Potential for Developing Biocarbon Briquettes for Foundry Industry

Abstract

1. Introduction

2. Materials and Methods

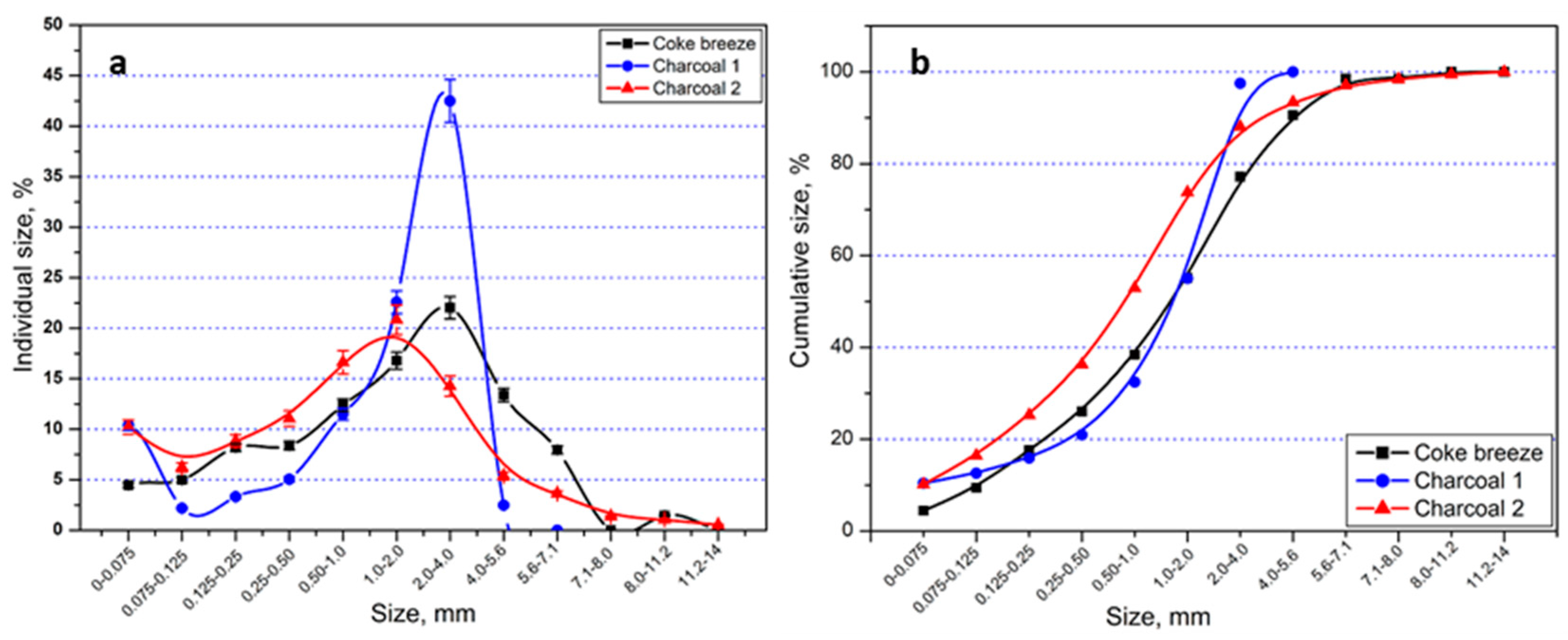

2.1. Coals and Particle Preparation

2.2. Binders Selected for Compaction

2.3. Design of Recipes

