Experimental and Numerical Energy Assessment of a Monolithic Aerogel Glazing Unit for Building Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Aerogel Sample Description

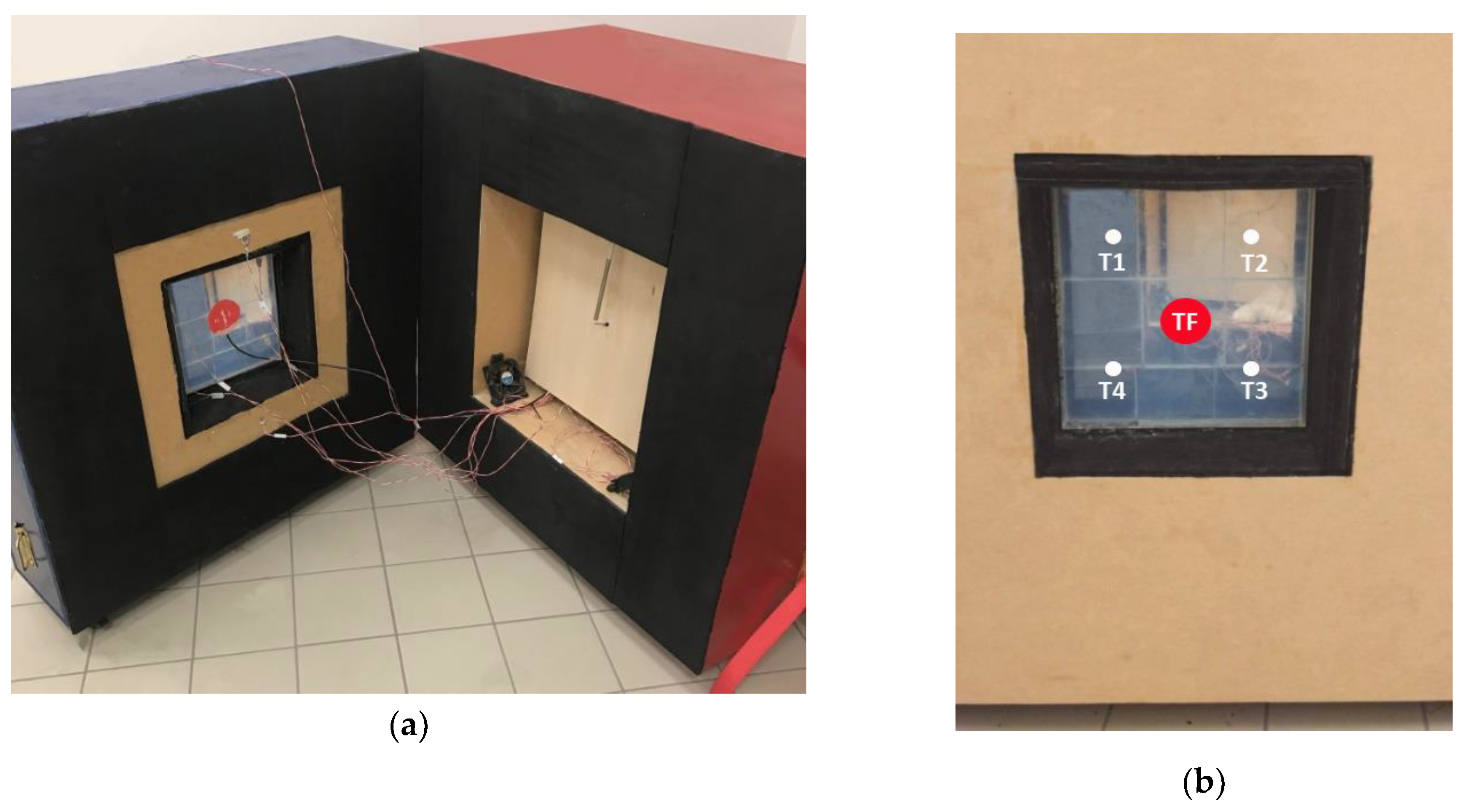

2.2. Thermal Resistance Measurements

2.3. Simplified Methodology for the Calculation of the Solar Heat Gain Factor

- τ (λ) = spectral transmittance of the whole sample;

- ρ (λ) = spectral reflectance of the whole sample measured in the direction of incident radiation;

