Lightweight Research in Engineering: A Review

Abstract

1. Introduction

2. Lightweight Research Background and Significance

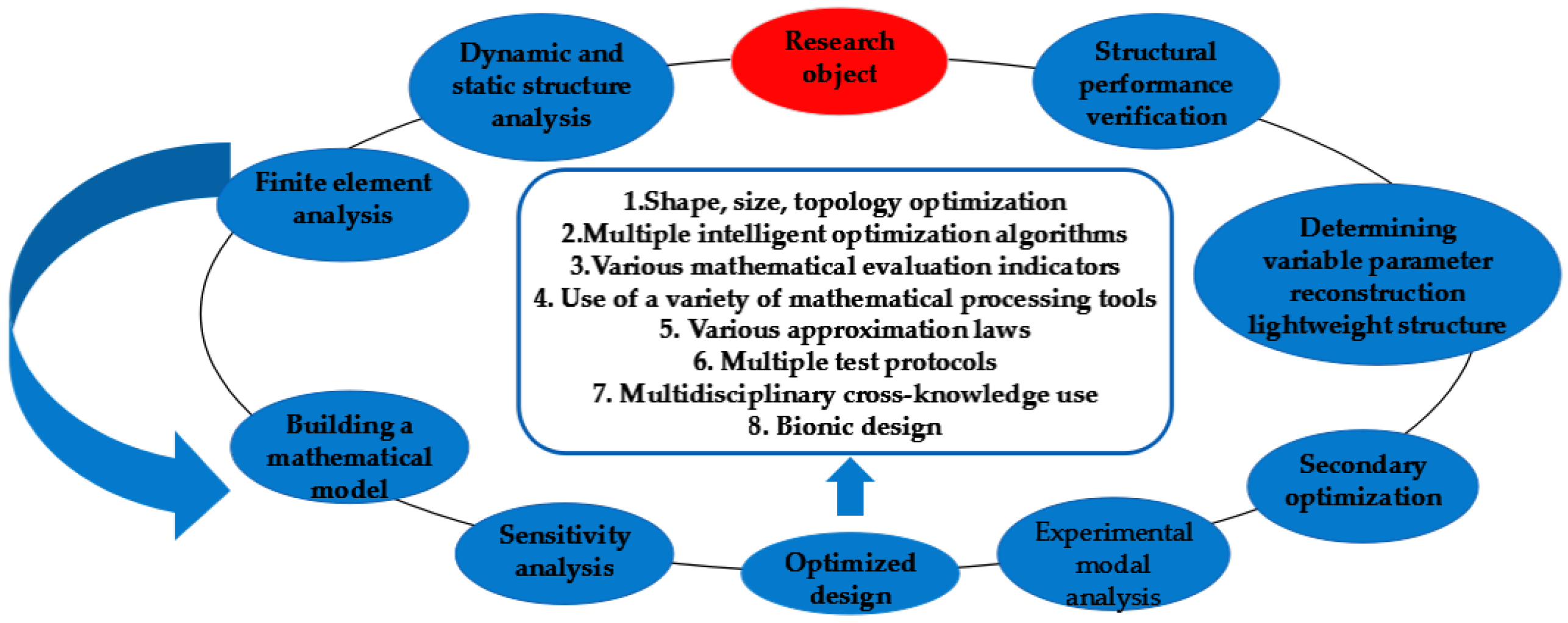

3. Lightweight Mathematical Model and Solution

- Design variables can be either continuous or discrete. For engineering structure design, the variables are usually a lot.

- The objective function and the constraint function are continuously differentiable in most cases and may also be noncontinuous and nondifferentiable.

- The constraint function is usually implicit and has a nonlinear nature. The degree of nonlinearity is different for different problems or different design points of the same problem. Because the constraint conditions in complex engineering may be very diverse, the degree of nonlinearity and linearity are also different for the structure’s design. At the same time, our solution was obtained through iterative optimization. For the optimization result, different variables are grouped with different requirements. Due to the fact that each set of variables must be fully analyzed, one by one, the amount of calculations is usually very large. Therefore, the number of times structural analysis is usually an important indicator of the efficiency of an optimization method [1].

