The Effect of Selected Additives on the Oil Uptake and Quality Parameters of Fried Instant Noodles

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Instant Fried Noodles

2.3. Moisture Analysis

2.4. Fat Analysis

2.5. Color Determination (L/, a/, b/ Parameters)

2.6. Water Activity Analysis

2.7. Density Analysis

2.8. Mechanical Properties Analysis

2.9. Acoustic Emission (AE) Analysis

2.10. Statistical Analysis

3. Results and Discussion

3.1. Moisture

Oil Uptake

3.2. Color

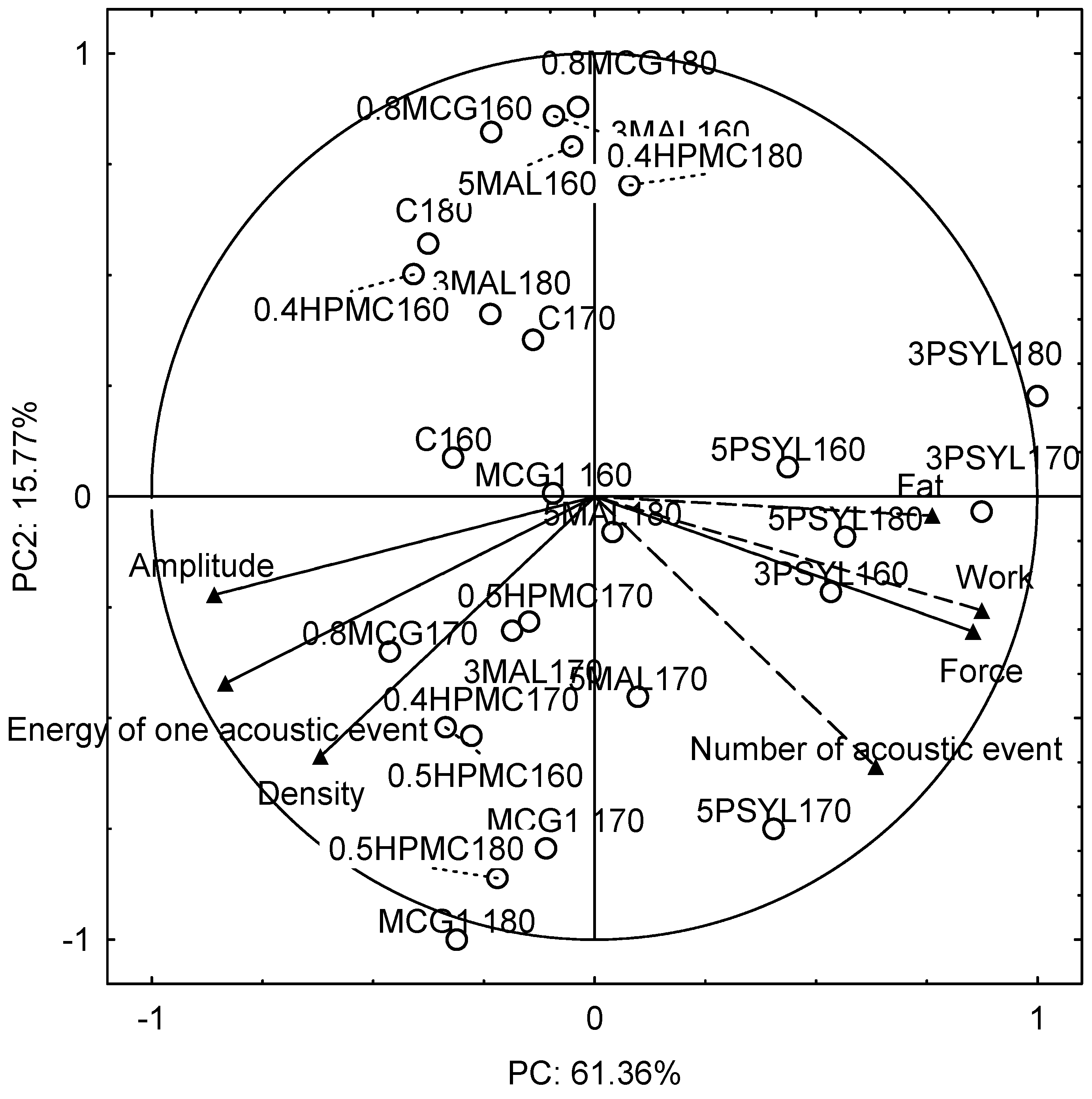

3.3. Water Activity, Density, Mechanical Properties, and Acoustic Emission

3.4. Temperature

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Available online: https://instantnoodles.org/en/noodles/report.html (accessed on 21 January 2019).

- Hou, G.; Kruk, M. Asian noodle technology. AIB Tech. Bull. 1998, 20, 1–10. [Google Scholar]

- Fu, B.X. Asian noodles: History, classification, raw materials, and processing. Food Res. Int. 2008, 41, 888–902. [Google Scholar] [CrossRef]

- Zhang, N.; Ma, G. Noodles, traditionally and today. J. Ethn. Foods 2016, 3, 209–212. [Google Scholar] [CrossRef]

- Naviglio, D.; Romano, R.; Pizzolongo, F.; Santini, A.; De Vito, A.; Schiavo, L.; Nota, G.; Spagna Musso, S. Rapid determination of esterified glycerol and glycerides in triglyceride fats and oils by means of periodate method after transesterification. Food Chem. 2007, 102, 399–405. [Google Scholar] [CrossRef]

- Mellema, M. Mechanism and reduction of fat uptake in deep-fat fried foods. Trends Food Sci. Technol. 2003, 119, 34–40. [Google Scholar] [CrossRef]

