Optimization Design and Analysis for a Single Motor Hybrid Powertrain Configuration with Dual Planetary Gears

Abstract

:1. Introduction

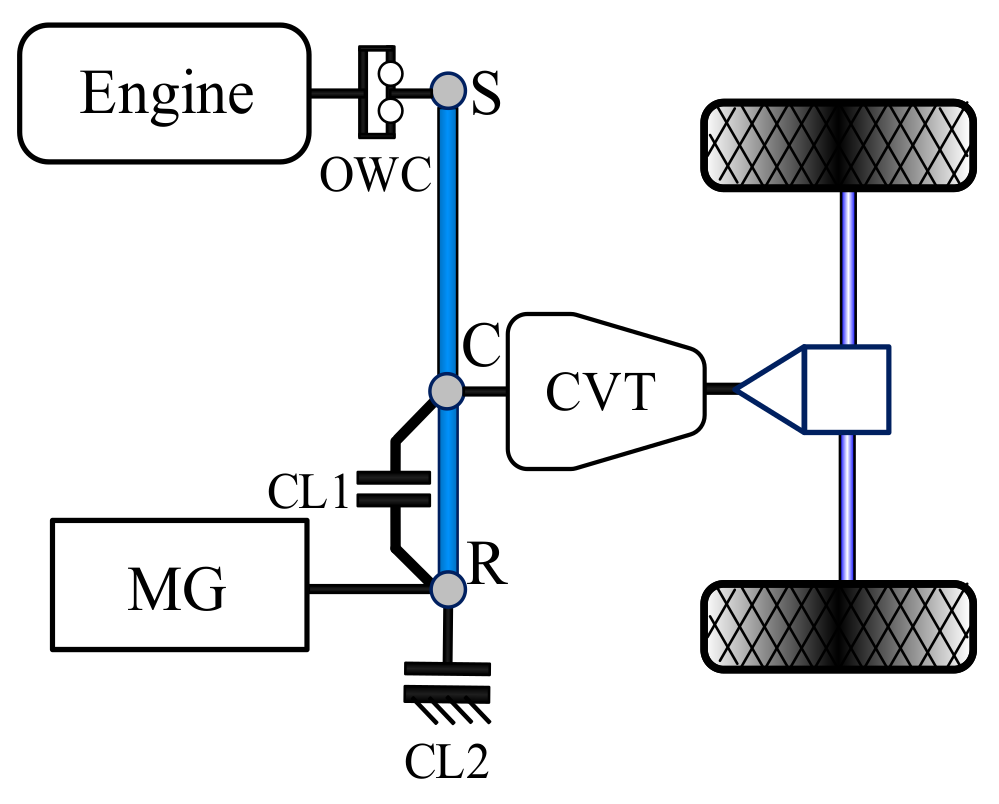

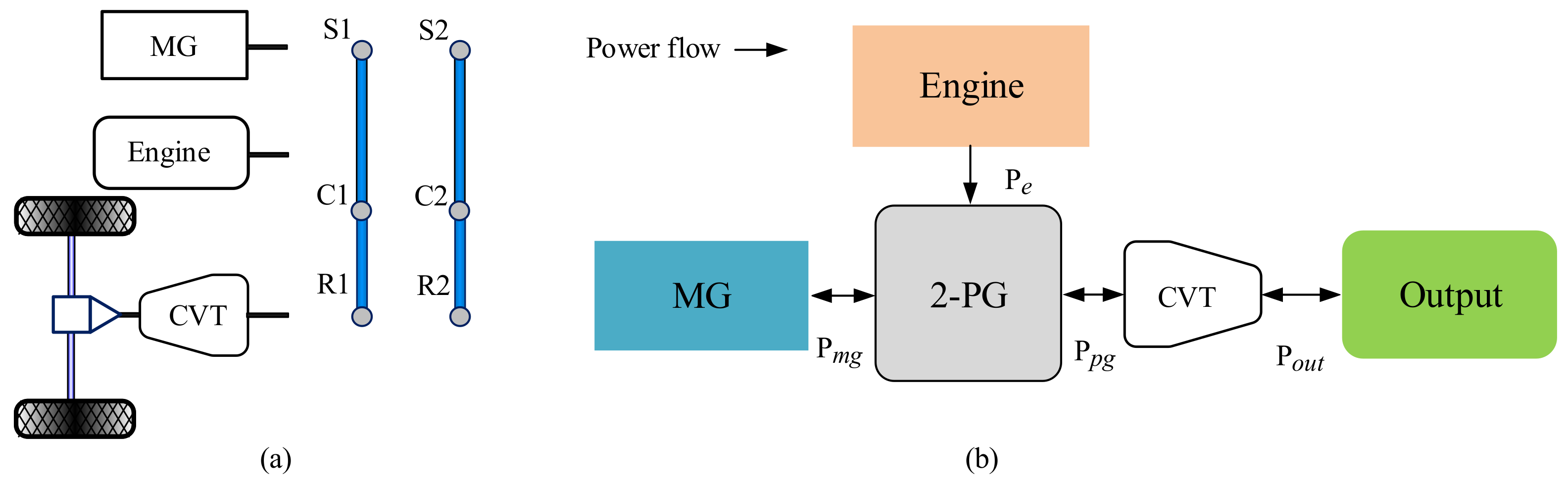

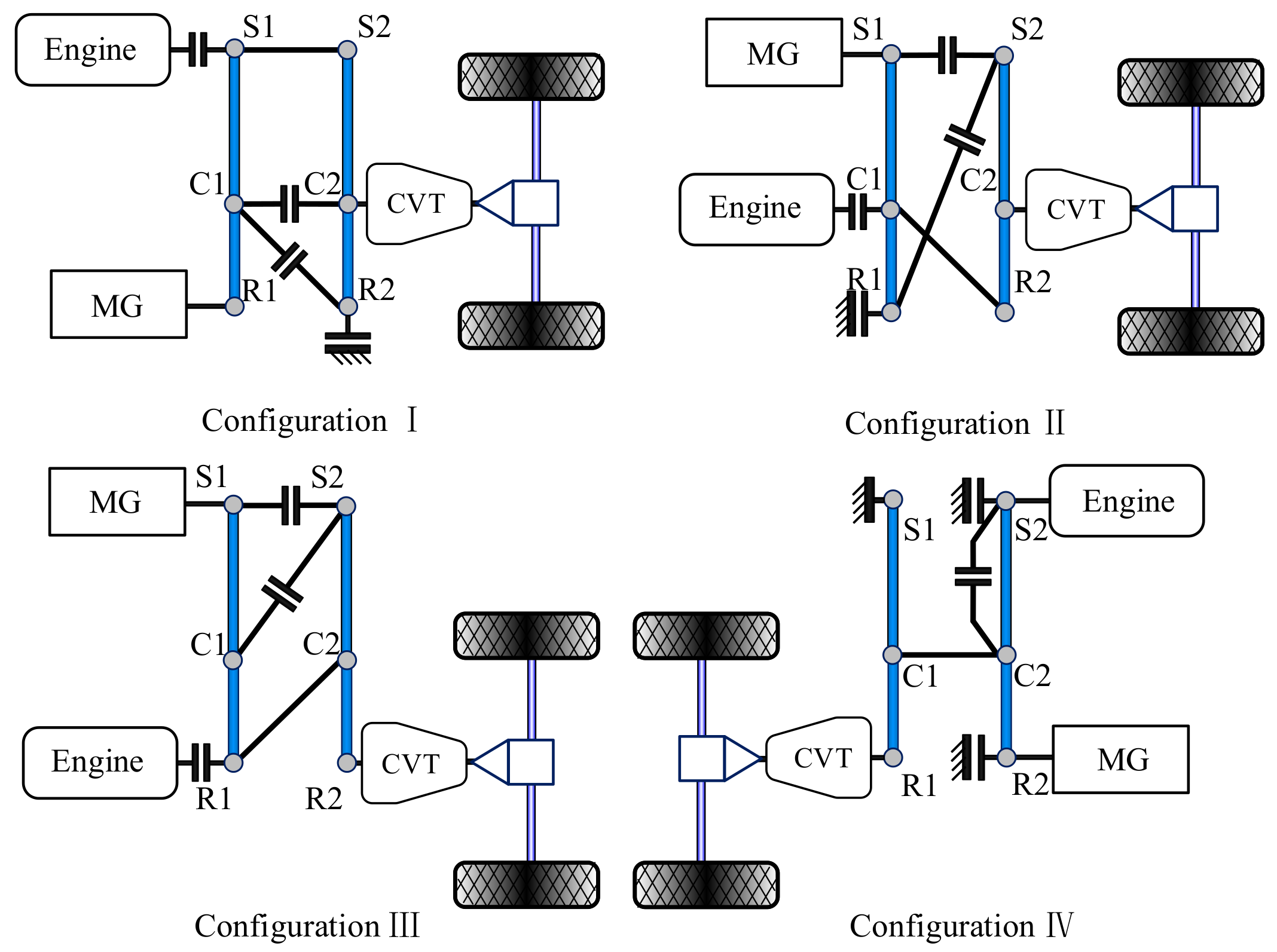

2. Single Motor Hybrid Powertrain Configuration with Dual Planetary Gears

2.1. Basic Configuration Scheme

- Any node of PG is connected to two or three nodes of the other PG at the same time.

- Three nodes of PG are grounded at the same time.

- Three nodes of PG have two or three interconnections at the same time.

