Simulation Models for Offshore Port Service Concepts

Abstract

:1. Introduction

2. Simulation Based Resource Optimization

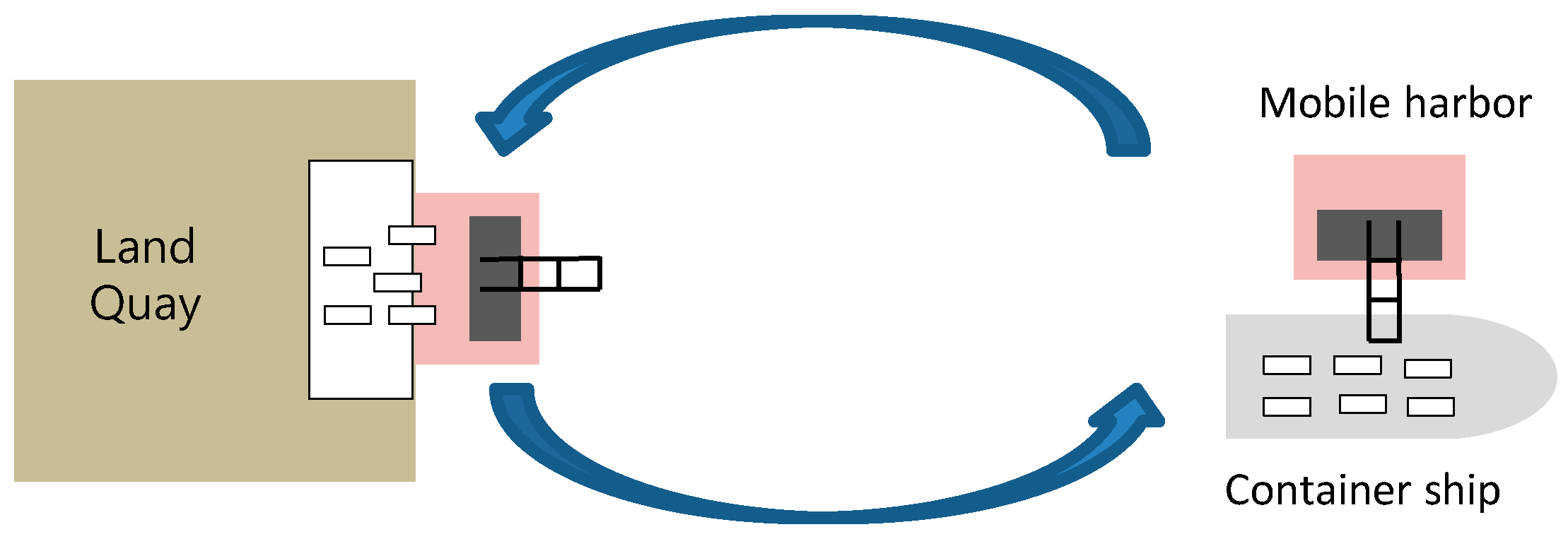

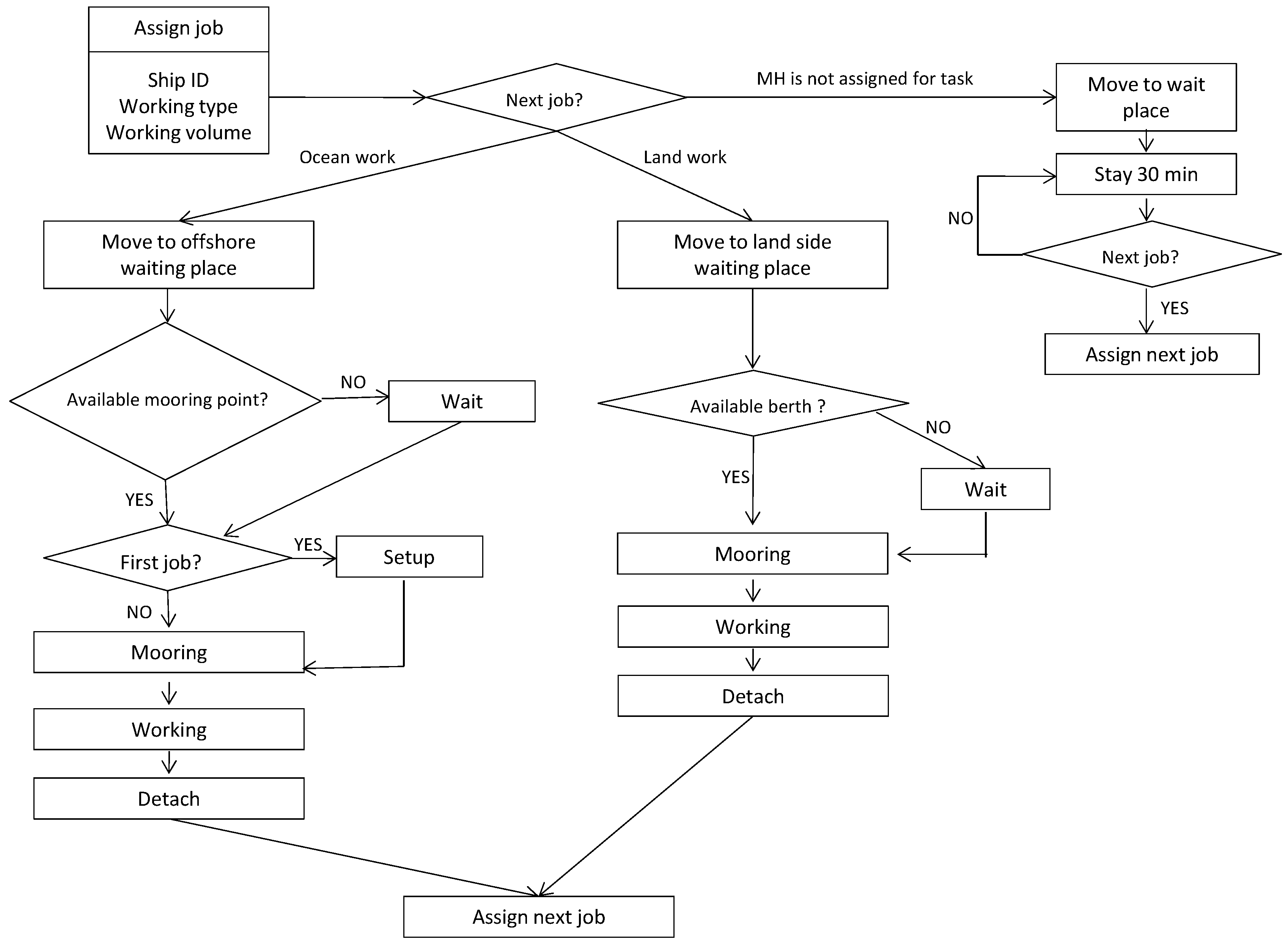

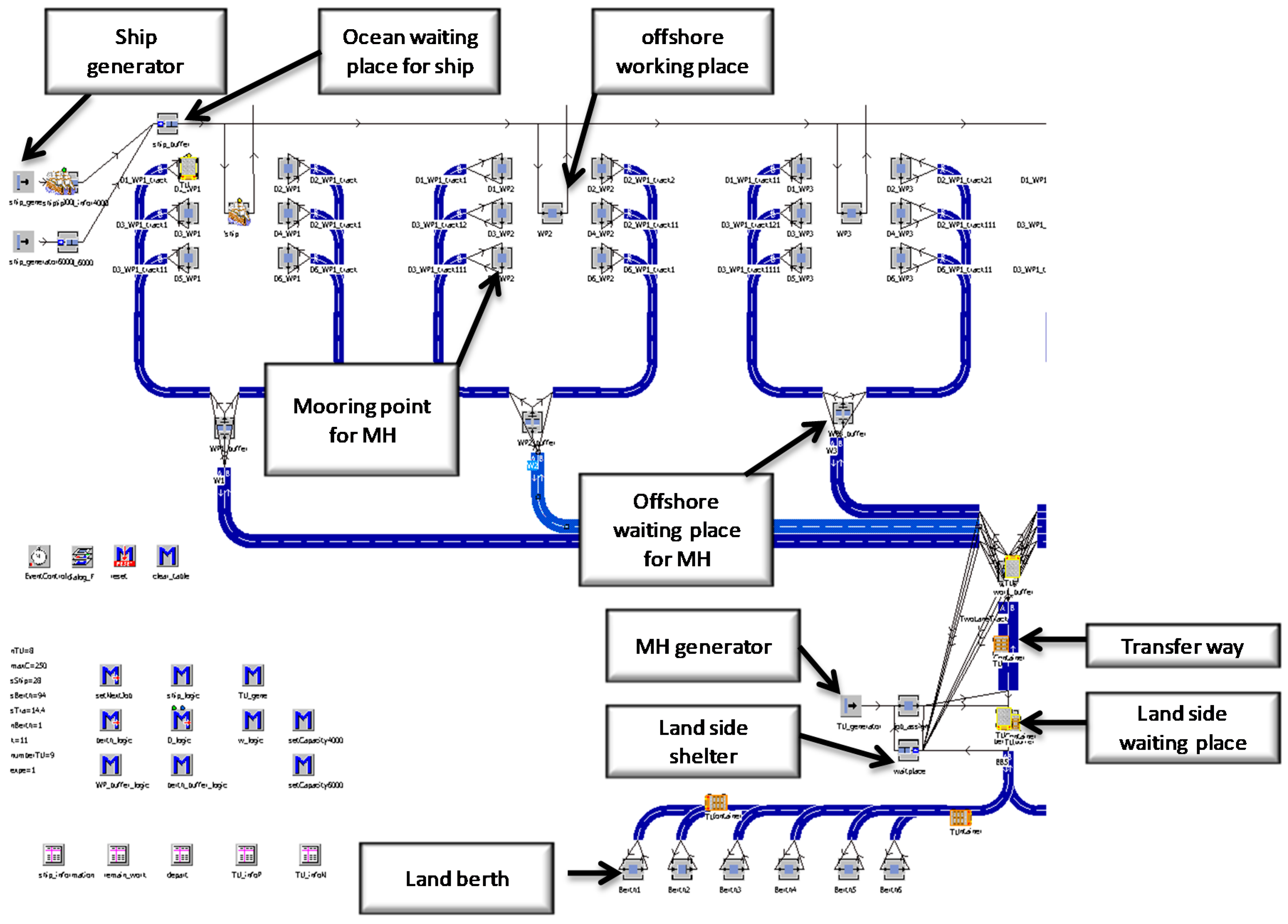

2.1. Description of Mobile Harbor Simulation

- The system operates 24 h/day and 365 days/year;

- We simulate for 3 years in each replication and discard data from the first 100 ships to assess when port is fully activated;

- We conduct 20 replications per case;

- The simulation model starts empty;

- All speeds are constant;

- The speed of all resources in the simulation is 0.75 of the ideal container handling speed of the resource (Yang el al. 2001). In the simulation study, no safety coefficient is used to account for queuing delay—we measure it.

2.2. Identifying an Optimal Number of Resources

- Property 1: If P(n) ≤ Ptgt, there is no need to evaluate P(n + b), for any b ∈ {0,1}2, as it will cost more and also satisfy the performance constraint.

