A Numerical Study on the Distribution and Evolution Characteristics of an Acoustic Field in the Time Domain of a Centrifugal Pump Based on Powell Vortex Sound Theory

Abstract

:1. Introduction

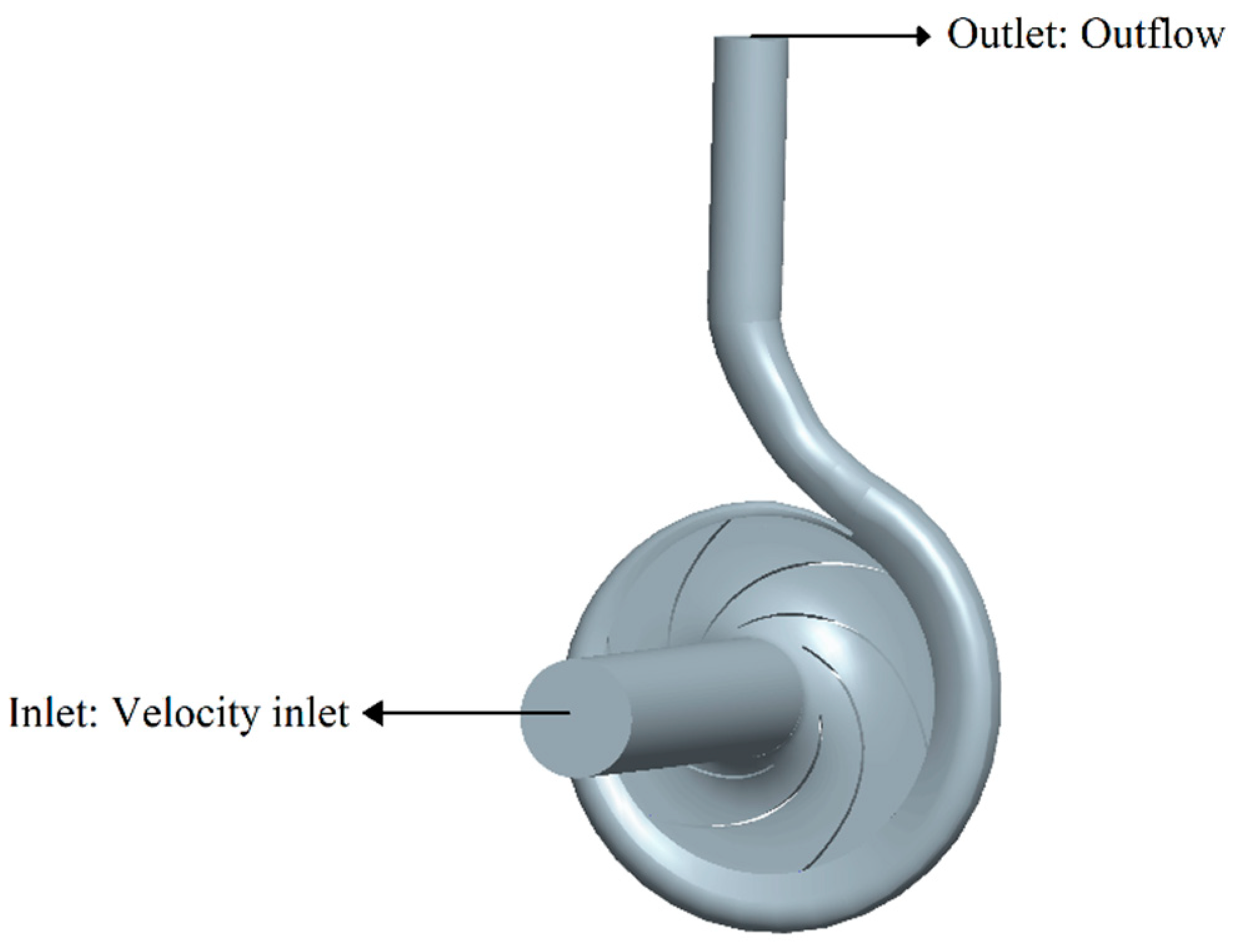

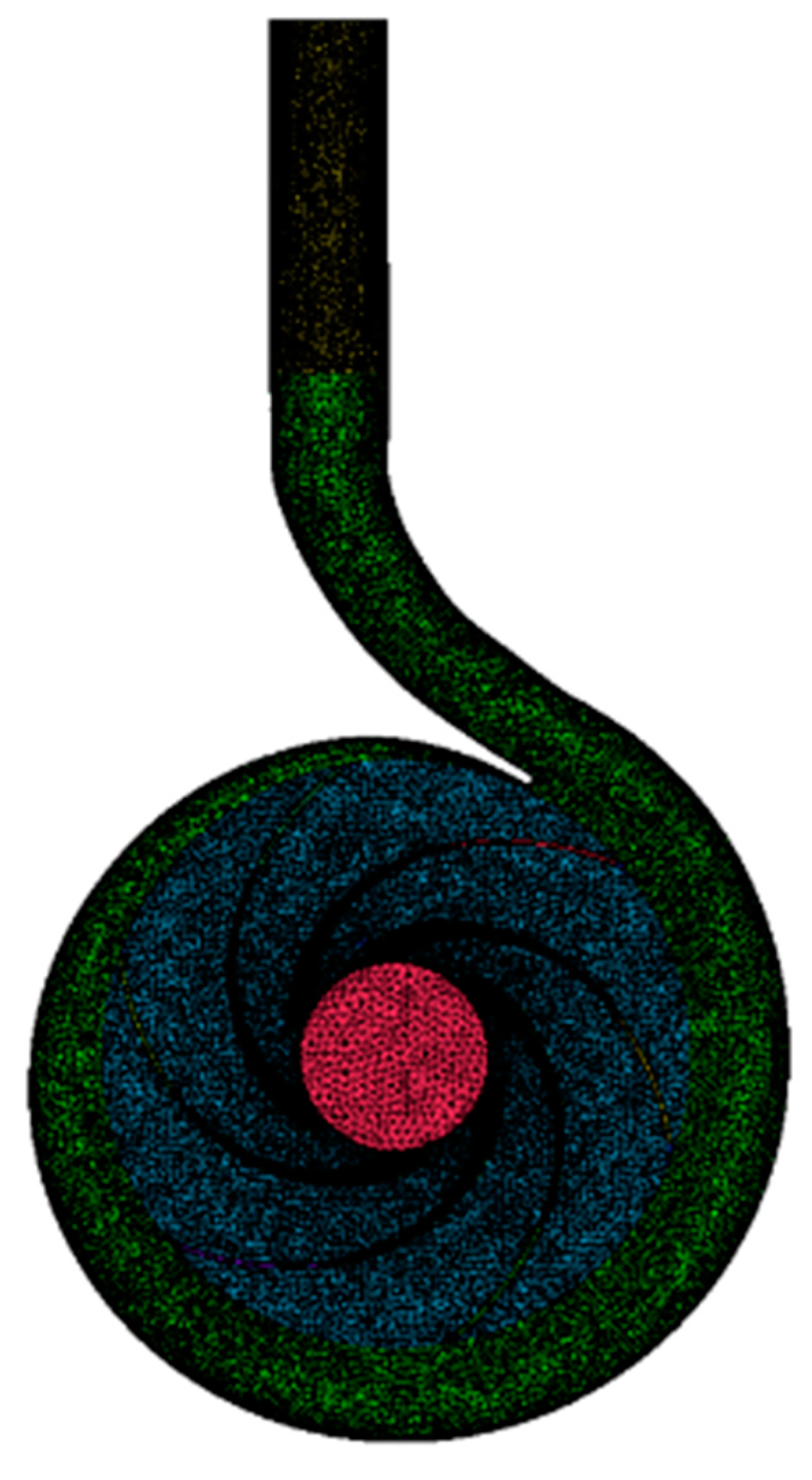

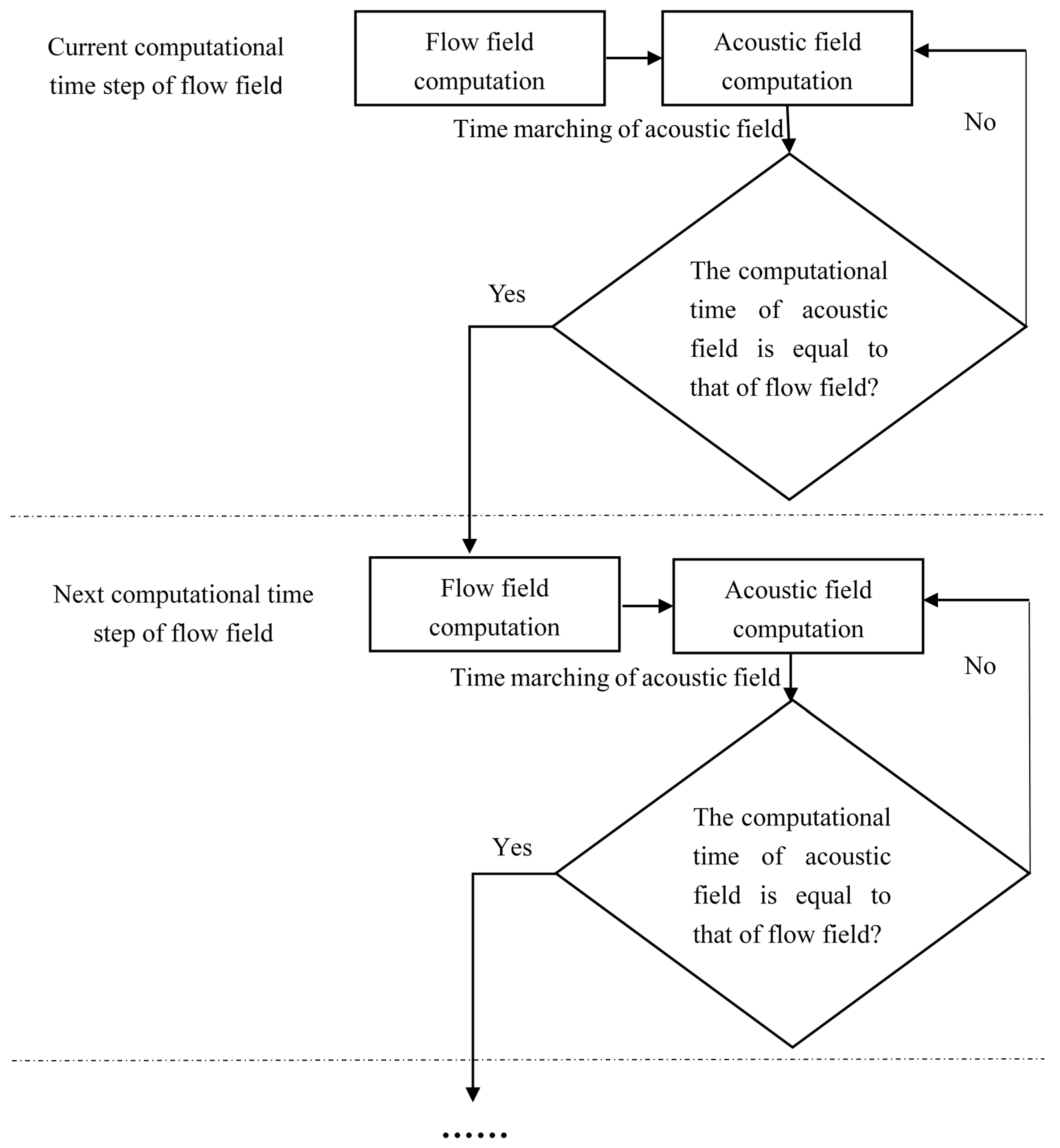

2. Computational Model and Solving Method

2.1. Flow Field Solver

2.2. Acoustic Field Solver

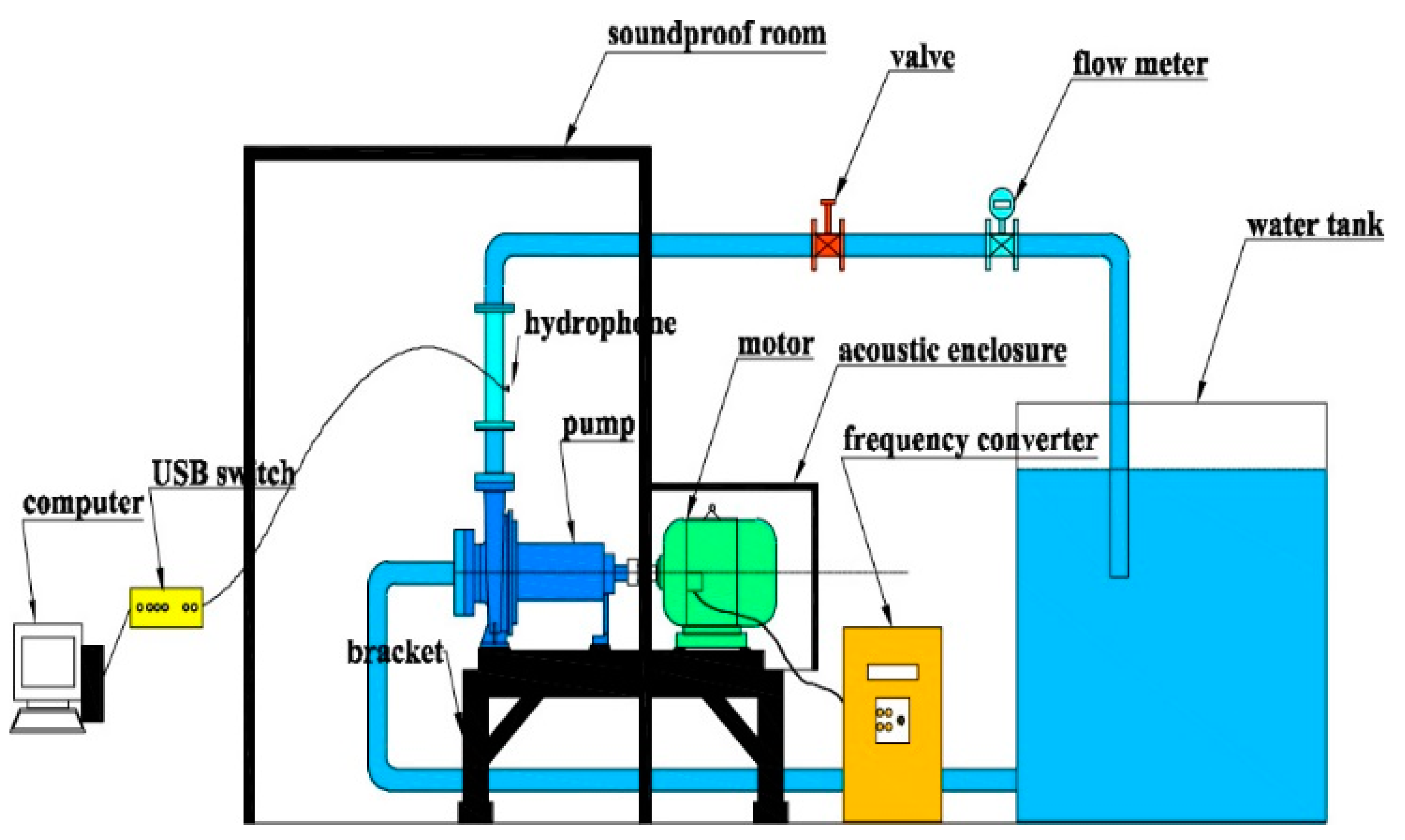

3. Test Facilities and Procedures

4. Results and Analysis

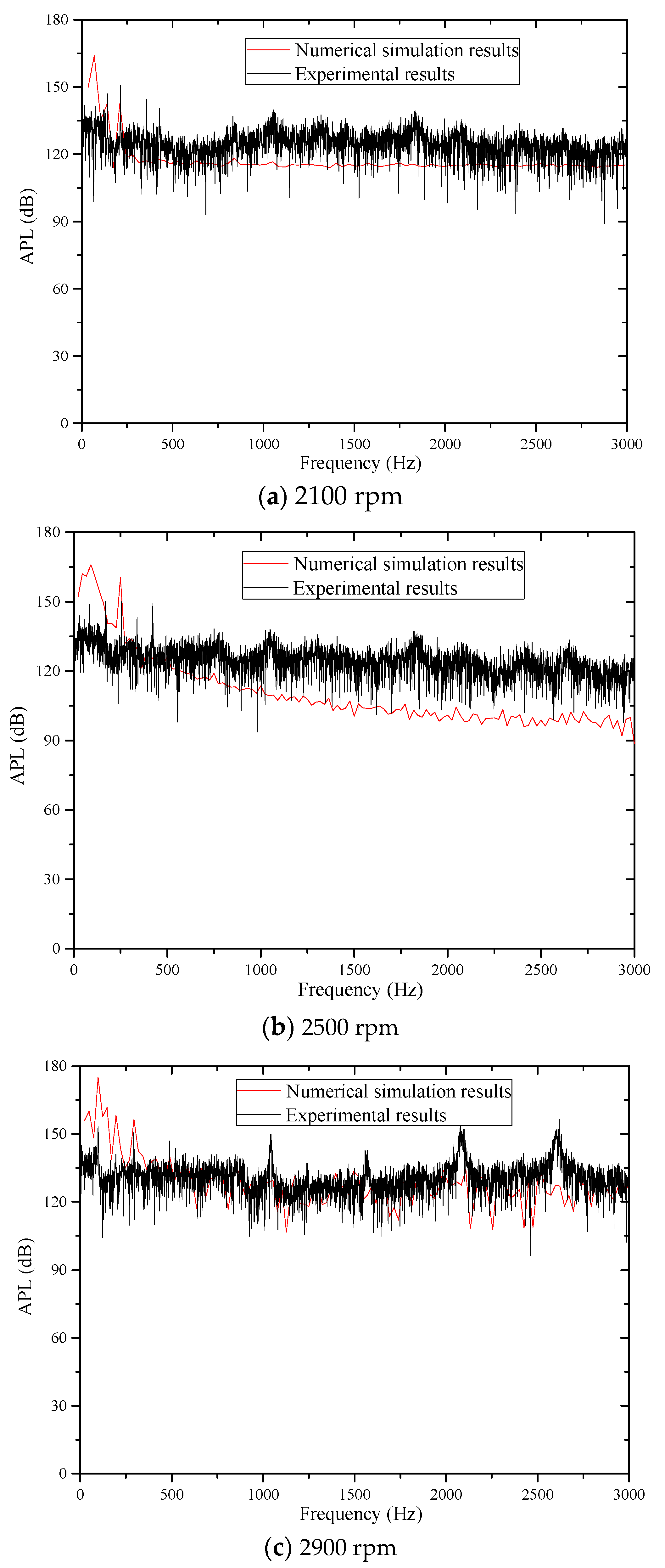

4.1. Verification of the Numerical Simulation Approach

4.2. The Distribution and Evolution Characteristics of Acoustic Field in Time Domain at Rated Operation Condition

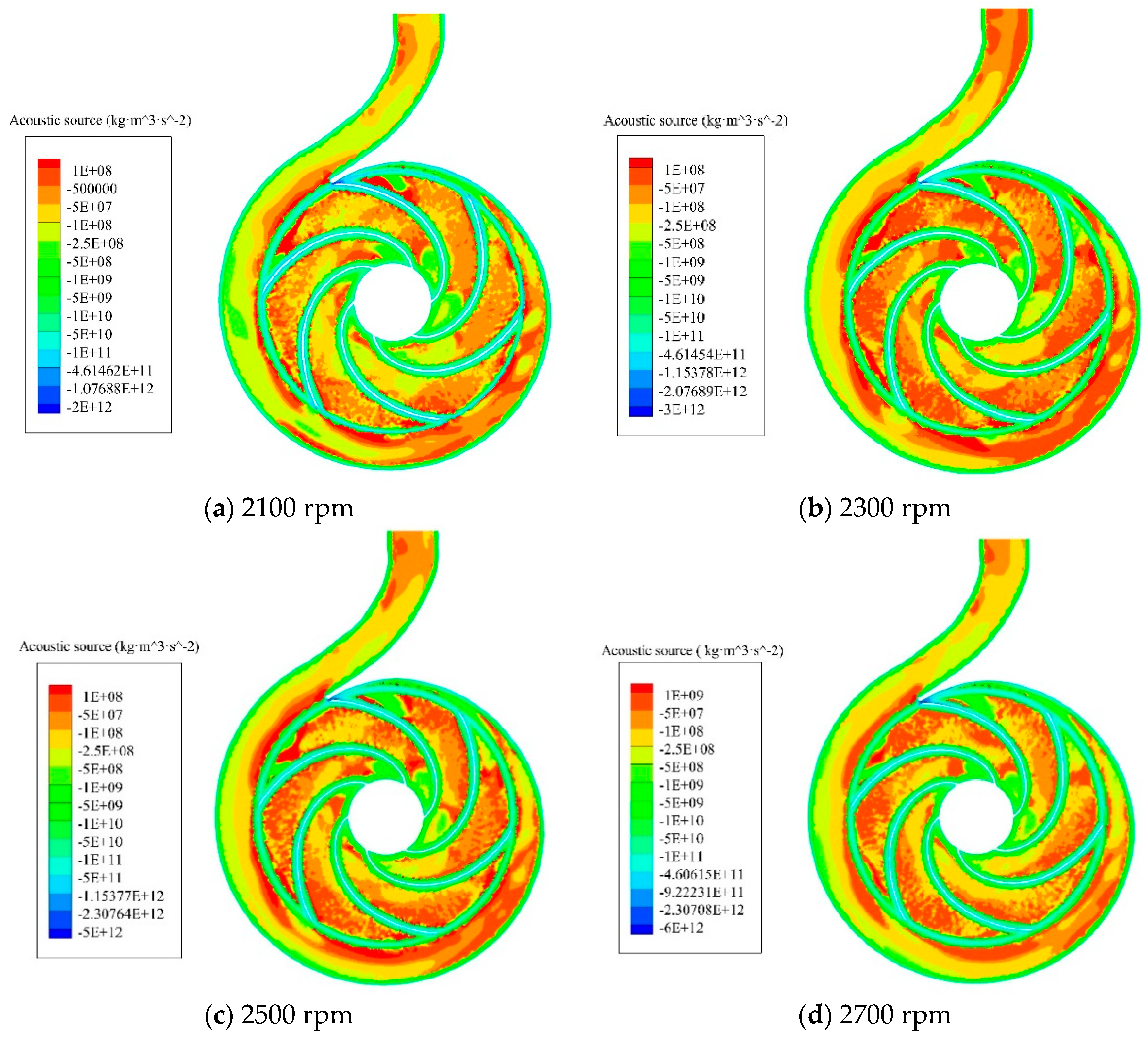

4.2.1. The Distribution and Evolution Characteristics of Acoustic Source

4.2.2. The Distribution and Evolution Characteristics of Acoustic Pressure