2.4. Determination of Physical Properties and Reactivity

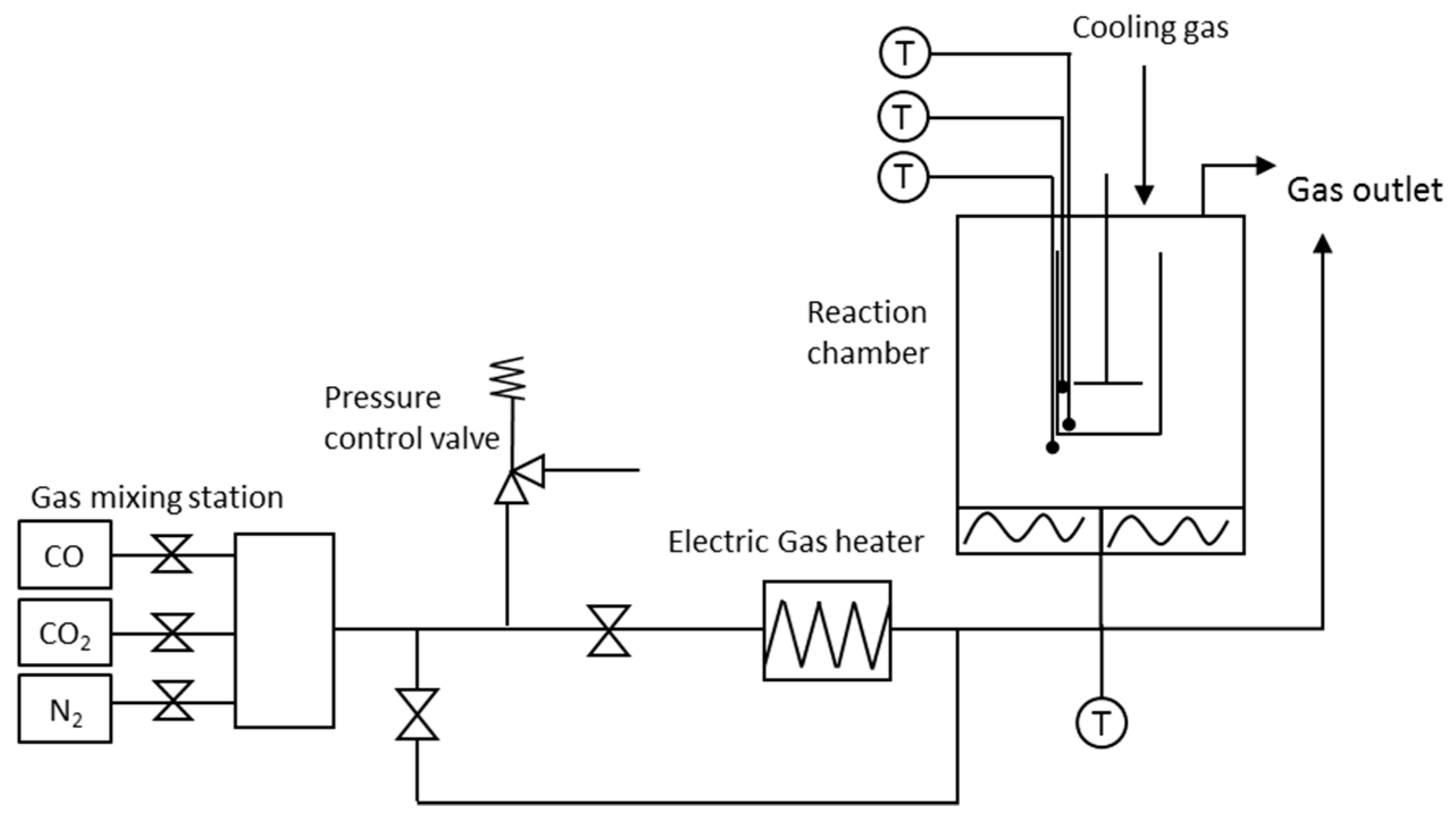

2.5. Evaluation of Behaviour of Briquettes at High Temperature

3. Results and Discussion

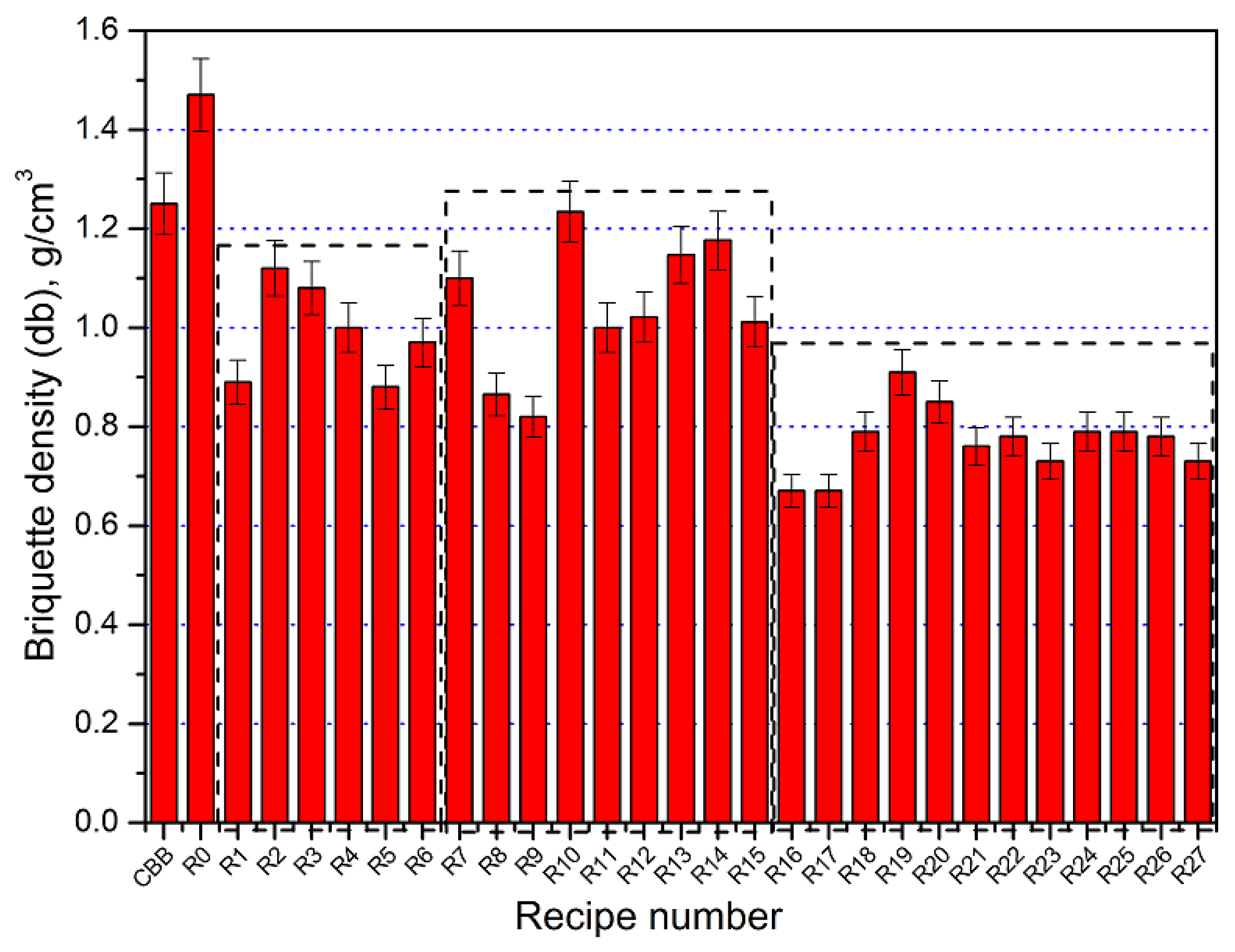

3.1. Densification of Biocarbon

