Calculation Model of High-Pressure Water Jet Slotting Depth for Coalbed Methane Development in Underground Coal Mine

Abstract

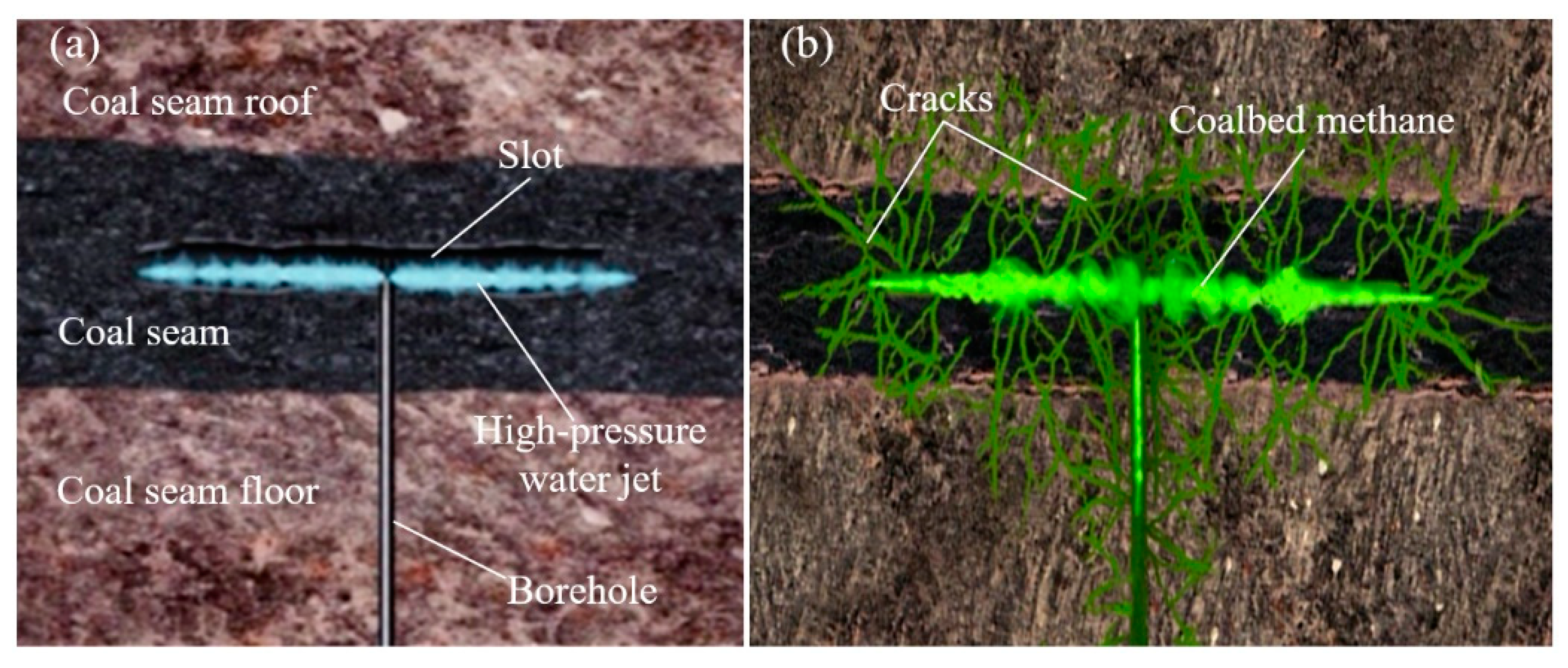

1. Introduction

2. Theory of Rock-Breaking for a High-Pressure Water Jet

2.1. Rock-Breaking Mechanism of High-Pressure Water Jet

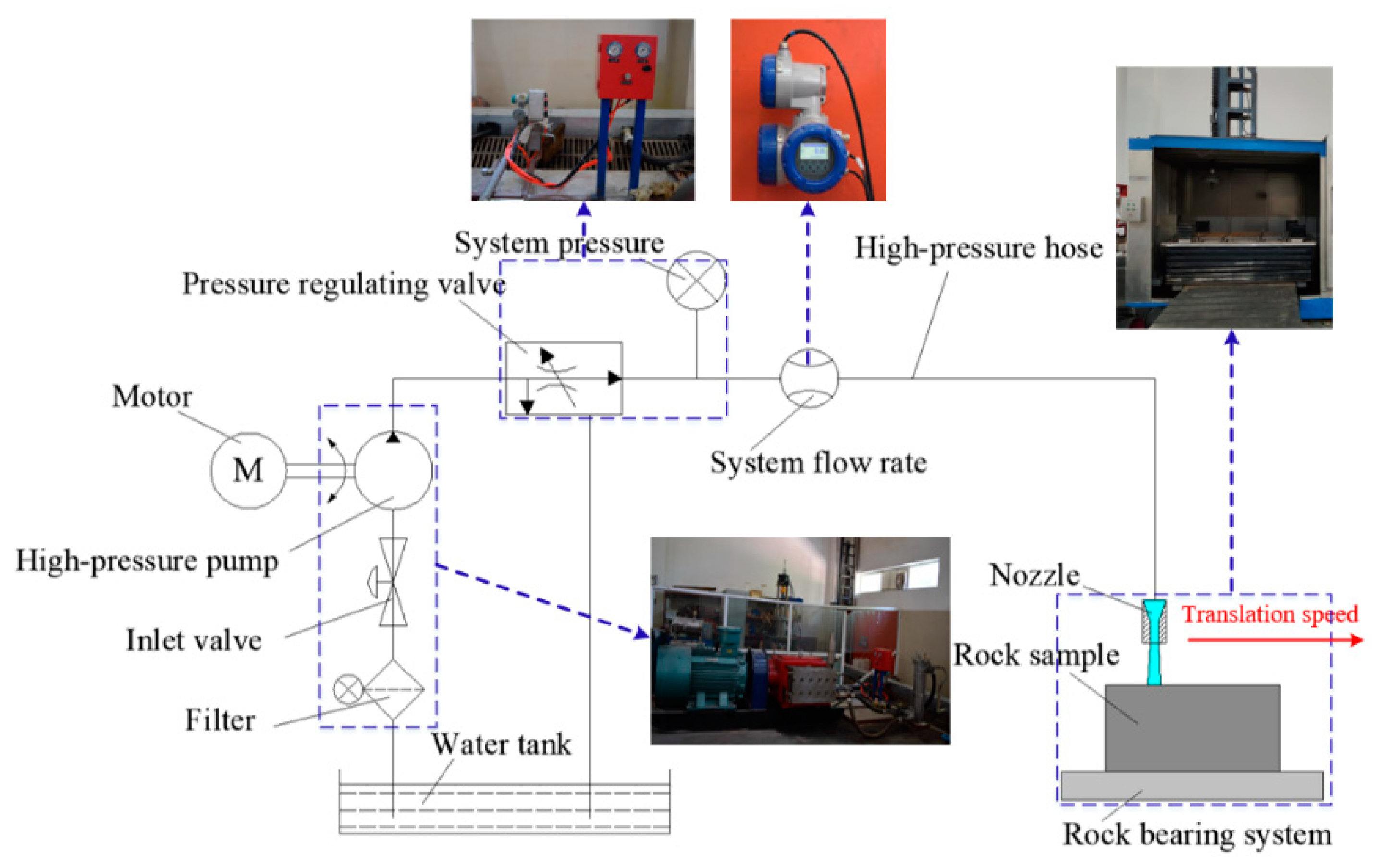

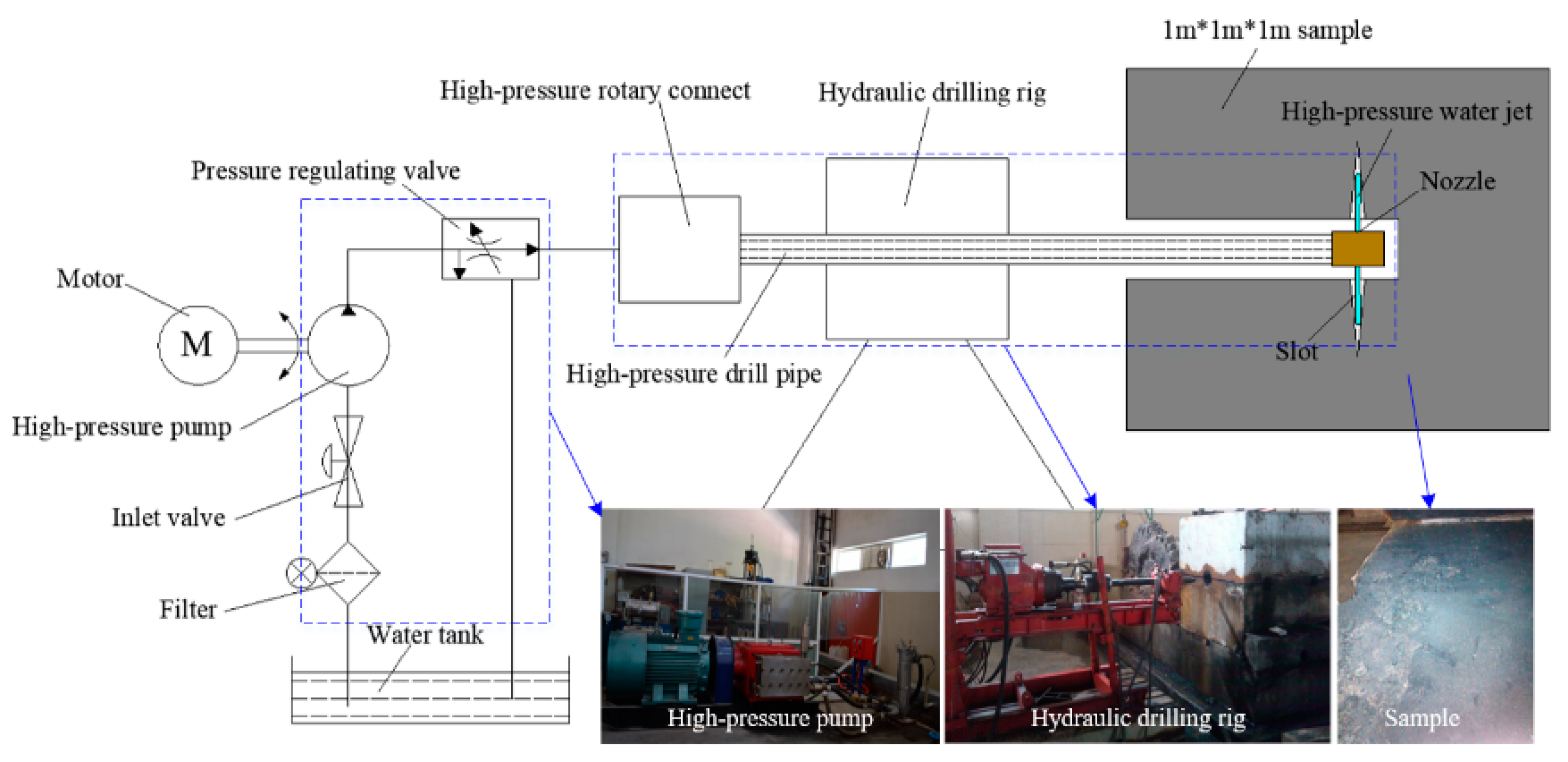

2.2. Rock-Cutting Model for a High-Pressure Water Jet

3. Influence Factor Analysis for Water Jet Slotting Depth

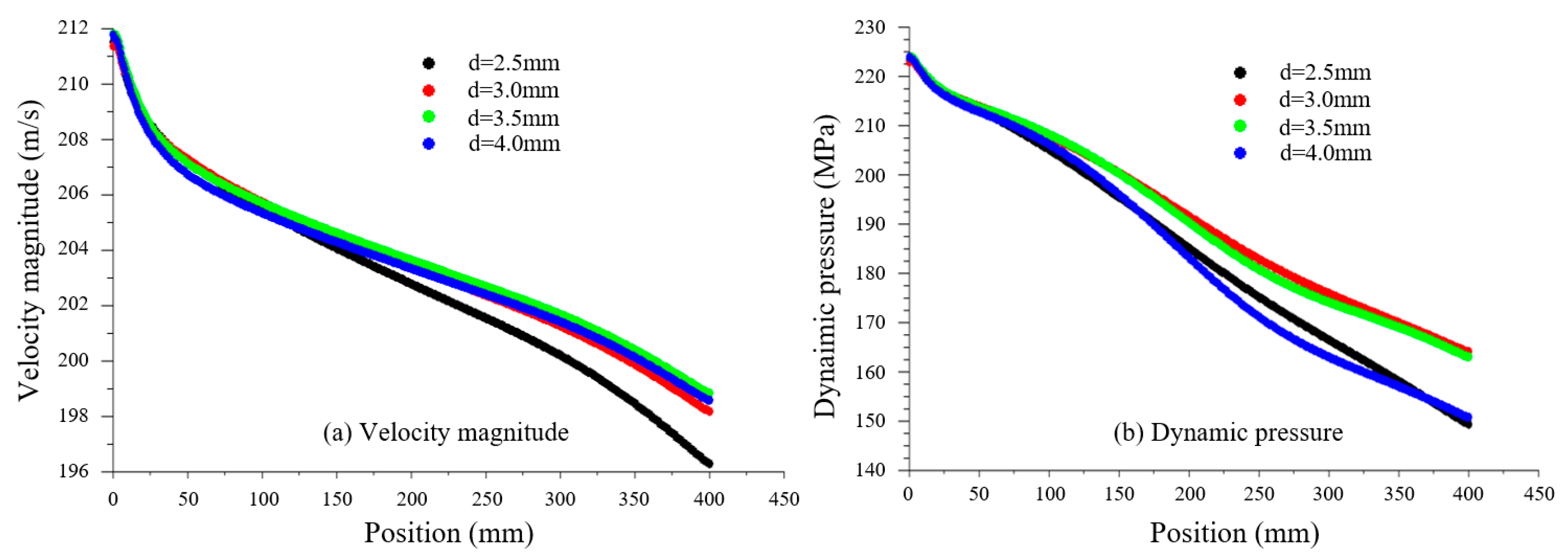

3.1. Nozzle Diameter

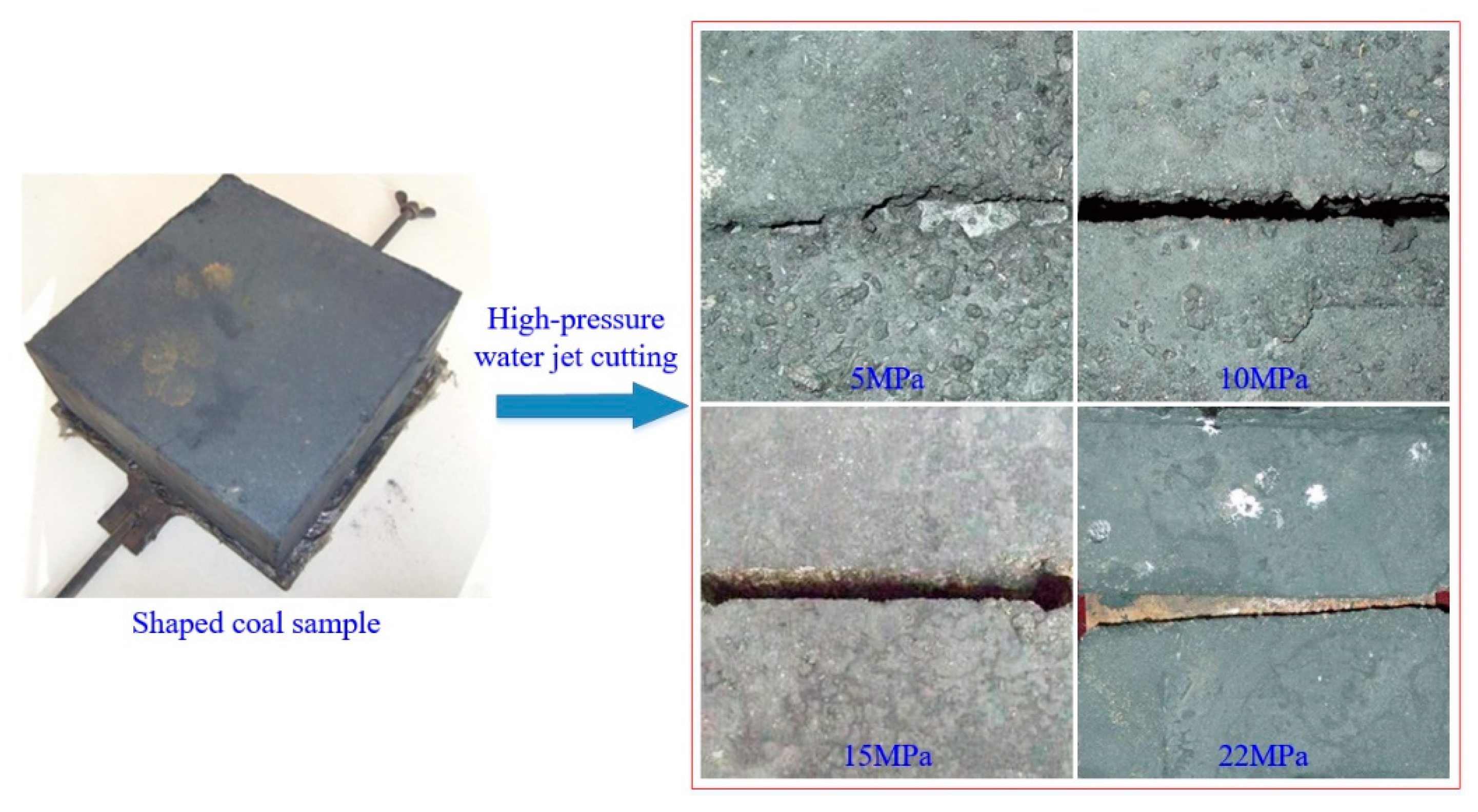

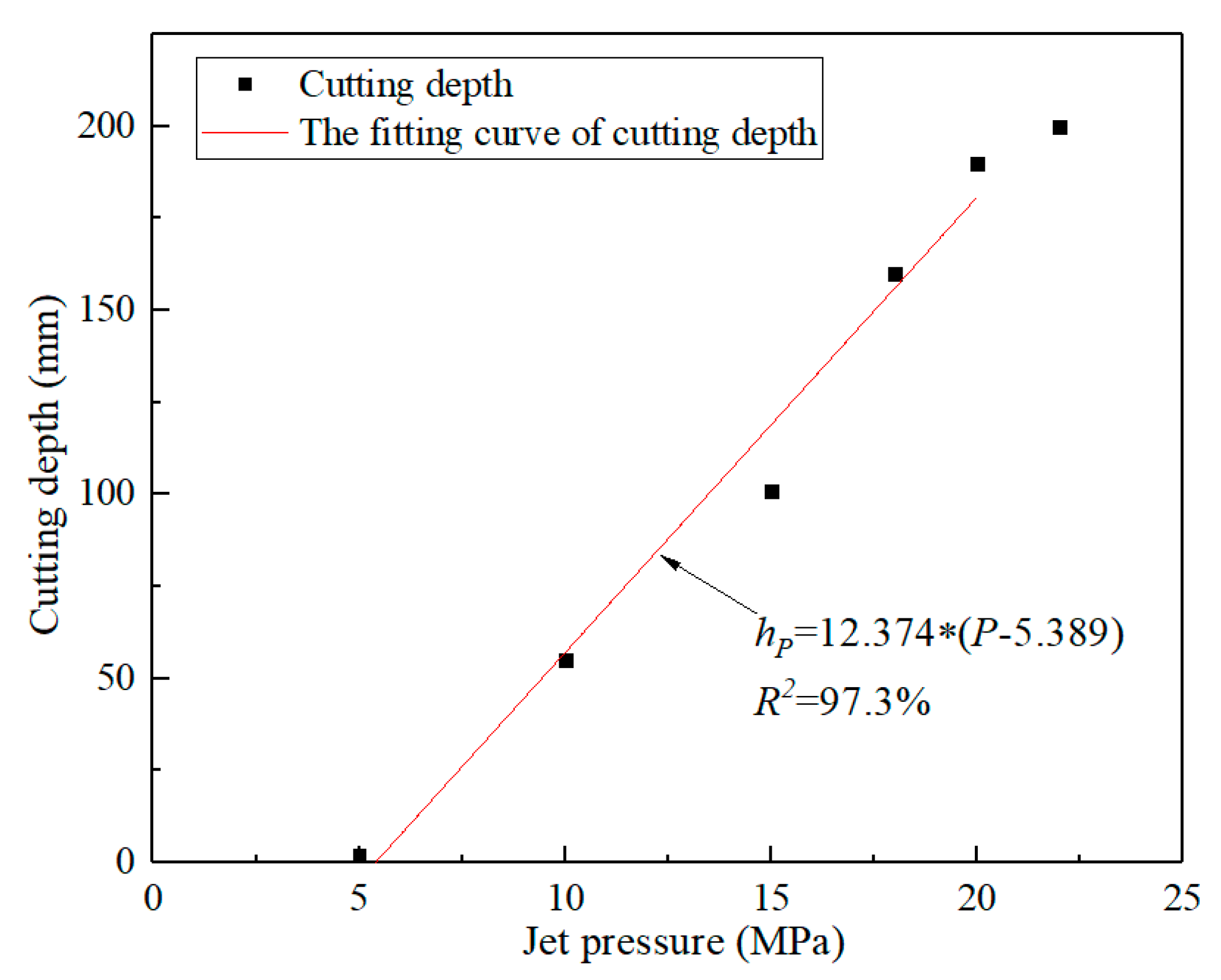

3.2. Jet Pressure