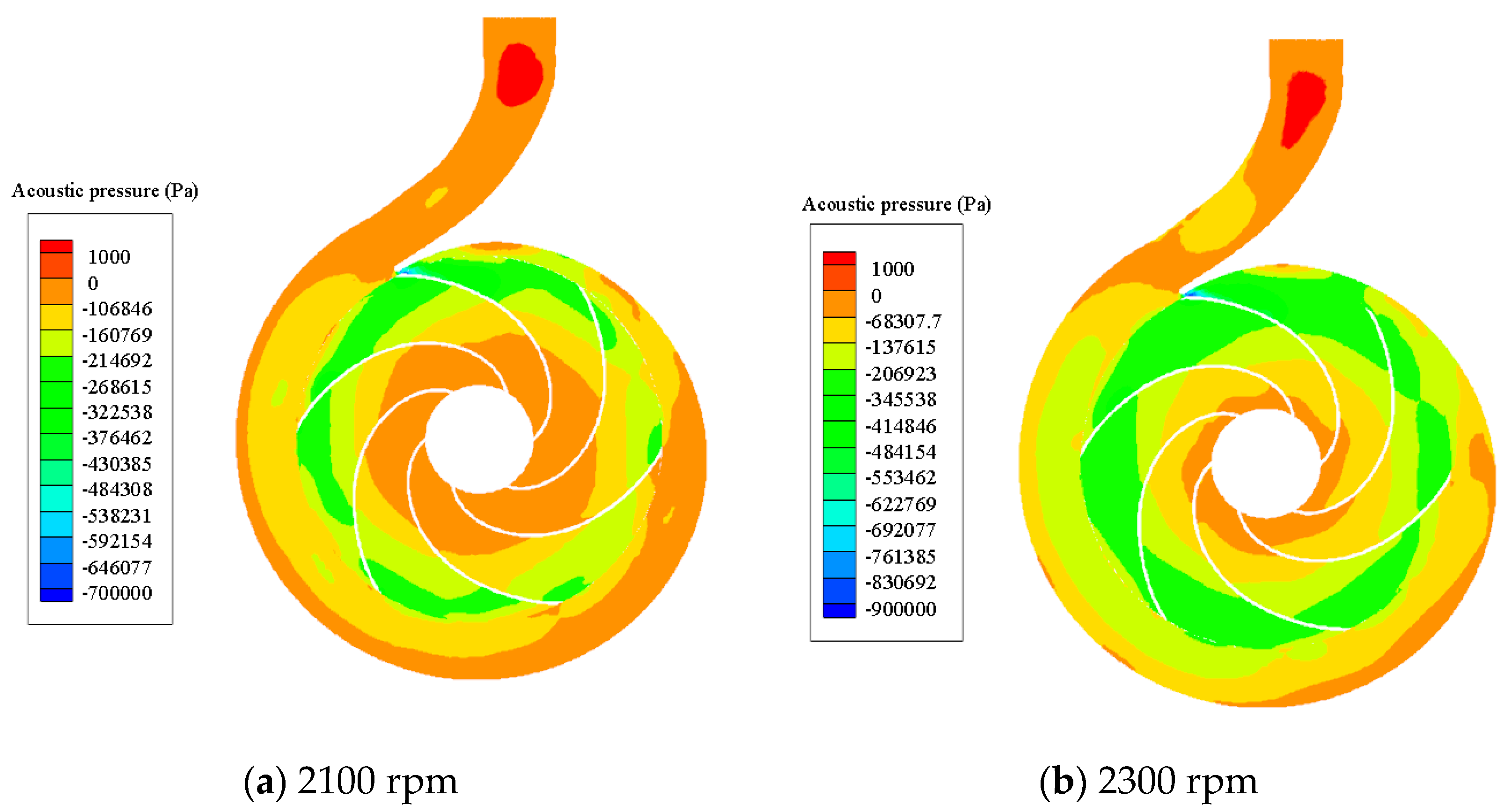

4.3. The Distribution Characteristics of Acoustic Source and Pressure at Various Rotational Speeds

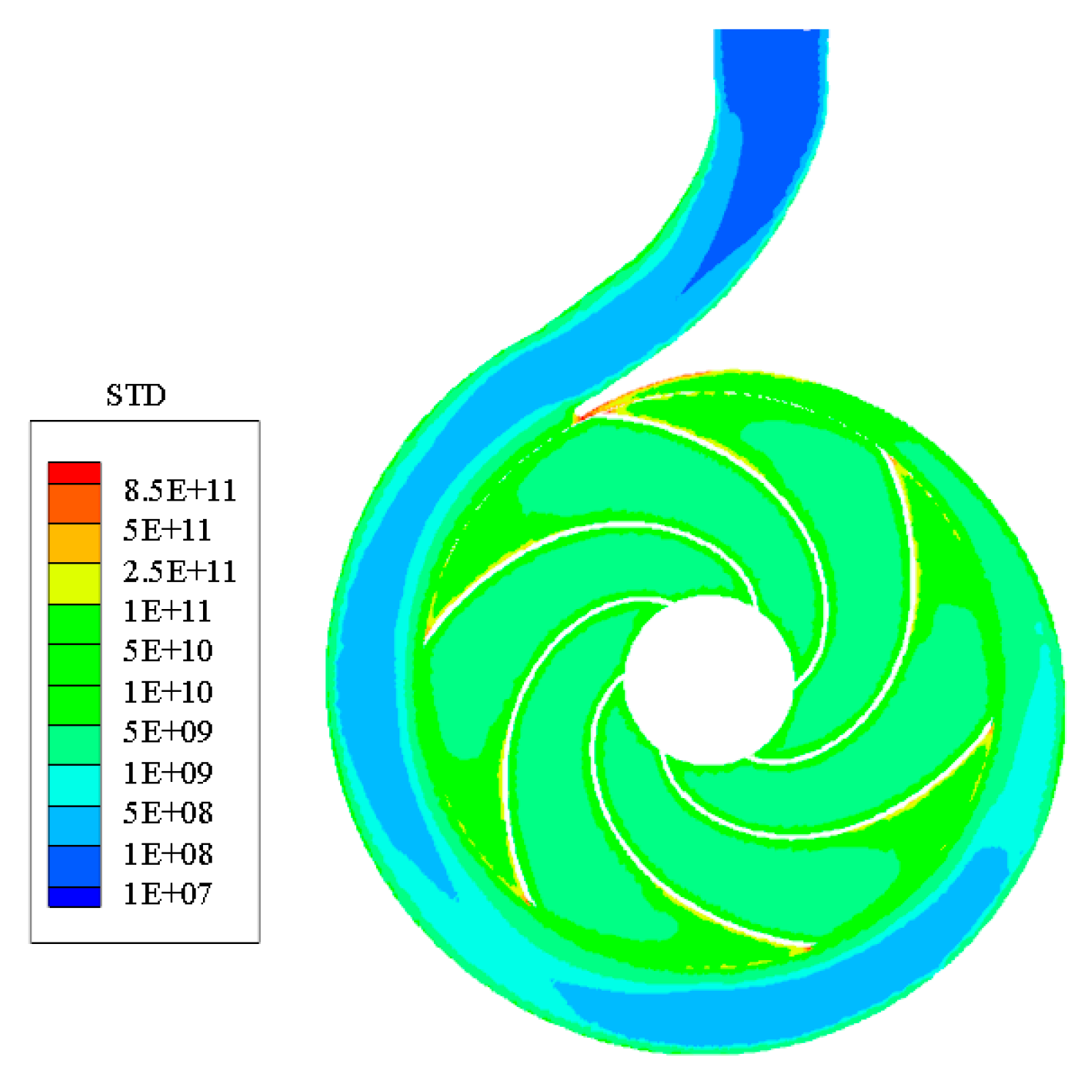

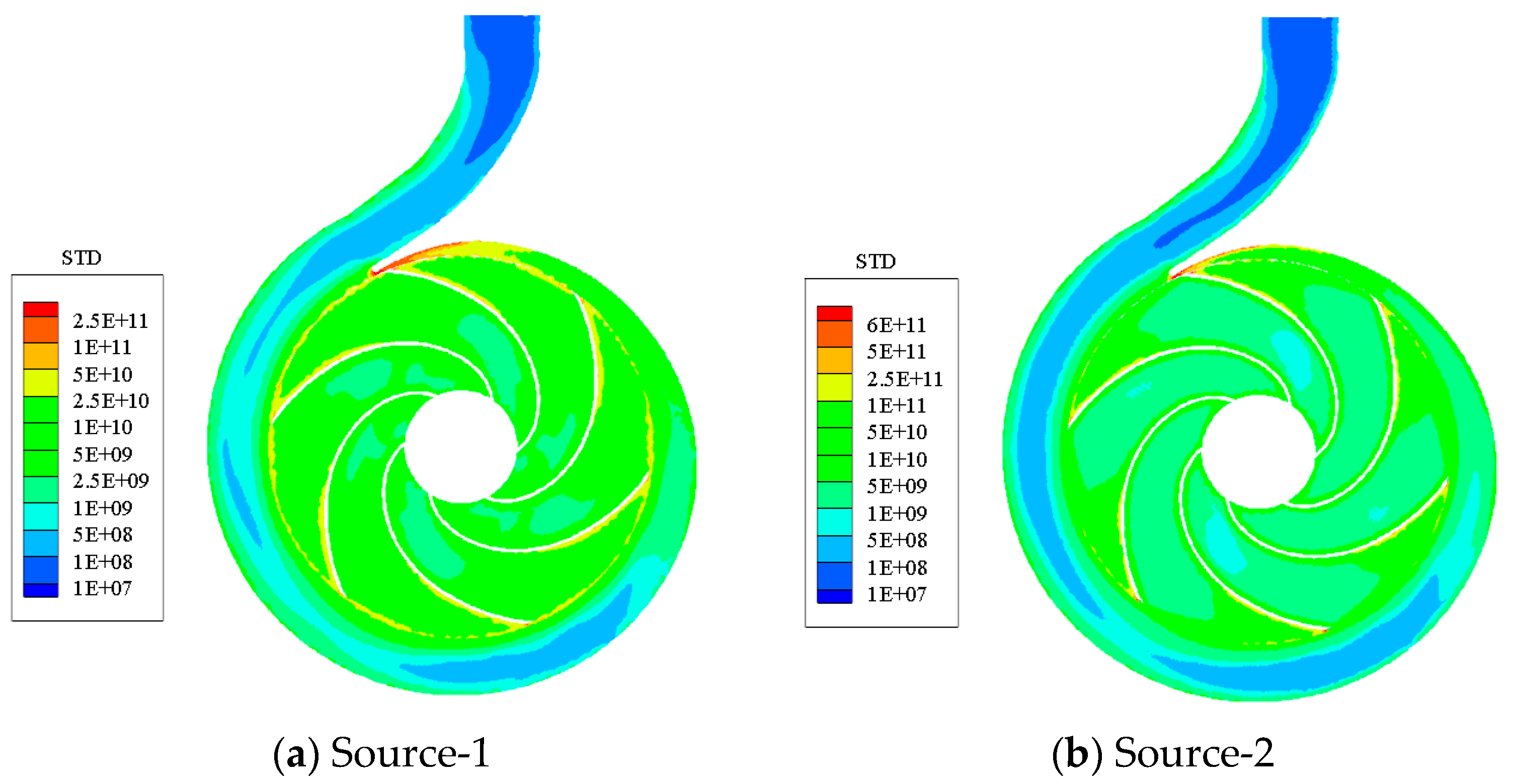

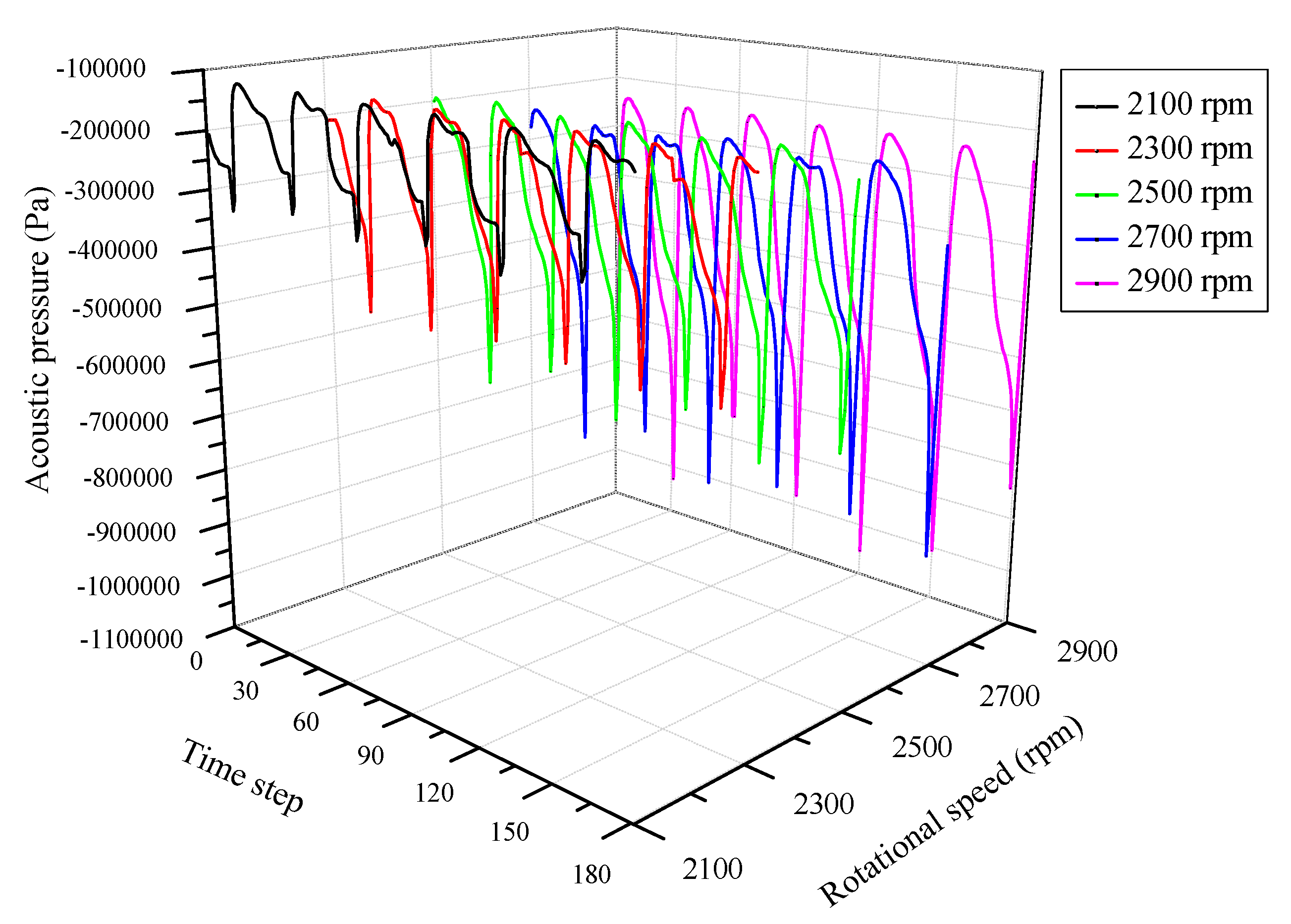

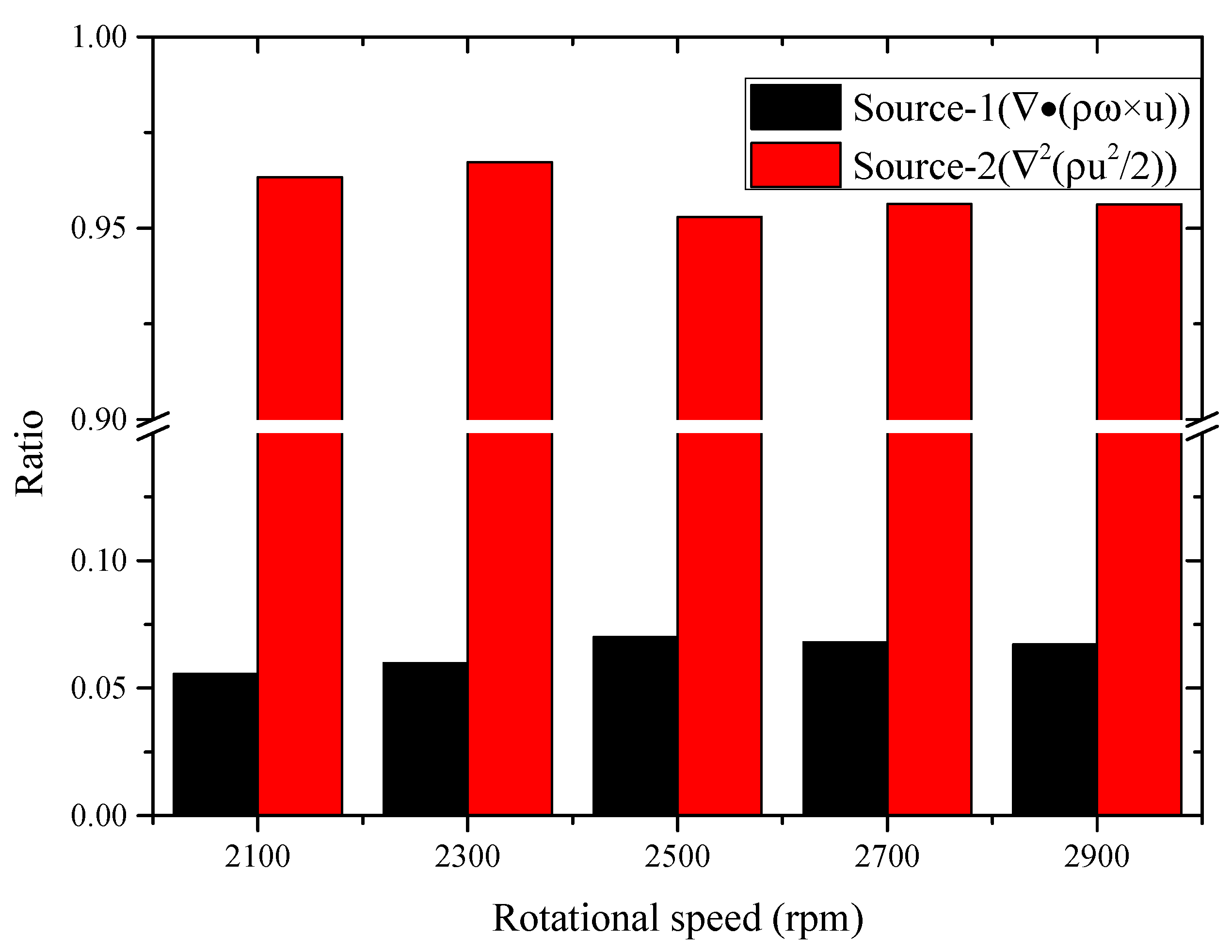

4.4. The Fluctuation Characteristics of Acoustic Source and Pressure Under Various Rotational Speeds

5. Conclusions

- (1)

- In the centrifugal pump, the acoustic source and acoustic pressure are less than 0 basically, and the minimum value of the two parameters is distributed near the volute tongue. Additionally, the concentration, break, extend, migration and reaggregation phenomena of the minimum acoustic source region exist during the fluid motion process. Specifically, the minimum acoustic source region concentrates on the tongue firstly, then extends and migrates downstream slightly, and aggregates again near