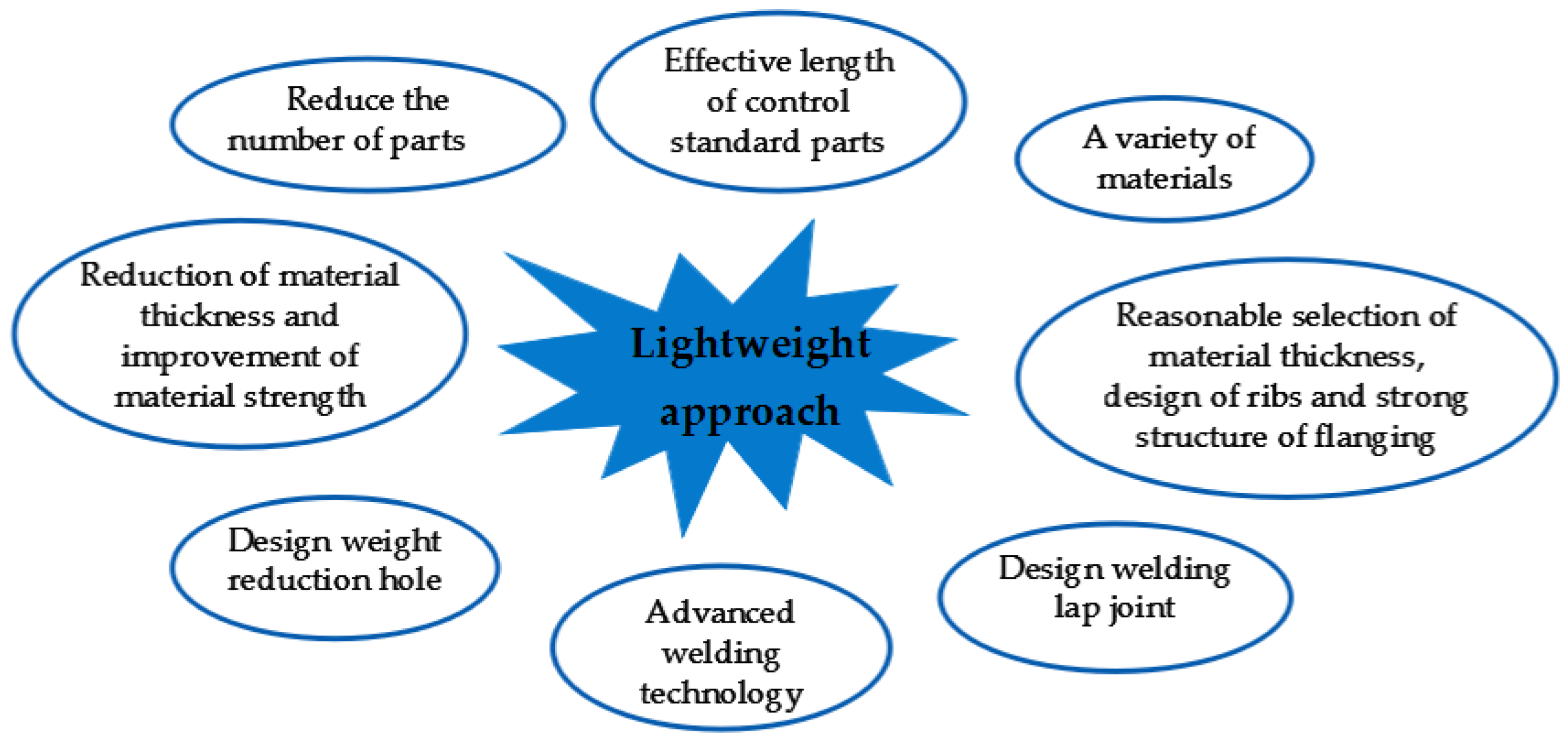

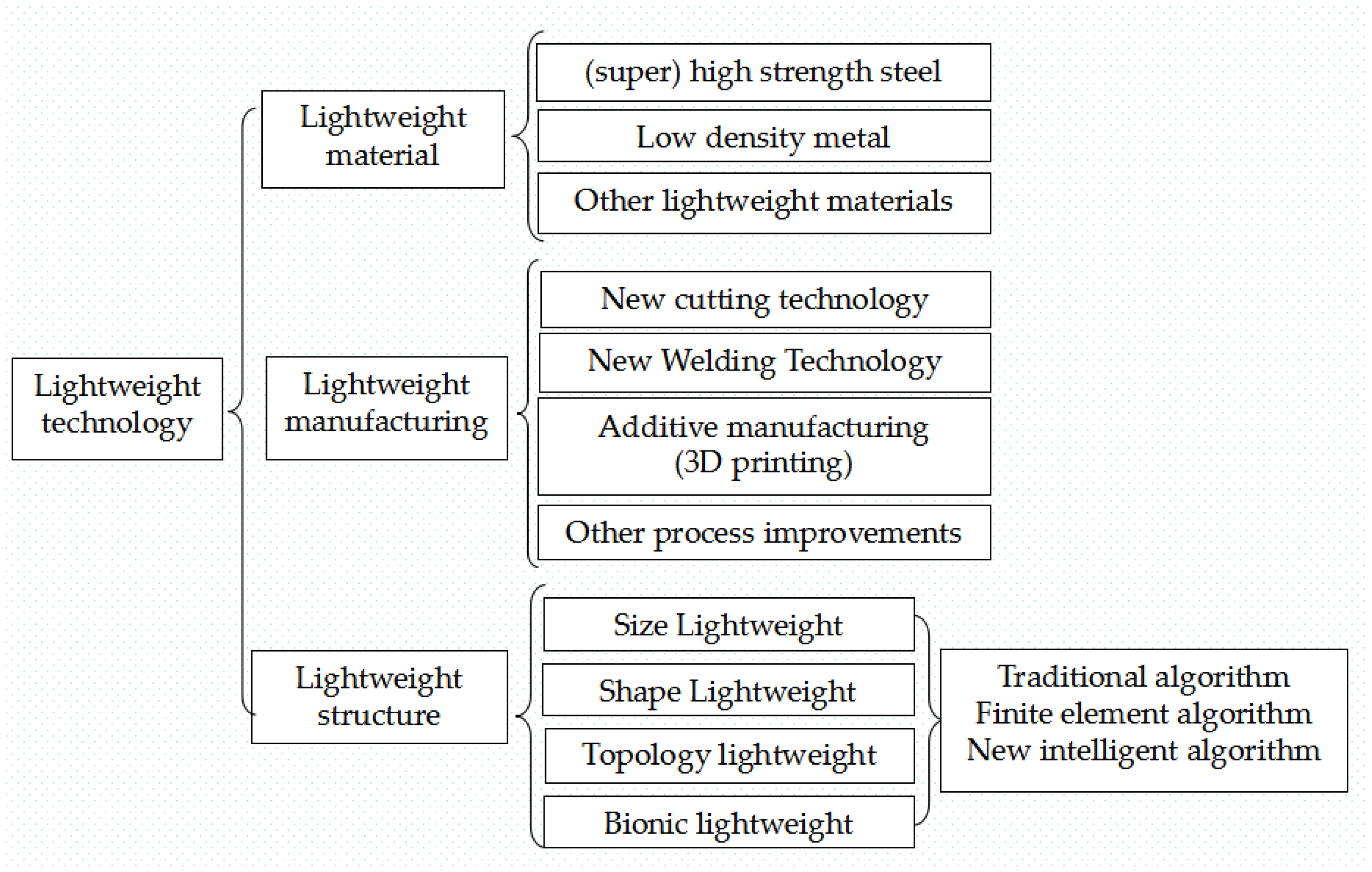

4. Lightweight Pathways and Research Progress

4.1. Material Lightweight

4.2. Structure Lightweight

4.2.1. Size Lightweight

4.2.2. Shape Lightweight

4.2.3. Topology Lightweight

4.2.4. Bionics lightweight

4.3. Lightweight Manufacturing Technology and 3D Printing

5. Conclusions and Prospect

- The research of lightweight model is limited to engineering software modeling. From the perspective of mathematics, we can describe the modeling by borrowing mathematical tools and specific mathematical relations guided by the physical background of the research object in the future.

