Influence of Multiple Openings on Reinforced Concrete Outrigger Walls in a Tall Building

Abstract

:Featured Application

Abstract

1. Introduction

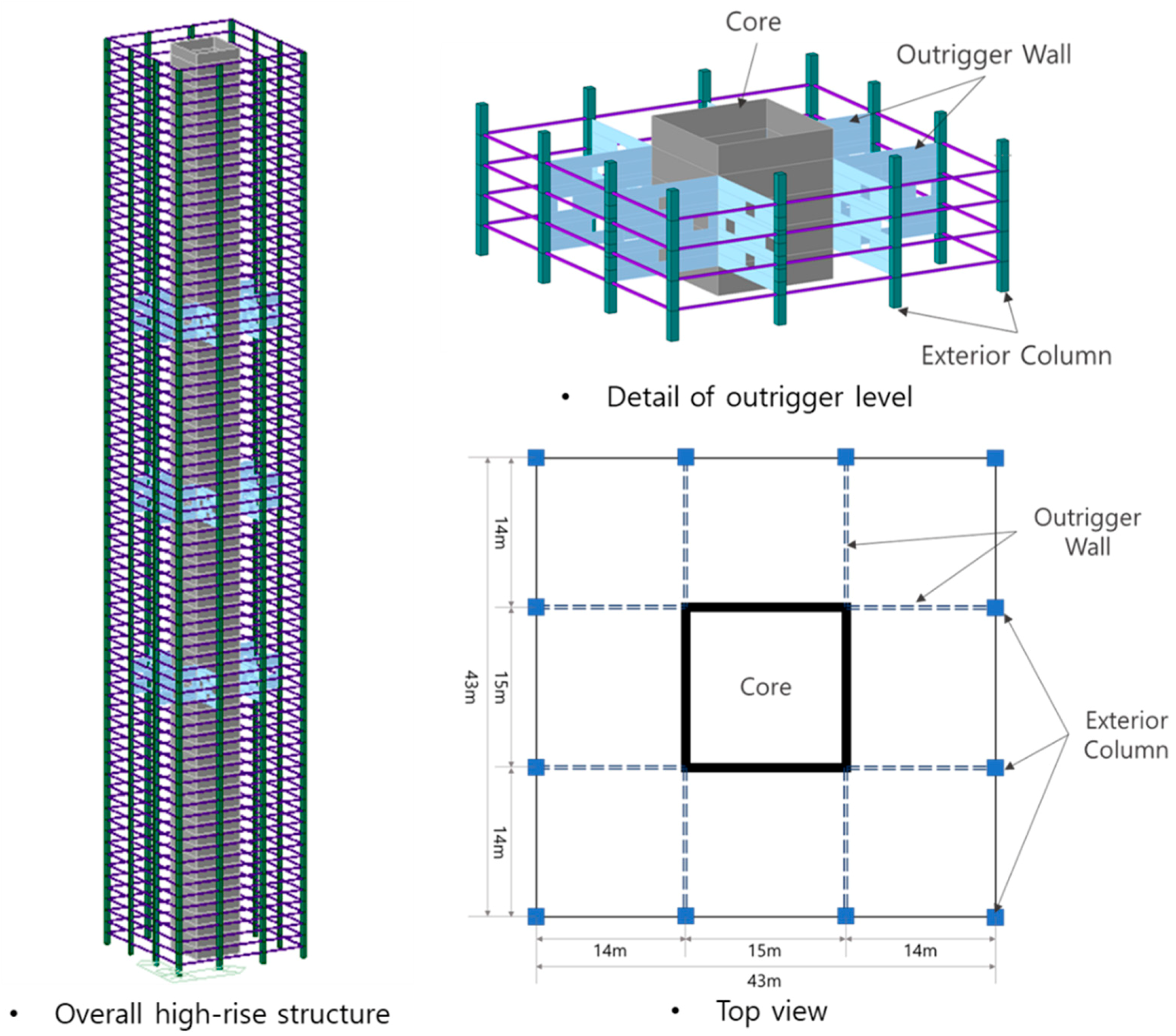

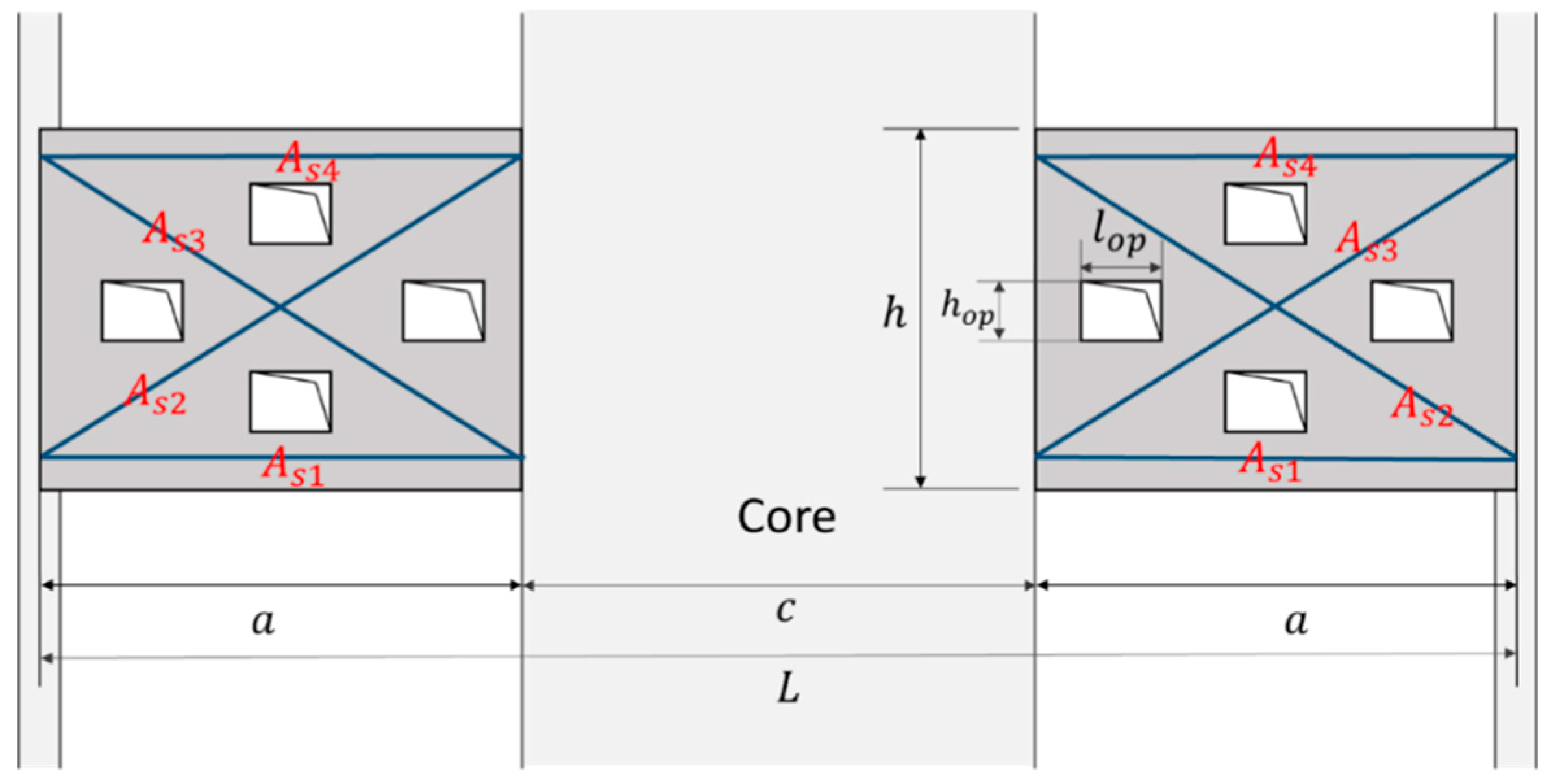

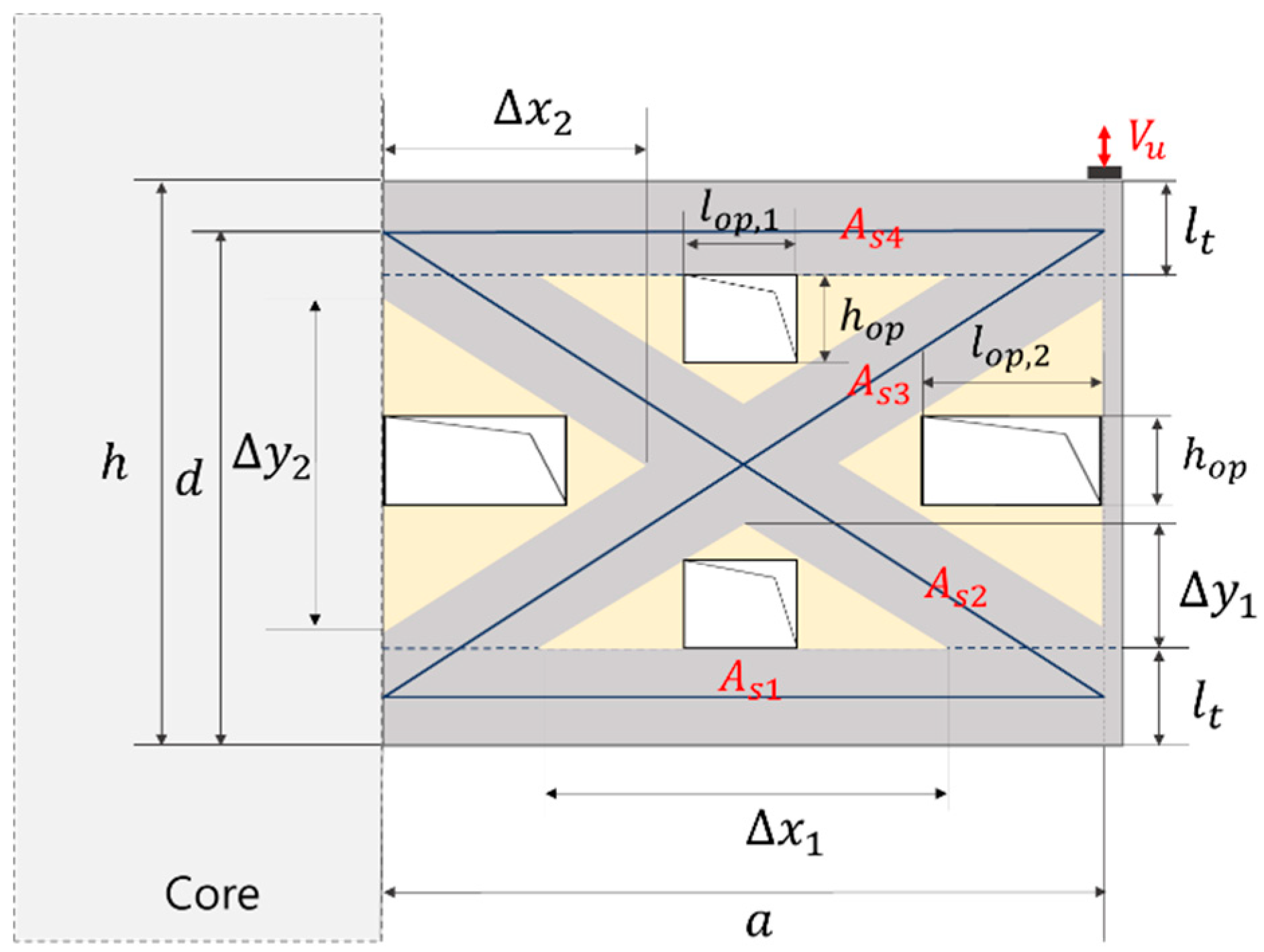

2. Design of Reinforced Concrete Outrigger Wall with Multiple Openings

