1. Introduction

To manufacture flat surfaces, face milling is widely used as a method of high productivity [

1,

2,

3], and other milling methods [

4,

5]. At the same time, when describing cutting modes, such as in Guzeev et al. [

6], usually there are recommendations about the amount of position symmetry of the cutter and workpiece with asymmetric processing circuits as a range

e = (0.03–0.06)

B, where

B—depth of milling. Moreover, very often cutting tool manufacturing handbooks only contain the processing circuit with position symmetry of the cutter and workpiece, or there is a given displacement range. For example, Coromant [

7] recommends using a range; however, there no is specific amount of displacement suggested. The work of Diniz and Filho [

8] demonstrated that an asymmetric circuit with an offset close to zero provided for the best tool list. The paper of Bağcı and Aykut [

9] proved that the cutting force in milling is lower when using an asymmetric scheme as opposed to symmetrical milling. In reference [

10], it is shown that the cutting force is pulsating, which is associated with a variable number of the cutter’s teeth involved in the process that will certainly cause vibrations in a real system.

This is why it is really important to define specific positions of the end of the cutter and the workpiece that provide the minimum roughness of the machined surface.

Today, many publications are dedicated to surface roughness models in face milling [

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28]. Baek et al. [

11], for the operation conducted as face milling, reported the influence of cutter runout errors on surface quality parameters. They have also investigated the role of changes in the feed rate. Saï and Bouzid [

12] optimized cutting parameters for face milling process to optimize the roughness parameter. Muñoz-Escalona and Maropoulos [

13] experimentally investigated the effects of machining parameters of face milling responses, such as on the material removal amount, then the performance of tool that served, and the surface roughness parameter. On the other hand, the Taguchi technique was applied by Fratila and Caizar [

14] in face milling of Al-Mg alloy. Their target was to maximize the surface quality at the lowest power usage. Considering multiple parameters, Yang et al. [

15] performed concurrent optimization of time, cost, and profit. In that problem, the limiting parameters were power, force, speed, feed, and roughness.

Cui et al. [

16] conducted an experimental investigation of face milling at two different domains of speed—high and super. They have focused on the machining force, the roughness value of surface, and the chip-morphology. Niu et al. [

17] conducted several experiments regarding tool wear study to reveal the tool life, taking into account the surface roughness in milling of TC6 alloy. Conversely, Pimenov [

18] formulated the model of height of micro-roughness parameter. In doing so, the author accounted for the wear of tool. Considering the same machining operation but for Inconel 718 superalloy, Tian et al. [

19] conducted research to evaluate the influence of machining speed on cutting forces, as well as on tool wear. The study of Pimenov [

20] revealed the influence of face mill wear on the surface roughness parameter when the subject material was steel-45. Cui and Zhao [

21] studied the machinability of AISI H13 steel, hardened and machined as face milling. The main focus was to observe the behavior of chips, service time of tools, wear mechanism of tools, and quality of surfaces. Also, the comparison was performed based on different conditions. Simunovic et al. [

22] considered the cooling-lubrication mode to be an important index to influence the face milling operation. The role of cooling-lubrication was reported alongside the influence of cutting parameters.

In a separate study, the face milling parameters were simulated using FEM (Finite element method) and empirical approach by Cui et al. [

23]. The authors’ major concentration was temperature of chips and its morphology, the generated forces, and profile of the machined surface. Their subject job material was AISI H13, machined with CBN (Cubic Boron Nitride) tool. Liu et al. [

24] conducted an experimental investigation of high-speed face milling of 17-4PH stainless steel to describe the insert damage process and how it affects surface roughness. Popov and Schindelarz [

25] investigated the influence of hydraulic oil that gets into various types of cutting fluids in milling. The stainless steel was machined to examine the tool behavior and roughness attitude.

Kundrák et al. [

26] studied the variation in cutting force and surface roughness for face milling resulting from variable magnitudes of cutting parameters. Lopes-da Silva and Hassui [

27] studied the effects of tool path along with the process parameters on cutting forces and surface roughness. Yıldırım et al. [

28] analyzed the effect of cutting parameters and cooling and lubrication conditions on tool wear and surface roughness when milling on the basis of Waspaloy nickel ceramic tools. However, references [

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28] were not concerned with proposing the optimal position of the face mill and the workpiece that provides the minimum surface roughness.