- τ1 (λ) = spectral transmittance of the outer (first) pane within the triple layer model (glass layer);

- τ2 (λ) = spectral transmittance of the second pane within the triple layer model (aerogel layer);

- τ3 (λ) = spectral transmittance of the inner pane within the triple layer model (glass layer), equal to τ1 (λ);

- ρ1 (λ) = spectral reflectance of the outer (first) pane within the triple layer model (glass layer) measured in the direction of incident radiation;

- ρ’1 (λ) = spectral reflectance of the outer (first) pane within the triple layer model (glass layer) measured in the opposite direction of incident radiation (ρ1 (λ) = ρ’1(λ));

- ρ2 (λ) = spectral reflectance of the second pane within the triple layer model (aerogel layer) measured in the direction of incident radiation;

- ρ’2 (λ) = spectral reflectance of the second pane within the triple layer model (aerogel layer) measured in the opposite direction of incident radiation. It was assumed equal to ρ2 (λ);

- ρ3 (λ) = spectral reflectance of the inner pane within the triple layer model (glass layer) measured in the direction of incident radiation (ρ3 (λ) = ρ1(λ));

- ρ’3 (λ) = spectral reflectance of the inner pane within the triple layer model (glass layer) measured in the opposite direction of incident radiation (ρ3 (λ) = ρ’3(λ)).

- αe1 = solar absorbance of the outer (first) pane within the triple glazing;

- αe2 = solar absorbance of the second pane within the triple glazing (aerogel pane);

- αe3 = solar absorbance of the inner pane (glass layer);

- he = heat transfer coefficient of the glazing towards the outside, assumed equal to 23 W/m2K;

- hi = heat transfer coefficient of the glazing towards the inside, assumed equal to 8 W/m2K;

- 12 = thermal conductance between the outer surface of the outer (first) pane and the centre of the second pane: it was estimated from the measured thermal conductance of the whole sample, by dividing the value into 2 identical contributions;

- 23 = thermal conductance between the centre of the second pane and the outer surface of the third pane: it was assumed equal to 12.