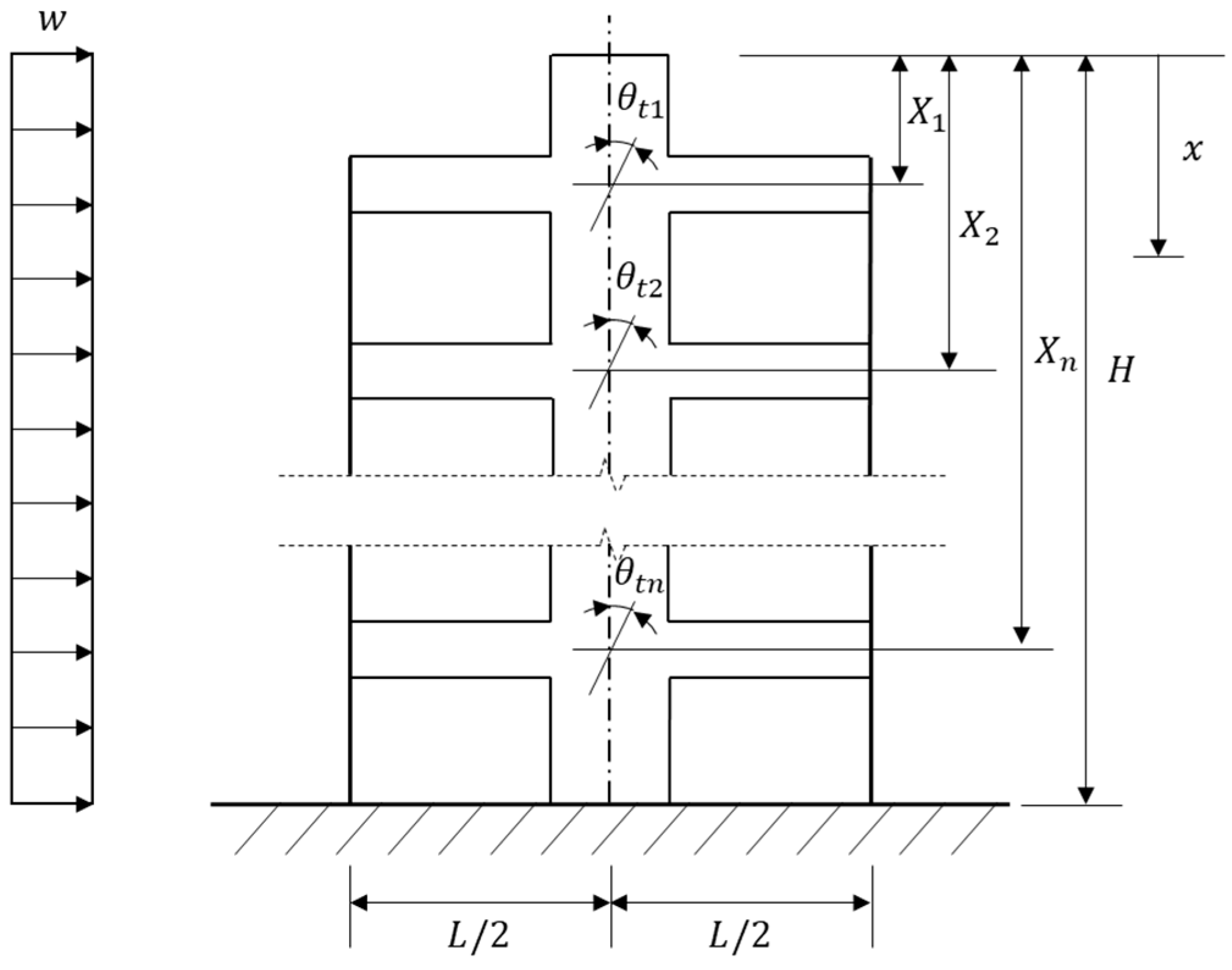

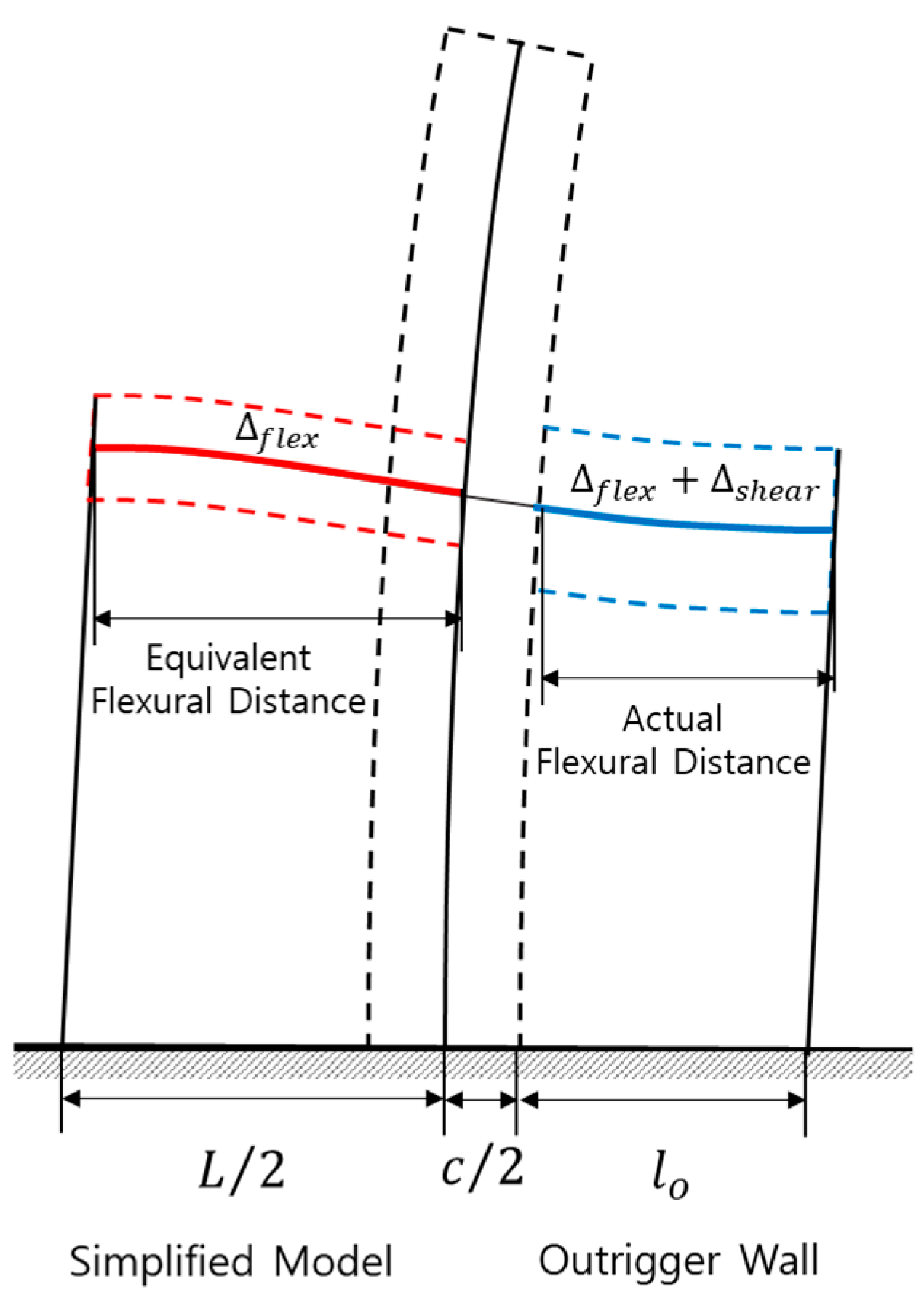

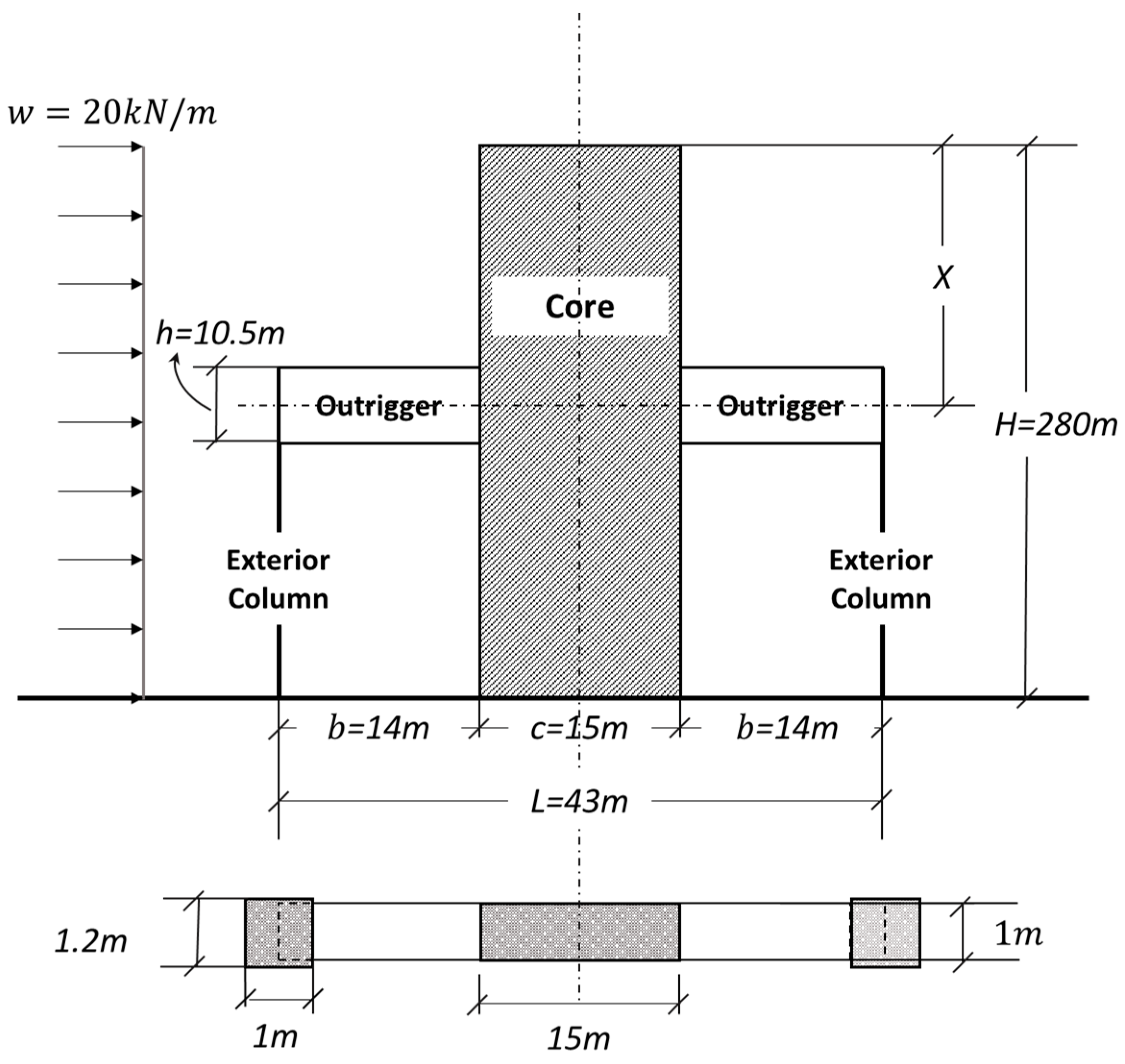

2.1. Effect and Demand of Outrigger Walls

2.2. Verification by Numerical Examples

2.3. Arrangement of Multiple Openings

3. Evaluation of the Influence of Multiple Openings

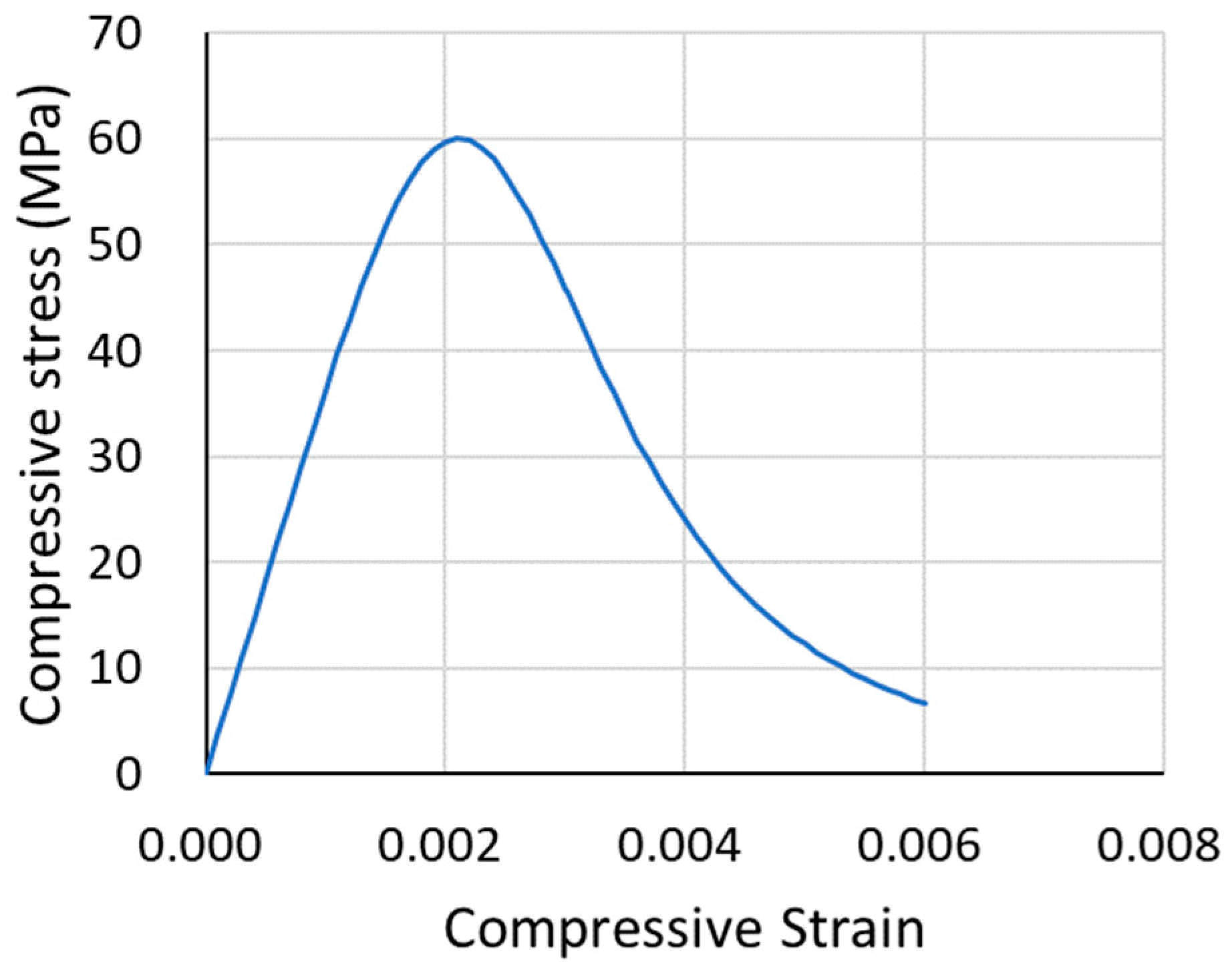

