Improvement Effect of Green Lubricants on the Tribological and Mechanical Performance of 4140 Steel

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Lubricants

2.2. Characterization of Lubricants

2.2.1. Physical Properties of Lubricants

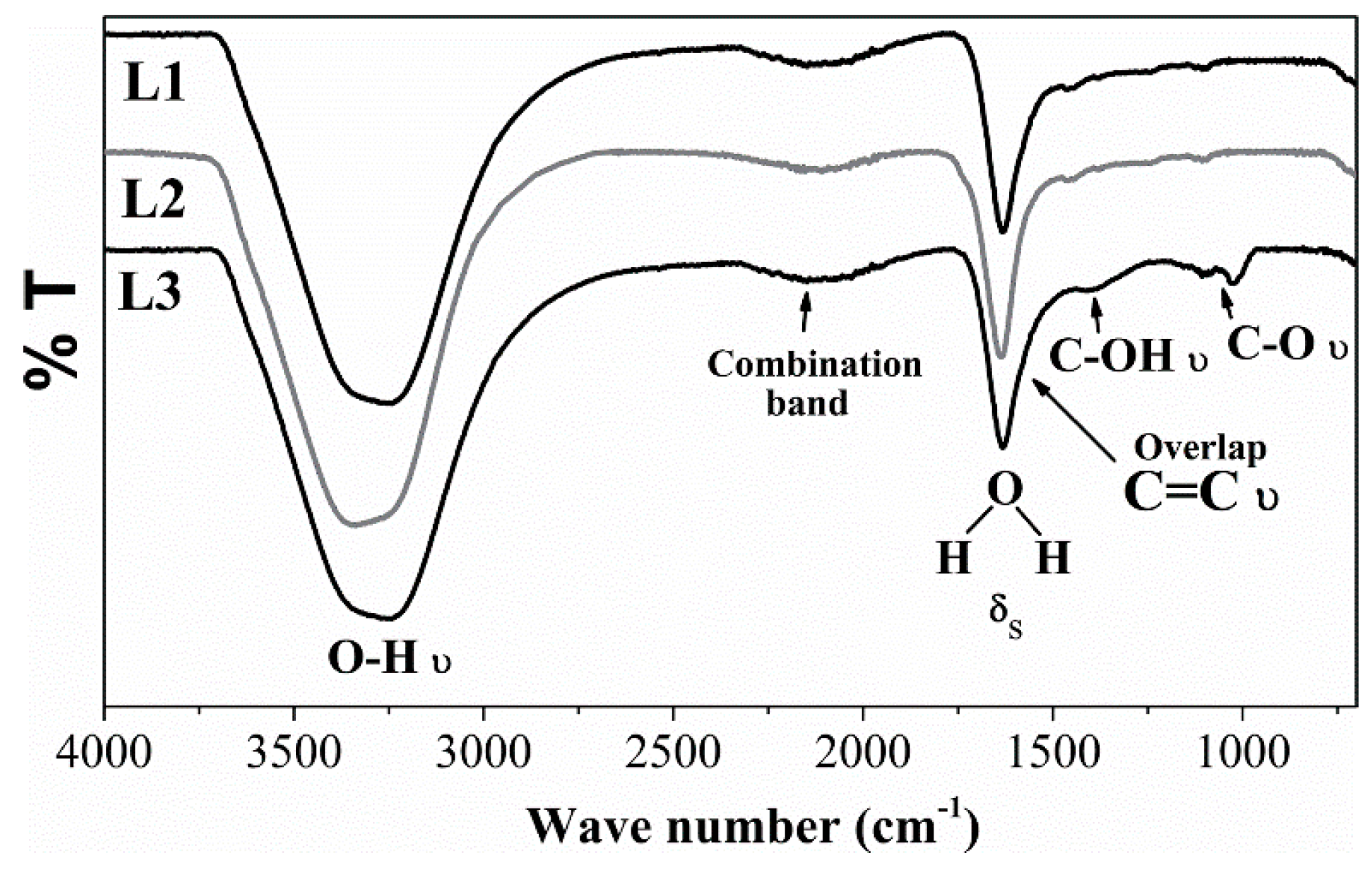