- Practicality and precision of construction machinery. Combine the specific dynamic and static problems of the project with lightweight design to make it closer to the actual machine.

- Optimization of reliability. The reliability of structure is increasingly becoming an important indicator of modern structural design. The comprehensive design based on reliability size, shape, and topology optimization should be a research direction in the future.

- The combination of lightweight and additive manufacturing can effectively reduce the risk of revision and optimization of design, which is a very new trend in the future.

- The new intelligent algorithm can be cited to solve the lightweight model.

- Multidisciplinary cross-bionic lightweight will also be an exploration trend in mechanical engineering in the future.

Author Contributions

Funding

Conflicts of Interest

References

- Xu, S.Q.; Xia, R.W. Methods of structural optimization: An overview. Acta Aeronaut. Astronaut. Sin. 1995, 16, 2–13. [Google Scholar]

- Sobieszczanski-Sobieski, J.; Haftka, R. Multidisciplinary aerospace design optimization: Survey of recent developments. Struct. Optim. 1997, 14, 1–23. [Google Scholar] [CrossRef]

- Chen, X.H. Brief Introduction of Structural Lightweight Design and Topology Optimization Technology. China High-Tech. Enterp. 2013, 2013, 29–30. [Google Scholar]

- Zhao, L.; Wang, T. Study of Structural Bionic Design and Progress in Mechanical Engineering. Mod. Mach. Tool Autom. Manuf. Tech. 2012, 2012, 12–15. [Google Scholar]

- Allaire, G.; Jouve, F.; Toader, A.M. Structural optimization using sensitivity analysis and a level-set method. J. Comput. Phys. 2004, 194, 363–393. [Google Scholar] [CrossRef]

- Xu, Z.G.; Zhu, Z.M.; Yu, C.G. Base on Discrete Variable Three-Stage of Frame Light Weight Design. Mach. Des. Manuf. 2018, 5, 25–27. [Google Scholar]

- Tao, Q.X.; Li, Z.J. Structural Optimization Design Method; Tsinghua University Press: Beijing, China, 1985; pp. 10–56. [Google Scholar]

- Fan, H. Research on Lightweight Design of Main Girder of Brider Crane Based on Improved FOA. Master’s Thesis, North University of China, Taiyuan, China, 2013. [Google Scholar]

- Li, Z.X.; Wang, Z.Y.; Dong, H.; Hou, Y.L. Optimization of the Main Beam Based on Improved Artificial Bee Colony Algorithm. Mach. Des. Res. 2017, 33, 99–104. [Google Scholar]

- Liu, Z.; Lu, J.H.; Zhu, P. Lightweight design of automotive composite bumper system using modified particle swarm optimizer. Compos. Struct. 2016, 140, 630–643. [Google Scholar] [CrossRef]

- Wang, H. Lightweight design for an electric vehicle front cabin. J. Plast. Eng. 2018, 25, 1–7. [Google Scholar]

- Li, Z.X. Research on Lightweight Method of Bridge Crane Main Girder Based on Improved Cuckoo Search Algorithm. Master’s Thesis, North University of China, Taiyuan, China, 2018. [Google Scholar]

- Wang, D.; Wang, L.J.; Chen, Z.Y.; Wu, X.D.; Zhang, S.S. Application of robustness and lightweight in optimal Design of door structure. Mech. Sci. Technol. Aerosp. Eng. 2019, 38, 626–633. [Google Scholar]

- Jiang, Q.Y. Research on Artificial Raindrop Algorithm and Its Applications. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2017. [Google Scholar]

- Mecklenburg, M.; Schuchardt, A.; Mishra, Y.K.; Kaps, S.; Adelung, R.; Lotnyk, A.; Kienle, L.; Schulte, K. Aerographite: Ultra lightweight, flexible nanowall, carbon microtube material with outstanding mechanical performance. Adv. Mater. 2012, 24, 3486–3490. [Google Scholar] [CrossRef]

- Alshmri, F. Lightweight material: Aluminium high silicon alloys in the automotive industry. Adv. Mater. Res. Trans Tech Public. 2013, 774, 1271–1276. [Google Scholar] [CrossRef]

- Sorrentino, L.; Cafiero, L.; D’Auria, M.; Iannace, S. Cellular thermoplastic fibre reinforced composite (CellFRC): A new class of lightweight material with high impact properties. Composites A Appl. Sci. Manuf. 2014, 64, 223–227. [Google Scholar] [CrossRef]

- Pu, Y.; Ma, F.; Zhang, J.Y.; Yang, M. Optimal lightweight material selection for automobile applications considering multi-perspective indices. IEEE Access 2018, 6, 8591–8598. [Google Scholar] [CrossRef]

- Lai, M.; Brun, R. Latest Developments in Sheet Metal Forming Technology and Materials for Automotive Application: The Use of Ultra High Strength Steels at Fiat to Reach Weight Reduction at Sustainable Costs. Key Eng. Mater. 2007, 344, 1–8. [Google Scholar] [CrossRef]

- San-Antonio-González, A.; Merino, M.D.R.; Arrebola, C.V.; Villoria-Sáez, P. Lightweight material made with gypsum and extruded polystyrene waste with enhanced thermal behaviour. Const. Build. Mater. 2015, 93, 57–63. [Google Scholar] [CrossRef]

