Numerical Analysis of Building Envelope with Movable Phase Change Materials for Heating Applications

Abstract

1. Introduction

2. Methodology

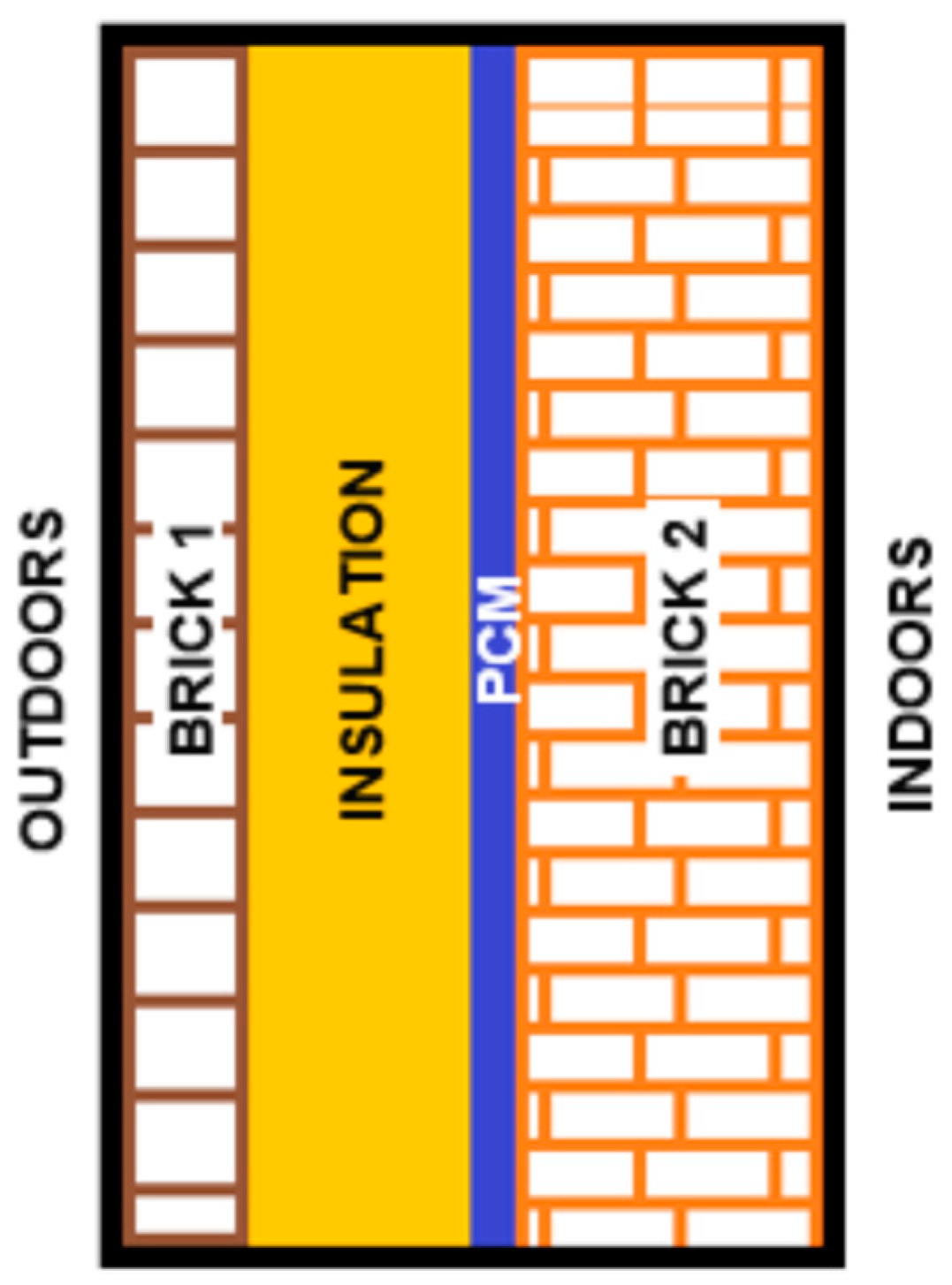

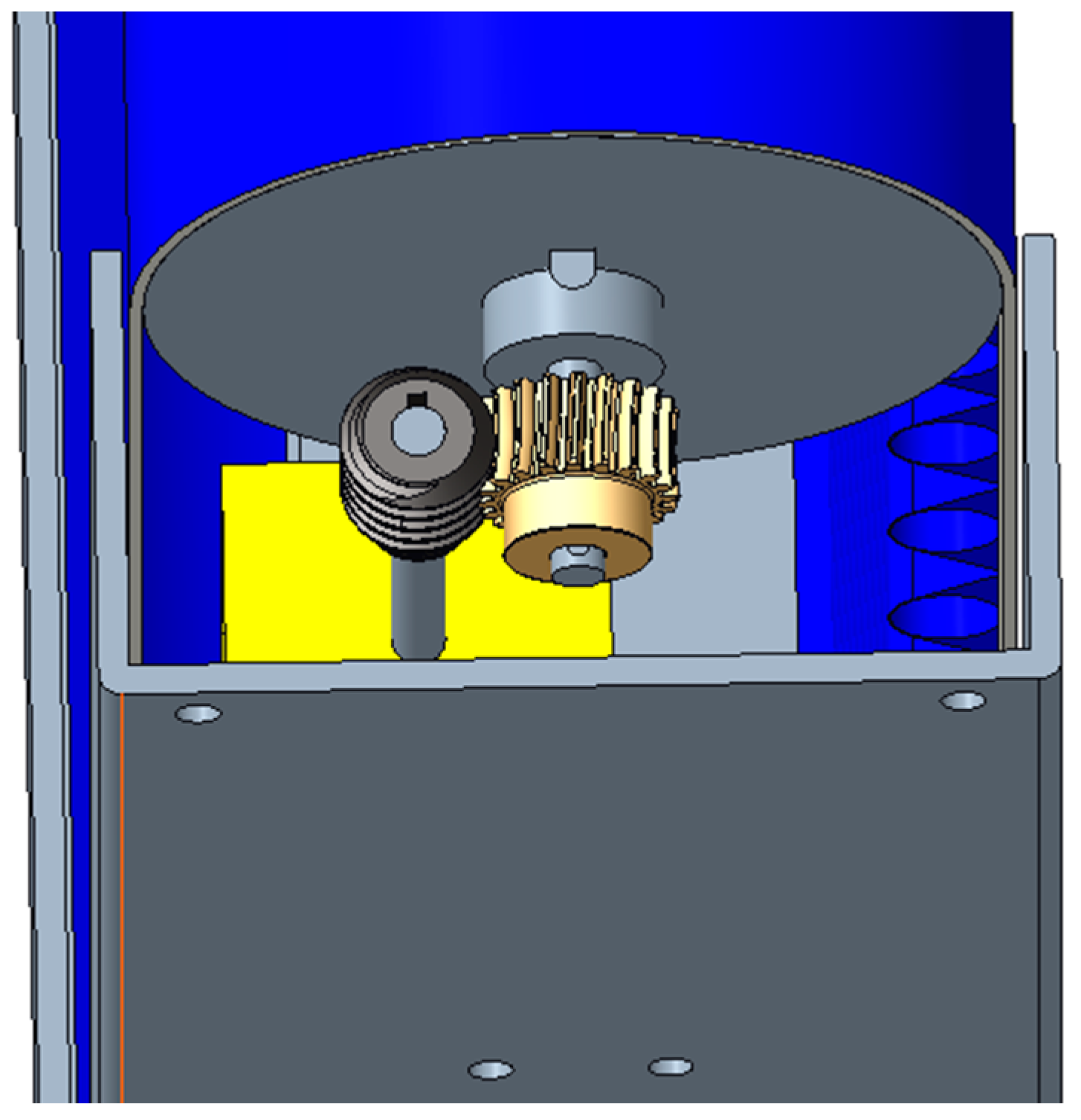

2.1. Dynamic PCM Wall Concept

2.2. Numerical Model Description

2.3. Optimization of Design and Control Parameters

- (i)

- PCM peak melting temperature () exploring integer values between 8 to 29 °C.

- (ii)

- Hour to start exposure of PCM to solar energy, POS [t] is set to 1 (). Continuous exploration between 0 to 24 h.

- (iii)

- Hour to finish exposure of PCM to solar energy, POS [t] is set to 0 (). Continuous exploration between 0 to 24 h.

2.4. Case Studies

- Wall 1: Typical Mediterranean constructive system based on two layers of bricks and 5 cm of mineral wool in between.

- Wall 2: Case-600 building prototype from ASHRAE Standard 140-2011 [29].

- Wall 3: Ideal envelope, which is based on a single layer of insulation surrounded by a polymeric sheet with and without PCM.

