A Mining Technology Collaboration Platform Theory and Its Product Development and Application to Support China’s Digital Mine Construction

Abstract

1. Introduction

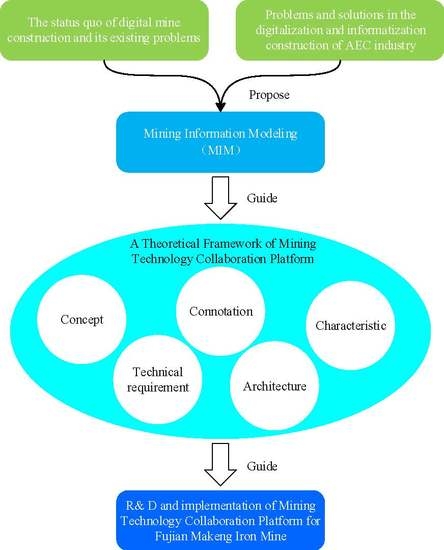

2. Methodology

- (1)

- Literature review method and desktop research method—(a) review the progress and achievements of digital mine construction at home and abroad and the research results, construction status and existing problems in the process of China’s digital mine construction; (b) analyze and summarize similar problems encountered in the process of digitalization and informatization construction in the AEC industry, put forward the concept of Building Information Modeling (BIM) and developed a series of collaborative platforms to solve the problems encountered under the guidance of the BIM concept; (c) based on the achievements of (a) and (b), the theoretical framework of the mining technology collaboration platform is proposed to solve the problems existing in the current digital mine construction in China.

- (2)

- Interview method—Based on the theoretical framework of the mining technology collaboration platform proposed in (1), the current situation and existing problems of the digital mine construction of Fujian Makeng Mining Co., Ltd. and the research and development requirements of the mining technology collaboration platform were investigated and analyzed.

- (3)

- System development and implementation method—Based on the results of (1) and (2), the mining technology collaboration platform of Fujian Makeng Mining Co., Ltd. is developed, designed and implemented, which verifies the accuracy of the theoretical framework of the mining technology collaboration platform from the results of the system’s research and development. The theoretical framework can also be optimized and improved through the implementation of the mining technology collaboration platform.

3. Related Research

3.1. Status of Digital Mine Construction

- (1)

- The lack of uniform standards and norms for digital mine related products has led to a serious “information island” phenomenon.The digital mine construction process is based on the existing digitalization and informatization level of the mine and the overall planning and deployment of digital mine related software and hardware products. However, the software and hardware products related to digital mine construction must come from different manufacturers and there is no uniform standard and norm existing between the manufacturers. As a result, interoperability between the products cannot be achieved and a large number of “information islands” are formed [18]. In the situation where there is information that cannot be used, sometimes it is necessary to reacquire the original data or reprocess the data to meet the needs of the products, resulting in the waste of information resources and labor costs. Moreover, due to the existence of a large number of “information islands,” the business processes in the mine’s whole life cycle are not smooth and the business is seriously disconnected and inefficient, which causes the digital mine construction investment and output to be inconsistent, which seriously hinders the digital mine construction process in China.

- (2)

- Existing products have difficulty supporting the full digital operation of the mine’s whole life cycle business process.The mine’s whole life cycle business process includes exploration, mining planning and design, production management, measurement and acceptance, mine closure and reclamation and involves mine geology, surveying and mining other business specialties and each professional and business has its own proprietary professional business software and each professional business software has its own proprietary data format. However, limited by practical conditions and technological development, the existing digital mine-related products only support the digitalization of a specific part of the mine’s life cycle business process, a specific business or a specific number of businesses. The fundamental reason is that there is no integrated platform to standardize the data and business processes; therefore, the interoperability, efficient flow and sharing of data in the mine’s whole life cycle business process cannot be guaranteed and the process, standardization and collaborative operation of professional business work, such as geology, surveying and mining in the whole life cycle of the mine cannot be realized, so, ultimately, the full digital operation of the mine’s whole life cycle business process cannot be supported.

- (3)

- There is a big difference between the traditional operation mode and the management mode of the mine and the informatization requirements.The development of China’s mining industry has gradually formed a traditional and solidified mode of work and management through historical precipitation. With the increasing trend of economic globalization and world economic integration and the rapid development of information technology, mining enterprises are facing increasingly fierce market competition. However, most mining enterprises in China still adopt the traditional linear functional organizational structure, which is managed by subdividing the business into various functional departments, separating the complete business process. The operators of each function or production department are usually only responsible for their respective departments, resulting in poor collaboration and coordination between departments; conflicts between departments and between employees in the departments are inevitable and the management efficiency of the “pyramid” organizational structure is low and is unable to adapt to the transient market environment. In the practice of digital mine construction, it is very difficult for mining enterprises to break the traditional solidification mode and try to adapt the digital mine products to the inherent mode or simply transform traditional manual drawing tools into digital operation tools. In essence, there is no change. The fundamental problems of the traditional work mode and management mode still exist, which leads to the system software and hardware construction being independent, serious information island problems, data sharing problems and interoperability difficulties. Therefore, the huge advantages of digital mine construction cannot be reflected. To some extent, it will bring a huge burden to mining enterprises and mine technicians and make it difficult to achieve the digitalization and informatization goals of the mine.

- (4)

- Lack of practical ideas to guide the research and development of digital mine products and the construction of the digital mine.In the research and development of digital mine products and the practice of digital mine construction in China, the digital data of the main objects, such as the mining environment, objects, activities and processes have not been effectively organized and expressed, resulting in the data not being able to be shared and the formation of “information islands”; thus, the digitized results of the mine cannot be served for the whole process and mine’s whole life cycle and collaborative operation based on three-dimensional data integration and exchange cannot be realized among participants, departments and professional posts. The fundamental cause of these problems is the lack of practical ideas to guide the research and development of digital mine products and the construction of the digital mine. Therefore, there is an urgent need to put forward a new idea to guide the research and development of future digital mine products and the construction of future digital mines to realize the information sharing and collaborative work of the mine’s whole life cycle.

3.2. Status of Digitalization and Informatization Construction in the AEC Industry

4. A Theoretical Framework of MTCP

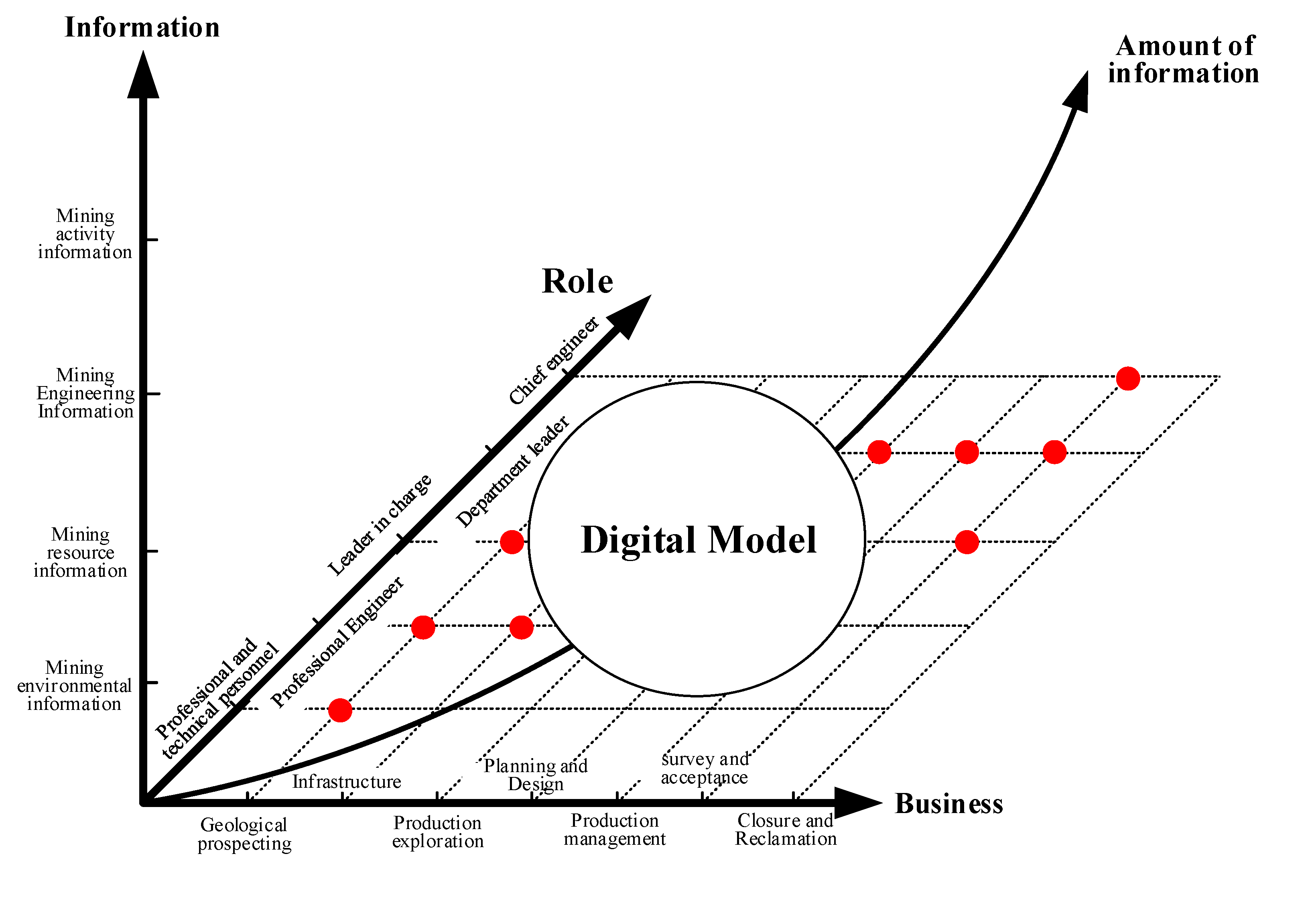

4.1. Mining Information Modeling (MIM)

4.2. Concept and Connotation of MTCP

- (1)

- Centralized storage of business data to achieve accurate and effective management of various structured and unstructured data and data relationships and to provide a good security access mechanism.