- Zaiß, M.; Demmerle, J.; Oergele, J.N.; Lanza, G. New concepts for quality assurance of lightweight material. Procedia CIRP 2017, 66, 259–264. [Google Scholar] [CrossRef]

- SJuraeva, M.; Ryu, K.J.; Noh, S.H.; Song, D.J. Lightweight material for the speed reducer housing of a car chassis. J. Mech. Sci. Technol. 2017, 31, 3219–3224. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, C.; Li, M. Optimal Design of Cargo-Box of Dump Truck Based on Structure Lightweight. Mach. Des. Manuf. 2018, 2018, 145–149. [Google Scholar]

- Zhong, J.; Zhong, X.; Lu, M.; Li, Z.; Dong, H. Lightweight structure improvement design of quadrotor UAV. China’s New Technol. New Prod. 2018, 2018, 18–19. [Google Scholar]

- Vyom, B.; Sanjay, D.Y. Design and Analysis of 30 Ton Trailer Chassis Frame to Reduce Pollution by Decreasing the Emission through Weight Reduction Using Advanced Lightweight Material. Int. J. Mech. Eng. Technol. 2018, 9, 705–722. [Google Scholar]

- Jarasjarungkiat, A.; Chuaisrinual, S. Development of Effective Lightweight Material for Construction Building. In IOP Conference Series: Materials Science and Engineering; IOP Publishing Ltd.: Bristol, UK, 2019; Volume 639, p. 012034. [Google Scholar]

- Ye, H.; Hu, P.; Shen, G.Z.; Sun, H.T.; Liu, B.; Zhou, D.L. Lightweight Optimization Design of Car Body Based on Sensitivity and Side Crash Simulation. Trans. Chin. Soc. Agric. Mach. 2010, 41, 18–22. [Google Scholar]

- Shi, C.J. Research on Structure Lightweight of Car-Door Base on Multidisciplinary Design Optimization. Master’s Thesis, Wuhan University of Science Technology, Wuhan, China, 2014. [Google Scholar]

- Zhang, S. Light Weight Design of Gantry Machining Center Crossbeam Based on Sensitivity and Finite Element Analysis. Master’s Thesis, Nantong University, Nantong, China, 2014. [Google Scholar]

- Zhang, H.X.; Yang, D.Q. Typical shape and topology optimization design of the ship grillage structure. Chin. J. Ship Res. 2015, 10, 27–33. [Google Scholar]

- Wang, C.H.; Zhu, F.Y.; Lu, M.; Chen, S. Lightweight Optimization Design of the Hollow Half Shaft of Steering Drive Axles Based on Response Surface Method. Automot. Eng. 2015, 37, 1477–1481. [Google Scholar]

- Liu, C.Y.; Tan, F.; Wang, L.P. Lightweight Design of Column Structure Based on Topology Optimization and reinforcing rib Layout. Modul. Mach. Tool Autom. Manuf. Tech. 2015, 4, 1–4. [Google Scholar]

- Chen, X.; Hu, C.S.; Ning, H.Y.; Wu, Y.Q.; Wang, S.; Yang, C.H. Implicit parameterization modeling and multi-performance lightweight Optimization for SVU body-in-white. J. Jilin Univ. Eng. Technol. Ed. 2016, 46, 1780–1785. [Google Scholar]

- Wang, H.T.; Xiao, P.; Huang, Z.F. Lightweight Optimization Design of a Certain Type Truck Frame. J. Huaiyin Inst. Technol. 2017, 26, 65–69. [Google Scholar]

- Li, X.F.; Gao, L.F.; Wang, W.; Wang, H.P. An additive manufacturing oriented structure design method for Trussed Bracked. J. Astronaut. 2017, 38, 751–757. [Google Scholar]

- Ma, F.W.; Chen, C.X.; Zhao, H.L.; Zuo, W.J.; Lu, H.Z.; Wu, L. Lightweight on Frame of FSC with Constriants of Strength, Stiffness and Modal. J. Hunan Univ. Nat. Sci. 2018, 45, 18–25. [Google Scholar]

- Jiang, X.B.; Zhang, H.; Zheng, Y.L.; Zhao, Z.B. Study on Structural Optimization Design of a Certain Type Wing Spar. Mech. Sci. Technol. Aerosp. Eng. 2018, 34, 652–656. [Google Scholar]

- Deng, Y.C.; Zhou, Y.; Liu, Y.; Zhou, S. Lightweight Design of Main Folding Frame for Foldable Electric Vehicle. J. Huaqiao Univ. Nat. Sci. 2018, 39, 496–501. [Google Scholar]

- Zhang, Y.C.; Luo, S.M. Structure characteristic analysis and lightweight design of horizontal machining center bed. J. Mach. Des. 2018, 35, 55–61. [Google Scholar]

- Gu, D.M.; Zhang, S.H. Optimization of section shape of telescopic boom of tire crane. Constr. Mach. 1988, 1988, 11–15. [Google Scholar]

- Wang, D.; Zhang, W.H.; Wang, Z.P.; Zhu, J.H. Slot shape optimization method on 3D curved surface and its squirrel cage elasticity Application in bearing design. Sci. China Phys. Mech. Astron. 2010, 40, 1001. [Google Scholar]

- Zhang, J.; Wang, D.; Zhang, W.H. Shape Optimization of Holes on Thin-walled Curved Composite Structures. Sci. Technol. Eng. 2011, 11, 1681–1685. [Google Scholar]

- Wang, D.; Zhang, W.H.; Yang, J.G.; Wang, Z.P. A virtual punching method for shape optimization of openings on curved panels using CAD-based Boolean operations. Comput. Aided Des. 2012, 44, 388–399. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, W.H.; Cai, S.Y. An equal eight-shaped shape optimization rhyme grid update method. Machinery. 2013, 51, 16–19. [Google Scholar]

- Sun, S.P.; Hu, J.T.; Zhang, W.H. Shape optimization of openings on rotation shells based on super-elliptic function and sequential response surface method. Acta Aeron. Astron. Sin. 2015, 36, 3595–3607. [Google Scholar]