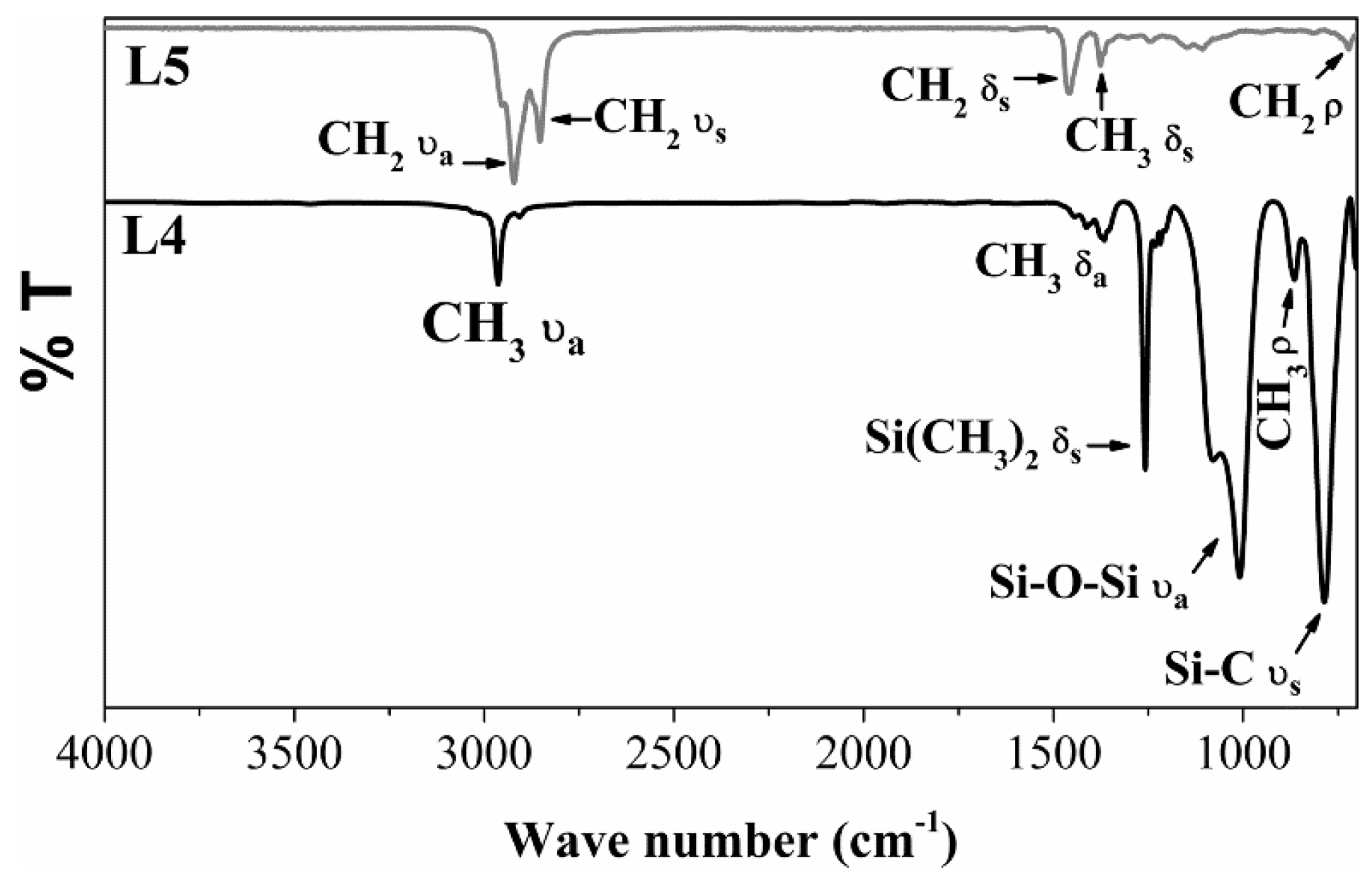

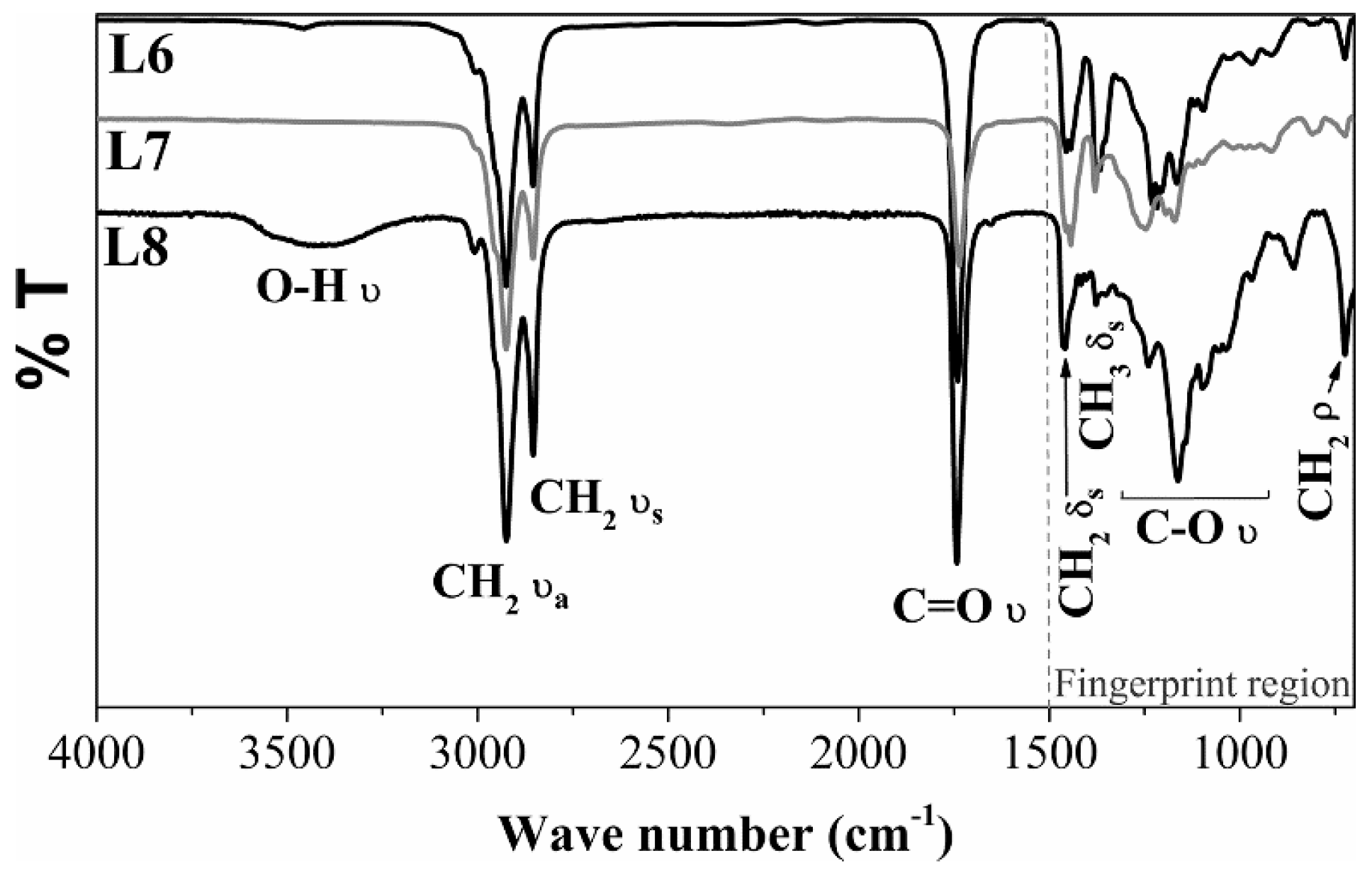

2.2.2. Chemical Characterization of the Lubricants

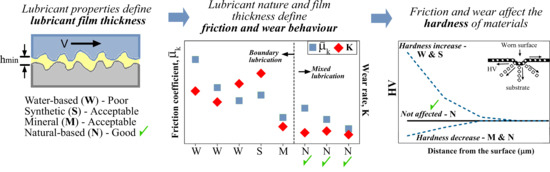

2.3. Evaluation of the Effect of Lubricants on the Lubrication Regime, Friction, and Wear

2.3.1. Lubrication Regime Estimation