- (2)

- Centralized management of the business work to realize centralized, unified and hierarchical management of the environmental parameters such as the design parameters, constraints, technical indicators and technical resources and the effective management and control of the parameters.

- (3)

- Centralized control of business processes to realize the transformation from “what to do” to “how to do” and “how well to do it” to achieve effective tracking, control and assessment of the business processes.

4.3. Characteristics of MTCP

- (1)

- Integration—The integration of the mining technology collaboration platform mainly includes the integration of all business in the whole life cycle of the mine, the integration of all business technology work and management work in the whole life cycle of the mine, the integration of all participants, all departments and all professional posts involved in the whole life cycle of the mine, the integration of digital mine related products in the whole life cycle of the mine and the integration of business data in the whole life cycle of the mine.

- (2)

- Process—The process of the mining technology collaboration platform is to use the idea of process management to efficiently flow all the business in the whole life cycle of the mine to break the barrier between the participants, between departments and between professional posts. In addition, the specific business workflow, that is, the specific business work process is carried out in a way so that the business work process is simplified and efficient.

- (3)

- Standardization—The standardization characteristics of the mining technology collaboration platform refer to the standardization of business data and business processes. The purpose of the standardization of business data is to realize the sharing of data between all the businesses and the software and hardware of each business in the whole mine life cycle. The standardization of the business process standardizes the business process in the whole life cycle of the mine as well as the business workflow.

- (4)

- Security—The security of the mining technology collaboration platform includes the control of login rights, access rights of functional modules and access rights of business data of the mining technology collaboration platform.

- (5)

- Completeness—The completeness of the mining technology collaboration platform includes all business, business processes and data generated by all businesses in the whole life cycle of the mine, such as geological exploration, infrastructure, production exploration, planning and design, production management, survey and acceptance, mine closures and reclamation and so forth. All business data of the mine’s whole life cycle include geological exploration data and production exploration data, such as borehole data, pit exploration data, trenching data and geological logging maps; design data, such as mine development design data, cutting design data and mining design data and so forth; planning data for long-term mining planning data, medium- and long-term mining planning data and short-term planning data; production management data generated by the mining processes and related processes, such as ore deposit development, mining accuracy, cutting and mining; and survey and acceptance data of engineering and ore quantity, such as mine development, cutting and mining and so forth.

- (6)

- Shareability—In the process of mine’s whole life cycle business processing, all participants, departments and professional posts can realize real-time sharing of mine business data through the mining technology collaboration platform.

- (7)

- Traceability—The mining technology collaboration platform can query and track business processes and business data according to business processes, participants, departments, professional posts and operators in the whole life cycle business process of mines to realize the traceability of business processes and business data.

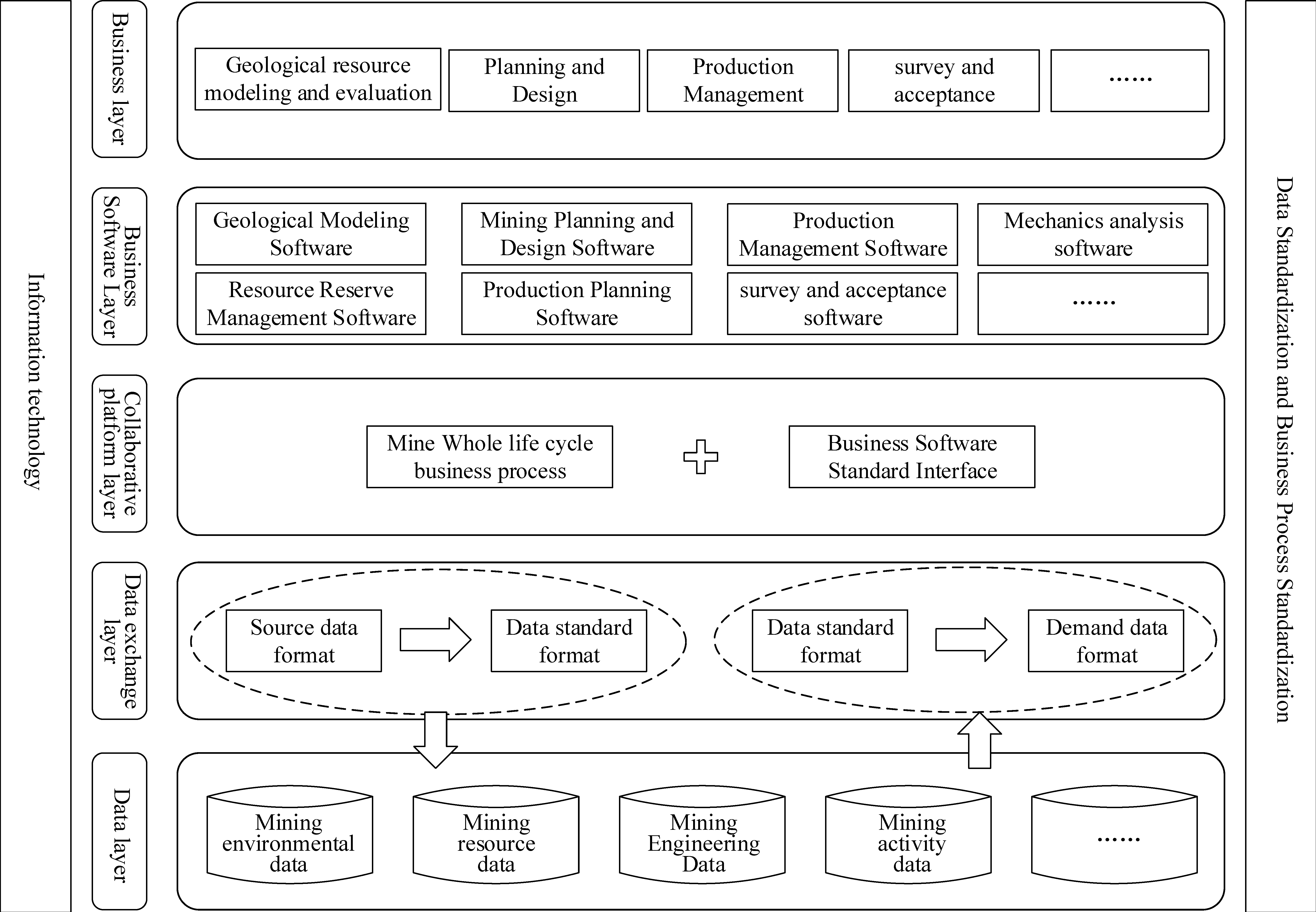

4.4. Architecture of MTCP

4.5. Technical Requirements of MTCP

- (1)

- Business process management-related requirements

- Hierarchical management of business processes—according to the different granularities of business divisions, the business has the characteristics of a hierarchy and the corresponding business processes also have the corresponding hierarchy. According to the profession, the first layer can be generally divided into geology, surveying and mining and the second layer can be refined on the basis of the first layer. For example, geology can also be divided into prospecting design, geological logging, geological interpretation, geological modeling, reserve estimation and so on, until it is divided into the appropriate levels.

- Business process definition—although the mine life cycle business phase is the same as the profession involved, with the refinement of the business, different mining enterprises have different business processes with different concerns and needs. Therefore, it should be able to flexibly define the business process according to the business concerns and needs of different mining enterprises and avoid the need for re-coding and developing for different business process definitions.

- Business process visualization—it can visualize the business process definition and simplify the complexity of the business process definition. Additionally, it can visually display the status of the business process flow, clearly show the current process node, each process node and the start and completion time of the whole business process, as well as which process nodes have been rejected and the number of rejections and so on.

- Status management of business processes—the business process status is fully managed, including defining the business processes, running the business processes, archived business processes and abnormal business processes, on the mining technology collaboration platform.

- Management of historical business processes—as business processes continue to be created, launched, streamed and archived, a large number of historical business processes will be accumulated. These historical business processes contain a large amount of valuable information. They can be queried and analyzed by the business, business process, business personnel and initiation and archiving time. The existing problems can be found and the business processes and business work can be optimized and improved to improve the flow speed of the business processes and the quality and efficiency of the work.

- (2)

- Business software system related requirements

- Compatible with the mining technology collaboration platform management side—since the business software systems required for all business processing in the mine’s whole life cycle are integrated on the management side of the mining technology collaboration platform, in the business process flow, the necessary information, such as the business process information, user information and authority information on the management side of the mining technology collaboration platform, will be transmitted to each business software system as the business software system is activated to ensure that the relevant information of the mining technology collaboration platform management side is consistent with the relevant information of the business software system to achieve compatibility between the two.