2.4. Building Simulations

3. Results and Discussion

3.1. Thermal and Solar Properties

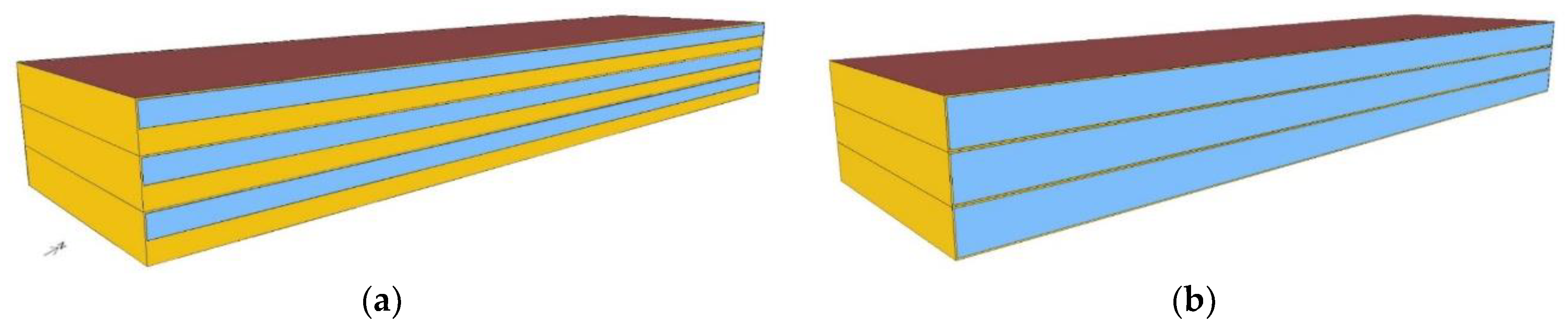

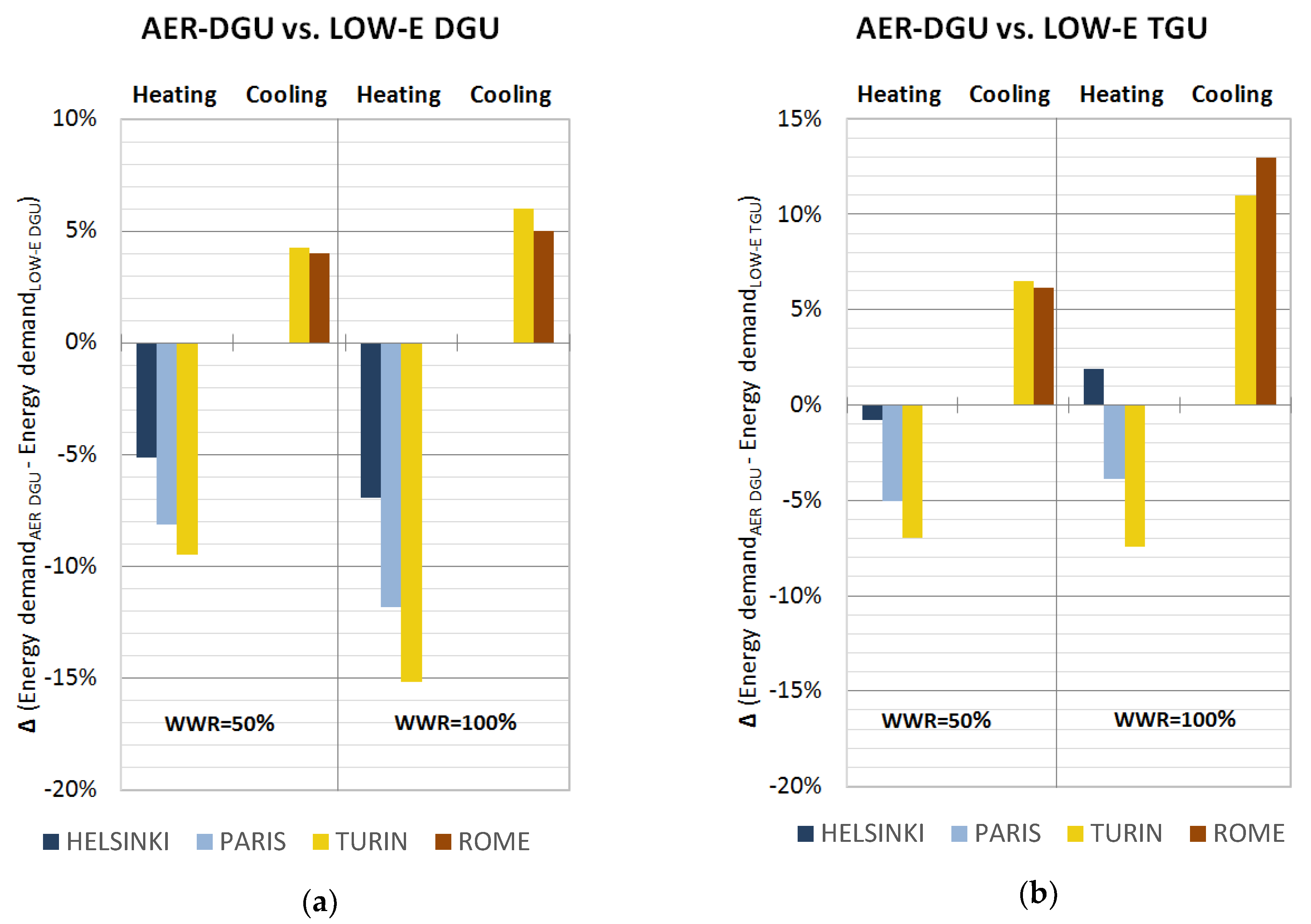

3.2. Simulation Results and Comparison with Conventional Glazing Solutions

- an argon (90%) filled double glazing embodying a low-e (Magnetron Sputter Vacuum Deposition) coating (here referred as LOW-E DGU);

- an argon (90%) filled triple glazing embodying two low-e (Magnetron Sputter Vacuum Deposition) coatings (here referred as LOW-E TGU).