- Property 2: If P(n) > Ptgt, then there is no need to evaluate P(n − b), for any b ∈ {0,1}2, with nk + bk ≥ 0, for all k = 1, …, K, as it will also not meet our service level requirement that is W/S ratio is less than 0.1.

- Property 3: nberth should be less than nMH. Berths need not be used if there are enough to provide uninterrupted service to all land-sea interface berth locations.

- Step 1: Initialize n with an arbitrary value. Set S’ to the empty set; it will contain resource level vectors that we have already considered.

- Step 2: Conduct numerous replications of the simulation to approximate P(n).

- Step 3: If P(n) ≤ Ptgt, go to step 4; else, go to step 5.

- Step 4: Calculate the resource cost with n resources and if it has the least cost so far, set that value as our current minimal cost. Include all resource vectors with greater resource cost according to Property 1 above in the set S’. Go to step 6.

- Step 5: Include all resource vectors with performance dominated by n according to Property 2 in the set S’. Go to step 6.

- Step 6: Employ Property 3 to add resource vectors to the set S’. Go to step 7.

- Step 7: If there is no resource vector remaining that is not included in S’, terminate the search. The resource vector with minimal cost that is not in S’ is optimal (or there is no solution if all are in S’). If the previous statements in Step 7 do not apply, select a new resource vector not in S’ by randomly increasing or decreasing the resource levels by one for one of the resources; Call the new resource levels nα. Go to Step 2.

3. Application to the Resource Allocation Problem in the Mobile Harbor System

3.1. Market Conditions

3.2. Operation Specification and Cost

3.3. Simulation for the Port of Surabaya

- The inter-arrival times (IAT) to the port for container ships with 1000–3999 TEU and 4000–5999 TEU capacities are exponentially and uniformly distributed, respectively. Larger capacity ships have more tightly controlled schedules and thus, we give the associated inter-arrival times a distribution with a smaller standard deviation. Several container ships can arrive at the same time since we use probability distribution for ship inter-arrival times.