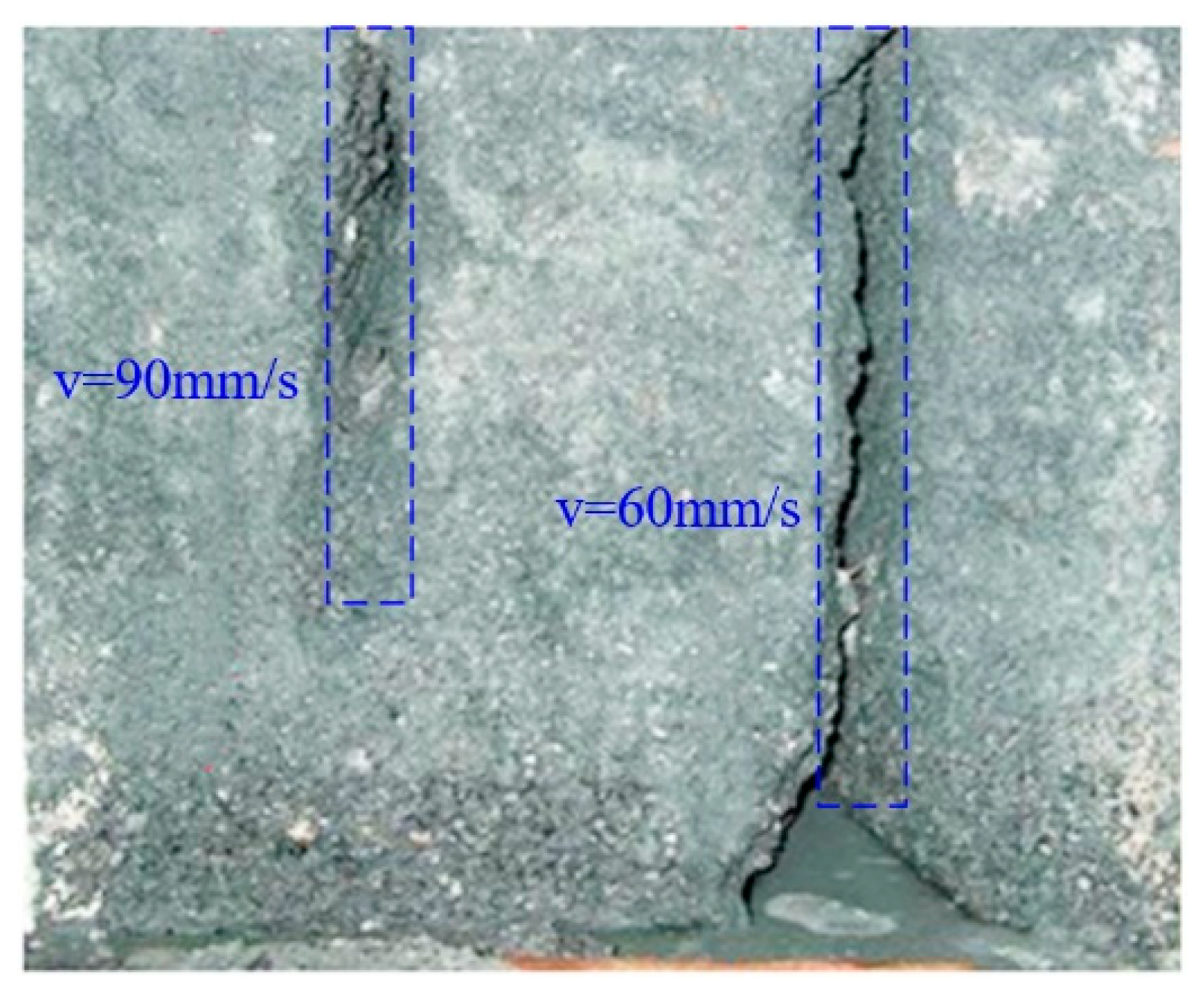

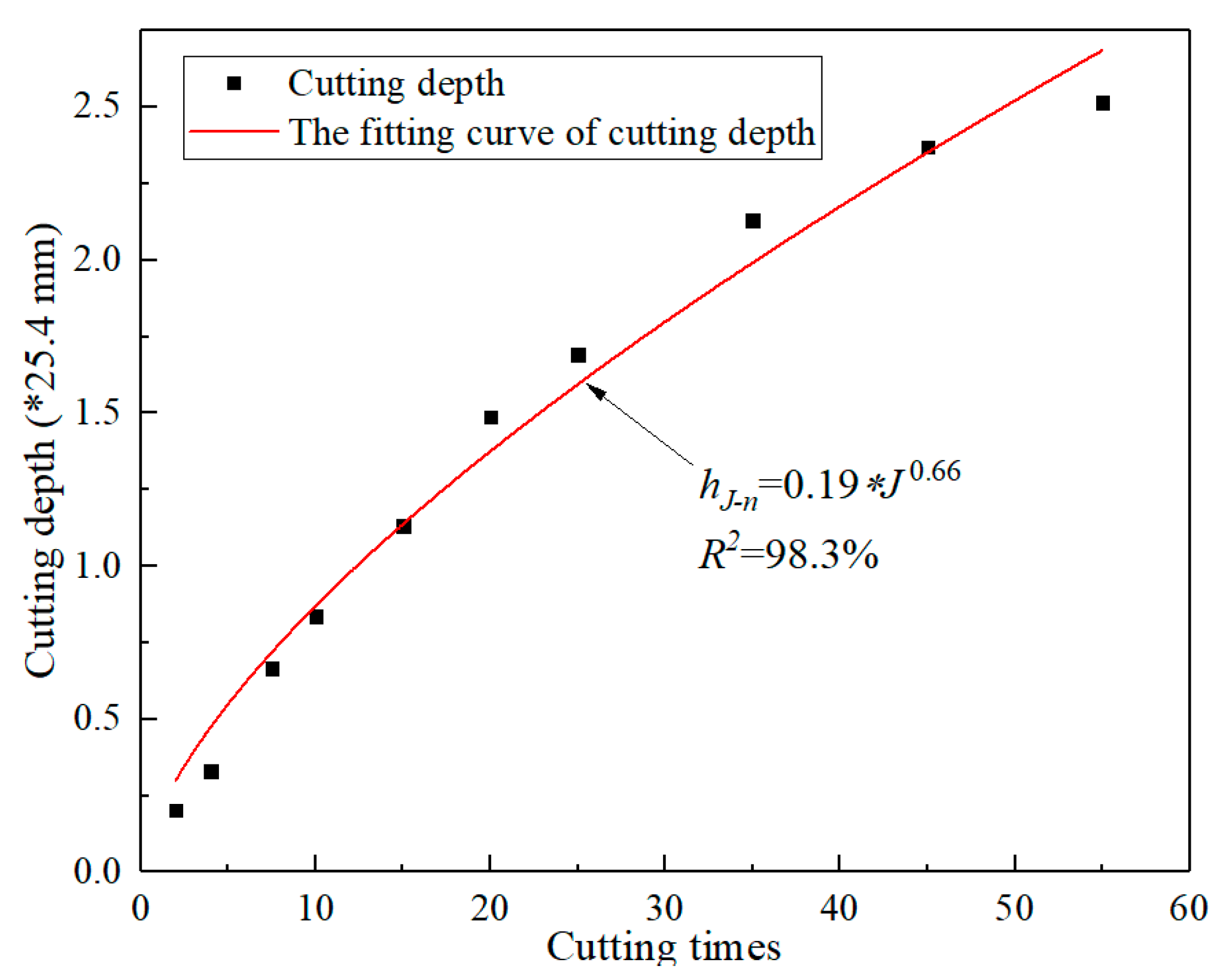

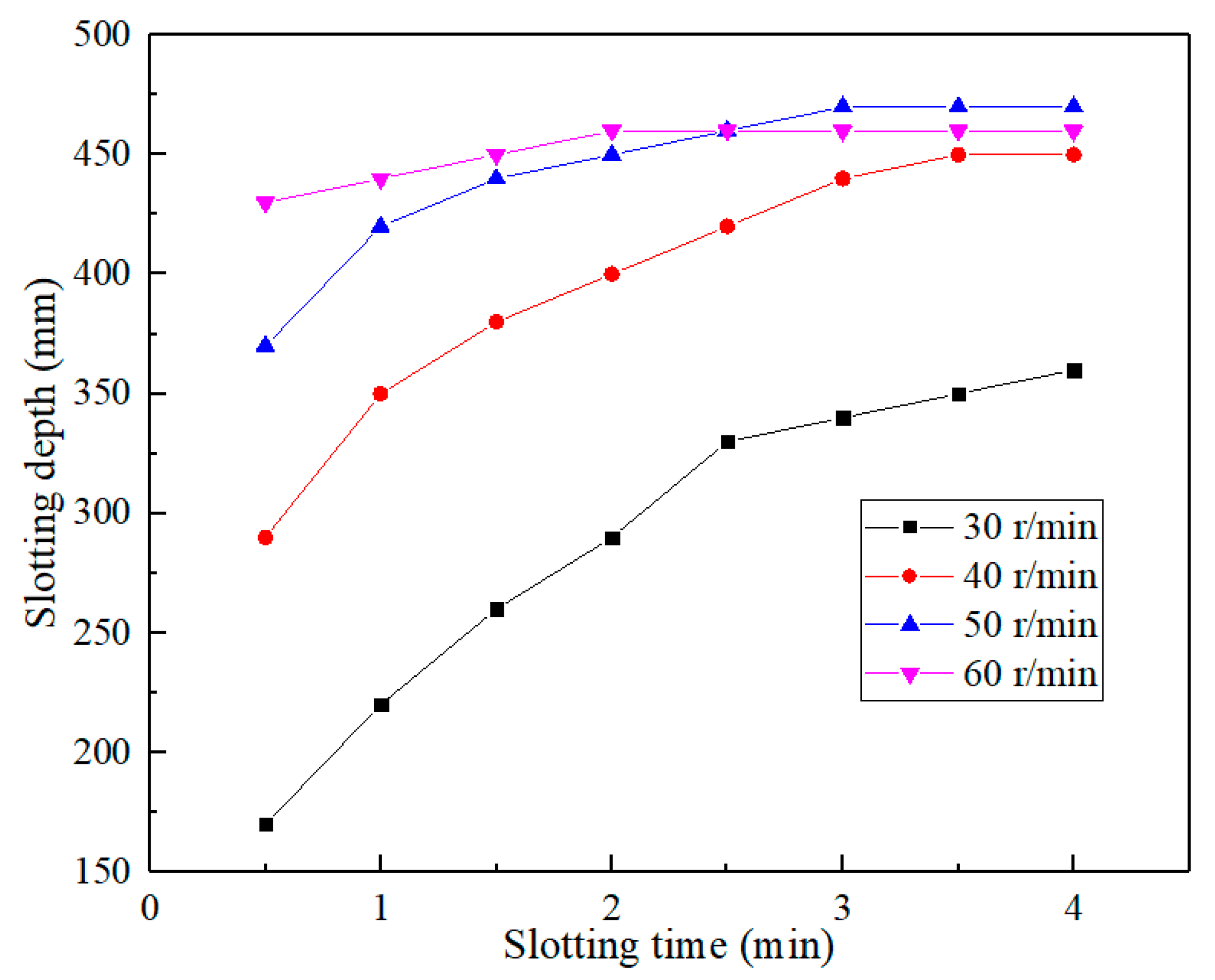

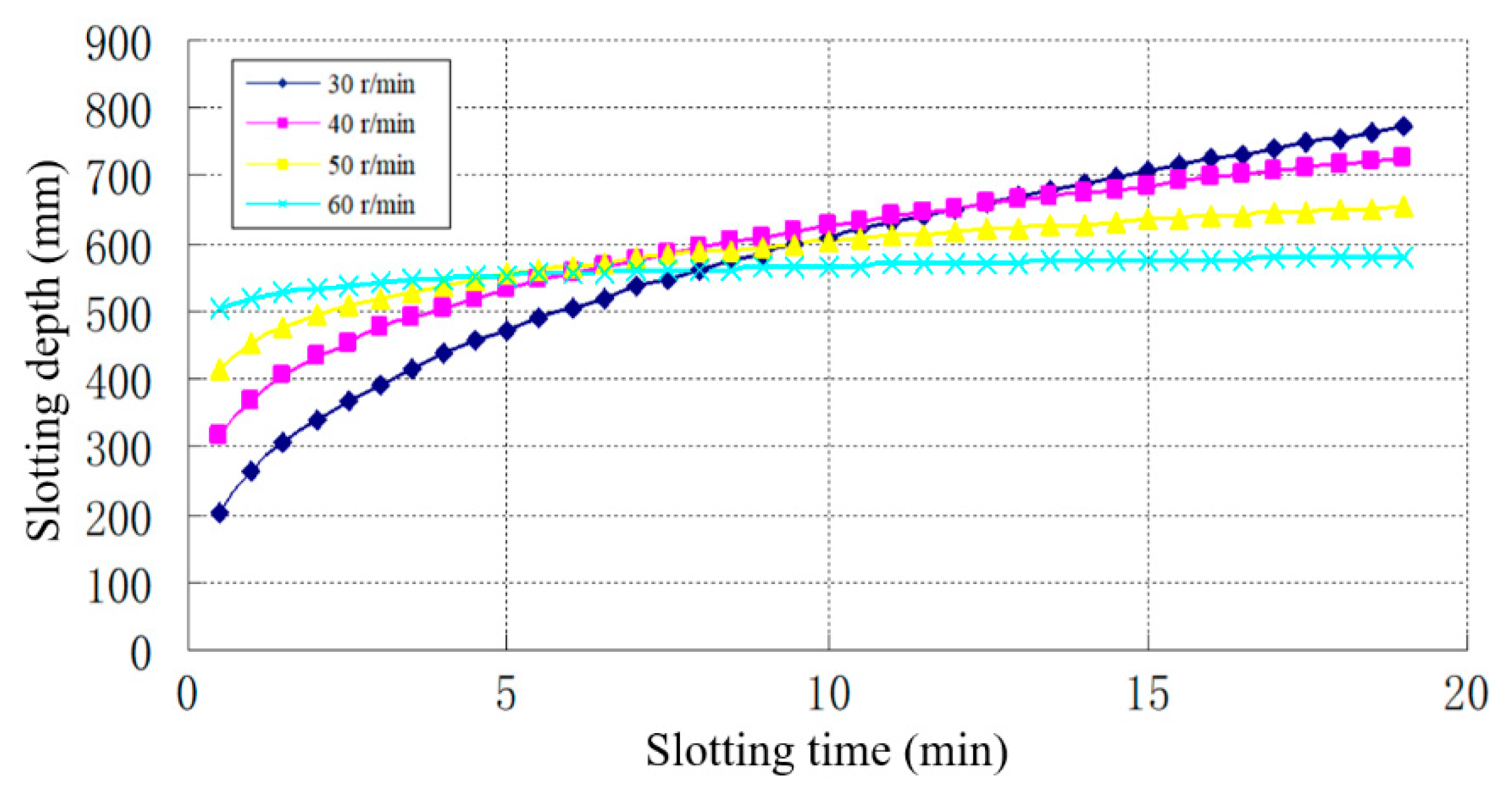

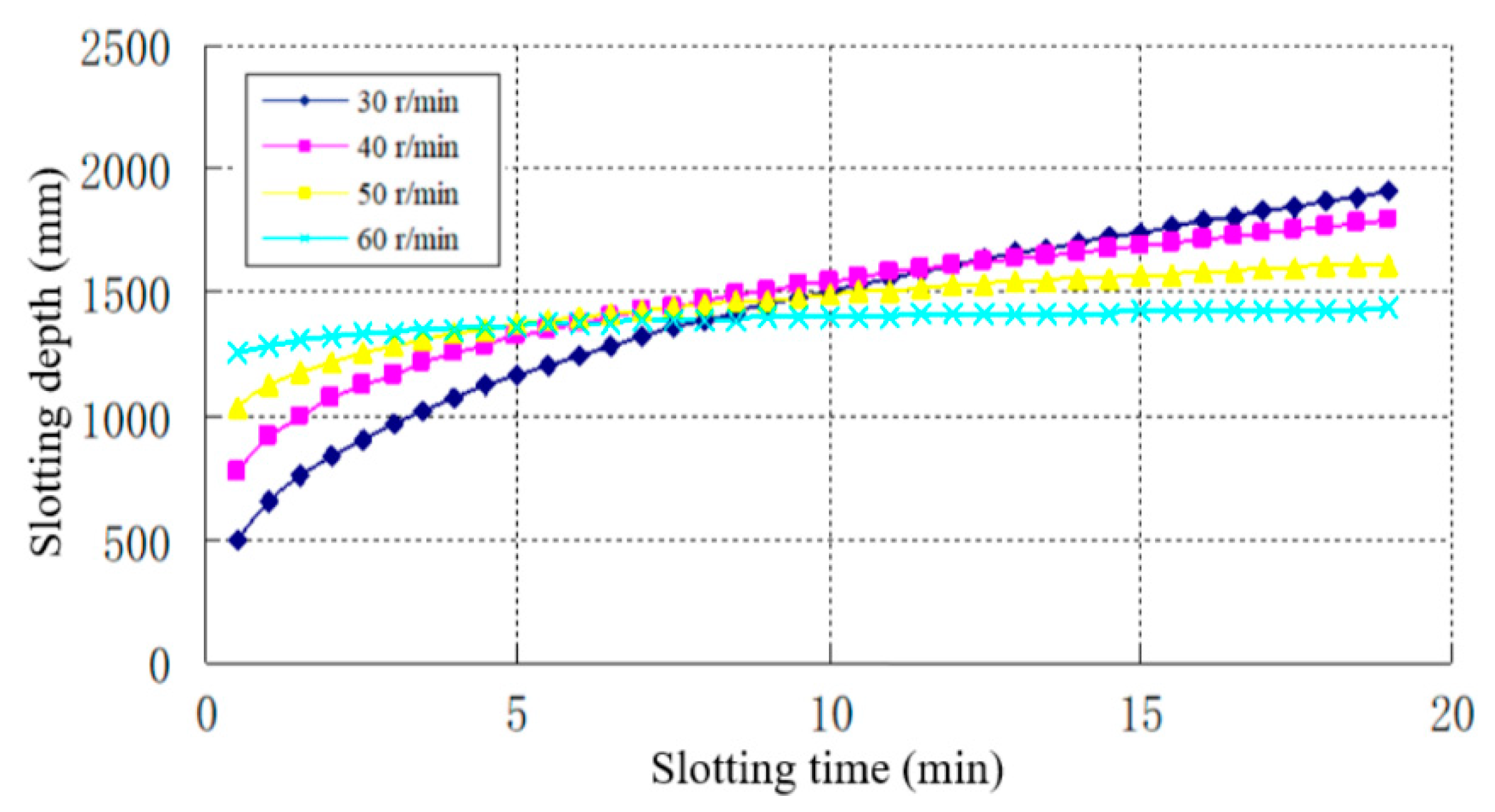

3.3. Rotation Speed and Slotting Time

4. Model for Calculating Water Jet Slotting Depth

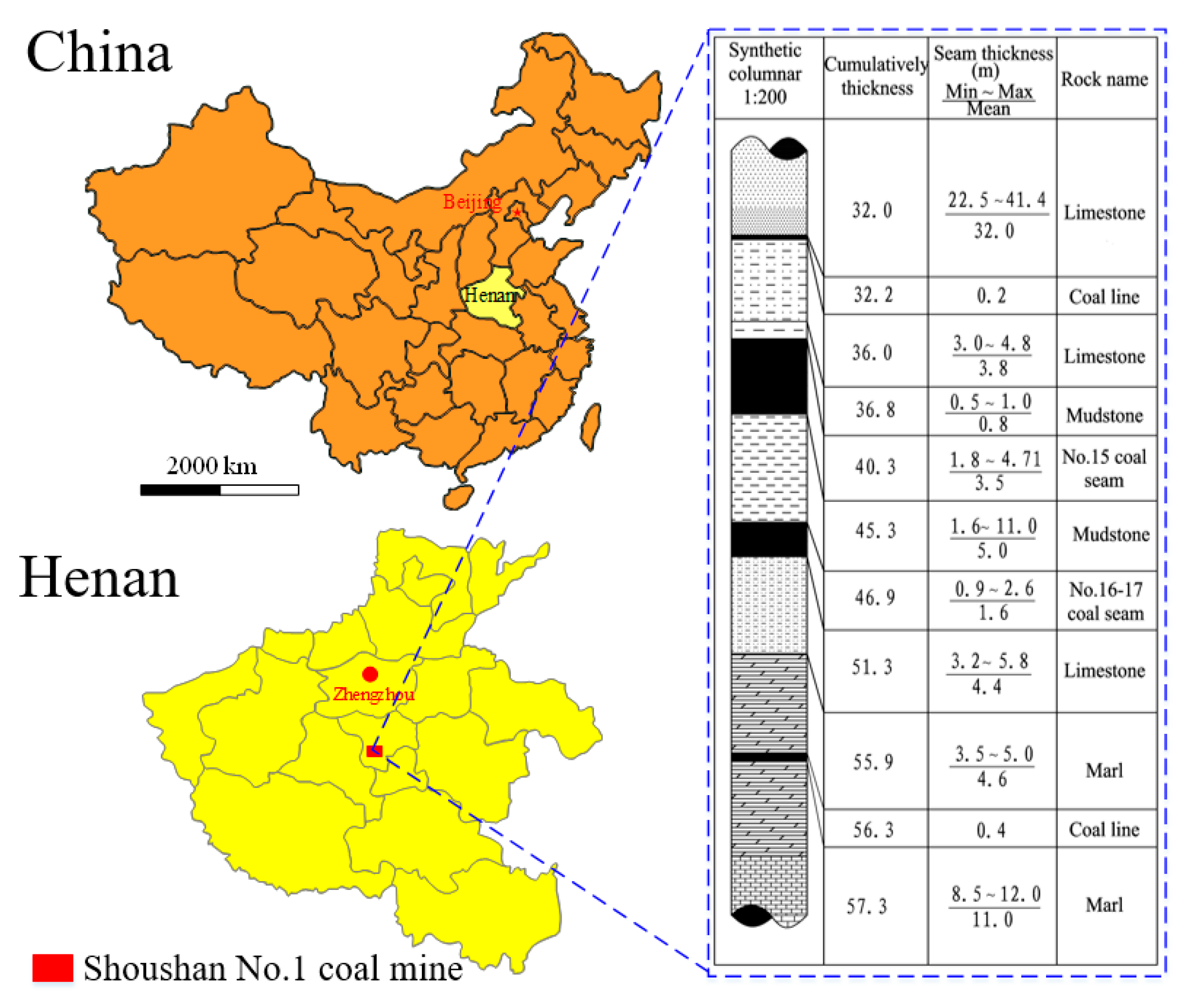

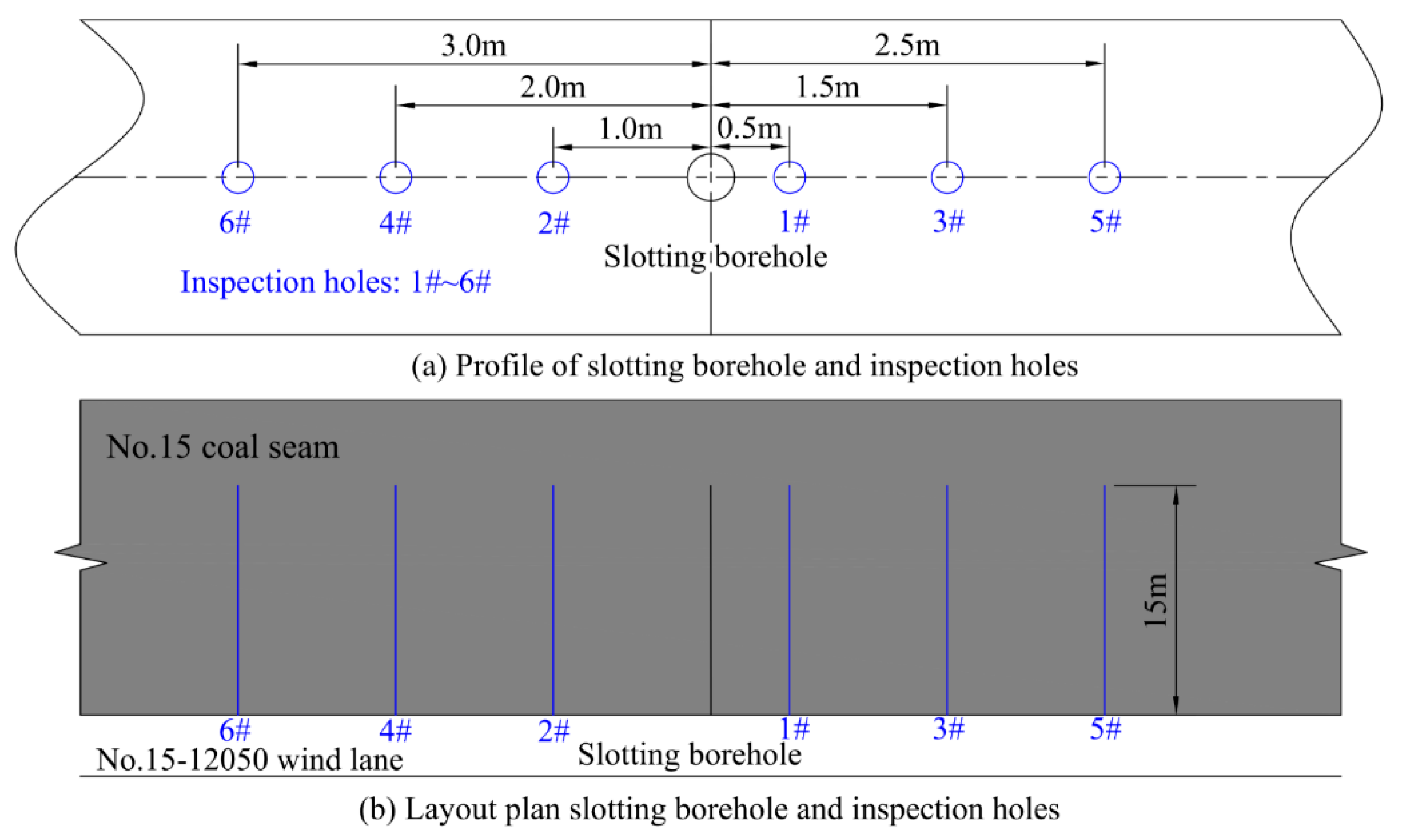

5. Field Test

5.1. Test Background

5.2. Verification of Slotting Depth Model

6. Conclusions

- (1)

- The attenuation coefficient of the jet axial dynamic pressure first decreased and then increased with the increase of the nozzle diameter. For a much higher jet impact velocity, there existed an optimal nozzle