Featured Application

Revealing the respective research foci and terminology of the concept of Industry 4.0 across different global regions.

Abstract

In 2011, the concept of Industry 4.0 was introduced and later adopted by the German government, paving the way for a new industrial revolution in Germany. The high significance of this topic is reflected by the large number of corresponding publications. Additionally, the regional focus of research is widespread on a global level and often differs even at a national level. This paper generates transparency regarding the adoption of the concept of Industry 4.0 by analyzing the locations of main contributors within the research field on an international, European, and German-national level. Further, it examines the regionally different foci concerning the concept of Industry 4.0. Having identified four main aspects linked to Industry 4.0 within a pre-study, a quantitative literature research was conducted based on over 800 published papers. The results were further visualized with QGIS. Looking at the results, it can be concluded that the German research community is virtually the only user of the term Industry 4.0, while other institutions seem to link their research to other related concepts. On a German level, the majority of the analyzed studies originate from Southern and Western Germany. North Rhine-Westphalia and the Aachen/Jülich region, in particular, represent main contributors.

1. Introduction

The Industrial Revolutions underpinned fundamental changes in the past 250 years. The First Industrial Revolution started around 1760 in Great Britain and marked the transition from the agricultural to the manufacturing economy. Along with innovations such as electrification and the assembly line, the Second Industrial Revolution commenced in 1879 and ended with the start of World War I. In the middle of the twentieth century, information technology increased in importance, presiding over the further automation of the manufacturing process. This development is referred to as the Third Industrial Revolution, and it enabled the beginning of digitization [1,2].

At the end of the twentieth century, the introduction of multiple technical innovations is claimed to have initiated a Fourth Industrial Revolution. This Fourth Industrial Revolution is characterized by the occurrence of technologies related to the Internet of Things, leading to a growing digital interconnection between machines, humans, and production lines [3]. In contrast to the previous industrial revolutions, where the manufacturing sector was the main driver, the currently unfolding industrial revolution is driven by the invention and application of smart devices and social networks [4]. In Germany, the term Industry 4.0 encapsulates the German idea of a Fourth Industrial Revolution. The concept originates from the high-tech strategy program of the German government, and was introduced in 2011 at the Hannover Fair [5]. Its focus is on the manufacturing sector and it targets the promotion of the computerization of manufacturing and strengthening Germany’s competitiveness in the global market. According to the originators of the term, Industry 4.0 will lead to smart factories, in which cyber–physical systems (CPS) will monitor and oversee the manufacturing process. These CPSs can send and receive data over the Internet of Things and, in doing so, can communicate with humans, as well as with each other, in real-time. Consequently, customers can convey their desires in the manufacturing process, leading to highly individualized mass products. Industry 4.0 is also said to be accompanied by great efficiency gains, more flexibility, and improvements in supply chain and life cycle management, even though some objections to the term Industry 4.0 exist [6,7,8,9,10].

The Industry 4.0 program represents a crucial part of Germany’s High-Tech Strategy 2020 initiative and is backed by a €200 million bursary fund [11]. Therefore, in 2013, the concept of Industry 4.0 was elaborated and published, along with recommendations for its implementation into the manufacturing process [12].

Outside of Germany, other countries have established similar, but not identical approaches to their Fourth Industrial Revolution. One of these countries is China, with its Made in China 2025 strategy. According to Wübbeke and Conrad [13], rising wages indicate the country’s emergence from “low-wage country” status. Another issue is the relatively low technical standard of many Chinese companies. Consequently, the Chinese government wants to increase efficiency and focus on quality, rather than quantity, through a modernization of the manufacturing sector [14]. Cooperation with German companies to accelerate this process is being pursued.

In contrast to centrally organized activities in Germany, China, or other countries, the Industrial Internet Consortium was founded by private companies and does not represent a strategy program imposed by the government. Rather, it is an open membership organization, founded in the US by AT&T, Cisco, General Electric, IBM, and Intel in March 2014. The Industrial Internet Consortium aims for the widespread adoption and development of interconnected machines in the healthcare, energy, manufacturing, smart city, and transportation sectors [15].

Given the high importance of digitization for the German industry, a lot of research is conducted in universities and institutes. However, paradoxically, it would seem that the increasing quantity of studies has led to an even vaguer understanding of the term Industry 4.0. Therefore, clear definitions of the term are difficult to find [7,9,10].

For this reason, the goal of this paper is to rectify this and lead the research community towards a better understanding of the contexts where concepts related to Industry 4.0 are used and what foci different regions put on the various aspects of Industry 4.0. In the following, an analysis is presented that demonstrates how the wording of Industry 4.0 and correlated topics, like CPS or Big Data, have been adopted at international, national, and regional levels, with a special focus on Germany and North Rhine-Westphalia. For our analysis, we conduct a quantitative literature evaluation using the scientific literature databases Scopus and ScienceDirect.

This approach was chosen to shed light on the distribution of main contributors to topics closely linked to Industry 4.0 and comes with three methodological steps that inherit major benefits: (1) our pre-study reveals key aspects of scientific literature surrounding the field Industry 4.0, (2) our quantitative literature review based on the identified keywords generates an extensive data basis on literature related to Industry 4.0, and (3) the generated geographic information system (GIS) based maps provide convenient overviews on the regional distribution of main scientific contributors, as well as main research foci on different scales.

Furthermore, we provide a comprehensive picture, while other reviews surrounding the research field Industry 4.0 have focused on special aspects of the term, such as:

- -

- edge computing [16];

- -

- additive manufacturing/three-dimensional printing [17];

- -

- cyber-physical production systems [18];

- -

- construction industry [19];

- -

- remanufacturing [20];

- -

- environmentally-sustainable manufacturing [21,22];

- -

- interactions with the energy system [23].

In addition, there have been methodologically different approaches towards reviews within the research area under investigation: [24] used text mining to carve-out main aspects of Industry 4.0 and to provide a future research agenda, whereas [25] applied three-stage qualitative research (identification, classification, and evaluation). Our research approach goes beyond current studies by analyzing the research in the field of Industry 4.0 in high regional resolution, which allows the analysis of the adoption of different terminology around the globe in much more detail.