- The number of mooring points on a 1000–2499 TEU capacity container ship for mobile harbors with capacity 250, 600, and 1200 TEU is 2, 1, and 1, respectively. For the small size container vessel, only 250 TEU MH is able to process both sides unloading due to the crane interference and safety issue which was determined when MH was conceptually designed by considering its physical and operational issues in 2011 (MH report 2010).

- The number of mooring points on a 2500–5999 TEU capacity containership for mobile harbors with capacity 250, 600, and 1200 TEU is 3, 2, and 2, respectively.

- Mooring time of MH at container ship is 30 min.

- The mean inter-arrival time obtained is 365 * 24/# of visiting ships per year for the scenario.

- The mean call size per ship is calculated as the yearly throughput/# of ships yearly.

- There are six offshore service locations that can be used at one time by container ships.

- The ratio of import cargo volume to export cargo volume is 1:1 based on the MH report 2011. These ratios each require a potentially different sequence of service events.

- The service level metric is the average W/S ratio (waiting time/service time) and we require it to be less than 0.1 (as recommended by UNCTAD [28]);

4. Concluding Remarks

Reference

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Drewry Shipping Consultants Ltd. Annual Container Market Review and Forecast; Drewry Shipping Consultants Publisher: London, UK, 2013. [Google Scholar]

- Tran, N.K.; Haasis, H.D. A research on operational patterns in container liner shipping. Transport 2018, 33, 619–632. [Google Scholar] [CrossRef]

- Osborne, A. Britain Makes Way for New £1.5bn Superport. 2012. Available online: http://www.telegraph.co.uk/finance/newsbysector/transport/9291583/Britain-makes-way-for-new-1.5bn-superport.html (accessed on 23 April 2017).

- Günther, H.-O.; Kim, K.-H. Container terminals and terminal operations. OR Spectr. 2006, 28, 437–445. [Google Scholar] [CrossRef]

- Fung, K.F. Competition between the ports of Hong Kong and Singapore: A structural vector error correction model to forecast the demand for container handling services. Marit. Policy Manag. 2001, 28, 3–22. [Google Scholar] [CrossRef]

- Suh, N.P. Mobile Harbor to Improve Ocean Transportation System and Transportation Method Using the Same. Korean Patent No. 100895604, 23 April 2008. [Google Scholar]

- Hong, K.S.; Ngo, Q.H. Dynamics of the container crane on a mobile harbor. Ocean Eng. 2012, 53, 16–24. [Google Scholar] [CrossRef]

- Jang, I.G.; Kim, K.S.; Kwak, B.M. Conceptual and basic designs of the Mobile Harbor crane based on topology and shape optimization. Struct. Multidiscip. Optim. 2014, 50, 505–515. [Google Scholar] [CrossRef]

- Kwak, B.M.; Oh, J.H. Balance Keeping Crane and Vessel with the Crane. South Korean Patent Application Filing Number 1020090070799, 31 July 2009. [Google Scholar]

- Kim, S.H.; Kim, U.H.; Hong, Y.S.; Ju, H.J.; Kim, J.; Kwak, Y.G.; Kwak, B.M. Auto Landing, Location, Locking Device for Spreader of Crane and Method Thereof. South Korean Patent Application 1020090074305, 12 August 2009. [Google Scholar]

- Shin, H.K.; Shin, J.W.; Kim, M.S.; Jung, W.J. Docking System of Ship. South Korean Patent Application 1020090093030, 30 September 2009. [Google Scholar]

- Kim, J.; Morrison, J.R. Offshore port service concepts: Classification and economic feasibility. Flex. Serv. Manuf. J. 2012, 24, 214–245. [Google Scholar] [CrossRef]

- Sung, I.; Nam, H.; Lee, T. Scheduling algorithms for mobile harbor: An extended m-parallel machine problem. Int. J. Ind. Eng. 2013, 20, 1–14. [Google Scholar]

- Shin, K.; Lee, T. Container loading and unloading scheduling for a Mobile Harbor system: A global and local search method. Flex. Serv. Manuf. J. 2013, 25, 557–575. [Google Scholar] [CrossRef]