- Zhang, W.H.; Zhao, L.Y.; Cai, S.Y. Shape optimization of Dirichlet boundaries based on weighted B-spline finite cell method and level-set function. Comput. Methods Appl. Mech. Eng. 2015, 294, 359–383. [Google Scholar] [CrossRef]

- Shi, P.C.; Wang, K.P.; Zhang, R.Y. Lightweight design of vehicle steering wheel framework. J. Mach. Des. 2018, 35, 89–96. [Google Scholar]

- Zhang, L. Research on Optimal Design of Honeycomb Structure and Its Mechanical Properties. Master’s Thesis, University of Chinese Academy of Sciences, Beijing, China, 2018. [Google Scholar]

- Zhao, L.H.; Guo, P.F.; Sun, H.J.; Ning, L.S. Development Actuality and Prospect on Research of Structural Topology Optimization. J. Liaoning Inst. Technol. 2004, 24, 46–49. [Google Scholar]

- Yang, D.; Sui, Y.; Liu, Z.; Sun, H. Topology optimization design of continuum structures under stress and displacement constraints. Appl. Math. Mech. 2000, 21, 19–26. [Google Scholar]

- Kim, Y.Y.; Kim, T.S. Topology optimization of beam cross sections. Int. J. Solids Struct. 2000, 37, 477–493. [Google Scholar] [CrossRef]

- Wang, M.Y.; Wang, X.M.; Guo, D.M. A level set method for structural topology optimization. Comput. Methods Appl. Mech. Eng. 2003, 192, 227–246. [Google Scholar] [CrossRef]

- Wang, S.Y.; Wang, M.Y. Radial basis functions and level set method for structural topology optimization. Int. J. Numer. Method. Eng. 2006, 65, 2060–2090. [Google Scholar] [CrossRef]

- Guo, Z.Z.; Zhang, W.H.; Chen, Y.Z. Summary of Structural Topology Optimization Design. J. Mach. Des. 2007, 24, 1–6. [Google Scholar]

- Chen, Y.B.; Luo, Z.; Zhong, Y.F. Structural topology optimization using topological description function. J. Huazhong Univ. Sci. Tech. Nat. Sci. Ed. 2007, 35, 102–105. [Google Scholar]

- Luo, J.Z.; Luo, Z.; Chen, L.P.; Tong, L.Y.; Wang, M.Y. A semi-implicit level set method for structural shape and topology optimization. J. Comput. Phys. 2008, 227, 5561–5581. [Google Scholar] [CrossRef]

- Liu, H.J.; Zhao, L.; Li, Y. Research on lightweight structure of engine hood based on topology optimization. Mod. Manuf. Eng. 2009, 2009, 4–7. [Google Scholar]

- Gao, T.; Zhang, W.H.; Zhu, J.H. Structural topology optimization under inertial loads. Chin. J. Theor. Appl. Mech. 2009, 41, 530–541. [Google Scholar]

- Sun, S.P.; Zhang, W.H. Topology optimal design of themo-elastic structures. Chin. J. Theor. Appl. Mech. 2009, 41, 878–887. [Google Scholar]

- Zhang, W.H.; Zhang, S.D.; Gao, T. Stiffener Layout Optimization of Thin Walled Structures. Acta Aeronaut. Astronaut. Sin. 2009, 30, 2126–2131. [Google Scholar]

- Qiu, K.P.; Zhang, W.H. Discussing Size Effecton Topological Design of Periodic Unit Cellsin Sandwich Core. J. North West. Polytech. Univ. 2010, 28, 375–380. [Google Scholar]

- Qiu, K.P.; Zhang, W.H. Improving Topological Design of FGM (Functionally Graded Material) Structure. J. North West. Polytech. Univ. 2010, 28, 851–857. [Google Scholar]

- Kang, Z.; Wang, Y.Q. Structural topology optimization based on non-local Shepard interpolation of density field. Comput. Methods Appl. Mech. Eng. 2011, 200, 3515–3525. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, J.H.; Zhang, W.H. Topology Optimization of Displacement Response of Continuum Structure under Harmonic Load. Machinery 2012, 50, 27–30. [Google Scholar]

- Liu, Y.; Hu, Y.; Wu, F. Topological Lightweight Design of Rectangle Mirror of Wafer Stage. Equip. Elect. Prod. Manuf. 2013, 5, 35–38. [Google Scholar]

- Yang, J.M.; Zhao, G.F.; Gu, H.M.; Qing, K. Topological Structure Optimization and Lightweight Design of the Car Engine Hood. Mach. Des. Manuf. 2013, 2013, 32–35. [Google Scholar]

- Zhang, W.H.; Zhang, Z.D.; Zhu, J.H.; Gao, T. Structural topology optimization: Extensibility and attainability. Sci. China Technol. Sci. 2014, 57, 1310–1321. [Google Scholar] [CrossRef]

- Zhu, J.H.; Li, Y.; Zhang, W.H. Topology optimization with Shape Preserving Design. In Proceedings of the 5th International Conference on Computational Methods, Cambridge, UK, 28–30 July 2014. [Google Scholar]

- Cai, S.B.; Zhang, W.H.; Zhu, J.H.; Gao, T. Stress constrained shape and topology optimization with fxed mesh: A B-spline finite cell method combined with level set function. Comput. Methods Appl. Mech. Eng. 2014, 278, 361–387. [Google Scholar] [CrossRef]

- Zhu, J.H.; Zhang, W.H.; Xia, L. Topology Optimization in Aircraft and Aerospace Structures Design. Arch. Comput. Methods Eng. 2016, 23, 595–622. [Google Scholar] [CrossRef]

- Lee, K.; Ahn, K.; Yoo, J. A novel P-norm correction method for lightweight topology optimization under maximum stress constraints. Comput. Struct. 2016, 171, 18–30. [Google Scholar] [CrossRef]