2. Materials and Methods

To achieve the goal of creating transparency within the usage of the term Industry 4.0, a quantitative literature review approach has been selected. The methodology that was chosen for our quantitative analysis is similar to that which was used by vom Brocke et al. [26]. To ensure the validity of our results, it is necessary to take into account:

- (1)

- the quality of the selected articles;

- (2)

- their relevance to the subject to be reviewed;

- (3)

- their completeness [27].

Advancements in information technology have led to a growing quantity of quickly accessible research articles, many of which focus on similar topics under different headings. Thus, modern literature reviews intrinsically carry the risk of overlooking relevant literature [28]. Therefore, Vom~Brocke et al. [26,27,29,30] underline the necessity of rigorously documented reviews. Systematic approaches have been introduced by [31,32,33].

Taking into account the aforementioned considerations and following the recommendations of the literature, our analysis consisted of a keyword-based approach that was executed using two different platforms, namely Scopus and ScienceDirect [34,35]. In methodological terms, a keyword search refers to the process of inserting the keyword in the search mask of a scientific platform and analyzing the given output against predetermined conditions. The reasoning behind the usage of two platforms lies within an accompanying increase in the robustness of our analysis, as well as a minimization of platform bias. It should be noted that on the scientific platform Scopus, the ranking by number of citations was utilized. On ScienceDirect, however, a ranking by relevance was followed, as it was not possible to rank by citations. The algorithm used by ScienceDirect to determine the relevance of a paper is based on the frequency of relevant keywords [36].

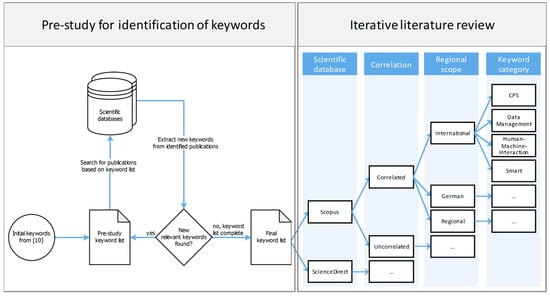

A summary of the quantitative literature review approach is depicted in Figure 1. All methodological steps are explained in further detail within the following paragraphs.

Figure 1.

Methodology for the quantitative literature review approach, separated into pre-study for identifying the final keywords and the iterative literature review process.

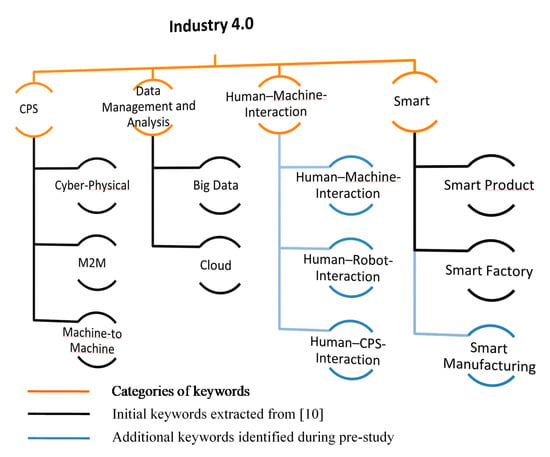

The keywords that were part of the final keyword list and thus were used for the quantitative assessment are depicted in Figure 2. Their assortment was based on a scientific working paper published by researchers from the TU Dortmund [10]. The set of keywords used in that study was further altered, divided, and expanded to depict a more holistic picture of Industry 4.0. Thus, we identified keywords linked to the terms Industrie 4.0 and Industry 4.0 in the course of a pre-study as follows: starting with the keywords provided by [10] the scope of relevant keywords was further expanded by searching for papers using the current set of keywords and adding further keywords according to their occurrence in the search results. In doing so, the papers were ranked by number of citations/relevance according to the databases Scopus and ScienceDirect. The resulting keywords are depicted in Figure 2.

Figure 2.

Categories and keywords used in the quantitative analysis. The following abbreviations are used: cyber–physical systems (CPS) and machine-to-machine (M2M).

As shown in Figure 2, the resulting set of keywords could be arranged in four main categories, namely cyber–physical systems (CPS), data management and analysis (For reasons of brevity, this term is referred to as data management or data in the following), human–machine interaction, and smart.

- CPS: This term revolves around the progressing topic of interconnected machine networks that can communicate with each other to optimize industrial processes. The keywords used here comprised the following: cyber–physical, machine-to-machine, and the abbreviation of the latter, M2M;

- Data management: The topic of data management is steadily increasing in size and importance due to the amount of data produced daily across industries. According to our pre-study, this topic was represented by the keywords big data and cloud.

- Human–machine interaction: This term focuses on the intersection between humans and machines in an industrial context. This topic is currently being discussed both from a technological and a social point of view: while the tech orientation focuses on the potential to optimize robotic systems, sensors, and augmented reality in order to smooth the interaction between humans and machines, the social orientation depicts upcoming ethical threads accompanying Industry 4.0, such as a shift in employment. The keywords used to depict discussions related to human–machine interaction were as follows: human–machine interaction, human–robot interaction, and human–CPS interaction.

- Smart: This rather broad term refers to advancing the interconnection of factories regarding both the products and the manufacturing processes. According to the pre-study, the following keywords are most relevant to cover this subject area: smart product, smart factory, and smart manufacturing (the well-known topic of the smart grid was not covered, since it only marginally overlaps with the topic of Industry 4.0. For further analyses of the intersection between energy system analysis and Industry 4.0, please see [23]).

The keywords generated within the pre-study were inserted into the search mask of both scientific platforms and the search results were further analyzed. The main step of the quantitative analysis, which was carried out between 2 December 2016 and 3 January 2017, was to count papers that implemented the selected keyword in either their title, abstract, or keyword list. Furthermore, the title, link, number of citations, and origin of every selected paper were archived in order to link them to one of the categories introduced above (cf. Figure 2), as well as the authors’ origin. Moreover, the listed papers were filtered manually to ensure that papers were only counted if they were related to industrial topics. To limit the size of our research and database and to ensure the quality of the research works under consideration, only the first 50 most cited/relevant papers for each category and scientific platform were taken into account.

Additionally, the limitation of the number of papers under consideration per search allowed us to conduct five repetitions of the above-mentioned procedure with different regional scope to create transparency regarding the origins of main contributors within the research area Industry 4.0.