- Upload/download model data—the upload/download mode of model data includes launching the corresponding business software system to upload/download model data during the business process flow and setting up necessary data organization management information to upload/download model data by login to the business software system separately. The downloading of model data should support selective downloading of model data for each historical version.

- Access control—the access control of the business software system includes the login access control, function access control and data access control. The business software system requires a username and password to log in and gain access and can access the corresponding function according to its permission and upload and download the model data under the corresponding authority.

- Data standardization management—to ensure the efficient flow and sharing of business data among participants, departments, professional posts and business software systems, it is necessary to standardize the management of all business data involved in the mine’s whole life cycle.

- Business workflow of business software system—to standardize the process of the business software system to handle the entire business work, the entire business process is streamlined and standardized to make the whole business process clear, simple and efficient.

- Two-dimensional drawing and document generation—the business software system can download the model data from the model data storage warehouse and generate various two-dimensional drawings and documents, such as a roadway logging map, geological plan and section map, development design drawings, mining and cutting design drawings, ventilation network solution reports and so forth according to the mine’s business needs.

- (3)

- Model data management-related requirements

- Model data storage warehouse—the mining technology collaboration platform is used to store the model data of the mine’s whole life cycle, including geological data, resource data, engineering data, activity data. It needs a storage warehouse to organize and manage all the business data effectively for centralized storage.

- Model data objects at different levels—the business data of mine’s whole life cycle is stored in the data warehouse at different levels to meet different levels of business needs. For example, the orebody model can be divided into four levels, that is, mine, mining area, level and stope. to meet different levels of reserve calculation, planning and design.

- Unique identification of model data in the data warehouse—to prevent duplicate business data stored in the data warehouse, a unique ID is used to identify the model data object.

- Model data version management—record, track, maintain and control the evolution of all data in the whole life cycle of the mine to avoid loss and confusion regarding the model data.

- Locking of model data—when the model data is being used, it needs to be locked and protected to avoid conflicts between different users.

- Model data security management—the security of model data is the basis for the smooth flow of business processes and business operations. Therefore, it is necessary to ensure the security of the model data in the data warehouse by setting various security mechanisms, including user authentication, access control, data encryption and data backup.

- (4)

- MTCP management-related requirements

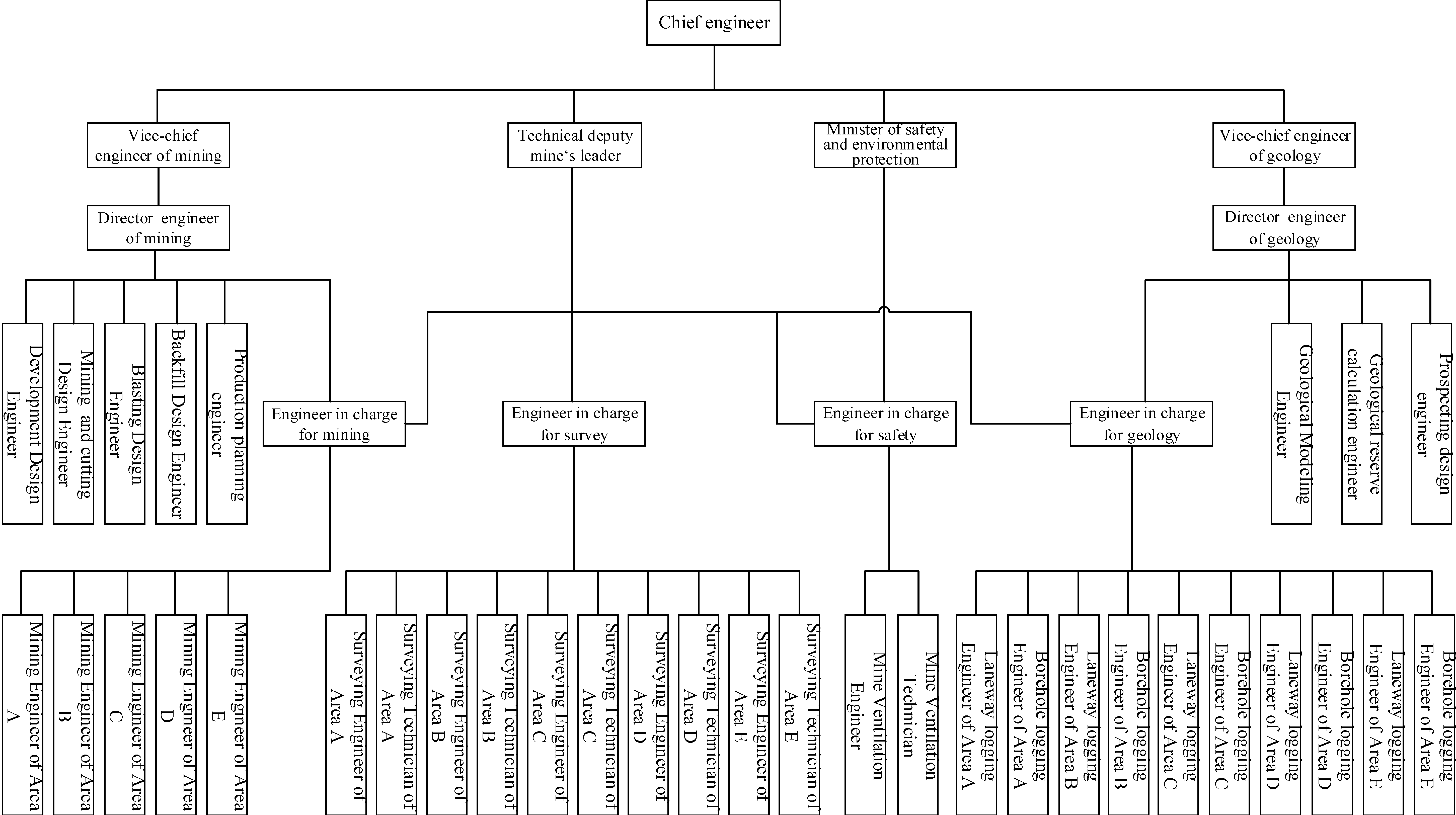

- Organizational structure, role and user information management—the purpose is mainly to manage the organizational structure, role information and user information of all participants and ensure that all the participants, departments and professional posts involved in the mine’s whole life cycle work and communicate on the mining technology collaboration platform.

- System status viewer—view the users who are logging in to access the system; view which model data is being used, added, modified and deleted by which users; view the status and quantity of the business processes, including the defined business processes, initiated business processes, running business processes, archived business processes and so forth in the system; view the operational status of the integrated business software in the system; view the system’s error information and warning information and so on.

- Data dictionary—the definition and detailed description of the data used in the system is the basis for system development, maintenance and use of data.

- System exception handling—the mining technology collaboration platform is based on the business processes and when the flow is smooth, the business will flow efficiently. However, when a process node in a business process cannot flow smoothly, it will cause the subsequent business to not be able to continue, resulting in delays in subsequent business. Therefore, the mining technology collaboration platform must be able to handle such anomalies quickly.

- System Configuration Manager—to ensure the safety of the mining technology collaboration platform, it is necessary to configure and manage the user’s access to the mining technology collaboration platform management side, the data warehouse and the business software system and to configure and manage the functional modules of the mining technology collaboration platform management side and business software system according to the business type and the nature of business posts.

- (5)

- Teamwork communication-related requirements

- Group collaboration communication tool—the mining technology collaboration platform is an integrated and collaborative platform for all business work in the mine’s whole life cycle. In the process of all business processing and management, between business technical personnel, business technicians and management personnel, they inevitably need to communicate with each other in terms of business and management issues. Therefore, the mining technology collaboration platform needs to integrate communication software (such as instant messaging tools, e-mail) with business and to consult, advise, answer and review questions through instant messaging, voice, video and e-mail in the business process. Therefore, the mining technology collaboration platform needs to integrate communication software (such as instant messaging tools, email) with the business in the business processing and management process through instant messaging, voice, video, email and other ways to consult the problem and provide suggestions, answers and reviews. In addition, the mining technology collaboration platform can provide knowledge sharing and communication modules, including a knowledge base, knowledge encyclopedia, knowledge circle and knowledge quiz, for the participants to share and exchange knowledge anytime and anywhere in the process of business processing and management.

