Femtosecond Pulse Laser Near-Field Ablation of Ag Nanorods

Abstract

1. Introduction

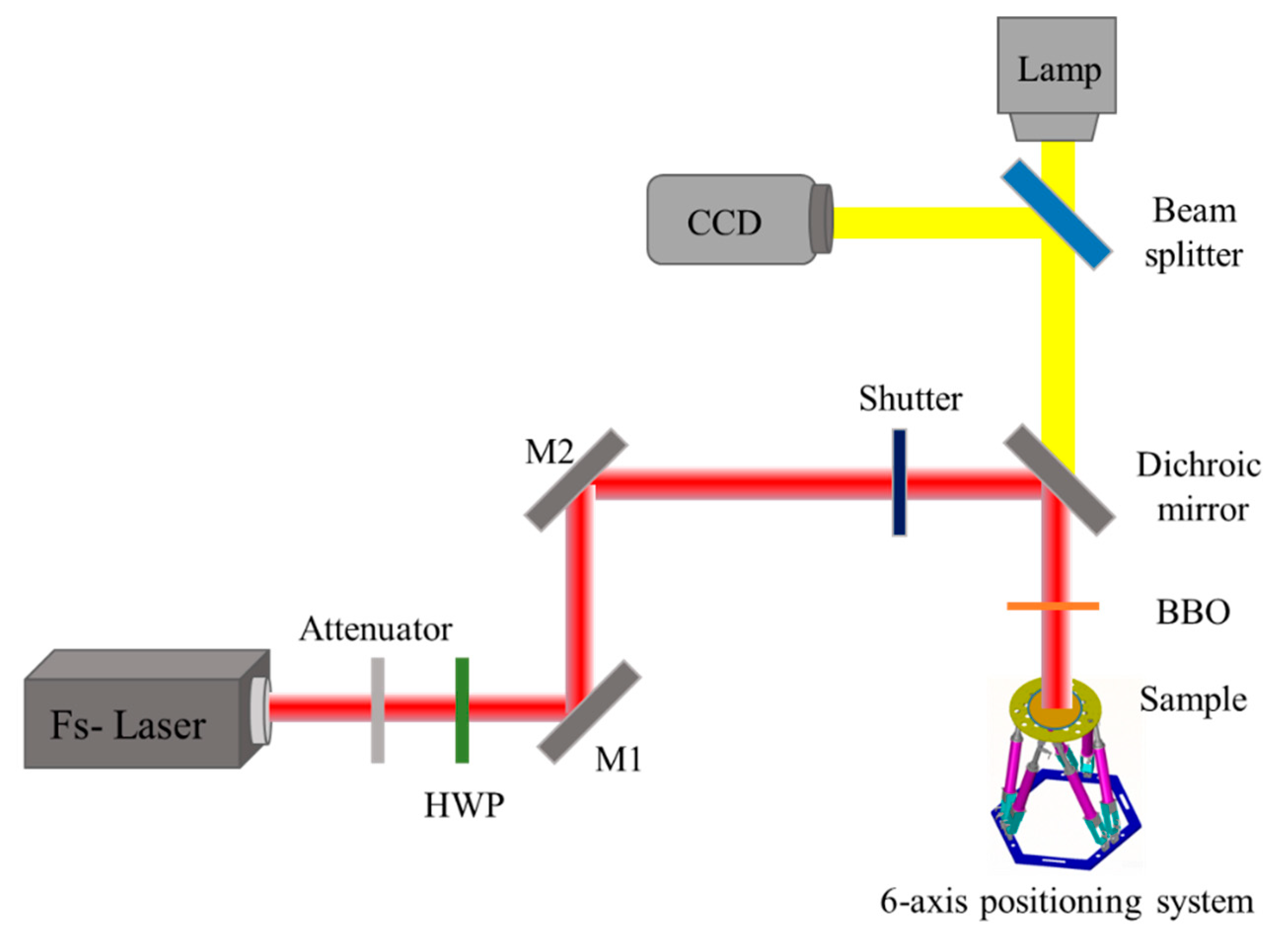

2. Experimental

3. Results and Discussion

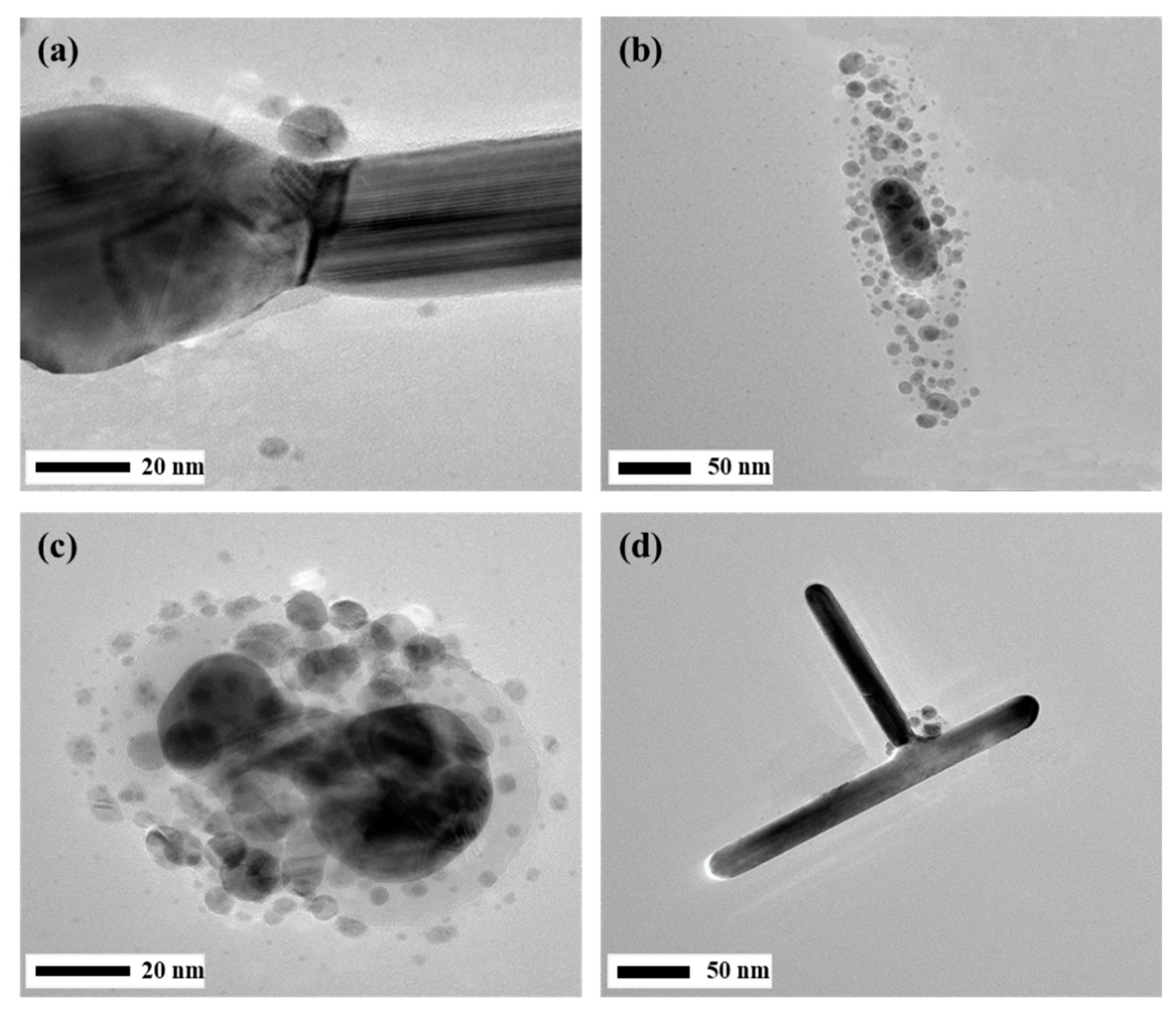

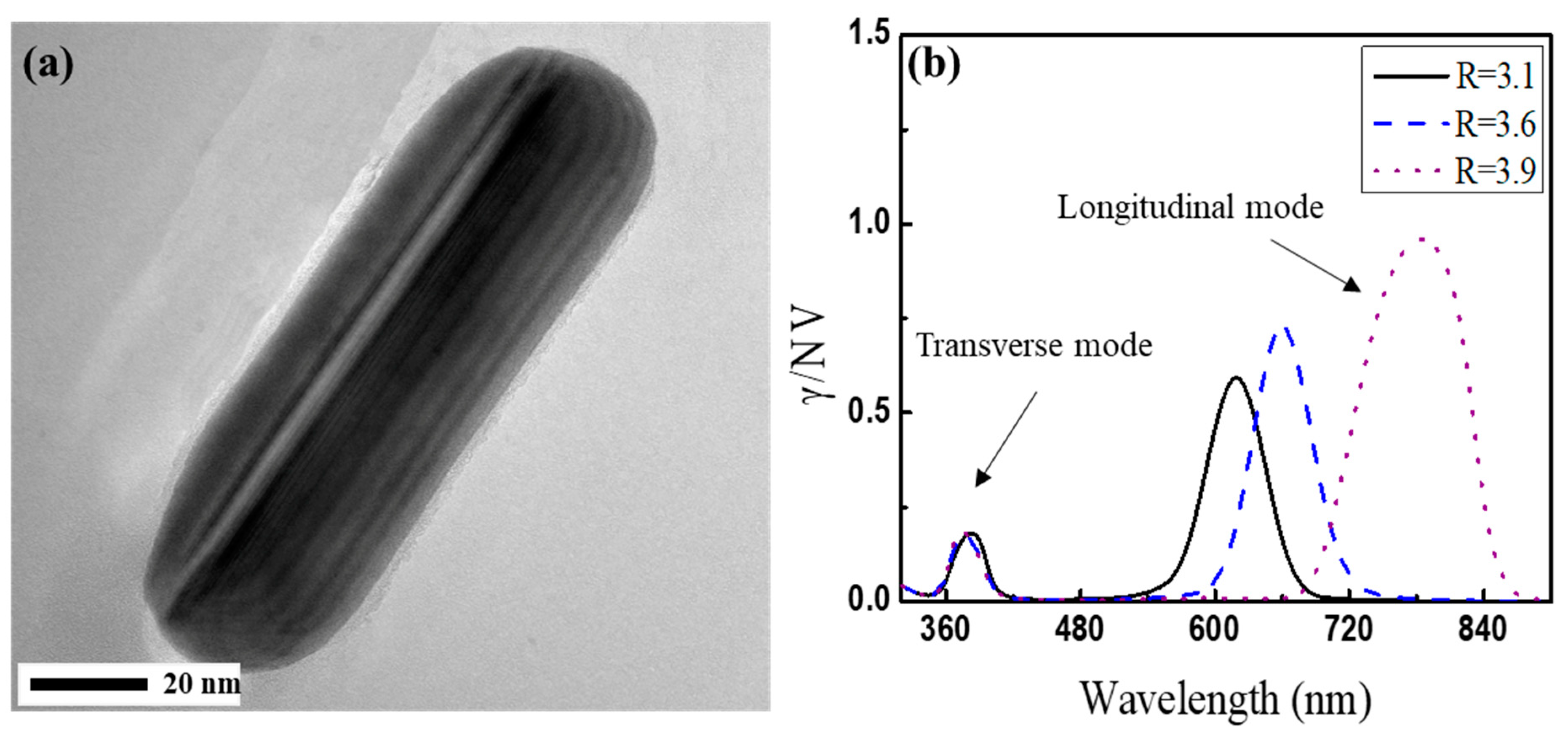

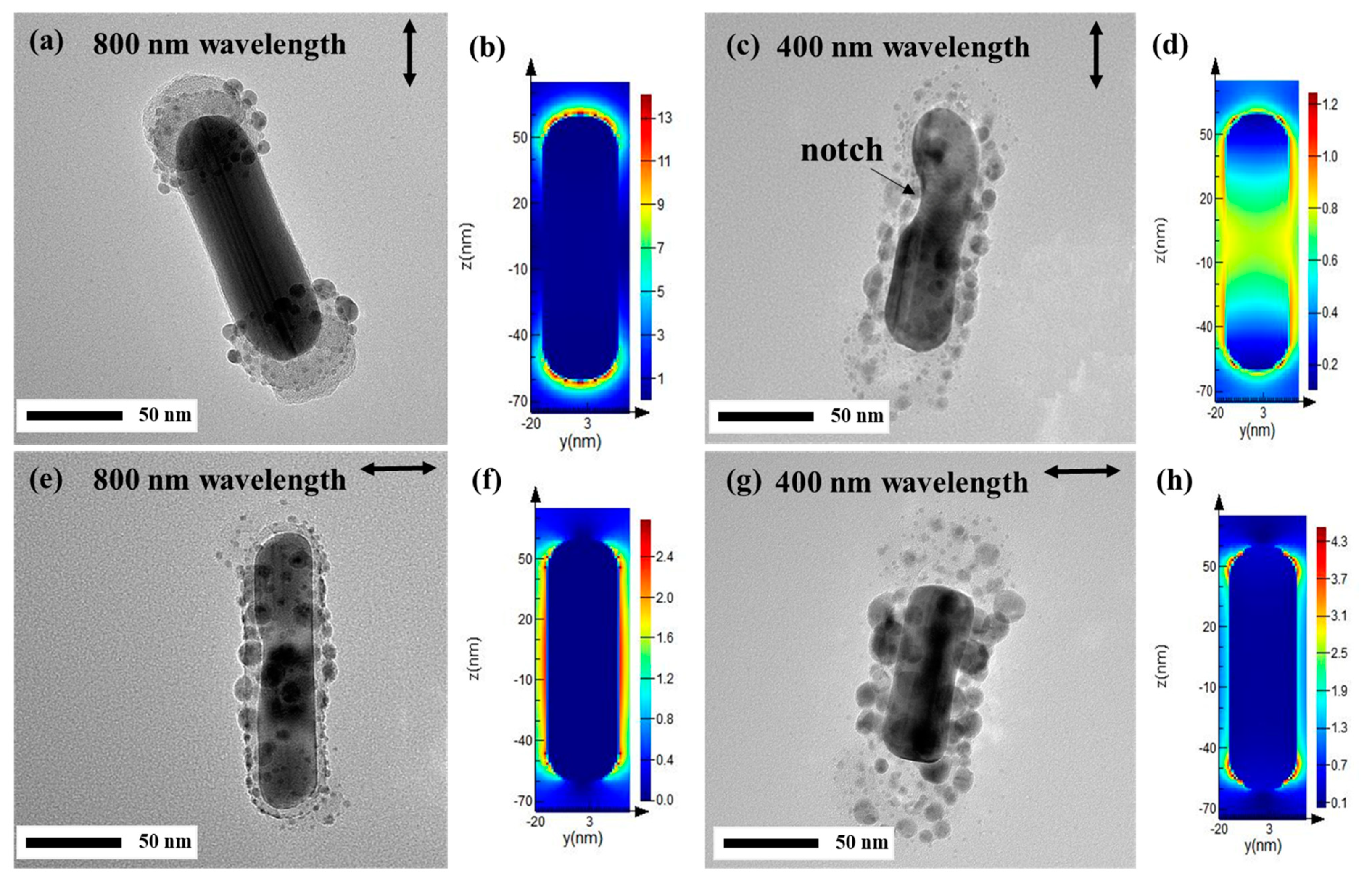

3.1. Controlling the Morphology of Ag NRs by Tuning the Laser Polarization and Wavelength

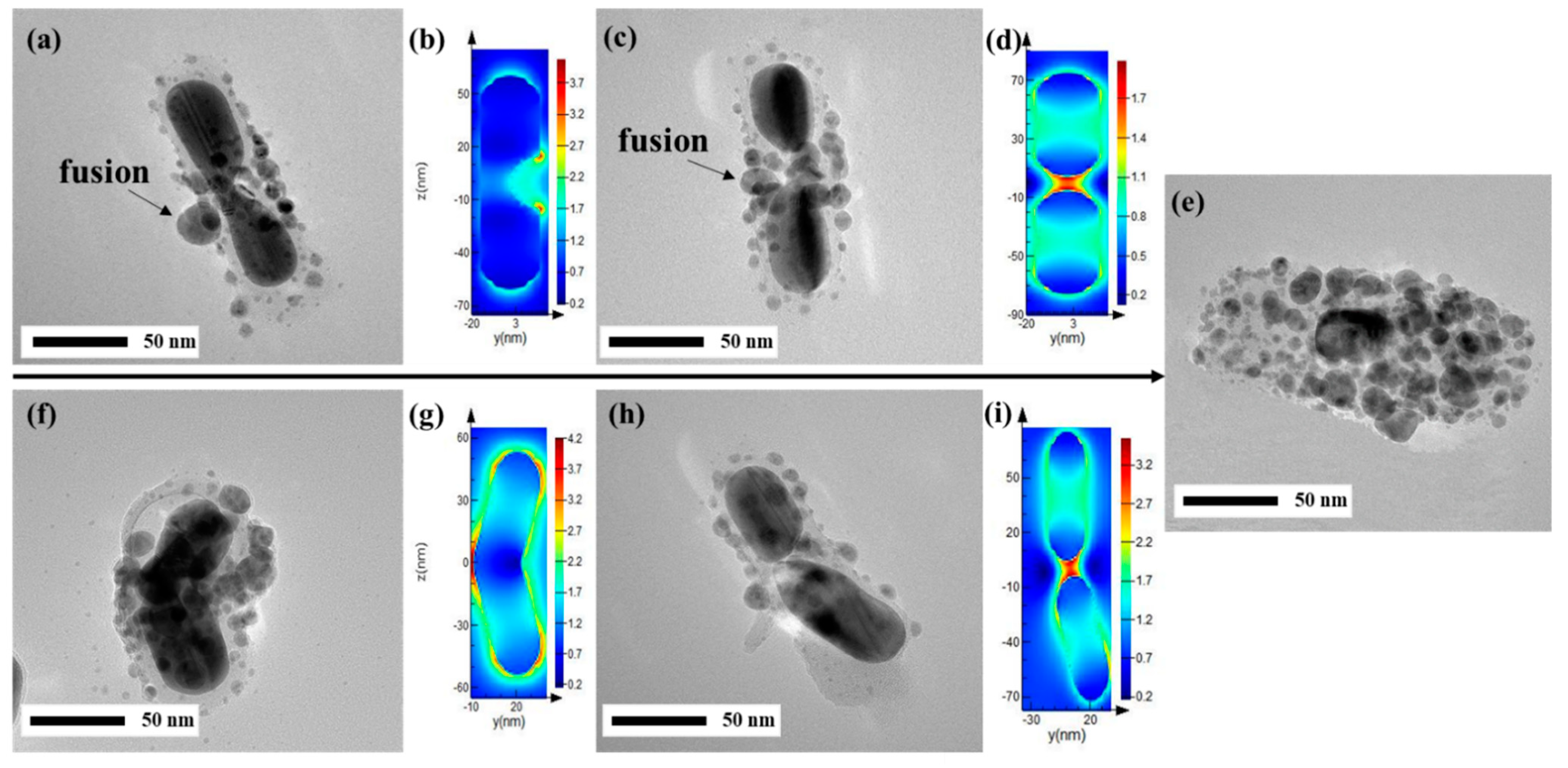

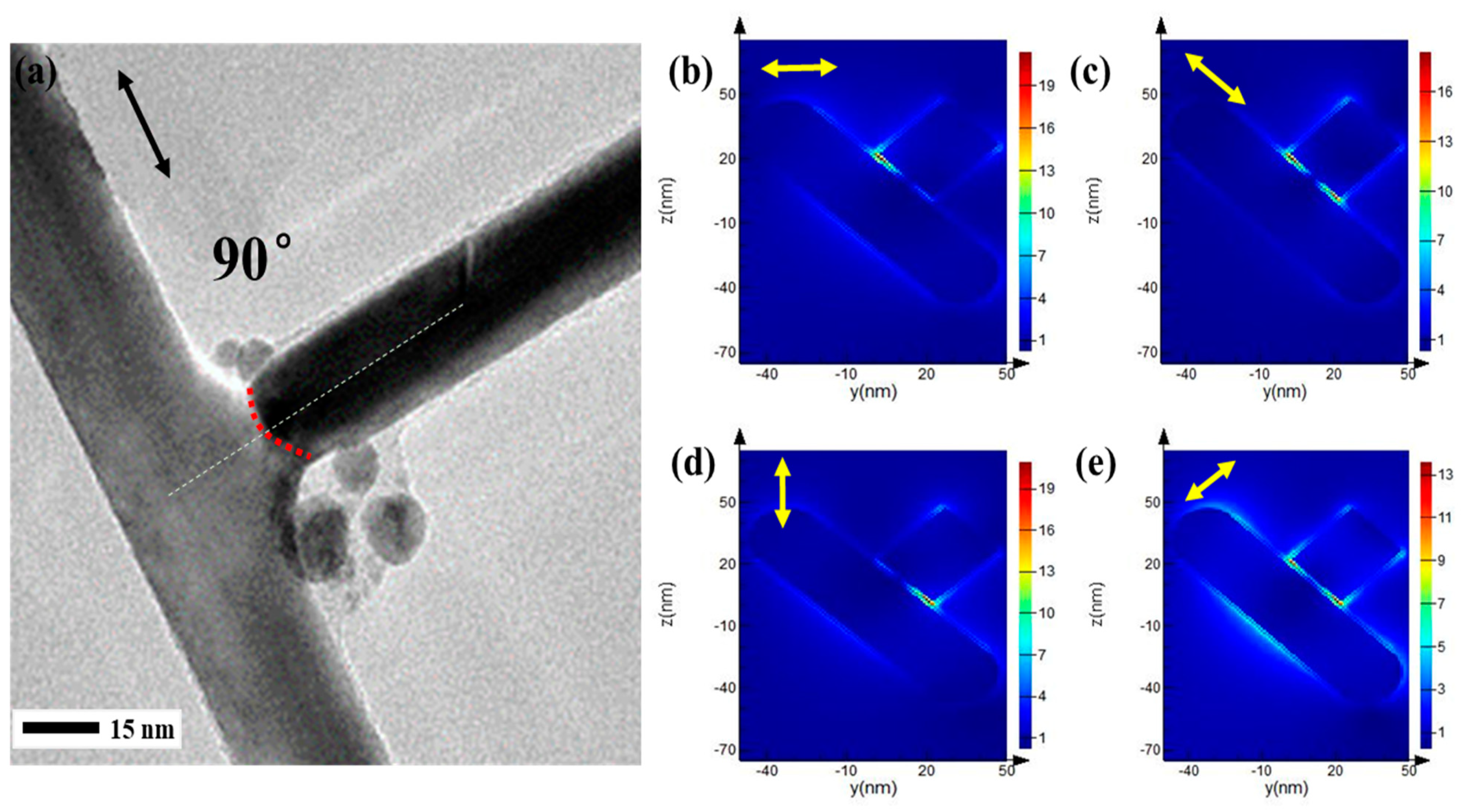

3.2. Near-Field Ablation Evolution of Ag