- Nam, H.; Lee, T. A scheduling problem for a novel container transport system: A case of mobile harbor operation schedule. Flex. Serv. Manuf. J. 2013, 25, 576–608. [Google Scholar] [CrossRef]

- Jahromi, A.E.; Yazdeli, R.I. A mixed integer-programming model for periodic routing of special vessels in offshore oil industry. Int. J. Ind. Eng. 2015, 22, 524–528. [Google Scholar]

- Kim, W.S.; Kim, J.H.; Kim, H.; Kwon, H.; Morrison, J.R. Capacity and queueing evaluation of port systems with offshore container unloading. In Proceedings of the International Conference Logistics and Maritime Systems, Busan, Korea, 15–17 September 2010. [Google Scholar]

- Ministry of Maritime Affairs and Fisheries of Korea (MMAFK). Modified Port Development Plan. Title Translated from Korean; 2001. Available online: http://academic.naver.com/view.nhn?doc_id=18075302&dir_id=0&field=0&sort=0&query=%EC%88%98%EC%A0%95%20%ED%95%AD%EB%A7%8C%20%EA%B3%84%ED%9A%8D&page=1 (accessed on 23 April 2017).

- Yang, C.H.; Kim, C.G.; Bae, J.W. Research on the Method to Estimate Container Terminal Capacity. Korea Maritime Institute (KMI) Technical Report. Title Translated from the Korean. 2001. Available online: http://academic.naver.com/view.nhn?doc_id=38120844&dir_id=1&field=0&sort=0&query=%EC%8B%A0%EC%84%9D%EC%B2%98%EB%A6%AC&page=1 (accessed on 23 April 2017).

- Korea Container Terminal Authority (KCTA). Third Phase Berth Construction Report of Gwang Yang Terminal in Korea. Title Translated from Korean. 2008. Available online: http://academic.naver.com/view.nhn?doc_id=18287378&dir_id=1&field=0&sort=0&query=%EA%B4%91%EC%96%91%ED%95%AD%201%EC%B0%A8&page=1 (accessed on 23 April 2017).

- Suzuki, K.A.O.; Kemper Filho, P.; Morrison, J.R. Automatic battery replacement system for UAVs: Analysis and design. J. Intell. Robot. Syst. 2012, 65, 563–586. [Google Scholar] [CrossRef]

- Ji, M.; Xia, J. Analysis of vehicle requirements in a general automated guided vehicle system based transportation system. Comput. Ind. Eng. 2010, 59, 544–551. [Google Scholar] [CrossRef]

- Godzdanker, R.; Rutherford, M.J.; Valavanis, K.P. ISLANDS: A self-leveling landing platform for autonomous miniature UAVs. In Proceedings of the 2011 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM2011), Budapest, Hungary, 3–7 July 2011; pp. 170–175. [Google Scholar]

- Godzdanker, R.; Rutherford, M.J.; Valavanis, K.P. Improving endurance of autonomous aerial vehicles through intelligent service-station placement. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, RiverCentre, Saint Paul, MN, USA, 14–18 May 2012; pp. 3179–3184. [Google Scholar]

- Zhen, L.; Lee, L.H.; Chew, E.P.; Chang, D.F.; Xu, Z.X. A Comparative Study on Two Types of Automated Container Terminal Systems. IEEE Trans. Autom. Sci. Eng. 2012, 9, 56–69. [Google Scholar] [CrossRef]

- Bugaric, U.; Petrovic, D.; Petrovic, Z.; Pajcin, M.; Markovic-Petrovic, G. Determining the capacity of unloading bulk cargo terminal using queuing theory. Stroj. Vestn. J. Mech. Eng. 2011, 57, 405–416. [Google Scholar] [CrossRef]

- Shabayek, A.A.; Yeung, W.W. Effect of seasonal factors on performance of container terminals. J. Waterw. Port Coast. Ocean Eng. 2001, 127, 135–140. [Google Scholar] [CrossRef]

- United Nations Conference on Trade and Development (UNCTAD). Port Development: A Handbook for Planners in Developing Countries; United Nations: New York, NY, USA, 1985. [Google Scholar]

- Liu, C.I.; Jula, H.; Ioannou, P.A. Design, simulation.; evaluation of automated container terminals. IEEE Trans. Intell. Transp. Syst. 2002, 3, 12–26. [Google Scholar] [CrossRef]