5. Case Study

5.1. Requirement Survey and Analysis

5.2. Research and Development of MTCP

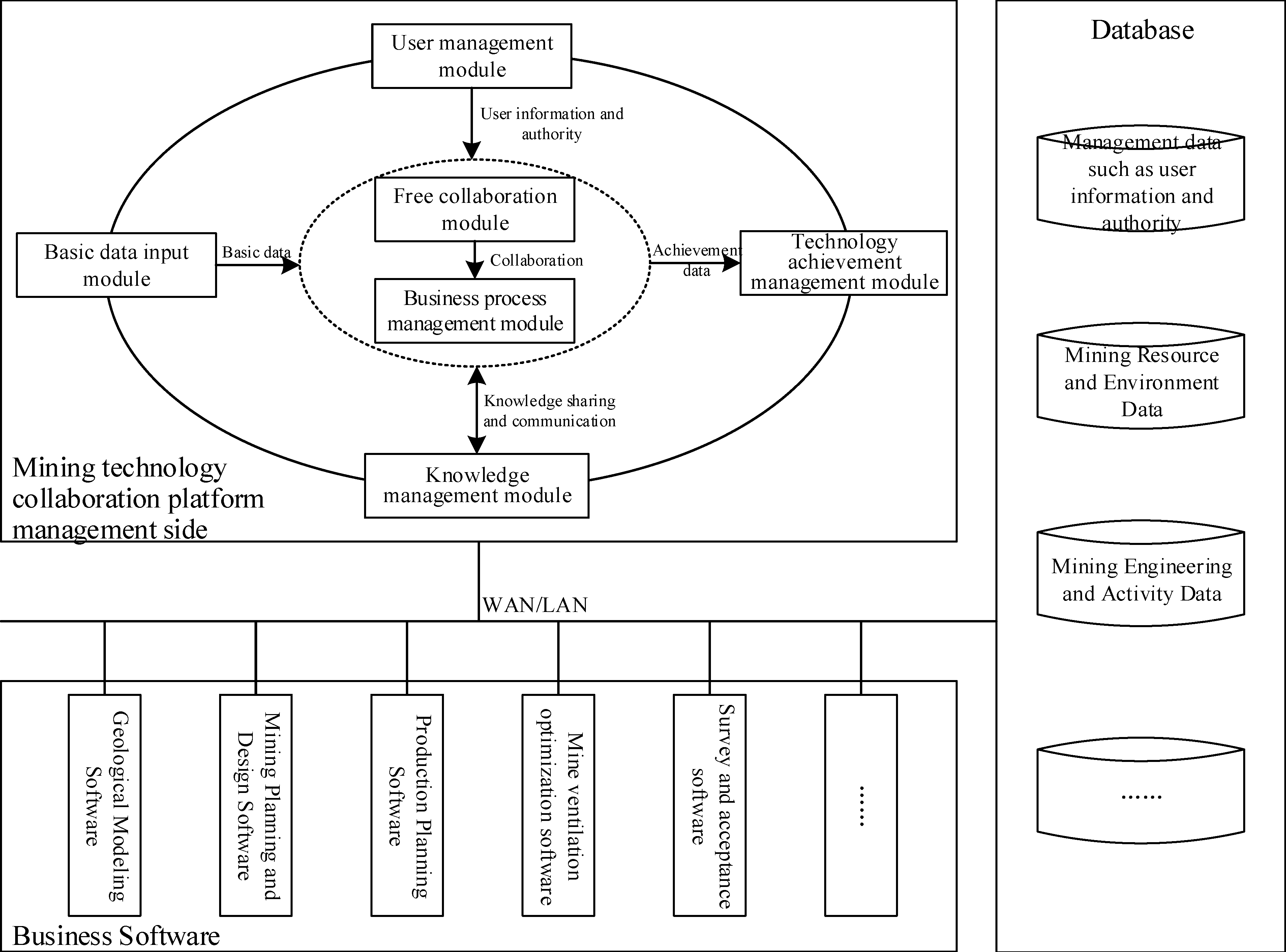

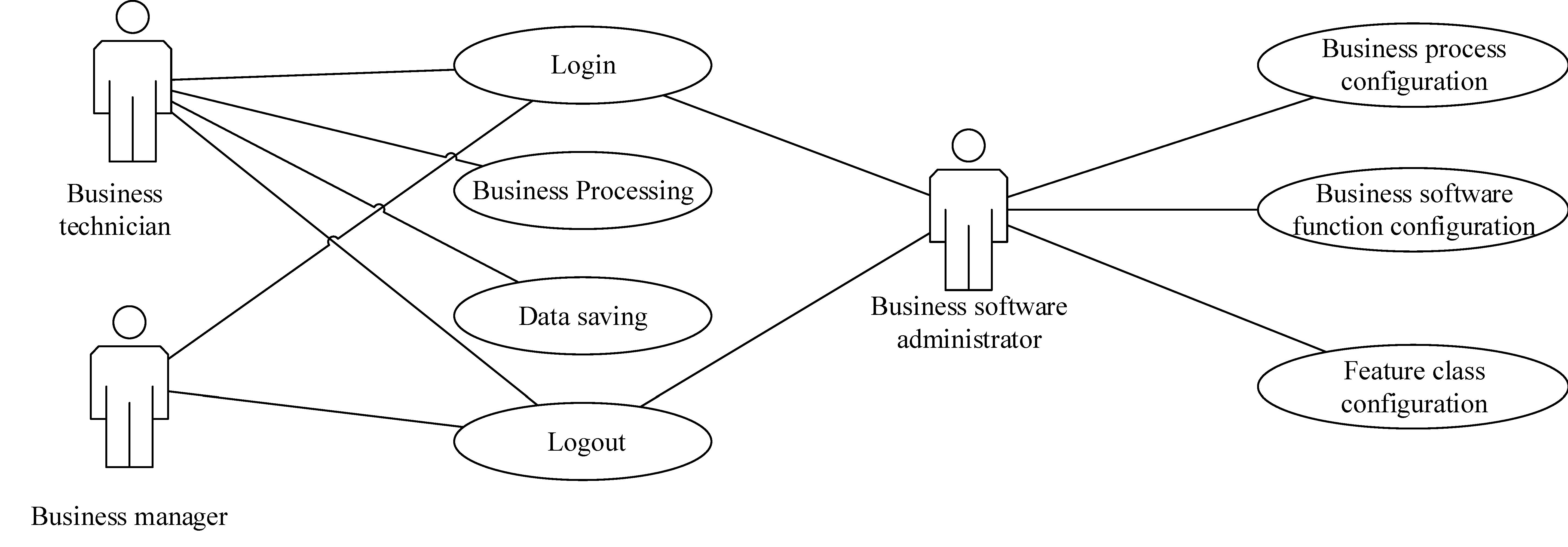

5.2.1. Mining Technology Collaboration Platform Management Side

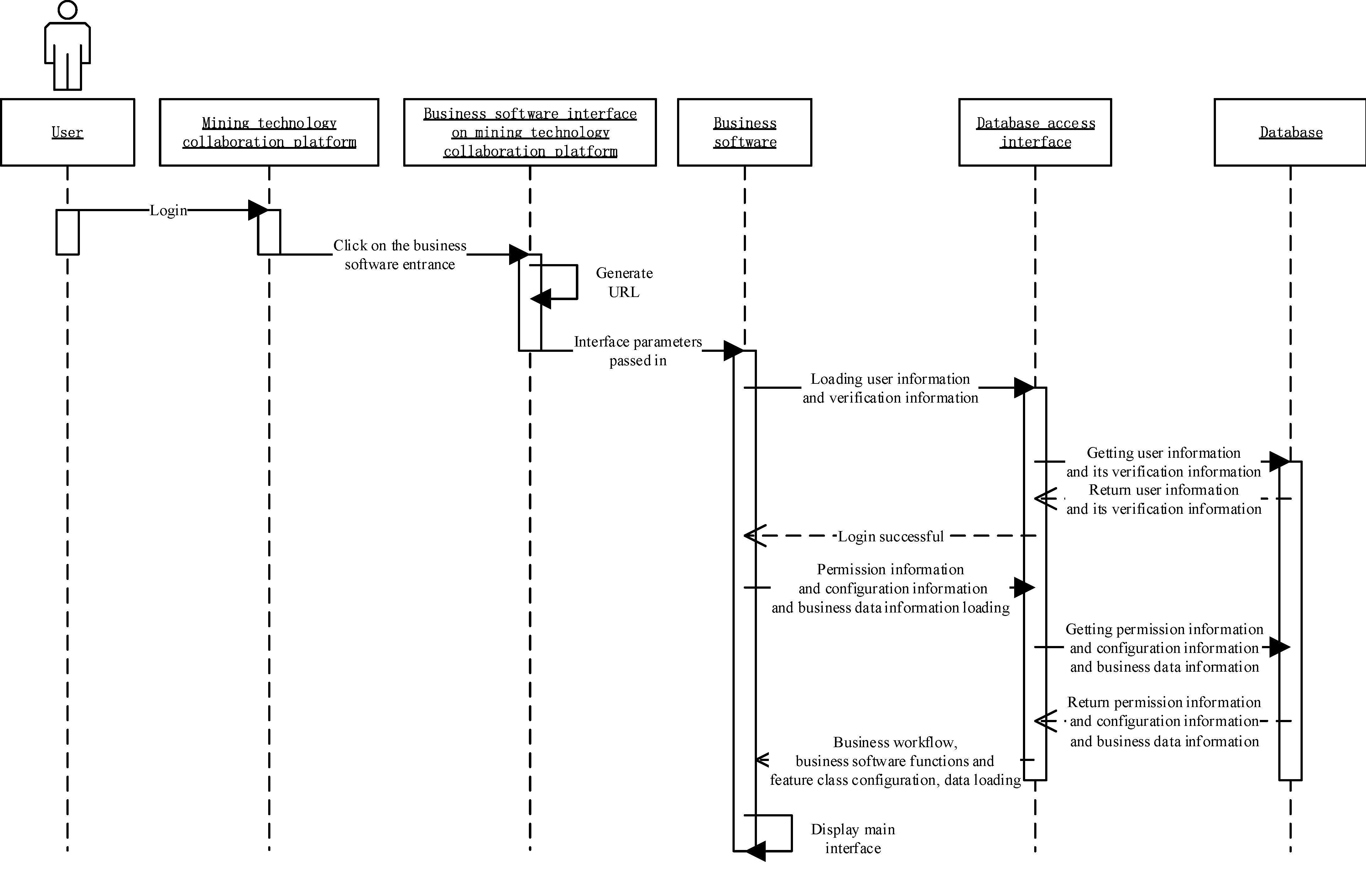

5.2.2. Transformation of Business Software

{

mine://

userid=00IT0001A10000000411

&token=5ec688c9-d508-4c3c-ae5c-adeb9ec27082

&ismytodo=true

&allowedit=true

&processid=304d07ffcd3f4f80851c80300c366823

&businessid=6855dc98-a750-49ce-afba-64dce85313ee

&isresult=false/

}

where “mine” is a custom URL protocol for locating the installation location of the business software; “userid” is a user ID with uniqueness; “token” is a token to verify the validity of the user’s identity; “ismytodo” is used to indicate whether the user of the userid is responsible for the business or cooperates to complete the business; “allowedit” means whether the user has editing rights; “processid” represents the business process ID; “business id” denotes the business ID of the business process node; “isresult” indicates whether the business process is an archived technical result and the business software can load the result data of its archived moment by this parameter.5.2.3. Database