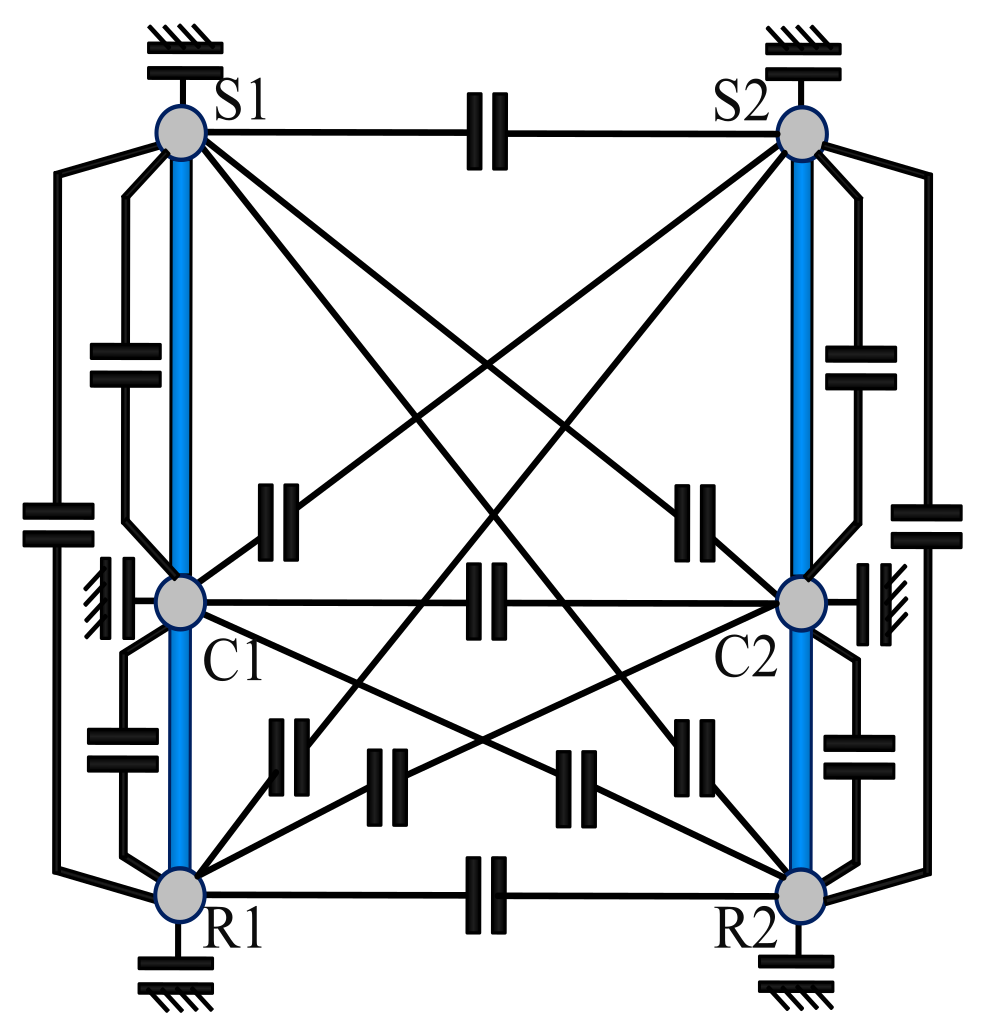

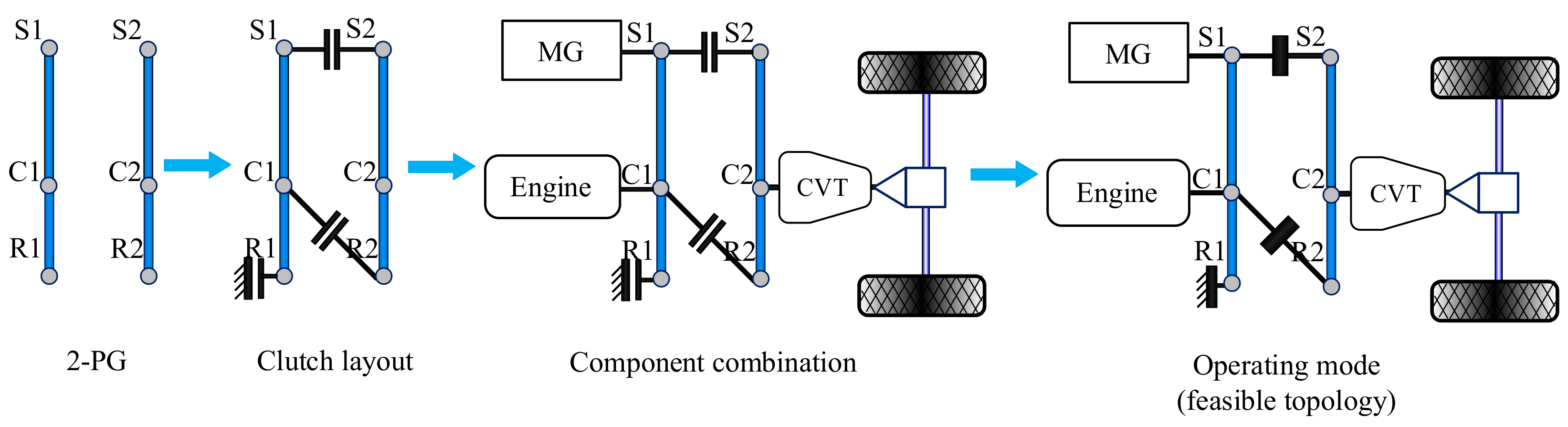

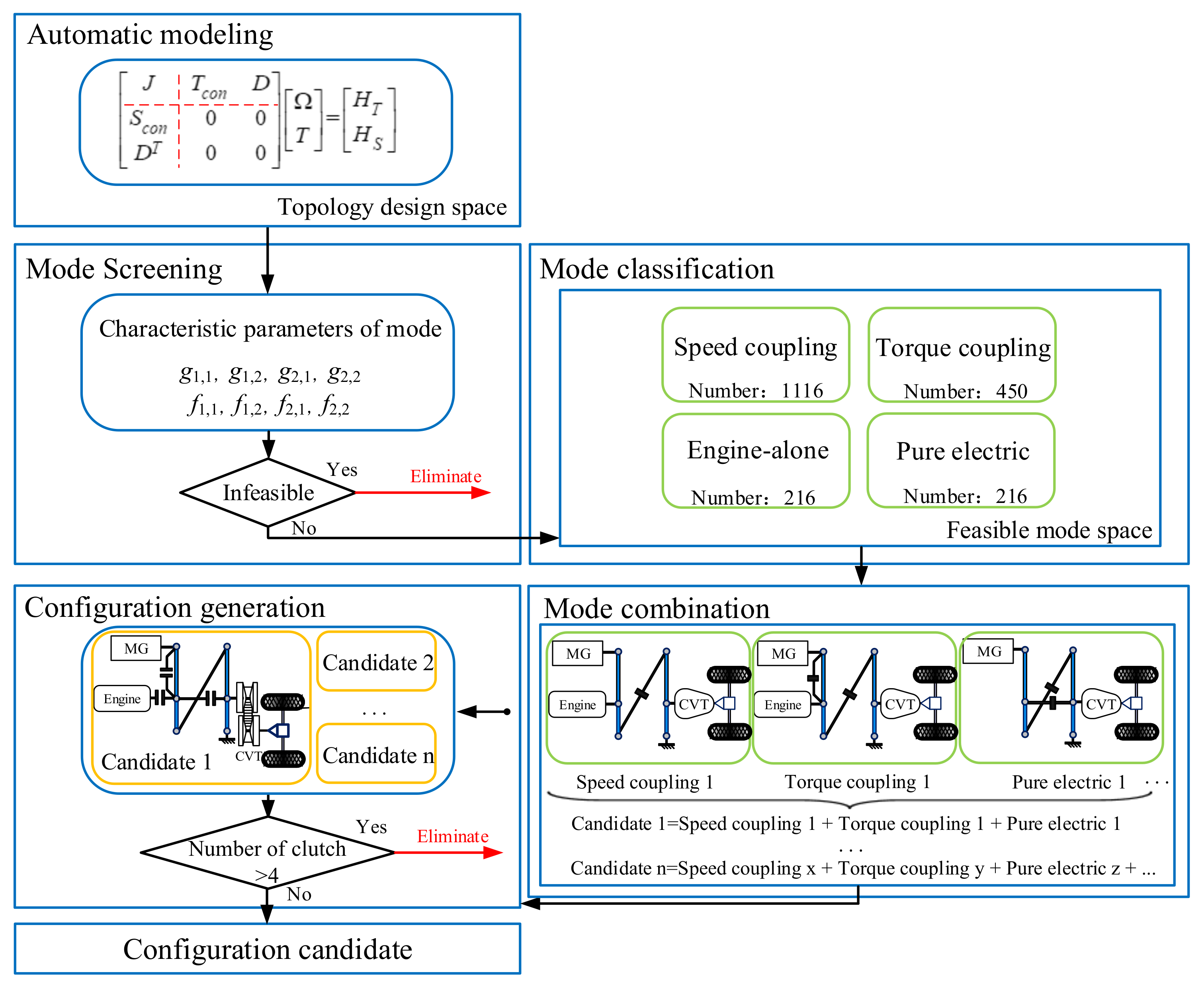

2.2. Topology Design Method

2.2.1. Automatic Modeling of Operating Mode

