Experimental Investigation of Concrete with Recycled Aggregates for Suitability in Concrete Structures

Abstract

1. Introduction

2. Materials and Methods

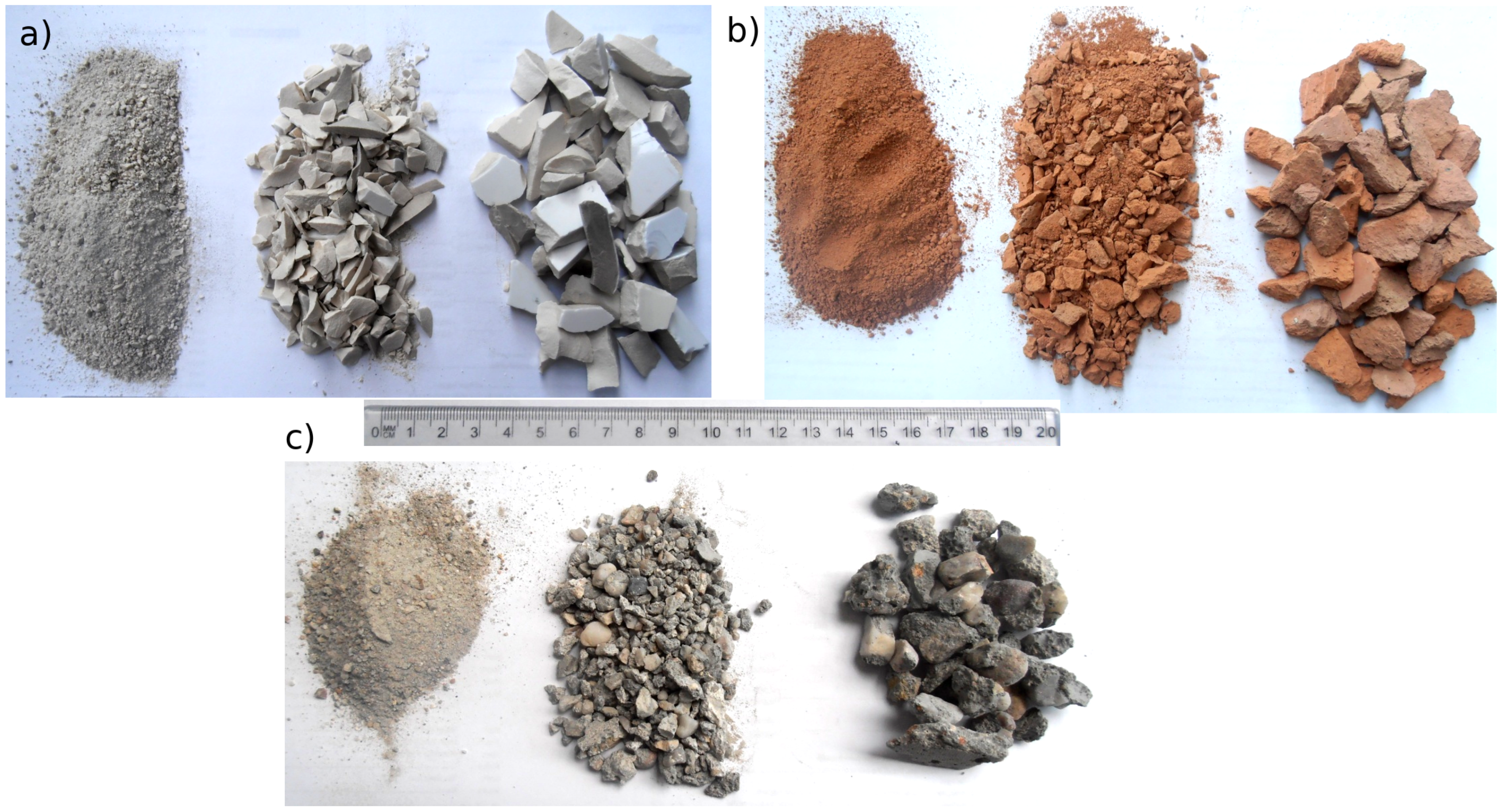

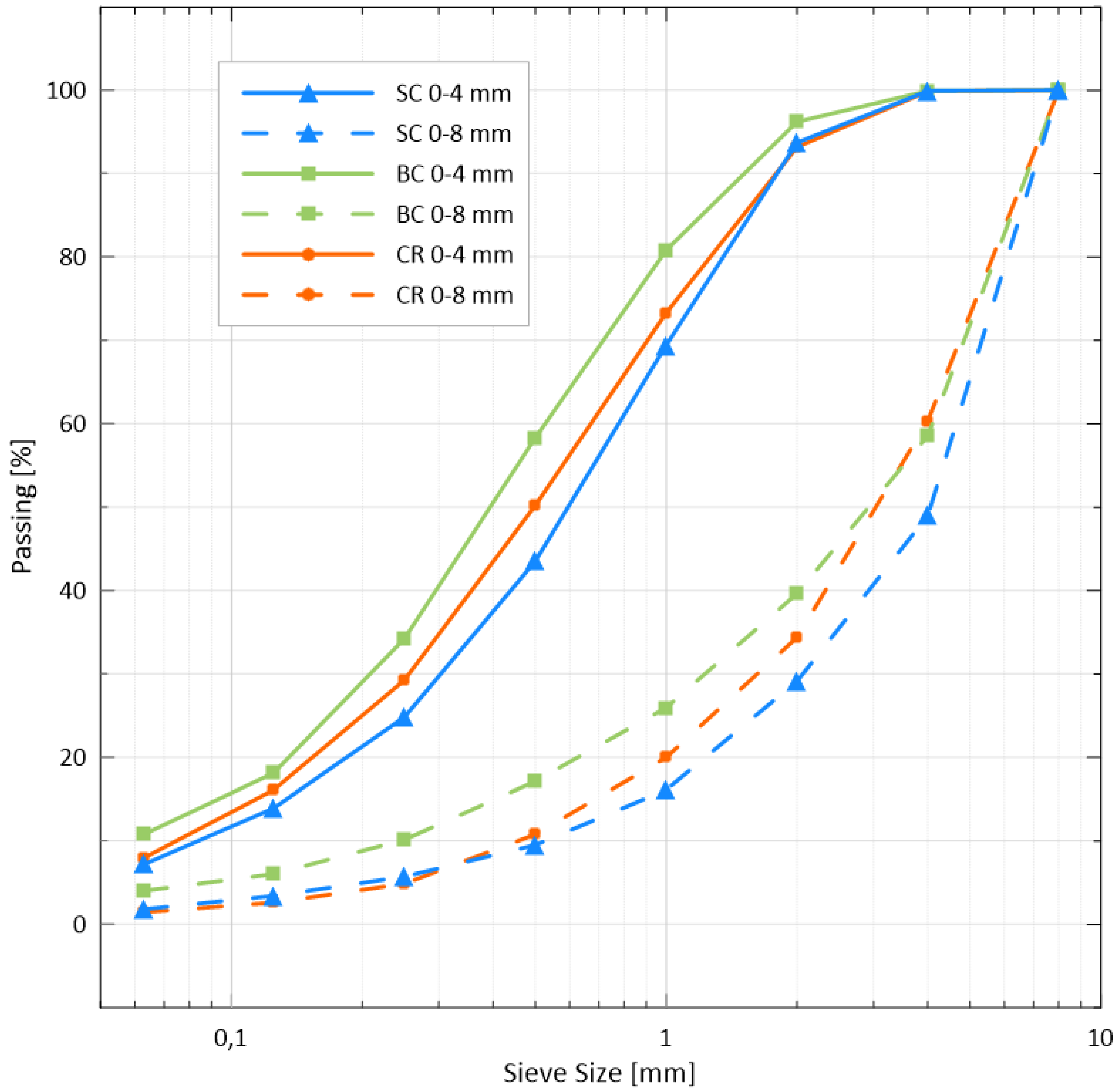

2.1. Aggregate

2.2. Mix Design

2.3. Types of Samples and Research Methods

- SC—concrete based on fine aggregate (fractions 0–4 mm and 0–8 mm) made of sanitary ceramics,

- BC—concrete based on fine aggregate (fractions 0–4 mm and 0–8 mm) made of building ceramics,

- CR—concrete based on aggregate made of concrete rubble (fractions 0–4 mm, 0–8 mm, and 8–16 mm).