The following are some examples of papers dedicated to determining surface roughness in face milling using artificial intelligence [

29,

30,

31,

32,

33,

34]. Lela et al. [

29] used statistical (i.e., RA (regression analysis)) as well as artificial intelligence (SVR (support vector machines), BNN (Bayesian neural network)) methods to correlate the process variables with surface roughness in face milling. In a separate study, Bajić et al. [

30] investigated, in the off-line mode of face milling process control, the roles of input cutting parameters on notable indices, such as roughness, wear, and force in machining. Yalcin et al. [

31] made use of a neural network to develop the models of force, roughness, and temperature in respect to process parameters. On the other hand, Kovac et al. [

32] used a novel fuzzy approach and regression system to model the responses. Pimenov et al. [

33] presented a study that takes tool wear into consideration to predict the surface roughness. This was possible by the use of an artificial intelligence-based approach with an integrated approach of main drive power consideration in real time. Grzenda and Bustillo [

34] examined the possibility of using unlabeled data streams to develop prediction models. However, papers [

26,

27,

28,

29,

30,

31,

32,

33,

34] did not describe the optimum position of the face mill and the workpiece that provides the minimum surface roughness either.

Currently, many research studies are dedicated to modeling cutting force in face milling [

35,

36,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47]. Kim and Ehmann [

35] studied forces in face milling—both static and dynamic type—and developed a method of simulation for them. Young et al. [

36] presented a method for predicting cutting forces in face milling using the orthogonal machining theory. Unlike this study, Li et al. [

37] took into account the material behavior, conditions of cutting, geometry of the used tools, vibration status, and variations in milling process to model the prediction of forces. Li and Li [

38] investigated the true tooth trajectories of a milling cutter and developed a shear length model that accounts for the characteristic wavy surface effects. Baro et al. [

39] also investigated cutting forces but considering the use of self-propelling inserts.

Aykut et al. [

40], for asymmetric milling, used ANN (artificial neural network) to model the influence of cutting parameters on chip removal process. Pittalà and Monno [

41] created a three-dimensional model of the insert geometry in a milling operation using 3D DEFORM™ that proved to be consistent with the empirical data of speed and feed assumed. Guzeev and Pimenov [

42] constructed cutting force models that include not only the shear zone processes, but also the constituents of the plowing force [

43,

44] related to the cutting tool wear. Altinas et al. [

45] reviewed the estimates of the cutting geometry of the cutting part and the geometry that are used to predict cutting forces, torque, power and the possibility of vibration and other states of the process along the tool path. Boz et al. [

46] experimentally and computationally tested methods for modeling milling of complex triaxial and five-axis examples, as well as for predicting cutting forces. Li and Wang [

47] developed a model of cutting forces in milling of hard-to-cut Inconel 718. Despite the fact that many papers take into account the relative positioning of the work-mill [

35,

36,

37,

38,

39,

40,

41,

42,

43,

44,

45,

46,

47], none of them are concerned with developing the conditions that ensure the optimum difference between the work-mill which will provide the minimum surface roughness.

The following papers are dedicated to theoretical and experimental studies of face milling processes [

48,

49,

50,

51,

52,

53]. Totis et al. [

48] investigated measurement of the cutting force in face milling and proposed a novel rotating dynamometer for this purpose. Rosales et al. [

49] focused on applying the novel method of dynamic register cutting forces using predictive statistical methods. Nguyen et al. [

50] presented a novel approach to monitoring the spindle title and deflection with the help of HDM (high-definition metrology) surface data. Pimenov [

51] developed a mathematical model for the main drive power expended in face milling, taking into consideration the wear of teeth on the back surface of the tool. Ghorbani and Moetakef-Imani [

52] investigated full immersion face milling with round inserts and proposed an approach for determining specific cutting force coefficients (SCFCs). Luan et al. [

53] structured a predictive model for power in face milling used in the manufacturing processes. However, papers [

48,

49,

50,

51,

52,

53] are not concerned with developing the conditions that ensure the optimum position of the face mill and the workpiece which provides the minimum surface roughness.

A few papers [

54,

55,

56,

57,

58,

59,

60] are also dedicated to studying acceleration of vibration in face milling. Lin et al. [

54] investigated variable speed cutting as a method for vibration control in face milling. Budak and Altintaş [

55,

56] proposed in their works an analytical method for predicting vibrations during face milling and implemented an analytical explanation of dynamic phenomena. Seguy et al. [

57], in their paper, using the finite element method, performed a dynamic evolution during the milling of a thin-walled part. Mori et al. [

58] proposed a novel energy-saving acceleration control method that involves a synchronized state between the acceleration of spindle and the feed unit. Čekić et al. [

59] presented the selection of optimal design variety of components integrated in the verbal message system (VBS). Agic et al. [

60] studied the effects of radial depth of cut and cutter geometry on cutting forces and vibration amplitudes. Olvera et al. [

61], in their article, presented a sustainability analysis for a milling operation with one degree of freedom in a thin-walled workpiece. However, papers [

54,

55,

56,

58,

59,

60,

61] are not concerned with developing the conditions that ensure the optimum position of the face mill and the workpiece which provides the minimum surface roughness in addition to acceleration.