3. Results and Discussion

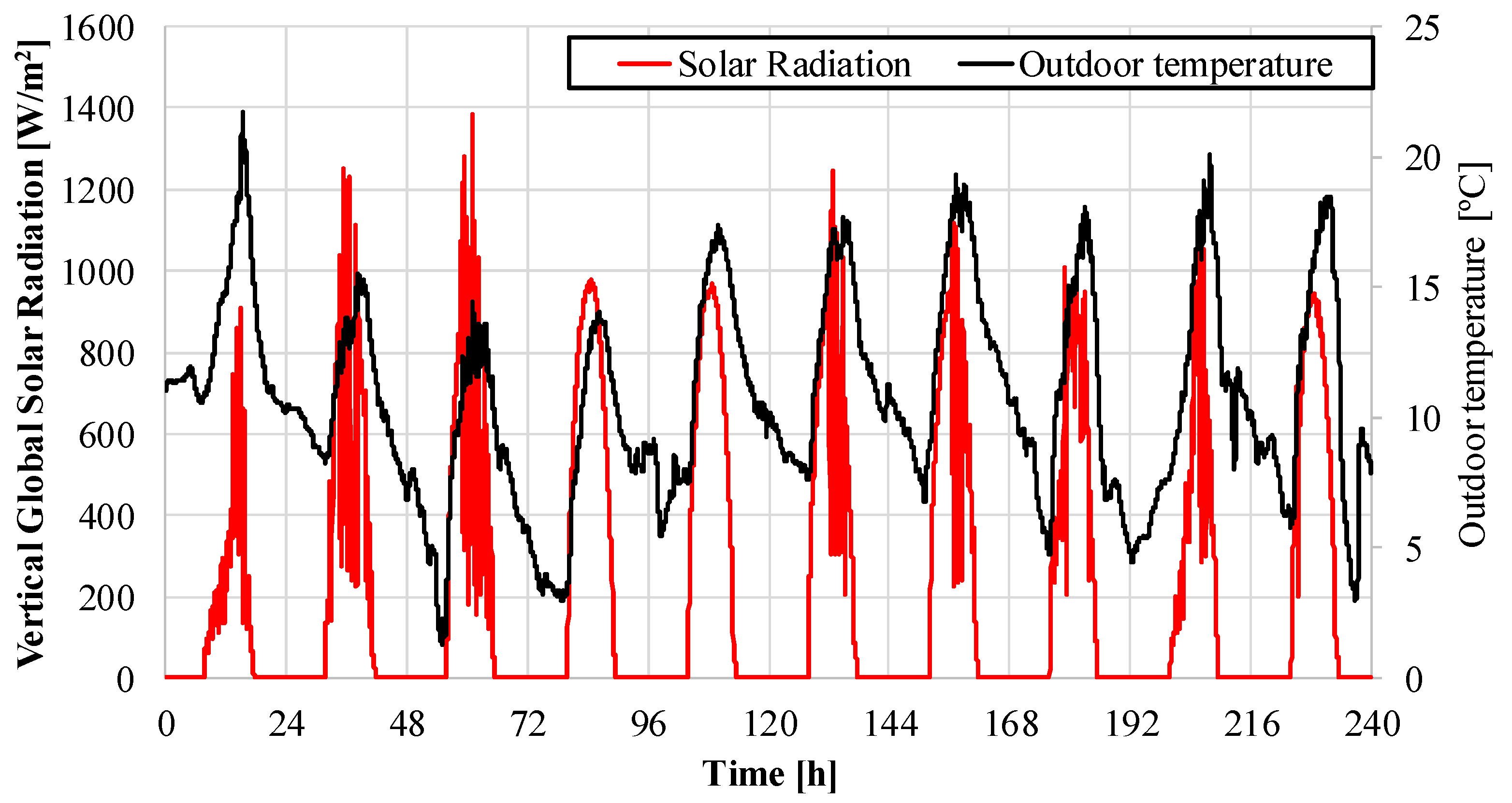

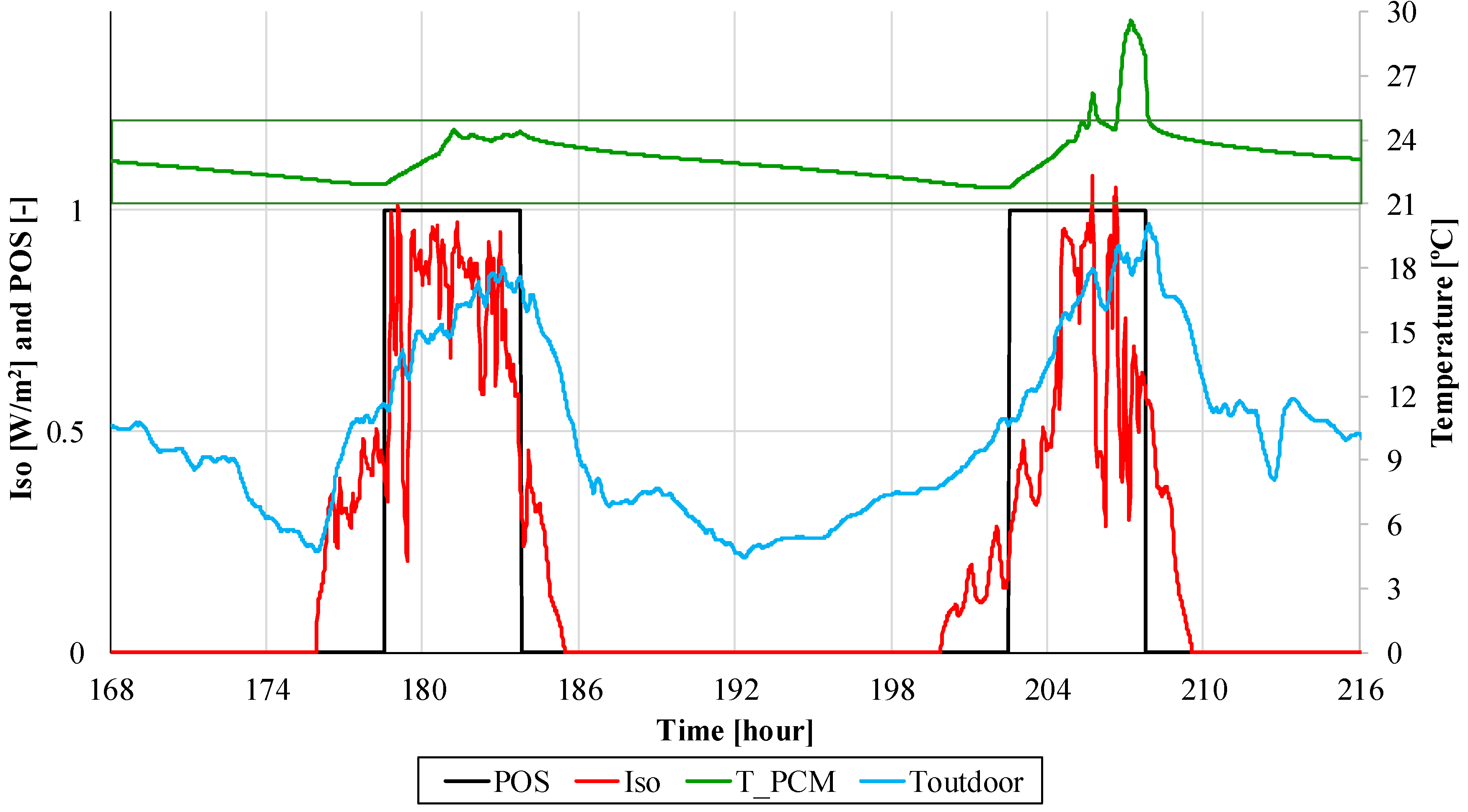

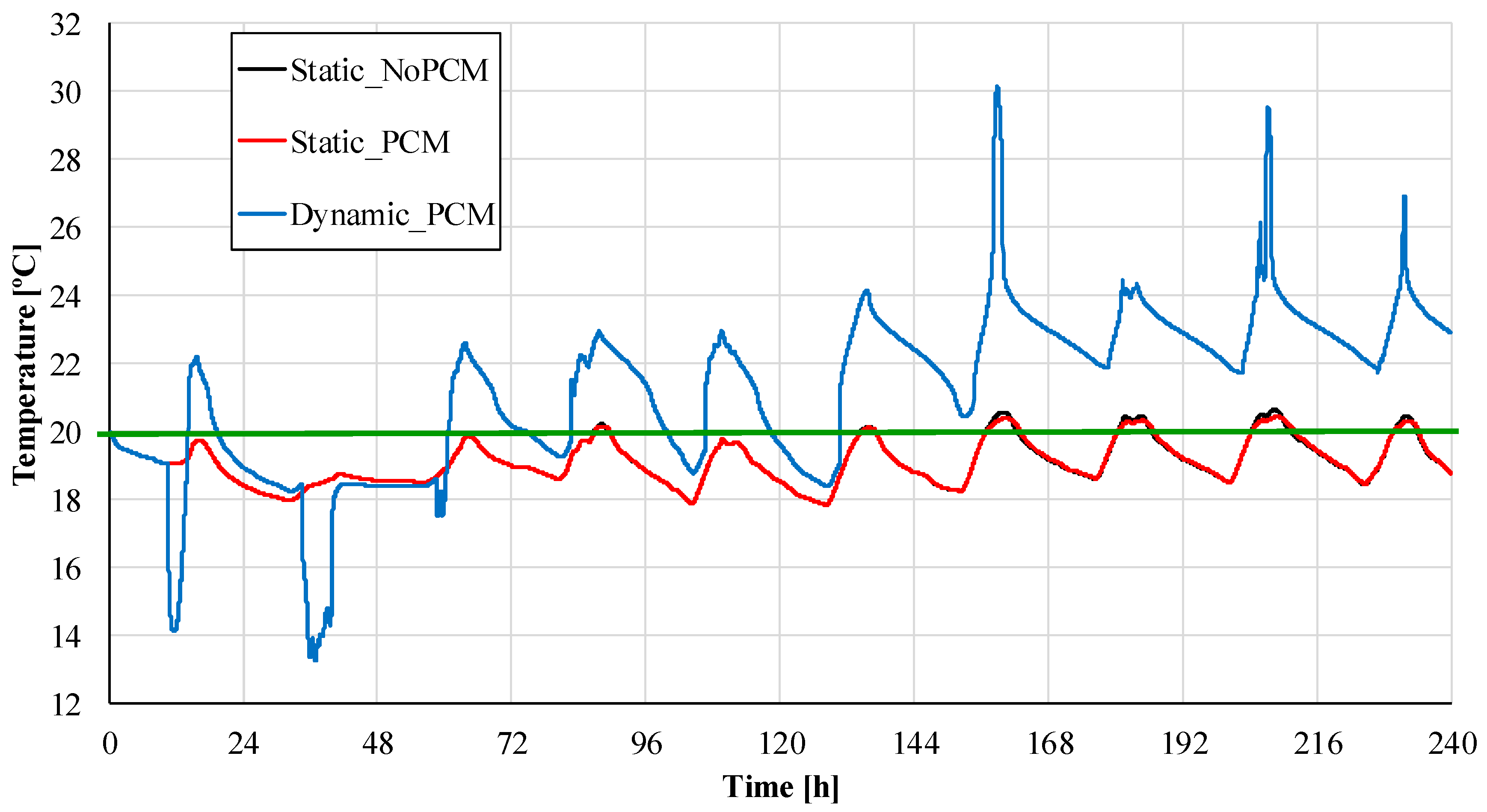

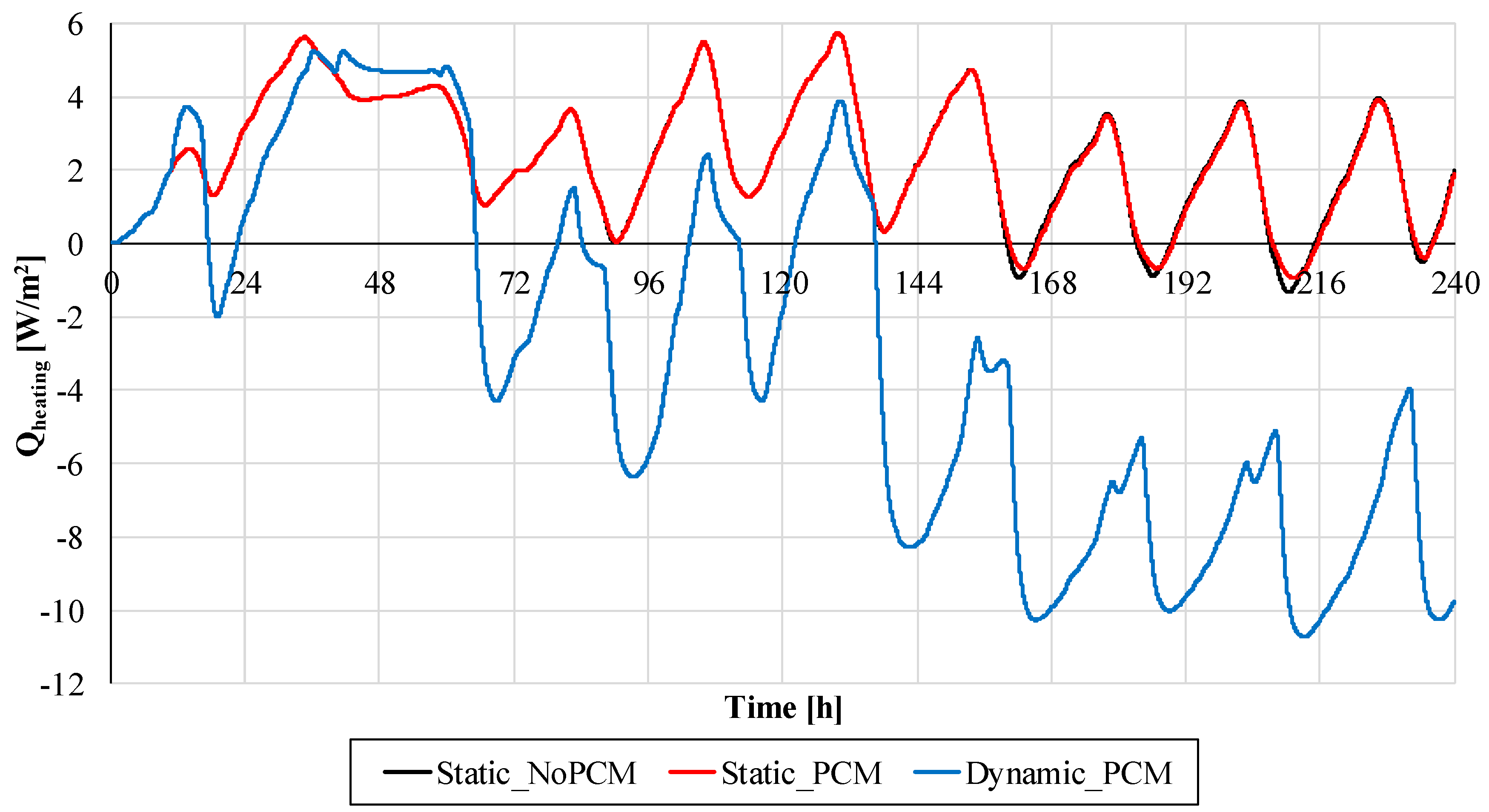

3.1. Thermal Behaviour of Dynamic PCM System

3.2. Heating Load Reduction by Using Dynamic PCM Wall

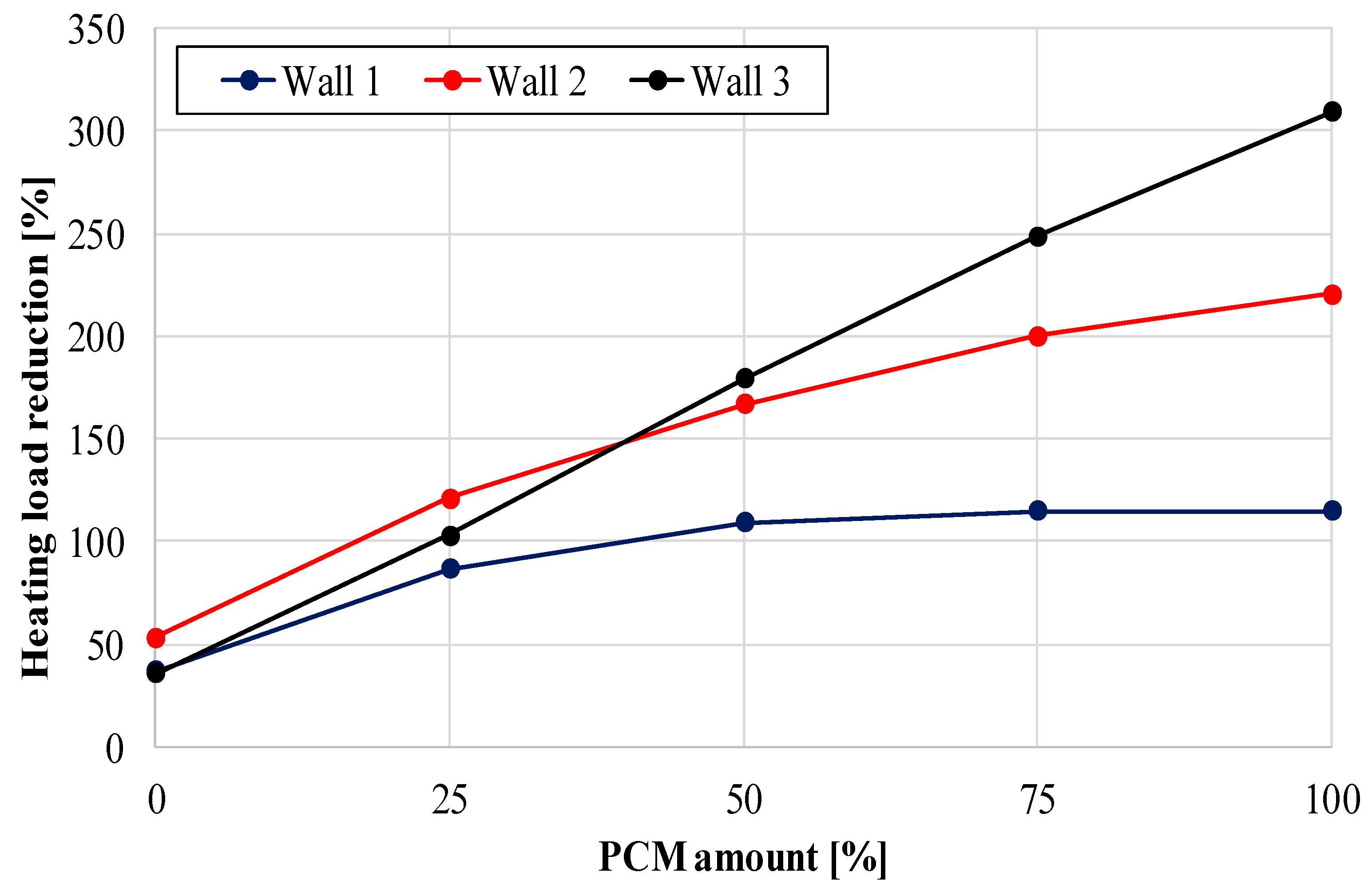

3.3. Parametric Analysis of Amount of PCM

4. Conclusions

Funding

Conflicts of Interest

References

- Omrany, H.; Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Raahemifar, K.; Tookey, J. Application of passive wall systems for improving the energy efficeing in