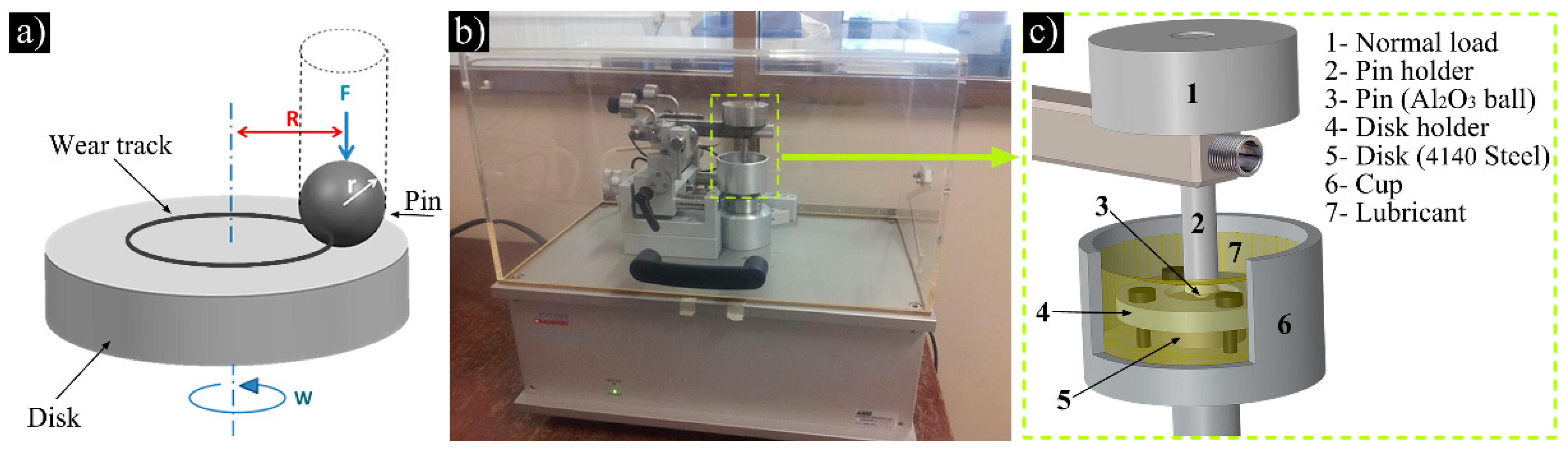

2.3.2. Sliding Friction and Wear Evaluation

2.3.3. Microhardness Evaluation

3. Results

3.1. Characterization of Lubricants

3.1.1. Physical Properties of Lubricants

3.1.2. Chemical Characterization of Lubricants