The main conclusion of this review is that no previous research seems to have posed the problem of investigating the complex relationship between the relative position of the face mill towards the workpiece, the milling kinematics and the surface roughness, cutting forces, and acceleration of vibrations. While investigating these parameters as a whole, it is planned to provide practical recommendations for technologists on the expediency of using the relative position of the face mill and workpiece and milling kinematics to ensure the minimum roughness of surfaces is obtained by face milling.

The purpose of this study is to investigate the influence of the relative position of the face mill towards the workpiece and milling kinematics on the cutting forces, vibration acceleration, and surface roughness obtained by face milling, and give practical recommendations on the assignment of the relative position of the face mill and workpiece and milling patterns.

2. Materials and Method

To get actual surface roughness data for the validation of the model attained through artificial intelligence, machining experiments were carried out. Several passes with different milling cutter position () related to the workpiece were done. During the tests, milling forces (3 directions) and vibrations (2 directions) were acquired. After each pass, the surface roughness was measured.

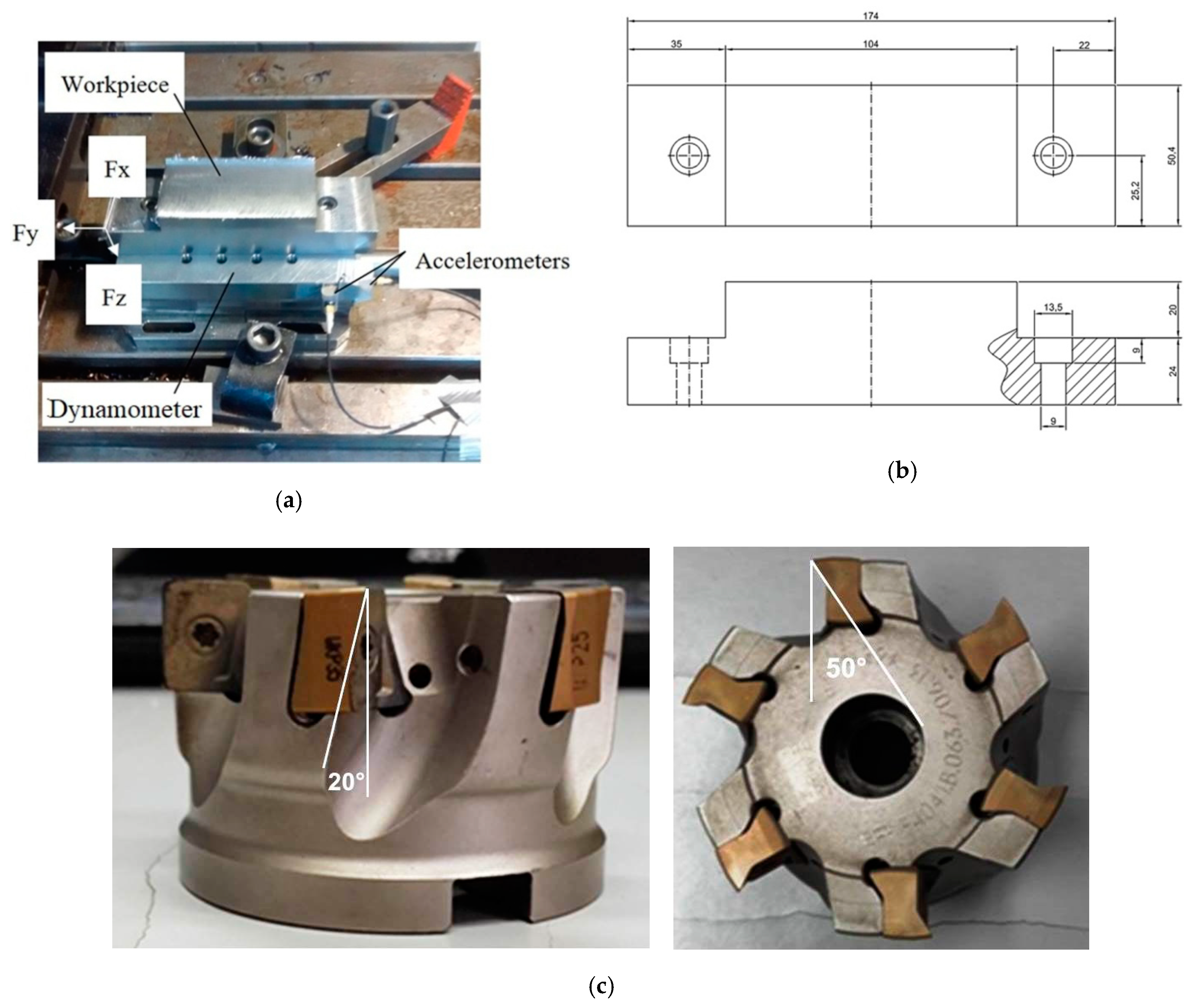

The experiments were carried out on Mori Seiki SV-40 (Nagoya, Japan), a 3 axis CNC (Computer Numeric Control) vertical machining center with 22 kW of power and a maximum rotational speed of 12,000 rpm. The setup is presented in the

Figure 1a; the workpiece and a dynamometer are over the machine tool table, as well as the accelerometers.

The cutting forces were measured using a Kistler 9257BA (Winterthur, Switzerland) stationary dynamometer connected to a Kistler 5019B signal conditioner. After this, a computer with a National Instruments PCI-6025E (Austin, TX, USA) A/D acquisition board and National Instruments LabVIEW 8.5 software were responsible for the acquisition and saving of the force signals. The data acquisition rate was 3 kHz/channel.

The vibrations were measured using accelerometers attached to the workpiece (as shown in