buildings: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 62, 1252–1269. [Google Scholar] [CrossRef]

- International Energy Agency. Transition to Sustainable Buildings Strategiesand Opportunities to 2050; International Energy Agency: Paris, France, 2013. [Google Scholar]

- Stritih, U.; Tyagi, V.V.; Stropnik, R.; Paksoy, H.; Haghighat, F.; Mastani Joybari, M. Integration of passive PCM technologies for net-zero energy buildings. Sustain. Cities Soc. 2018, 41, 286–295. [Google Scholar] [CrossRef]

- De Gracia, A.; Cabeza, L.F. Phase change materials and thermal energy storage for buildings. Energy Build. 2015, 103, 414–419. [Google Scholar] [CrossRef]

- Navarro, L.; de Gracia, A.; Niall, D.; Castell, A.; Browne, M.; McCormack, S.J.; Griffiths, P.; Cabeza, L.F. Thermal energy storage in building integrated thermal systems: A review. Part 2. Integration as passive system. Renew. Energy 2016, 85, 1334–1356. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castellón, C.; Nogués, M.; Medrano, M.; Leppers, R.; Zubillaga, O. Use of microencapsulated PCM in concrete walls for energy savings. Energy Build. 2007, 39, 113–119. [Google Scholar] [CrossRef]

- Schossig, P.; Henning, H.-M.; Gschwander, S.; Haussmann, T. Micro-encapsulated phase-change materials integrated into construction materials. Sol. Energy Mater. Sol. Cells 2005, 89, 297–306. [Google Scholar] [CrossRef]

- Kosny, J.; Kossecka, E.; Brzezinski, A.; Tleoubaev, A.; Yarbrough, D. Dynamic thermal performance analysis of fiber insulations containing bio-based phase change materials (PCMs). Energy Build. 2012, 52, 122–131. [Google Scholar] [CrossRef]

- Scalat, S.; Banu, D.; Hawes, D.; Paris, J.; Haghighat, F.; Feldman, D. Full scale thermal testing of latent heat storage in wallboard. Sol. Energy Mater. Sol. Cells 1996, 44, 46–61. [Google Scholar] [CrossRef]