the tongue, which leads to the similar evolution characteristics of acoustic pressure. Moreover, the distribution and fluctuation characteristics of the two parameters have little change with increasing rotational speed, while the minimum value of the two parameters decreases and the fluctuation range extends generally. The acoustic source distribution and evolution are the fundamental causes of the acoustic pressure distribution and evolution.

- (2)

- The maximum standard deviation (STD) of acoustic source inside the impeller is located near the pressure side of blade tail, while that inside the volute is located near the volute tongue, which is also the region with the largest STD of the whole pump. Compared with the STD of acoustic source component induced by the stretching of the vortex caused by change of velocity (Source-1), the STD of acoustic source component induced by the non-uniformity of fluid kinetic energy (Source-2) is closer to that of overall acoustic source, which is the main noise source. Take the volute tongue as an example, at different rotational speeds, the STD of Source-1 and Source-2 accounts for about 5% and 95%, respectively, which shows that the change of operation condition has little effect on the proportions of different acoustic source components.

Author Contributions

Funding

Conflicts of Interest

References

- Cai, J.; Pan, J.; Guzzomi, A. The flow field in a centrifugal pump with a large tongue gap and back blades. J. Mech. Sci. Technol. 2014, 28, 4455–4464. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, L.; Zhan, Q.; Jiang, K.; Tie, Y.; Wang, S. Effects of the Second-Stage of Rotor with Single Abnormal Blade Angle on Rotating Stall of a Two-Stage Variable Pitch Axial Fan. Energies 2018, 11, 3293. [Google Scholar] [CrossRef]