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liang, Y.; Wu, H.; Huang, G.; Yang, J.; Wang, H. Thermal performance and service life of vacuum insulation panels with aerogel composite cores. Energy Build. 2017, 154, 606–617. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions—Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Moretti, E.; Belloni, E.; Merli, F.; Zinzi, M.; Buratti, C. Laboratory and pilot scale characterization of granular aerogel glazing systems. Energy Build. 2019, 202, 109349. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Aerogel insulation for building applications: A state-of-the-art review. Energy Build. 2011, 43, 761–769. [Google Scholar] [CrossRef]

- Jensen, K.I.; Schultz, J.M.; Kristiansen, F.H. Development of windows based on highly insulating aerogel glazings. J. Non-Cryst. Solids 2004, 350, 351–357. [Google Scholar] [CrossRef]

- Carroll, M.K.; Anderson, A.M.; Gorka, C.A. preparing silica aerogel monoliths via a rapid supercritical extraction method. J. Vis. Exp. 2014, 84, e51421. [Google Scholar] [CrossRef]

- Bhuiya, M.M.H.; Anderson, A.M.; Carroll, M.K.; Bruno, B.A.; Ventrella, J.L.; Silberman, B.; Keramati, B. Preparation of monolithic silica aerogel for fenestration applications: Scaling up, reducing cycle time, and improving performance. Ind. Eng. Chem. Res. 2016, 55, 6971–6981. [Google Scholar] [CrossRef]

- Guoqing, Z.; Jun, S.; Xiaoqing, W.; Xingyuan, N.; Zhihua, Z.; Jichao, W.; Guangwu, L. Preparation and characterization of monolithic alumina aerogels. J. Non-Cryst. Solids 2011, 357, 2903–2906. [Google Scholar]

- Duer, K.; Svendsen, S. Monolithic silica aerogel in superinsulating glazings. Sol. Energy 1998, 63, 259–267. [Google Scholar] [CrossRef]

- Wong, J.C.H.; Kaymak, H.; Brunner, S.; Koebel, M.M. Mechanical properties of monolithic silica aerogels made from polyethoxydisiloxanes. Microporous Mesoporous Mater. 2014, 183, 23–29. [Google Scholar] [CrossRef]

- Cai, J.; Liu, S.; Feng, J.; Kimura, S.; Wada, M.; Kuga, S.; Zhang, L. Cellulose-silica nanocomposite aerogels by in situ formation of silica in cellulose gel. Angew. Chem. Int. Ed. 2012, 51, 2076–2079. [Google Scholar] [CrossRef] [PubMed]

- Buratti, C.; Moretti, E. Experimental performance evaluation of aerogel glazing systems. Appl. Energ. 2012, 97, 430–437. [Google Scholar] [CrossRef]

- Schultz, J.M.; Jensen, K.I.; Kristiansen, F.H. Super insulating aerogel glazing. Solar Energy Mater. Sol. Cells 2005, 89, 275–285. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E.; Belloni, E. Nanogel windows for energy building efficiency. In Nano and Biotech Based Materials for Energy Building Efficiency; Torgal, F.P., Buratti, C., Kalaiselvam, S., Granqvist, C.G., Ivanov, V., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 41–69. [Google Scholar]

- Mujeebu, M.A.; Ashraf, N.; Alsuwayigh, A.H. Effect of nano vacuum insulation panel and nanogel glazing on the energy performance of office building. Appl. Energy 2016, 173, 141–151. [Google Scholar] [CrossRef]

- Ihara, T.; Gao, T.; Grynning, S.; Jelle, B.P.; Gustavsen, A. Aerogel granulate glazing facades and their application potential from an energy saving perspective. Appl. Energy 2015, 142, 179–191. [Google Scholar] [CrossRef]

- Zinzi, M.; Rossi, G.; Anderson, A.M.; Carroll, M.K.; Moretti, E.; Buratti, C. Optical and visual experimental characterization of a glazing system with monolithic silica aerogel. Sol. Energy 2019, 183, 30–39. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Lunghi, L.; Barbanera, M. Thermal conductivity measurements by means of a new ‘Small Hot-Box’ apparatus: Manufacturing, calibration and preliminary experimental tests on different materials. Int. J. Thermophys. 2016, 37, 47. [Google Scholar] [CrossRef]

- JCGM/WG 1. Evaluation of Measurement Data–GUM, Guide to the Expression of Uncertainty in Measurement; Technical Report JCGM 100:2008; ISO: Geneva, Switzerland, 2008. [Google Scholar]

- International Organization for Standardization. Building Materials and Products—Hygrothermal Properties—Tabulated Design Values and Producers for Determining Declared and Design Thermal Values; Technical Report ISO/FDIS 10456:2007(E); ISO: Geneva, Switzerland, 2007. [Google Scholar]