The first segregation by regional context gave way to an analysis with an international focus, German national focus, and regional focus for North Rhine-Westphalia, which tripled the data input. The goal of this segregation was to highlight the differences in the usage of the term Industry 4.0, as well as the differences in research performed utilizing the selected keywords on each mentioned regional level. For the international analysis, the first 50 papers that fulfilled our conditions were selected for each platform and division. However, in the German national-based analysis, an additional condition was implemented, namely the papers’ origin from Germany. For the regional-based analysis, the condition was altered to an origin from North Rhine-Westphalia. To further enhance the scope of our quantitative results, papers in the German language were also taken into account for the national and regional-based analyses. To this end, the list of keywords was further expanded by the corresponding German equivalences.

The second segregation by means of terminological correlation doubled the data input and allowed for further specifications. This segregation was performed to highlight the difference in conducted research of a keyword with and without correspondence to the topic of Industry 4.0. Therefore, we conducted the keyword research at the global, German national, and regional levels in a correlated and uncorrelated manner. The term correlation describes the connection to the terminology, Industry 4.0. Consequently, in the uncorrelated analysis, only the keywords were typed into the scientific platforms. However, in the correlated version, the keyword, as well as the term Industry 4.0, or alternatively its German equivalent of Industrie 4.0, were entered. In order to avoid a language bias, papers related to Industrie 4.0 were only considered in the national and regional analysis, as this term is mostly used in German papers.

As a consequence of these subdivided analyses, a database of more than 800 different papers was created that sought to include up to 50 of the most relevant papers for each division, platform, region, and correlational context. The reasons that our database did not comprise a total number of 2400 papers (i.e., 50 paper × 4 divisions × 3 regional areas × 2 correlational contexts × 2 databases) are as follows:

- (1)

- Papers that appeared in both scientific databases, Scopus and ScienceDirect, were only counted once;

- (2)

- Papers were allowed to appear in more than one analysis if:

- their authors originated from more than one geological area;

- they met the conditions of the uncorrelated and correlated keyword search;

- they originated from Germany/North Rhine-Westphalia, due to their downward regional compatibility;

- they meet the conditions of more than one category;

- (3)

- In very specific analyses, such as the North Rhine-Westphalia-correlated analysis, it was not possible to find 50 papers for each division and platform due to the strict conditions that were maintained.

Finally, the results were visualized using QGIS [37], which is a free and open source geographic information system that provided us with the capability to display our raw data very clearly. Therefore, we mapped our results showing the regional distributions, as can be seen below.

3. Results

Having described our methodology, we can now present the results gained within our study. We will first show the results of the uncorrelated analysis, zooming in on different regional scales: starting from the international analysis reducing the scope to a European continental level, German national analysis, and a regional analysis of North Rhine-Westphalia.

3.1. Results of the Uncorrelated Analysis

3.1.1. International Analysis

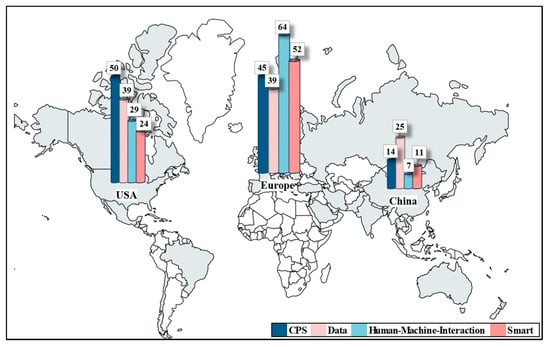

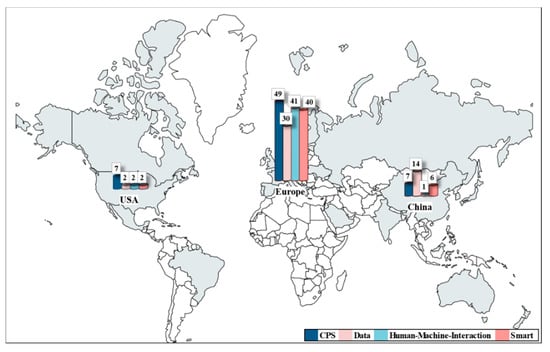

In total, 52 countries could be identified that contributed to the research area Industry 4.0. With that number in mind, the amount of research from around the globe that contains the above-mentioned keywords becomes evident. However, it is possible to identify three main players that have published the largest amount of research and are visualized in Figure 3: the USA, China, and Europe. Each of these regions has a different research approach and focus, such as the Chinese Made in China 2025 strategy described in Section 1. It is apparent that the majority of analyzed studies related to the topic of “CPS” origins from the USA (50) and Europe (45), whereas 14 articles were published in China. Comparing the number of papers related to data management, the USA and Europe achieve 39 publications each, while China achieves 25. Looking at human–machine interaction, significant differences between the regions can be observed. European institutions have published 64 articles, the Americans 29, and the Chinese 7. A similar distribution can be detected when comparing the keywords linked to the category smart: Europe has published 52 papers, the USA 24, and China 11. When comparing the relative number of articles in each region, it is evident that China’s focus lies in data management, with no special interest in the related topics of human–machine interaction. The research in Europe, on the other hand, is focused on human–machine interaction, followed by smart and CPS topics. Compared to these other areas, data management features the lowest number of publications. Looking at the USA, it can be seen that the American research community primarily focuses on CPS, followed by data management, human–machine interaction, and smart.

Figure 3.

Number of papers identified in the uncorrelated international analysis (worldwide scale). Sources of the shapefile: [38,39].