- Xue, R.; Cai, Y.; Fang, X.; Chen, L.; Zhang, X.; Hou, Y. Optimization Study on a Novel High-Speed Oil-Free Centrifugal Water Pump with Hydrodynamic Bearings. Appl. Sci. 2019, 9, 3050. [Google Scholar] [CrossRef]

- Dong, R.; Chu, S.; Katz, J. Effect of Modification to Tongue and Impeller Geometry on Unsteady Flow, Pressure Fluctuations, and Noise in a Centrifugal Pump. J. Turbomach. 1997, 119, 506–515. [Google Scholar] [CrossRef]

- Rzentkowski, G.; Zbroja, S. Experimental characterization of centrifugal pumps as an acoustic source at the bladde-pasing frequency. J. Fluid Struct. 2000, 14, 529–558. [Google Scholar] [CrossRef]

- Guo, C.; Gao, M.; Lu, D.; Wang, K. An Experimental Study on the Radiation Noise Characteristics of a Centrifugal Pump with Various Working Conditions. Energies 2017, 10, 2139. [Google Scholar] [CrossRef]

- Guo, C.; Gao, M.; Lu, D.; Guan, H. Experimental Study on Radiation Noise Frequency Characteristics of a Centrifugal Pump with Various Rotational Speeds. Appl. Sci. 2018, 8, 796. [Google Scholar] [CrossRef]