- Zheng, W.J.; Lan, F.C.; Chen, J. Research on Topology Optimization and Lightweight Design for Frame Structure of FSAE Racing Car. Chin. J. Autom. Eng. 2016, 6, 35–42. [Google Scholar]

- Zhou, Y.; Zhang, W.H.; Zhu, J.H.; Zhao, X. Feature-driven topology optimization method with signed distance function. Comput. Methods Appl. Mech. Eng. 2016, 310, 1–32, S004578251630634X. [Google Scholar] [CrossRef]

- Perez, C.H.V. Topology Optimization Using the Level Set and Extended Finite Element Methods: Theory and Applications. Ph.D. Thesis, University of Colorado at Boulder, Boulder, CO, USA, 2016. [Google Scholar]

- Chen, A.R.; Cheng, C.; Ma, R.J.; Ren, L.S. Structural Topology Optimization Theory and Its Application in Form Finding of Bridges. J. Tongji Univ. Nat. Sci. 2016, 44, 657–663. [Google Scholar]

- Zhu, J.H.; Li, Y.; Zhang, W.H.; Hou, J. Shape preserving design with structural topology optimization. Struct. Multidiscip. Optim. 2016, 53, 893–906. [Google Scholar] [CrossRef]

- Zhang, W.H.; Zhao, Y.Y.; Gao, T.; Cai, S.Y. Topology optimization with closed B-splines and Boolean operations. Comput. Methods Appl. Mech. Eng. 2017, 315, 652–670. [Google Scholar] [CrossRef]

- Xie, H.; Tao, Z.; Li, F. Lightweight Optimization Design for Front Side Rail of Electric Car. Comput. Simul. 2017, 34, 142–146. [Google Scholar]

- Teng, X.Y.; Jiang, X.D.; Sun, Y.X.; Shi, D.Y. Structural topology optimization using equivalent static load and Mode-tracking. J. Vib. Eng. 2017, 30, 349–356. [Google Scholar]

- Gao, T.; Qiu, L.B.; Zhang, W.H. Topology optimization of continuum structures subjected to the variance constraint of reaction forces. Struct. Multidiscip. Optim. 2017, 56, 755–765. [Google Scholar] [CrossRef]

- Picelli, R.; Townsend, S.; Brampton, C.; Norato, J.; Kim, H.A. Stress-based shape and topology optimization with the level set method. Comput. Methods Appl. Mech. Eng. 2018, 329, 1–23. [Google Scholar] [CrossRef]

- Zhu, J.H.; He, F.; Liu, T.; Zhang, W.; Liu, Q.; Yang, C. Structural topology optimization under harmonic base acceleration excitations. Struct. Multidiscip. Optim. 2018, 57, 1061–1078. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.X.; Chen, J.F.; Jiang, Q.L. The Study on Lightweight Optimization Design Methodology of the Bearer Frame of the Solar PV Module Cleaning Robot. Mach. Des. Res. 2018, 34, 182–185. [Google Scholar]

- Hou, J.; Zhu, J.H.; Wang, J.; Zhang, W.H. Topology optimization of the multi-fasteners jointed structure considering fatigue constraints. Int. J. Simul. Multidiscip. Des. Optim. 2018, 9, A4. [Google Scholar] [CrossRef]

- Wang, P.Y.; Ruan, J.K. Topology Optimization of Steering Pitman Arm Based on HyperWorks. J. Hubei Univ. Automot. Technol. 2018, 32, 23–25. [Google Scholar]

- Huang, G.M.; Yang, H.L.; Zhang, J.B.; Liu, S.Q. Topology optimization design of a certain type of naval gun bracket based on Ansys. Ship Sci. Technol. 2018, 40, 142–145. [Google Scholar]

- Bai, J.J.; Han, B.B.; Feng, K. Topology Optimization of Jack rack for Aircraft. Mach. Build. Autom. 2018, 47, 159–162. [Google Scholar]

- Shen, W.; Liao, M.; Wang, Q.; Wang, S.; Yi, J.; Wang, C.D.; He, X. Lightweight Design of the Transmission Case Based on Topology Optimization. J. Agric. Mech. Res. 2018, 40, 234–241. [Google Scholar]

- Wu, Y.F.; Zheng, B.L.; Yang, B. Topological optimization design of aero-engine blade Consider bird strike. J. Aerosp. Power 2018, 33, 1923–1932. [Google Scholar]

- Jang, G.W.; Kambampati, S.; Chung, H.; Kim, H. Configuration optimization for thin structures using level set method. Struct. Multidiscip. Optim. 2019, 59, 1881–1893. [Google Scholar] [CrossRef]

- Cai, S.Y.; Zhang, W.H.; Gao, T.; Zhao, J. Adaptive bubble method using fixed mesh and topological derivative for structural topology optimization. Chin. J. Theor. Appl. Mech. 2019, 51, 1235–1244. [Google Scholar]

- Qiao, H.T.; Wang, S.J.; Zhao, T.J.; Tang, H.N. Topology optimization for lightweight cellular material and structure simultaneously by combining SIMP with BESO. J. Mech. Sci. Technol. 2019, 33, 729–739. [Google Scholar] [CrossRef]

- Wu, Z.X. Bio-inspired Optimization Method for Component Design. China Mech. Eng. 2005, 16, 869–872. [Google Scholar]

- Cen, H.T.; Chen, W.Y. Conception and evolvement of bionics. J. Mach. Des. 2007, 24, 1–2. [Google Scholar]

- Zhang, J.Z.; Wang, J.G.; Ma, J.J. Porous structures of natural materials and bionic design. J. Zhejiang Univ. Sci. A 2005, 6, 1095–1099. [Google Scholar] [CrossRef]

- Zhou, K.; Fang, Z.D.; Cao, X.M.; Zhang, M.W. Optimization design for single-crank and double-rocker kind of driving mechanism of FMAV. J. Aerosp. Power 2008, 23, 184–188. [Google Scholar]

