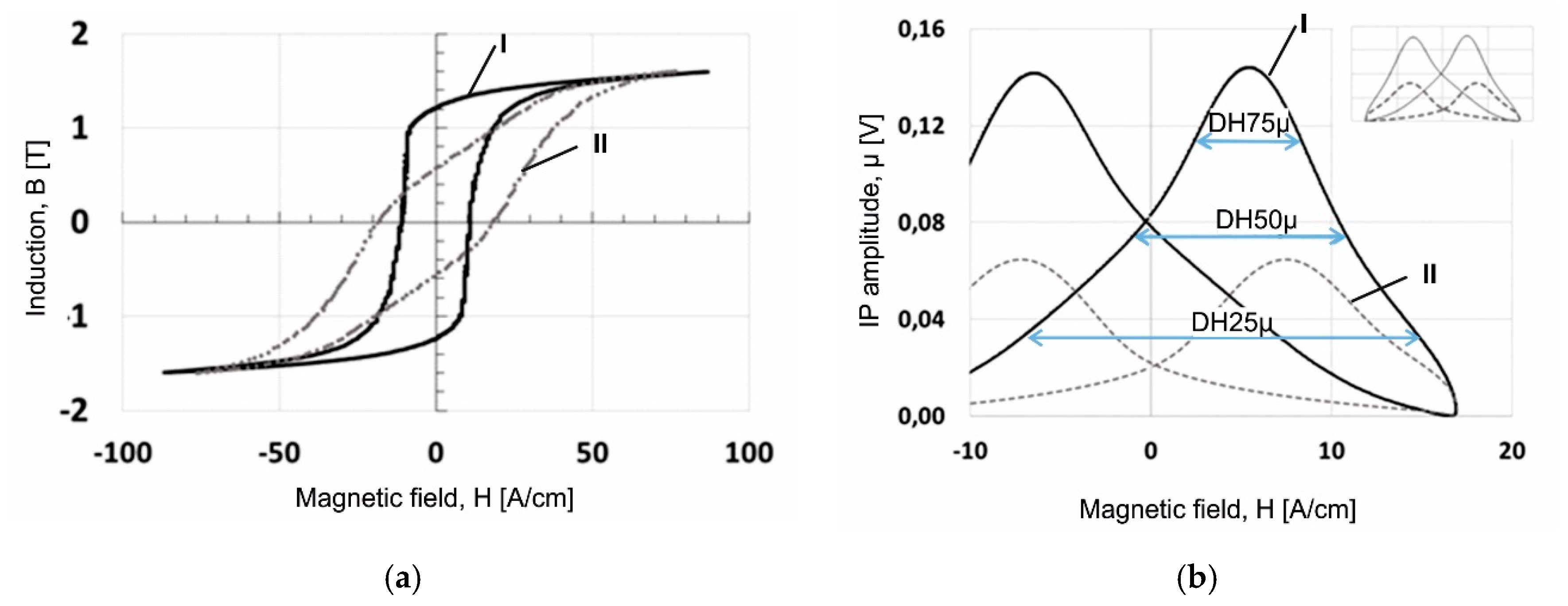

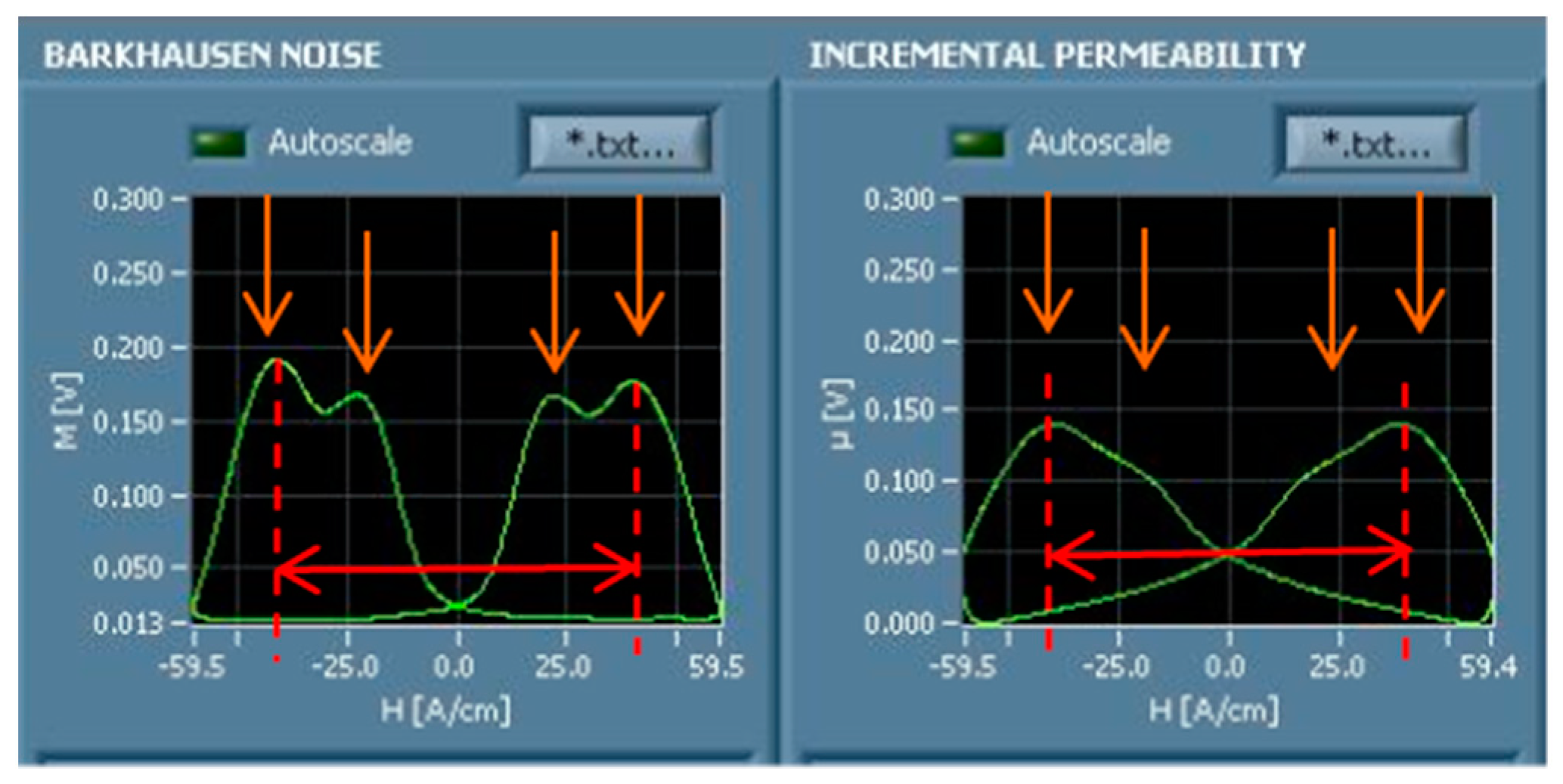

3.3. Barkhausen Noise (BN) Method

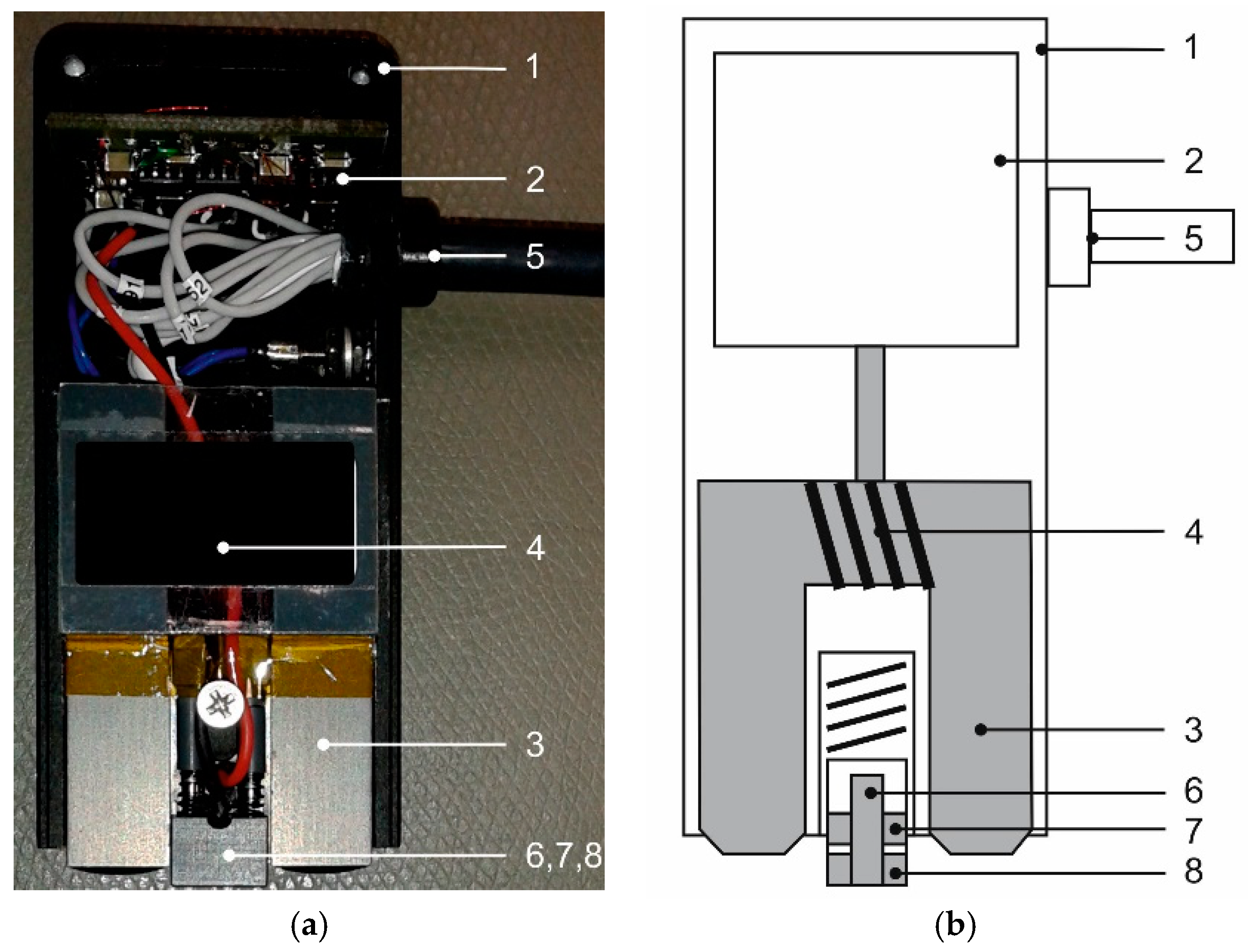

3.4. Incremental Permeability (IP) Method

3.5. Correlations to Microstructure and Material Properties

3.6. Set-up Optimization and Calibration

4. Applications

4.1. Overview

4.2. Applications in the Steel Industry

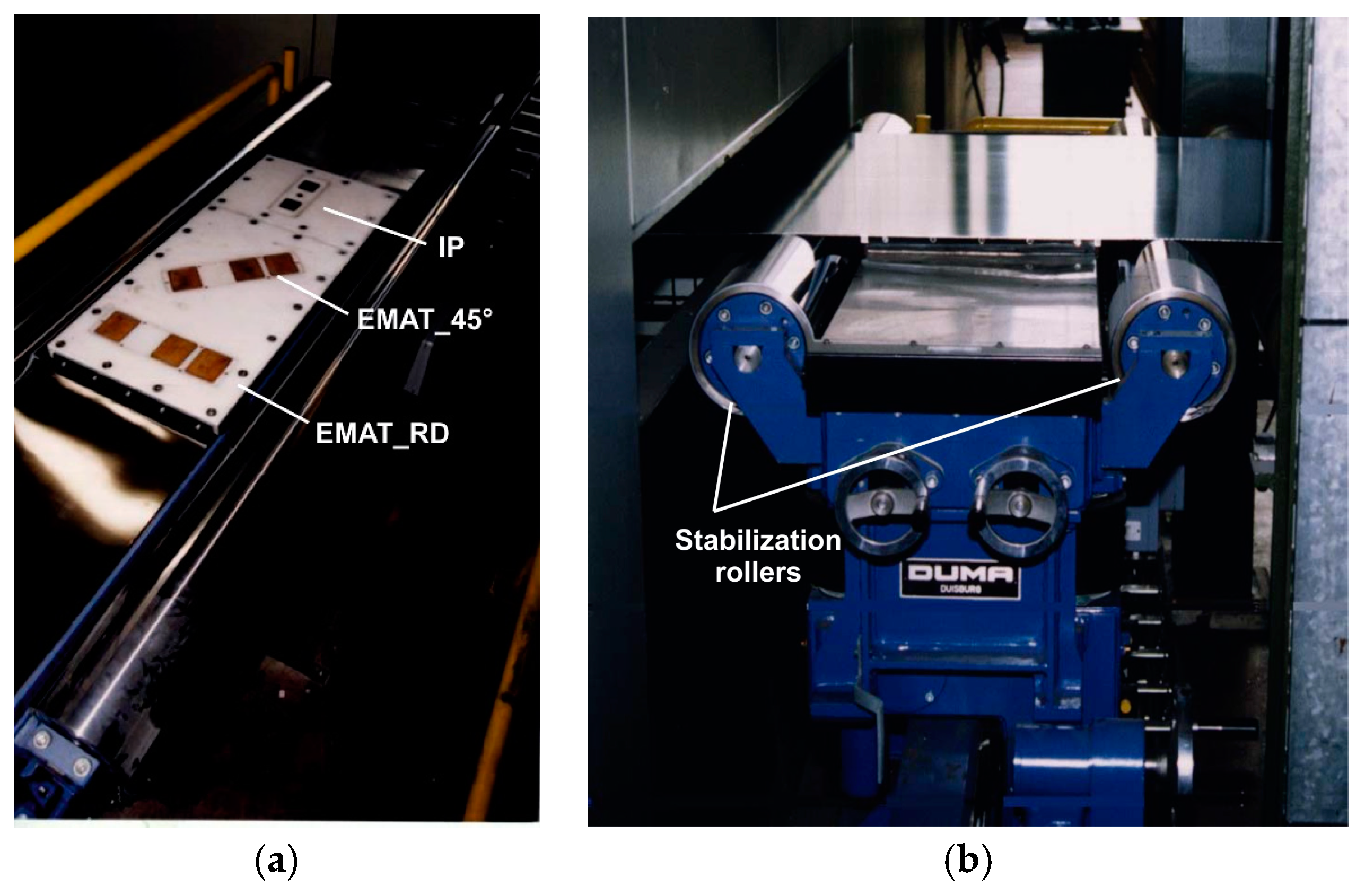

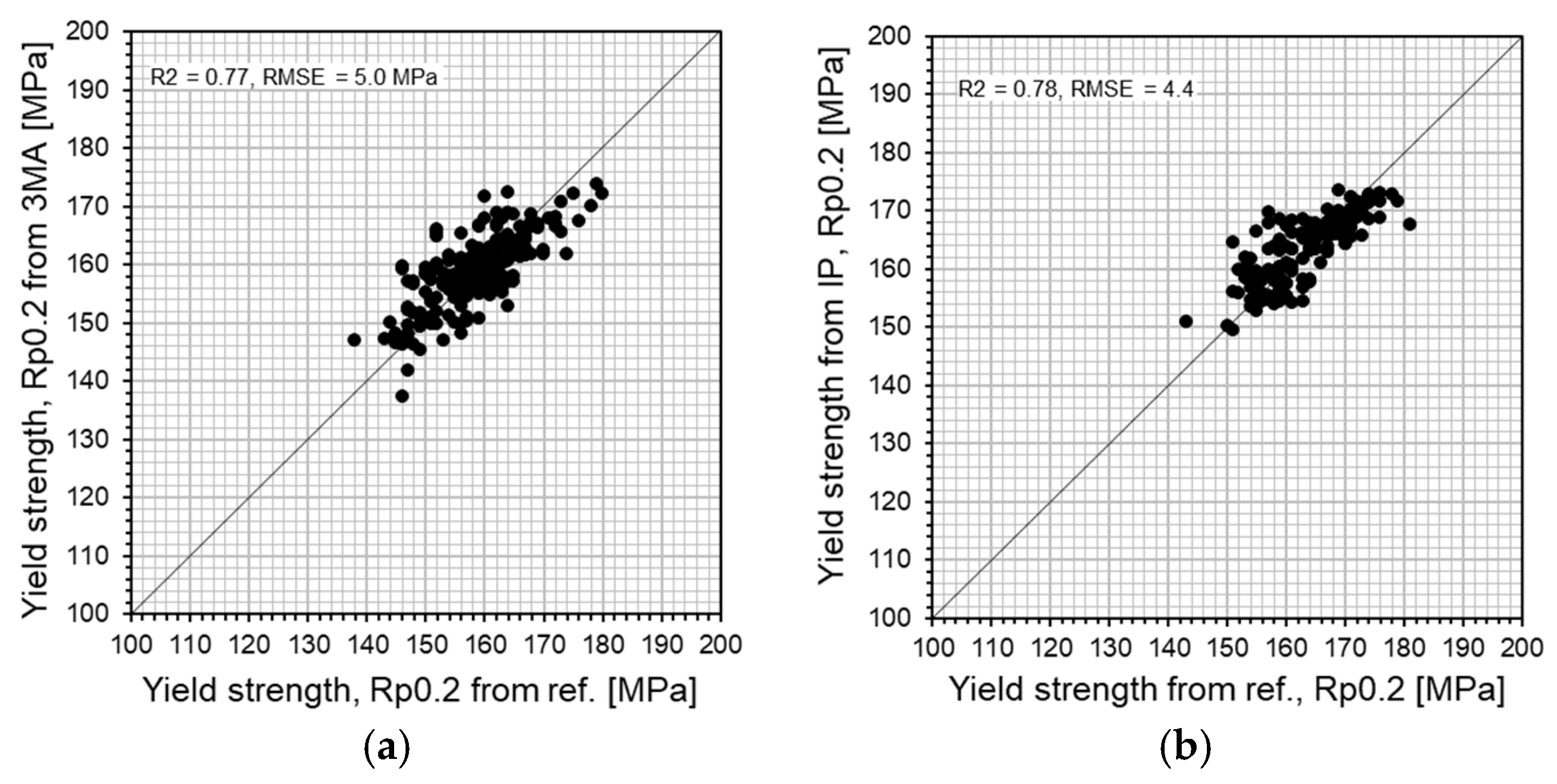

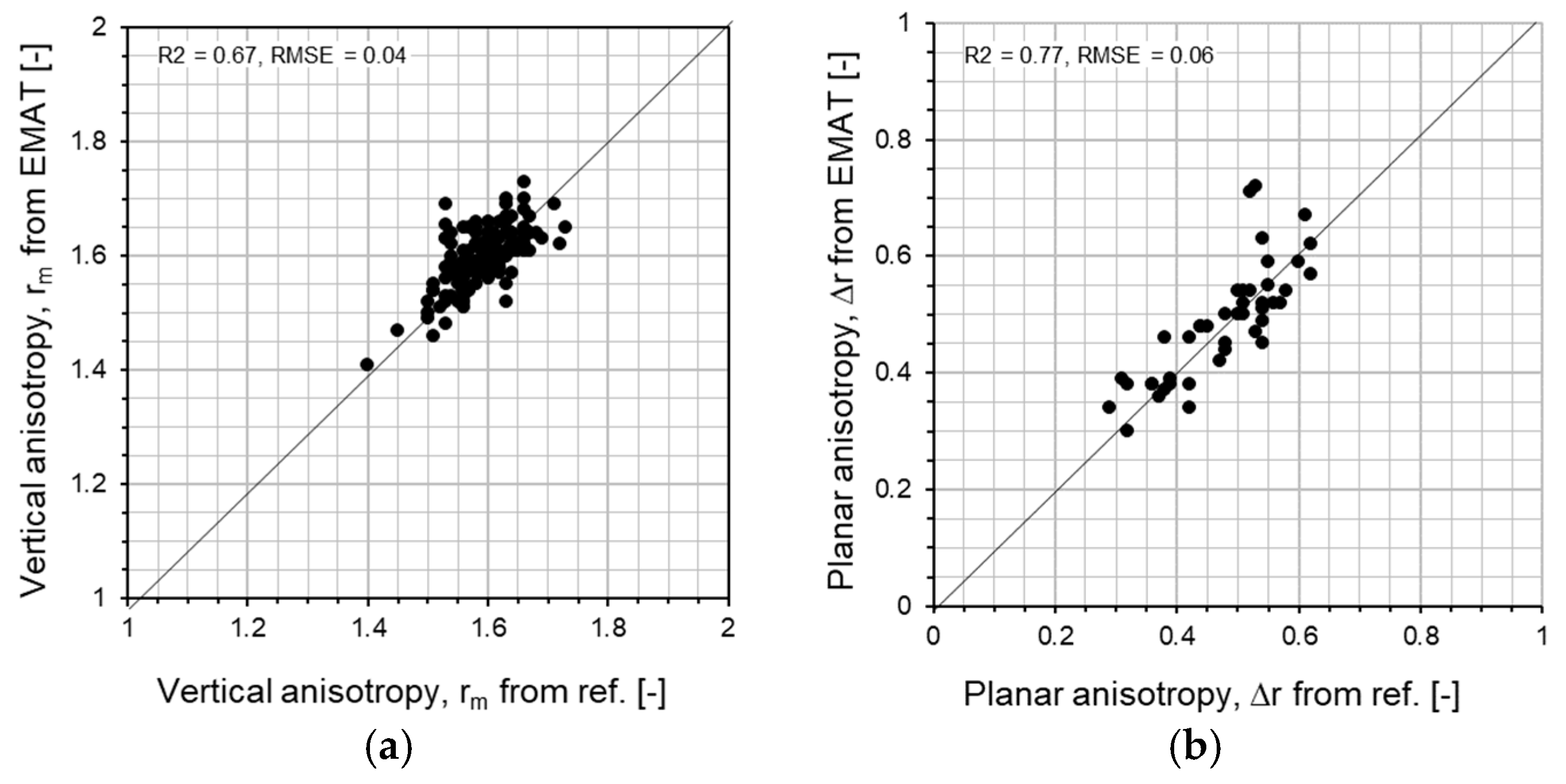

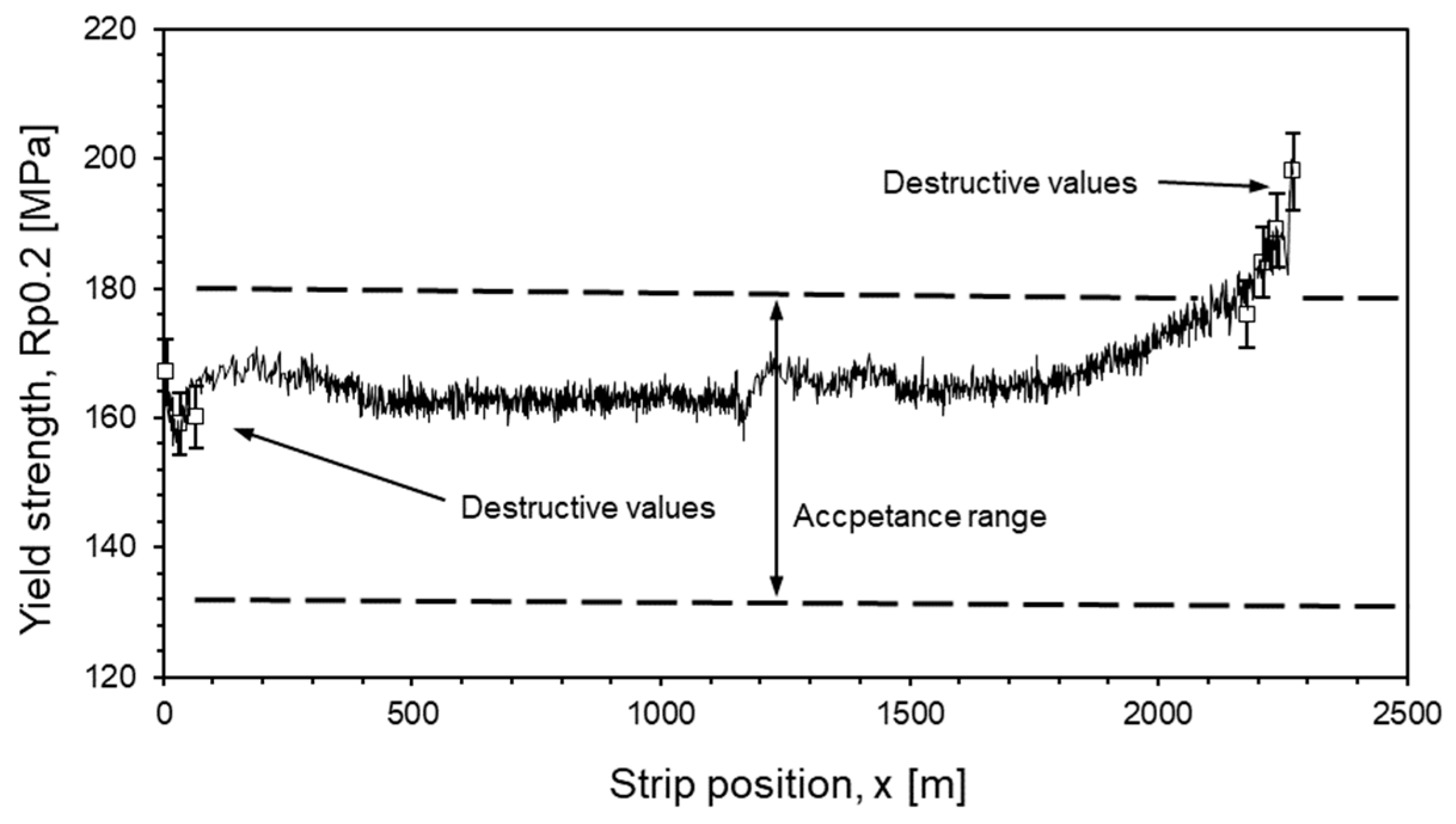

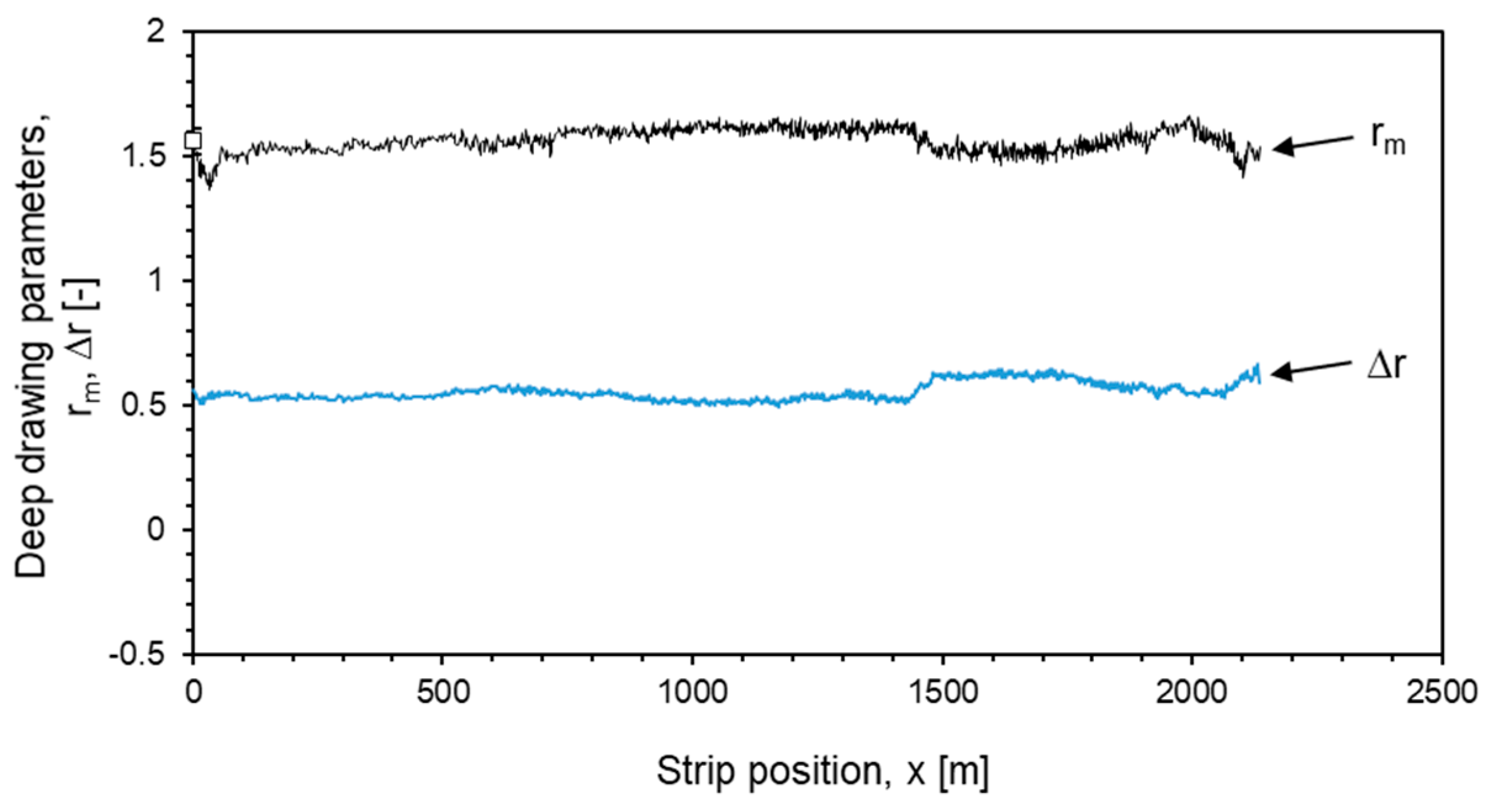

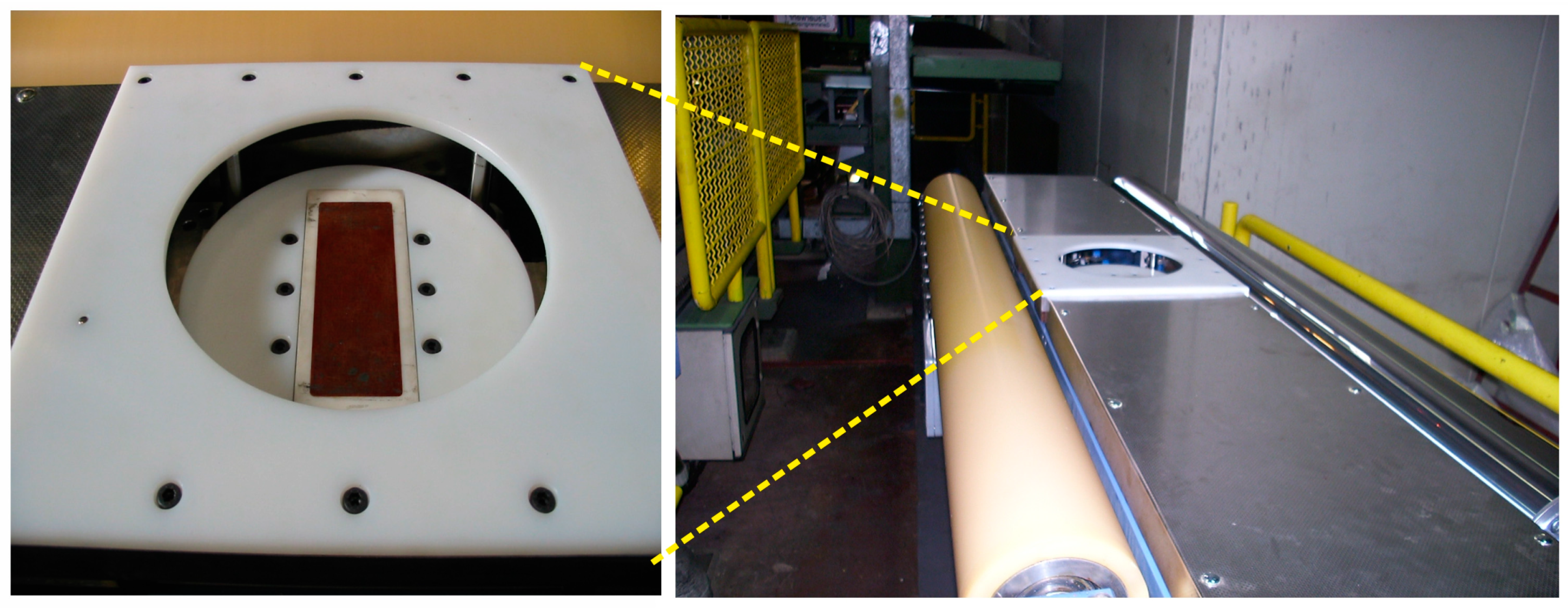

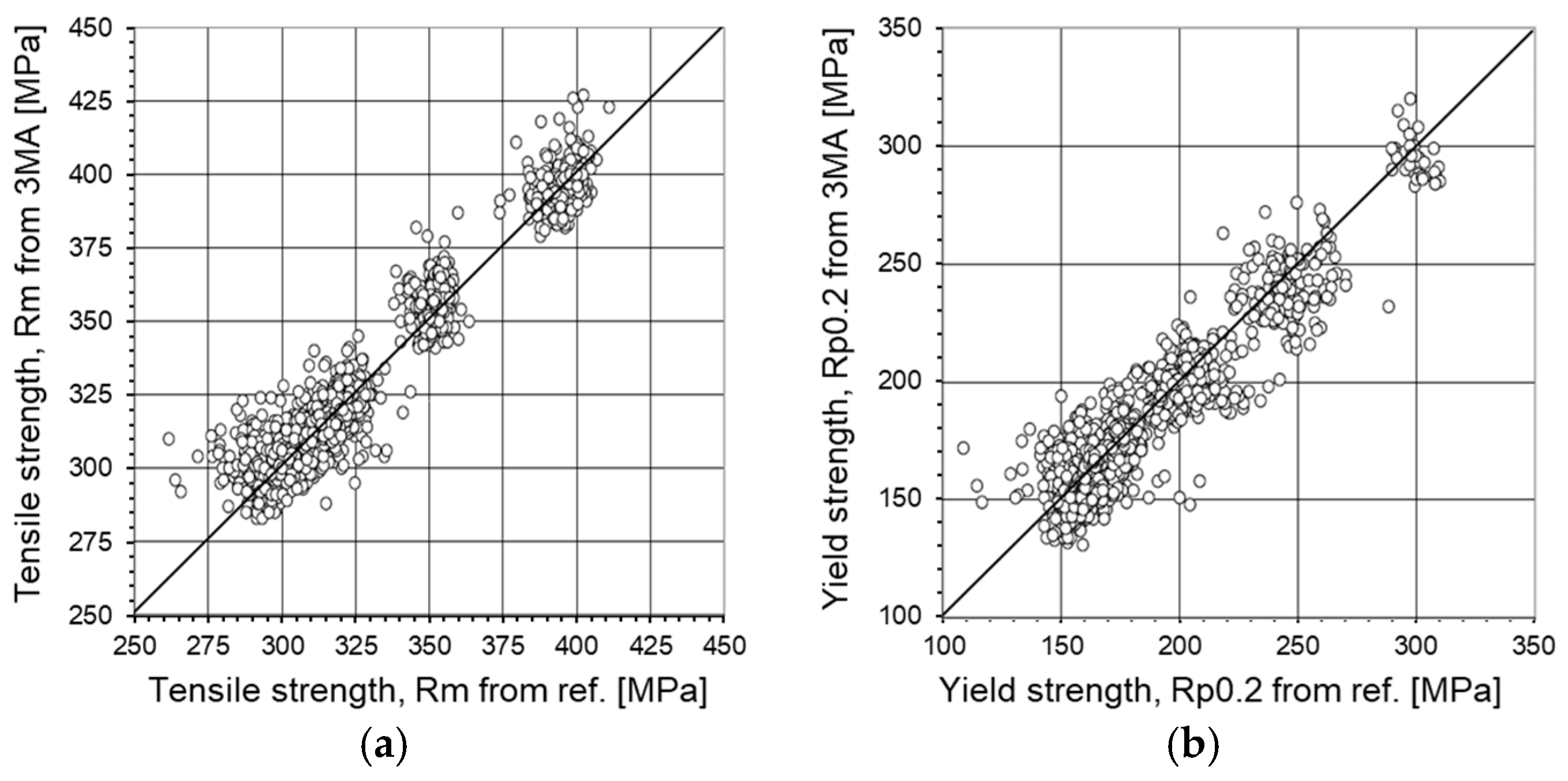

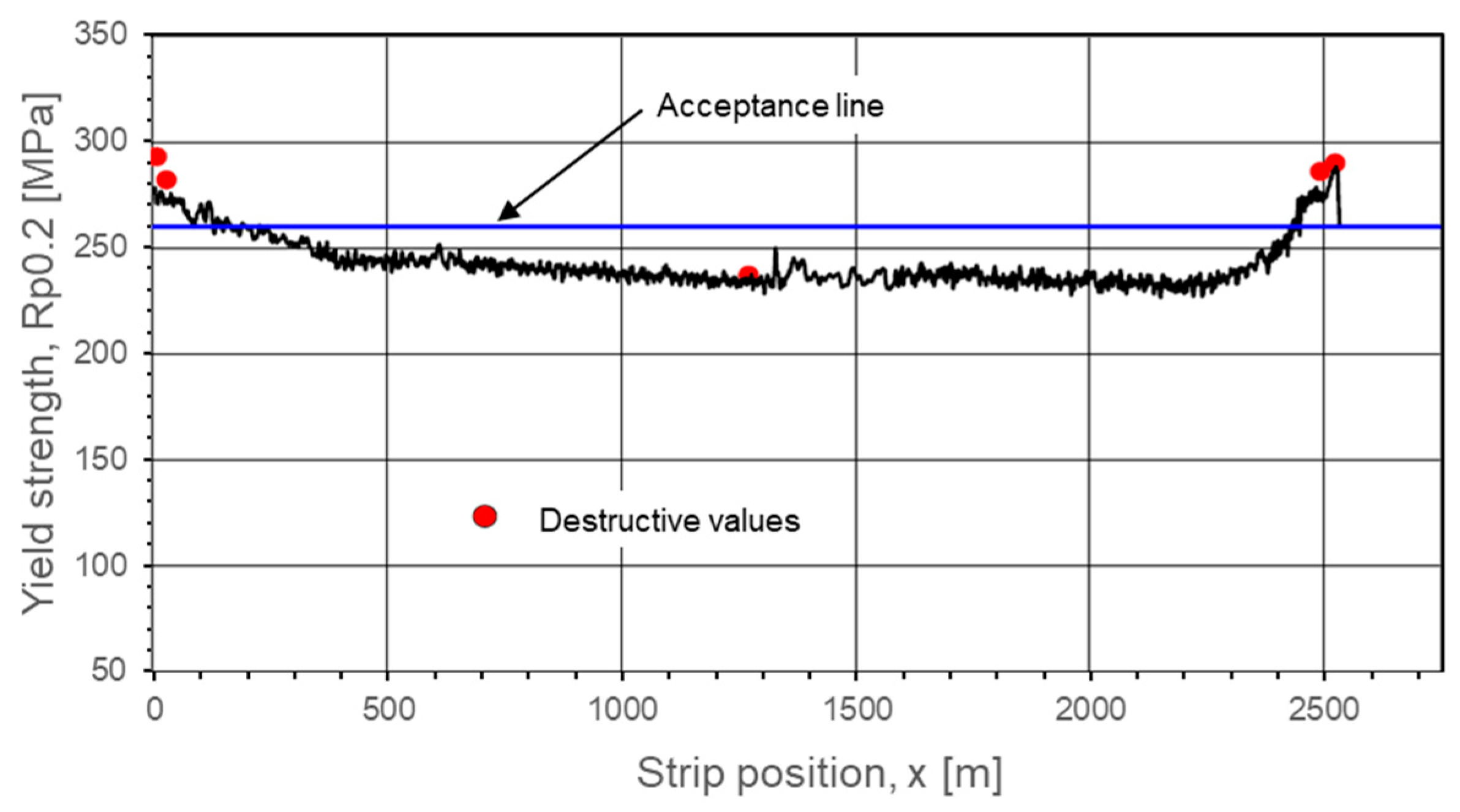

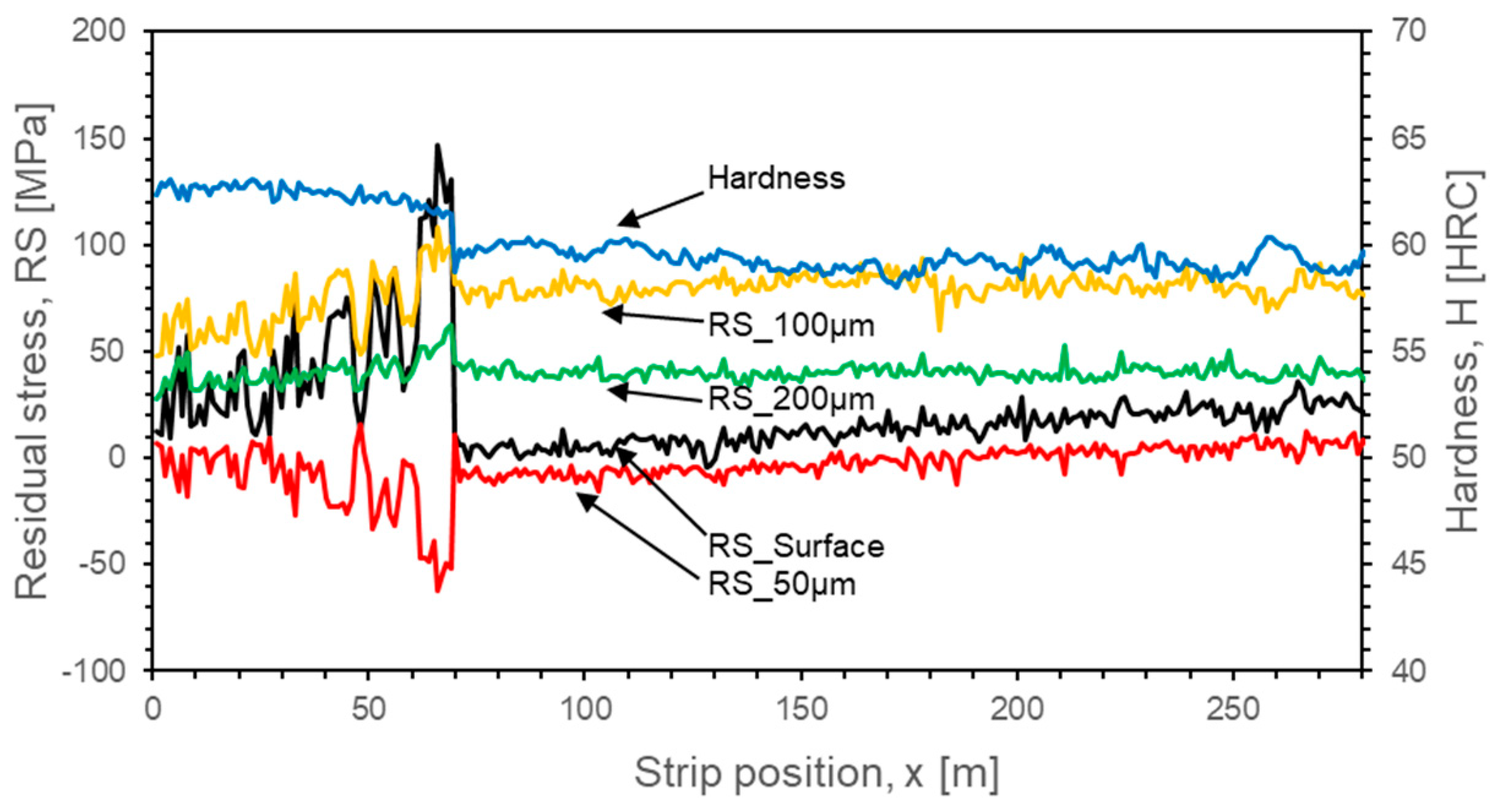

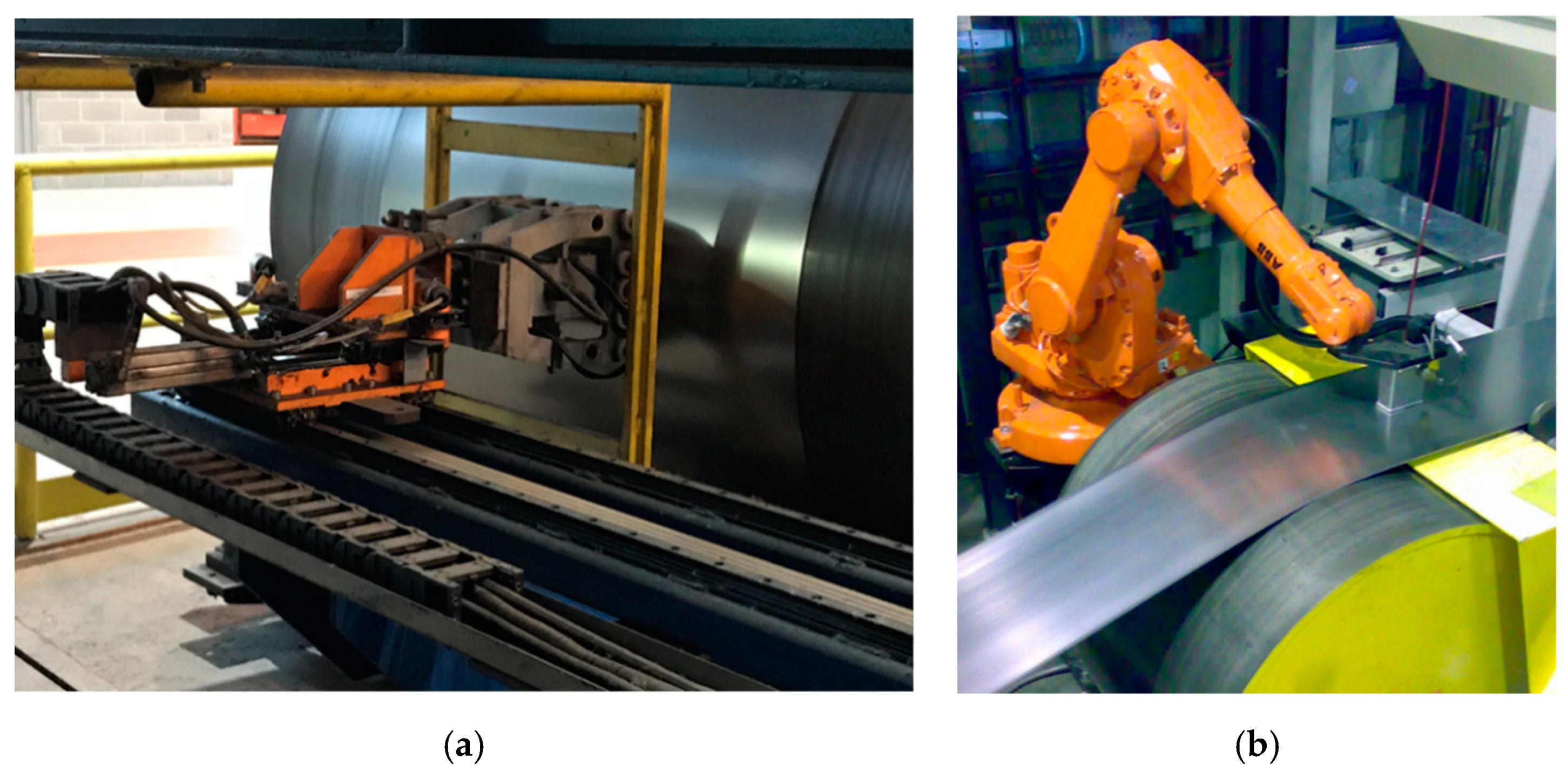