5.3. Project Implementation

5.3.1. Implementation of Overall Business Process

- (1)

- According to the prospecting plan, the standardized business process of prospecting design for a working site was created and initiated. The prospecting design engineer started the DIMINE software through the business software entrance on the mining technology collaboration platform and completed the prospecting design work under his job duty and saved the data of the prospecting design results (including design borehole database, design borehole plan and profile map) to the database and submitted the prospecting design business form. According to the standardized business process of prospecting design, it flows to the supervisor, department head and chief engineer of the prospecting design successively. The supervisor, department head and chief engineer review the prospecting design results data according to their job duties. If they do not meet the requirements, they can be directly rejected and returned to the prospecting design engineers until the results data is approved and archived.

- (2)

- The resulting data of prospecting design (design borehole database, design borehole plan and profile) are used to guide on-site prospecting construction and data such as opening, inclination, lithology and grade are obtained during the prospecting construction process and corresponding sample tests. On this basis, through the creation and initiation of standardized business processes of geological logging, geological logging engineer started geological modeling software through the business software entrance on the mining technology collaboration platform and completed the geological logging work under his job duty and the result data (including borehole database, pit exploration database and laneway logging map) are saved to the database. In accordance with the standardized business process of geological logging, it flows to the supervisor and department head of the geological logging successively. The supervisor and department head review the geological logging results data according to their job duties, until the results data is approved and archived.

- (3)

- The relevant personnel of geological modeling received the reminder of the standardized business process of geological logging at work site A and created and initiated the geological modeling standardization business process. The geological modeling engineer started the geological modeling software through the business software entrance on the mining technology collaboration platform and the geological modeling software automatically loaded the result data of geological logging from the database according to configuration information (including borehole database, pit exploration database and laneway logging map). The detailed business processing, transfer, approval, submission and archiving of the geological modeling business process can be observed in the example of the orebody modeling business process.

- (4)

- The relevant personnel of the reserve calculation received the reminder of the standardized business process of geological modeling at work site A and created and initiated the reserve calculation standardized business process. The reserve calculation engineer started the geological modeling software through the business software entrance on the mining technology collaboration platform and the geological modeling software automatically loaded the result data of geological modeling from database according to configuration information (including borehole database, pit exploration database, orebody model, level model, stope model and shaft and laneway engineering model) and completed the reserve calculation work under his job duty. The result data (including block model, level ore reserve, stope ore reserve, stope engineering ore reserve) are saved to the database. According to the standardized business process of reserve calculation, it flows to the department head and chief engineer of the reserve calculation successively. The department head and chief engineer review the reserve calculation results data according to their job duties, until the results data are approved and archived.

5.3.2. Implementation of the Orebody Modeling Business Process

- (1)

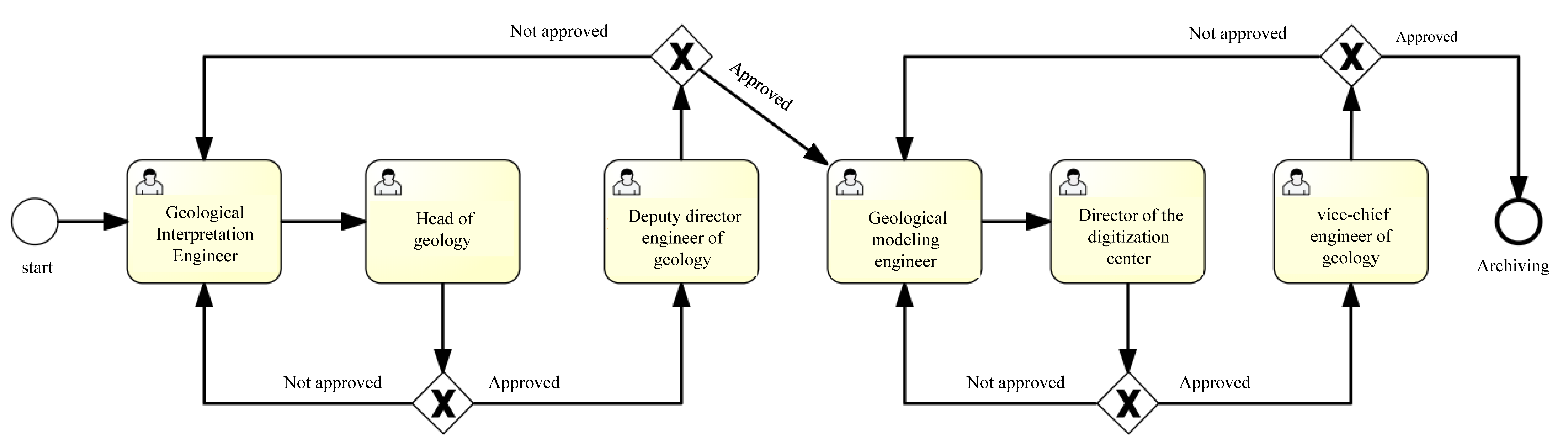

- Definition and configuration of orebody modeling business processAccording to the results of the requirement survey and analysis, including the standardized orebody modeling business process, the job duty of each process node and its input and output data, the business process of orebody modeling in Fujian Makeng Iron Mine is defined and the roles of each business process node, the users corresponding to the roles, the roles corresponding to the business software and its functions and business data are configured. The professional post duty and its input and output data tables and the business flow charts of the orebody modeling are shown in Table 1 and Figure 5, respectively.

- (2)

- Creation and initiation of the orebody modeling business processThe creation of the orebody modeling business process is mainly to create business forms and determine the site and content of the work. This task is to complete the construction of the orebody model of the 100 m level, 200 m level and 300 m level of the E mine area of Fujian Makeng Iron Mine and submit the created orebody modeling business form and initiate the orebody modeling business process, as shown in Figure 11.

- (3)

- Geological interpretation engineer conducts geological interpretationThe geological interpretation engineer receives reminders of to-do items, signs the to-do items and starts the geological modeling software under his/her authority through the business software entrance on the business form and then automatically loads the input data under his/her authority from the database (see Table 1) for geological interpretation.Since the geological interpretation of the orebody modeling business process involves a total of 15 levels, including 100 m level, 200 m level and 300 m level and 12 sublevels between the three levels, the geological interpretation workload is large. Therefore, to increase the speed of the progress of geological interpretation work, the geological interpretation engineers, through the mining technology collaboration platform management side of the free collaboration module, set up a free collaboration group to work together to complete the geological interpretation work. The free collaboration group provides a unified and data-sharing digital working environment for all collaborators through the mining technology collaboration platform and the team members can communicate with each other through instant messaging tools integrated in the mining technology collaboration platform, which changes the traditional decentralized collaboration mode and data exchange based on paper or electronic documents and changes the problem that communication information in the traditional collaboration process cannot be effectively preserved. In the free collaboration group, the approvers and the follow-up users of the business achievement data can be added to enable the relevant personnel to timely understand and grasp the business work, business progress and achievement data and to give timely advice and guidance on the problems existing in the process of business collaboration to avoid rework due to noncompliance and to accelerate the completion of the business collaboration and review of the achievement data.This free collaboration group includes not only those who directly participate in the collaboration but also the approvers of the geological interpretation line, such as the head of geology for Fujian Makeng Iron Mine, the deputy director engineer of geology, the geological modeling engineer, the director of the digitization center and the vice-chief engineer of geology. The members of the free collaboration group who have editing rights are the collaborators, while those without editing authority are the follow-up reviewers and geological modelers. In addition, during the collaboration process, the free collaboration group can communicate technical issues through instant messaging tools, where the communication records are archived as the business process is archived.When all the collaborators complete the geological interpretation work, the geological interpretation engineer approved the collaborators’ achievement data and submitted the business form of the mining technology collaboration platform management side and the business form flowed to the head of geology for Fujian Makeng Iron Mine. The collaborative achievement data of geological interpretation is the geological interpretation line, as shown in Figure 12.