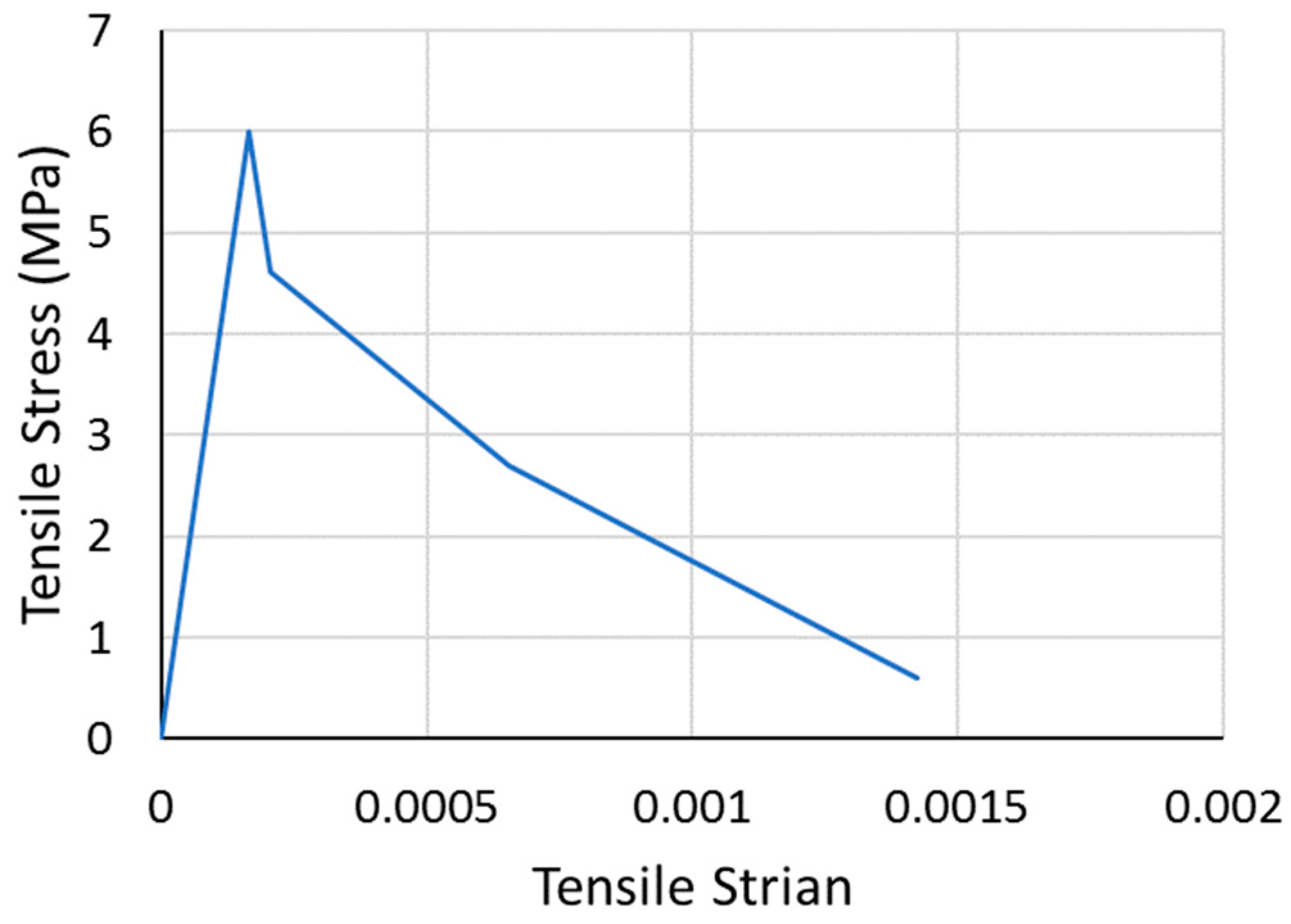

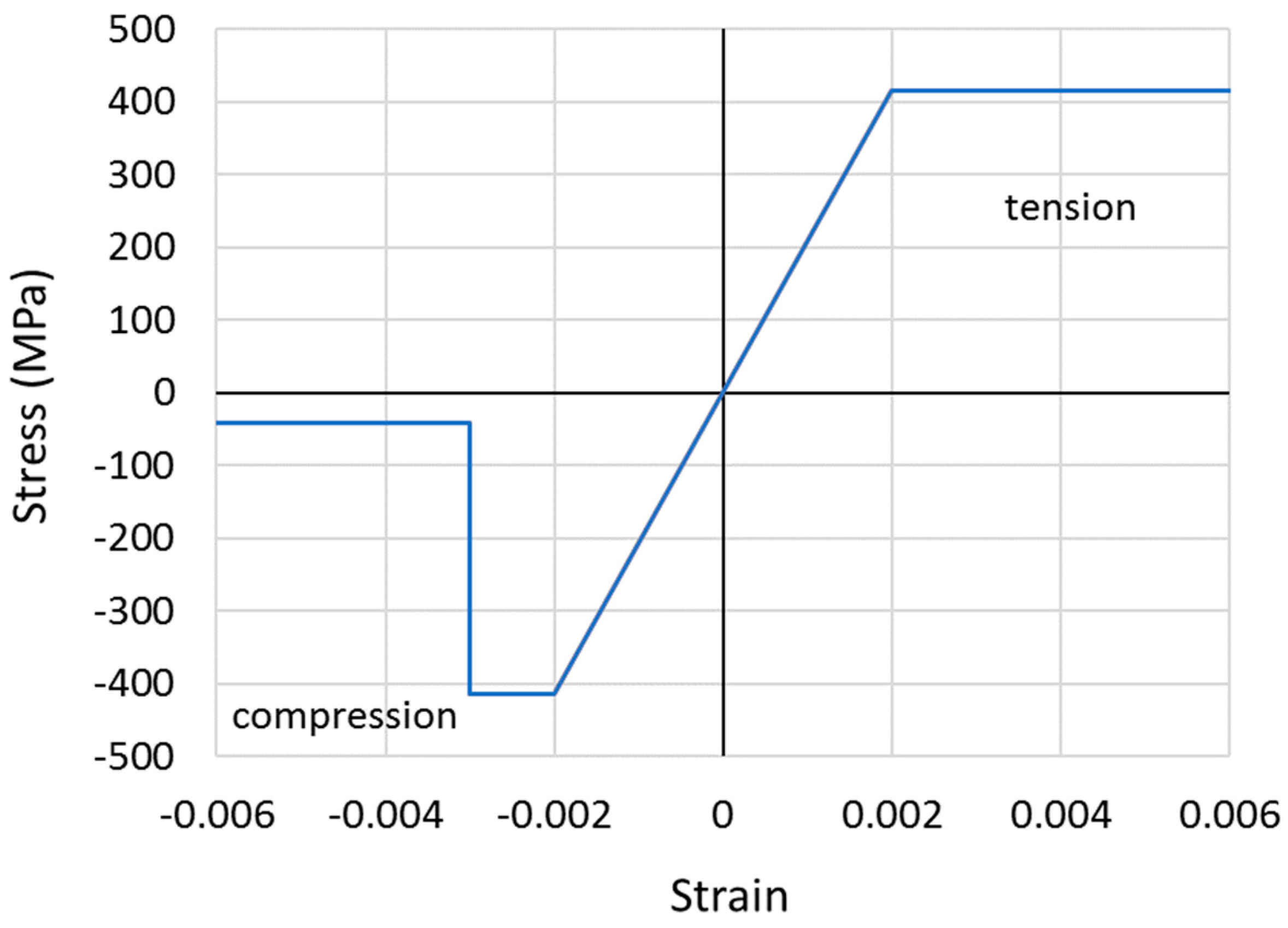

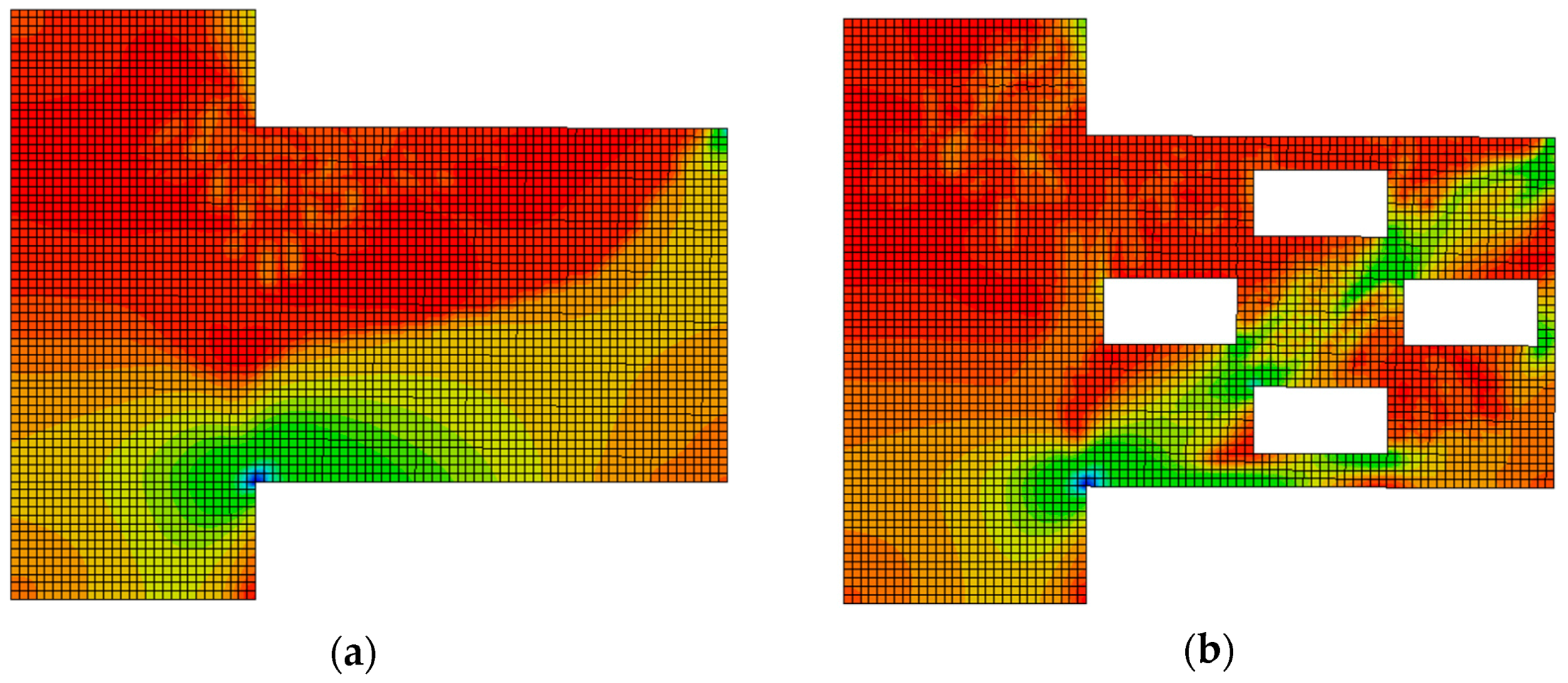

3.1. Finite Element Modelling

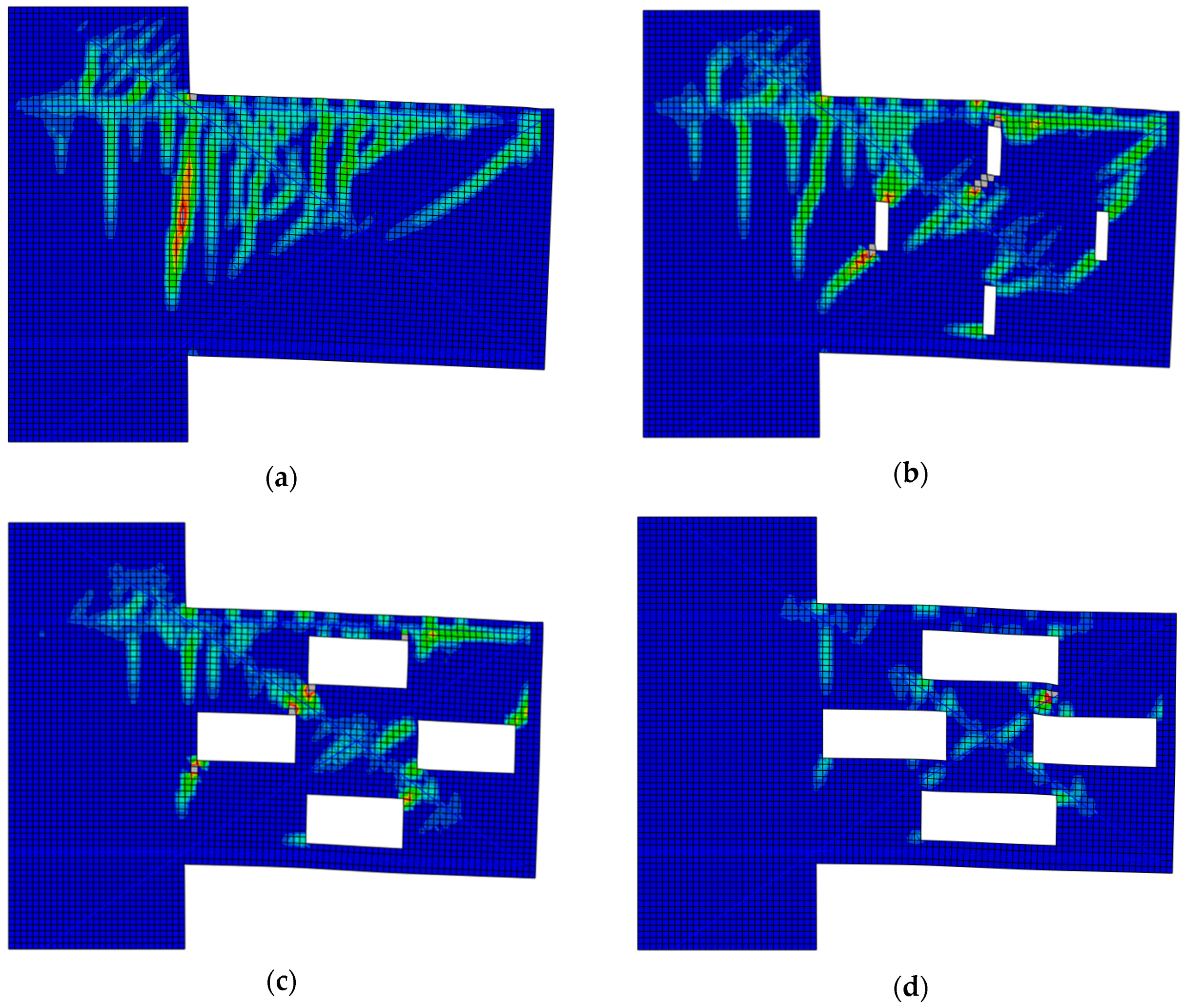

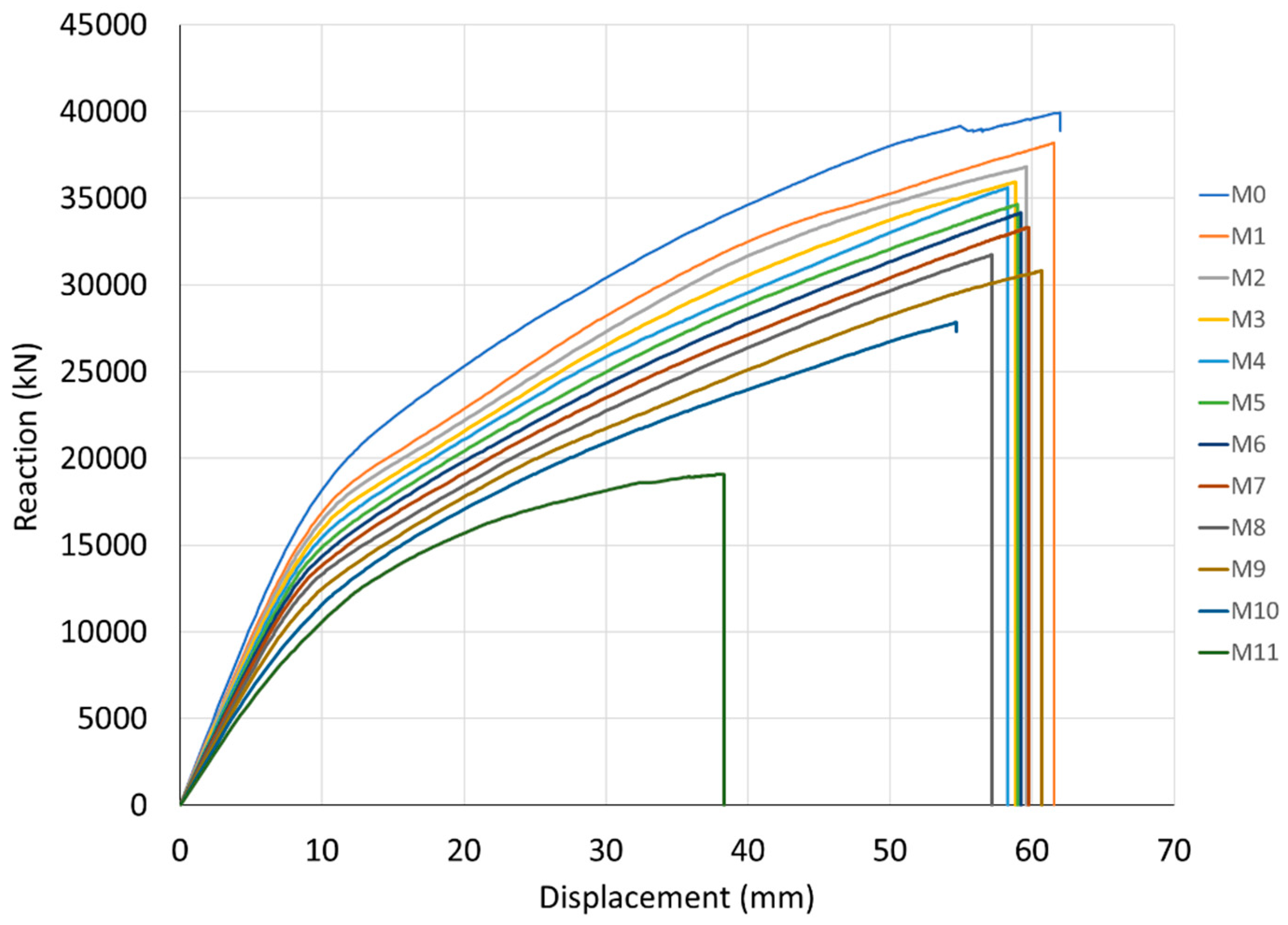

3.2. Results of Finite Element Analysis

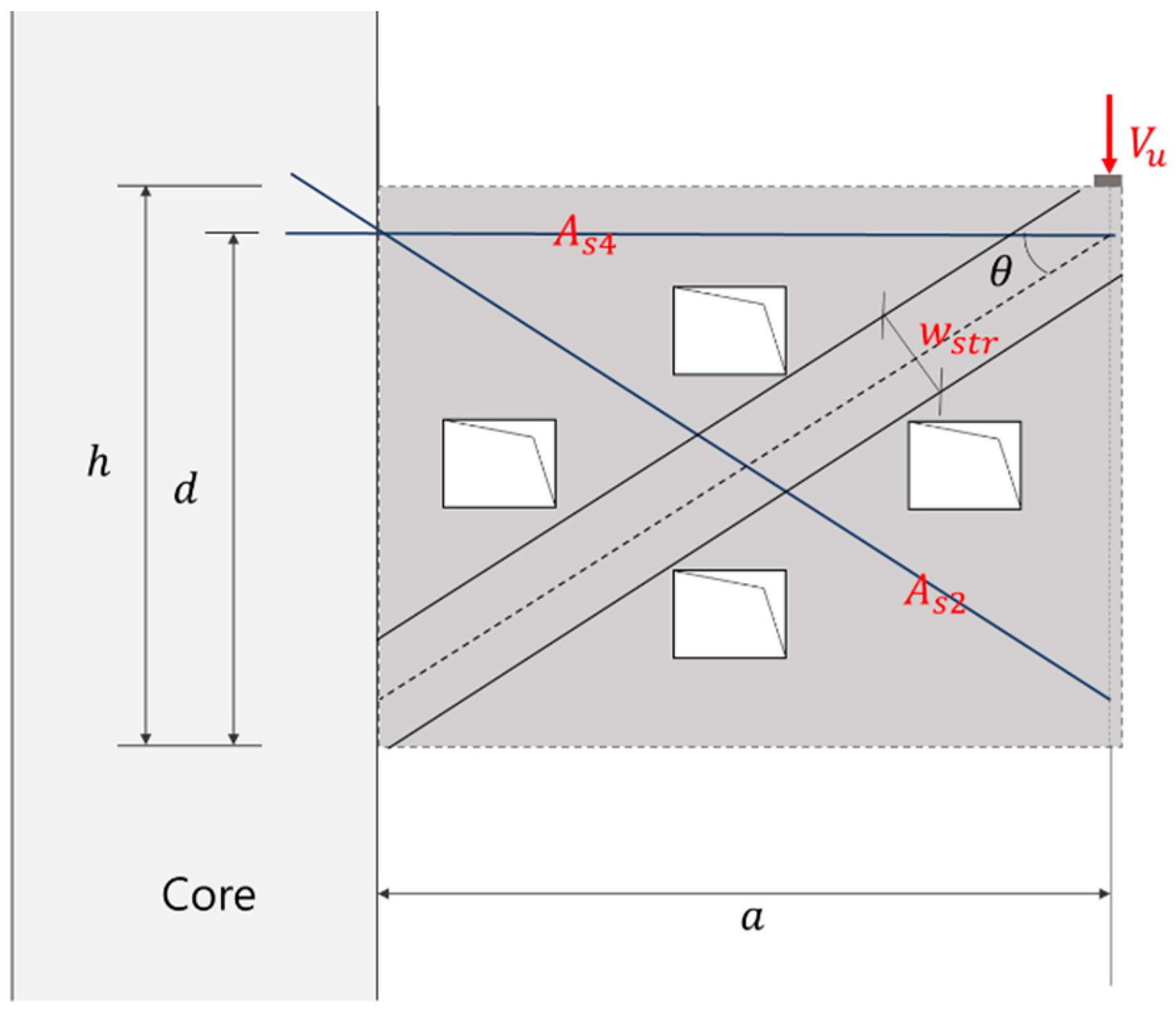