2.2.2. Mode Screening and Classification

2.2.3. Mode Combination and Configuration Generation

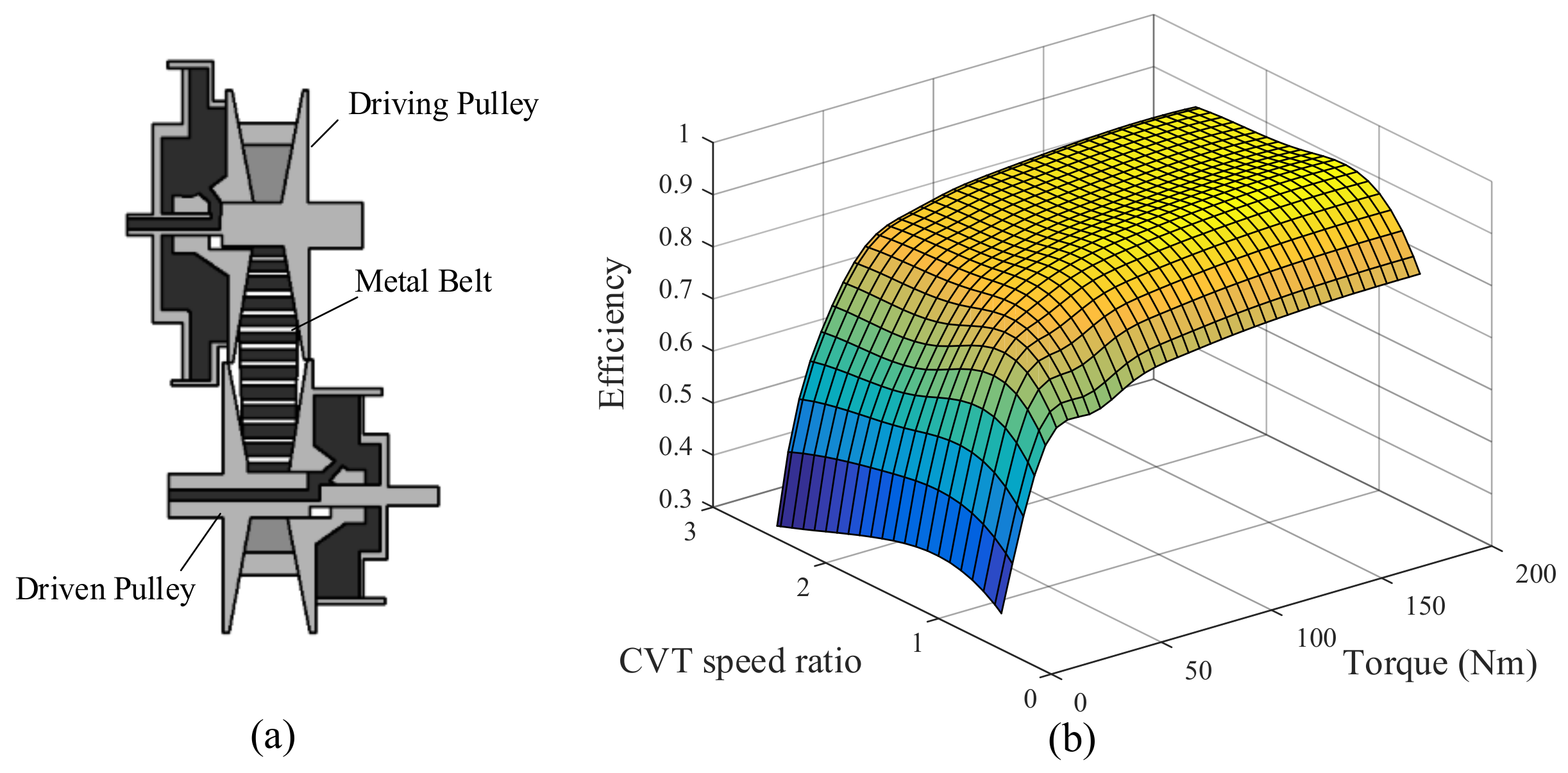

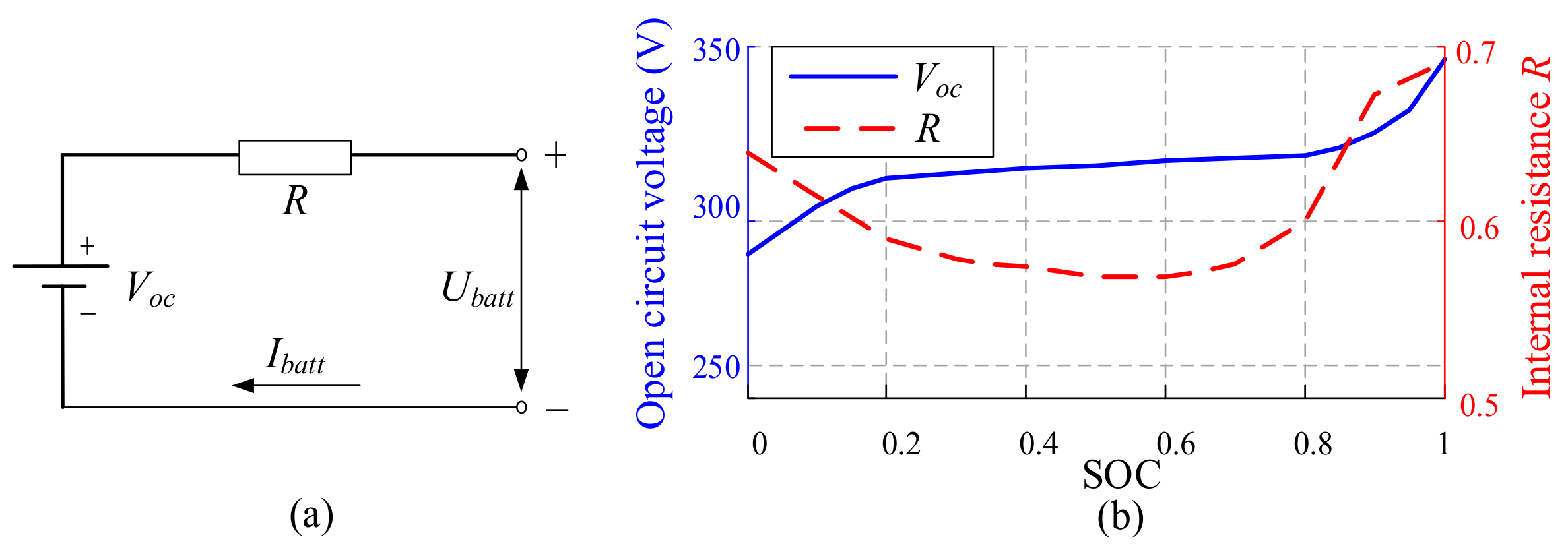