- Zhang, M.; Medina, M.A.; King, J.B. Development of a thermally enhanced frame wall with phase change materials for on-peak air conditioning demand reduction and energy savings in residential buildings. Int. J. Energy Res. 2005, 29, 795–809. [Google Scholar] [CrossRef]

- Kuznik, F.; Virgone, J. Experimental assessment of phase change material for wall building use. Appl. Energy 2009, 86, 2038–2046. [Google Scholar] [CrossRef]

- Castell, A.; Martorell, I.; Medrano, M.; Pérez, G.; Cabeza, L.F. Experimental study of using PCM in brick constructive solutions for passive cooling. Energy Build. 2010, 42, 534–540. [Google Scholar] [CrossRef]

- Saffari, M.; de Gracia, A.; Fernández, C.; Cabeza, L.F. Simulation-based optimization of PCM melting temperatura to improve the energy performence in buildings. Appl. Energy 2017, 202, 420–434. [Google Scholar] [CrossRef]

- Mandilaras, I.; Stamatiadou, M.; Katsourinis, D.; Zannis, G.; Founti, M. Experimental thermal characterisation of a Mediterranean residential building with PCM gypsum board walls. Build. Environ. 2013, 61, 93–103. [Google Scholar] [CrossRef]

- Navarro, L.; de Gracia, A.; Castell, A.; Cabeza, L.F. Thermal behaviour of insulation and phase change materials in buildings with internal heat loads: Experimental study. Energy Effic. 2015, 8, 895–904. [Google Scholar] [CrossRef]

- Marin, P.; Saffari, M.; de Gracia, A.; Zhu, X.; Farid, M.M.; Cabeza, L.F.; Ushak, S. Energy savings due to the use of PCM for relocatable lightweight buildings passive heating and cooling in different weather conditions. Energy Build. 2016, 129, 274–283. [Google Scholar] [CrossRef]

- Stamatiadou, M.; Antonopoulos, K.; Founti, M. Energy savings using floor tiles with phase change materials in a S. European country. In Proceedings of the 11th International Conference on Thermal Energy Storage for Energy Efficiency and Sustainability (Effstock), Stockholm, Sweden, 14–17 June 2009. [Google Scholar]

- Loonen, R.C.; Trčka, M.; Cóstola, D.; Hensen, J.L. Climate adaptive building shells: State-of-the-art and future challenges. Renew. Sustain. Energy Rev. 2013, 25, 483–493. [Google Scholar] [CrossRef]

- Mols, T.; Blumberga, A.; Karklina, I. Evaluation of climate adaptive building shells: Multi-criteria analysis. Energy Procedia 2017, 128, 292–296. [Google Scholar] [CrossRef]

- Lee, C.; Hoes, P.; Cóstola, D.; Hensen, J.L. Assessing the performance potential of climate adaptive greenhouse shells. Energy 2019, 175, 534–545. [Google Scholar] [CrossRef]

- Simko, M.; Krajcik, M.; Sikula, O.; Simko, P.; Kalús, D. Insulation panels for active control of heat transfer in walls operated as space heating or as a thermal barrier: Numerical simulations and experiments. Energy Build. 2018, 158, 135–146. [Google Scholar] [CrossRef]

- De Gracia, A. Dynamic building envelope with PCM for cooling purposes—Proof of concept. Appl. Energy 2019, 235, 1245–1253. [Google Scholar] [CrossRef]

- Barreneche, C.; Fernández, A.I.; Niubó, M.; Chimenos, J.M.; Espiell, F.; Segarra, M.; Solé, C.; Cabeza, L.F. Development and characterization of new shape-stabilized phase change material PCM—Polymer including electrical arc furnace dust EAFD, for acoustic and thermal comfort in buildings. Energy Build. 2013, 61, 210–214. [Google Scholar] [CrossRef]

- Izquierdo-Barrientos, M.A.; Belmonte, J.F.; Rodríguez-Sánchez, D.; Molina, A.E.; Almendros-Ibáñex, J.A. A numerical study of external building walls containing phase change materials PCM. Appl. Therm. Eng. 2012, 47, 73–85. [Google Scholar] [CrossRef]

- Ministerio Fomento. Código Técnico de la Edificación, Documento Básico HE. Ahorro de Energía; Ministerio Fomento: Madrid, Spain, 2013. [Google Scholar]

- Lamberg, P.; Lehtiniemi, R.; Henell, A.M. Numerical and experimental investigation of melting and freezing processes in phase change material storage. Int. J. Therm. Sci. 2004, 43, 277–287. [Google Scholar] [CrossRef]

- Farid, M.M. A new approach in the calculation of heat transfer with phase change. In Proceedings of the 9th International Congress on Energy and Environment, Miami, FL, USA, 13–15 December 1989; pp. 1–19. [Google Scholar]

- De Gracia, A.; Navarro, L.; Castell, A.; Cabeza, L.F. Numerical study on the thermal performance of a ventilated facade with PCM. Appl. Therm. Eng. 2013, 61, 372–380. [Google Scholar] [CrossRef]