4.2.1. Inline Strip Steel Testing

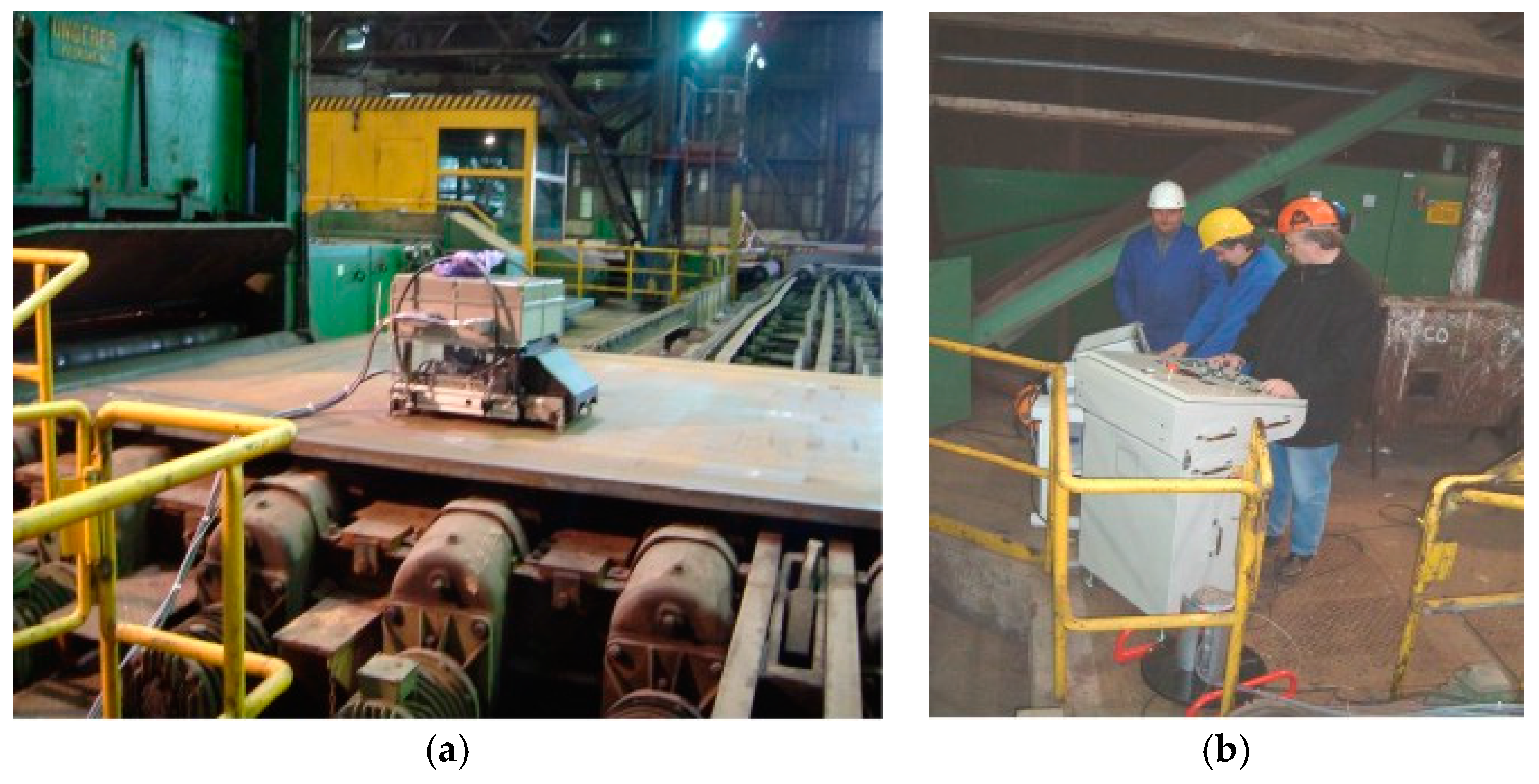

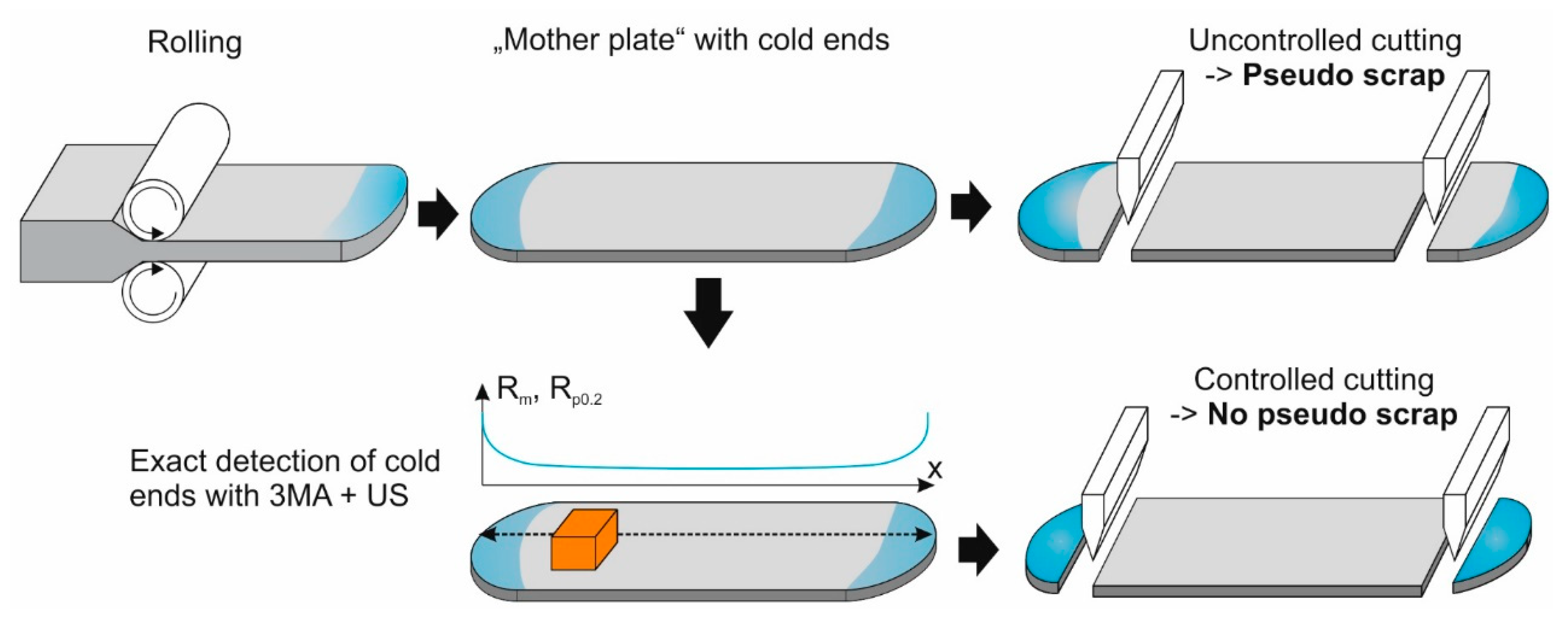

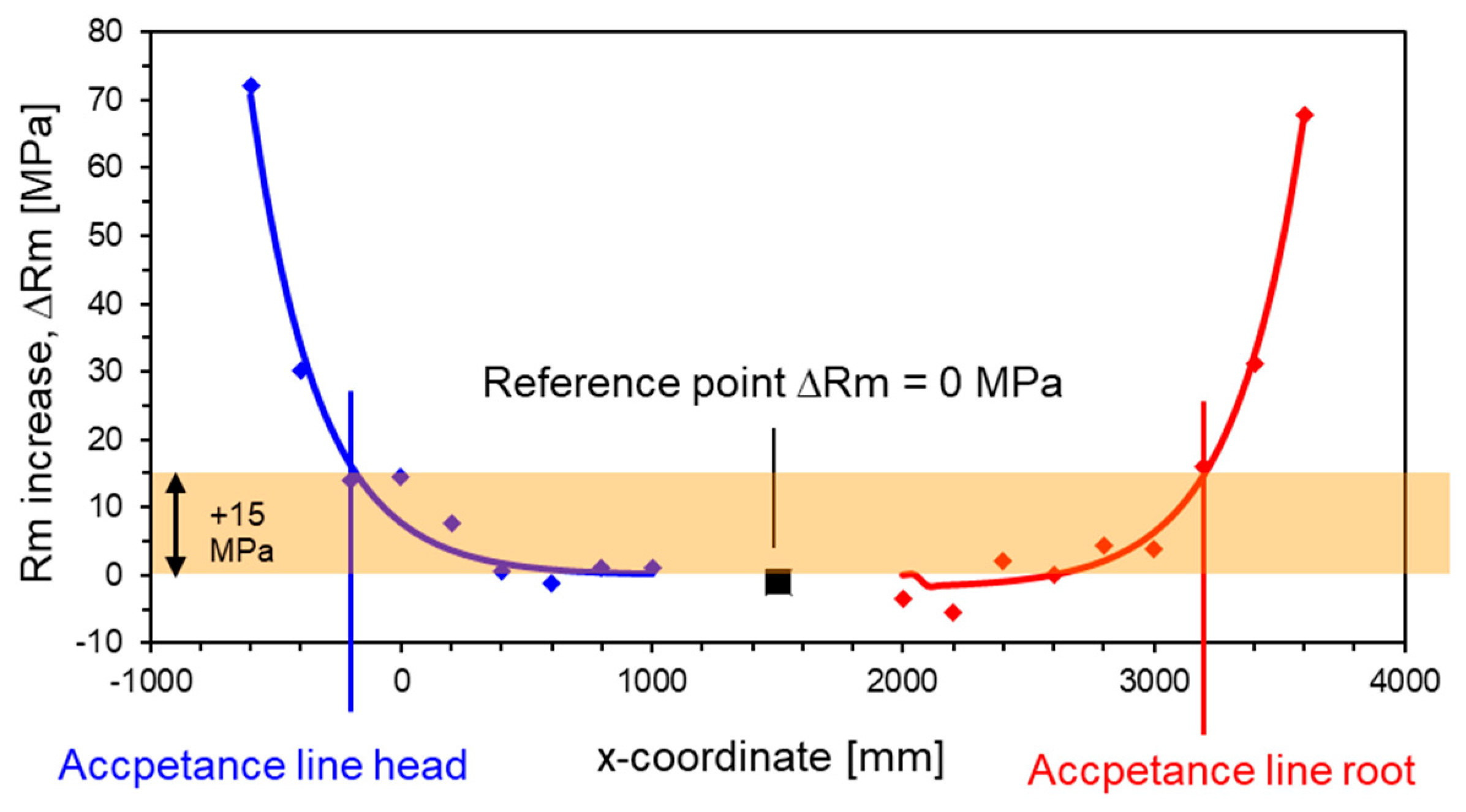

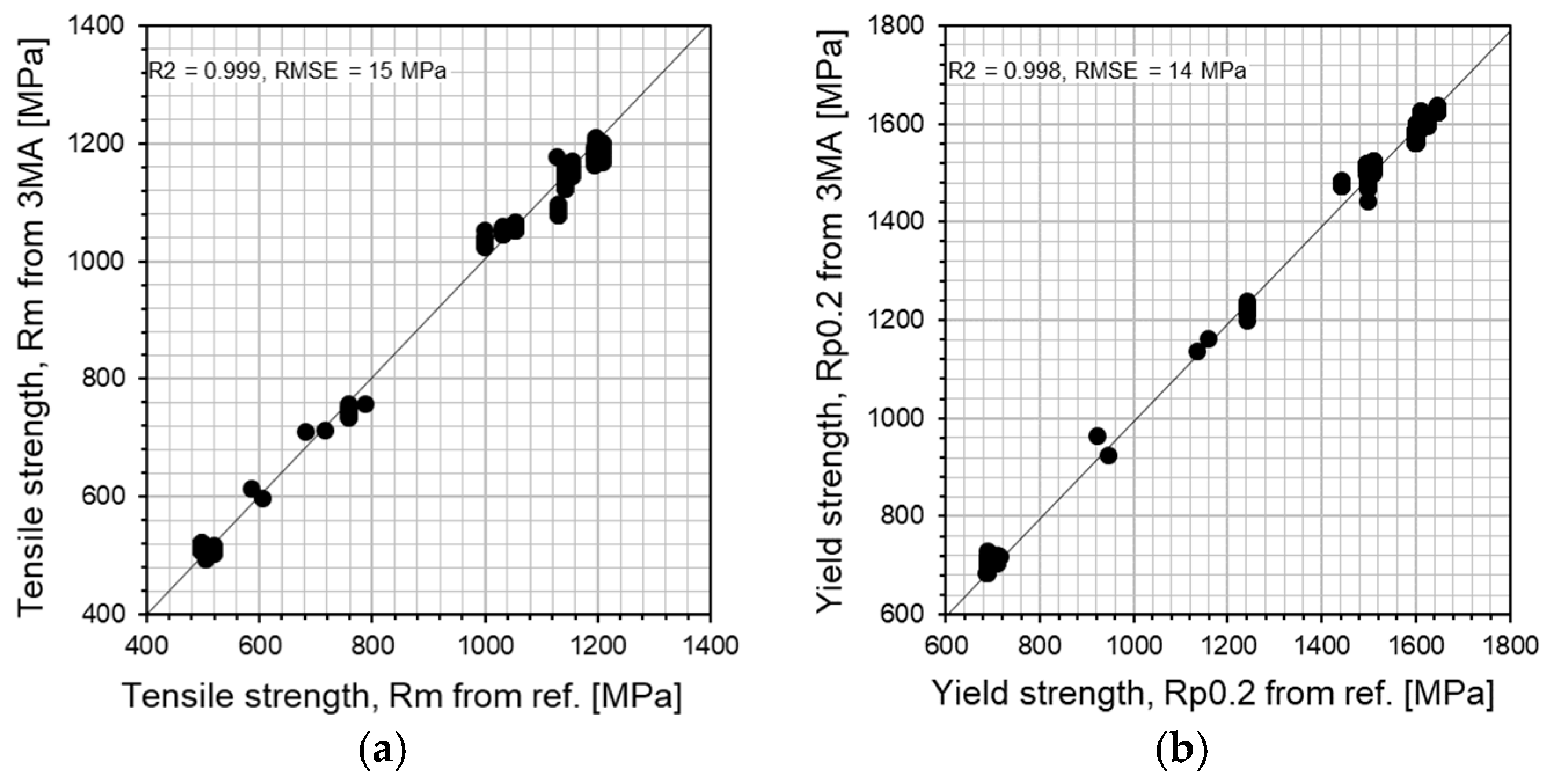

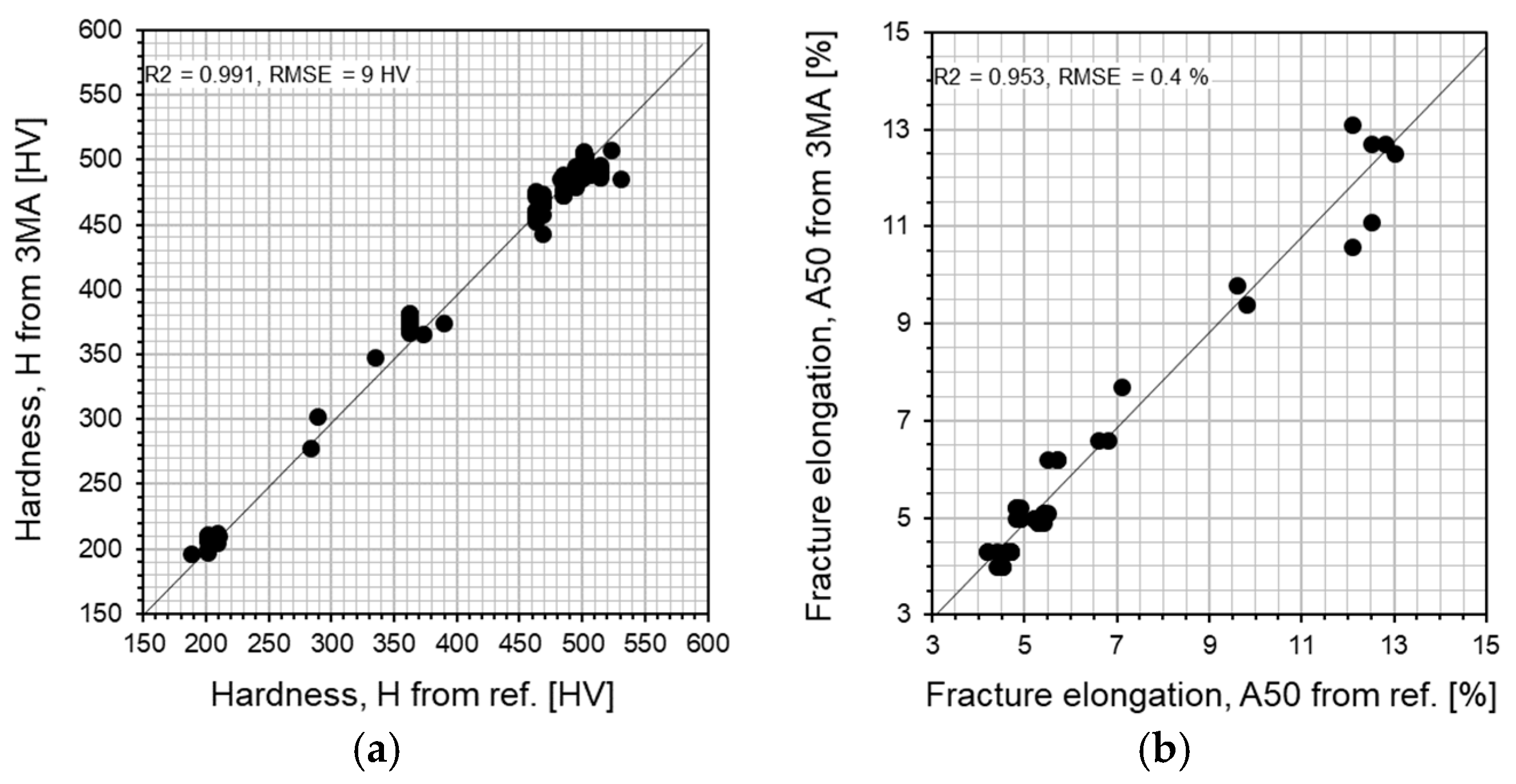

4.2.2. Heavy Plate Testing

4.3. Applications in the Automotive Industry

4.3.1. Car Body Parts

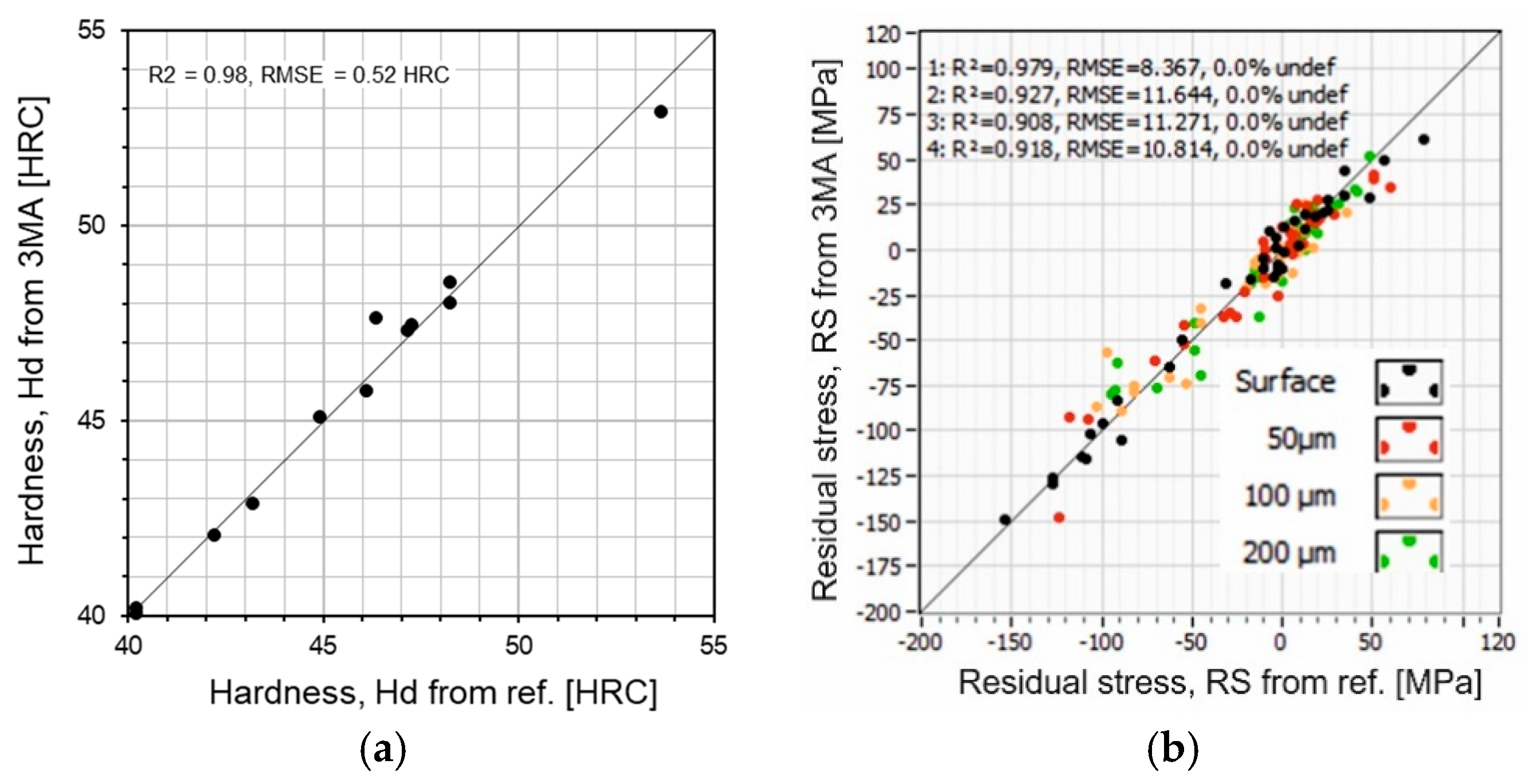

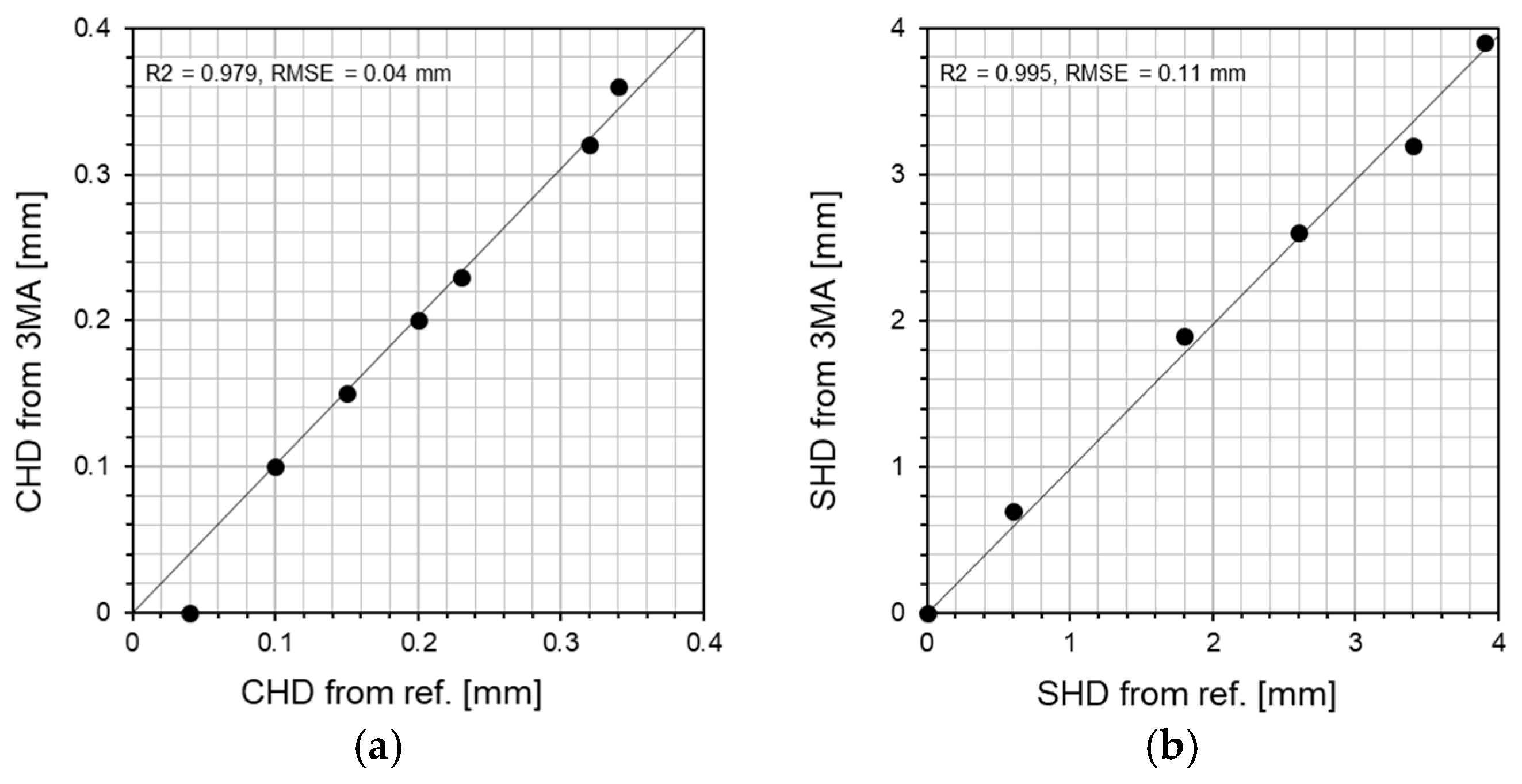

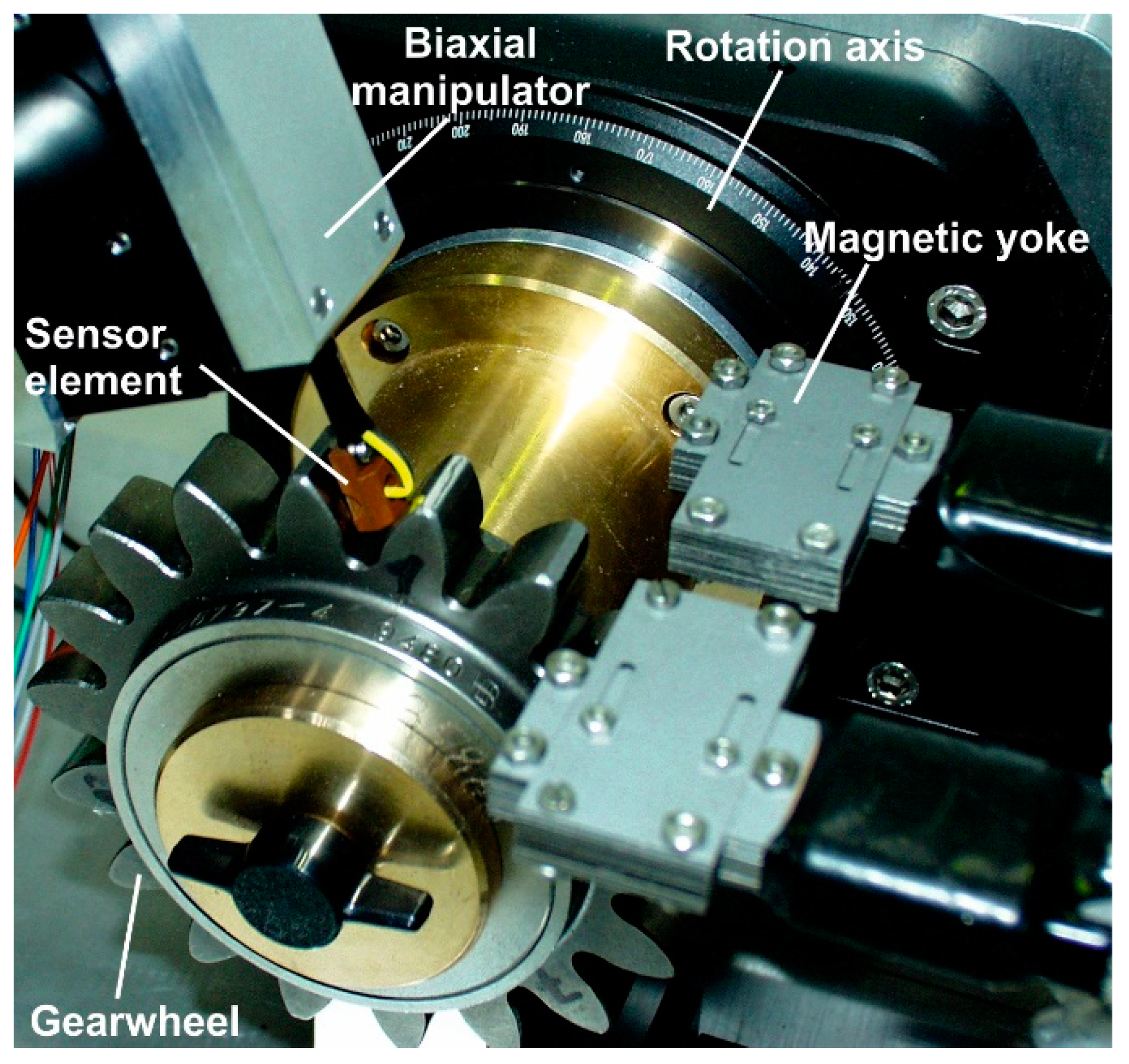

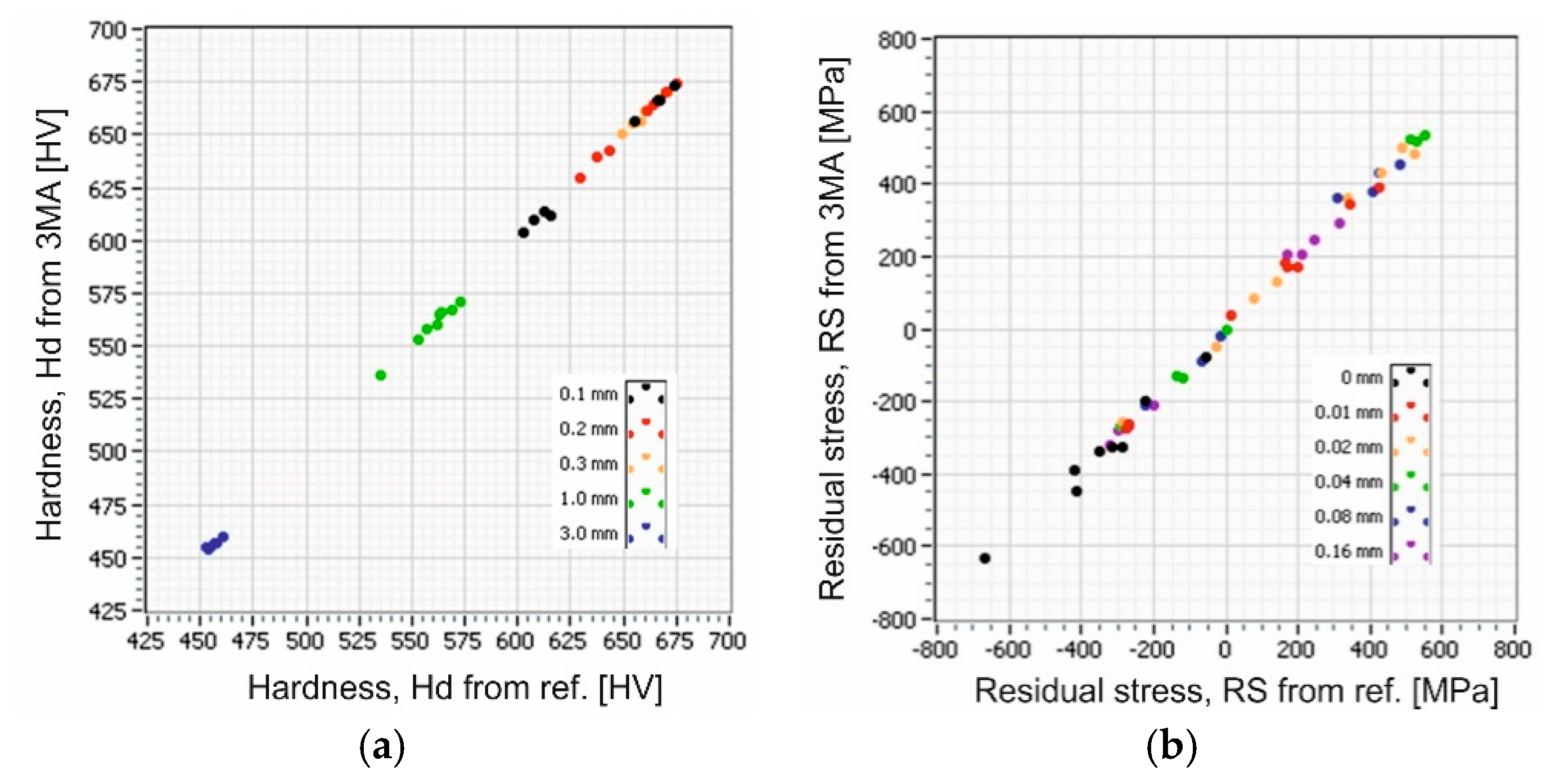

4.3.2. Surface-Hardened Parts and Machined Parts

5. Limitations

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ono, K.; Dobmann, G. Nondestructive testing, 1. general. In Ullmann’s Encyclopedia of Industrial Chemistry; Ono, K., Erhard, A., Eds.; Wiley: Hoboken, NJ, USA, 2000. [Google Scholar] [CrossRef]