3.2. Effect of Lubricants on the Lubrication Regime, Friction, and Wear

3.2.1. Lubrication Regime Estimation

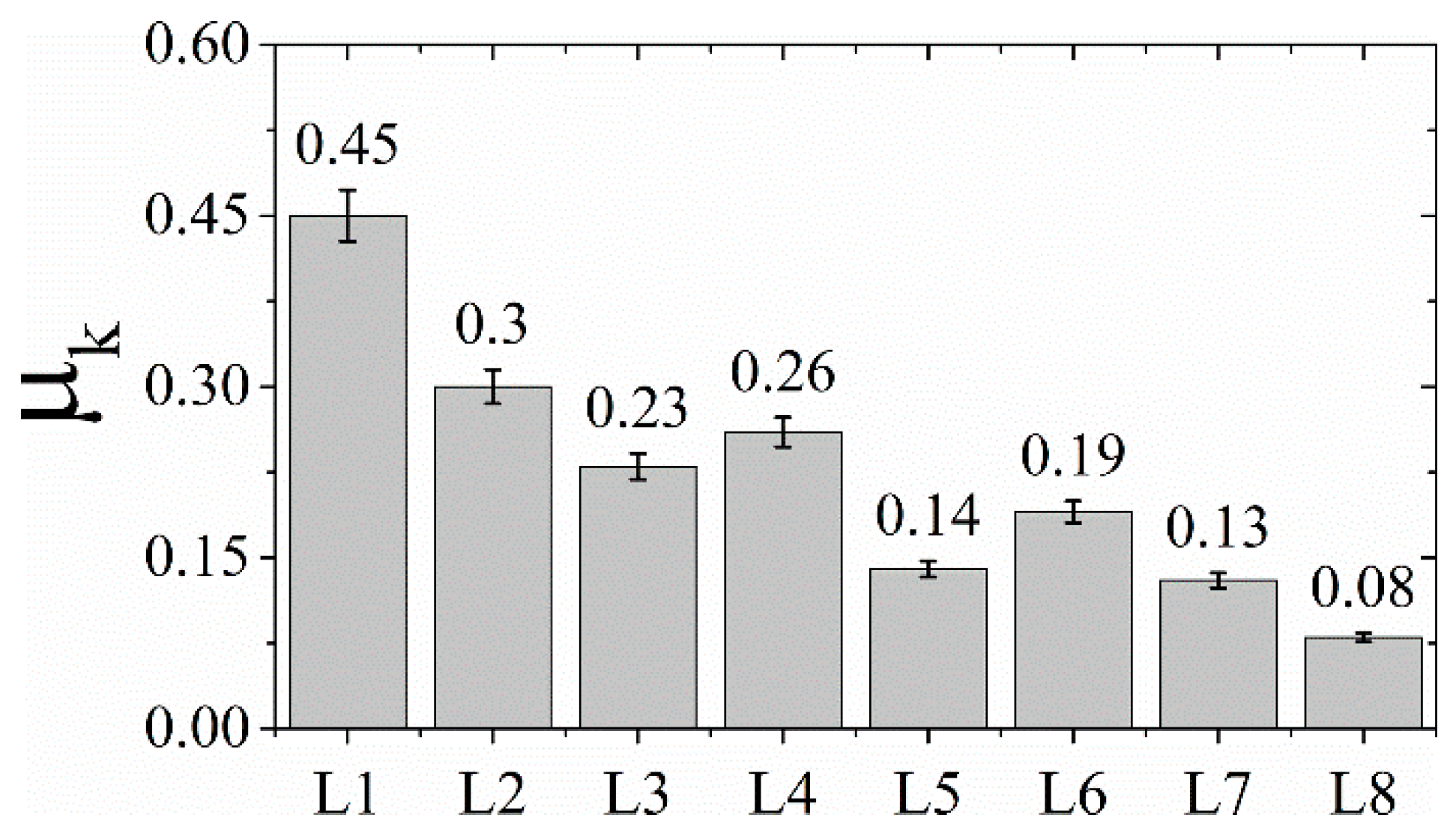

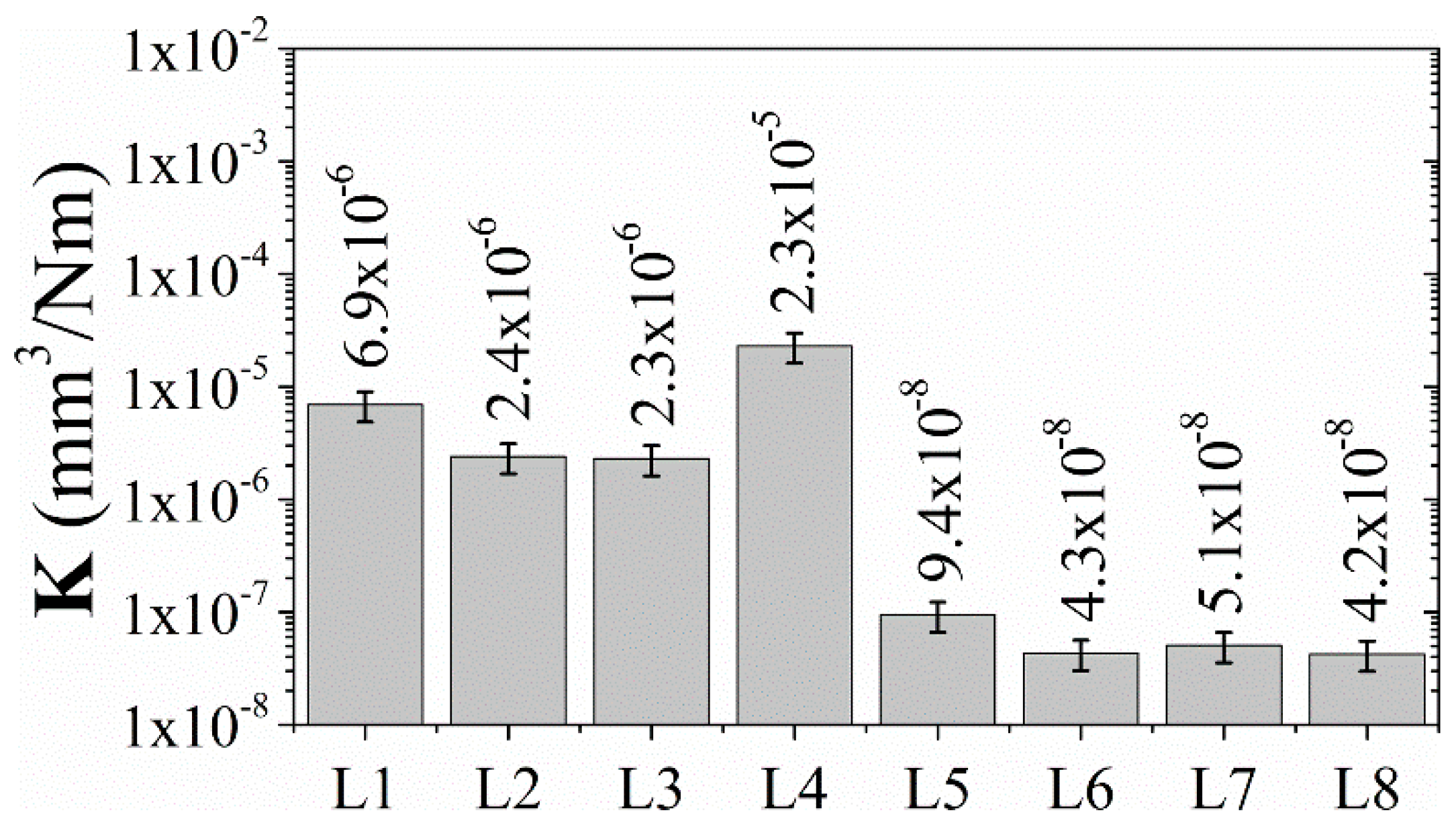

3.2.2. Effect of Lubricants on Friction and Wear

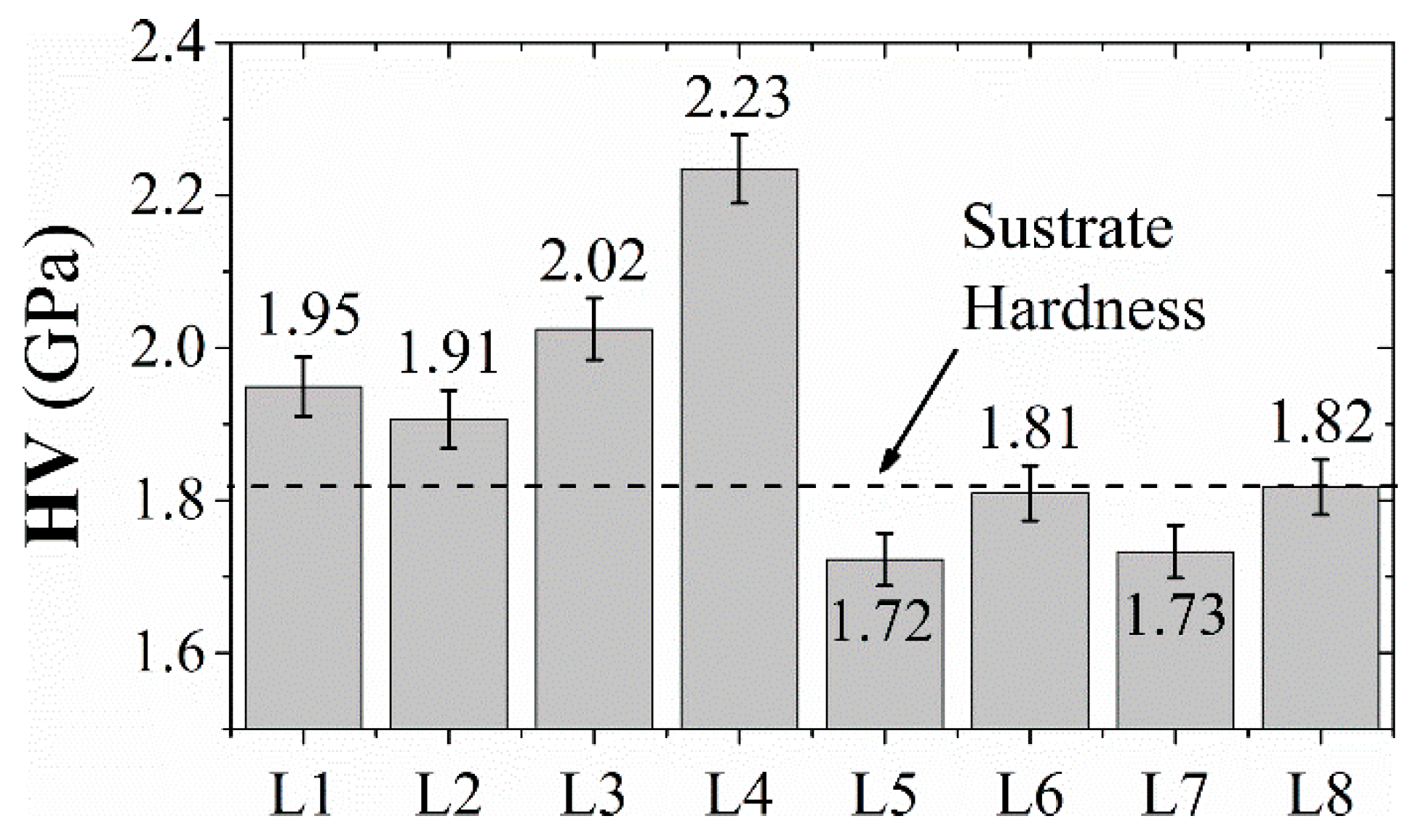

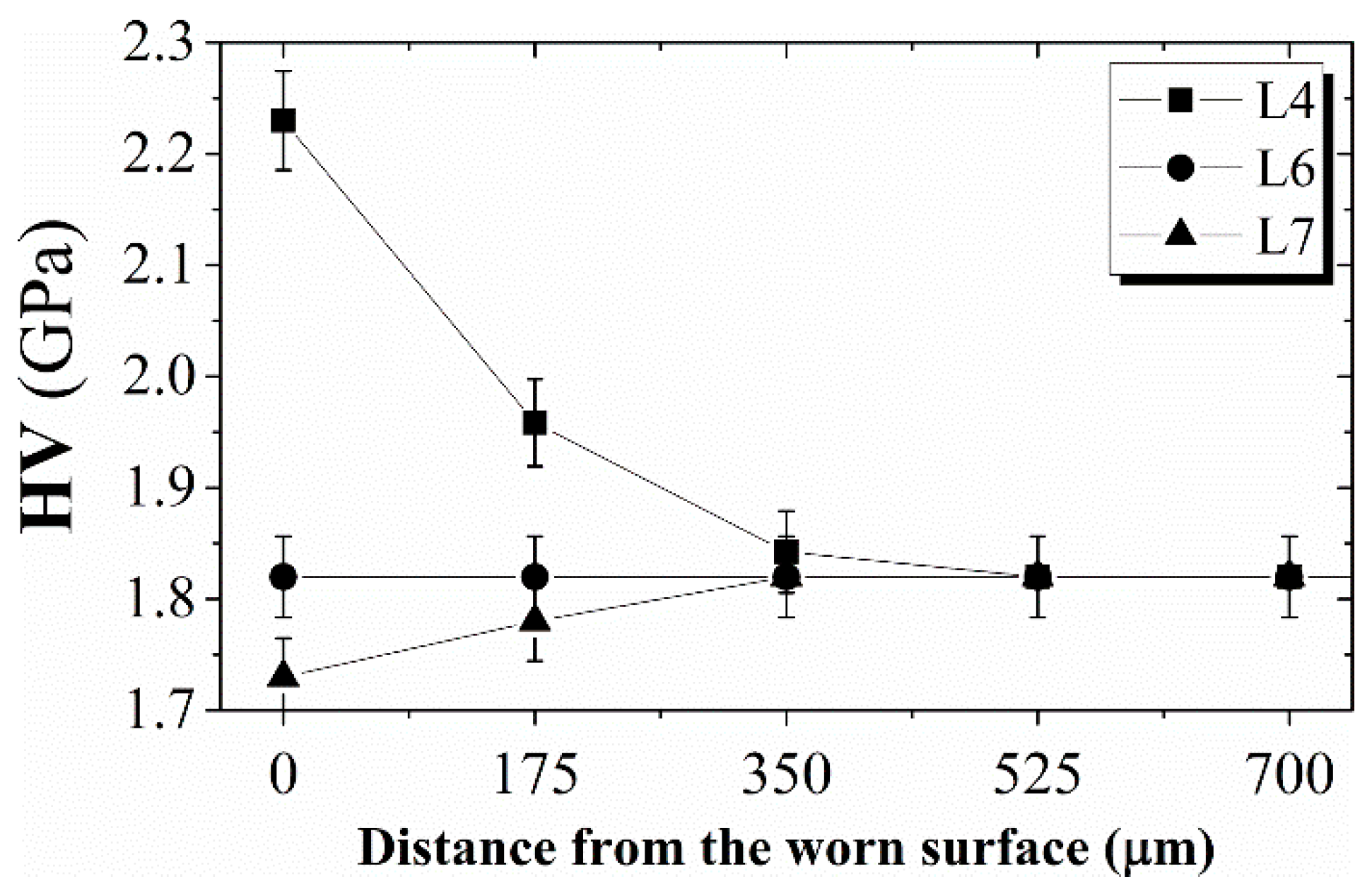

3.2.3. Effect of Lubricants on Microhardness

4. Conclusions

- It was observed that bio-based lubricants created thicker lubricating films than the other analyzed lubricants due to their high viscosity and high pressure-viscosity coefficients.

- The bio-based lubricants exhibited the lowest friction values, reducing on average up to 50% in comparison to the other lubricants in this study.

- The bio-based lubricants exhibited the lowest wear with similar mechanisms of wear.

- Bio-lubrication almost entirely reduced the damage to the microhardness of steel.