NRs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sokolov, K.; Follen, M.; Aaron, J.; Pavlova, I.; Malpica, A.; Lotan, R.; Richardskortum, R. Real-Time Vital Optical Imaging of Precancer Using Anti-Epidermal Growth Factor Receptor Antibodies Conjugated to Gold Nanoparticles. Cancer Res. 2004, 63, 1999. [Google Scholar]

- Murphy, C.J.; Gole, A.M.; Stone, J.W.; Sisco, P.N.; Alkilany, A.M.; Goldsmith, E.C.; Baxter, S.C. Gold nanoparticles in biology: Beyond toxicity to cellular imaging. Acc. Chem. Res. 2008, 40, 1721–1730. [Google Scholar] [CrossRef] [PubMed]

- Kneipp, J.; Kneipp, H.; Kneipp, K. SERS—A single-molecule and nanoscale tool for bioanalytics. Chem. Soc. Rev. 2008, 37, 1052–1060. [Google Scholar] [CrossRef] [PubMed]

- Brus, L. Noble metal nanocrystals: Plasmon electron transfer photochemistry and single-molecule Raman spectroscopy. Acc. Chem. Res. 2008, 41, 1742. [Google Scholar] [CrossRef] [PubMed]

- Kamat, P.V. Quantum Dot Solar Cells. Semiconductor Nanocrystals as Light Harvesters. J. Phys. Chem. C 2008, 112, 18737–18753. [Google Scholar] [CrossRef]

- Darroudi, M.; Ahmad, M.B.; Zamiri, R.; Abdullah, A.H.; Ibrahim, N.A.; Shameli, K.; Husin, M.S. Preparation