Figure 1a). The measurements were conducted in two orthogonal directions (+x and +y in the experiment). At the same time, the signal of acceleration was recorded using Brüel and Kjaer Photon+ (Nærum, Denmark) dynamic signal analyzer. It had 1 kHz sampling rate with default setting for anti-aliasing and phase-distortion filters. The material used for the workpiece was SAE 1045. Its chemical composition is presented in

Table 1.

The hardness of the workpiece was established at НV 184 using a Struers (Westlake, OK, USA) Vickers indenter with a load of 30 kgf. The workpiece has the geometry and dimensions presented in

Figure 1b. The width of the workpiece was determined according to the milling cutter diameter and the length to fit into the dynamometer. Two screws (M8) were used to attach the workpiece in the dynamometer.

Dry machining tests were carried out using a Walter (Tübingen, Germany) LNGX 130708 R-L55 insert (insert shape rectangular, rake angle 0°, edge length 13 mm, insert width 11 mm, insert thickness 7 mm, tool nose radius 0.8 mm) grade WKP 25 (recommended for machining of steels). The milling cutter, also a Walter (Tübingen, Germany), was a F 4041.B.063.Z06 13. After the indexable inserts were attached to the milling cutter, the tool geometry consisted of the following angles: radial rake angle + 50°, axial rake angle + 20°, clearance angle + 5° in both main and secondary cutting edges, and lead angle 90°. This geometry was chosen because the 90° lead angle tends to generate a higher effort in the plane of the surface being machined. This would increase the trend of vibration and highlight the benefits of the methodology being proposed in the present work. It is worth mentioning that this kind of tool is used in face milling, especially when a 90° shoulder is necessary. The characteristics of the used tools are specified in

Table 2. The milling cutter can be seen in

Figure 1c.

All cutting conditions used for the face milling operations are specified in

Table 3.

For each pass, a new set of inserts was used in order to eliminate tool wear as a variable.

The cutting force and vibrations were acquired during milling in a dynamically stable process. After each pass, the surface roughness was measured three times in the region where the feed per tooth was at its maximum, and 10 mm after the tool entry in the middle part of the workpiece, and 10 mm before the tool exits the workpiece.