- Romano, R.; Giordano, A.; Le Grottaglie, L.; Manzo, N.; Paduano, A.; Sacchi, R.; Santini, A. Volatile compounds in intermittent frying by gas chromatography and nuclear magnetic resonance. Eur. J. Lipid Sci. Technol. 2013, 115, 764–773. [Google Scholar] [CrossRef]

- Kubomura, K. Instant noodles in Japan. Cereals Foods World 1998, 4, 194–197. [Google Scholar]

- Perczyńska, A.; Marciniak-Lukasiak, K. Wpływ dodatku β-glukanu na jakość smażonych makaronów instant. Bromat. Chem. Toksykol Xlix 2016, 3, 373–377. [Google Scholar]

- Pedreschi, F.; Cocio, C.; Moyano, P.; Troncoso, E. Oil distribution in potato slices during frying. J. Food Eng. 2008, 87, 200–212. [Google Scholar] [CrossRef]

- Jurga, R. Makarony podgotowane i smażone typu orientalnego. Przegląd Zbożowo Młynarski 2001, 45, 19–20. [Google Scholar]

- Czerwińska, D. Charakterystyka mąk makaronowych. Przegląd Zbożowo Młynarski 2010, 54, 11–12. [Google Scholar]

- Choy, A.-L.; Hughes, J.G.; Small, D.M. The effects of microbial transglutaminase, sodium stearoyl lactylate and water on the quality of instant fried noodles. Food Chem. 2010, 122, 957–964. [Google Scholar] [CrossRef]

- Borowy, T.; Kubiak, M.S. Zamienniki tłuszczu w przemyśle mięsnym-cz. II. Technol. Transp. Chłodnictwo 2009, 6–7, 31–33. [Google Scholar]

- Wu, J.; Aluko, R.E.; Corke, H. Partial least-squares regression study of the effects of wheat flour composition, protein and starch quality characteristics on oil content of steamed-and-fried instant noodles. J. Cereal Sci. 2006, 44, 117–126. [Google Scholar] [CrossRef]

- Huang, Y.Ch.; Lai, H.M. Noodle quality affected by different cereal starches. J. Food Eng. 2010, 97, 135–143. [Google Scholar] [CrossRef]