3. Results

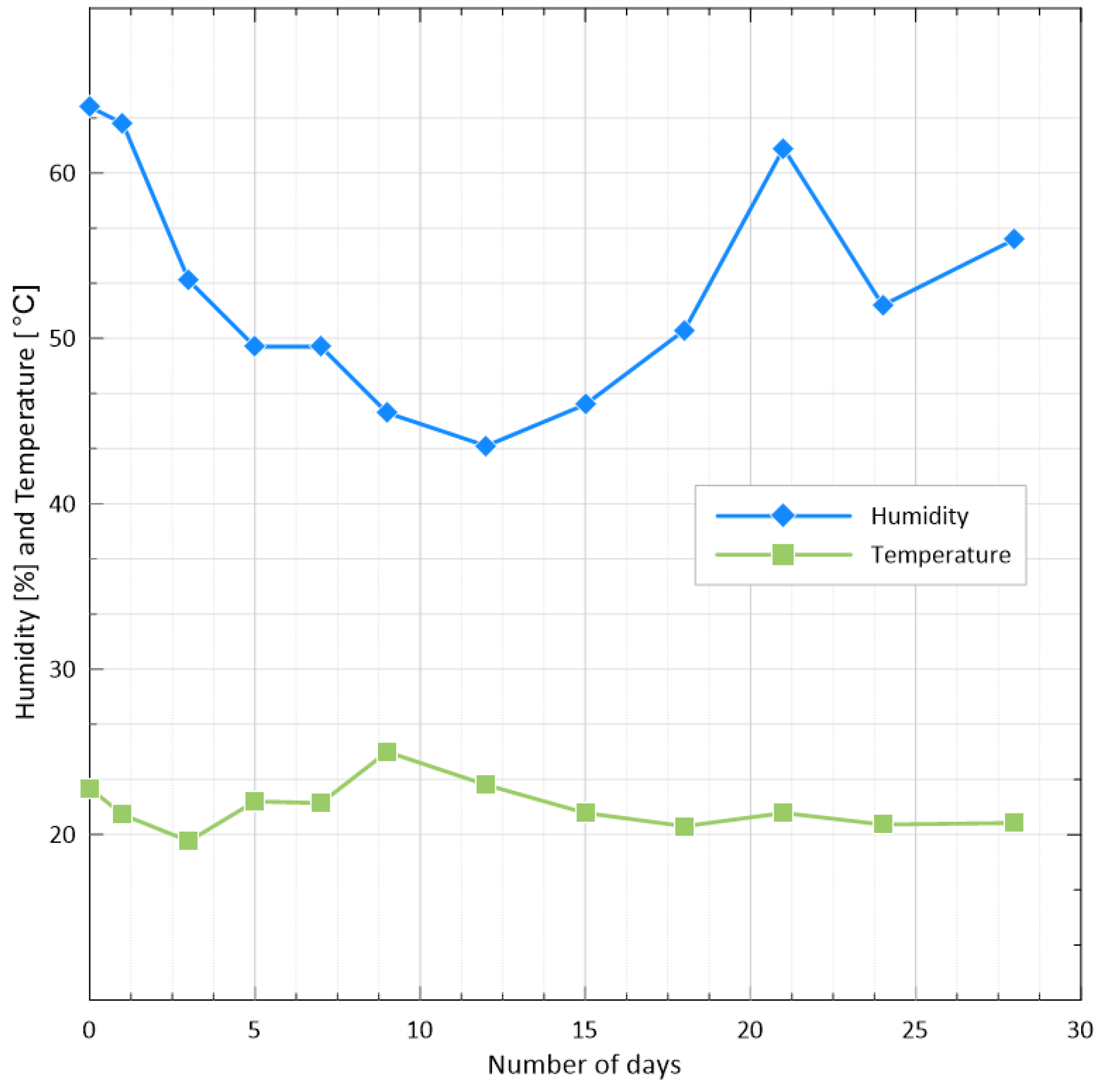

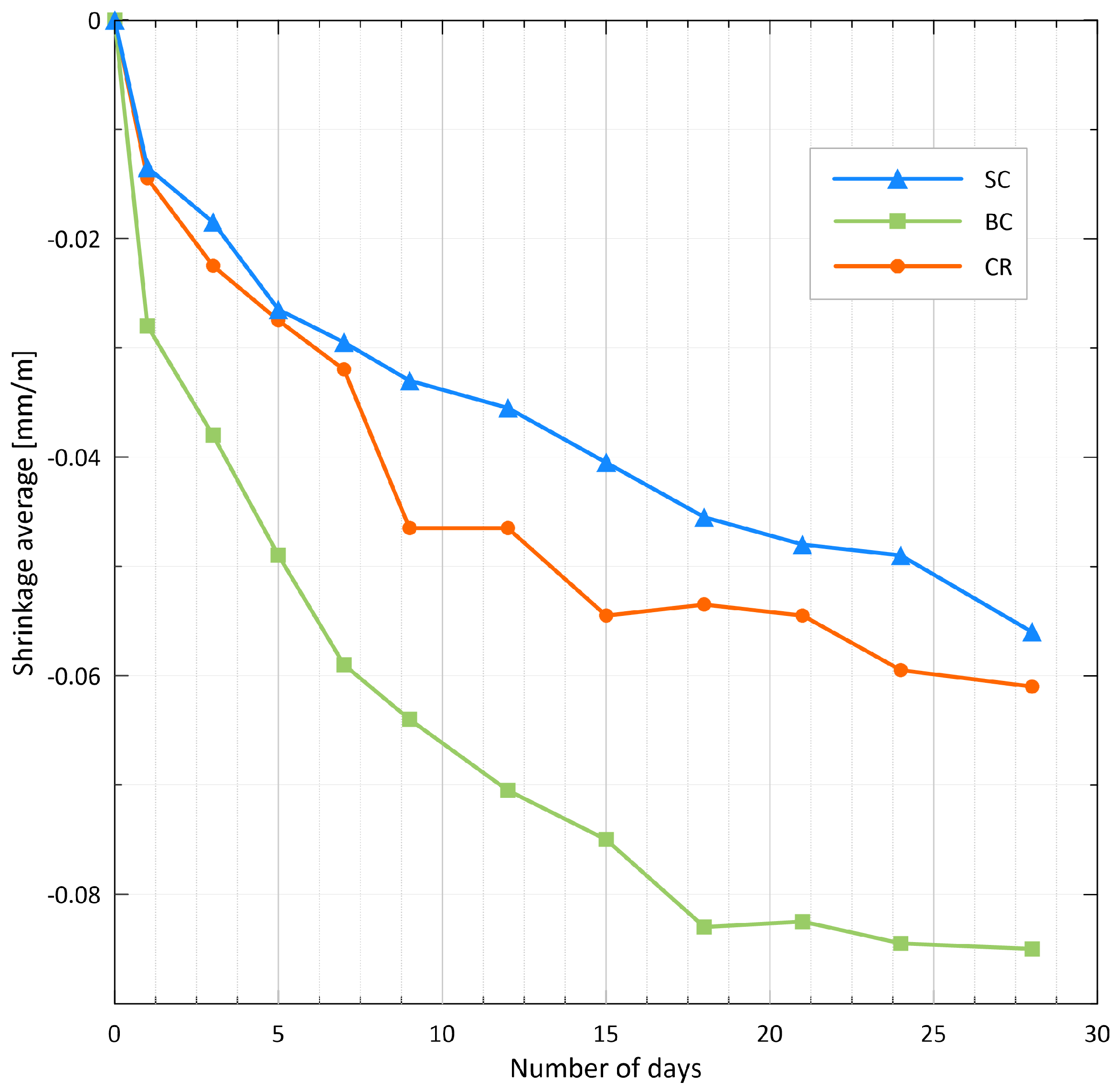

3.1. Shrinkage

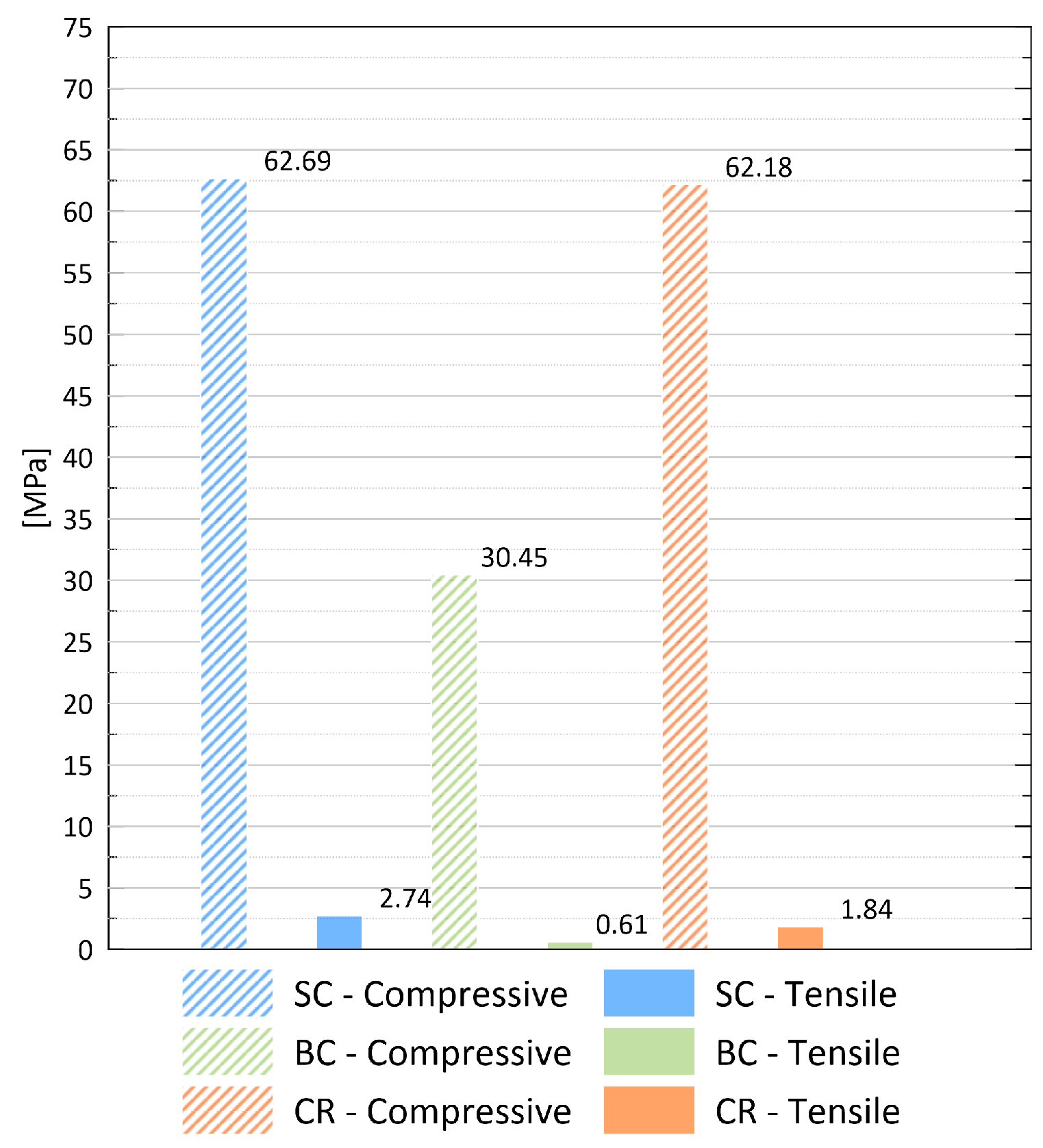

3.2. Strength

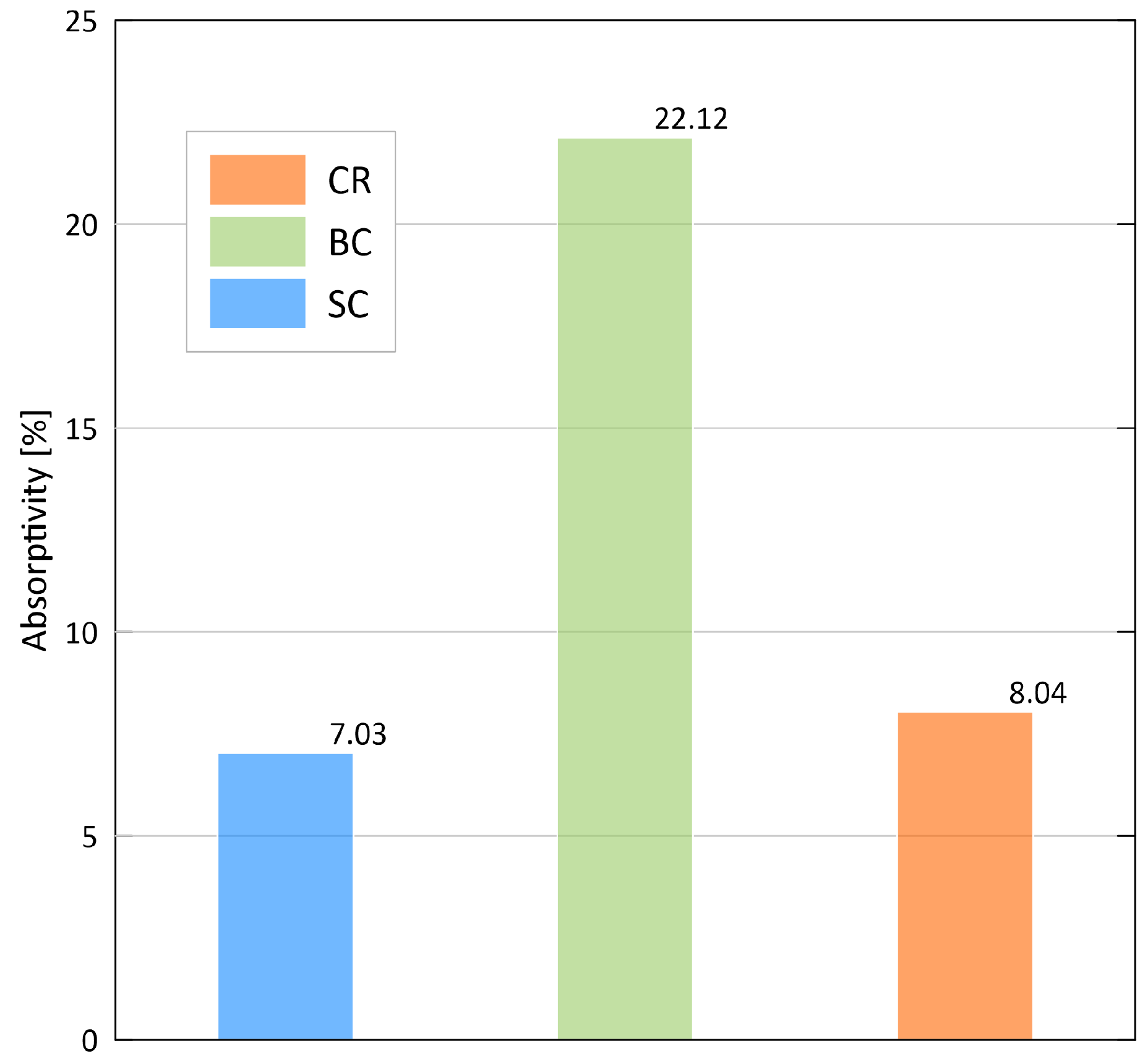

3.3. Water Absorption

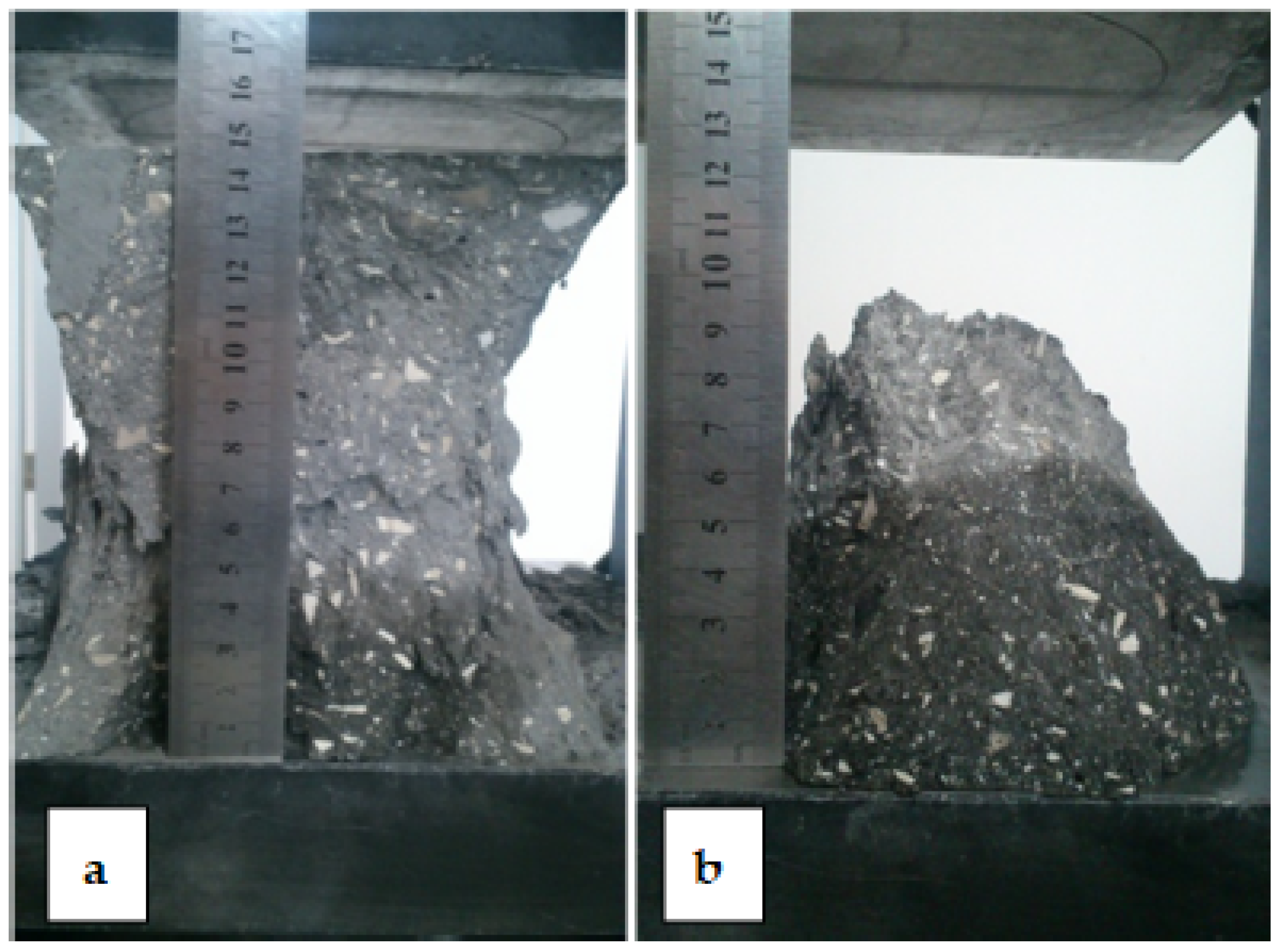

3.4. Water Tightness

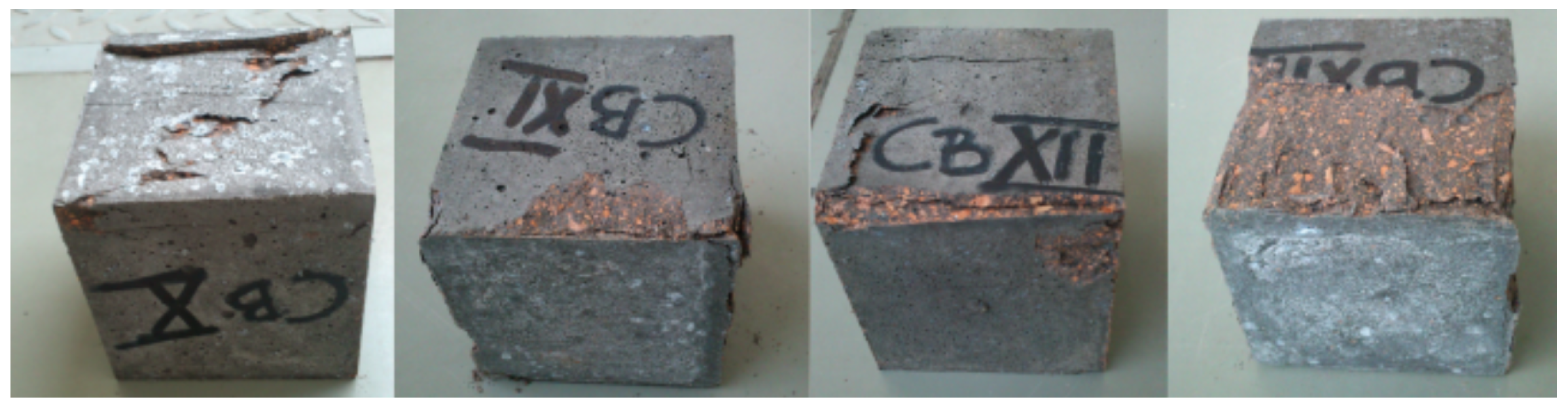

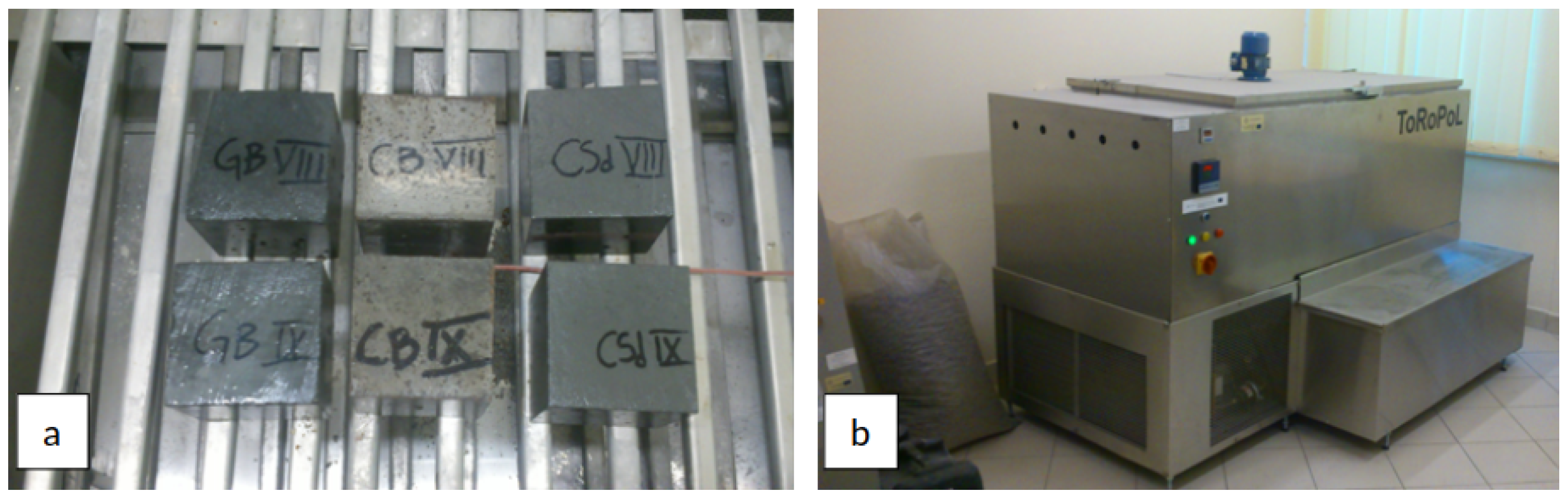

3.5. Frost Resistance

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Alexander, M.; Mindess, S. Aggregates in Concrete; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Kozioł, W.; Kawalec, P.; Cheaper