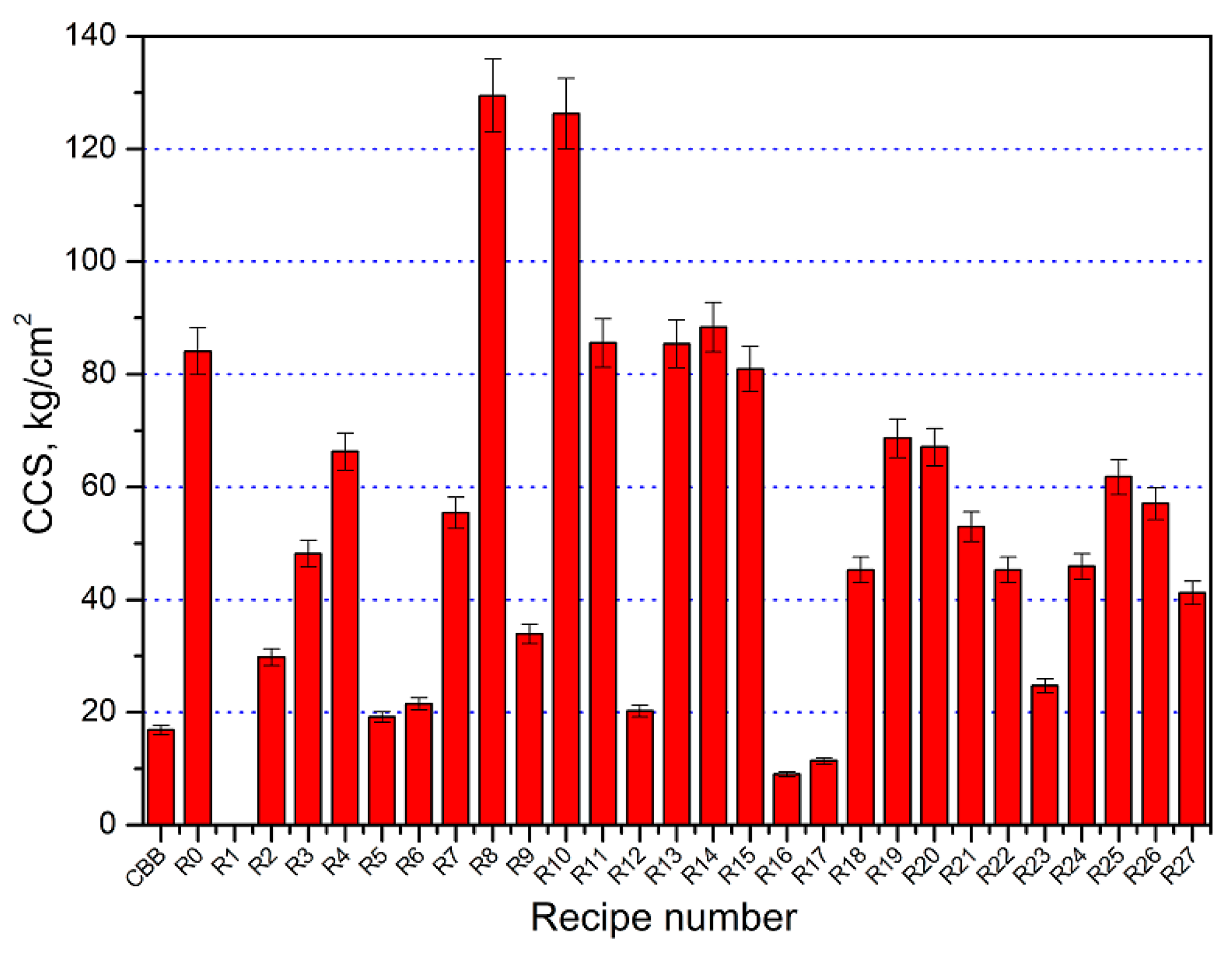

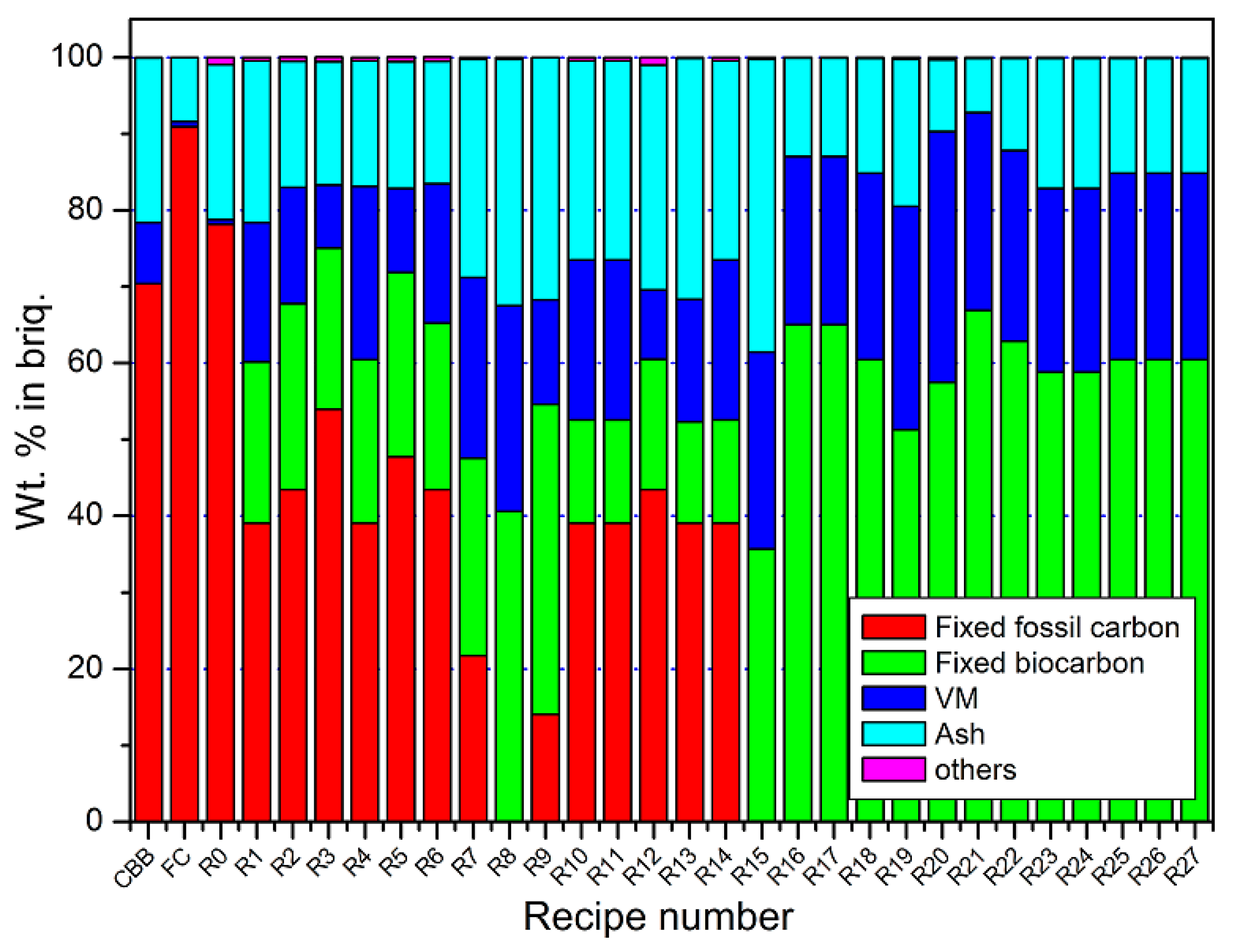

3.2. Cold Mechanical Strength of Biocarbon Briquettes

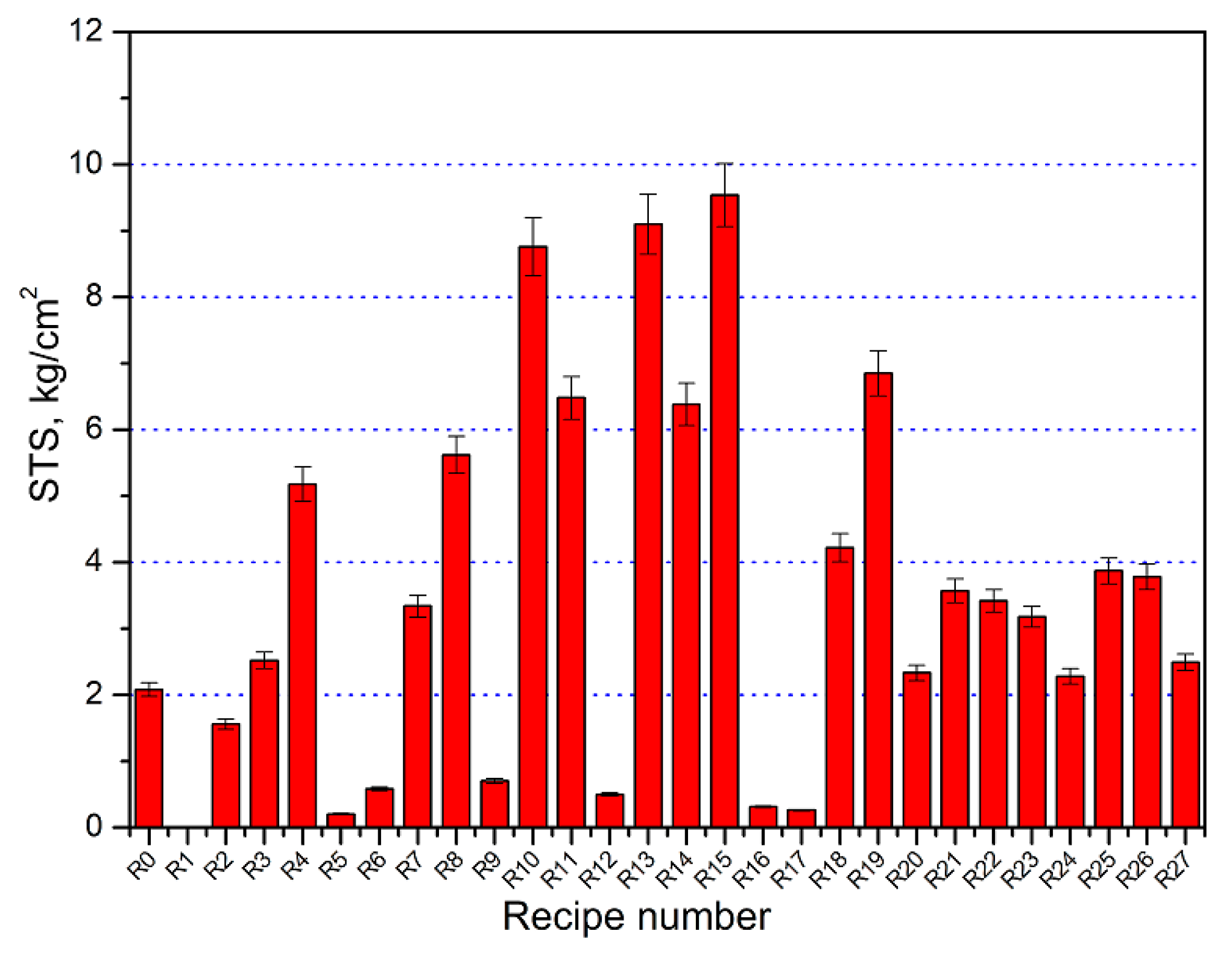

3.3. Reactivity of Biocarbon Briquettes

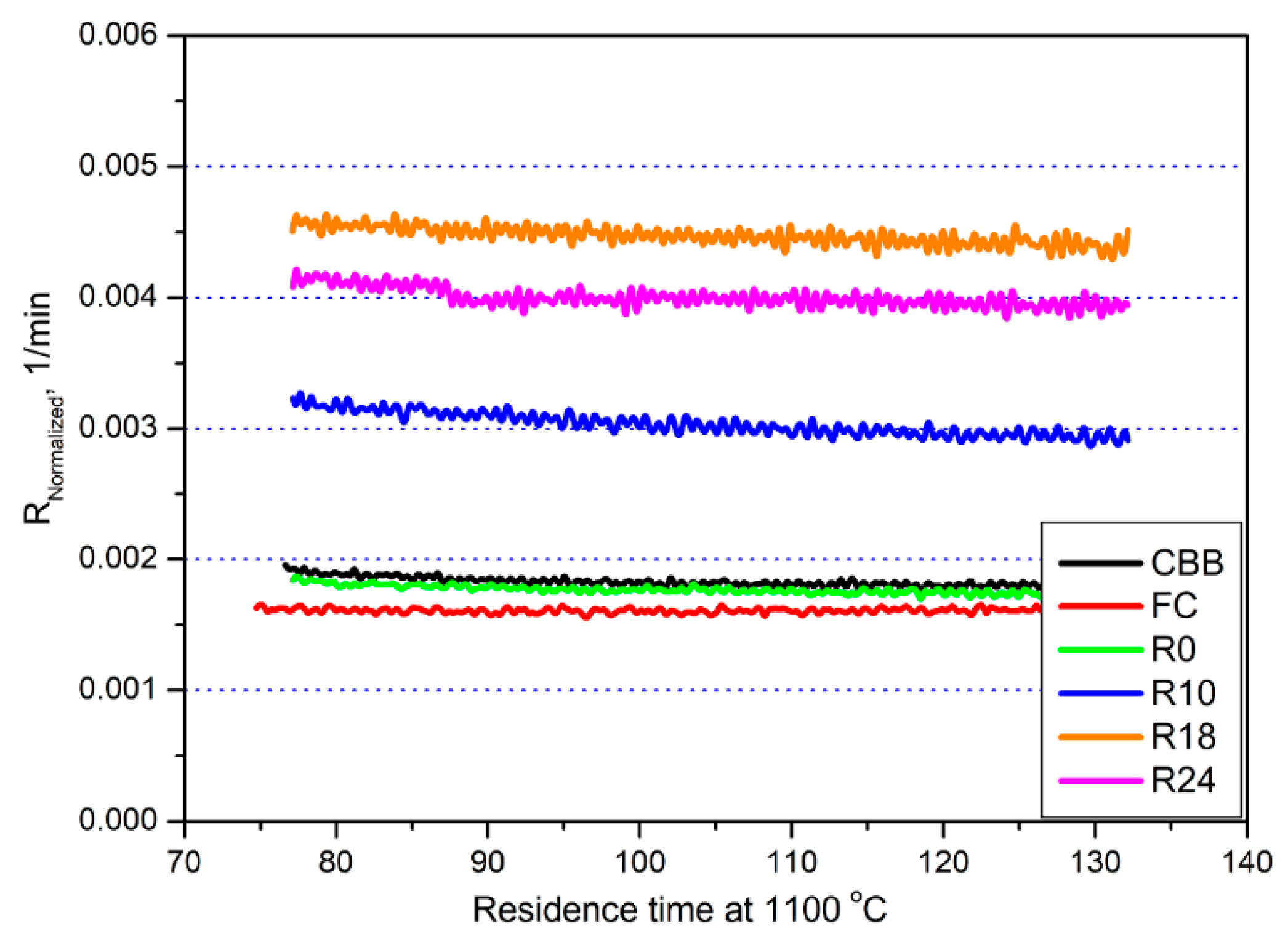