- Choy, A.L.; May, B.K.; Small, D.M. The effects of acetylated potato starch and sodium carboxymethyl cellulose on the quality of instant fried noodles. Food Hydrocoll. 2012, 26, 2–8. [Google Scholar] [CrossRef]

- Marciniak-Lukasiak, K.; Anna Zbikowska, A.; Marcinkowska-Lesiak, M.M. Wpływ dodatku skrobi na jakość smażonych makaronów instant. Postępy Techniki Przetwórstwa Spożywczego 2012, 22, 27–31. [Google Scholar]

- Ding, S.; Yang, J. The influence of emulsifiers on the rheological properties of wheat flour dough and quality of fried instant noodles. LWT Food Sci. Technol. 2013, 53, 61–69. [Google Scholar] [CrossRef]

- Rekas, A.; Marciniak-Lukasiak, K. A multivariate study of the correlation between addition of maltodextrin, MCG, HPMC and psyllium on the quality of instant fried noodles. LWT Food Sci. Technol. 2015, 62, 689–696. [Google Scholar] [CrossRef]

- Rho, K.L.; Seib, P.A.; Chung, O.K.; Chung, D.S. Retardation of rancidity in deep-fried instant noodles (ramyon). J. Am. Oil Chem. Soc. 1986, 63, 251–256. [Google Scholar] [CrossRef]

- Varela, P.; Fiszman, S.M. Hydrocolloids in fried foods. A review. Food Hydrocoll. 2012, 25, 1801–1812. [Google Scholar] [CrossRef]

- Arendt, E.; Zannini, E. Cereals. W: Cereal Grains for the Food and Beverage Industries; Woodhead Publishing Limited: Cambridge, UK, 2013. [Google Scholar]

- Dziki, D.; Różyło, R.; Biernacka, B. Jakość makaronów fortyfikowanych dodatkiem mąki sojowej. Inżynieria Przetwórstwa Spożywczego 2013, 3, 11–16. [Google Scholar]

- Gulia, N.; Khatkar, B.S. Effect of processing variables on the oil uptake, textural properties and cooking quality of instant fried noodles. J. Food Qual. 2013, 36, 181–189. [Google Scholar] [CrossRef]

- Hou, G. Oriental noodles. Adv. Food Nutr. Res. 2001, 43, 141–193. [Google Scholar]

- Yu, L.J.; Ngadi, M.O. Textural and other quality properties of instant fried noodles as affected by some ingredients. Cereal Chem. 2004, 81, 772–776. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, H.S.; Kim, Y.K.; Beak, H.H.; Park, H.J. Application of HPMC for the food industry. Food Sci. Ind. 2010, 43, 76–84. [Google Scholar]

- American Association of Cereal Chemists, AACC International. Approved Methods of the American Association of Cereal Chemists: Method 44-15A, 9th ed.; The Association: St. Paul, MN, USA, 1995. [Google Scholar]

- Papadakis, S.E.; Abdul-Malek, S.; Kamdem, R.E.; Yam, K.L. A versatile and inexpensive technique for measuring color of foods. Food Technol. 2000, 54, 48–51. [Google Scholar]

- Lewicki, P.P.; Marzec, A.; Ranachowski, Z. Acoustic properties of foods. In Food Properties Handbook, 2nd ed.; Rahman, M.S., Ed.; Taylor & Francis Group: New York, NY, USA, 2009; pp. 811–841. [Google Scholar]

- Stanisz, A. The Affordable Price Statistic Using STATISTICA PL Examples from Medicine. Multivariate Analysis; StatSoft: Krakow, Poland, 2011; Volume 3. (In Polish) [Google Scholar]

- Romankiewicz, D.; Cacak-Pietrzak, G.; Gońda, M. Ocena jakości makaronów handlowych typu świderki. Acta Agrophysica 2014, 21, 327–335. [Google Scholar]

- Kim, M.Y.; Freund, W.; Popper, L. Noodles and pasta. In Future of Flour; Popper, L., Schäfer, W., Freund, W., Eds.; Agrimedia Verlag: Clenze, Germany, 2007; pp. 330–353. [Google Scholar]