- The best friction and wear response of the 4140/Al2O3 system was achieved under lubrication with neat castor oil (L8). The kinetic friction coefficient and wear rate were 0.08 and 4.3 × 10−8 mm3/Nm, respectively. Further, this lubricant did not modify the hardness of the steel sample.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cai, M.R.; Guo, R.S.; Zhou, F.; Liu, W.M. Lubricating a bright future: Lubrication contribution to energy saving and low carbon emission. Sci. China Technol. Sci. 2013, 56, 2888–2913. [Google Scholar] [CrossRef]

- Zainal, N.A.; Zulkifli, N.W.M.; Gulzar, M.; Masjuki, H.H. A review on the chemistry, production, and technological potential of biobased lubricants. Renew. Sustain. Energy Rev. 2018, 82, 80–102. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Schmid, S.R.; Jacobson, B.O. Fundamentals of Fluid Film Lubrication; Marcel Dekker Inc.: New York, NY, USA, 2004. [Google Scholar]

- Gschwender, L.J.; Kramer, D.C.; Lok, B.K.; Sharma, S.K.; Snyder, C.E.; Sztenderowicz, M.L. Liquid lubricants and lubrication. In Modern Tribology Handbook; Bhushan, B., Ed.; CRC Press LLC: Boca Raton, FL, USA, 2001; Volume 1, pp. 361–382. [Google Scholar]

- Nosonovsky, M.; Bhushan, B. Green tribology: Principles, research areas and challenges. Philos. Trans. R. Soc. A 2010, 368, 4677–4694. [Google Scholar] [CrossRef]

- Hernández-Sierra, M.T.; Aguilera-Camacho, L.D.; Baez-García, J.E.; García-Miranda, J.S.; Moreno, K.J. Thermal stability and lubrication properties of biodegradable castor oil on AISI 4140 steel. Metals 2018, 8, 428. [Google Scholar] [CrossRef]

- Hernández-Sierra, M.T.; Ortega-Álvarez, R.; Bravo-Sánchez, M.G.; Aguilera-Camacho, L.D.; García-Miranda, J.S.; Moreno, K.J. Tribological improvement of hardened and tempered AISI 4140 steel against Al2O3 by using bio-lubricant. MRS Adv. 2017, 2, 3873–3881. [Google Scholar] [CrossRef]

- Torbacke, M.; Rudolphi, Å.K.; Kassfeldt, E. Lubricants: Introduction to Properties and Performance; E. John Wiley & Sons Ltd: West Sussex, UK, 2014. [Google Scholar]

- Minami, I. Molecular Science of Lubricant Additives. Appl. Sci. 2017, 7, 445. [Google Scholar] [CrossRef]

- Xu, Z.; Lou, W.; Zhao, G.; Zhang, M.; Hao, J.; Wang, X. Pentaerythritol rosin ester as an environmentally friendly multifunctional additive in vegetable oil-based lubricant. Tribol. Int. 2019, 135, 213–218. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Aviña, K.; Diabb, J.M. Tribological and thermal transport performance of SiO2-based natural lubricants. Lubricants 2019, 7, 71. [Google Scholar] [CrossRef]

- Zheng, D.; Wang, X.; Zhang, M.; Liu, Z.; Ju, C. Anticorrosion and lubricating properties of a fully green lubricant. Tribol. Int. 2018, 130, 324–333. [Google Scholar] [CrossRef]

- Yu, R.; Liu, J.; Zhou, Y. Experimental study on tribological property of MoS2 nanoparticle in castor oil. J. Tribol. 2019, 141, 102001. [Google Scholar] [CrossRef]

- Lorenzo-Martín, C.; Ajayi, O.O. Rapid Surface hardening and enhanced tribological performance of 4140 steel by friction stir processing. Wear 2015, 332–333, 962–970. [Google Scholar] [CrossRef]

- Suresh, S.; Venkatesan, K.; Natarajan, E.; Rajesh, J. Influence of tool rotational speed on the properties of friction stir spot welded AA7075-T6/Al2O3 composite joint. Mater. Today-Proc. 2019. [Google Scholar] [CrossRef]

- Kestin, J.; Sokolov, M.; Wakeham, W.A. Viscosity of liquid water in the range-SoC to 150 °C. J. Phys. Chem. Ref. Data 1978, 7, 941–948. [Google Scholar] [CrossRef]

- Sharqawy, M.H.; Lienhard, V.J.H.; Zubair, S.M. Thermophysical properties of seawater: A review of existing correlations and data. Desalin. Water Treat. 2010, 16, 354–380. [Google Scholar] [CrossRef]

- Hamrock, B.J.; Dowson, D. Isothermal elastohydrodynamic lubrication of point contacts: Part 111—Fully flooded results. J. Tribol. 1977, 99, 264–275. [Google Scholar] [CrossRef]

- Johnston, W.G. A method to calculate the pressure-viscosity coefficient from bulk properties of lubricants. ASLE Trans. 1981, 24, 232–238. [Google Scholar] [CrossRef]

- Hodges, P.K.B. (Ed.) Compressibility. In Hydraulic Fluids; Butterworth-Heinemann: Waltham, MA, USA, 1996; pp. 55–66. [Google Scholar]

- Mojet, B.L.; Ebbesenz, S.D.; Lefferts, L. Light at the interface: The potential of attenuated total reflection infrared spectroscopy for understanding heterogeneous catalysis in water. Chem. Soc. Rev. 2010, 39, 4643–4655. [Google Scholar] [CrossRef]

- Si, Y.; Samulski, E.T. Synthesis of water soluble graphene. Nano Lett. 2008, 8, 1679–1682. [Google Scholar] [CrossRef]