- Zhao, L.; Chen, W.Y.; Ma, J.F. Lightweight Design of High-speed Working Table Based on Structural Bionic. Mod. Mach. Tool Autom. Manuf. Tech. 2008, 1, 1–4. [Google Scholar]

- Qing, Z.H.; Xie, F.; Zhang, C.G.; Yang, H.D.; Zhou, Z.J. Primary Research of Cutting Tool Based on Bionics. Tool Eng. 2008, 42, 3–6. [Google Scholar]

- Liu, G.L.; Xie, F. Research of bionics cutting tools. Mech. Res. Appl. 2010, 23, 3–6. [Google Scholar]

- Helms, M.; Vattam, S.S.; Goel, A.K. Biologically inspired design: Process and products. Des. Stud. 2009, 30, 606–622. [Google Scholar] [CrossRef]

- Ma, J.F.; Chen, W.Y.; Zhao, L.; Zhao, D.H. Bionic Design of Aircraft Reinforced Frame Based on Structure of Dragonfly Wing. Acta Aeron. Asron. Sin. 2009, 30, 562–569. [Google Scholar]

- Liu, W.Y.; Zhang, H.Q.; Li, M.G. Experimental Study of Mechanical Performance of Wind Turbine Blade Based on Bionic Design. J. Exp. Mech. 2009, 24, 121–126. [Google Scholar]

- Liu, W.Y.; Zhang, H.Q.; Zeng, L. Rellability analysis of wind turbine blade based on bionic design. Acta Energiae Solaris Sin. 2010, 31, 1204–1208. [Google Scholar]

- Zheng, M.R. Analysis of Flow Field for the Automobile Exhaust Manifold Based on Human Bionic. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2009. [Google Scholar]

- Zhao, Y. Analysis of Temperature Field and Vibration Characteristics for the Automotive Exhaust Manifold Based on Bionics. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2009. [Google Scholar]

- Zheng, M.R. Discussion on the Model of the Exhaust Manifold Based on Human Bionic. Autom. Res. Dev. 2010, 2010, 95–98. [Google Scholar]

- Yang, Y. Exhaust Manifold Design Based on the Respiratory System and Finite Element Analysis. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2010. [Google Scholar]

- Quinn, S.; Gaughran, W. Bionics—An inspiration for intelligent manufacturing and engineering. Robot Comput. Integr. Manuf. 2010, 26, 616–621. [Google Scholar] [CrossRef]

- Han, Z.W.; Lu, Y.; Dong, L.C.; Zhang, J.Q.; Niu, S.C.; Ma, R.F.; Ren, L.Q. Modal analysis of gear with bionic surface morphology. J. Jilin Univ. 2010, 40, 1604–1608. [Google Scholar]

- Han, Z.W.; Lu, Y.; Ma, R.F.; Niu, S.C.; Ren, L.Q. Dynamic Performance of Gear Surface With Bionic Micro-morphology. J. Beijing Univ. Technol. 2011, 37, 806–810. [Google Scholar]

- Shu, L.H.; Ueda, K.; Chiu, I.; Cheong, H. Biologically inspired design. CIRP Ann. 2011, 60, 673–693. [Google Scholar] [CrossRef]

- Cadman, J.; Zhou, S.; Chen, Y.; Li, Q. Cuttlebone: Characterization, application and development of biomimetic materials. J. Bionic Eng. 2012, 9, 367–376. [Google Scholar] [CrossRef]

- Li, Y.J.; Xie, Z.K.; Yi, G. The Application Research of the Honeycomb Structure Column in the Bridge Moving Gantry Machining Center. Mech. Eng. 2012, 2012, 91–92. [Google Scholar]

- Wang, Y.H.; Chen, W.Y. Lightweight design of aircraft support based on structural bionics. J. Mach. Des. 2012, 29, 77–79. [Google Scholar]

- Fu, W.G.; Chen, W.Y.; Wang, H.; Lin, B.K. Local Stability Analysis of Bionic Simple Supported Plate for Crane’S Top Flange. Comput. Simul. 2012, 29, 396–400. [Google Scholar]

- Wang, X.B. Research on Optimization Design of the Rotary Worktable for Vertical Lathe Based on Structural Bionic Method. Master’s Thesis, Jilin University, Jilin, China, 2012. [Google Scholar]

- Pan, B. Optimization Design of Bridge Crane Box Girder Based on Structural Bionic Method. Master’s Thesis, North University of China, Taiyuan, China, 2013. [Google Scholar]

- Wu, H.F. Research on Structure and Mechanical Property of the Family Palame and Boinic Design of Wind Turbine. Master’s Thesis, South China University of Technology, Guangzhou, China, 2013. [Google Scholar]

- Meng, X.G. Application Research of Structure Bionics in Structure Design of Engineering Machinary. Master’s Thesis, Shijiazhuang Tiedao University, Hebei, China, 2013. [Google Scholar]

- Liu, L.B.; Chen, W.Y. Structural bionic design for aircraft cover plate based on leaf vein branched structure. J. Beijing Univ. Aeronaut. Astronaut. 2013, 39, 1596–1600. [Google Scholar]

- Fu, W.G.; Cheng, W.M.; Yu, L.F.; Pu, D.Z. Bionics Design of Transverse Stiffener in the Upright Rail Box Girder Based on Bamboo Structure. J. Southwest Jiaotong Univ. 2013, 48, 211–216. [Google Scholar]

- Qi, F.; Zhou, F.; Hou, J.H.; Yang, P.L.; Jiang, G.P. Discussion on Lightweight Design of Tower Equipment Based on Bionics Principle. Petro. Chem. Equip. 2013, 16, 25–26. [Google Scholar]

- Li, B.T.; Hong, J.; Liu, Z.F. Stiffness design of machine tool structures by a biologically inspired topology optimization method. Int. J. Mach. Tools Manuf. 2014, 84, 33–44. [Google Scholar] [CrossRef]