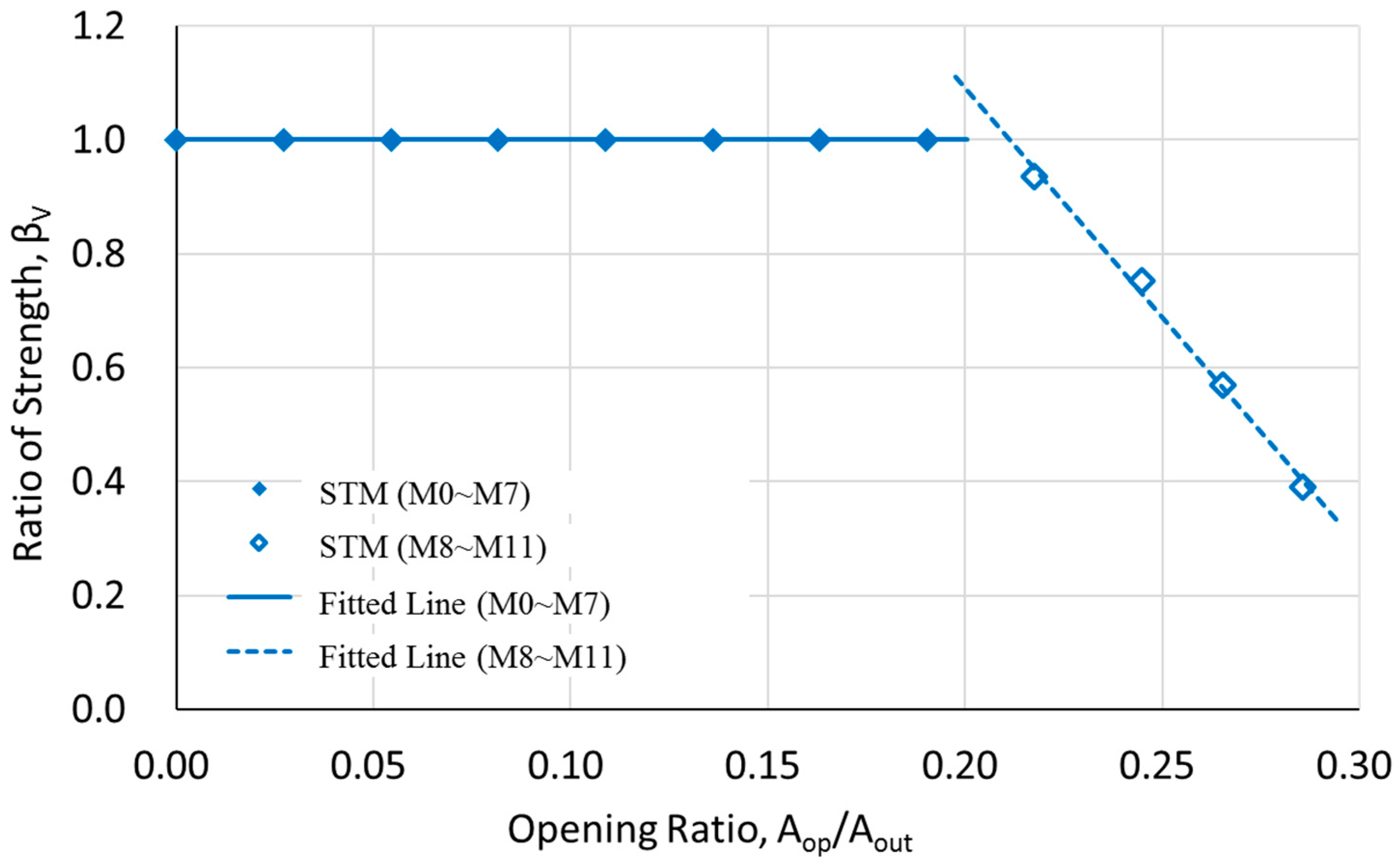

3.3. Strength Predicted by Strut-and-Tie Models

3.4. Influence on Lateral Stiffness of Tall Buildings

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Choi, H.S.; Joseph, L. Outrigger system design considerations. Int. J. High-Rise Build. 2012, 1, 237–246. [Google Scholar]

- Ali, M.M.; Moon, K.S. Structural developments in tall buildings: Current trends and future prospects. Archit. Sci. Rev. 2007, 50, 205–223. [Google Scholar] [CrossRef]

- Taranath, B.S. Optimum belt truss location for high-rise structures. Struct. Eng. 1975, 53, 18–21. [Google Scholar]

- McNabb, J.W.; Muvdi, B.B. Drift reduction factors for belt high-rise structures. Eng. J. AISC 1975, 12, 88–91. [Google Scholar]

- Smith, B.S.; Nwaka, I.O. The behaviour of multi-outrigger braced tall buildings. ACI SP-63 1980, 515–541. [Google Scholar]

- Smith, B.S.; Salim, I. Parameter study of outrigger-braced tall building structures. J. Str. Div. ASCE 1981, 107, 2001–2014. [Google Scholar]