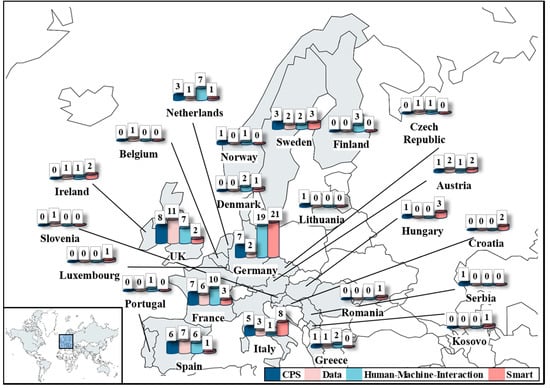

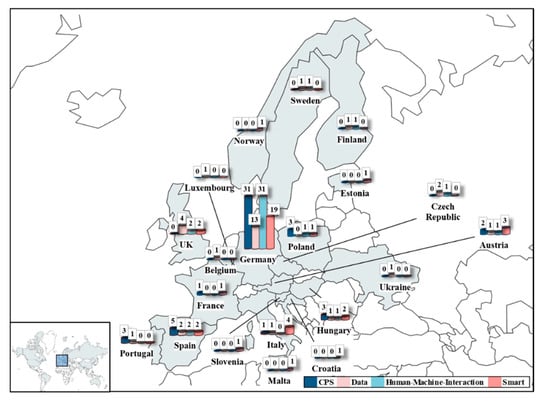

Zooming in on a European Scale, three main countries held the highest significance in the conducted research, namely Germany, France, and the UK (see Figure 4). On the international level, Germany’s focus turns out to be topics related to the categories smart, with 21, and human–machine interaction, with 19 publications, whereas data management seems to be of less interest (2). The UK, on the other hand, published most of its papers around data management (11), followed by CPS (8), human–machine interaction (7), and smart (2). In France, 10 papers were published on human–machine interaction, 7 on CPS, 6 on data management, and only 3 on topics linked to the category smart. Apart from these three main players, Spain and Italy have also conducted some research in the aforementioned fields. Eastern Europe, on the other hand, only made a small contribution to the selected topics.

Figure 4.

Papers identified in the uncorrelated international analysis (European scale). Sources of the shapefile: [38,39].

3.1.2. National Analysis

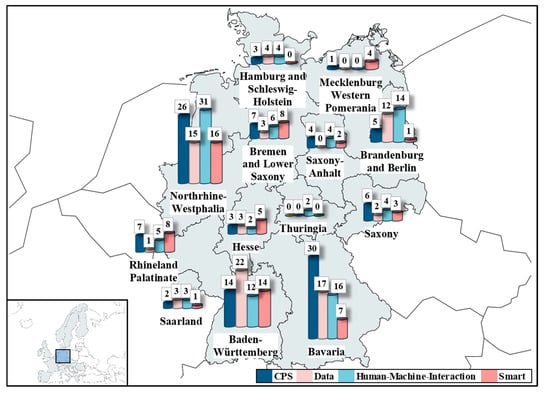

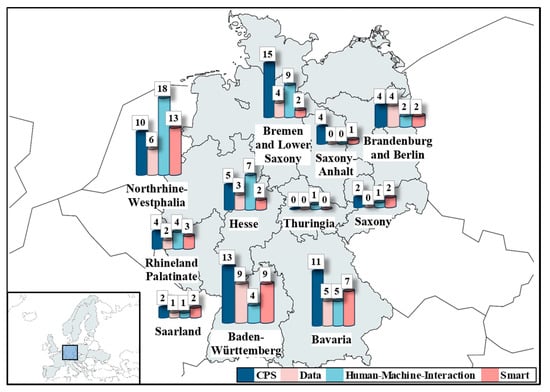

Figure 5 displays the national research situation in Germany. North Rhine-Westphalia (88), Bavaria (70), Baden Württemberg (62), and Berlin and Brandenburg (32) can be identified as the main contributors, with the highest amount of relevant research papers. These regions are also home to Germany’s automotive sector, as well as the biggest universities and technical institutes, namely RWTH Aachen (North Rhine-Westphalia), TU Karlsruhe, TU Stuttgart (both Baden Württemberg), TU München (Bavaria), and TU Berlin. Most of the publications from North Rhine-Westphalia deal with human–machine interaction (31) and CPS (26). Data management and smart follow in equal measure, with 15 and 16 publications, respectively. In Bavaria, research referring to CPS predominates (30), followed by data management (17), human–machine interaction (16), and smart (7). In Baden Württemberg, the research society concentrates on data management (22). CPS and smart both comprise 14 publications, while 12 publications are linked to human–machine interaction. Berlin’s and Brandenburg’s focus lies on human–machine interaction (14) and data management (12). CPS (5) and smart (1) seem to be of less importance.

Figure 5.

Papers identified in the uncorrelated national analysis. Sources of the shapefile: [38,39,40].

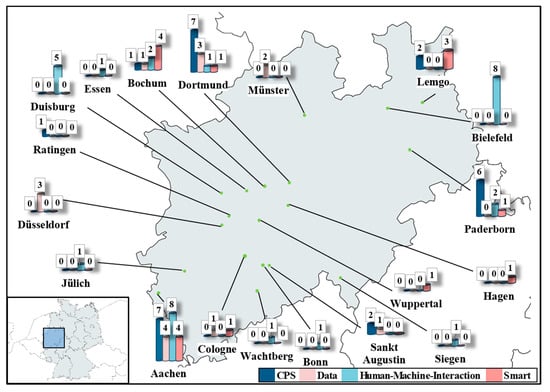

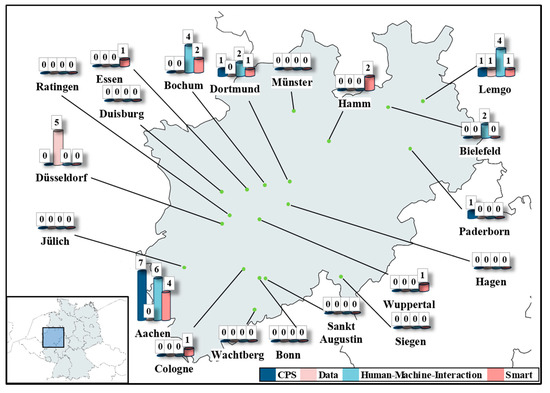

Taking a closer look at the federal state of North Rhine-Westphalia (NRW) (Figure 6), the dominant role of the Aachen/Jülich region can be observed, accounting for a total of 23 publications. Research in Aachen focuses on human–machine interaction (eight) and CPS (seven). Data management and smart are represented by four publications each. Aside from Aachen, TU Dortmund represents the second most significant body of research in NRW, with 12 papers. Most of this research is based on CPS (seven), followed by data management (three) and human–machine interaction, as well as smart with one paper each. Researchers in Paderborn mostly analyze topics relating to CPS (six). Human–machine interaction (one), smart (one), and data management (zero) seem to find little attention, whereas Bielefeld only concentrates on human–machine interaction (eight). Bochum’s focus lies on smart (four), followed by human–machine interaction (two), CPS (zero), and data management (one).

Figure 6.