- Buratti, C.; Merli, F.; Moretti, E. Aerogel-based materials for building applications: Influence of granule size on thermal and acoustic performance. Energy Build. 2017, 152, 472–482. [Google Scholar] [CrossRef]

- Gao, T.; Jelle, B.P.; Ihara, T.; Gustavsen, A. Insulating glazing units with silica aerogel granules: The impact of particle size. Appl. Energy 2014, 128, 27–34. [Google Scholar] [CrossRef]

- CEN. Glass in Building—Determination of Luminous and Solar Characteristics of Glazing; Technical Report BS EN 410:1998; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- International Organization for Standardization. Glass in Building—Determination of Light Transmittance, Solar Direct Transmittance, Total Solar Energy Transmittance, Ultraviolet Transmittance and Related Glazing Factors; Technical Report ISO 9050:2003; ISO: Geneva, Switzerland, 2013. [Google Scholar]

- CEN. Light and Lighting—Lighting of Work Places—Part 1: Indoor Work Places; Technical Report BS EN 12464-1:2011; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- Goia, F.; Haase, M.; Perino, M. Optimizing the configuration of a facade module for office buildings by means of integrated thermal and lighting simulations in a total energy perspective. Appl. Energy 2013, 108, 515–527. [Google Scholar] [CrossRef]

- Ihara, T.; Gustavsen, A.; Jelle, B.P. Effect of facade components on energy efficiency in office buildings. Appl. Energy 2015, 158, 422–432. [Google Scholar] [CrossRef]

- WINDOW; version 7.4; Lawrence Berkeley National Laboratory, University of California: Berkeley, CA, USA, 2016. Available online: https://windows.lbl.gov/software/window (accessed on 10 January 2019).

- Optics; version 5.0; Lawrence Berkeley National Laboratory, University of California: Berkeley, CA, USA, 2013. Available online: https://windows.lbl.gov/software/optics (accessed on 10 January 2019).

| Building Elements | Thickness [m] | Thermal Transmittance [W/m2K] |

|---|---|---|

| External wall | 0.24 | 0.57 |

| Internal wall | 0.11 | 3.41 |

| Ground floor (including gravel layer) | 0.99 | 0.48 |

| Roof | 0.52 | 0.32 |

| Floor between storeys | 0.50 | 0.52 |

| Internal Loads | Schedule | ||

|---|---|---|---|

| Lighting peak power (500 lux [30], fully dimmable lamps) | 7 W/m2 | 8:00 a.m. to 6:00 p.m. weekdays | |

| People | 0.05 people/m2 | ||

| Equipment | 7 W/m2 | ||

| Operating periods of heating and cooling system | |||

| Location | Heating (20 °C) | Cooling (26 °C) | |

| Helsinki | 01/01–12/31 | 05/01–09/04 | 8:00 a.m. to 6:00 p.m. weekdays |

| Paris | 10/15–04/30 | 05/01–10/14 | |

| Turin | 10/15–04/15 | 04/16–10/14 | |

| Rome | 11/01–04/15 | 04/16–10/14 | |

| Infiltration rate | |||

| Whole building | 0.3 vol/h | 12:00 p.m. to 08:00 a.m. 6:00 p.m. to 12:00 p.m. | All days |

| 0.6 vol/h | 08:00 a.m. to 6:00 p.m. | ||

| ΔTair [°C] | Ts Mean [°C] | ΔTs [°C] | Heat Flux Φ [W/m2] | Thermal Resistance R [m2K/W] | Relative Uncert. [%] | U [W/m2K] | λ Monolit. Aerogel [W/mK] | U at 10 °C [W/m2K] | λ Monolit. Aerogel at 10 °C [W/mK] | |

|---|---|---|---|---|---|---|---|---|---|---|

| Test 1 (TH = 45 °C) | 18.3 | 37.7 | 16.8 | 22.7 | 0.74 | 3.5 | 1.099 | 0.0204 | 0.997 | 0.0182 |

| Test 2 (TH = 50 °C) | 22.9 | 40.9 | 21.7 | 30.1 | 0.72 | 6.2 | 1.124 | 0.0209 | 1.009 | 0.0185 |

| Test 3 (TH = 50 °C) | 22.7 | 40.7 | 21.0 | 29.1 | 0.72 | 2.6 | 1.124 | 0.0209 | 1.010 | 0.0185 |