- Hatcher, D.W. Asian noodle processing. In Cereals Processing Technology; Owens, G., Ed.; Woodhead Publishing Limited and CRC Press LLC: Cambridge, UK; Boca Raton, FL, USA, 2001; pp. 131–154. [Google Scholar]

- Drozdowski, B. Lipidy. W: Chemia żywności. Sacharydy, lipidy, białka, 2nd ed.; Sikorski, E., Ed.; Naukowo-Techniczne: Warszawa, Poland, 2007; pp. 136–142. [Google Scholar]

- Crosbie, G.B.; Ross, A.S. Asian wheat flour noodles. In The Encyclopedia of Grain Science; Wrigley, C.W., Corke, H., Walker, C.E., Eds.; Elsevier Academic Press: Oxford, UK, 2004; pp. 304–312. [Google Scholar]

- Marciniak-Lukasiak, K.; Ciszek, G. Wpływ wybranych czynników na jakość makaronów instant. Przemysł Spożywczy 2011, 65, 44–46. [Google Scholar]

- Park, C.S.; Hong, B.H.; Baik, B.-K. Protein quality of wheat desirable for making fresh white salted noodles and its influences on processing and texture of noodles. Cereal Chem. 2003, 80, 297–303. [Google Scholar] [CrossRef]

- Park, C.S.; Baik, B.K. Relationship between protein characteristics and instant noodle making quality of wheat flour. Cereal Chem. 2004, 81, 159–164. [Google Scholar] [CrossRef]

- Dueik, V.; Robert, P.; Bouchon, P. Vacuum frying reduces oil uptake and improves the quality parameters of carrot crisps. Food Chem. 2010, 119, 1143–1149. [Google Scholar] [CrossRef]

- Chon-Sik, K.; Yong-Won, S.; Sun-Hee, W.; Jong-Chul, P.; Young-Keun, C.; Jung-Gon, K.; Chul-Soo, P. Influences of protein characteristics on processing and texture of noodles from Korean and US wheats. J. Crop Sci. Biotechnol. 2004, 10, 133–140. [Google Scholar]

- Aravind, N.; Sissons, M.; Egan, N.; Fellows, C. Effect of insoluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chem. 2012, 130, 299–309. [Google Scholar] [CrossRef]

- Marzec, A. Textural Properties of Shortbread Cookies in Terms of Their Structure. Treatises and Monographs; Warsaw University of Life Sciences SGGW: Warsaw, Poland, 2012. (In Polish) [Google Scholar]

- Gull, A.; Prasad, K.; Kumar, P. Full length article nutritional, antioxidant, microstructural and pasting properties of functional pasta. J. Saudi Soc. Sci. 2018, 17, 147–153. [Google Scholar]

- Pilecki, S. Metody akustyczne w badaniach metali. In Problemy współczesnej akustyki; Ranachowski, J., Ed.; IPPT PAN: Warszawa, Poland, 1991; pp. 157–186. [Google Scholar]

- Marzec, A.; Lewicki, P.P.; Ranachowski, Z. Influence of water activityon acoustic properties of flat extruded bread. J. Food Eng. 2007, 79, 410–422. [Google Scholar] [CrossRef]

- Mieszkowska, A.; Marzec, A. Effect of polydextrose and inulin on texture and consumer preference of short-dough biscuits with chickpea flour. LWT Food Sci. Technol. 2016, 73, 60–66. [Google Scholar] [CrossRef]

- Błońska, A.; Marzec, A.; Błaszczyk, A. Instrumental evaluation of acoustic and mechanical texture properties of short-dough biscuits with different content of fat and inulin. J. Texture Stud. 2014, 45, 225–234. [Google Scholar] [CrossRef]