- Hanke, R. Fraunhofer institute for non-destructive testing IZFP—Expanding the potential of NDT across the entire product life cycle. In Proceedings of the 55th Annual Conference of the British Institute of Non-Destructive Testing, NDT 2016, Nottingham, UK, 12–14 September 2016; pp. 305–308. [Google Scholar]

- Wolter, B.; Dobmann, G.; Boller, C. NDT Based Process Monitoring and Control. J. Mech. Eng. 2011, 57, 218–226. [Google Scholar] [CrossRef]

- Kersten, M. Special behavior of modulus of elasticity of ferro-magnetic materials. Z. für Metallkunde 1935, 5, 97–101. [Google Scholar]

- In Memoriam Friedrich Förster. Available online: https://www.ndt.net/article/ndtnet/2009/foerster.pdf (accessed on 6 March 2019).

- Föster, F. Ein messgerät zu schnellen bestimmung magnetischer größen. Z. für Metallkunde 1940, 32, 184–187. [Google Scholar]

- Förster, F.; Stambke, K. Magnetische untersuchungen innerer spannungen. Z. für Metallkunde 1941, 33, 97–104. [Google Scholar]

- Hainz, R. Beispiel einer einführung der elektromagnetischen sortierverfahren in die fertigung von dieseleinspritzpumpen und -düsen. Z. für Metallkunde 1955, 46, 358–370. [Google Scholar]

- Hatch, H.P.; Fowler, K.A. Electromagnetic Method for Nondestructively Examining Components for Excessive Decarburization. Springfield Armory; Technical Report SA-TR19-1508; Springfield Armory: Springfield, MA, USA, 14 April 1964. [Google Scholar]

- Leep, R.W.; Pasley, R. Method and System for Investigating the Stress Condition of Magnetic Materials. U.S. Patent No. US3427872, 18 February 1969. [Google Scholar]