diameter. Additionally, the cutting depth linearly increased with the jet pressure and decreased as a power function with the increase of the jet translation speed. Moreover, the number of cuttings had a significant impact on the cutting depth, and the several previous cuttings played a major role in the jet cutting. With the further increase of cutting times, the cutting depth slowly increased, but the increment was small.

- (2)

- Water jet slotting experiments were conducted with different rotation speeds and slotting times. The results revealed that the slotting depth increased with the slotting time, but the growth rate gradually decreased and tended to be stable. As the rotation speed increased, the slotting depth became greater at the initial period, and the limit depth was reached faster. At the early slotting stages, more slotting repetitions were helpful in increasing the slotting depth. At the later slotting stages, a longer single impact improved the slotting efficiency.

- (3)

- A model for calculating the water jet slotting depth was established according to the effects of key parameters on the cutting depth. This model was subsequently verified using the rotatory slotting experiment data, and the results revealed that the fitting was good. Based on the proposed model, the slotting depths under different jet pressures and the threshold rock-breaking pressures were calculated.

- (4)

- Water jet slotting field tests were carried out. The slotting depths at different rotation speeds with different slotting times were analyzed. Comparisons with the depths predicted by the calculation model were made, which revealed that the differences are acceptable.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, T.; Lin, B.Q.; Yang, W.; Zou, Q.L.; Kong, J.; Yan, F.Z. Cracking process and stress field evolution in specimen containing combined flaw under uniaxial compression. Rock Mech. Rock Eng. 2016, 49, 3095–3113. [Google Scholar] [CrossRef]