- (4)

- The head of geology for Fujian Makeng Iron Mine reviewed the achievement data of the geological interpretation engineer.The head of geology for Fujian Makeng Iron Mine received the reminder of the to-do items, signed and received the to-do items and started the geological modeling software through the entrance of the business software on the business form and automatically loads the input data and the achievement data under his authority (see Table 1) to review the achievement data (that is, geological interpretation line) of the geological interpretation engineer.The head of geology for Fujian Makeng Iron Mine reviewed the achievement data of the geological interpretation engineer (i.e., geological interpretation line). If it met the requirements, the head of geology for Fujian Makeng Iron Mine would select the approval option on the business form of the mining technology collaboration platform management side as “Agree,” then submit the business form; the business form the flowed to the deputy director engineer of geology; if it does not meet the requirements, the approval option on the business form is selected as “Reject” and the reasons for the noncompliance are explained in the approval comments column, then submit the business form and the business form is returned to the geological interpretation engineer and the geological interpretation engineer modifies the geological interpretation line based on the review opinion.

- (5)

- The deputy director engineer of geology reviewed the achievement data of the geological interpretation engineer.The duty of the deputy director engineer of geology is the same as the head of geology for Fujian Makeng Iron Mine. They are all reviewing the achievement data of the geological interpretation engineer (that is, the geological interpretation line). Therefore, see list (4) for details.

- (6)

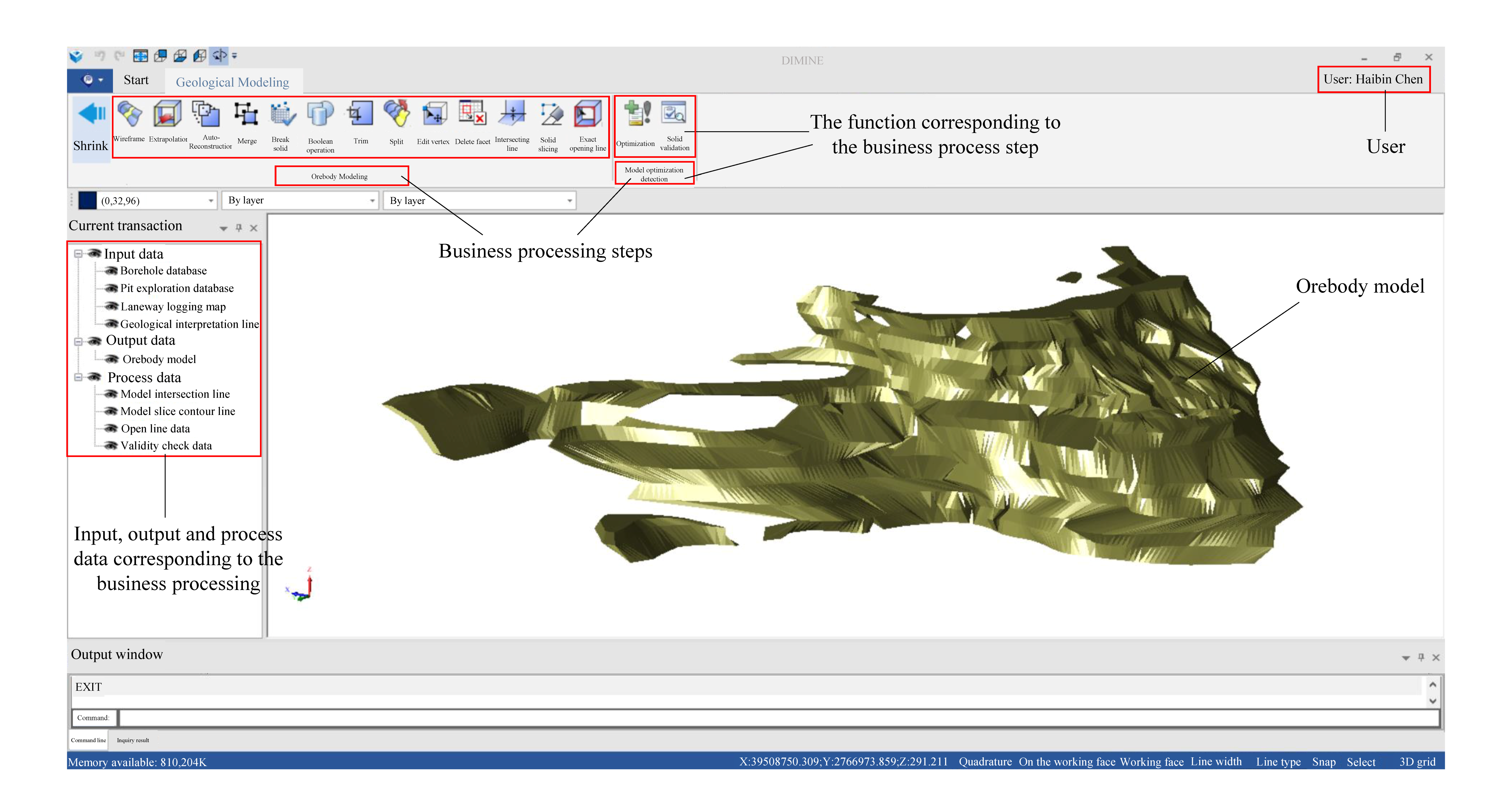

- The geological modeling engineer conducted orebody modeling based on the approved geological interpretation line.The geological modeling engineer received reminders of to-do items, signed and received the to-do items, started the geological modeling software through the business software entrance on the business form and automatically loaded the input data and achievement data under his/her authority (see Table 1) for orebody modeling.Geological modeling can also form a free collaboration group by the free collaboration module and the free collaboration team can collaborate to complete the orebody modeling work; for details, see the free collaboration in the geological interpretation work. Based on the input data, the geological modeling engineer completed the construction of the orebody model through the two process steps of orebody modeling and model optimization detection and saved and submitted the achievement data (i.e., the orebody model) to the database. The resulting data are shown in Figure 13. The geological modeling engineer submitted the business form of the mining technology collaboration platform management side and the business form flowed to the director of the digitization center.

- (7)

- The director of the digitization center reviewed the achievement data of the geological modeling engineer.The director of the digitization center received the to-do reminder, signed and received the to-do items, started the geological modeling software from the business software entrance on the business form of the mining technology collaboration platform management side and automatically loaded the input data and the achievement data under his/her authority (see Table 1) to review the achievement data (i.e., the orebody model) of the geological modeling engineer.If it met the requirements, the director of the digitization center will select the approval option on the business form of the mining technology collaboration platform management side as “Agree,” then submit the business form; then, the business form flowed to the vice-chief engineer of geology; if it does not meet the requirements, the approval option on the business form is selected as “Reject” and the reasons for the rejection are explained and the business form is submitted; then the business form is returned to the geological modeling engineer and the geological modeling engineer makes the targeted modifications to the review comments and instructions and resubmits the model after the modification is completed.

- (8)

- The vice-chief engineer of geology reviewed the achievement data of the geological modeling engineer.

- (9)

- The duty of the vice-chief engineer of geology is the same as the director of the digitization center, that is, to review the achievement data (i.e., the orebody model) of the geological modeling engineer. Therefore, for details see list (7). When the vice-chief engineer of geology’s review opinion was “Agree” and he/she submits the business form, the orebody modeling business process is completed and is entered into the technical achievements management module for archiving.

5.4. Application Results

- (1)

- The centralized storage of all data. Compared with traditional paper and electronic documents scattered in the hands of participants, departments and professional positions, it saves a lot of time and effort for technicians to collect large amounts of data before the business processing and ensures the integrity, accuracy, safety and the latest version of the data, so as to solve the problems of data faults, data loss and data version confusion under the traditional mode.

- (2)

- The standardized processing of all data. In the traditional mode, only the data results of the business or business phase are considered, which leads to the subsequent business obtaining the data that cannot be directly utilized and needs to be further processed into data that meets the requirements of the business. After data standardization processing, this paper can ensure that data is directly used by each business. It ensures the interconnection and high sharing of data among all participants, departments and professional posts and also saves the time and resources for further processing of data and solves the traditional problem of “information island.”

- (3)

- The high-speed flow between each business is through the standardized business process. The traditional functional management mode based on the division of labor theory makes the business process fragmented and the business flow is not smooth and extremely slow. Through standardized business processes, it ensures the smooth flow of business processes and the unity of objectives and interests of participants, departments and professionals, breaks the organizational boundaries between participants and departments and solves the problem that the participants and departments often conflict with each other in maintaining their own goals and interests under the traditional mode.

- (4)

- Its organizational structure was optimized and the duties of each position and its input and output data were clearly defined. Compared with the traditional “pyramid” organizational structure, which is characterized by overstaffed organization, low management efficiency and high cost and unclear responsibilities of each post, which leads to the duplication of work content and work prevarication and so forth, by using information technology such as the Internet, this paper reduces the middle management, achieves flat management, improves its decision-making ability and reduces operating costs.

- (5)

- Through the research and development of the mining technology collaboration platform, it integrates geological, surveying, mining and other business and and its required business software for Fujian Makeng Iron Mine and integrates all the involved participants, departments and professional positions, improving the across time and space and multidisciplinary collaborations ability of all participants, departments and professional posts.

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, L. Thoughts on digital mine technology and mine technology’s upgrading in china. Min. Technol. 2015, 131–138. Available online: http://www.cnki.com.cn/Article/CJFDTotal-COLO201507005.htm (accessed on 6 December 2019).