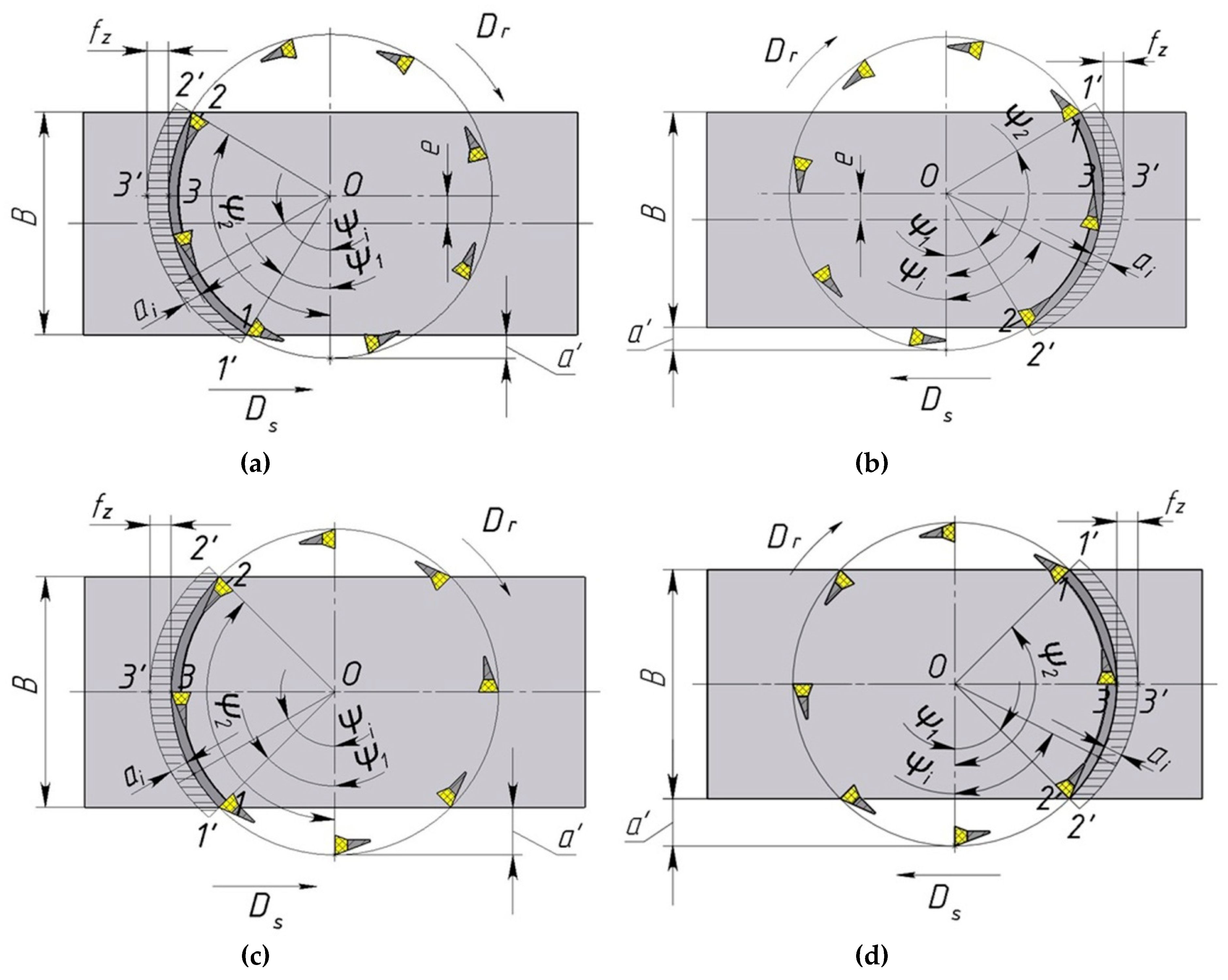

Below in

Figure 2a–d, the diagrams are depicted which represent the positions of the cutter and workpiece, described by the

a′ factor during the flat face milling, with the milling width

B lower than the cutter’s diameter

D. The

a′ parameter is defined as a translation of cutter’s rotational axis in the direction perpendicular to the feed motion towards the workpiece’s axis of symmetry, parallel to the feed motion. Asymmetric face milling (with positions symmetry of cutter and workpiece in direction that is transverse to feed е, e; positions the end of the cutter diameter and the beginning of the workpiece,

) is depicted in

Figure 2a,b, whereas the symmetric face milling is presented in

Figure 2c,d.

Table 4 shows the types of installation of face Up and Down milling.

Note that a′ = 0 mm means that e = 12.6/2 = 6.3 mm and when a′ = 12.6 mm then e = −12.6/2 = −6.3 mm.

We show the formulas for calculating the parameters given in the table.

In Equations (1) and (2), is the depth of milling; is diameter of milling; is relative positions symmetry of cutter and workpiece.

Through the

, correlations (see

Figure 2) and Equations (1) and (2) are converted to the form shown in Equations (3) and (4), respectively.

The contact angle of a face mill with the workpiece

generally is determined:

The angle between adjacent teeth would be multiple to the contact angle (see

Figure 2).

where

= 3.14159, …, i.e., Pi number—a mathematical constant that expresses the ratio of circumference to its diameter length [

38].