| Test 4 (TH = 45 °C) | 18.9 | 37.7 | 16.5 | 22.5 | 0.74 | 2.9 | 1.099 | 0.0204 | 0.997 | 0.0182 |

| Glazing | Description | Thickness [mm] | τv [-] | g [-] | U [W/m2K] |

|---|---|---|---|---|---|

| AER- DGU | Float clear glass (4.7 mm), monolithic aerogel (15 mm), float clear glass (4.7 mm) | 24.4 | 0.69 | 0.70 | 1.0 |

| LOW-E DGU | Float clear glass (6 mm), Air (10%) and Argon (90%) (16 mm), Low-e float clear glass (4 mm) | 26 | 0.76 | 0.55 | 1.1 |

| LOW-E TGU | Low-e float clear glass (4 mm), Air (10%) and Argon (90%) (12 mm), float clear glass (4 mm), Air (10%) and Argon (90%) (12 mm), Low-e float clear glass (4 mm) | 36 | 0.66 | 0.44 | 0.7 |

| Glazing | Heating Energy Demand [kWh/m2] | Cooling Energy Demand [kWh/m2] | Lighting Energy Use [kWhe/m2] | |

|---|---|---|---|---|

| LOW-E DGU | 52.6 | 0.4 | 8.6 | |

| HELSINKI | LOW-E TGU | 50.3 | 0.4 | 9.1 |

| AER-DGU | 49.9 | 0.5 | 8.9 | |

| LOW-E DGU | 14.8 | 9.4 | 7.5 | |

| TURIN | LOW-E TGU | 14.4 | 9.2 | 8 |

| AER-DGU | 13.4 | 9.8 | 7.7 | |

| LOW-E DGU | 18.5 | 2.8 | 7.8 | |

| PARIS | LOW-E TGU | 17.9 | 2.8 | 8.3 |

| AER-DGU | 17 | 3.1 | 8.1 | |

| LOW-E DGU | 2.9 | 14.9 | 7.2 | |

| ROME | LOW-E TGU | 3.1 | 14.6 | 7.6 |

| AER-DGU | 2.2 | 15.5 | 7.3 |

| Glazing | Heating Energy Demand [kWh/m2] | Cooling Energy Demand [kWh/m2] | Lighting Energy Use [kWhe/m2] | |

|---|---|---|---|---|

| LOW-E DGU | 51.9 | 0.7 | 7.9 | |

| HELSINKI | LOW-E TGU | 47.4 | 0.6 | 8.2 |

| AER-DGU | 48.3 | 0.8 | 8 | |

| LOW-E DGU | 13.2 | 10.2 | 6.8 | |

| TURIN | LOW-E TGU | 12.1 | 9.7 | 7 |

| AER-DGU | 11.2 | 10.8 | 6.9 | |

| LOW-E DGU | 16.9 | 3.5 | 7 | |

| PARIS | LOW-E TGU | 15.5 | 3.2 | 7.2 |

| AER-DGU | 14.9 | 3.9 | 7.1 | |

| LOW-E DGU | 1.7 | 16.9 | 6.5 | |

| ROME | LOW-E TGU | 1.7 | 15.8 | 6.7 |

| AER-DGU | 1.1 | 17.8 | 6.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buratti, C.; Moretti, E.; Belloni, E.; Zinzi, M. Experimental and Numerical Energy Assessment of a Monolithic Aerogel Glazing Unit for Building Applications. Appl. Sci. 2019, 9, 5473. https://doi.org/10.3390/app9245473

Buratti C, Moretti E, Belloni E, Zinzi M. Experimental and Numerical Energy Assessment of a Monolithic Aerogel Glazing Unit for Building Applications. Applied Sciences. 2019; 9(24):5473. https://doi.org/10.3390/app9245473

Chicago/Turabian StyleBuratti, Cinzia, Elisa Moretti, Elisa Belloni, and Michele Zinzi. 2019. "Experimental and Numerical Energy Assessment of a Monolithic Aerogel Glazing Unit for Building Applications" Applied Sciences 9, no. 24: 5473. https://doi.org/10.3390/app9245473

APA StyleBuratti, C., Moretti, E., Belloni, E., & Zinzi, M. (2019). Experimental and Numerical Energy Assessment of a Monolithic Aerogel Glazing Unit for Building Applications. Applied Sciences, 9(24), 5473. https://doi.org/10.3390/app9245473