- Hoenderkamp, J.C.D.; Bakker, M.C.M. Analysis of high-rise braced frames with outriggers. Struct. Des. Tall Spec. Build. 2003, 12, 335–350. [Google Scholar] [CrossRef]

- Wu, J.R.; Li, Q.S. Structural performance of multi-outrigger-braced tall buildings. Struct. Des. Tall Spec. Build. 2003, 12, 155–176. [Google Scholar] [CrossRef]

- Kim, H.S.; Lee, H.L.; Lim, Y.J. Multi-objective optimization of dual-purpose outriggers in tall buildings to reduce lateral displacement and differential axial shortening. Eng. Struct. 2019, 189, 296–308. [Google Scholar] [CrossRef]

- Wang, A. Multi-dimensional hybrid design and construction of skyscraper cluster-innovative engineering of Raffles City. Int. J. High-Rise Build. 2017, 6, 261–269. [Google Scholar] [CrossRef]

- Ho, G.W.M. The evolution of outrigger system in tall buildings. Int. J. High-Rise Build. 2016, 5, 21–30. [Google Scholar] [CrossRef]

- Kong, F.K.; Sharp, G.R. Structural idealization for deep beams with web openings. Mag. Concr. Res. 1977, 29, 81–91. [Google Scholar] [CrossRef]

- Tan, K.H.; Tong, K.; Tang, C.Y. Consistent strut-and-tie modeling of deep beams with web openings. Mag. Concr. Res. 2003, 55, 65–75. [Google Scholar] [CrossRef]

- Tang, C.Y.; Tan, K.H. Interactive mechanical model for shear strength of deep beams. J. Struct. Eng. 2004, 130, 1534–1544. [Google Scholar] [CrossRef]

- Smith, B.S.; Coull, A. Tall Building Structures: Analysis and Design; John Wiley & Sons: New York, NY, USA, 1991. [Google Scholar]

- ACI Committee 318. Building Code Requirements for Structural Concrete (ACI 318-14) and Commentary (318R-14); American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Midas-Gen On-Line Manual; MIDAS Information Technology Co. Ltd. Available online: http://manual.midasuser.com/EN_Common/Gen/855/whnjs.htm. (accessed on 10 September 2019).

- Schlaich, J.; Schäfer, K.; Jennewein, M. Towards a consistent design of structural concrete. PCI J. 1987, 32, 74–150. [Google Scholar] [CrossRef]

- Schlaich, J.; Schäfer, K. Design and detailing of structural concrete using strut-and-tie models. Struct. Eng. 1991, 69, 113–125. [Google Scholar]

- Abaqus. Abaqus Analysis User’s Guide; Dassault Systems Simulia Corp. Available online: http://130.149.89.49:2080/v2016/books/usb/default.htm, (accessed on 10 September 2019).

- Wosatko, A.; Pamin, J.; Polak, M.A. Application of damage-plasticity models in finite element analysis of punching shear. Comput. Struct. 2015, 151, 73–85. [Google Scholar] [CrossRef]

- Tao, Y.; Chen, J.F. Concrete damage plasticity model for modeling FRP-to-concrete bond behavior. J. Compos. Const. 2015, 19. [Google Scholar] [CrossRef]

- Mohamed, K.; Farghaly, A.S.; Benmokrane, B.; Neale, K.W. Nonlinear finite-element analysis for the behavior prediction and strut efficiency factor of GFRP-reinforced concrete deep beams. Eng. Struct. 2017, 137, 145–161. [Google Scholar] [CrossRef]

- Genikomsou, A.S.; Polak, M.A. Finite element analysis of punching shear of concrete slabs using damaged plasticity model in ABAQUS. Eng. Struct. 2015, 98, 38–48. [Google Scholar] [CrossRef]

- Ombres, L.; Verre, S. Flexural strengthening of RC beams with steel-reinforced grout: Experimental and numerical investigation. J. Compos. Const. 2019, 23. [Google Scholar] [CrossRef]

- Fortunato, G.; Funari, M.F.; Lonetti, P. Survey and seismic vulnerability assessment of the Baptistery of San Giovanni in Tumba (Italy). J. Cult. Herit. 2017, 26, 64–78. [Google Scholar] [CrossRef]

- Lee, J.; Fenves, G.L. Plastic-damage model for cyclic loading of concrete structures. J. Eng. Mech. 1998, 124, 892–900. [Google Scholar] [CrossRef]

- Carreira, D.J.; Chu, K.H. Stress-strain relationship for plain concrete in compression. ACI Struct. J. 1985, 82, 797–804. [Google Scholar]

- Wahalathantri, B.L.; Thambiratnam, D.P.; Chan, T.H.T.; Fawzia, S. A material model for flexural crack simulation in reinforced concrete elements using Abaqus. In Proceedings of the First International Conference on Engineering, Designing and Developing the Built Environment for Sustainable Wellbeing, Brisbane, Australia, 28 April 2011; pp. 260–264. [Google Scholar]

- Kim, H.J.; Kim, H.S. Finite element analysis to determine shear behavior of prestressed concrete deep beams. J. Comput. Struct. Eng. Inst. Korea 2019, 32, 165–172. [Google Scholar] [CrossRef]

- Kim, H.S. Optimum design of outriggers in a tall building by alternating nonlinear programming. Eng. Struct. 2017, 150, 91–97. [Google Scholar] [CrossRef]