Papers identified in the uncorrelated regional analysis. Sources of the shapefile: [38,39,40].

3.2. Results of the Correlated Analysis

3.2.1. International Analysis

The international analysis on the worldwide scale in Figure 7 clearly displays Europe’s dominant role in the correlated analysis. In comparison to the USA and China, Europe produces 78% of all papers linked to the category CPS, 65% of all papers referring to data management, 83% of all papers that fall within the category smart, and even 93% of all papers dealing with human–machine interaction, in correlation to the term Industry 4.0. Meanwhile, the USA shows very little to no use of the term in correlation to the selected keywords. China has some contributions, with 14 papers identified in the data management category, followed by CPS (7) and smart (6). Publications around the topic human–machine interaction are of no special interest in the USA (two) and China (one).

Figure 7.

Papers identified in the correlated international analysis (worldwide scale). Sources of the shapefile [38,39].

On a European scale, the dominant use of the term Industry 4.0 within Germany becomes evident (cf. Figure 8). The country is particularly focused on CPS (31) and human–machine interaction (31), while data management (13) and smart (19) are falling behind. Only two more countries appear to implement the term Industry 4.0 to at least some degree: Spain and the UK. The latter seems to focus on data management (four), followed by human–machine interaction (two) and smart (two). Spain, on the other hand, published most of its studies around CPS (five), followed by smart (two), data management (two), and human–machine interaction (two). Apart from these three main countries, Austria, Portugal, Hungary, and Italy have also conducted some amount of research in the aforementioned fields in relation to the term Industry 4.0. The rest of Europe does not appear to use this term to any significant extent in the context of the selected keywords.

Figure 8.

Papers identified in the correlated international analysis (European scale). Sources of the shapefile [38,39].

3.2.2. National Analysis

The German national correlated analysis, displayed in Figure 9, depicts a similar picture as in the uncorrelated analysis. The main contributors are North Rhine-Westphalia with 47, Bavaria with 28, Hesse with 17, Bremen and Lower Saxony with 30, and Baden-Württemberg with 35 publications. Compared to the uncorrelated analysis, Brandenburg and Berlin are overall decreasing in significance, declining from 32 to 12 studies. In North Rhine-Westphalia, most of the publications deal with human–machine interaction (18), followed by smart (13), CPS (10), and data management (6), while in Hesse most of the publications are related to human–machine interaction (7), followed by CPS (5), data management (3), and smart (2). In Bavaria (11), Bremen and Lower Saxony (15), and Baden-Württemberg (13), most of the studies deal with CPS.

Figure 9.

Papers identified in the correlated national analysis; Source of shapefile [38,39,40].

Zooming in on North Rhine-Westphalia, Aachen can be identified as the leading city, with a total of 17 publications (cf. Figure 10). Research in Aachen focuses on human–machine interaction (six) and CPS (seven), followed by smart, with four publications. The only other contributors that have some degree of significance are Bochum (six), Lemgo (seven), Dortmund (four), and Düsseldorf (five), the latter of which can be identified as the leader in correlated data management research (five). Lemgo’s, as well as Bochum’s, research focus lies in human–machine interaction, with four publications each. Apart from Lemgo (one) and Düsseldorf (five), no other regional study related to data management could be found in the correlated analysis (for further details regarding the results of the correlated and uncorrelated analysis, please see Table A1 and Table A2 in the Appendix A of this manuscript).

Figure 10.

Papers identified in the correlated regional analysis. Sources of the shapefile [38,39,40].

4. Discussion

In summary, our work sought a novel approach to illuminating the field of Industry 4.0 by performing a quantitative keyword search on two scientific platforms with predetermined conditions and keywords, taking into account a total number of more than 800 published papers. This search was performed on different regional levels in an uncorrelated and correlated way with the term Industry 4.0, further analyzed and visualized using QGIS. As a consequence, the main research locations, as well as their different foci, were identified on every regional level for both analytical approaches. Most importantly, the differences in research under the topics of Industry 4.0 to the international adaption of the term became clear.

Therefore, our suggestion for future research is to investigate the perception of different countries towards their equivalent to Industry 4.0 more clearly, highlighting the distinctive foci, differences, and similarities. Also, an adaption of our displayed methodology and analysis approach for a different terminology, such as the “Internet of Things”, would be of interest. In addition, more recent developments, such as the emergence of blockchain technologies and their implications for Industry 4.0, could be analyzed (cf. [41,42,43]). Consequently, one could determine whether the displayed phenomenon only applies to Industry 4.0 or not, and potentially find an already superior term on an international level.

In order to compare our results to those from other studies, we look at our identified keywords and the regional distribution of the adoption of those keywords. Galati and Bigliardi [31] applied a solely correlated analysis on publications related to the term Industry 4.0 and did not include any other keywords in their analysis. They found that Germany is by far the most active country in terms of publications in the field of Industry 4.0. Kang et al. [44] used similar keywords in their systematic literature review, however, the category of human–machine interaction was not present in their analysis. They did not distribute their results to different regions. Rojas and Rauch [27] identified similar keywords by conducting a term frequency analysis as part of their systematic review that was based on the database Scopus. Kadir et al. [33] again identified similar keywords using a systematic literature review, however, their sample size was small compared to ours due to their specific focus on human factors and ergonomics in Industry 4.0. Overall, our results are in line with available systematic reviews on the research are of Industry 4.0. However, going beyond the current studies, the high regional resolution of our results makes it possible to analyze the adoption of the different terminology around the globe in much more detail.

Even though the core results of the presented study are very clear and robust, there are some distortions that must be addressed, most importantly the implicit drawbacks of a keyword-based research approach: as already mentioned above, it is hard to give Industry 4.0 a clear definition. Therefore, we conducted a pre-study to elaborate keywords that set appropriate boundaries for this field of research. However, the keywords used cannot fully cover every single aspect of Industry 4.0, nor can it be ensured at 100% significance level that all papers counted have a link to Industry 4.0, in particular within the uncorrelated analysis. The manual filtering process to guarantee the consideration of papers with a direct link to processes addressed this issue.

To address a possible database bias that might be linked with our methodology, two different scientific databases were considered. However, we cannot completely preclude the existence of database bias due to the small number of considered data sources. On the other hand, the considered databases comprised around 40,000 journals and had high coverage in the research field of Industry 4.0, indicating the high validity of our results.