3. Parameter and Model

4. Control Strategy and Configuration Optimization

4.1. Control Strategy

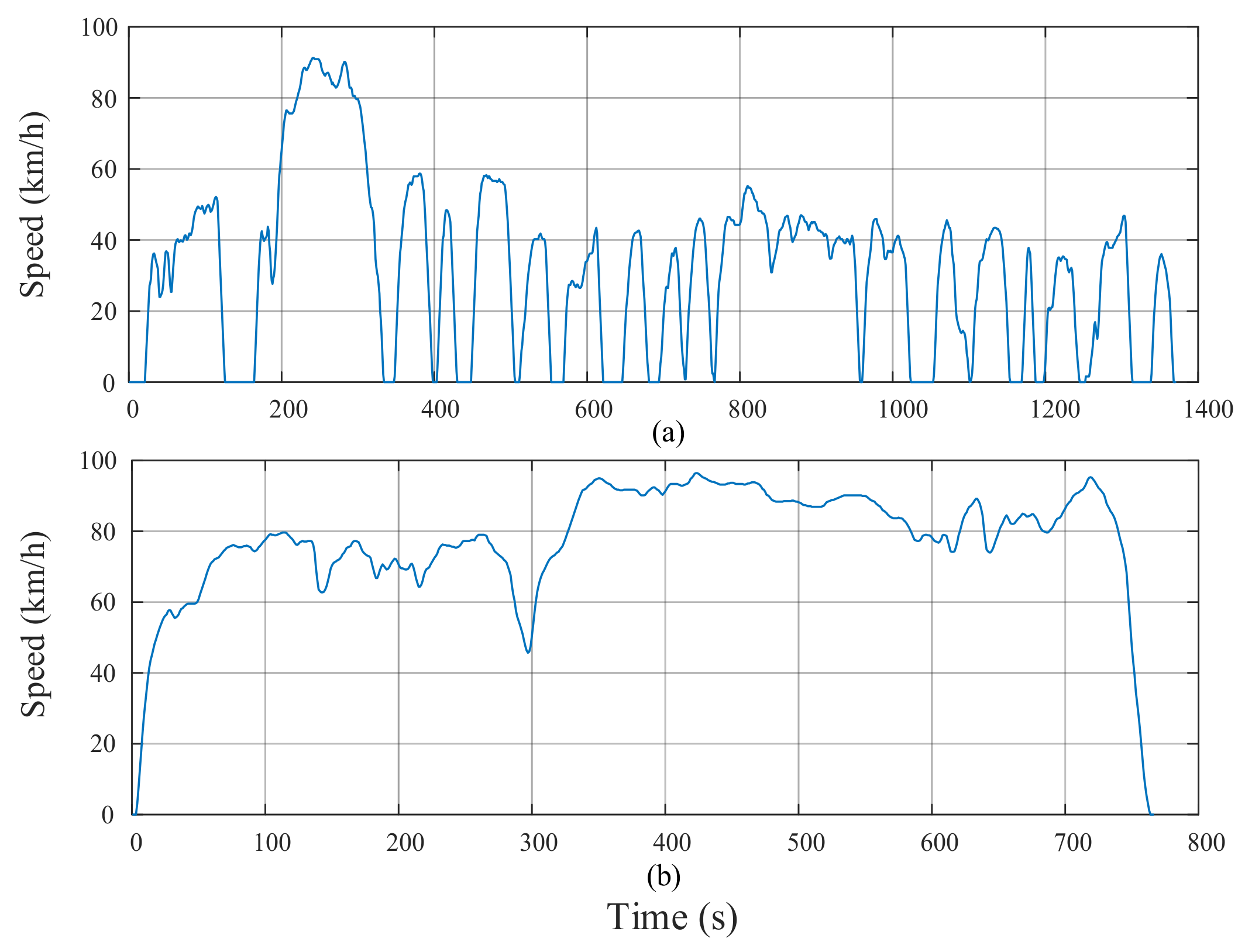

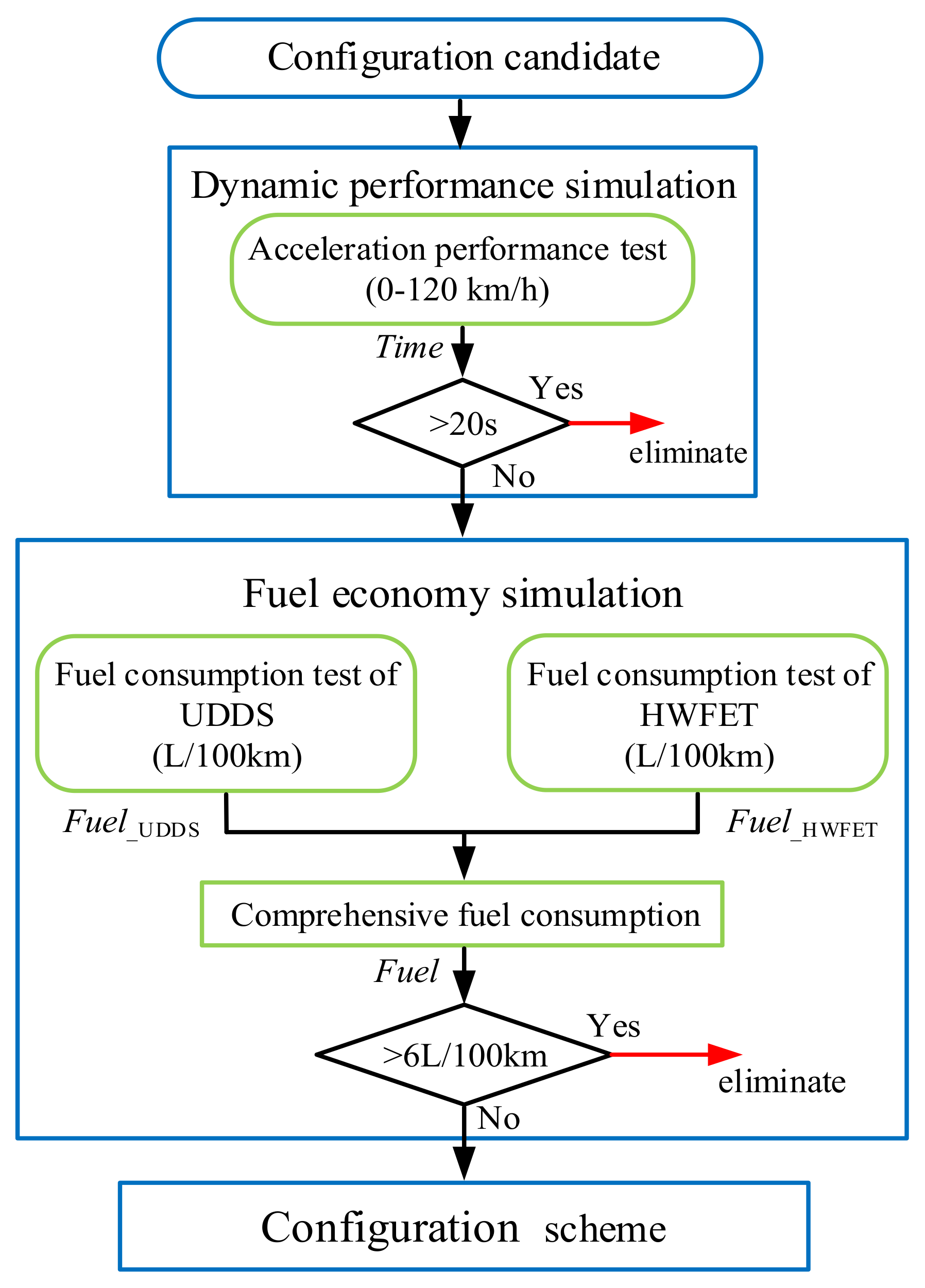

4.2. Performance Simulation

5. Results and Analysis

6. Conclusions

- The main purpose of this paper was to provide a new design idea and scheme for the single motor hybrid powertrain configuration.