and friendlier for the environment. Alternative aggregates in construction. Mod. Constr. Eng. 2008, 4, 34–37. (In Polish) [Google Scholar]

- Gonzalez-Corominas, A.; Etxeberria, M.; Poon, C.S. Influence of steam curing on the pore structures and mechanical properties of flyash high performance concrete prepared with recycled aggregates. Cem. Concr. Compos. 2016, 71, 77–84. [Google Scholar] [CrossRef]

- Pacheco, J.; Brito, J.; Ferreira, J.; Soares, D. Dynamic characterization of full-scale structures made with recycled coarse aggregates. J. Clean. Prod. 2017, 142, 4195–4205. [Google Scholar] [CrossRef]

- Dong, S.; Hao, P.; Tighe, S.L. A diagnostic method for evaluating the condition index of cement-stabilised base using T-S fuzzy neural network. Int. J. Pavement Eng. 2017, 20, 1140–1153. [Google Scholar] [CrossRef]

- Li, X. Recycling and reuse of waste concrete in china: Part I. material behaviour of recycled aggregate concrete. Resour. Conserv. Recycl. 2008, 53, 36–44. [Google Scholar] [CrossRef]

- Abbas, A.; Fathifazl, G.; Fournier, B.; Isgor, O.B.; Zavadil, R.; Razaqpur, A.G.; Foo, S. Quantification of the residual mortar content in recycled concrete aggregates by image analysis. Mater. Charact. 2009, 60, 716–728. [Google Scholar] [CrossRef]

- Cao, W.; Zhang, J.; Dong, H.; Qiao, Q.; Zhou, Z. Experimental research on moderate strength recycled aggregate concrete floor slabs. J. Nat. Disasters 2015, 3, 112–119. [Google Scholar]

- De Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- López-Gayarre, F.; Serna, P.; Domingo-Cabo, A.; Serrano-López, M.A.; López-Colina, C. Influence of recycled aggregate quality and proportioning criteria on recycled concrete properties. Waste Manag. 2009, 29, 3022–3028. [Google Scholar] [CrossRef]

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Tam, V.W.; Gao, X.F.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef]

- Tam, V.W.; Le, K.N. Aggregate testing using 2nd-, 7th- and 10th-order interpolation polynomials. Resour. Conserv. Recycl. 2007, 52, 39–57. [Google Scholar] [CrossRef][Green Version]

- Xiao, J.; Li, H.; Yang, Z. Fatigue behavior of recycled aggregate concrete under compression and bending cyclic loadings. Constr. Build. Mater. 2013, 38, 681–688. [Google Scholar] [CrossRef]