- Liu, S.M.; Harpalani, S. Permeability prediction of coalbed methane reservoirs during primary depletion. Int. J. Coal Geol. 2013, 113, 1–10. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Xiao, S.Q.; Ge, Z.L.; Zhou, Z.; Ling, Y.F.; Wang, L. Experimental study on rock-breaking performance of water jets generated by self-rotatory bit and rock failure mechanism. Powder Technol. 2019, 346, 203–216. [Google Scholar] [CrossRef]

- Xiao, S.Q.; Ge, Z.L.; Lu, Y.Y.; Zhou, Z.; Li, Q.; Wang, L. Investigation on coal fragmentation by high-velocity water jet in drilling: Size distributions and fractal characteristics. Appl. Sci. 2018, 8, 1988. [Google Scholar] [CrossRef]

- Hu, S.S.; Cheng, Y.Q. Discussions on key development fields of China’s coal science and technology at early stage of 21st century. J. China Coal Soc. 2005, 30, 1–7. [Google Scholar]

- Ge, Z.L.; Mei, X.D.; Jia, Y.J.; Lu, Y.Y.; Xia, B.W. Influence radius of slotted borehole drainage by high pressure water jet. J. Min. Saf. Eng. 2014, 31, 657–664. [Google Scholar]

- Lin, B.Q.; Lv, Y.C.; Li, B.Y.; Zhai, C. High-pressure abrasive hydraulic cutting seam technology and its application in outbursts prevention. J. China Coal Soc. 2007, 32, 959–963. [Google Scholar]

- Shen, C.M.; Lin, B.Q.; Zhang, Q.Z. Induced drill-spray during hydraulic slotting of a coal seam and its influence on gas extraction. Int. J. Min. Sci. Technol. 2012, 22, 785–791. [Google Scholar] [CrossRef]