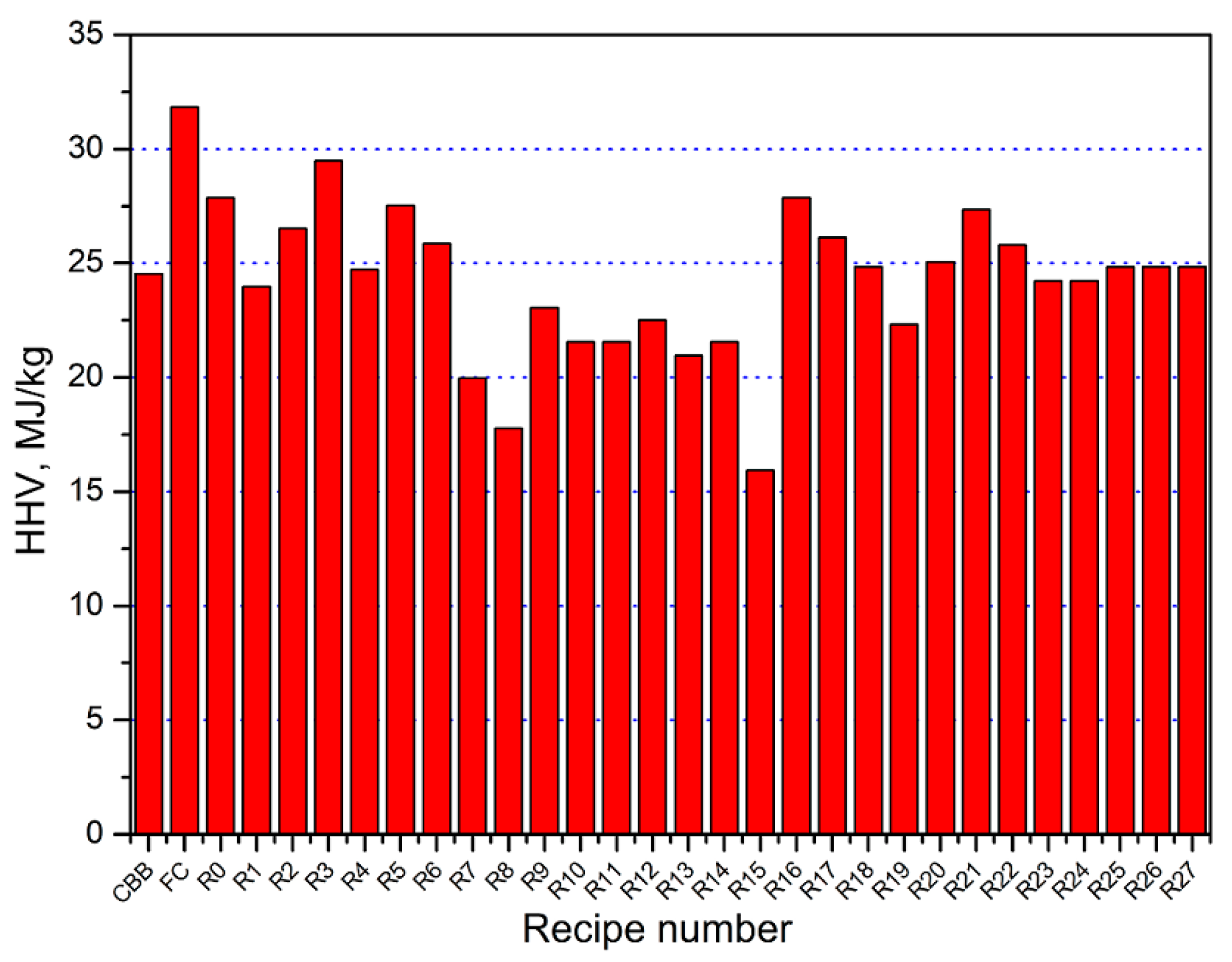

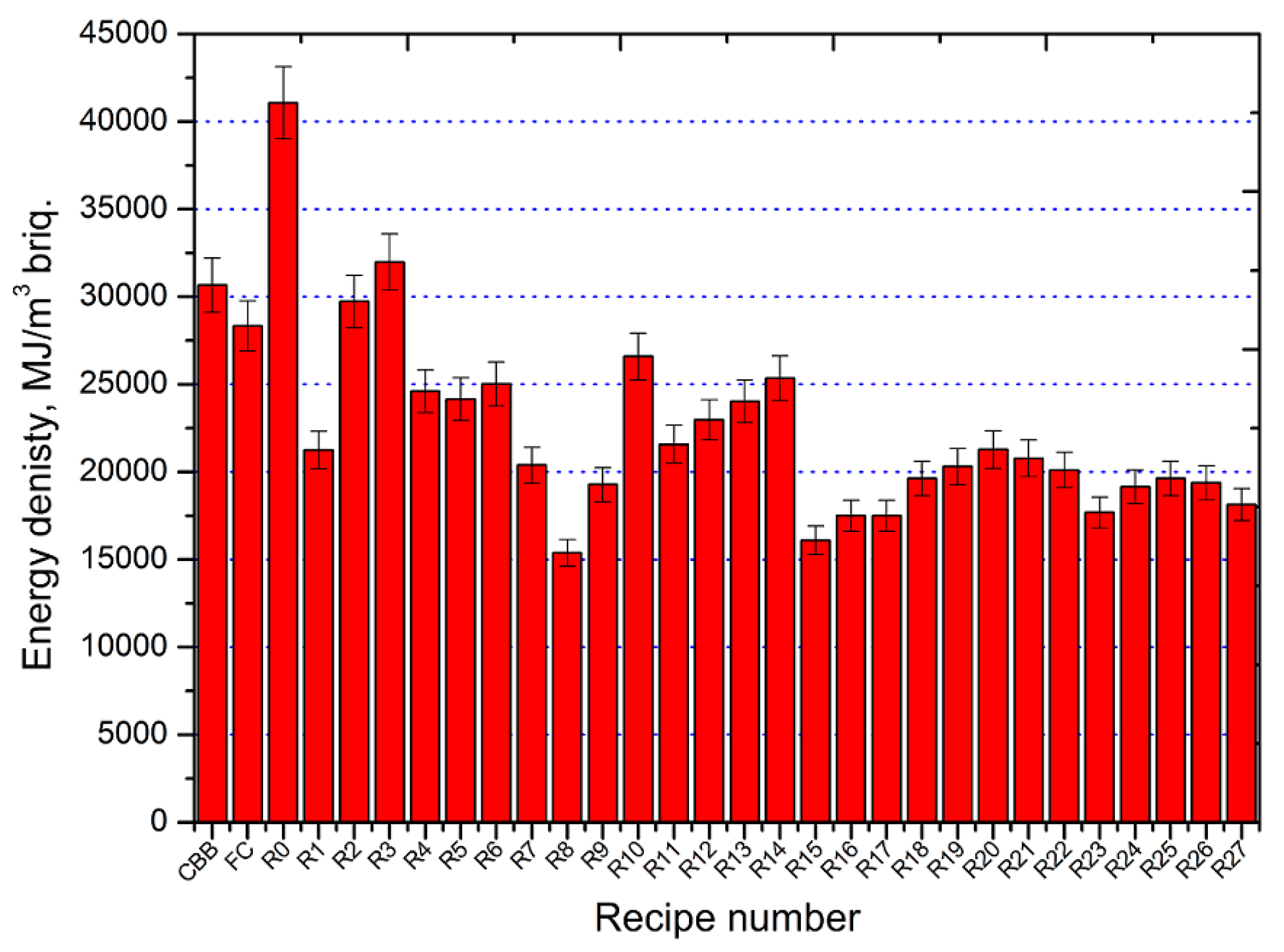

3.4. Heating Value and Energy Density of Biocarbon Briquettes

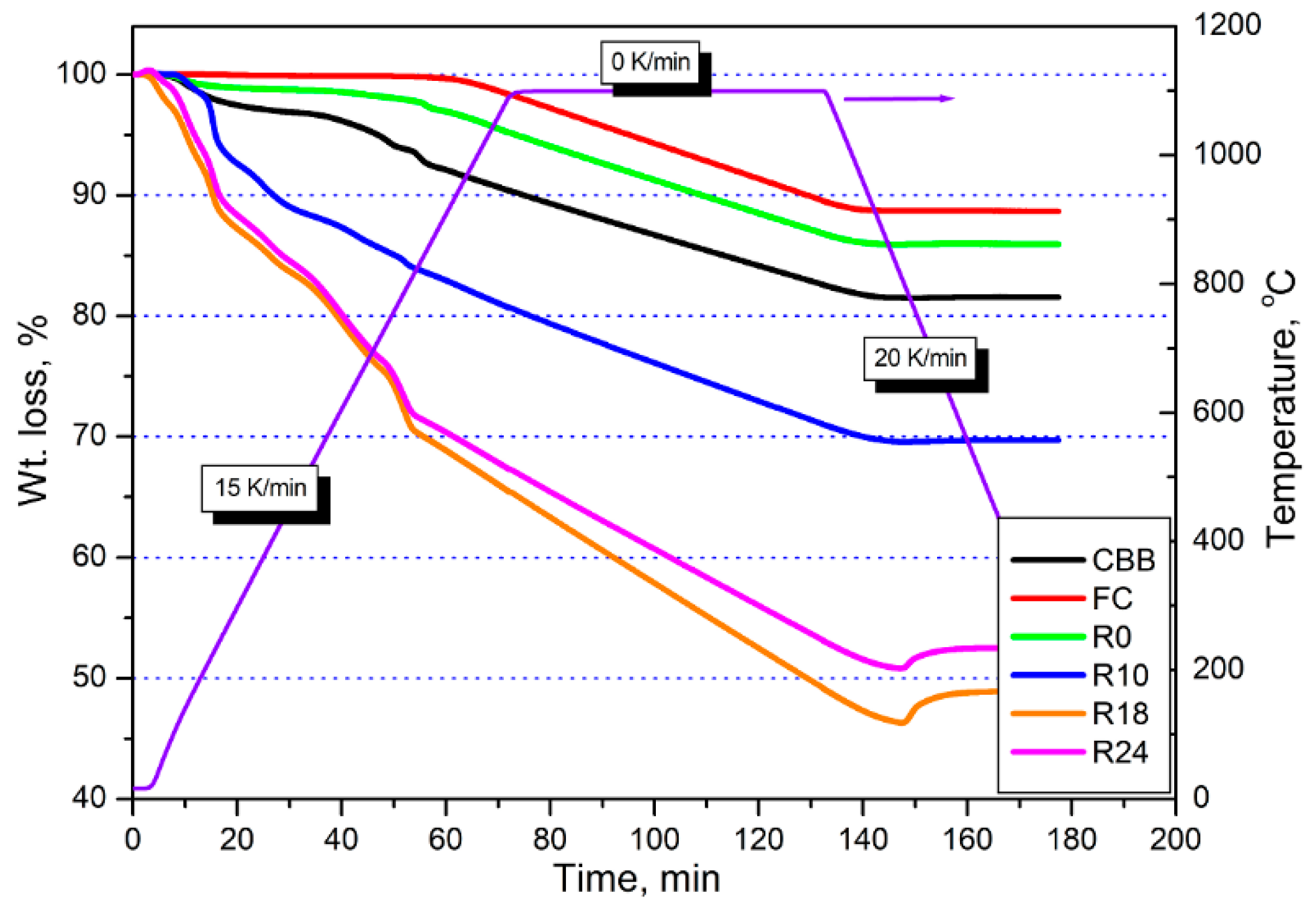

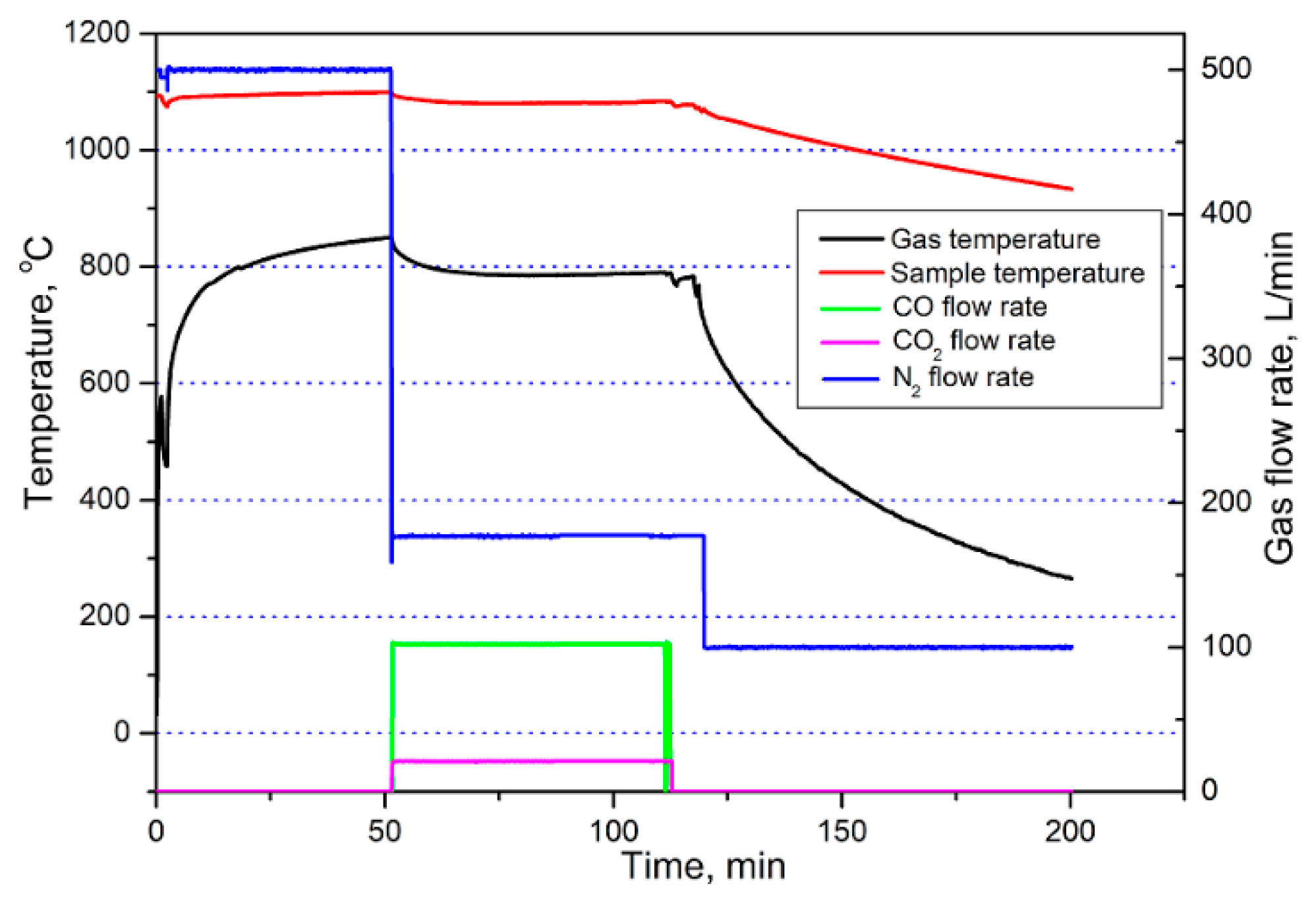

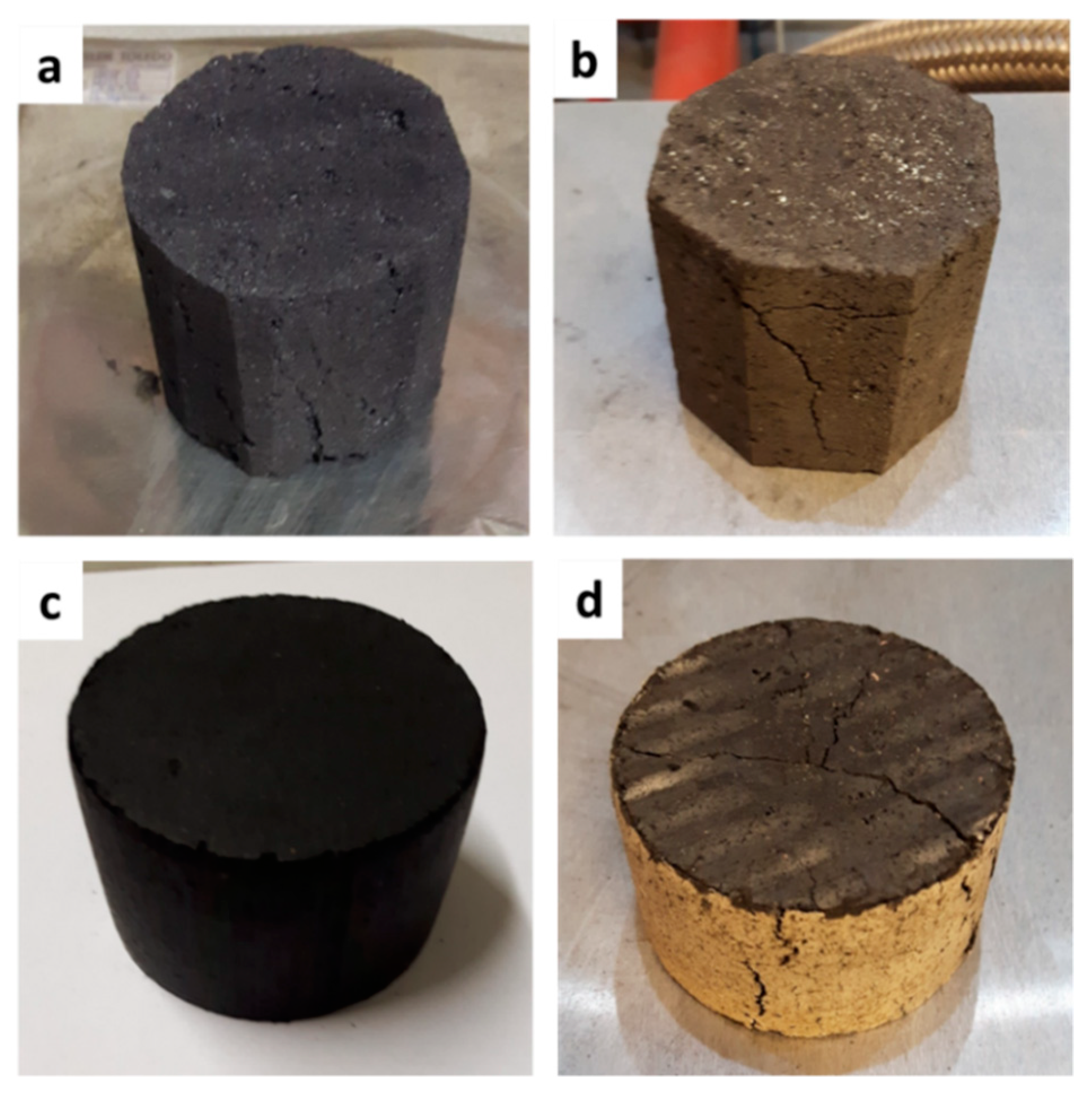

3.5. Behaviour of Upscaled Biocarbon Briquettes at High Temperature

4. Concluding Remarks

- In this study, combination of 20% molasses with 10% lime and 8% cement is the most suitable binder compared to other types of binders tested for enhancing the mechanical strength of biocarbon briquettes. Cement is required to improve the tensile strength and hot strength of biocarbon briquettes. The results illustrated that the optimum amount of binders varies with the compaction method and size of produced briquettes.