- Kronmüller, H. Magnetic Techniques for the Study of Dislocations in Ferromagnetic Materials. Int. J. NDT 1972, 3, 315–350. [Google Scholar]

- Förster, F. Messung physikalischer und mechanisch-technologischer Werkstoffeigenschaften mit zerstörungsfreien Methoden. In Proceedings of the Jahrestagung der DGZfP-Jahrestagung 1973, Salzburg, Austria, 18–19 October 1973. [Google Scholar]

- Förster, F.; Köster, W. Messung physikalischer und technologischer Materialeigenschaften mit Hilfe magnetischer und elektromagnetischer Meßmethoden. Industrie Anzeiger 1974, 96, 687–690. [Google Scholar]

- Tiitto, S. On the mechanism of magnetization transitions in steel. IEEE Trans. Magn. 1978, 14, 527–529. [Google Scholar] [CrossRef]

- Matzkanin, G.A.; Beissner, R.E.; Teller, C.M. The Barkhausen Effect and Its Applications to Nondestructive Evaluation; NTIAC Publications 79-2; Southwest Research Institute, SwRI: San Antonio, TX, USA, 1979. [Google Scholar]

- Theiner, W.A.; Grossmann, J.; Repplinger, W. Zerstoerungsfreier Nachweis von Spannungen insbesondere Eigenspannungen mit magnetostriktiv angeregten Ultraschallwellen, Messung der Magnetostriktion mit DMS bzw. mittels des Barkhausenrauschens. In Proceedings of the Internationales Symposium Neue Verfahren der zerstoerungsfreien Werkstoffpruefung und deren Anwendung insbesondere in der Kerntechnik, Berlin, Germany, 17–19 September 1979. [Google Scholar]

- Theiner, W.A.; Schorr, P.; Reimringer, B.; Deimel, P.; Herz, K.; Kuppler, D. Bestimmung der Mikrogefüge von Druckbehälterstählen mit Magnetisch Induzierten Messgrößen; Berichts Nr. 800413-TW; Fraunhofer IZFP: Saarbrücken, Germany, 1980. [Google Scholar]