5. Conclusions

The goal of this study was to generate transparency within the worldwide usage of this expression by conducting a keyword-based literature search, quantitatively assessing the results, and visualizing the regional distribution of main contributors in research areas linked to the term Industry 4.0. In addition to the regional distribution of main contributors to the field, our results also indicate differences regarding the main foci of research linked to Industry 4.0. A promising, novel methodology was implemented that is easily applicable to a variety of research sectors and may lay the foundation for further research investigating the equivalents of Industry 4.0 around the globe, as well as the different national perceptions behind them.

According to the correlated analyses, the core outcome of the presented study becomes evident.

Germany is the main leader in research featuring the term Industry 4.0, covering 40% of the conducted research worldwide (i.e., 94 out of 232 relevant publications, cf. Table A2 in the Appendix A).

However, the results of the uncorrelated analysis also revealed significant contributions from other countries, such as the USA and China. Furthermore, many countries around the globe also have their own terminology for the phenomenon referred to as Industry 4.0 within Germany, such as China’s Made in China 2025 strategy. This leads to the following conclusion: there is a lack of adaption of the term Industry 4.0 on a worldwide basis, even though the term is currently presented to be highly international. However, related topics are considered worldwide for which different terminologies are used (See Table A1 in the Appendix A).

Additionally, our results indicate that different perceptions and foci of the topic come along with different designations, as each region has a distinctive plan and strategy on how their Fourth Industrial Revolution will look: the uncorrelated analysis revealed that the USA predominantly focuses on CPS, whereas Europe’s research is mainly focused on human–machine interaction and China emphasizes topics related to data. The correlated analysis showed that European publications mainly focused on CPS in this case, whereas the USA and China kept the same foci as before (i.e., CPS for the case of the USA and data for China). In future works, the different terminologies on aspects of Industry 4.0 should be further investigated. This could be achieved by dissembling the different concepts into their technical and organizational core components and conducting a similarity analysis based on these core components to overcome the problem of tautology.

Author Contributions

Conceptualization: L.N. and A.P.; Project administration: A.P.; Supervision: M.R. and A.P.; Validation: L.N., J.P., C.K., I.H., M.R. and A.P.; Visualization: G.R. and T.B.; Writing—original draft: G.R. and T.B.; Writing—review and editing: L.N., J.P., C.K., I.H., M.R. and A.P.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Number of papers identified in the uncorrelated international analysis.

Table A1.

Number of papers identified in the uncorrelated international analysis.

| Uncorrelated Analysis | CPS | Data Management | Human–Machine Interaction | Smart |

|---|---|---|---|---|

| Australia | 2 | 10 | 2 | 1 |

| Austria | 1 | 2 | 1 | 2 |

| Belgium | 0 | 1 | 0 | 0 |

| Brazil | 0 | 1 | 1 | 1 |

| Canada | 6 | 3 | 2 | 2 |

| Chile | 1 | 0 | 0 | 1 |

| China | 14 | 25 | 7 | 11 |

| Croatia | 0 | 0 | 0 | 2 |

| Czech Republic | 0 | 1 | 1 | 0 |

| Denmark | 0 | 0 | 2 | 1 |

| Estonia | 0 | 0 | 0 | 0 |

| Finland | 0 | 0 | 3 | 0 |

| France | 7 | 6 | 10 | 3 |

| Germany | 7 | 2 | 19 | 21 |

| Greece | 1 | 1 | 2 | 0 |

| Hungary | 1 | 0 | 0 | 3 |

| India | 3 | 8 | 1 | 0 |

| Iran | 1 | 2 | 0 | 0 |

| Ireland | 0 | 1 | 1 | 2 |

| Israel | 0 | 1 | 2 | 0 |

| Italy | 5 | 3 | 1 | 8 |

| Japan | 1 | 1 | 6 | 3 |

| Kosovo | 0 | 0 | 0 | 1 |

| Lithuania | 1 | 0 | 0 | 0 |

| Luxembourg | 0 | 0 | 0 | 1 |

| Macau | 0 | 1 | 0 | 0 |

| Malaysia | 0 | 4 | 0 | 0 |

| Malta | 0 | 0 | 0 | 0 |

| Mexico | 0 | 0 | 1 | 0 |

| Netherlands | 3 | 1 | 7 | 1 |

| New Zealand | 0 | 4 | 1 | 0 |

| Norway | 1 | 0 | 1 | 0 |

| Pakistan | 0 | 3 | 0 | 0 |

| Palestine | 0 | 0 | 2 | 0 |

| Poland | 0 | 0 | 0 | 0 |

| Portugal | 0 | 0 | 1 | 0 |

| Romania | 0 | 0 | 0 | 1 |

| Russia | 0 | 0 | 0 | 4 |

| Saudi Arabia | 1 | 1 | 0 | 0 |

| Serbia | 1 | 0 | 0 | 0 |

| Singapore | 0 | 2 | 5 | 0 |

| Slovenia | 0 | 1 | 0 | 0 |

| South Korea | 5 | 2 | 1 | 5 |

| Spain | 6 | 7 | 6 | 1 |

| Sweden | 3 | 2 | 2 | 3 |

| Taiwan | 4 | 2 | 2 | 0 |

| Thailand | 0 | 0 | 2 | 0 |

| Turkey | 1 | 0 | 2 | 0 |

| UK | 8 | 11 | 7 | 2 |

| Ukraine | 0 | 0 | 0 | 0 |

| United Arab Emirates | 0 | 0 | 1 | 0 |

| USA | 50 | 39 | 29 | 24 |

Table A2.

Amount of papers identified in the correlated international analysis.

Table A2.