- Morris, E.R. Mixed polymer gels. In Food Gels; Harris, P., Ed.; Elsevier Applied Science: New York, NY, USA; London, UK, 1990; pp. 291–359. [Google Scholar]

| Sample | Temperature | Fat | Moisture | |

|---|---|---|---|---|

| Control | - | 160 | 21.08 a ± 1.06 | 3.79 d ± 0.16 |

| 170 | 22.67 b ± 0.93 | 3.56 c ± 0.13 | ||

| 180 | 24.48 c ± 1.01 | 3.33 c ± 0.14 | ||

| Maltodextrin | 3.0% | 160 | 22.51 b ± 0.99 | 3.46 c ± 0.20 |

| 170 | 23.97 b ± 1.12 | 3.34 c ± 0.12 | ||

| 180 | 26.17 c ± 1.21 | 3.12 b ± 0.11 | ||

| 5.0% | 160 | 24.52 c ± 1.15 | 3.16 b ± 0.06 | |

| 170 | 26.17 c ± 1.13 | 2.96 b ± 0.09 | ||

| 180 | 27.85 d ± 1.26 | 2.82 b ± 0.12 | ||

| MCG | 0.8% | 160 | 20.50 a ± 1.01 | 3.80 d ± 0.18 |

| 170 | 22.17 b ± 0.86 | 3.60 cd ± 0.09 | ||

| 180 | 23.86 b ± 0.99 | 3.37 c ± 0.21 | ||

| 1.0% | 160 | 20.18 a ± 1.02 | 3.76 d ± 0.19 | |

| 170 | 21.89 ab ± 0.78 | 3.55 c ± 0.21 | ||

| 180 | 23.53 b ± 1.11 | 3.40 c ± 0.17 | ||

| HPMC | 0.4% | 160 | 20.07 a ± 1.05 | 3.85 d ± 0.17 |

| 170 | 21.66 ab ± 1.17 | 3.61 cd ± 0.14 | ||

| 180 | 23.37 b ± 1.22 | 3.31 c ± 0.19 | ||

| 0.5% | 160 | 19.86 a ± 0.87 | 3.77 d ± 0.13 | |

| 170 | 21.33 a ± 0.86 | 3.51 c ± 0.13 | ||

| 180 | 22.65 b ± 1.09 | 3.29 c ± 0.16 | ||

| Psyllium | 3.0% | 160 | 25.14 c ± 1.31 | 3.03 b ± 0.13 |

| 170 | 26.93 c ± 1.26 | 2.86 b ± 0.11 | ||

| 180 | 29.41 d ± 1.36 | 2.74 b ± 0.09 | ||

| 5.0% | 160 | 26.56 c ± 1.23 | 2.80 b ± 0.11 | |

| 170 | 28.38 d ±1.27 | 2.57 a ± 0.12 | ||

| 180 | 30.51 d ±1.26 | 2.40 a ± 0.08 |

| Sample | Temperature (°C) | L* | a* | b* | |

|---|---|---|---|---|---|

| Control | - | 160 | 76.97 ± 1.45 | −1.11 ± 0.03 | 18.56 ± 1.43 |

| 170 | 76.68 ± 2.09 | −0.65 ± 0.05 | 20.18 ± 0.74 | ||

| 180 | 74.89 ± 2.24 | 1.31 ± 0.03 | 22.47 ± 1.08 | ||

| Maltodextrin | 3.0% | 160 | 75.67 ± 2.50 | 0.41 ± 0.04 | 21.36 ± 0.62 |

| 170 | 74.75 ± 3.03 | 0.92 ± 0.04 | 21.99 ± 0.65 | ||

| 180 | 74.64 ± 3.56 | 2.59 ± 0.12 | 23.89 ± 0.65 | ||

| 5.0% | 160 | 76.68 ± 2.66 | −0.89 ± 0.12 | 18.49 ± 0.71 | |

| 170 | 74.77 ± 2.65 | −0.03 ± 0.01 | 22.10 ± 1.01 | ||

| 180 | 74.11 ± 1.16 | 2.14 ± 0.09 | 24.52 ± 1.08 | ||