- Lu, J.; Wang, X.; Ma, L.; Zhao, A. Informationization of coal enterprises and digital mine. J. Coal Sci. Eng. (China) 2008, 14, 512–516. [Google Scholar] [CrossRef]

- Zhang, Y.; Song, H.; Li, J.; Dong, Z. The application of triple-play integrated automation network on xinglong coal mine. In Proceedings of the 2010 International Conference on Intelligent Control and Information Processing, Dalian, China, 13–15 August 2010; pp. 4304–4334. [Google Scholar]

- Zhang, J.; Xiao, J. Architecture and application of integrated spatial information service platform for digital mine. Trans. Nonferr. Met. Soc. China 2011, 21, s706–s711. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, X. Research on key technology of coal mine automation based on internet of things. In Proceedings of the 3rd International Conference on Science and Social Research (ICSSR 2014), Tianjin, China, 14–15 June 2014. [Google Scholar] [CrossRef]

- Zhang, J. On-line inspection system of integrated automation network equipment in coal mine. In Proceedings of the 2018 8th International Conference on Mechatronics, Computer and Education Informationization (MCEI 2018), Shenyang, China, 18–20 May 2018. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, M.; Wang, K.; Fu, G. A dynamic information platform for underground coal mine safety based on internet of things. Saf. Sci. 2019, 113, 9–18. [Google Scholar] [CrossRef]

- Ji, X.; Luo, D.; Wei, R. Overall planning and application of the digital mine in dahongshan copper mine. Met. Mine 2018, 5, 143–147. [Google Scholar]

- He, Y.; Zhang, D.; Liang, L. Practice of digital mine construction in three dao zhuang open pit mine. In Proceedings of the Third National Digital Mine High and New Technology Achievement Exchange Meeting, Dandong, China, 13 May 2014. [Google Scholar]

- Shi, H.; Zhao, T. Barun digitized mine construction. Sci. Technol. Innov. Her. 2014, 29, 90. [Google Scholar]

- Dou, F.; Lin, Z. An application of gocad in three-dimensional geological modeling. China’s Manganese Ind. 2017, 4, 147–149. [Google Scholar]

- Mu, C. Construction of geological database and application of three-dimensional orebody model in ashele copper mine based on surpac. World Nonferr. Met. 2019, 12, 203–205. [Google Scholar]

- Cui, C.; Yuan, F.; Li, X.; Zhang, M.; Jia, C.; Zhou, T. Optimization of open-pit mining limit of tongling xinqiao deposit based on surpac. Met. Mine 2012, 10, 15–18. [Google Scholar]

- Zuo, F.; Luo, Q. 3d Modeling and Blasting Design Based on 3dmine Software. Mod. Min. 2016, 32, 20–22. Available online: http://www.cnki.com.cn/Article/CJFDTotal-KYKB201602006.htm (accessed on 25 June 2019).

- Li, N.; Du, G.; Luo, C.; Yang, C.; Li, W.; Xu, J. Application of Dimine Software in 3d Geological Modeling in Chundu Copper Mine. World Nonferr. Met. 2017, 1801–1881. Available online: http://www.cnki.com.cn/Article/CJFDTotal-COLO201701094.htm (accessed on 25 June 2019).

- Jiang, J. Application Study of Dahongshan Copper Mine for Production Planning Based on Dimine Three-Dimensional Visualization Software. Master’s Thesis, Central South University, Changsha, China, May 2010. [Google Scholar]

- Han, Q. Study on Key Issues of Intellimine Informatization Standardization System. Ph.D. Thesis, China University of Mining & Technology, Beijing, China, June 2016. [Google Scholar]

- Wang, J.; Wang, Y.; Fu, J. Crucial technology research and demonstration of digital mines. J. China Coal Soc. 2016, 41, 1323–1331. [Google Scholar] [CrossRef]

- Yu, Z.; Song, L. Research on standardization of space information in coal mine. In Proceedings of the 2018 International Conference on Internet and e-Business, Singapore, 25–27 Apirl 2018; pp. 162–165. [Google Scholar]

- Krige, D.G. A Review of the Development of Geostatistics in South Africa; Springer: Dordrecht, The Netherlands, 1976; pp. 2792–2793. [Google Scholar]

- Mallet, J.L. Gocad: A computer aided design program for geological applications. In Three-Dimensional Modeling with Geoscientific Information Systems; Turner, A.K., Ed.; Springer: Dordrecht, The Netherlands, 1992; pp. 1231–1241. [Google Scholar]

- Onions, R.; Tweedie, J. Development of a field computer data logger and its integration with the datamine mining software. Geol. Soc. Lond. Spec. Publ. 1992, 63, 125–133. [Google Scholar] [CrossRef]

- Agrawal, H. Modeling of Opencast Mines Using Surpac and Its Optimization. Ph.D. Thesis, Department of Mining Engineering National Institute of Technology Rourkela, Rourkela, India, May 2012. [Google Scholar]

- Radulescu, A.T.G.M.; Radulescu, V.M.G.M. Brief Analysis on Software for the Mining Industry, with Operational Applications. Scientific Bulletin Series D: Mining, Mineral Processing, Non-Ferrous Metallurgy. Geol. Environ. Eng. 2012, 26, 157. Available online: https://search.proquest.com/openview/697399b248ea9ecb6f09c52913022a66/1?pq-origsite=gscholar&cbl=376316 (accessed on 25 June 2019).

- Peng, J. Research on Digital Mine Production Information Integration Platform Based on b/s Architecture. Master’s Thesis, Northeastern University, Shenyang, China, June 2013. [Google Scholar]

- Golosinski, T.; Ataman, I. Total open pit mining systems: A dream or a reality? In Proceedings of the 16th Mining Congress of Turkey, Ankara, Turkey, 15–18 June 1999. [Google Scholar]

- Bi, L. Study of Key Technology of Platform of Digital Mining Software System. Ph.D. Thesis, Central South University, Changsha, China, March 2010. [Google Scholar]

- Wu, L. The Digital Earth, Digital China and Digital Mine. Mine Surv. 2000, 69. Available online: http://www.cnki.com.cn/Article/CJFDTOTAL-KSCL200001001.htm (accessed on 25 June 2019).

- Wu, L. Progress of Digital Mine in China. Geomat. World 2008, 61–63. Available online: http://www.cnki.com.cn/Article/CJFDTotal-CHRK200805005.htm (accessed on 25 June 2019).

- Wu, L.; Wang, Y.; Ding, E.; Zhu, W.; Zhang, R.; Zhang, S.; Wang, Z. Thirdly study on digital mine: Serve for mine safety and intellimine with support from iot. J. China Coal Soc. 2012, 37, 357–365. [Google Scholar] [CrossRef]

- Wu, L.; Yin, Z.; Zhong, Y. Restudy on digital mine: Characteristics, framework and key technologies. J. China Coal Soc. 2003, 28, 1–7. [Google Scholar] [CrossRef]

- Wang, L.; Zeng, Q.; Jia, M. Integral implementation scheme and key technologies for digital mine. Min. Technol. 2006, 6, 493–498. [Google Scholar] [CrossRef]

- Wang, L.; Chen, X. Advancing technologies for digital mine. Chin. J. Nonferr. Met. 2016, 26, 1693–1710. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, H.; Niu, J. Functions and Components of a Digital Mine Operation System. China Min. Mag. 2004, 13, 7–10. Available online: http://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA200401001.htm (accessed on 25 June 2019).

- Lu, X.; Yin, H. Definition, connotations and progress of digital mine. Coal Sci. Technol. 2010, 38, 48–52. [Google Scholar] [CrossRef]

- Sun, H.; Xu, S. On Digital Mine. Metal Mine 2007, 368, 1–5. Available online: http://www.cnki.com.cn/Article/CJFDTotal-JSKS200702000.htm (accessed on 25 June 2019).

- Zhang, Y. Research on BIM-Based Building Information Integration and Management. Ph.D. Thesis, Tsinghua University, Beijing, China, April 2009. [Google Scholar]

- Li, Y. Study on Theory and How to Realize Building Lifecycle Management(BLM)-Organization, Process, Information and System Integration. Ph.D. Thesis, Tongji University, Shanghai, China, May 2007. [Google Scholar]

- Singh, V.; Gu, N.; Wang, X. A theoretical framework of a bim-based multi-disciplinary collaboration platform. Autom. Constr. 2011, 20, 134–144. [Google Scholar] [CrossRef]

- Azhar, S. Building information modeling (bim): Trends, benefits, risks, and challenges for the aec industry. Leadersh. Manag. Eng. 2011, 11, 241–252. [Google Scholar] [CrossRef]

- Bargstädt, H.-J. Challenges of bim for construction site operations. Procedia Eng. 2015, 117, 52–59. [Google Scholar] [CrossRef]

- Van Nederveen, G.; Tolman, F. Modelling multiple views on buildings. Autom. Constr. 1992, 1, 215–224. [Google Scholar] [CrossRef]

- Eastman, C.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Buildingsmart Alliance Releases nbims-us™ Version 3. Available online: https://www.nationalbimstandard.org/buildingSMART-alliance-Releases-NBIMS-US-Version-3 (accessed on 25 June 2019).