- ASHRAE. ANSI/ASHRAE Standard 55-2013. Thermal Environmental Conditions for Human Occupancy; ASHRAE: Atlanta, GA, USA, 2013. [Google Scholar]

- Wetter, M. GenOpt—A generic optimization program. In Proceedings of the Seventh International IBPSA Conference, Rio de Janeiro, Brazil, 13–15 August 2001; pp. 601–608. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. Proc. IEEE Int. Conf. Neural Netw. 1995, 4, 1942–1948. [Google Scholar] [CrossRef]

- De Gracia, A.; Navarro, L.; Coma, J.; Serrano, S.; Romaní, J.; Pérez, G.; Cabeza, L.F. Experimental set-up for testing active and passive systems for energy savings in buildings—Lessons learnt. Renew. Sustain. Energy Rev. 2018, 82, 1014–1026. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World map of the Köppen-Geiger climate classification. Meteorologische Zeitschrift 2006, 15, 259–263. [Google Scholar] [CrossRef]

| Construct System | Layer | Thickness (m) | Thermal Conductivity (W/m·K) | Heat Capacity (J/kg·K) | Density (kg/m3) |

|---|---|---|---|---|---|

| Wall 1 | Hollow Brick | 0.07 | 0.375 | 1000 | 930 |

| PCM | 0.007 | 0.2 | f(T) | 800 | |

| Insulation | 0.05 | 0.05 | 1000 | 35 | |

| Plastic sheet | 0.007 | 0.3 | 1250 | 900 | |

| Perforated brick | 0.14 | 0.543 | 1000 | 900 | |

| Wall 2 | Wood siding | 0.01 | 0.14 | 900 | 530 |

| PCM | 0.007 | 0.2 | f(T) | 800 | |

| Insulation | 0.0615 | 0.04 | 1400 | 40 | |

| Plastic sheet | 0.007 | 0.3 | 1250 | 900 | |

| Concrete block | 0.1 | 0.51 | 1000 | 1400 | |

| Wall 3 | PCM | 0.007 | 0.2 | f(T) | 800 |

| Insulation | 0.072 | 0.05 | 1000 | 35 | |

| Plastic sheet | 0.007 | 0.3 | 1250 | 900 |

| Construction System | System | Optimized TPCM (°C) | Qload [kJ/m2] | Heating Load Reduction (%) |

|---|---|---|---|---|

| Wall 1 | Static NoPCM | - | 2085.2 | - |

| Static PCM | 23 | 2085.2 | 0,00 | |

| Dynamic | 21 | −311.6 | 114.94 | |

| Wall 2 | Static NoPCM | - | 2033.7 | - |

| Static PCM | 22 | 2035.1 | −0,07 | |

| Dynamic | 23 | −2452.4 | 220.59 | |

| Wall 3 | Static NoPCM | - | 2869.6 | - |

| Static PCM | 22 | 2871.0 | −0,05 | |

| Dynamic | 23 | −5994.4 | 308.89 |

| Constructive System | PCM % w/w | t1 | t0 | Qload [kJ/m2] | Heating Load Reduction (%) |

|---|---|---|---|---|---|

| Wall 1 | 0 | 14:14 | 16:01 | 1319.8 | 36.71 |

| 25 | 13:29 | 16:36 | 278.9 | 86.63 | |

| 50 | 12:37 | 16:44 | −189.8 | 109.10 | |

| 75 | 12:17 | 16:53 | −309.9 | 114.86 | |

| 100 | 12:26 | 16:58 | −311.6 | 114.94 | |

| Wall 2 | 0 | 13:12 | 15:07 | 949.1 | 53.33 |

| 25 | 11:25 | 15:01 | −425.5 | 120.92 | |

| 50 | 10:43 | 15:31 | −1359.8 | 166.86 | |

| 75 | 10:42 | 15:24 | −2041.6 | 200.39 | |

| 100 | 10:32 | 15:47 | −2452.3 | 220.59 | |

| Wall 3 | 0 | 12:02 | 13:11 | 1833.6 | 36.10 |

| 25 | 13:08 | 15:15 | −95.0 | 103.31 | |

| 50 | 11:49 | 14:59 | −2281.3 | 179.50 | |

| 75 | 11:52 | 16:41 | −4260.8 | 248.48 | |

| 100 | 11:49 | 15:49 | −5994.4 | 308.89 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Gracia, A. Numerical Analysis of Building Envelope with Movable Phase Change Materials for Heating Applications. Appl. Sci. 2019, 9, 3688. https://doi.org/10.3390/app9183688

de Gracia A. Numerical Analysis of Building Envelope with Movable Phase Change Materials for Heating Applications. Applied Sciences. 2019; 9(18):3688. https://doi.org/10.3390/app9183688

Chicago/Turabian Stylede Gracia, Alvaro. 2019. "Numerical Analysis of Building Envelope with Movable Phase Change Materials for Heating Applications" Applied Sciences 9, no. 18: 3688. https://doi.org/10.3390/app9183688

APA Stylede Gracia, A. (2019). Numerical Analysis of Building Envelope with Movable Phase Change Materials for Heating Applications. Applied Sciences, 9(18), 3688. https://doi.org/10.3390/app9183688