- Gao, R.; Hu, N.; Yang, Z.; Zhu, Q.; Chai, J.; Su, Y.; Zhang, L.; Zhang, Y. Paper-like graphene-Ag composite films with enhanced mechanical and electrical properties. Nanoscale Res. Lett. 2013, 8, 32. [Google Scholar] [CrossRef]

- Velasco, M.J.; Rubio, J.; Oteo, J.L. Estudio por espectroscopía infrarroja de la reacción de hidrólisis y policondensación del IEOS en presencia de PDMS. Boletín Soc. Española Cerámica Vidr. 2001, 40, 37–42. Available online: http://hdl.handle.net/10261/4760 (accessed on 16 January 2018). [CrossRef]

- Téllez, L.; Rubio, F.; Peña-Alonso, R.; Rubio, J. Seguimiento por espectroscopia infrarroja (FT-IR) de la copolimerización de TEOS (tetraetilortosilicato) y PDMS (polidimetilsiloxano) en presencia de tbt (tetrabutiltitanio). Boletín Soc. Española Cerámica Vidr. 2004, 43, 883–890. Available online: http://hdl.handle.net/10261/4416 (accessed on 16 January 2018). [CrossRef]

- Mentlík, V.; Polanský, R.; Prosr, P.; Pihera, J.; Trnka, P. Synthetic ester-based oils and their application in power industry. RE&PQJ 2009, 1, 215–219. [Google Scholar] [CrossRef]

- Hentschel, K.H. The influence of molecular structure on the frictional behaviour of lubricating fluids. J. Synth. Lubr. 1985, 2, 143–165. [Google Scholar] [CrossRef]

- Erhan, S.Z.; Sharma, B.K.; Perez, J.M. Oxidation and low temperature stability of vegetable oil-based lubricants. Ind. Crops Prod. 2006, 24, 292–299. [Google Scholar] [CrossRef]

| Designation | Lubricating Medium |

|---|---|

| L1 | Water |

| L2 | Seawater |

| L3 | Graphite nanoparticles in water |

| L4 | Synthetic oil |

| L5 | Mineral oil |

| L6 | Natural oil with Mineral oil and *EP |

| L7 | Natural oil with Synthetic esters and *EP |

| L8 | Natural oil (Castor oil) |

| Property at 25 °C | Lubricant | |||||||

|---|---|---|---|---|---|---|---|---|

| L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | |

| ρ (Kg/m3) | 997 | 1027 | 1035 | 976 | 914 | 1126 | 1159 | 961 |

| µ (×10−3 Pa·s) | 0.89 | 0.98 | 53 | 1093 | 260 | 798 | 883 | 691 |

| υ (×10−6 m2/s) | 0.89 | 0.95 | 51 | 1120 | 285 | 709 | 762 | 719 |

| Lubricant | U | αp (Pa−1) | G | hmin (nm) | λmin | Lubrication Regime |

|---|---|---|---|---|---|---|

| L1 | 2.81 × 10–14 | 2.32 × 10−8 | 6135 | 0.6 | 0.01 | Boundary |

| L2 | 3.08 × 10–14 | 2.10 × 10−8 | 5542 | 0.6 | 0.01 | Boundary |

| L3 | 1.67 × 10–12 | 2.57 × 10−8 | 6777 | 10.3 | 0.21 | Boundary |

| L4 | 3.45 × 10–11 | 0.91 × 10−8 | 2392 | 48.5 | 0.97 | Boundary |

| L5 | 8.20 × 10–12 | 1.81 × 10−8 | 4787 | 25.7 | 0.51 | Boundary |

| L6 | 2.52 × 10–11 | 4.30 × 10−8 | 11369 | 84.1 | 1.68 | Mixed |

| L7 | 2.79 × 10–11 | 3.63 × 10−8 | 9587 | 82.9 | 1.66 | Mixed |

| L8 | 2.18 × 10–11 | 3.86 × 10−8 | 10193 | 72.2 | 1.44 | Mixed |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-Sierra, M.T.; Bravo-Sánchez, M.G.; Báez, J.E.; Aguilera-Camacho, L.D.; García-Miranda, J.S.; Moreno, K.J. Improvement Effect of Green Lubricants on the Tribological and Mechanical Performance of 4140 Steel. Appl. Sci. 2019, 9, 4896. https://doi.org/10.3390/app9224896

Hernández-Sierra MT, Bravo-Sánchez MG, Báez JE, Aguilera-Camacho LD, García-Miranda JS, Moreno KJ. Improvement Effect of Green Lubricants on the Tribological and Mechanical Performance of 4140 Steel. Applied Sciences. 2019; 9(22):4896. https://doi.org/10.3390/app9224896

Chicago/Turabian StyleHernández-Sierra, María T., Micael G. Bravo-Sánchez, José E. Báez, Luis D. Aguilera-Camacho, J. Santos García-Miranda, and Karla J. Moreno. 2019. "Improvement Effect of Green Lubricants on the Tribological and Mechanical Performance of 4140 Steel" Applied Sciences 9, no. 22: 4896. https://doi.org/10.3390/app9224896

APA StyleHernández-Sierra, M. T., Bravo-Sánchez, M. G., Báez, J. E., Aguilera-Camacho, L. D., García-Miranda, J. S., & Moreno, K. J. (2019). Improvement Effect of Green Lubricants on the Tribological and Mechanical Performance of 4140 Steel. Applied Sciences, 9(22), 4896. https://doi.org/10.3390/app9224896