- Lin, Y.; Lee, H.-Y.; Yang, I.T. Developing as-built bim model process management system for general contractors: A case study. J. Civ. Eng. Manag. 2015, 22, 608–621. [Google Scholar] [CrossRef]

- Poirier, E.A.; Forgues, D.; Staub-French, S. Understanding the impact of bim on collaboration: A canadian case study. Build. Res. Inf. 2017, 45, 681–695. [Google Scholar] [CrossRef]

- Almuntaser, T.; Sanni-Anibire, M.O.; Hassanain, M.A. Adoption and implementation of bim—Case study of a saudi arabian aec firm. Int. J. Manag. Proj. Bus. 2018, 11, 608–624. [Google Scholar] [CrossRef]

- Bryde, D.; Broquetas, M.; Volm, J.M. The project benefits of building information modelling (bim). Int. J. Proj. Manag. 2013, 31, 971–980. [Google Scholar] [CrossRef]

- Gu, N.; London, K. Understanding and facilitating bim adoption in the aec industry. Autom. Constr. 2010, 19, 988–999. [Google Scholar] [CrossRef]

- Arayici, Y.; Coates, P.; Koskela, L.; Kagioglou, M.; Usher, C.; O’Reilly, K. Technology adoption in the bim implementation for lean architectural practice. Autom. Constr. 2011, 20, 189–195. [Google Scholar] [CrossRef]

- Shafiq, M.T.; Matthews, J.; Lockley, S. A study of bim collaboration requirements and available features in existing model collaboration systems. J. Inf. Technol. Constr. (Itcon) 2013, 18, 148–161. Available online: http://www.itcon.org/2013/8 (accessed on 25 June 2019).

- Bi, L.; Wang, J. The construction target, task and method of digital mine. Metal Mine 2019, 148–156. [Google Scholar] [CrossRef]

- Brief Introduction of Fujian Makeng Mining Co., Ltd. Available online: http://www.mkky.cn/about.aspx?BaseInfoCateId=65&CateId=65 (accessed on 25 November 2019).

- The Organizational Structure of Fujian Makeng Mining Co., Ltd. Available online: http://www.mkky.cn/about.aspx?BaseInfoCateId=68&CateId=68 (accessed on 25 November 2019).

- O’Neill, P.; Sohal, A.S. Business process reengineering a review of recent literature. Technovation 1999, 19, 571–581. [Google Scholar] [CrossRef]

- Aguilar-Savén, R.S. Business process modelling: Review and framework. Int. J. Prod. Econ. 2004, 90, 129–149. [Google Scholar] [CrossRef]

- Kruger, D. Application of business process reengineering as a process improvement tool: A case study. In Proceedings of the 2017 Portland International Conference on Management of Engineering and Technology (PICMET), Portland, OR, USA, 9–13 July 2017. [Google Scholar]

| No. | Professional Post | Duty of Professional Post | Input Data | Output Data |

|---|---|---|---|---|

| 1 | Geological interpretation engineer | Geological interpretation | Borehole database, pit exploration database, laneway logging map | Geological interpretation line |

| 2 | Head of geology for Fujian Makeng Iron Mine | Review geological interpretation line | Borehole database, pit exploration database, laneway logging map, geological interpretation line | Postreview geological interpretation line |

| 3 | Deputy director engineer of geology | Review geological interpretation line | Borehole database, pit exploration database, laneway logging map, geological interpretation line | Postreview geological interpretation line |

| 4 | Geological modeling engineer | Orebody Modeling | Borehole database, pit exploration database, laneway logging map, geological interpretation line | Orebody model |

| 5 | Director of the digitization center | Review the orebody model | Borehole database, pit exploration database, laneway logging map, geological interpretation line, Orebody model | Postreview Orebody model |

| 6 | Vice-chief engineer of geology | Review the orebody model | Borehole database, pit exploration database, laneway logging map, geological interpretation line, Orebody model | Postreview Orebody model |

| No. | Feature Group | Feature Class |

|---|---|---|

| 1 | Exploration line | Exploration line |

| 2 | Mining right | Mining right boundary line, Mining right boundary model |

| 3 | Engineering point | Control point, Survey point, Setting out point |

| 4 | Engineering boundary | Laneway measured waistline, Shaft and laneway engineering measured centerline, Laneway floor measured centerline, Shaft measured centerline, Shaft and laneway engineering design centerline, Shaft design centerline, Laneway engineering design centerline, Laneway design double line, Goaf boundary line, Land acquisition boundary line, Mine heap boundary line, Topographic status line, Chamber design centerline, Chamber roof measured centerline, Chamber floor measured centerline, Chamber measured contour line, Chamber design contour line |

| 5 | Engineering entity | Stope model, Goaf model, Stope design model, Shaft and laneway engineering design model, Shaft and laneway engineering measured model, Mine heap model, Surface model, Mining Area Model, Level model, Retaining wall model |

| 6 | Geological entity | Orebody model, Rock model in orebody, Surrounding rock model, Fault model, Orebody delineation model, Rock delineation model in orebody, Surrounding rock delineation model, Fault delineation model |

| 7 | Geological interpretation line | Geological interpretation line, Delineation interpretation line, Plane geological interpretation line, Profile geological interpretation line, Plane orebody interpretation line, Plane interpretation line of rock model in orebody, Plane surrounding rock interpretation line, Plane fault interpretation line, Profile orebody interpretation line, Profile interpretation line of rock model in orebody, Profile surrounding rock interpretation line, Profile fault interpretation line |

| 8 | Borehole database | Borehole database, Design borehole database, Pit exploration database |

| 9 | Engineering dimensioning | Shaft and laneway engineering footage line, Shaft and laneway engineering dimensioning point |

| 10 | Block model | Block model |

| 11 | Mine ventilation model | Mine ventilation model |

| 12 | Process data | Filtration borehole database, Sample-length composite borehole database, Design borehole trajectory line, Validity check data, Open line data, Laneway sampling line, Trend point data, Model slice contour line, Model intersection line, Model partitioning aided data, Section contour line, Retaining wall position line, Exploration line profile data, |

| 13 | Drawing and document | Laneway logging map, Design borehole plan map, Design borehole profile map, Monthly report on hydrological monitoring, Hydrogeological plan map, Shaft and laneway engineering measured map, Geological plan map, Geological profile map, Development design drawing, Mining and cutting design drawing, Shallow-hole stope design drawing, Medium-length hole stope design drawing, Large diameter deep hole stope design drawing, Backfill design drawing |

| 14 | Blasthole | Position line of a row of blasthole, A row of blasthole |

| 15 | Ore reserve table | Geological reserve table, Level ore reserve table, Goaf ore reserve table, Stope ore reserve table, Stope engineering ore reserve table, Stope production ore reserve table |

| No. | Field Name | Field Code | Field Type |

|---|---|---|---|

| 1 | ID of Orebody model | Uuid | uniqueidentifier |

| 2 | Orebody name | Name | varchar |

| 3 | Orebody number | OrebodyNumber | int |

| 4 | Mineral resources species | OreClass | varchar |

| 5 | Ore type | OreType | varchar |

| 6 | Ore volume | Volume | double |

| 7 | Ore weight | Weight | double |

| 8 | Description | Description | varchar |

| 9 | Whether it is a delineation model? | IsDelimitationModel | bit |

| 10 | ID of Work site | WorkPlace ID | varchar |

| 11 | Orebody model ID | Shell ID | uniqueidentifier |

| 12 | Orebody modeling business process ID | Workflow ID | varchar |

| 13 | Is it approved? | ApprovalFlag | integer |

| 14 | Start version number | VerFrom | bigint |

| 15 | End version number | VerTo | bigint |

| No | Field Name | Field Code | Field Type |

|---|---|---|---|

| 1 | Geological Interpretation Line ID | Uuid | uniqueidentifier |

| 2 | Name of geological interpretation line | Name | varchar |

| 3 | Type of geological interpretation lines | GeologicalInterpretationLineType | varchar |

| 4 | Number of Geological body | GeologicalBodyNumber | int |

| 5 | ID of Work site | WorkPlace ID | varchar |

| 6 | Line ID of Geological Interpretation Line | LineID | uniqueidentifier |

| 7 | Orebody modeling business process ID | Workflow ID | varchar |

| 8 | Is it approved? | ApprovalFlag | integer |

| 9 | Start version number | VerFrom | bigint |

| 10 | End version number | VerTo | bigint |

| 11 | Description | Comment | varchar |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Bi, L.; Wang, L.; Jia, M.; Mao, D. A Mining Technology Collaboration Platform Theory and Its Product Development and Application to Support China’s Digital Mine Construction. Appl. Sci. 2019, 9, 5373. https://doi.org/10.3390/app9245373

Wang J, Bi L, Wang L, Jia M, Mao D. A Mining Technology Collaboration Platform Theory and Its Product Development and Application to Support China’s Digital Mine Construction. Applied Sciences. 2019; 9(24):5373. https://doi.org/10.3390/app9245373

Chicago/Turabian StyleWang, Jinmiao, Lin Bi, Liguan Wang, Mingtao Jia, and Du Mao. 2019. "A Mining Technology Collaboration Platform Theory and Its Product Development and Application to Support China’s Digital Mine Construction" Applied Sciences 9, no. 24: 5373. https://doi.org/10.3390/app9245373

APA StyleWang, J., Bi, L., Wang, L., Jia, M., & Mao, D. (2019). A Mining Technology Collaboration Platform Theory and Its Product Development and Application to Support China’s Digital Mine Construction. Applied Sciences, 9(24), 5373. https://doi.org/10.3390/app9245373