- Koh, P.H.; Goh, J.L.; Ng, H.S.; Ng, H.C. Using simulation to preview plans of a container port operations. In Proceedings of the Winter Simulation Conference, Lake Buena Vista, FL, USA, 11–14 December 1994; pp. 1109–1115. [Google Scholar]

- Young, Y.W.; Seok, C.Y. A simulation model for container-terminal operation analysis using an object-oriented approach. Int. J. Prod. Econ. 1999, 59, 21–230. [Google Scholar]

- Demirci, E. Simulation modeling and analysis of a port investment. Simulation 2003, 79, 94–105. [Google Scholar] [CrossRef]

- Fowler, J.W.; Mönch, L.; Ponsignon, T. Discrete-Event Simulation for Semiconductor Wafer Fabrication Facilities: A Tutorial. Int. J. Ind. Eng. Theory Appl. Pract. 2015, 22, 661–682. [Google Scholar]

- Japan International Cooperation Agency (JICA). The Study for the Development of the Greater Surabaya Metropolitan Ports in the Republic of Indonesia; Technical Report; Japan International Cooperation Agency : ALMEC Corp. : Japan Port Consultants, Ltd.: Tokyo, Japan, 2007. [Google Scholar]

- Zis, T.; North, R.J.; Angeloudis, P.; Ochieng, W.Y.; Bell, M.G.H. Evaluation of cold ironing and speed reduction policies to reduce ship emissions near and at ports. Marit. Econ. Logist. 2014, 16, 371–398. [Google Scholar] [CrossRef]

- Golias, M.; Boile, M.; Theofanis, S.; Efstathiou, C. The berth-scheduling problem: Maximizing berth productivity and minimizing fuel consumption and emissions production. Transp. Res. Rec. J. Transp. Res. Board. 2010, 2166, 20–27. [Google Scholar] [CrossRef]

| No. | Ship Size (TEU) | # of Visiting Ships | Throughput (TEU) |

|---|---|---|---|

| 1 | 0–499 | 39 | 9750 |

| 2 | 500–999 | 108 | 81,000 |

| 3 | 1000–2499 | 1080 | 1,512,000 |

| 4 | 2500–3999 | 589 | 382,850 |

| 5 | 4000–5999 | 147 | 73,500 |

| Total | 1963 | 2,059,100 | |

| Design # | Capacity (TEU) | Loading or Unloading Speed (TEU/h) | Travel Time (h) | Cost of MH (M US$/year) | Cost of Berth (M US$/year) | |

|---|---|---|---|---|---|---|

| Sea | Land Berth | |||||

| 1 | 250 | 37.5 | 250 | 2.70 | 4.30 | 1.63 |

| 2 | 250 | 37.5 | 125 | 2.70 | 3.90 | 1.62 |

| 3 | 1200 | 75 | 500 | 3.07 | 11.30 | 2.40 |

| 4 | 1200 | 75 | 250 | 3.07 | 10.60 | 2.10 |

| Ship Size | Average IAT (Hours) | IAT Pattern | Cargo Pattern | # of Docking Points (250 TEU) | # of Docking Points (1200 TEU) |

|---|---|---|---|---|---|

| 1000–2499 | 8.11 | exp (8.11) | uniform (1350;1450) | 2 | 1 |

| 2500–3999 | 14.87 | exp (14.87) | uniform (600;700) | 3 | 2 |

| 4000–5999 | 59.59 | uniform (54.59,64.59) | uniform (450;550) | 3 | 2 |

| Design | # of MHs | # of Berths | Total Cost (M USD/year) |

|---|---|---|---|

| 1 | 36 | 3 | 159.7 |

| 2 | 39 | 6 | 161.8 |

| 3 | 14 | 2 | 163 |

| 4 | 15 | 3 | 165.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, W.-s.; Kim, J. Simulation Models for Offshore Port Service Concepts. Appl. Sci. 2019, 9, 584. https://doi.org/10.3390/app9030584

Kim W-s, Kim J. Simulation Models for Offshore Port Service Concepts. Applied Sciences. 2019; 9(3):584. https://doi.org/10.3390/app9030584

Chicago/Turabian StyleKim, Woo-sung, and Jonghoe Kim. 2019. "Simulation Models for Offshore Port Service Concepts" Applied Sciences 9, no. 3: 584. https://doi.org/10.3390/app9030584

APA StyleKim, W.-s., & Kim, J. (2019). Simulation Models for Offshore Port Service Concepts. Applied Sciences, 9(3), 584. https://doi.org/10.3390/app9030584