and characterization of gelatin mediated silver nanoparticles by laser ablation. J. Alloys Compd. 2011, 509, 1301–1304. [Google Scholar] [CrossRef]

- Yan, J.; Zou, G.; Wu, A.-P.; Ren, J.; Yan, J.; Hu, A.; Zhou, Y. Pressureless bonding process using Ag nanoparticle paste for flexible electronics packaging. Scr. Mater. 2012, 66, 582–585. [Google Scholar] [CrossRef]

- Hu, A.; Guo, J.Y.; Alarifi, H.; Patane, G.; Zhou, Y.; Compagnini, G.; Xu, C.X. Low temperature sintering of Ag nanoparticles for flexible electronics packaging. Appl. Phys. Lett. 2010, 97, 153117. [Google Scholar] [CrossRef]

- Nakamura, T.; Magara, H.; Herbani, Y.; Sato, S. Fabrication of silver nanoparticles by highly intense laser irradiation of aqueous solution. Appl. Phys. A 2011, 104, 1021–1024. [Google Scholar] [CrossRef]

- Hartland, G.V. Optical studies of dynamics in noble metal nanostructures. Chem. Rev. 2011, 111, 3858–3887. [Google Scholar] [CrossRef]

- Yeshchenko, O.A.; Dmitruk, I.M.; Alexeenko, A.A.; Losytskyy, M.Y.; Kotko, A.V.; Pinchuk, A.O. Size-dependent surface-plasmon-enhanced photoluminescence from silver nanoparticles embedded in silica. Phys. Rev. B 2009, 79, 1377–1381. [Google Scholar] [CrossRef]

- Akman, E.; Oztoprak, B.G.; Gunes, M.; Kacar, E.; Demir, A. Effect of femtosecond Ti:Sapphire laser wavelengths on plasmonic behaviour and size evolution of silver nanoparticles. Photonics Nanostruct. Fundam. Appl. 2011, 9, 276–286. [Google Scholar] [CrossRef]

- Giorgetti, E.; Marsili, P.; Muniz-Miranda, M.; Gellini, C.; Giammanco, F. Spectroscopic evidence of positive clusters in Ag colloids obtained by laser ablation in aqueous solutions. Appl. Phys. A 2014, 117, 327–331. [Google Scholar] [CrossRef]