- Compared with the reference configuration, four Pareto optimal configurations obtained by screening and optimization have obvious advantages in fuel economy and dynamic performance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zheng, C.; Hengjie, H.; Yitao, W.; Renxin, X.; Jiangwei, S.; Yonggang, L. Energy management for a power-split plug-in hybrid electric vehicle based on reinforcement learning. Appl. Sci. 2018, 8, 2494. [Google Scholar]

- He, H.; Guo, X. Multi-objective optimization research on the start condition for a parallel hybrid electric vehicle. Appl. Energy 2018, 227, 294–303. [Google Scholar] [CrossRef]

- Insu, C.; Jongwon, B.; Junha, P.; Jinwook, L. Experimental evaluation and prediction algorithm suggestion for determining SOC of lithium polymer battery in a parallel hybrid electric vehicle. Appl. Sci. 2018, 8, 1641. [Google Scholar]

- Xiao, R.; Liu, B.; Shen, J.; Guo, N.; Yan, W.; Chen, Z. Comparisons of energy management methods for a parallel plug-in hybrid electric vehicle between the convex optimization and dynamic programming. Appl. Sci. 2018, 8, 218. [Google Scholar] [CrossRef]

- Qin, Z.; Luo, Y.; Zhuang, W.; Pan, Z.; Li, K.; Peng, H. Simultaneous optimization of topology, control and size for multi-mode hybrid tracked vehicle. Appl. Energy 2018, 212, 1627–1641. [Google Scholar] [CrossRef]

- Vinot, E.; Trigui, R.; Cheng, Y.; Bouscayrol, A.; Espanet, C. Optimal management and comparison of SP-HEV vehicles using the dynamic programming method. In Proceedings of the Vehicle Power and Propulsion Conference IEEE, Belfort, France, 14–17 December 2017; pp. 944–949. [Google Scholar]

- Yue, T.; Lior, N. Thermodynamic analysis of hybrid Rankine cycles using multiple heat sources of different temperatures. Appl. Energy 2018, 222, 564–583. [Google Scholar] [CrossRef]

- Yue, H.; Weimin, L. Energy management strategy for a hybrid electric vehicle based on deep reinforcement learning. Appl. Sci. 2018, 8, 187. [Google Scholar]

- Zhang, X.; Li, C.T.; Peng, H. Prius+ and Volt−: Configuration analysis of power-split hybrid vehicles with a single planetary gear. IEEE Trans. Veh. Technol. 2012, 61, 857–865. [Google Scholar]

- Zhuang, W.; Zhang, X.; Li, D.; Wang, L. Mode shift map design and integrated energy management control of a multi-mode hybrid electric vehicle. Appl. Energy 2017, 204, 476–88. [Google Scholar] [CrossRef]

- Barhoumi, T.; Kum, D. Automatic enumeration of feasible kinematic diagrams for power-split hybrid configurations with a single planetary gear. J. Mech. Design 2017, 139, 083301. [Google Scholar] [CrossRef]

- Zhang, X.; Li, S.E.; Peng, H.; Sun, J. Design of multimode power-split hybrid vehicles—A case study on the Voltec powertrain system. IEEE Trans. Veh. Technol. 2016, 65, 4790–4801. [Google Scholar] [CrossRef]

- Kim, H.; Kum, D. Comprehensive design methodology of input- and output-split hybrid electric vehicles: In search of optimal configuration. IEEE/ASME Trans. Mechatron. 2016, 21, 2912–2923. [Google Scholar] [CrossRef]

- Zhang, X.; Peng, H.; Sun, J. A near-optimal power management strategy for rapid component sizing of power split hybrid vehicles with multiple operating modes. IEEE Trans. Control Syst. Technol. 2015, 23, 609–618. [Google Scholar] [CrossRef]

- Zhang, X.; Li, S.E.; Peng, H.; Sun, J. Efficient exhaustive search of power-split hybrid powertrains with multiple planetary gears and clutches. J. Dyn. Syst. Meas. Control 2015, 137, 121006. [Google Scholar] [CrossRef]

- Zhuang, W.; Zhang, X.; Ding, Y.; Wang, L.; Hu, X. Comparison of multi-mode hybrid powertrains with multiple planetary gears. Appl. Energy 2016, 178, 624–632. [Google Scholar] [CrossRef]

- Bayrak, A.E.; Kang, N.; Papalambros, P.Y. Decomposition-based design optimization of hybrid electric powertrain architectures: Simultaneous configuration and sizing design. J. Mech. Des. 2016, 138, 071405. [Google Scholar] [CrossRef]

- Yang, Y.; Hu, X.; Pei, H.; Peng, Z. Comparison of power-split and parallel hybrid powertrain architectures with a single electric machine: Dynamic programming approach. Appl. Energy 2016, 168, 683–690. [Google Scholar] [CrossRef]

- Wang, W.; Song, R.; Guo, M.; Liu, S. Analysis on compound-split configuration of power-split hybrid electric vehicle. Mech. Mach. Theory 2014, 78, 272–288. [Google Scholar] [CrossRef]

- Sundström, O.; Guzzella, L.; Soltic, P. Optimal hybridization in two parallel hybrid electric vehicles using dynamic programming. IFAC Proc. Vol. 2008, 41, 4642–4647. [Google Scholar] [CrossRef]

- Debal, P.; Faid, S.; Tricoche, L.; Bervoets, S. CVT-based full hybrid powertrain offering high efficiency at lower cost. In Proceedings of the SAE World Congress, Detroit, MI, USA, 13–15 April 2010. [Google Scholar]

- Sun, J.K.; Kim, K.S.; Kum, D. Feasibility assessment and design optimization of a clutchless multimode parallel hybrid electric powertrain. IEEE/ASME Trans. Mechatron. 2016, 21, 774–786. [Google Scholar]

- Kim, N.; Kwon, J.; Rousseau, A. Comparison of powertrain configuration options for plug-in hevs from a fuel economy perspective. SAE Tech. Paper 2012. [Google Scholar] [CrossRef]

- Lee, S.; Lee, B.; McDonald, J.; Sanchez, L.J.; Nam, E. Modeling and validation of power-split and P2 parallel hybrid electric vehicles No. 2013-01-1470. SAE Tech Paper 2013. [Google Scholar] [CrossRef]

- Liu, G.; Zhou, M.Z.; Wang, L.L.; Wang, H. A radar-based door open warning technology for vehicle active safety. In Proceedings of the International Conference on Information System & Artificial Intelligence, Tianjin, China, 14–16 July 2017. [Google Scholar]