- Wang, M.; Freund, J.B.; Lele, S.K. Computational prediction of flow-generated sound. Annu. Rev. Fluid Mech. 2005, 38, 483–512. [Google Scholar] [CrossRef]

- Zhang, N.; Shen, H.; Yao, H. Numerical simulation of cavity flow induced noise by LES and FW-H acoustic analogy. J. Hydrodyn. 2010, 22, 242–247. [Google Scholar] [CrossRef]

- Jung, S.; Sung, H. Flow structure and flow-induced noise in an axisymmetric cavity with lids. J. Mech. Sci. Technol. 2016, 30, 3229–3241. [Google Scholar] [CrossRef]

- Sanghyeon, K.; Cheolung, C.; Warn-Gyu, P. Numerical Investigation into Effects of Viscous Flux Vectors on Hydrofoil Cavitation Flow and Its Radiated Flow Noise. Appl. Sci. 2018, 8, 289. [Google Scholar] [CrossRef]

- Wang, K.; Zhang, Z.; Xia, C.; Liu, Z. Experimental investigation of pressure fluctuation, vibration, and noise in a multistage pump. Shock Vib. 2018, 2018, 2784079. [Google Scholar] [CrossRef]

- Pang, Q. Influence of Radial Clearance of Pump Chamber on Hydraulic and Noise Performance of Multistage Centrifugal Pump. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2018. [Google Scholar]

- Wang, K.; Li, Y.; Liu, H.; Xia, C.; Liu, Z. Numerical simulation for hydrodynamic noise of a multistage centrifugal pump under multi-working condition. J. Vib. Shock 2018, 37, 50–55. [Google Scholar]

- Liu, H.; Ding, J.; Dai, H.; Tan, M.; Tang, X. Numerical Research on Hydraulically Generated Vibration and Noise of a Centrifugal Pump Volute with Impeller Outlet Width Variation. Math. Probl. Eng. 2014, 2014, 620389. [Google Scholar] [CrossRef]

- Liu, H.; Dai, H.; Ding, J.; Tan, M.; Wang, Y.; Huang, H. Numerical and experimental studies of hydraulic noise induced by surface dipole sources in a centrifugal pump. J. Hydrodyn. 2016, 28, 43–51. [Google Scholar] [CrossRef]