- Šmejkal, P.; Pfleger, J.; Vlčková, B. Study of laser fragmentation process of silver nanoparticles in aqueous media. Appl. Phys. A 2008, 93, 973–976. [Google Scholar] [CrossRef]

- Werner, D.; Hashimoto, S. Improved Working Model for Interpreting the Excitation Wavelength- and Fluence-Dependent Response in Pulsed Laser-Induced Size Reduction of Aqueous Gold Nanoparticles. J. Phys. Chem. C 2016, 115, 5063–5072. [Google Scholar] [CrossRef]

- Werner, D.; Furube, A.; Okamoto, T.; Hashimoto, S. Femtosecond Laser-Induced Size Reduction of Aqueous Gold Nanoparticles: In Situ and Pump-Probe Spectroscopy Investigations Revealing Coulomb Explosion. J. Phys. Chem. C 2011, 115, 8503–8512. [Google Scholar] [CrossRef]

- Takami, A.; Kurita, H.; Koda, S. Laser-Induced Size Reduction of Noble Metal Particles. J. Phys. Chem. B 2003, 103, 1226–1232. [Google Scholar] [CrossRef]

- Susumu, I.; Masakazu, S.; Yukio, Y. Bimodal Size Distribution of Gold Nanoparticles under Picosecond Laser Pulses. J. Phys. Chem. B 2005, 109, 9404. [Google Scholar]

- Pyatenko, A.; Yamaguchi, M.; Suzuki, M. Mechanisms of Size Reduction of Colloidal Silver and Gold Nanoparticles Irradiated by Nd:YAG Laser. J. Phys. Chem. C 2009, 113, 9078–9085. [Google Scholar] [CrossRef]

- Kamat, P.V.; Flumiani, M.; Hartland, G.V. Picosecond Dynamics of Silver Nanocluster. Photoejection of Electrons and Fragmentation. J. Phys. Chem. B 1998, 102, 2123–3128. [Google Scholar] [CrossRef]

- Muto, H.; Miyajima, K.; Mafuné, F. Mechanism of Laser-Induced Size Reduction of Gold Nanoparticles As Studied by Single and Double Laser Pulse Excitation. J. Phys. Chem. C 2008, 112, 5810–5815. [Google Scholar] [CrossRef]

- Giammanco, F.; Giorgetti, E.; Marsili, P.; Giusti, A. Experimental and Theoretical Analysis of Photofragmentation of Au Nanoparticles by Picosecond Laser Radiation. J. Phys. Chem. C 2010, 114, 3354–3363. [Google Scholar] [CrossRef]

- Plech, A.; Kotaidis, V.; Lorenc, M.; Boneberg, J. Femtosecond laser near-field ablation from gold nanoparticles. Nat. Phys. 2005, 2, 44–47. [Google Scholar] [CrossRef]

- Plech, A.; Ibrahimkutty, S.; Reich, S.; Newby, G. Thermal dynamics of pulsed-laser excited gold nanorods in suspension. Nanoscale 2017, 9, 17284–17292. [Google Scholar] [CrossRef] [PubMed]

- Danny, P.; Laurent, J.L. Ablation of solids under femtosecond laser pulses. Phys. Rev. Lett. 2002, 89, 255504. [Google Scholar]

- Nedyalkov, S.; Miyanishi, O. Near field properties in the vicinity of gold nanoparticles placed on various substrates for precise nanostructuring. J. Phys. D Appl. Phys. 2006, 39, 5037. [Google Scholar] [CrossRef]

- Kolloch, A.; Geldhauser, T.; Ueno, K.; Misawa, H.; Boneberg, J.; Plech, A.; Leiderer, P. Femtosecond and picosecond near-field ablation of gold nanotriangles: Nanostructuring and nanomelting. Appl. Phys. A 2011, 104, 793–799. [Google Scholar] [CrossRef]

- Plech, A.; Leiderer, P.; Boneberg, J. Femtosecond laser near field ablation. Laser Photonics Rev. 2009, 3, 435–451. [Google Scholar] [CrossRef]

- Harrison, R.K.; Adela, B.Y. Role of near-field enhancement in plasmonic laser nanoablation using gold nanorods on a silicon substrate. Opt. Express 2010, 18, 22556–22571. [Google Scholar] [CrossRef]

- Hu, J.Q.; Chen, Q.; Xie, Z.X.; Han, G.B.; Wang, R.H.; Ren, B.; Zhang, Y.; Yang, Z.L.; Tian, Z.Q. A Simple and Effective Route for the Synthesis of Crystalline Silver Nanorods and Nanowires. Adv. Funct. Mater. 2010, 14, 183–189. [Google Scholar] [CrossRef]