- Zhang, X.; Peng, H.; Sun, J. Not just for fuel economy: A systematic design and exhaustive search for hybrid multimode light trucks. IFAC PapersOnLine 2015, 48, 1–7. [Google Scholar] [CrossRef]

- Liu, J.; Peng, H. Modeling and control of a power-split hybrid vehicle. IEEE Trans. Control Syst. Technol. 2008, 16, 1242–1251. [Google Scholar]

- Dagci, O.H.; Peng, H.; Grizzle, J.W. Hybrid electric powertrain design methodology with planetary gear sets for performance and fuel economy. IEEE Access 2018, 99, 1. [Google Scholar] [CrossRef]

- Zhuang, W.; Zhang, X.; Peng, H.; Wang, L. Rapid configuration design of multiple-planetary-gear power-split hybrid powertrain via mode combination. IEEE/ASME Trans. Mechatron. 2016, 21, 2924–2934. [Google Scholar] [CrossRef]

- Zhou, X.; Qin, D.; Hu, J. Multi-objective optimization design and performance evaluation for plug-in hybrid electric vehicle powertrains. Appl. Energy 2017, 208, 1608–1625. [Google Scholar] [CrossRef]

- Bellman, R. Dynamic programming. Science 1966, 153, 34–7. [Google Scholar] [CrossRef] [PubMed]

- Peng, J.; He, H.; Xiong, R. Rule based energy management strategy for a series-parallel plug-in hybrid electric bus optimized by dynamic programming. Appl. Energy 2016, 185, 1633–1643. [Google Scholar] [CrossRef]

- Kang, M.; Kim, H.; Kum, D. Systematic configuration selection methodology of power-split hybrid electric vehicles with a single planetary gear. In ASME 2014 Dynamic Systems and Control Conference; American Society of Mechanical Engineers: New York, NY, USA, 2014; p. V001T15A001. [Google Scholar]

| Mode Type | Switching Criteria |

|---|---|

| Speed coupling mode | f21,1 + f 21,2 ≠ 0, f 22,1 + f 22,2 ≠ 0, g1,1g1,2 ≠ 0, g2,1g2,2≠0. |

| Torque coupling mode | f1,1f1,2 ≠ 0, f2,1f2,2 ≠ 0, g21,1 + g21,2 ≠ 0, g22,1 + g22,2 ≠ 0. |

| Pure electric mode | Te = 0, ωe = 0, f2,2 = -f1,2/f1,1 ≠ 0, g2,2 = -g1,2/ g1,1 ≠ 0. |

| Engine-alone driving mode | Tmg = 0, ωmg = 0, f1,1= 1/f2,1 ≠ 0, g1,1 = 1/g2,1 ≠ 0. |

| Component | Parameter | Value |

|---|---|---|

| Vehicle | Mass (kg) | 1600 |

| Aerodynamic drag factor | 0.301 | |

| Rolling resistance factor | 0.012 | |

| Wheel radius (m) | 0.307 | |

| Engine | Maximum power (kW) | 93 |

| Maximum torque (Nm) | 138 | |

| Range of speed (r/min) | 800~5600 | |

| MG | Maximum torque (Nm) | 271 |

| Maximum speed (r/min) | 10000 | |

| Battery | Capacity (Ah) | 6.5 |

| Nominal voltage (V) | 352 | |

| Transmission system | Range of CVT speed ratio Final drive gear ratio | 0.442~2.432 3.95 |

| R1:S1(k1), R2:S2(k2) | 2.6, 2.63 |

| Simulation Project | State Variable | Control Variable |

|---|---|---|

| Fuel economy | SOC | ωe Tmg Mode iCVT |

| Dynamic performance | ωe | ωmg Tmg Mode iCVT |

| Configuration | Fuel Economy (L/100 km) | Acceleration Capacity (s) | Operating Mode |

|---|---|---|---|

| I | 3.7141 | 12.3412 | 1-spd, 2-trq, 1-EV |

| II | 3.9251 | 10.2124 | 1-spd, 2-trq, 1-EV |

| III | 4.0350 | 10.1334 | 1-spd, 1-trq, 1-EV |

| IV | 4.1629 | 10.0642 | 1-spd, 1-trq, 1-EV, 1-eng |

| Arrizo 7e | 4.4231 | 13.6895 | 1-spd, 1-trq, 1-eng |

| UDDS | HWFET | |

|---|---|---|

| Configuration II | 61.20% | 79.05% |

| Reference configuration | 53.45% | 78.12% |

| UDDS | HWFET | |

|---|---|---|

| Configuration II | 78.61% | 78.85% |

| Reference configuration | 75.23% | 73.38% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.; Mei, B.; Peng, H.; Jiang, X. Optimization Design and Analysis for a Single Motor Hybrid Powertrain Configuration with Dual Planetary Gears. Appl. Sci. 2019, 9, 707. https://doi.org/10.3390/app9040707

Hu J, Mei B, Peng H, Jiang X. Optimization Design and Analysis for a Single Motor Hybrid Powertrain Configuration with Dual Planetary Gears. Applied Sciences. 2019; 9(4):707. https://doi.org/10.3390/app9040707

Chicago/Turabian StyleHu, Jianjun, Bo Mei, Hang Peng, and Xingyue Jiang. 2019. "Optimization Design and Analysis for a Single Motor Hybrid Powertrain Configuration with Dual Planetary Gears" Applied Sciences 9, no. 4: 707. https://doi.org/10.3390/app9040707

APA StyleHu, J., Mei, B., Peng, H., & Jiang, X. (2019). Optimization Design and Analysis for a Single Motor Hybrid Powertrain Configuration with Dual Planetary Gears. Applied Sciences, 9(4), 707. https://doi.org/10.3390/app9040707