The number of active teeth involved in the work is determined by the formula:

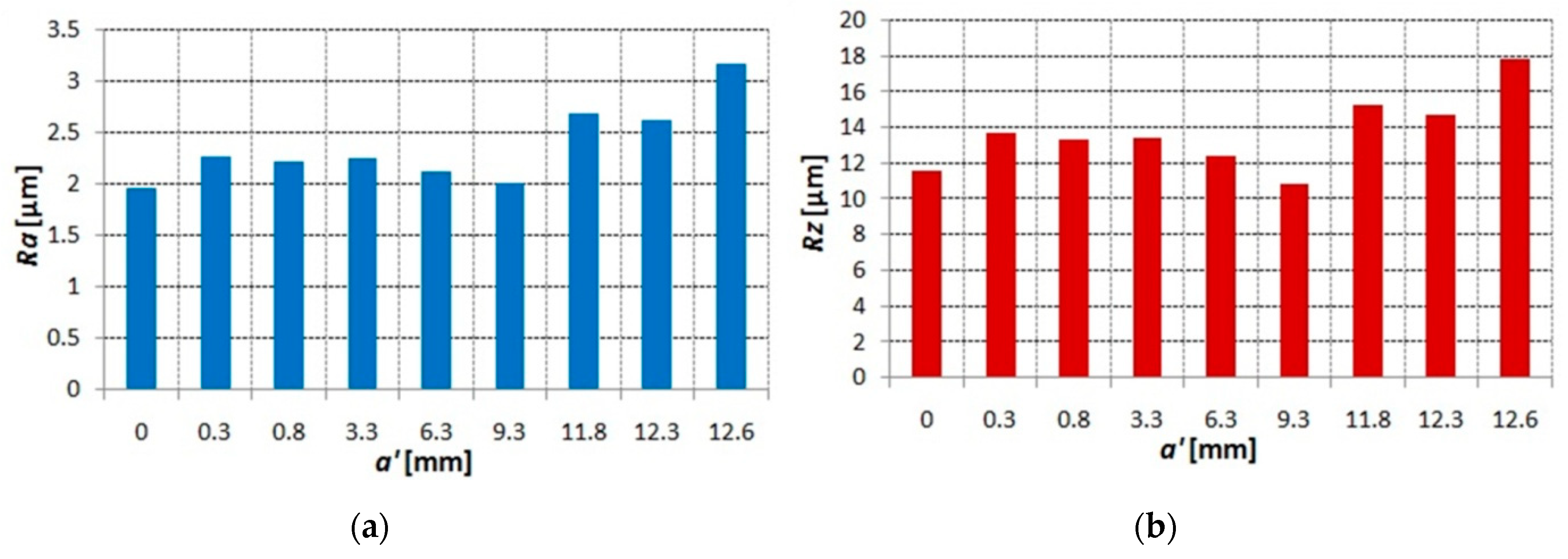

Table 5 shows the experimental values of the roughness of the surfaces

Ra and

Rz (for four runs and average values) for different values of the relative position of the face mill and workpiece

a′.