- Theiner, W.A.; Ayere, Q.; Salzburger, H.-J.; Herz, K.; Kuppler, D.; Deimler, P. Neue Verfahrensansaetze fuer die magnetische und magnetoelastische Gefuegepruefung. In Proceedings of the Internationale Konferenz über Zerstörungsfreie Prüfung in der Kerntechnik, Lindau, Germany, 1 April 1981. [Google Scholar]

- Theiner, W.A.; Altpeter, I.; Becker, R.; Herz, R.; Repplinger, W. Eigenspannungsmessung an Stahl der Guete 22 NiMoCr 3 7 mit magnetischen und magnetoelastischen Pruefverfahren. In Proceedings of the Internationale Konferenz über Zerstörungsfreie Prüfung in der Kerntechnik, Lindau, Germany, 1 April 1981. [Google Scholar]

- Tiitto, S. Über die Zerstörungsfreie Ermittlung der Eigenspannungen in ferromagnetischen Stählen. In Eigenspannungen: Entstehung, Berechnung, Messung, Bewertung; Deutsche Gesellschaft für Metallkunde: Oberursel, Germany, 1980; pp. 261–270. [Google Scholar]

- Dobmann, G. Physical basics and industrial applications of 3MA—Micromagnetic multiparameter microstructure and stress analysis. In Proceedings of the 10th European Conference on Nondestructive Testing, ECNDT 2010, Moscow, Russia, 7–11 June 2010. [Google Scholar]

- Becker, R.; Dobmann, G.; Rodner, C. Quantitative eddy current variants for micromagnetic microstructure multiparameter analysis-3MA. Rev. Prog. Quant. Nondestruct. Eval. 1987, 7B, 1703–1707. [Google Scholar]

- Dobmann, G.; Pitsch, H. Magnetic tangential field-strength-inspection, a further ndt-tool for 3MA. In Proceedings of the 3rd International Symposium on Nondestructive Characterization of Materials, Saarbrücken, Germany, 3–6 October 1988; pp. 636–643. [Google Scholar]

- Adler, E.; Pfeiffer, H. The influence of grain size and impurities on the magnetic properties of the soft magnetic alloy 47.5%NiFe. IEEE Trans. Magn. 1974, 10, 172–174. [Google Scholar] [CrossRef]

- Höller, P. Nondestructive analysis of structure and stresses by ultrasonic and micromagnetic methods. In Nondestructive Characterization of Materials II; Green, R.E., Kozaczek, K.J., Ruud, C., Eds.; Springer: Boston, MA, USA, 1987; pp. 211–212. [Google Scholar]

- Altpeter, I.; Dobmann, G.; Theiner, W.A. Quantitative hardening-depth-measurements up to 4 mm by means of micromagnetic microstructure multiparameter analysis-3MA. Rev. Prog. Quant. Nondestruct. Eval. 1987, 7B, 1471–1475. [Google Scholar]

- Becker, R.; Döring, W. Ferromagnetismus; Springer: Berlin, Germany, 1939. [Google Scholar]

- Kersten, M. Zur Theorie der Koerzitivkraft. Z. Phys. 1948, 124, 714–741. [Google Scholar] [CrossRef]

- Néel, L. Effet des cavités et des inclusions sur le champ coercitif. Cah. Phys. 1944, 25, 21–44. [Google Scholar]

- Kittel, C. Theory of the structure of ferromagnetic domains in films and small particles. Phys. Rev. 1946, 70, 965–971. [Google Scholar] [CrossRef]

- Néel, L. Théorie des lois d’aimantation de Lord Rayleigh. 2ère partie: Multiples domaines et champ coercitif. Cah. Phys. 1943, 13, 18–30. [Google Scholar]

- Guillaud, C. Propriétés ferromagnétiques des alliages manganèse-antimoine et manganèse-arsenic. Ann. Phys. 1949, 12, 671–703. [Google Scholar] [CrossRef]

- Weil, L.; Marfoure, S. Variation thermique du champ coercitif du nickel aggloméré. J. Phys. Radium 1947, 8, 358–361. [Google Scholar] [CrossRef]

- Hoslitz, K.; Sucksmith, A. Magnetic study of the two-phase iron-nickel alloys. Proc. R. Soc. Lond. 1943, 181, 303–313. [Google Scholar]

- Dobmann, G. Non-Destructive Testing for Ageing Management of Nuclear Power Components. In Nuclear Power-Control, Reliability and Human Factors; Tsvetkov, P., Ed.; InTech: Zagreb, Croatia, 2011; pp. 311–338. [Google Scholar]

- Alpeter, I.; Dobmann, G.; Hübschen, G.; Kopp, M.; Tschuncky, R. Nondestructive characterization of neutron induced embrittlement in nuclear pressure vessel steel microstructure by using electromagnetic testing. In Electromagnetic Nondestructive Evaluation XIV, Proceedings of the International Workshop on Electromagnetic Nondestructive Evaluation, Szczecin, Poland, 13–16 June 2010; Chady, T., Gratkowski, S., Takagi, T., Udpa, S.S., Eds.; IOS Press: New York, NY, USA, 2011; pp. 322–329. [Google Scholar]

- Theiner, W.A.; Deimel, P. Non-destructive testing of welds with the 3MA-analyzer. Nuclear Eng. Des. 1987, 102, 257–264. [Google Scholar] [CrossRef]

- Becker, R.; Dobmann, G.; Theiner, W.A. Progress in the micromagnetic multiparameter microstructure and stress analysis—3MA. In Nondestructive Characterization of Materials III, Proceedings of the International Symposium on Nondestructive Characterization of Materials, Saarbruecken, Germany, 3–6 October 1988; Höller, P., Ed.; Springer: Berlin, Germany, 1989; pp. 515–523. [Google Scholar]

- Wolter, B. Zerstörungsfrei prüfen. Automobil Entwicklung 2004, Mai 2004, 58. [Google Scholar]

- Wolter, B.; Theiner, W.A.; Kern, R.; Becker, R.; Rodner, C.; Kreier, P.; Ackeret, P. Detection and quantification of grinding damage by using EC and 3MA techniques. In Proceedings of the ICBM4—4th International Conference on Barkhausen Noise and Micromagnetic Testing, Brescia, Italy, 3–4 July 2003. [Google Scholar]

- Wolter, B. Zerstörungsfreie charakterisierung von schleifbrand. In Proceedings of the VDI-Fachtagung Windkraftanlagen—Sicherheit und Zuverlässigkeit, Darmstadt, Germany, 4 November 2004. [Google Scholar]

- Alpeter, I.; Boller, C.; Kopp, M.; Wolter, B.; Fernath, R.; Hirninger, B.; Werner, S. Zerstörungsfreie Detektion von Schleifbrand mittels elektromagnetischer Prüftechniken. In Proceedings of the DGZfP-Jahrestagung 2011, Bremen, Germany, 30 May–1 June 2011. [Google Scholar]

- Alpeter, I.; Kröning, M. Nondestructive determination of the hardening depth in inductive hardened steels. In Nondestructive Characterization of Materials VI; Green, R.E., Kozaczek, K.J., Ruud, C., Eds.; Plenum Press: New York, NY, USA, 1994; pp. 659–668. [Google Scholar]

- Dobmann, G.; Altpeter, I.; Wolter, B.; Kern, R. Industrial applications of 3MA—Micromagnetic multiparameter microstructure and stress analysis. In Electromagnetic Nondestructive Evaluation (XI)—ENDE 2007; Tamburino, A., Ed.; IOS Press: Amsterdam, The Netherlands, 2008; pp. 18–25. [Google Scholar]

- Cosarinsky, G.; Kopp, M.; Rabung, M.; Seiler, G.; Petragalli, A.; Vega, D.; Sheikh-Amiri, M.; Ruch, M.; Boller, C. Non-destructive characterisation of laser-hardened steels. Insight 2014, 56, 553–559. [Google Scholar] [CrossRef]

- Dobmann, G.; Kröning, M.; Koblé, T.D. Steel-grading by micromagnetic techniques. In Nondestructive Characterization of Materials V; Green, R.E., Ed.; Plenum Press: New York, NY, USA, 1992; pp. 615–621. [Google Scholar]

- Ewen, M.; Blaes, N.; Bokelmann, D.; Braun, P.; Conrad, C.; Gabi, Y.; Kern, R.; Kopp, H.; Wolter, B. Nondestructive determination of mechanical properties of open-die forgings and potentials for full implementation in production process chain. In Proceedings of the 11th European Conference on Nondestructive Testing, ECNDT 2014, Prague, Czech Republic, 6–10 October 2014. [Google Scholar]

- Alpeter, I. Nondestructive evaluation of cementite content in steel and white cast iron using inductive Barkhausen noise. J. Nondestruct. Eval. 1996, 15, 45–60. [Google Scholar] [CrossRef]

- Maisl, U.; Kopp, M.; Altpeter, I. Electromagnetic testing methods for the detection of tendency to chilling. Cast. Plant Technol. Int. 1999, 15, 44–47. [Google Scholar]

- Maisl, U.; Frauendorfer, R.; Kopp, M.; Altpeter, I. Zerstörungsfreies prüfverfahren zur bestimmung von werkstoffeigenschaften von gußeisen. Gießerei Praxis 2000, Heft 3, 113–121. [Google Scholar]

- Borsutzki, M.; Dobmann, G.; Theiner, W.A. On-line ND-characterization and mechanical property determination of cold rolled stell strips. In Advanced Sensors for Metals Processing; Brusey, B.W., Bussière, J.F., Dubois, M., Moreau, A., Eds.; Canadian Institute of Mining: Montreal, QC, Canada, 1999; pp. 77–84. [Google Scholar]

- Wolter, B.; Dobmann, G. Micromagnetic testing for rolled steel. In Proceedings of the 9th European Conference on Nondestructive Testing, ECNDT 2006, Berlin, Germany, 25–29 September 2006. [Google Scholar]

- Gabi, Y.; Wolter, B.; Gerbershagen, A.; Ewen, M.; Braun, P.; Martins, O. FEM simulations of incremental permeability signals of a multi-layer steel with consideration of the hysteretic behaviour of each layer. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Wolter, B.; Müller, T.; Behrens, B.-A.; Hübner, S.; Gaebel, C.M. Prüfsysteme zur prozessüberwachung beim Kragenziehen—Blechteilen geht es an den “Kragen”. QZ 2015, 60, 44–47. [Google Scholar]

- Wolter, B.; Straß, B.; Müller, T.; Behrens, B.-A.; Hübner, S.; Wölki, K. Einsatzmöglichkeiten von zerstörungsfreien sensortechniken innerhalb der wertschöpfungskette blechverarbeitung. In Proceedings of the 38. EFB-Kolloquium Blechverarbeitung 2018, Bad Boll, Germany, 17–28 April 2018. [Google Scholar]

- Wolter, B. Pressgehärtete karosserieteile zerstörungsfrei geprüft. Blechnet 2013, 5, 114–117. [Google Scholar]

- Conrad, C.; Goebel, M.; Kern, R.; Lambert, T.; Wolter, B. Nondestructive testing for quality assurance and monitoring in the press hardening process. In Proceedings of the Strategien des Karosseriebaus 2015, Bad Nauheim, Germany, 17–19 March 2015. [Google Scholar]

- Gabi, Y.; Wolter, B.; Kern, R.; Conrad, C.; Gerbershagen, A. Simulation of electromagnetic inspection techniques using FEM analysis. In Proceedings of the 19th World Conference on Nondestructive Testing—WCNDT 2016, Munich, Gemany, 13–17 June 2016. [Google Scholar]

- Gabi, Y.; Böttger, D.; Straß, B.; Wolter, B.; Conrad, C.; Leinenbach, F. local electromagnetic investigations on electrical steel FeSi 3% via 3MA micromagnetic NDT system. In Proceedings of the 12th European Conference on Nondestructive Testing, ECNDT 2018, Gothenburg, Sweden, 11–15 June 2018. [Google Scholar]

- Dobmann, G.; Seibold, A. First attempts towards the early detection of fatigued substructures using cyclic-loaded 20 MnMoNi 5 5 steel. Nucl. Eng. Des. 1992, 137, 363–369. [Google Scholar] [CrossRef]

- Dobmann, G.; Kröning, M.; Theiner, W.A.; Willems, H.; Fiedler, U. Nondestructive characterization of materials (ultrasonic and micromagnetic techniques) for strength and toughness prediction and the detection of early creep damage. Nucl. Eng. Des. 1995, 157, 137–158. [Google Scholar] [CrossRef]

- Lang, M.A. A way to detect hydorgen-induced stress corrosion cracking (HISCC) at an early stage. Matériaux Techniques 1998, 7–8, 27–32. [Google Scholar] [CrossRef]

- Borsutzki, M. Prozeßorientierte Ermittlung der Streckgrenze und der Tiefziehkenngrößen rm und Delta r an Kaltgewalztem, Feuerverzinktem Feinblech. Ph.D. Thesis, Saarland University, Saarbruecken, Germany, 1997. [Google Scholar]

- Salzburger, H.-J.; Niese, F.; Dobmann, G. Emat Pipe inspection with guided Waves. Weld World 2012, 56, 35–43. [Google Scholar] [CrossRef]

- Meilland, P.; Marmulev, A.; Wolter, B.; Conrad, C.; Hofmann, U.; Dussaulx, J.; Weber, W. European Commission. Combined Ultrasound and Micromagnetic Measurements for Non-Destructive Assessment of Textured Heavy Plate Properties (PLATEND); Final Report, Research Fund for Coal and Steel, Project ID: RFSR-CT-2005-00044, 2005-07-01 to 2008-06-30; Publications Office of the European Communities: Luxemburg, 1 June 2010. [Google Scholar]

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Neugebauer, R.; Schieck, F.; Polster, S.; Mosel, A.; Rautenstrauch, A.; Schönherr, J.; Pierschel, N. Press hardening—An innovative and challenging technology. Arch. Civ. Mech. Eng. 2012, 12, 113–118. [Google Scholar] [CrossRef]

- Wolter, B.; Conrad, C.; Kern, R.; Wicke, T.; Tonne, J. Industrial demands and nondestructive testing (NDT) solutions for process monitoring and quality control in hot and cold formed steel production. In Proceedings of the 5th International Conference Hot Sheet Metal Forming of High-Performance Steel, Toronto, ON, Canada, 31 May–3 June 2015. [Google Scholar]

- Neugebauer, R.; Wienera, T.; Zösch, A. Quality control of resistance spot welding of high strength steels. Procedia CIRP 2013, 12, 139–144. [Google Scholar] [CrossRef]