Amount of papers identified in the correlated international analysis.

| Uncorrelated Analysis | CPS | Data Management | Human–Machine Interaction | Smart |

|---|---|---|---|---|

| Australia | 3 | 0 | 0 | 1 |

| Austria | 2 | 1 | 1 | 3 |

| Belgium | 0 | 1 | 0 | 0 |

| Brazil | 2 | 0 | 0 | 1 |

| Canada | 1 | 0 | 1 | 0 |

| Chile | 0 | 0 | 0 | 0 |

| China | 7 | 14 | 1 | 6 |

| Croatia | 0 | 0 | 0 | 1 |

| Czech Republic | 0 | 2 | 1 | 0 |

| Denmark | 0 | 0 | 0 | 0 |

| Estonia | 0 | 0 | 0 | 1 |

| Finland | 0 | 1 | 1 | 0 |

| France | 1 | 0 | 0 | 1 |

| Germany | 31 | 13 | 31 | 19 |

| Greece | 0 | 0 | 0 | 0 |

| Hungary | 3 | 1 | 1 | 2 |

| India | 0 | 0 | 0 | 2 |

| Iran | 0 | 0 | 0 | 0 |

| Ireland | 0 | 0 | 0 | 0 |

| Israel | 0 | 0 | 0 | 0 |

| Italy | 1 | 1 | 0 | 4 |

| Japan | 1 | 1 | 0 | 0 |

| Kosovo | 0 | 0 | 0 | 0 |

| Lithuania | 0 | 0 | 0 | 0 |

| Luxembourg | 0 | 1 | 0 | 0 |

| Macau | 0 | 0 | 0 | 0 |

| Malaysia | 0 | 0 | 0 | 1 |

| Malta | 0 | 0 | 0 | 1 |

| Mexico | 1 | 0 | 0 | 0 |

| Netherlands | 0 | 0 | 0 | 0 |

| New Zealand | 1 | 2 | 0 | 0 |

| Norway | 0 | 0 | 0 | 1 |

| Pakistan | 0 | 0 | 0 | 0 |

| Palestine | 0 | 0 | 0 | 0 |

| Poland | 3 | 0 | 1 | 1 |

| Portugal | 3 | 1 | 0 | 0 |

| Romania | 0 | 0 | 0 | 0 |

| Russia | 2 | 0 | 0 | 1 |

| Saudi Arabia | 0 | 1 | 0 | 1 |

| Serbia | 0 | 0 | 0 | 0 |

| Singapore | 0 | 0 | 0 | 0 |

| Slovenia | 0 | 0 | 0 | 1 |

| South Korea | 0 | 2 | 0 | 4 |

| Spain | 5 | 2 | 2 | 2 |

| Sweden | 0 | 1 | 1 | 0 |

| Taiwan | 2 | 4 | 0 | 0 |

| Thailand | 0 | 0 | 0 | 0 |

| Turkey | 0 | 0 | 0 | 0 |

| UK | 0 | 4 | 2 | 2 |

| Ukraine | 0 | 1 | 0 | 0 |

| United Arab Emirates | 0 | 0 | 0 | 0 |

| USA | 7 | 2 | 2 | 2 |

References

- Industrie-Wegweiser. Von Industrie 1.0 bis 4.0—Industrie im Wandel der Zeit. Available online: http://industrie-wegweiser.de/von-industrie-1-0-bis-4-0-industrie-im-wandel-der-zeit/ (accessed on 18 February 2017).

- Stearns, P.N. The Industrial Revolution in World History; Westview Press: Philadelphia, PA, USA, 2013. [Google Scholar]

- Rifkin, J. The Third Industrial Revolution: How Lateral Power Is Transforming Energy, the Economy, and the World; Palgrave Macmillan: New York, NY, USA, 2011. [Google Scholar]

- Schuh, G.; Potente, T.; Wesch-Potente, C.; Weber, A.R.; Prote, J.P. Collaboration Mechanisms to Increase Productivity in the Context of Industrie 4.0. Procedia CIRP 2014, 19, 51–56. [Google Scholar] [CrossRef]

- Kagermann, H.; Lukas, W.; Wahlster, W. Industrie 4.0: Mit dem Internet der Dinge auf dem Weg zur 4. Industriellen Revolution; VDI Nachrichten: Berlin, Germany, 2011. [Google Scholar]

- Posada, J.; Toro, C.; Barandiaran, I.; Oyarzun, D.; Stricker, D.; de Amicis, R.; Pinto, E.B.; Eisert, P.; Dollner, J.; Vallarino, I. Visual Computing as a Key Enabling Technology for Industrie 4.0 and Industrial Internet, Computer Graphics and Applications. IEEE 2015, 35, 26–40. [Google Scholar]

- Drath, R.; Horch, A. Industrie 4.0: Hit or Hype? IEEE Ind. Electron. Mag. 2014, 8, 56–58. [Google Scholar] [CrossRef]

- Blanchet, M.; Rinn, T.; von Thaden, G.; de Thieulloy, G. Industry 4.0: The New Industrial Revolution. How Europe will Succeed; Roland Berger Strategy Consultants GmbH: Munich, Germany, 2014. [Google Scholar]

- Bauernhansl, T.; ten Hompel, M.; Vogel-Heuser, B. Industrie 4.0 in Produktion, Automatisierung und Logistik; Springer: Wiesbaden, Germany, 2014. [Google Scholar]

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios: A Literature Review. 2015. Available online: http://www.snom.mb.tu-dortmund.de/cms/de/forschung/Arbeitsberichte/Design-Principles-for-Industrie-4_0-Scenarios.pdf (accessed on 18 February 2017).

- Kagermann, H.; Wahlster, W. Industrie 4.0—Smart Manufacturing for the Future. German Trade and Investment. 2014. Available online: http://www.gtai.de/GTAI/Content/EN/Invest/_SharedDocs/Downloads/GTAI/Brochures/Industries/industrie4.0-smart-manufacturing-for-the-future-en.pdf (accessed on 18 February 2017).

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative Industrie 4.0: Final Report of the Industrie 4.0 Working Group; Forschungsunion, Acatech: Frankfurt, Germany, 2013. [Google Scholar]

- Wübbeke, J.; Conrad, B. Industrie 4.0: Deutsche Technologie für Chinas Industrielle Aufholjagd? 2015. Available online: http://www.merics.org/fileadmin/templates/download/china-monitor/China_Monitor_No_23.pdf (accessed on 18 February 2017).

- The State Council of the People’s Republic of China. “Made in China 2025” Plan Issued. 2015. Available online: http://english.gov.cn/policies/latest_releases/2015/05/19/content_281475110703534.htm (accessed on 18 February 2017).

- Industrial Internet Consortium (IIC). Available online: http://www.iiconsortium.org/ (accessed on 18 February 2017).