- Li, C.; Geng, H.; Deng, C.; Li, B.; Zhao, S. Experimental Investigation on Columns of Steel Fiber Reinforced Concrete with Recycled Aggregates under Large Eccentric Compression Load. Materials 2019, 12, 445. [Google Scholar] [CrossRef]

- Kim, J.-H.; Sung, J.-H.; Jeon, C.-S.; Lee, S.-H.; Kim, H.-S. A Study on the Properties of Recycled Aggregate Concrete and Its Production Facilities. Appl. Sci. 2019, 9, 1935. [Google Scholar] [CrossRef]

- Junak, J.; Sicakova, A. Effect of Surface Modifications of Recycled Concrete Aggregate on Concrete Properties. Buildings 2018, 8, 2. [Google Scholar] [CrossRef]

- Al Ajmani, H.; Suleiman, F.; Abuzayed, I.; Tamimi, A. Evaluation of Concrete Strength Made with Recycled Aggregate. Buildings 2019, 9, 56. [Google Scholar] [CrossRef]

- Shaikh, F. Mechanical and Durability Properties of Green Star Concretes. Buildings 2018, 8, 111. [Google Scholar] [CrossRef]

- Yang, J.; Peng, G.-F.; Shui, G.-S.; Zhang, G. Mechanical Properties and Anti-Spalling Behavior of Ultra-High Performance Concrete with Recycled and Industrial Steel Fibers. Materials 2019, 12, 783. [Google Scholar] [CrossRef]

- Everaert, M.; Stein, R.; Michaux, S.; Goovaerts, V.; Groffils, C.; Delvoie, S.; Zhao, Z.; Snellings, R.; Nielsen, P.; Broos, K. Microwave Radiation as a Pre-Treatment for Standard and Innovative Fragmentation Techniques in Concrete Recycling. Materials 2019, 12, 488. [Google Scholar] [CrossRef]

- Rodríguez, C.; Miñano, I.; Aguilar, M.Á.; Ortega, J.M.; Parra, C.; Sánchez, I. Properties of Concrete Paving Blocks and Hollow Tiles with Recycled Aggregate from Construction and Demolition Wastes. Materials 2017, 10, 1374. [Google Scholar] [CrossRef] [PubMed]

- Fraile-Garcia, E.; Ferreiro-Cabello, J.; López-Ochoa, L.M.; López-González, L.M. Study of the Technical Feasibility of Increasing the Amount of Recycled Concrete Waste Used in Ready-Mix Concrete Production. Materials 2017, 10, 817. [Google Scholar] [CrossRef] [PubMed]

- Pawluczuk, E.; Kalinowska-Wichrowska, K.; Bołtryk, M.; Jiménez, J.R.; Fernández, J.M. The Influence of Heat and Mechanical Treatment of Concrete Rubble on the Properties of Recycled Aggregate Concrete. Materials 2019, 12, 367. [Google Scholar] [CrossRef] [PubMed]

- Ogrodnik, P.; Szulej, J.; Franus, W. The Wastes of Sanitary Ceramics as Recycling Aggregate to Special Concretes. Materials 2018, 11, 1275. [Google Scholar] [CrossRef] [PubMed]

- Duan, Z.; Hou, S.; Poon, C.-S.; Xiao, J.; Liu, Y. Using Neural Networks to Determine the Significance of Aggregate Characteristics Affecting the Mechanical Properties of Recycled Aggregate Concrete. Appl. Sci. 2018, 8, 2171. [Google Scholar] [CrossRef]

- Tamayo-García, B.; Albareda-Valls, A.; Rivera-Rogel, A.; Cornado, C. Mechanical Characterization of a New Architectural Concrete with Glass-Recycled Aggregate. Buildings 2019, 9, 145. [Google Scholar] [CrossRef]

- Gawenda, T.; Naziemiec, Z.; Walerak, A. Studies of selected properties of aggregates from waste ceramic and concrete prepared with their participation. Yearb. Environ. Prot. 2013, 15, 2003–2021. (In Polish) [Google Scholar]

- Halicka, A.; Zegardło, B. Sanitary ceramic waste as a concrete aggregate. Build. Rev. 2011, 7–8, 51–55. (In Polish) [Google Scholar]

- Zegardło, B.; Halicka, A. Properties of concrete with aggregate obtained from waste sanitary ceramics. Build. Rev. 2012, 11, 24–28. (In Polish) [Google Scholar]

- Halicka, A.; Ogrodnik, P.; Zegardło, B. The use of sanitary ceramic waste as aggregate in the concrete resistant to high temperatures. Build. Archit. 2013, 12, 153–160. (In Polish) [Google Scholar]

- Zegardło, B.; Brzyski, P.; Rymuza, K.; Bombik, A. Analysis of the Effects of Aggressive Environments Simulating Municipal Sewage on Recycled Concretes Based on Selected Ceramic Waste. Materials 2018, 11, 2565. [Google Scholar] [CrossRef] [PubMed]

- Zaharieva, R.; Buyle-Bodin, F.; Wirquin, E. Frost resistance of recycled aggregate concrete. Cem. Concr. Res. 2004, 34, 1927–1932. [Google Scholar] [CrossRef]

- Šeps, K.; Fládr, J.; Broukalová, I. Resistance of recycled aggregate concrete to freeze-thaw and deicing salts. Procedia Eng. 2016, 151, 329–336. [Google Scholar] [CrossRef]

- Denisiewicz, A. Reactive powder concrete and their use in complex constructions. Constr. Build. Mater. 2014, 85, 18–23. (In Polish) [Google Scholar]

- Śliwiński, J. General principles of designing high-quality concretes. Build. Technol. Archit. Spec. Issue Admix. Concr. 2003, 2, 29–31. (In Polish) [Google Scholar]

- Polish Committee for Standardization. PN-EN 197-1:2012 Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Use Cements; PKN: Warsaw, Poland, 2012. [Google Scholar]