- Lin, B.Q.; Yan, F.Z.; Zhu, C.J.; Zhou, Y.; Zou, Q.L.; Guo, C.; Liu, T. Cross-borehole hydraulic slotting technique for preventing and controlling coal and gas outbursts during coal roadway excavation. J. Nat. Gas. Sci. Eng. 2015, 26, 518–525. [Google Scholar] [CrossRef]

- Yu, H.; Lu, T.K. Research on high pressure water jet cutting to improve gas drainage efficiency. Coal Sci. Technol. 2009, 37, 48–50. [Google Scholar]

- Zhang, Q.Z.; Lin, B.Q.; Meng, F.W.; Shen, C.M. Research and application on disturbance influence law of seam slot cutting with high pressurized water jet. Coal Sci. Technol. 2011, 39, 49–52. [Google Scholar]

- Shen, C.M.; Lin, B.Q.; Wu, H.J. High-pressure water jet slotting and influence on permeability of coal seams. J. China Coal Soc. 2011, 36, 2058–2063. [Google Scholar]

- Lu, Y.Y.; Ge, Z.L.; Li, X.H.; Chen, J.F.; Liu, Y. Investigation of a self-excited pulsed water jet for rock cross-cutting to uncover coal. J. China Univ. Min. Technol. 2010, 39, 55–58. [Google Scholar]

- Lu, Y.Y.; Jia, Y.J.; Ge, Z.L.; Xia, B.W. Coupled fluid-solid model of coal bed methane and its application after slotting by high-pressure water jet. J. China Univ. Min. Technol. 2014, 43, 23–29. [Google Scholar]

- Tang, J.R.; Lu, Y.Y.; Ouyang, M.D.; Zhang, W.F.; Zhang, X.W. Optimal design and performance evaluation of a new hydrajet-fracturing nozzle. J. China Univ. Petrol. 2015, 39, 72–78. [Google Scholar]

- Lu, Y.Y.; Ge, Z.L.; Tang, J.R. A Multi-Functional Self-Oscillating Abrasive Water Jet Generator. Patent CN102133562A, 28 January 2011. [Google Scholar]

- Xu, Y.P.; Lin, B.Q.; Zhu, C.J.; Liu, Y. The dynamic characteristic of abrasive and its parameter optimization based on the drilling-cutting integration of high-pressure abrasive water jet. J. Min. Saf. Eng. 2011, 28, 623–627. [Google Scholar]

- Lu, Y.; Huang, F.; Liu, X.C.; Ao, X. On the failure pattern of sandstone impacted by high-velocity water jet. Int. J. Impact Eng. 2015, 76, 67–74. [Google Scholar] [CrossRef]

- Dehkhoda, S.; Hood, M. An experimental study of surface and sub-surface damage in pulsed water-jet breakage of rocks. Int. J. Rock Mech. Min. Sci. 2013, 63, 138–147. [Google Scholar] [CrossRef]

- Momber, A.W. The response of geo-materials to high-speed liquid drop impact. Int. J. Impact Eng. 2016, 89, 83–101. [Google Scholar] [CrossRef]

- Field, J.E.; Lesser, M.B.; Dear, J.P. Studies of two-dimensional liquid-wedge impact and their relevance to liquid-drop impact problems. Proc. R. Soc. Lond. A 1985, 401, 225–249. [Google Scholar] [CrossRef]

- Lesser, M.B. Analytic solutions of liquid-drop impact problems. Proc. R. Soc. Lond. A 1981, 377, 289–308. [Google Scholar] [CrossRef]

- Lesser, M.B.; Field, J.E. The impact of compressible liquids. Annu. Rev. Fluid Mech. 1983, 15, 97–122. [Google Scholar] [CrossRef]

- Rehbinder, G. Some aspects on the mechanism of erosion of rock with high speed water jet. In Proceedings of the Third International Symposium on Jet Cutting Technology, BHRA Fluid Engineering, Chicago, IL, USA, 11–13 May 1976. Paper No E1. [Google Scholar]

- Rehbinder, G. Erosion resistance of rock. In Proceedings of the Fourth International Symposium on Jet Cutting Technology, BHEA Fluid Engineering, Kent, UK, 12–14 April 1978. Paper No E1. [Google Scholar]

- Hashish, M.; Duplessis, M.P. The application of generalized jet-cutting equation. In Proceedings of the Fourth International Symposium on Jet Cutting Technology, BHEA Fluid Engineering, Ken, UK, 12–14 April 1978. Paper No E1. [Google Scholar]

- Xue, S.X. High. Pressure Water Jet Technology and Engineering; Hefei University of Technology Press: Hefei, China, 2006. [Google Scholar]

- Huang, X.B. Critical Parameters of High-Pressure Water Jet Slotting in Coal Seam. Master’s Thesis, College of Resources and Environment Science, Chongqing University, Chongqing, China, 2012. [Google Scholar]

- Zuo, B.C.; Chen, C.X.; Liu, C.H.; Shen, Q.; Xiao, G.F.; Liu, X.W. Research on similar material of slope simulation experiment. Rock Soil Mech. 2004, 11, 1805–1808. [Google Scholar]

- Li, H.C. Similar Simulation Test of Mine Pressure; China University of Mining and Technology Press: Xuzhou, China, 1988. [Google Scholar]

- Shen, Z.H. Theory and Technology of Water Jet; University of Petroleum Press: Dongying, China, 1998. [Google Scholar]

- Li, X.W. Mechanical Properties of Rock Blocks; Coal Industry Publishing House: Beijing, China, 1983. [Google Scholar]

| Number | Test Condition | Whether There is Water Flowing Out from Inspection Hole or Not | Slotting Depth (m) | Prediction Depth (m) |

|---|---|---|---|---|

| 1 | n = 60 r/min, t = 5 min | 1#~2#: Yes, 3#~6#: No | 1.0~1.5 m | 1.37 m |

| 2 | n = 50 r/min, t = 10 min | 1#~2#: Yes, 4#~6#: No 3#: a little water | 1.0~1.5 m, close to 1.5 m | 1.48 m |

| 3 | n = 40 r/min, t = 15 min | 1#~3#: Yes, 4#~6#: No | 1.5~2.0 m | 1.69 m |

| 4 | n = 30 r/min, t = 20 min | 1#~3#: Yes, 5#~6#: No 4#: a little water | 1.5~2.0 m, close to 2.0 m | 1.91 m |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Wang, Y.; Ge, Z.; Xiao, S.; Zhao, H.; Huang, X. Calculation Model of High-Pressure Water Jet Slotting Depth for Coalbed Methane Development in Underground Coal Mine. Appl. Sci. 2019, 9, 5250. https://doi.org/10.3390/app9235250

Zhang J, Wang Y, Ge Z, Xiao S, Zhao H, Huang X. Calculation Model of High-Pressure Water Jet Slotting Depth for Coalbed Methane Development in Underground Coal Mine. Applied Sciences. 2019; 9(23):5250. https://doi.org/10.3390/app9235250

Chicago/Turabian StyleZhang, Jianguo, Yingwei Wang, Zhaolong Ge, Songqiang Xiao, Hanyun Zhao, and Xiaobo Huang. 2019. "Calculation Model of High-Pressure Water Jet Slotting Depth for Coalbed Methane Development in Underground Coal Mine" Applied Sciences 9, no. 23: 5250. https://doi.org/10.3390/app9235250

APA StyleZhang, J., Wang, Y., Ge, Z., Xiao, S., Zhao, H., & Huang, X. (2019). Calculation Model of High-Pressure Water Jet Slotting Depth for Coalbed Methane Development in Underground Coal Mine. Applied Sciences, 9(23), 5250. https://doi.org/10.3390/app9235250