| Model | Outrigger | X (m) | Diff. (%) | Diff. (%) | ||||

|---|---|---|---|---|---|---|---|---|

| Equation (6) | FEA | Equation (7) | FEA | |||||

| A1 | O11 | 89.25 | 0.4964 | 0.5134 | 3.30 | 6790 | 6876 | 1.25 |

| A2 | O21 | 138.25 | 0.4715 | 0.4905 | 3.87 | 8267 | 8331 | 0.77 |

| A3 | O31 | 183.75 | 0.5782 | 0.5985 | 3.39 | 9842 | 9840 | 0.02 |

| A4 | O41 | 89.25 | 0.3701 | 0.3789 | 2.34 | 3669 | 3808 | 3.65 |

| O42 | 183.75 | 6273 | 6225 | 0.77 | ||||

| A5 | O51 | 68.25 | 0.3831 | 0.3908 | 1.96 | 3908 | 4028 | 2.97 |

| O52 | 208.25 | 6967 | 6890 | 1.11 | ||||

| A6 | O61 | 68.25 | 0.3412 | 0.3429 | 0.42 | 2111 | 2220 | 4.92 |

| O62 | 138.25 | 3597 | 3528 | 1.95 | ||||

| O63 | 208.25 | 5232 | 5155 | 1.51 | ||||

| Parameter | Value |

|---|---|

| 38 | |

| 0.1 | |

| 1.16 | |

| 0.667 | |

| Viscosity parameter | 0.0001 |

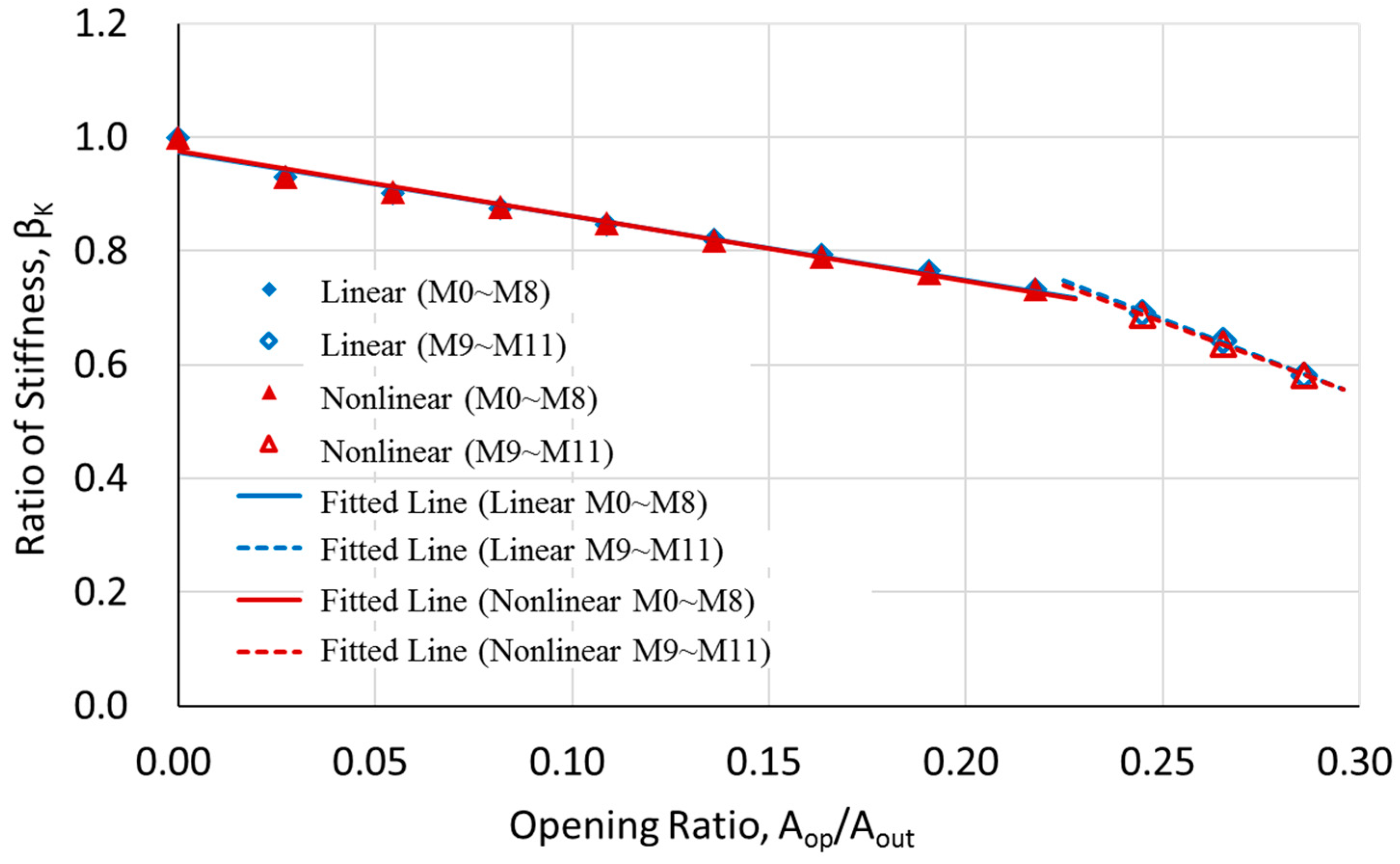

| Model | Linear Analysis | Nonlinear Analysis | |||

|---|---|---|---|---|---|

| M0 | 0.00 | 2124 | 1.00 | 1817 | 1.00 |

| M1 | 0.03 | 1973 | 0.93 | 1690 | 0.93 |

| M2 | 0.05 | 1914 | 0.90 | 1642 | 0.90 |

| M3 | 0.08 | 1858 | 0.87 | 1593 | 0.88 |

| M4 | 0.11 | 1801 | 0.85 | 1542 | 0.85 |

| M5 | 0.14 | 1742 | 0.82 | 1487 | 0.82 |

| M6 | 0.16 | 1685 | 0.79 | 1435 | 0.79 |

| M7 | 0.19 | 1625 | 0.76 | 1383 | 0.76 |

| M8 | 0.22 | 1557 | 0.73 | 1332 | 0.73 |

| M9 | 0.24 | 1468 | 0.69 | 1248 | 0.69 |

| M10 | 0.27 | 1365 | 0.64 | 1156 | 0.64 |

| M11 | 0.29 | 1234 | 0.58 | 1056 | 0.58 |

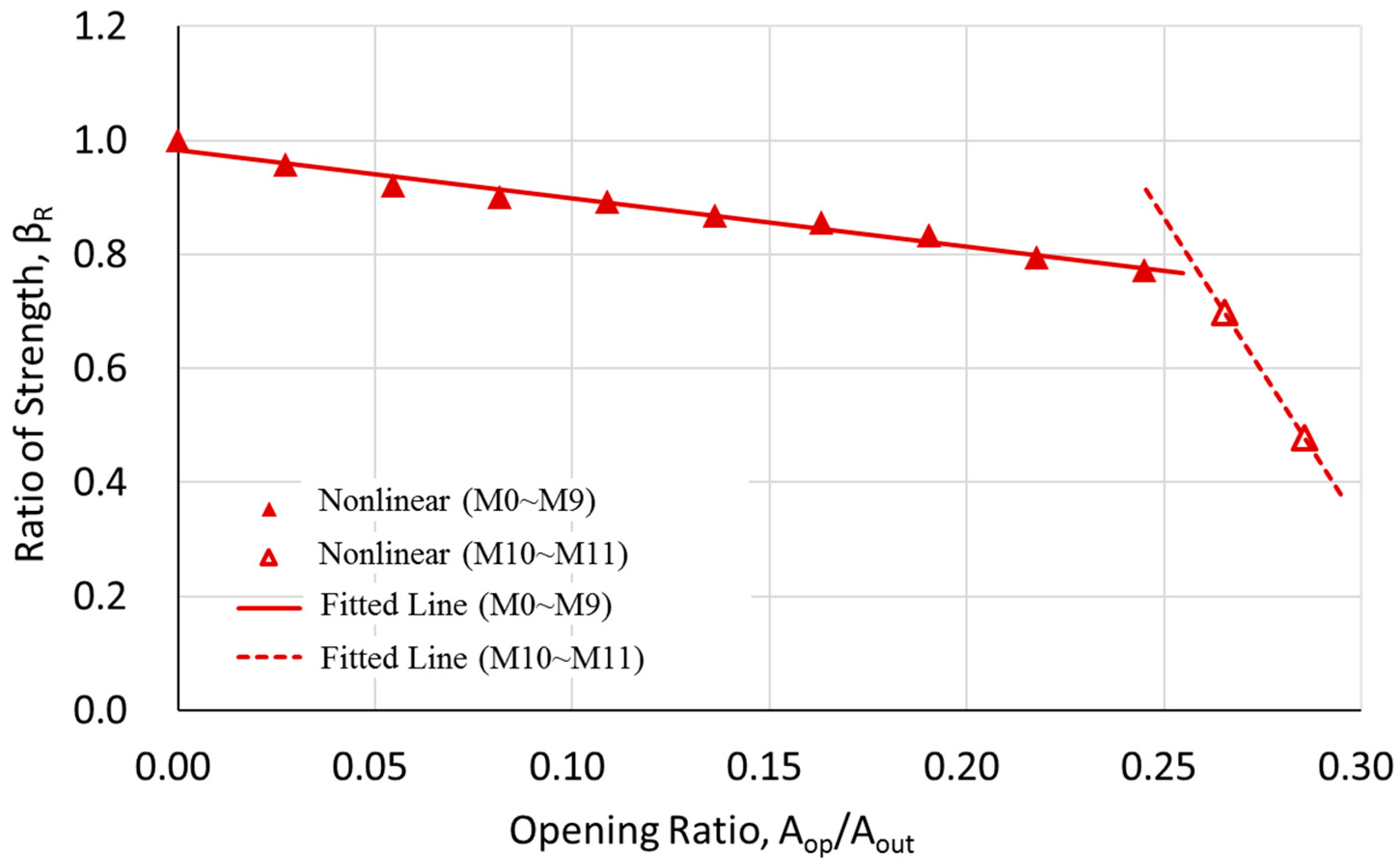

| Model | Nonlinear Analysis | ||

|---|---|---|---|

| M0 | 0.00 | 39,932 | 1.00 |

| M1 | 0.03 | 38,193 | 0.96 |

| M2 | 0.05 | 36,798 | 0.92 |

| M3 | 0.08 | 35,938 | 0.90 |

| M4 | 0.11 | 35,604 | 0.89 |

| M5 | 0.14 | 34,635 | 0.87 |

| M6 | 0.16 | 34,150 | 0.86 |

| M7 | 0.19 | 33,314 | 0.83 |

| M8 | 0.22 | 31,729 | 0.79 |

| M9 | 0.24 | 30,815 | 0.77 |

| M10 | 0.27 | 27,853 | 0.70 |

| M11 | 0.29 | 19,083 | 0.48 |

| Model | Outrigger | Diff. (%) | Diff. (%) | ||||

|---|---|---|---|---|---|---|---|

| M11 | M0 | M11 | |||||

| A1 | O11 | 0.4964 | 0.5050 | 1.73 | 6790 | 6732 | 0.85 |

| A2 | O21 | 0.4715 | 0.4833 | 2.50 | 8267 | 8173 | 1.14 |

| A3 | O31 | 0.5782 | 0.5935 | 2.65 | 9842 | 9679 | 1.66 |

| A4 | O41 | 0.3701 | 0.3777 | 2.01 | 3669 | 3707 | 1.04 |

| O42 | 6273 | 6133 | 2.23 | ||||

| A5 | O51 | 0.3831 | 0.3918 | 2.22 | 3908 | 3938 | 0.77 |

| O52 | 6967 | 6786 | 2.60 | ||||

| A6 | O61 | 0.3412 | 0.3470 | 1.70 | 2111 | 2144 | 1.56 |

| O62 | 3597 | 3594 | 0.08 | ||||

| O63 | 5232 | 5089 | 2.73 | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-S.; Huang, Y.-T.; Jin, H.-J. Influence of Multiple Openings on Reinforced Concrete Outrigger Walls in a Tall Building. Appl. Sci. 2019, 9, 4913. https://doi.org/10.3390/app9224913

Kim H-S, Huang Y-T, Jin H-J. Influence of Multiple Openings on Reinforced Concrete Outrigger Walls in a Tall Building. Applied Sciences. 2019; 9(22):4913. https://doi.org/10.3390/app9224913

Chicago/Turabian StyleKim, Han-Soo, Yi-Tao Huang, and Hui-Jing Jin. 2019. "Influence of Multiple Openings on Reinforced Concrete Outrigger Walls in a Tall Building" Applied Sciences 9, no. 22: 4913. https://doi.org/10.3390/app9224913

APA StyleKim, H.-S., Huang, Y.-T., & Jin, H.-J. (2019). Influence of Multiple Openings on Reinforced Concrete Outrigger Walls in a Tall Building. Applied Sciences, 9(22), 4913. https://doi.org/10.3390/app9224913