- Polish Committee for Standardization. PN-EN 13263-1+A1:2010 Silica Fume for Concrete—Part 1: Definitions, Requirements and Conformity Criteria; PKN: Warsaw, Poland, 2010. [Google Scholar]

- Polish Committee for Standardization. PN-EN 934-2+A1:2012 Admixtures for Concrete, Mortar and Grout—Part 2: Concrete Admixtures—Definitions, Requirements, Conformity, Labeling; PKN: Warsaw, Poland, 2012. [Google Scholar]

- Polish Committee for Standardization. PN-88/B-06250 Plain Concrete in Polish; PKN: Warsaw, Poland, 1988. [Google Scholar]

- Polish Committee for Standardization. PN-EN 206:2014-04 Concrete—Requirements, Properties, Production and Compliance; PKN: Warsaw, Poland, 2014. [Google Scholar]

| Symbol | Fraction [mm] | Volumetric Density [kg/m] | Average Volumetric Density [kg/m] |

|---|---|---|---|

| 0–4 | 1463.3 | ||

| SC | 0–8 | 1212.2 | 1274.3 |

| 8–16 | 1147.3 | ||

| 0–4 | 1067.2 | ||

| BC | 0–8 | 976.6 | 932.9 |

| 8–16 | 755.1 | ||

| 0–4 | 1518.1 | ||

| CR | 0–8 | 1376.1 | 1347.1 |

| 8–16 | 1147.0 |

| Mixture SC [kg/m] | Mixture BC [kg/m] | Mixture CR [kg/m] | |

|---|---|---|---|

| Cement CEM I 42,5R | 600 | 600 | 600 |

| Silica fume | 150 | 150 | 150 |

| Water | 300 | 490 | 300 |

| Plasticizer | 20 | 20 | 20 |

| SC 0–4 mm | 760 | - | - |

| SC 0–8 mm | 330 | - | - |

| BC 0–4 mm | - | 460 | - |

| BC 0–8 mm | - | 150 | - |

| CR 0–4 mm | - | - | 740 |

| CR 0–8 mm | - | - | 250 |

| CR 8–16 mm | - | - | 100 |

| Tightness | 1.0 | 1.0 | 1.0 |

| Strength estimated using Formula (1) [Mpa] | 61.8 | 28.3 | 61.8 |

| w/c | 0.50 | 0.82 | 0.50 |

| w/b | 0.40 | 0.65 | 0.40 |

| Pk/C | 0.25 | 0.25 | 0.25 |

| P/c [%] | 3.33 | 3.33 | 3.33 |

| P/s [%] | 2.67 | 2.67 | 2.67 |

| w/c—water–cement ratio | |||

| S—binder = cement + silca fume | |||

| w/b—water–binder ratio | |||

| Pk/C—silca fume–cement ratio | |||

| P/C—plasticizer–cement ratio | |||

| P/S—plasticizer–binder ratio | |||

| Sample | Compressive Strength | Maximum Height of Water Absorption [mm] | ||||

|---|---|---|---|---|---|---|

| F [kN] | R [N/mm] | At the Edge | Average | In the Middle | Average | |

| SC III | 1437.5 | 63.9 | 47 | 65 | ||

| SC IV | 956.8 | 42.5 | 40 | 39 | 47 | 57 |

| SC V | 930.7 | 41.4 | 30 | 59 | ||

| CR III | 1242.2 | 55.2 | 40 | 68 | ||

| CR IV | 1206.3 | 53.6 | 55 | 44 | 80 | 69 |

| CR V | 1437.7 | 63.9 | 38 | 60 | ||

| BC III | 641.6 | 28.5 | 58 | 100 | ||

| BC IV | 760.8 | 33.8 | 50 | 54 | 60 | 86 |

| BC V | 699.1 | 31.1 | 54 | 97 | ||

| Sample | [g] | [g] | [%] | [MPa] | [MPa] | [%] |

|---|---|---|---|---|---|---|

| SC | 1942.9 | 1933.3 | 0.5 | 50.5 | 45.3 | 10.3 |

| CR | 2121.8 | 2076.1 | 2.2 | 55.3 | 53.5 | 3.3 |

| BC | 1674.0 | 1632.7 | 2.5 | 26.7 | 23.5 | 11.9 |

| Parameter | SC | CR | BC |

|---|---|---|---|

| Water–cement ratio | 0.5 | 0.5 | 0.82 |

| Consistency class | S1 | S1 | S3 |

| Compressive strength [Mpa] | 62.7 | 62.2 | 30.5 |

| Tensile strength in bending [Mpa] | 2.7 | 1.8 | 0.6 |

| Water absorption [%] | 8 | 7 | 22 |

| Watertightness | W12 | W12 | W12 |

| Frost resistance class | ≥F25 | ≥F25 | ≥F25 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Denisiewicz, A.; Śliwa, M.; Kula, K.; Socha, T. Experimental Investigation of Concrete with Recycled Aggregates for Suitability in Concrete Structures. Appl. Sci. 2019, 9, 5010. https://doi.org/10.3390/app9235010

Denisiewicz A, Śliwa M, Kula K, Socha T. Experimental Investigation of Concrete with Recycled Aggregates for Suitability in Concrete Structures. Applied Sciences. 2019; 9(23):5010. https://doi.org/10.3390/app9235010

Chicago/Turabian StyleDenisiewicz, Arkadiusz, Małgorzata Śliwa, Krzysztof Kula, and Tomasz Socha. 2019. "Experimental Investigation of Concrete with Recycled Aggregates for Suitability in Concrete Structures" Applied Sciences 9, no. 23: 5010. https://doi.org/10.3390/app9235010

APA StyleDenisiewicz, A., Śliwa, M., Kula, K., & Socha, T. (2019). Experimental Investigation of Concrete with Recycled Aggregates for Suitability in Concrete Structures. Applied Sciences, 9(23), 5010. https://doi.org/10.3390/app9235010