| MCG | 0.8% | 160 | 74.98 ± 1.35 | −0.59 ± 0.04 | 19.39 ± 0.58 |

| 170 | 74.34 ± 1.32 | 0.74 ± 0.10 | 21.57 ± 0.59 | ||

| 180 | 73.39 ± 1.84 | 0.79 ± 0.03 | 22.19 ± 1.48 | ||

| 1.0% | 160 | 76.99 ± 2.74 | 0.97 ± 0.08 | 17.95 ± 0.56 | |

| 170 | 76.27 ± 2.61 | −0.36 ± 0.04 | 20.34 ± 1.20 | ||

| 180 | 75.69 ± 2.46 | −1.02 ± 0.02 | 21.99 ± 1.13 | ||

| HPMC | 0.4% | 160 | 80.26 ± 1.14 | −1.40 ± 0.11 | 19.36 ± 1.45 |

| 170 | 79.12 ± 2.20 | −0.89 ± 0.04 | 19.87 ± 1.44 | ||

| 180 | 77.28 ± 1.39 | −0.79 ± 0.06 | 20.31 ± 1.03 | ||

| 0.5% | 160 | 80.13 ± 2.63 | −1.38 ± 0.09 | 19.43 ± 1.40 | |

| 170 | 79.16 ± 1.60 | −1.30 ± 0.11 | 20.44 ± 0.74 | ||

| 180 | 78.43 ± 1.97 | 0.05 ± 0.01 | 21.65 ± 0.67 | ||

| Psyllium | 3.0% | 160 | 75.12 ± 1.32 | 0.57 ± 0.06 | 18.12 ± 1.27 |

| 170 | 74.21 ± 1.33 | 0.68 ± 0.03 | 18.56 ± 0.52 | ||

| 180 | 73.34 ± 2.05 | 1.32 ± 0.09 | 19.67 ± 0.98 | ||

| 5.0% | 160 | 71.27 ± 1.19 | 1.65 ± 0.08 | 18.33 ± 1.32 | |

| 170 | 70.85 ± 1.32 | 1.75 ± 0.07 | 19.37 ± 1.30 | ||

| 180 | 69.77 ± 1.38 | 1.79 ± 0.09 | 21.78 ± 1.07 |

| Sample Code | Temperature (°C) | Water Activity | Density (g/cm3) | Number of Acoustic Event | Energy of One Acoustic Event (a.u.) | Amplitude (mV) | Force (N) | Work (mJ) |

|---|---|---|---|---|---|---|---|---|

| Control | 160 | 0.181 b ± 0.001 | 1.220 ± 0.018 | 2505 ± 724 b | 4669 ± 199 b | 1404 ± 77 b | 136 ± 21 | 436 ± 128 |

| 170 | 0.201 c ± 0.001 | 1.226 ± 0.035 | 263 ± 5675 b | 4431± 168 a | 1333 ± 40 a | 142 ± 24 | 358 ± 92 | |

| 180 | 0.172 a ± 0.001 | 1.232 ± 0.021 | 935 ± 228 a | 4434 ± 199 a | 1478 ± 43 c | 129 ± 18 | 394 ± 94 | |

| P-value | <0.001 * | 0.902 | <0.001 * | 0.002 * | <0.001 * | 0.286 | 0.162 | |

| Maltodextrin 3.00% | 160 | 0.182 ± 0.003 a | 1.236 ± 0.013 ab | 1827 ± 511 a | 4533 b ± 297 | 1378 ± 112 b | 112 ± 23 a | 259 ± 109 a |

| 170 | 0.196 ± 0.002 b | 1.274 ± 0.011 b | 2804 ± 473 b | 4568 b ± 149 | 1357 ± 37 b | 198 ± 23 c | 482 ± 110 b | |

| 180 | 0.191 ± 0.003 b | 1.208 ± 0.008 a | 2745 ± 868 b | 4167 a ± 232 | 1280 ± 88 b | 168 ± 23 b | 499 ± 104 b | |

| P-value | 0.031 * | 0.020 * | 0.001 * | <0.001 * | 0.030 * | <0.001 * | <0.001 * | |