- The normalized gasification rate of the fossil and biocarbon samples increased by increasing the total biocarbon content in the recipes due to higher reactivity and the more porous nature of biocarbon compared to fossil carbon. Addition of a silica suspension to the mixtures can be a potential method to reduce the surface area for reaction and, therefore, lower the reactivity of biocarbon-containing briquettes.

- Upscaling of biocarbon briquettes and testing of hot strength under a mechanical load resulted in generation of cracks and disintegration of briquettes, which can be mainly attributed to the presence of mechanical stresses during the compaction cycle from compression, decompression, ejection of briquettes to curing and drying of briquettes.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mousa, E.A.; Wang, C.; Riesbeck, J.; Larsson, M. Biomass Applications in Iron and Steel Industry: An Overview of Challenges and Opportunities. Renew. Sustain. Energy Rev. 2016, 65, 1247–1266. [Google Scholar] [CrossRef]

- Suopajärvia, H.; Umekib, K.; Mousa, E.A.; Hedayati, A.; Romar, H.; Kemppainen, A.; Wang, C.; Phounglamcheik, A.; Tuomikoski, S.; Norberg, N.; et al. Use of biomass in integrated steelmaking- Status quo, future needs and comparison to other low-CO2 steel production technologies. Appl. Energy 2018, 213, 384–407. [Google Scholar] [CrossRef]

- Isnugroho, K.; Birawidha, D.C.; Hendronursito, Y. The biomass waste use as a secondary energy source for metal foundry process. In Proceedings of the 2016 Conference on Fundamental and Applied Science for Advanced Technology (ConFAST 2016), Yogyakarta, Indonesia, 25–26 January 2016; Volume 1746, pp. 020001-1–020001-5. [Google Scholar]

- Schulten, M.; Pena Chipatecua, G.; Quicker, P.; Seabra, S. Investigations on the application of biochar as an alternative for foundry coke. In Proceedings of the 21st European Biomass Conference, Copenhagen, Denmark, 3–7 June 2013. [Google Scholar]

- Echterhof, T.; Demus, T.; Schulten, M.; Noel, Y.; Pfeifer, H. Substituting fossil carbon sources in the electric arc and cupola furnace with biochar. In European Steel Environment & Energy Congress (ESEC); Teesside University: Middlesbrough, UK, 2014. [Google Scholar]

- Nieto-Delgado, C.; Cannon, F.S.; Paulsen, P.D.; Furness, J.C.; Voigt, R.C.; Pagnotti, J.R. Bindered anthracite briquettes as fuel alternative to metallurgical coke: Full scale performance in cupola furnaces. Fuel 2014, 121, 39–47. [Google Scholar] [CrossRef]

- Noh, Y.D.; Komarneni, S.; Cannon, F.S.; Brown, N.R.; Katsuki, H. Anthracite briquettes with plant byproducts as an ecofriendly fuel for foundries. Fuel 2016, 175, 210–216. [Google Scholar] [CrossRef]

- Torielli, R.M.; Cannon, F.S.; Voigt, R.C.; Considine, T.J.; Furness, J.C.; Fox, J.T.; Goudzwaard, J.E.; Huang, H. The environmental performance and cost of innovative technologies for ductile iron foundry production. Int. J. Met. 2014, 8, 37–48. [Google Scholar] [CrossRef]

- Gabra, M.H.; Jain, R.K.; Tiwari, A. Energy efficient cupola furnace via hybridization with a biomass gasifier. Int. J. Emerg. Technol. Eng. Res. 2017, 5, 54–62. [Google Scholar]

- Wang, L.; Buvarp, F.; Skreiberg, Ø.; Bartocci, P.; Fantozzi, F. A study on densification and CO2 gasification of biocarbon. Chem. Eng. Trans. 2018, 65, 145–150. [Google Scholar]

- Rahman, A.N.E.; Masood, M.A.; Prasad, C.S.N.; Venkatesham, M. Influence of size and shape on the strength of briquettes. Fuel Process. Technol. 1989, 23, 185–195. [Google Scholar] [CrossRef]

- Ifa, L.; Kusuma, H.; Sabara, Z.; Mahfud, M. Production of bio-briquette from biochar derived from pyrolysis of cashew nut waste. Ecol. Environ. Conserv. 2019, 25, 125–131. [Google Scholar]

- Keracoal Binder. Available online: https://www.keramicalia.com/binders/6-keracoal-binder (accessed on 10 November 2019).

- Aristizabal, R.E.; Silva, C.M.; Perez, P.A. Studies of a quenched cupola Part I: Overview of experimental studies. AFS Trans. 2009, 117, 681–691. [Google Scholar]

- Iwai, Y.; Ishiwata, N.; Murai, R.; Matsuno, H. Control technique of coke rate in shaft furnace by controlling coke reactivity. ISIJ Int. 2016, 56, 1723–1727. [Google Scholar] [CrossRef]

- Wu, C.Y.; Hancock, B.C.; Mills, A.; Bentham, A.C.; Best, S.M.; Elliott, J.A. Numerical and experimental investigation of capping mechanisms during pharmaceutical table compaction. Powder Technol. 2008, 181, 121–129. [Google Scholar] [CrossRef]

- The European Foundry Industry at a Glance. Available online: https://www.caef.eu/statistics/ (accessed on 10 November 2019).

- Rao, N.M. Iron Foundry and Pig Iron Industries in India. Available online: http://www.isrinfomedia.com/main/archive/1 (accessed on 10 November 2019).