- Sittón-Candanedo, I.; Alonso, R.S.; Rodríguez-González, S.; García Coria, J.A.; De La Prieta, F. Edge Computing Architectures in Industry 4.0: A General Survey and Comparison. Advances in Intelligent Systems and Computing. 2019. Available online: https://www2.scopus.com/inward/record.uri?eid=2-s2.0-85065921255&doi=10.1007%2f978-3-030-20055-8_12&partnerID=40&md5=90b2d6ea943b97751b56a6d752a36cc3 (accessed on 7 October 2019).

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The potential of additive manufacturing in the smart factory industrial 4.0: A review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef]

- Rojas, R.A.; Rauch, E. From a literature review to a conceptual framework of enablers for smart manufacturing control. Int. J. Adv. Manuf. Technol. 2019, 104, 517–533. [Google Scholar] [CrossRef]

- Schimanski, C.P.; Monizza, G.P.; Marcher, C.; Matt, D.T. Pushing digital automation of configure-to-order services in small and medium enterprises of the construction equipment industry: A design science research approach. Appl. Sci. 2019, 9, 3780. [Google Scholar] [CrossRef]

- Kerin, M.; Pham, D.T. A review of emerging industry 4.0 technologies in remanufacturing. J. Clean. Prod. 2019, 237, 117805. [Google Scholar] [CrossRef]

- De Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Foropon, C.; Filho, M.G. When titans meet—Can industry 4.0 revolutionise the environmentally-sustainable manufacturing wave? The role of critical success factors. Technol. Forecast. Soc. Chang. 2018, 132, 18–25. [Google Scholar] [CrossRef]

- Scharl, S.; Praktiknjo, A. The Role of a Digital Industry 4.0 in a Renewable Energy System. Int. J. Energy Res. 2019, 43, 3891–3904. [Google Scholar] [CrossRef]

- Nolting, L.; Kies, A.; Schönegge, M.; Robinius, M.; Praktiknjo, A. Locating Experts and Carving out the State of the Art: A Systematic Review on Industry 4.0 and Energy System Analysis. Int. J. Energy Res. 2019, 43, 3981–4002. [Google Scholar] [CrossRef]

- Galati, F.; Bigliardi, B. Industry 4.0: Emerging themes and future research avenues using a text mining approach. Comput. Ind. 2019, 109, 100–113. [Google Scholar] [CrossRef]

- Esmaeilian, B.; Behdad, S.; Wang, B. The evolution and future of manufacturing: A review. J. Manuf. Syst. 2016, 39, 79–100. [Google Scholar] [CrossRef]

- Vom Brocke, J.; Simons, A.; Niehaves, B.; Reimer, K.; Plattfaut, R.; Cleven, A. Reconstructing The Giant: On The Importance of Rigour in Documenting the Literature Search Process. In Proceedings of the European Conference of Information Systems, Verona, Italy, 8–10 June 2009. [Google Scholar]

- Levy, Y.; Ellis, T.J. A systems approach to conduct an effective literature review in support of information systems research. Inf. Sci. Int. J. Emerg. Transdiscipl. 2006, 9, 181–212. [Google Scholar] [CrossRef]

- Vom Brocke, J.; Simons, A.; Riemer, K.; Niehaves, B.; Plattfaut, R.; Cleven, A. Standing on the shoulders of giants: Challenges and recommendations of literature search in information systems research. Commun. Assoc. Inf. Syst. 2015, 37, 205–224. [Google Scholar] [CrossRef]

- Bandara, W.; Miskon, S.; Fielt, E. A systematic, tool-supported method for conducting literature reviews in information systems. In Proceedings of the ECIS, Helsinki, Finland, 9–11 June 2011. [Google Scholar]

- Wolfswinkel, J.F.; Furtmueller, E.; Wilderom, C.P.M. Using grounded theory as a method for rigorously reviewing literature. Eur. J. Inf. Syst. 2013, 22, 45–55. [Google Scholar] [CrossRef]

- Okoli, C. A Guide to Conducting a Standalone Systematic Literature Review. Inf. Syst. 2015, 37, 880–910. [Google Scholar] [CrossRef]

- Mancarella, P. MES (multi-energy systems): An overview of concepts and evaluation models. Energy 2014, 65, 1–17. [Google Scholar] [CrossRef]

- Kadir, B.A.; Broberg, O.; da Conceição, C.S. Current research and future perspectives on human factors and ergonomics in Industry 4.0. Comput. Ind. Eng. 2019, 137, 106004. [Google Scholar] [CrossRef]

- Scopus. Available online: https://www.scopus.com/ (accessed on 18 February 2017).

- ScienceDirect. Available online: http://www.sciencedirect.com/ (accessed on 18 February 2017).

- ScienceDirect. Available online: https://service.elsevier.com/app/answers/detail/a_id/28453/supporthub/sciencedirect/kw/relevance/ (accessed on 18 February 2017).

- QGIS Development Team. QGIS Geographic Information System. Open Source Geospatial Foundation Project. 2017. Available online: http://www.qgis.org/ (accessed on 18 February 2017).

- Geofabrik. OpenStreetMap Data Extracts. [Dataset]. Available online: http://download.geofabrik.de/ (accessed on 3 January 2017).

- Natural Earth. Admin 0—Countries. [Dataset]. Available online: http://www.naturalearthdata.com/downloads/110m-cultural-vectors/110m-admin-0-countries/ (accessed on 3 January 2017).

- Arcgis. Verwaltungsgrenzen Deutschland (De, Länder, Rgbz, Kreise). [Dataset]. Available online: https://www.arcgis.com/home/item.html?id=ae25571c60d94ce5b7fcbf74e27c00e0 (accessed on 3 January 2017).

- Dick, C.I.; Praktiknjo, A. Blockchain Technology and Electricity Wholesale Markets: Expert Insights on Potentials and Challenges for OTC Trading in Europe. Energies 2019, 12, 832. [Google Scholar] [CrossRef]

- Mora, C.; Rollins, R.L.; Taladay, K.; Kantar, M.B.; Chock, M.K.; Shimada, M.; Franklin, E.C. Bitcoin emissions alone could push global warming above 2 C. Nat. Clim. Chang. 2018, 8, 931. [Google Scholar] [CrossRef]

- Dittmar, L.; Praktiknjo, A. Could Bitcoin emissions push global warming above 2 °C? Nat. Clim. Chang. 2019, 9, 656–657. [Google Scholar] [CrossRef]

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S.D. Smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).