| Maltodextrin 5.00% | 160 | 0.163 a ± 0.001 | 1.258 ± 0.007 b | 2854 ± 489 | 4688 ± 229 | 1405 ± 52 | 220 ± 47 | 475 ± 151 |

| 170 | 0.189 b ± 0.000 | 1.229 ± 0.008 a | 3553 ± 865 | 4569 ± 201 | 1373 ± 46 | 194 ± 36 | 452 ± 149 | |

| 180 | 0.192 b ± 0.004 | 1.281 ± 0.001 c | 3369 ± 740 | 4615 ± 235 | 1376 ± 59 | 219 ± 41 | 471 ± 108 | |

| P-value | 0.001 * | 0.008 * | 0.056 | 0.550 | 0.649 | 0.218 | 0.929 | |

| MCG 0.80% | 160 | 0.189 b ± 0.001 | 1.224 ± 0.011 | 2091 ± 533 | 4458 ± 129 a | 1335 ± 37 a | 123 ± 25 a | 266 ± 72 |

| 170 | 0.182 b ± 0.001 | 1.267 ± 0.022 | 2034 ± 564 | 4774 ± 190 b | 1411 ± 44 b | 161 ± 26 b | 331 ± 98 | |

| 180 | 0.164 a ± 0.001 | 1.230 ± 0.010 | 2214 ± 599 | 4355 ± 152 a | 1315 ± 42 a | 145 ± 22 b | 338 ± 103 | |

| P-value | <0.001 * | 0.122 | 0.553 | <0.001 * | <0.001 * | 0.002 * | 0.067 | |

| MCG 1.00% | 160 | 0.179 a ± 0.003 | 1.179 ± 0.016 a | 2986 ± 720 a | 4519 ± 225 a | 1363 ± 55 a | 221 ± 28 ab | 588 ± 119 |

| 170 | 0.178 a ± 0.003 | 1.241 ± 0.014 b | 4113 ± 764 b | 4725 ± 161 b | 1411 ± 38 b | 229 ± 44 b | 653 ± 187 | |

| 180 | 0.193 b ± 0.001 | 1.233 ± 0.013 b | 3506 ± 1013 ab | 4811 ± 185 b | 1440 ± 42 b | 192 ± 20 a | 522 ± 119 | |

| P-value | 0.014 * | 0.041 * | 0.005 * | 0.001 * | 0.003 * | 0.012 * | 0.052 | |

| HPMC 0.40% | 160 | 0.194 ± 0.001 b | 1.203 ± 0.025 a | 2076 ± 490 b | 4254 ± 211 a | 1289 ± 47 a | 126 ± 21 a | 290 ± 121 a |

| 170 | 0.193 ± 0.001 b | 1.266 ± 0.012 b | 2284 ± 507 b | 4536 ± 104 b | 1367 ± 25 b | 217 ± 25 c | 483 ± 105 b | |

| 180 | 0.178 ± 0.004 a | 1.198 ±.0003 a | 1500 ± 275 a | 4548 ± 252 b | 1393 ± 97 b | 158 ± 19 b | 330 ± 64 a | |

| P-value | 0.009 | 0.040 * | <0.001 * | 0.001 * | 0.001 * | <0.001 * | <0.001 * | |

| HPMC 0.50% | 160 | 0.202 ± 0.006 c | 1.215 ± 0.023 | 1979 ± 417 a | 4527 ± 120 | 1355 ± 29 | 183 ± 30 a | 431 ± 93 a |

| 170 | 0.190 ± 0.001 b | 1.225 ±0.019 | 3412 ± 623 c | 4468 ±118 | 1351 ± 29 | 250 ± 50 b | 662 ± 154 b | |

| 180 | 0.185 ± 0.001 a | 1.258 ± 0.033 | 2837 ± 382 b | 4484 ±151 | 1352 ± 36 | 206 ± 33 a | 529 ± 125 a | |