- Gao, M.; Dong, P.; Lei, S.; Turan, A. Computational Study of the Noise Radiation in a Centrifugal Pump When Flow Rate Changes. Energies 2017, 10, 221. [Google Scholar] [CrossRef]

- Liu, H.; Li, Y.; Wang, K.; Liu, Z. Study on radiated noise characteristics of multistage centrifugal pump under fluid excitation. J. Huazhong Univ. Sci. Technol. 2017, 45, 92–97. [Google Scholar]

- Zhang, Q. Fundamentals of Aeroacoustics; National Defense Industry Press: Beijing, China, 2012. [Google Scholar]

- Powell, A. Theory of vortex sound. J. Acoust. Soc. Am. 1964, 36, 177–195. [Google Scholar] [CrossRef]

- Howe, M.S. Contributions to the theory of aerodynamic sound with application to excess jet noise and the theory of the flute. J. Fluid Mech. 1975, 71, 625–673. [Google Scholar] [CrossRef]

- Takaishi, T.; Miyazawa, M.; Kato, C. A computational method of evaluating noncompact sound based on vortex sound theory. J. Acoust. Soc. Am. 2007, 121, 1353–1361. [Google Scholar] [CrossRef]

- Schram, C.; Hirschberg, A. Application of vortex sound theory to vortex-pairing noise: Sensitivity to errors in flow data. J. Sound Vib. 2003, 266, 1079–1098. [Google Scholar] [CrossRef]

- Liu, Q.; Qi, D.; Tang, H. Computation of aerodynamic noise of centrifugal fan using large eddy simulation approach, acoustic analogy, and vortex sound theory. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2007, 221, 1321–1332. [Google Scholar] [CrossRef]

- Ou, Y.; Tian, J.; Wu, Y.; Du, Z. Research of aerodynamic noise source of low speed axial fans based on vortex-sound theory. J. Eng. Therm. 2009, 30, 765–768. [Google Scholar]

- Wang, C.; Zhang, T.; Hou, G. Noise Prediction of Submerged Free Jet Based on Theory of Vortex Sound. J. Ship Mech. 2010, 14, 670–677. [Google Scholar]

- Cao, Y.; Ke, H.; Lin, Y.; Zeng, M.; Wang, Q. Investigation on the flow noise propagation mechanism in pipelines of shell-and-tube heat exchangers based on synergy principle of flow and sound fields. Appl. Therm. Eng. 2017, 122, 339–349. [Google Scholar] [CrossRef]

- Guo, C.; Gao, M.; Wang, J.; Shi, Y.; He, S. The effect of blade outlet angle on the acoustic field distribution characteristics of a centrifugal pump based on Powell vortex sound theory. Appl. Acoust. 2019, 155, 297–308. [Google Scholar] [CrossRef]

- Du, G.; Zhu, Z.; Gong, X. Fundamentals of Acoustics; Nanjing University Press: Nanjing, China, 2001. [Google Scholar]

- Li, J. The Influence of the Uneven Spaced Stator Cascade on the Flow-Induced Noise Characteristics in a Vaned Centrifugal Pump. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China, 2015. [Google Scholar]

- Xuan, L.; Gong, J.; Zhang, W.; Yuan, X. An implicit finite volume method for the acoustic wave equation. J. Harbin Inst. Technol. 2016, 48, 145–149. [Google Scholar]

- Zhang, N.; Li, Y.; Wang, Z.; Wang, X.; Zhang, X. Numerical simulation on the flow-induced noise of cavity by LES and Powell vortex sound theory. J. Ship Mech. 2015, 19, 1393–1408. [Google Scholar]

| Parameter | Value |

|---|---|

| Inlet diameter | 80 mm |

| Impeller diameter | 250 mm |

| Outlet diameter | 50 mm |

| Rated rotating speed | 2900 rpm |

| Rated flow rate | 50 m3/h |

| Design head | 80 m |

| Blade number | 6 |

| Steady Simulation | Unsteady Simulation | |

|---|---|---|

| Viscous model | k-ε model | |

| Motion type | Moving Reference Frame | Moving Mesh |

| Inlet | Velocity inlet | |

| Outlet | Outflow | |

| Walls | No slip boundary conditions | |

| Pressure-velocity coupling algorithm | SIMPLE | |

| Discretization principle | Second order upwind | |

| Apparatus | Type | Range | Accuracy or Sensitivity |

|---|---|---|---|

| Hydrophone | DHP8501 | 20–20 kHz | −210 dB (sensitivity) ±1.5 dB (accuracy) |

| USB switch | / | / | / |

| Noise analysis software | / | / | / |

| Flow meter | SLDG-800 | 0–100 m3/h | 0.2% (accuracy) |

| Rotational Speed (rpm) | Flow-Induced Noise | Experiment (dB) | Simulation (dB) | Deviation (%) |

|---|---|---|---|---|

| 2100 | APL (fb) | 150.55 | 142.66 | −5.24% |

| APL (2fb) | 120.56 | 117.67 | −2.40% | |

| TAPL | 171.18 | 169.22 | −1.15% | |

| 2500 | APL (fb) | 150 | 160.35 | 6.90% |

| APL (2fb) | 131.13 | 126.24 | −3.73% | |

| TAPL | 174.48 | 172.07 | −1.38% | |

| 2900 | APL (fb) | 152 | 156.33 | 2.85% |

| APL (2fb) | 136.41 | 135.13 | −0.94% | |

| TAPL | 181.82 | 180.57 | −0.69% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, C.; Wang, J.; Gao, M. A Numerical Study on the Distribution and Evolution Characteristics of an Acoustic Field in the Time Domain of a Centrifugal Pump Based on Powell Vortex Sound Theory. Appl. Sci. 2019, 9, 5018. https://doi.org/10.3390/app9235018

Guo C, Wang J, Gao M. A Numerical Study on the Distribution and Evolution Characteristics of an Acoustic Field in the Time Domain of a Centrifugal Pump Based on Powell Vortex Sound Theory. Applied Sciences. 2019; 9(23):5018. https://doi.org/10.3390/app9235018

Chicago/Turabian StyleGuo, Chang, Jingying Wang, and Ming Gao. 2019. "A Numerical Study on the Distribution and Evolution Characteristics of an Acoustic Field in the Time Domain of a Centrifugal Pump Based on Powell Vortex Sound Theory" Applied Sciences 9, no. 23: 5018. https://doi.org/10.3390/app9235018

APA StyleGuo, C., Wang, J., & Gao, M. (2019). A Numerical Study on the Distribution and Evolution Characteristics of an Acoustic Field in the Time Domain of a Centrifugal Pump Based on Powell Vortex Sound Theory. Applied Sciences, 9(23), 5018. https://doi.org/10.3390/app9235018