- Huang, S.M.; Wu, Y.H.; Liu, L.G. The mechanism design of the biomimetic robotic fishtail based on Adams. Electron. World 2014, 12, 526. [Google Scholar]

- Chen, Z.C.; Zhan, J.L.; Zhou, B.; Sun, P. Wing Structural Layout Design Based on Bionics Theory. Dev. Innovation Machinery Elec. Prod. 2014, 27, 12–14. [Google Scholar]

- You, D.Z.; Tao, Y.; Yang, Q.B. Optimization Design of Nasal Type Gear Milling Machine Column. Mach. Build Autom. 2015, 44, 33–35. [Google Scholar]

- Wang, Q.W. Bionics Design and Mechanical Properties Analysis of Large-Scale Wind Turbine Tower. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China, 2016. [Google Scholar]

- Bao, N.; Ma, J.M.; Zhang, X.Q.; Zhong, Z.H. Structural bionic lightweight design for the stiffened plate of base structure. In Proceedings of the 2016 7th International Conference on Mechanical and Aerospace Engineering (ICMAE), London, UK, 18–20 July 2016; pp. 244–247. [Google Scholar]

- Chen, J.X.; Tuo, W.Y.; Guo, Z.S.; Yan, L.L. The 3D lightweight structural characteristics of the beetle forewing. Mater. Sci. Eng. 2017, 71, 1347–1351. [Google Scholar] [CrossRef]

- Jia, L.L.; Liu, W.J.; Li, Z.L. Application Research of Structural Bionics in Structural Design of Construction Machinery. Inform. Record. Mater. 2017, 18, 36–37. [Google Scholar]

- Shan, L.J.; Wu, B.; Guan, T.M. Design and Rapid Prototyping Technology of Lightweight Structure of Humanoid Robot Thigh. Mech. Sci. Tech. Aerosp. Eng. 2019, 38, 1343–1349. [Google Scholar]

- Cao, Y.W.; Yang, X.; Wang, J.W.; Zhou, H. Research and Design of Bionic Stiffened Plate Structure of SCARA Mechanical Arm. Mach. Tool Hydraul. 2018, 46, 71–75. [Google Scholar]

- Wang, B.; Peng, J.S. Bionics design of bamboo structure with transverse ribs of normal rail box girder. China Equip. Eng. 2018, 2018, 170–171. [Google Scholar]

- Zhao, Z.L.; Zhou, S.W.; Feng, X.Q.; Xie, Y.M. On the internal architecture of emergent plants. J. Mech. Phys. Solids 2018, 119, 24–239. [Google Scholar] [CrossRef]

- Moon, S.K.; Tan, Y.E.; Hwang, J.; Yoon, Y. Application of 3D printing technology for designing light-weight unmanned aerial vehicle wing structures. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 223–228. [Google Scholar] [CrossRef]

- Li, D.W.; Dai, N.; Jiang, X.T.; Cheng, X.S. Density Aware Internal Supporting Structure Light-Weighting Modeling of 3D Printed Objects. J. Comput. Aided Des. Comput. Graph. 2016, 28, 841–848. [Google Scholar]

- Jiang, X.T.; Cheng, X.S.; Dai, N.; Jiang, X.N.; Zhu, B.B.; Cheng, C.; Li, D.W. A Weak-balance Light-weighting Modeling Method for 3D Printed Objects. J. Mech. Eng. 2016, 52, 198–204. [Google Scholar] [CrossRef]

- Tao, W.; Leu, M.C. Design of lattice structure for additive manufacturing. In Proceedings of the 2016 International Symposium on Flexible Automation Cleveland (ISFA), Cleveland, OH, USA, 1–3 August 2016; pp. 325–332. [Google Scholar]

- Eichenhofer, M.; Wong, J.C.H.; Ermanni, P. Continuous lattice fabrication of ultra-lightweight composite structures. Addit. Manuf. 2017, 18, 48–57. [Google Scholar] [CrossRef]

- Nguyen, D.S.; Vignat, F. Topology optimization as an innovative design method for additive manufacturing. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 10–13 December 2017; pp. 304–308. [Google Scholar]

- Sun, D.G.; Dai, N.; Huang, R.K.; Zhang, M.; Meng, L.Y.; Zhang, Z. Adaptive path generation for 3D printing of light-weight cellular. Comput. Integr. Manuf. Syst. 2018, 24, 1902–1909. [Google Scholar]

- Song, J.; Wang, Y.J.; Zhou, W.Z.; Fan, R.; Yu, B.; Lu, Y.; Li, L.X. Topology optimization-guided lattice composites and their mechanical characterizations. Compos. B Eng. 2019, 160, 402–411. [Google Scholar] [CrossRef]

- Quan, D.L.; Shi, G.H.; Guan, C.Q.; Wang, J.; Luo, J.H.; Song, F.; Wang, B.; Gao, T.; Zhu, J.H.; Zhang, W.H. Applications and challenges of structural optimization in high-speed aerocraft. Mech. Eng. 2019, 41, 373–381. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Li, Y.; Hu, G.; Yang, M. Lightweight Research in Engineering: A Review. Appl. Sci. 2019, 9, 5322. https://doi.org/10.3390/app9245322

Wang J, Li Y, Hu G, Yang M. Lightweight Research in Engineering: A Review. Applied Sciences. 2019; 9(24):5322. https://doi.org/10.3390/app9245322

Chicago/Turabian StyleWang, Jiao, Yan Li, Gang Hu, and Mingshun Yang. 2019. "Lightweight Research in Engineering: A Review" Applied Sciences 9, no. 24: 5322. https://doi.org/10.3390/app9245322

APA StyleWang, J., Li, Y., Hu, G., & Yang, M. (2019). Lightweight Research in Engineering: A Review. Applied Sciences, 9(24), 5322. https://doi.org/10.3390/app9245322