| P-value | 0.032 * | 0.349 | <0.001 * | 0.365 | 0.807 | <0.001 * | <0.001 * | |

| Psyllium 3.00% | 160 | 0.163 ± 0.001 a | 1.196 ± 0.013 | 3872 ± 691 a | 4209 ± 107 b | 1291 ± 22 ab | 271 ± 45 | 762 ± 152 |

| 170 | 0.166 ± 0.002 a | 1.164 ± 0.017 | 4994 ± 811 ab | 4175 ± 157 ab | 1274 ± 21 b | 265 ± 55 | 729 ± 166 | |

| 180 | 0.181 ± 0.001 b | 1.175 ± 0.059 | 4852 ± 658 a | 4005 ± 121 a | 1196 ± 32 a | 228 ± 53 | 600 ± 179 | |

| P-value | 0.002 * | 0.701 | 0.021 * | 0.001 * | <0.001 * | 0.100 | 0.063 | |

| Psyllium 5.00% | 160 | 0.170 ± 0.001 a | 1.225 ± 0.012 | 4350 ± 692 b | 4164 ± 91 b | 1292 ± 23 b | 380 ± 92 a | 879 ± 293 a |

| 170 | 0.178 ± 0.001 b | 1.241 ± 0.009 | 3481 ± 838 a | 4168 ± 79 b | 1273 ± 21 b | 504 ± 119 b | 1436 ± 408 b | |

| 180 | 0.177 ± 0.001 b | 1.225 ± 0.011 | 3525 ± 817 ab | 4070 ± 157 a | 1203 ± 44 a | 463 ± 38 ab | 1306 ± 151 | |

| P-value | 0.007 * | 0.363 | 0.003 * | 0.004 * | 0.009 * | 0.008 * | <0.001 * | |

| Source of variation | ||||||||

| P-value | Addition | 0.441 | 0.030 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * | <0.001 * |

| Temperature | 0.269 | 0.023 * | <0.001 * | 0.002 * | 0.621 | <0.001 * | 0.001 * | |

| Addition X Temperature | 0.397 | 0.005 * | <0.001 * | <0.001 * | <0.001 * | 0.251 | 0.040 | |

| Parameters | Force (N) | Work (mJ) | Density (g/cm3) | Fat (%) |

|---|---|---|---|---|

| Number of acoustic event | 0.581 * | 0.575 * | −0.061 | 0.459 * |

| Energy of one acoustic event (a.u.) | −0.510 * | −0.542 * | 0.613 * | −0.653 * |

| Amplitude (mV) | −0.560 * | −0.564 * | 0.520 * | −0.614 * |

| Force (N) | 1.000 | 0.976 * | −0.441 * | 0.545 * |

| Work (mJ) | 0.976 * | 1.000 | −0.499 * | 0.570 * |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marciniak-Lukasiak, K.; Zbikowska, A.; Marzec, A.; Kozlowska, M. The Effect of Selected Additives on the Oil Uptake and Quality Parameters of Fried Instant Noodles. Appl. Sci. 2019, 9, 936. https://doi.org/10.3390/app9050936

Marciniak-Lukasiak K, Zbikowska A, Marzec A, Kozlowska M. The Effect of Selected Additives on the Oil Uptake and Quality Parameters of Fried Instant Noodles. Applied Sciences. 2019; 9(5):936. https://doi.org/10.3390/app9050936

Chicago/Turabian StyleMarciniak-Lukasiak, Katarzyna, Anna Zbikowska, Agata Marzec, and Mariola Kozlowska. 2019. "The Effect of Selected Additives on the Oil Uptake and Quality Parameters of Fried Instant Noodles" Applied Sciences 9, no. 5: 936. https://doi.org/10.3390/app9050936

APA StyleMarciniak-Lukasiak, K., Zbikowska, A., Marzec, A., & Kozlowska, M. (2019). The Effect of Selected Additives on the Oil Uptake and Quality Parameters of Fried Instant Noodles. Applied Sciences, 9(5), 936. https://doi.org/10.3390/app9050936