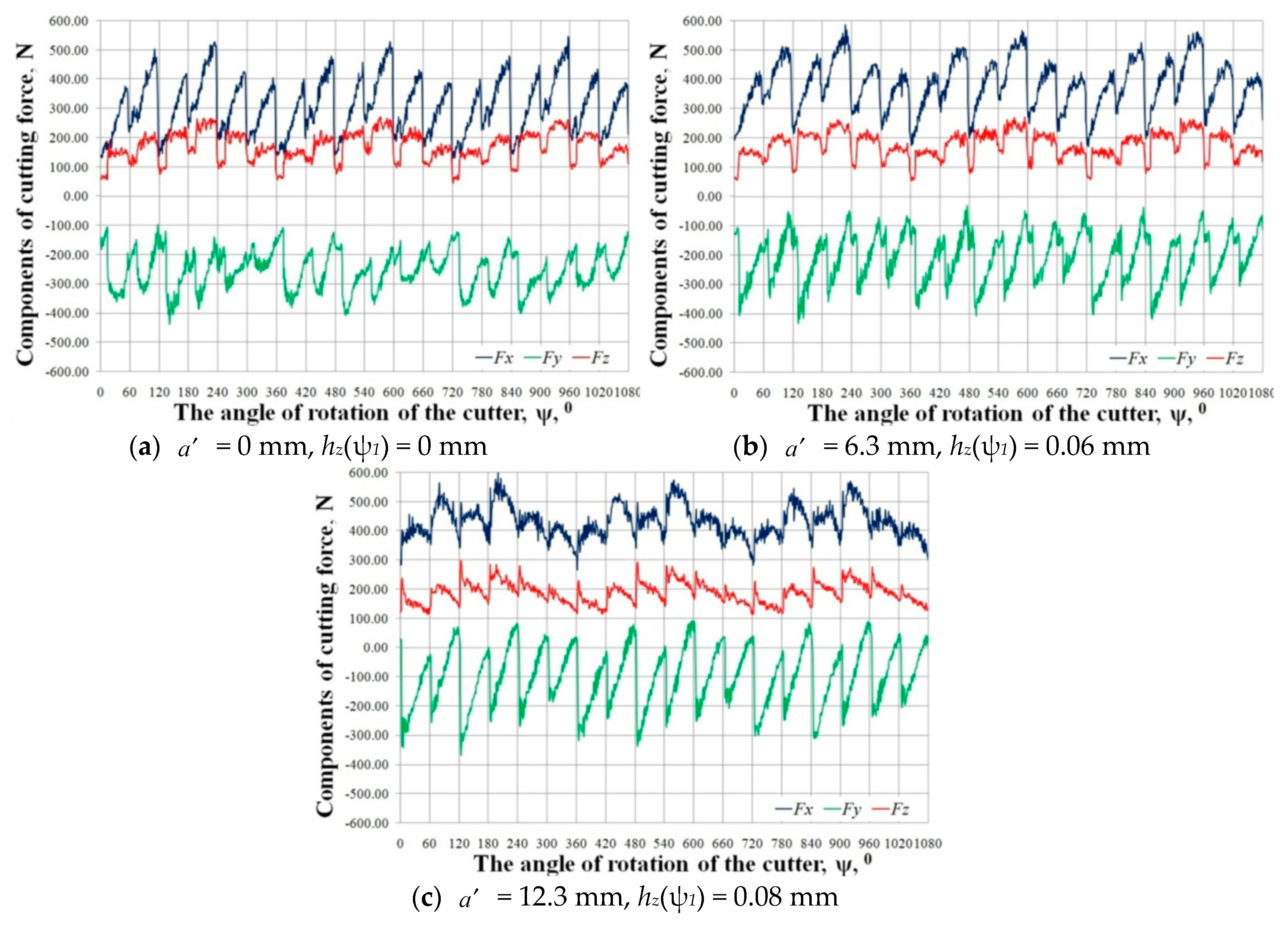

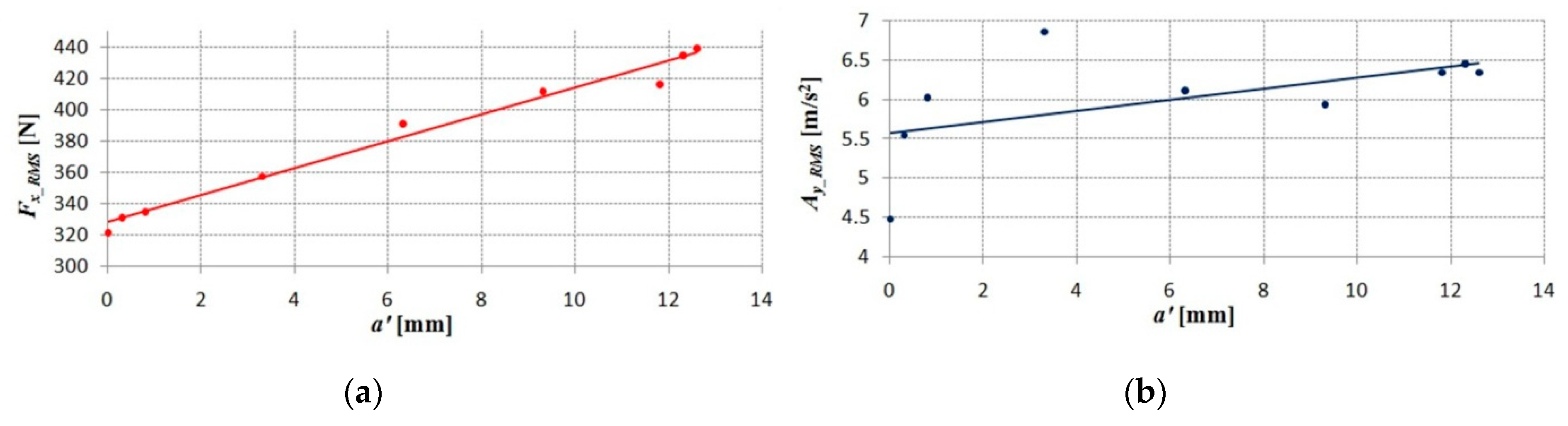

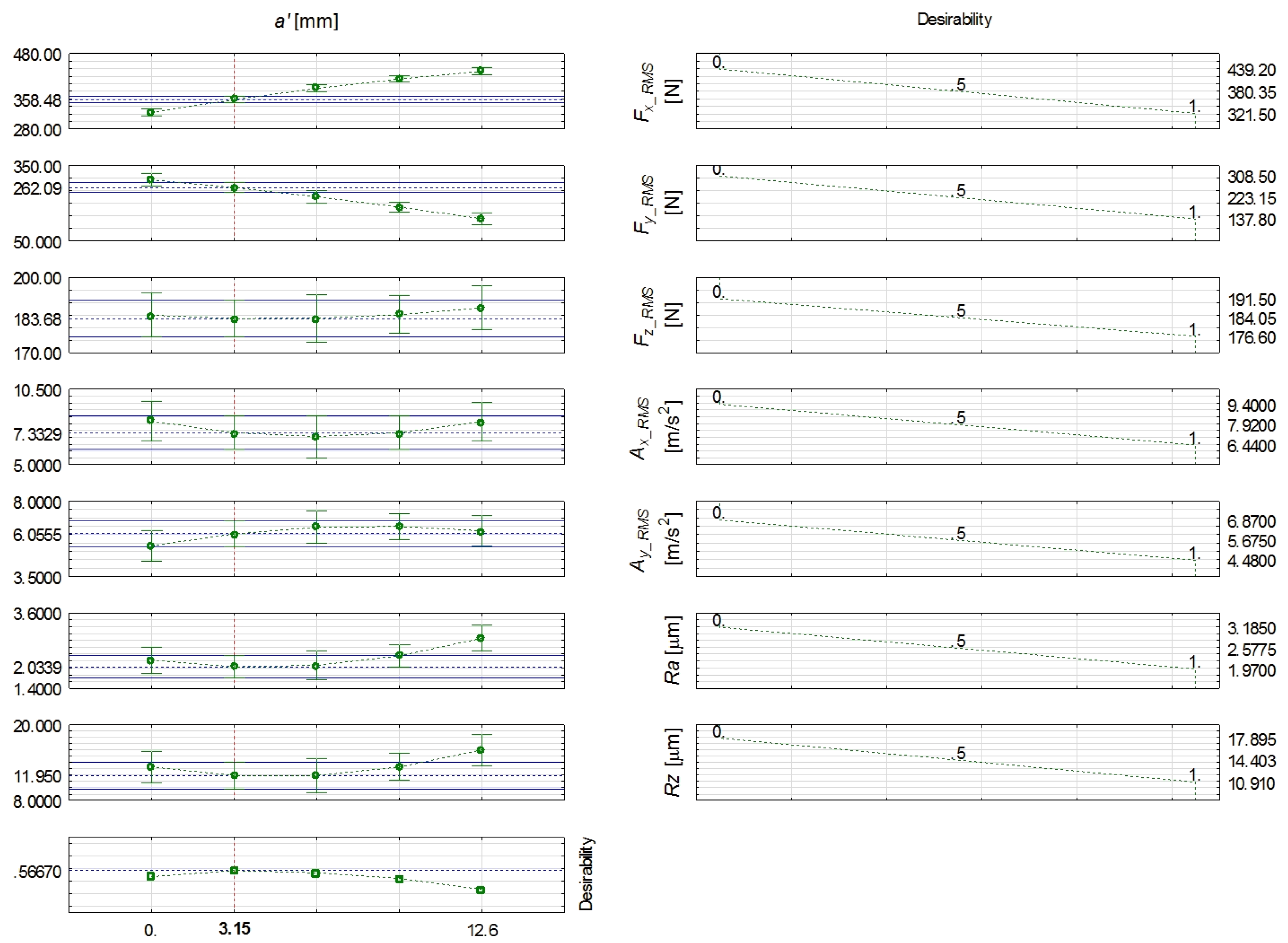

Table 6 shows the experimental components of the cutting forces

Fx,

Fy,

Fz (minimum, maximum, average, and RMS (Root-mean-square)) and accelerations of vibrations

ax and

ay (RMS) for different values of relative position of face mill and workpiece,

a′.