- Liu, L.; Peng, P.; Hu, A.; Zou, G.; Duley, W.W.; Zhou, Y.N. Highly localized heat generation by femtosecond laser induced plasmon excitation in Ag nanowires. Appl. Phys. Lett. 2013, 102, 073107. [Google Scholar] [CrossRef]

- Hashimoto, S.; Werner, D.; Uwada, T. Studies on the interaction of pulsed lasers with plasmonic gold nanoparticles toward light manipulation, heat management, and nanofabrication. J. Photochem. Photobiol. C Photochem. Rev. 2012, 13, 28–54. [Google Scholar] [CrossRef]

- Wei, H.; Wang, Z.; Tian, X.; Kall, M.; Xu, H. Cascaded logic gates in nanophotonic plasmon networks. Nat. Commun. 2011, 2, 387. [Google Scholar] [CrossRef] [PubMed]

- Garnett, E.C.; Cai, W.; Cha, J.J.; Mahmood, F.; Connor, S.T.; Greyson Christoforo, M.; Cui, Y.; McGehee, M.D.; Brongersma, M.L. Self-limited plasmonic welding of silver nanowire junctions. Nat. Mater. 2012, 11, 241–249. [Google Scholar] [CrossRef] [PubMed]

- Petryayeva, E.; Krull, U.J. Localized surface plasmon resonance: Nanostructures, bioassays and biosensing—A review. Anal. Chim. Acta 2011, 706, 8–24. [Google Scholar] [CrossRef] [PubMed]

- Yan, B.; Yang, Y.; Wang, Y. Comment on “Simulation of the Optical Absorption Spectra of Gold Nanorods as a Function of Their Aspect Ratio and the Effect of the Medium Dielectric Constant”. J. Phys. Chem. B 1999, 107, 315–319. [Google Scholar] [CrossRef]

- Solati, E.; Mashayekh, M.; Dorranian, D. Effects of laser pulse wavelength and laser fluence on the characteristics of silver nanoparticle generated by laser ablation. Appl. Phys. A 2013, 112, 689–694. [Google Scholar] [CrossRef]

- Ghenuche, P.; Cherukulappurath, S.; Taminiau, T.H.; van Hulst, N.F.; Quidant, R. Spectroscopic mode mapping of resonant plasmon nanoantennas. Phys. Rev. Lett. 2008, 101, 116805. [Google Scholar] [CrossRef]

- Khlebtsov, N.G. Optics and biophotonics of nanoparticles with a plasmon resonance. Quantum Electron. 2008, 38, 504–529. [Google Scholar] [CrossRef]

- Huang, W.; Qian, W.; El-Sayed, M.A. Gold nanoparticles propulsion from surface fueled by absorption of femtosecond laser pulse at their surface plasmon resonance. J. Am. Chem. Soc. 2006, 128, 13330–13331. [Google Scholar] [CrossRef]

- Song, T.-B.; Chen, Y.; Chung, C.-H.; Yang, Y.; Bob, B.; Duan, H.-S.; Li, G.; Tu, K.-N.; Huang, Y.; Yang, Y. Nanoscale joule heating and electromigration enhanced ripening of silver nanowire contacts. ACS Nano 2014, 8, 2804–2811. [Google Scholar] [CrossRef] [PubMed]

- Peng, P.; Hu, A.; Gerlich, A.P.; Zou, G.; Liu, L.; Zhou, Y.N. Joining of Silver Nanomaterials at Low Temperatures: Processes, Properties, and Applications. ACS Appl. Mater. Interfaces 2015, 7, 12597–12618. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Liu, L.; Peng, P.; Zou, G.; Duley, W.W.; Zhou, Y.N. In situ nanojoining of Y- and T-shaped silver nanowires structures using femtosecond laser radiation. Nanotechnology 2016, 27, 125201. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, D.; Yan, J. Femtosecond Pulse Laser Near-Field Ablation of Ag Nanorods. Appl. Sci. 2019, 9, 363. https://doi.org/10.3390/app9030363

Zhu D, Yan J. Femtosecond Pulse Laser Near-Field Ablation of Ag Nanorods. Applied Sciences. 2019; 9(3):363. https://doi.org/10.3390/app9030363

Chicago/Turabian StyleZhu, Dezhi, and Jianfeng Yan. 2019. "Femtosecond Pulse Laser Near-Field Ablation of Ag Nanorods" Applied Sciences 9, no. 3: 363. https://doi.org/10.3390/app9030363

APA StyleZhu, D., & Yan, J. (2019). Femtosecond Pulse Laser Near-Field Ablation of Ag Nanorods. Applied Sciences, 9(3), 363. https://doi.org/10.3390/app9030363