| Materials | Moisture, % | Ash, % (db) | VM, % (db) | C-Fix, % (db) | C-Total, % (db) | H, % (db) | N, % (db) | O, % (db) | S, % (db) | HHV, MJ/kg |

|---|---|---|---|---|---|---|---|---|---|---|

| Charcoal 1 | 3.5 | 0.7 | 18.6 | 80.7 | 87.0 | 3.4 | 0.2 | 8.3 | 0.0 | 31.1 |

| Charcoal 2 | 2.4 | 39.2 | 11.6 | 49.2 | 54.2 | 1.6 | 0.1 | 4.8 | 0.0 | 18.4 |

| Coke breeze | 8.6 | 11.4 | 0.6 | 87.8 | 86.8 | 0.2 | 1.3 | 0.2 | 0.5 | 30.9 |

| Molasses | 19.0 | 5.6 | 88.4 | 6.1 | 42.7 | 3.8 | 0.9 | 52.6 | 0.78 | 15.0 |

| Wood tar | 12.6 | 4.1 | 67.9 | 28.0 | 40.0 | 6.3 | 0.1 | 53.7 | 0.0 | 21.6 |

| Bitumen | 0 | 1.7 | 22.0 | 70.0 | 85.7 | 5.3 | 1.9 | 3.6 | 1.8 | 41.4 |

| Lignin | 11.0 | 0.8 | 59.6 | 39.6 | 59.3 | 5.9 | 0.1 | 26.7 | 1.2 | 26.9 |

| Nanocellulose | 10.9 | 0.7 | 88.3 | 10.9 | 43.3 | 6.5 | 0.2 | 49.3 | 0.0 | 17.2 |

| Recipe No. | Coke Breeze, wt.% (db *) | Charcoal 1, wt.% (db) | Cement, wt.% (db) | Organic Binder Type and Percent, wt.% (db) | Other Additives, wt.% (db) | Pressure, MPa |

|---|---|---|---|---|---|---|

| R0 (Ref.) | 90 | 0 | 10 | - | - | 160 |

| R1 | 45 | 25 | 10 | 15 Molasses | 5 CaO | 160 |

| R2 | 50 | 25 | 10 | 15 Wood tar | - | 160 |

| R3 | 50 | 25 | 10 | 15 Bitumen | - | 160 |

| R4 | 45 | 25 | 10 | 20 Molasses | - | 160 |

| R5 | 55 | 25 | 10 | 9.5 Lignin | 0.5 Collagen | 160 |

| R6 | 50 | 25 | 10 | 15 Nanocellulose | - | 160 |

| Recipe No. | Coke Breeze, wt.%, dry basis (db) | Charcoal 2, wt.% (db) | Cement, wt.% (db) | Organic Binder Type and Percent, wt.% (db) | Other Additives, wt.% (db) | Pressure, MPa |

|---|---|---|---|---|---|---|

| R7 | 25 | 50 | 5 | 20 Molasses | - | 160 |

| R8 | 0 | 80 | 0 | 20 Molasses | - | 160 |

| R9 | 0 | 80 | 0 | 20 Bitumen | - | 160 |

| R10 | 45 | 25 | 10 | 20 Molasses | - | 80 |

| R11 | 50 | 34 | 10 | 5 Keracoal | 1 Activator | 16 |

| R12 | 45 | 25 | 10 | 16 Keracoal | 4 Activator | 160 |

| R13 | 45 | 25 | 10 | 16 Keracoal | 4 Activator | 80 |

| R14 | 45 | 25 | 10 | 20 Molasses | - | 160 |

| R15 | 0 | 70 | 10 | 20 Molasses | - | 160 |

| Recipe No. | Charcoal 1, wt.% (db) | Cement, wt.% (db) | Organic Binder Type and Percent, wt.% (db) | Other Additives, wt.% (db) | Pressure, MPa |

|---|---|---|---|---|---|

| R16 | 80 | 8 | 8 Molasses | 4 Hydrated lime | 160 |

| R17 | 80 | 8 (CA) | 8 Molasses | 4 Hydrated lime | 160 |

| R18 | 74 | 8 | 12 Molasses | 6 Hydrated lime | 160 |

| R19 | 62 | 8 | 20 Molasses | 10 Hydrated lime | 160 |

| R20 | 69.5 | 8 | 22.5 Molasses | - | 160 |

| R21 | 82 | 0 | 12 Molasses | 6 Hydrated lime | 160 |

| R22 | 77 | 0 | 12 Molasses | 6 Hydrated lime 5 Silica suspension | 160 |

| R23 | 72 | 0 | 12 Molasses | 6 Hydrated lime 10 Silica suspension | 160 |

| R24 | 72 | 5 | 12 Molasses | 6 Hydrated lime 5 Silica suspension | 160 |

| R25 | 74 | 8 | 12 Molasses | 6 Hydrated lime | 120 |

| R26 | 74 | 8 | 12 Molasses | 6 Hydrated lime | 80 |

| R27 | 74 | 8 | 12 Molasses | 6 Hydrated lime | 40 |

| Mixture Recipe | Coke Breeze | Charcoal 1 | Charcoal 2 | Molasses | Hydrated Lime | Portland Cement | SiO2 Suspension | Charcoal Size, mm |

|---|---|---|---|---|---|---|---|---|

| wt.% | ||||||||

| M1 | 90 | 0 | 0 | 0 | 0 | 10 | 0 | - |

| M2 | 0 | 69.5 | 0 | 15 | 7.5 | 8 | 0 | 0–4 |

| M3 | 0 | 62 | 0 | 20 | 10 | 8 | 0 | 0–4 |

| M4 | 0 | 69.5 | 0 | 15 | 7.5 (CL) | 8 | 0 | 0–4 |

| M5 | 0 | 62 | 0 | 20 | 10 (CL) | 8 | 0 | 0–4 |

| M6 | 0 | 65 | 0 | 18 | 9 (CL) | 8 | 0 | 0–4 |

| M7 | 0 | 70 | 0 | 20 | 10 (CL) | 0 | 0 | 0–4 |

| M8 | 0 | 62 | 0 | 20 | 10 (CL) | 4 | 4 | 0–4 |

| M9 | 0 | 62 | 0 | 20 | 10 (CL) | 0 | 8 | 0–4 |

| M10 | 0 | 62 | 0 | 20 | 10 (CL) | 8 | 0 | 0–0.5 |

| M11 | 0 | 62 | 0 | 20 | 10 (CL) | 8 | 0 | 0–2 |

| M12 | 0 | 0 | 62 | 20 | 10 (CL) | 8 | 0 | 0–2 |

| M13 | 10 | 52 | 0 | 20 | 10 (CL) | 8 | 0 | 0–2 |

| M14 | 20 | 42 | 0 | 20 | 10 (CL) | 8 | 0 | 0–2 |

| Test No. | Sample | Gas Composition (vol%) | Total Load (t/m2) | Total Weight Loss (%) | ||

|---|---|---|---|---|---|---|

| CO | CO2 | N2 | ||||

| 1, 2, 3 | M5 | - | - | 100 | 0 | - |

| 4 | M5 | - | - | 100 | 8 | 35.3 |

| 5, 6 | M5 | 34 | 7 | 59 | 8 | 36 |

| 7 | CBB | 34 | 7 | 59 | 8 | 5.3 |

| 8, 9 | Foundry coke (FC) | 34 | 7 | 59 | 8 | 0.6 |

| 10 | M11 | 34 | 7 | 59 | 8 | 36.5 |

| 11 | M13 | 34 | 7 | 59 | 8 | 34.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mousa, E.; Kazemi, M.; Larsson, M.; Karlsson, G.; Persson, E. Potential for Developing Biocarbon Briquettes for Foundry Industry. Appl. Sci. 2019, 9, 5288. https://doi.org/10.3390/app9245288

Mousa E, Kazemi M, Larsson M, Karlsson G, Persson E. Potential for Developing Biocarbon Briquettes for Foundry Industry. Applied Sciences. 2019; 9(24):5288. https://doi.org/10.3390/app9245288

Chicago/Turabian StyleMousa, Elsayed, Mania Kazemi, Mikael Larsson, Gert Karlsson, and Erik Persson. 2019. "Potential for Developing Biocarbon Briquettes for Foundry Industry" Applied Sciences 9, no. 24: 5288. https://doi.org/10.3390/app9245288

APA StyleMousa, E., Kazemi, M., Larsson, M., Karlsson, G., & Persson, E. (2019). Potential for Developing Biocarbon Briquettes for Foundry Industry. Applied Sciences, 9(24), 5288. https://doi.org/10.3390/app9245288