- Bastuck, M. In-Situ-Überwachung von Laserschweißprozessen Mittels Höherfrequenter Schallemissionen, Dissertation. Ph.D. Thesis, Saarland University, Saarbruecken, Germany, 2016. [Google Scholar]

- Kern, R.; Theiner, W.-A.; Höller, P. Residual stress- and microstructure anisotropies in laser-hardened or shot peened surfaces. In Proceedings of the 9th International Conference on Experimental Mechanics, Lyngby, Denmark, 20–24 August 1990. [Google Scholar]

- Kern, R.; Theiner, W.-A. Non-destructive magnetic testing of laser hardening parameters. In Laser Treatment of Materials; Mordlike, B., Ed.; Deutsche Gesellschaft für Materialkunde (DGM): Oberursel, Germany, 1987; pp. 427–434. [Google Scholar]

- Schwienbacher, S.; Wolter, B. Randzonentragfähigkeit-Zahnflanke-Ermittlung und Charakterisierung von Randzonen-Kennwerten und -eigenschaften und deren Einfluss auf die Flankentragfähigkeit einsatzgehärteter, geschliffener Zahnräder-Abschlussbericht Forschungsvorhaben Nr. 453 (AVIF-Nr. A200); Forschungsvereinigung Antriebstechnik e.V. (FVA): Frankfurt am Main, Germany, 2007. [Google Scholar]

- Gabi, Y.; Martins, O.; Wolter, B.; Strass, B. Combination of electromagnetic measurements and FEM simulations for nondestructive determination of mechanical hardness. AIP Adv. 2017, 8. [Google Scholar] [CrossRef]

- Gabi, Y. Modélisation FEM du Système de Contrôle non Destructif 3MA en Ligne de Production des Aciers Dual Phase. Ph.D. Thesis, Grenoble University, Grenoble, France, 2012. [Google Scholar]

- Meilland, P.; Lombard, A. Improved modelling of the 3MA system’s incremental permeability for on-line steel strip property assessment. In Proceedings of the 19th World Conference on Nondestructive Testing—WCNDT 2016, Munich, Gemany, 13–17 June 2016. [Google Scholar]

| Measuring Parameter | Description |

|---|---|

| A1 | Amplitude of the fundamental wave. |

| A3, A5, A7, A9 | Amplitudes of the 3rd, 5th, 7th and 9th harmonics. |

| P3, P5, P7, P9 | Phases of the 3rd, 5th, 7th and 9th harmonics. |

| UHS | Sum of all upper harmonics, |

| K | Distortion factor, |

| HCO | Coercive magnetic field from harmonic analysis |

| Hro | Harmonic content of the magnetic field strength at zero crossing |

| Vmag | Final stage voltage of the electromagnet |

| Measuring Parameter | Description |

|---|---|

| Re1–Re4 | Real parts of EC signals at frequencies 1, 2, 3 and 4. |

| Im1–Im4 | Imaginary parts of EC signals at frequencies 1, 2, 3 and 4. |

| Mag1–Mag4 | Signal magnitudes at frequencies 1, 2, 3 and 4. |

| Ph1–Ph4 | Signal phases at frequencies 1, 2, 3 and 4. |

| Measuring Parameter | Description |

|---|---|

| MMAX | Maximum amplitude |

| MMEAN | Amplitude averaged over one magnetization cycle |

| MR | Amplitude at remanence point |

| HCM | Coercive magnetic field, derived from Barkhausen Noise (magnetic field strength at M = MMax) |

| DH25M | Curve width at 25% of MMAX |

| DH50M | Curve width at 50% of MMAX |

| DH75M | Curve width at 75% of MMAX |

| Measuring Parameter | Description |

|---|---|

| µMAX | Maximum amplitude |

| µMEAN | Amplitude averaged over one magnetization cycle |

| µR | Amplitude at remanence point |

| HCµ | Coercive magnetic field, derived from Incremental Permeability (magnetic field strength at µ = µMax) |

| DH25µ | Curve width at 25% of µMAX |

| DH50µ | Curve width at 50% of µMAX |

| DH75µ | Curve width at 75% of µMAX |

| No. | Component | Main Application/Description | Ref. |

|---|---|---|---|

| 1 | Components in nuclear power plants | Materials damage and degradation; Neutron-induced embrittlement | [35,36] |

| 2 | Welds (laser, etc.), turbine blades, bearing rings, etc. | Hardness and residual stress | [37,38,39] |

| 3 | Machined parts (gear wheels, etc.) | Thermally induced material damage due to machining | [40,41,42] |

| 4 | Surface hardened or nitrated parts | Hardening depth, depth profiles of hardness and residual stress, retained austenite content | [43,44,45] |

| 5 | Steel grades | Classification of steel grades and microstructure variants | [46,47] |

| 6 | Cast iron | Residual stress, cementite content, primary chill, microstructure gradient | [48,49,50] |

| 7 | Strip steel | Mechanical properties, microstructure features (texture, grain size) and residual stress | [51,52] |

| 8 | Heavy plate and forged parts | Mechanical properties, microstructure features, residual stress, hard spots | [52,53] |

| 9 | Cold formed steel sheets | Residual stress and spring back angle | [54,55] |

| 10 | Hot formed steel sheets | Mechanical properties of steel, coating thickness, resistance spot weld size | [56,57] |

| 11 | Electrical steel | Inspection of cut edges; cutting quality | [57,58] |

| 12 | Miscellaneous | Hydrogen-induced embrittlement, fatigue, toughness, notch impact strength, creep damage | [59,60,61,62] |

| Steel Grade Class | RMSE of Rm [MPa] | RMSE of Rp0.2 [MPa] | No. of Strips |

|---|---|---|---|

| IF, conventional | 5.4 | 8.2 | 2667 |

| IF, high strength | 11.3 | 12.3 | 7764 |

| Bakehardening | 5.8 | 8.8 | 1294 |

| Structural | 7.9 | 10.1 | 164 |

| Steel Grade Class | RMSE of Rm [MPa] | RMSE of Rp0.2 [MPa] | No. of Strips |

|---|---|---|---|

| IF, conventional | 5.3 | 7.4 | 1985 |

| IF, high strength | 6.8 | 9.3 | 68 |

| Bakehardening | 11.2 | 15.6 | 55 |

| Structural | 7.5 | 12.4 | 34 |

| Steel Grade | Residual Stress, RS | |||

|---|---|---|---|---|

| At the Surface | At 50 µm Depth | At 100 µm Depth | At 200 µm Depth | |

| RMSE [MPa] | RMSE [MPa] | RMSE [MPa] | RMSE [MPa] | |

| 75Cr1 | 47 | 1 | 3 | 4 |

| 80CrV2 | 15 | 1 | 9 | 31 |

| 50CrMo4 | 4 | 4 | 4 | 11 |

| Parameters in Calibration Functions | RMSE of Rm [MPa] | RMSE of Rp0.2 [MPa] | RMSE of Hardness [HB] |

|---|---|---|---|

| Only 3MA parameters | 12 | 23 | 5 |

| 3MA and US parameters | 10 | 11 | 4 |

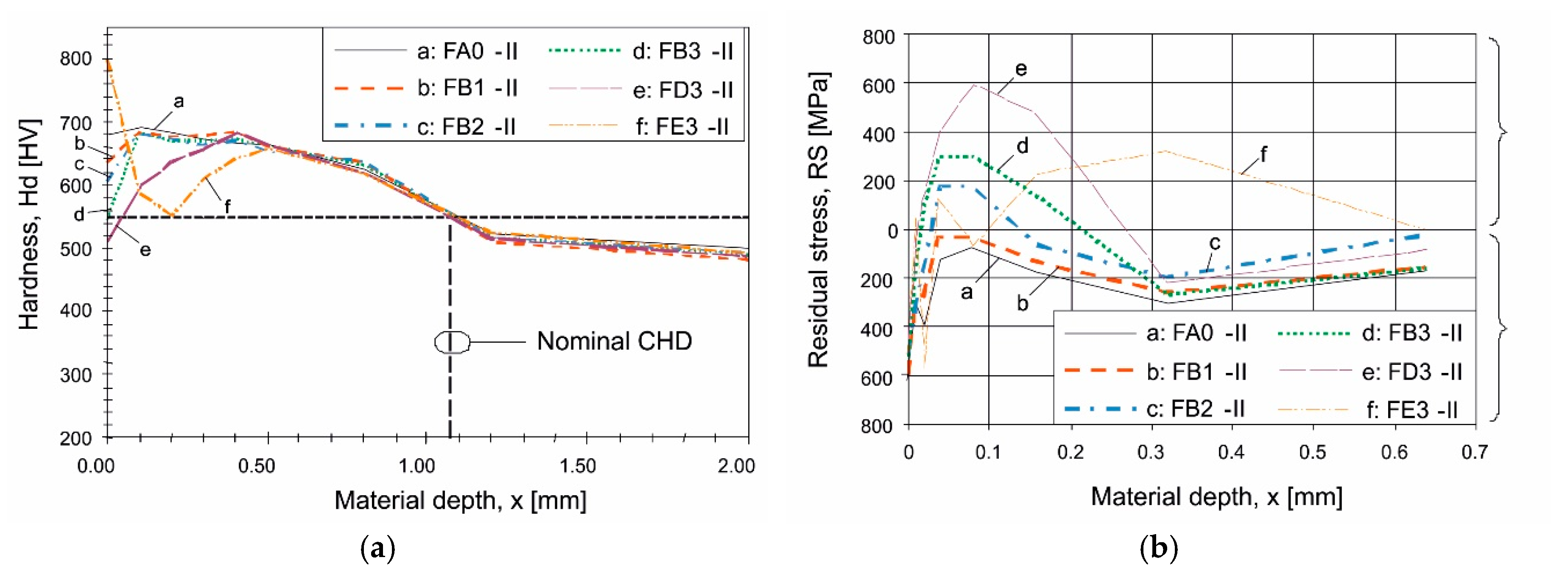

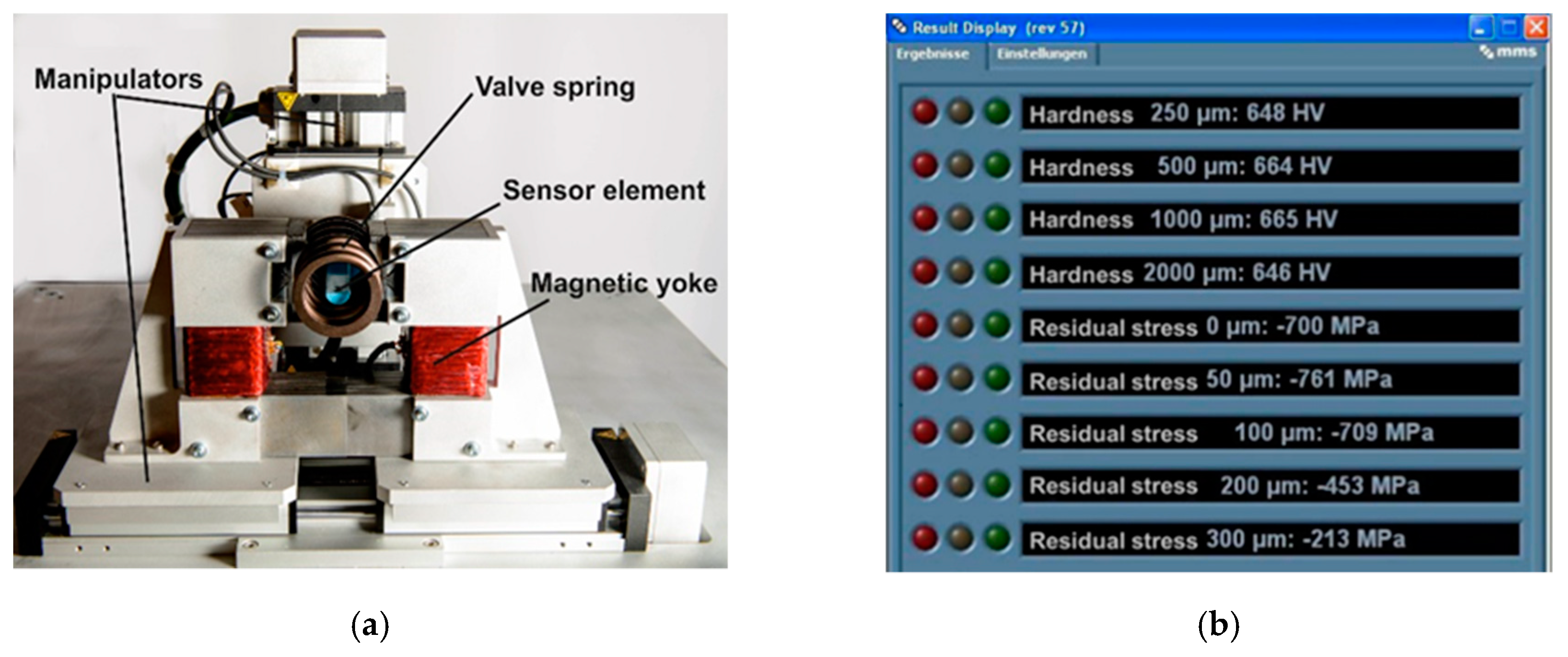

| FA0-II | No grinding damage | FB1-II | Light tempered zones at < 10% of the flank |

| FB2-II | Light tempered zones at 10 to 25% of tooth flank | FB3-II | Light tempered zones at > 25% of tooth flank |

| FD3-II | Strong tempered zones | FE3 | Re-hardening |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wolter, B.; Gabi, Y.; Conrad, C. Nondestructive Testing with 3MA—An Overview of Principles and Applications. Appl. Sci. 2019, 9, 1068. https://doi.org/10.3390/app9061068

Wolter B, Gabi Y, Conrad C. Nondestructive Testing with 3MA—An Overview of Principles and Applications. Applied Sciences. 2019; 9(6):1068. https://doi.org/10.3390/app9061068

Chicago/Turabian StyleWolter, Bernd, Yasmine Gabi, and Christian Conrad. 2019. "Nondestructive Testing with 3MA—An Overview of Principles and Applications" Applied Sciences 9, no. 6: 1068. https://doi.org/10.3390/app9061068

APA StyleWolter, B., Gabi, Y., & Conrad, C. (2019). Nondestructive Testing with 3MA—An Overview of Principles and Applications. Applied Sciences, 9(6), 1068. https://doi.org/10.3390/app9061068