Performance and Loss Analysis of Squirrel Cage Induction Machine Based Flywheel Energy Storage System

Abstract

1. Introduction

2. Flywheel Theory and Structure

2.1. Background

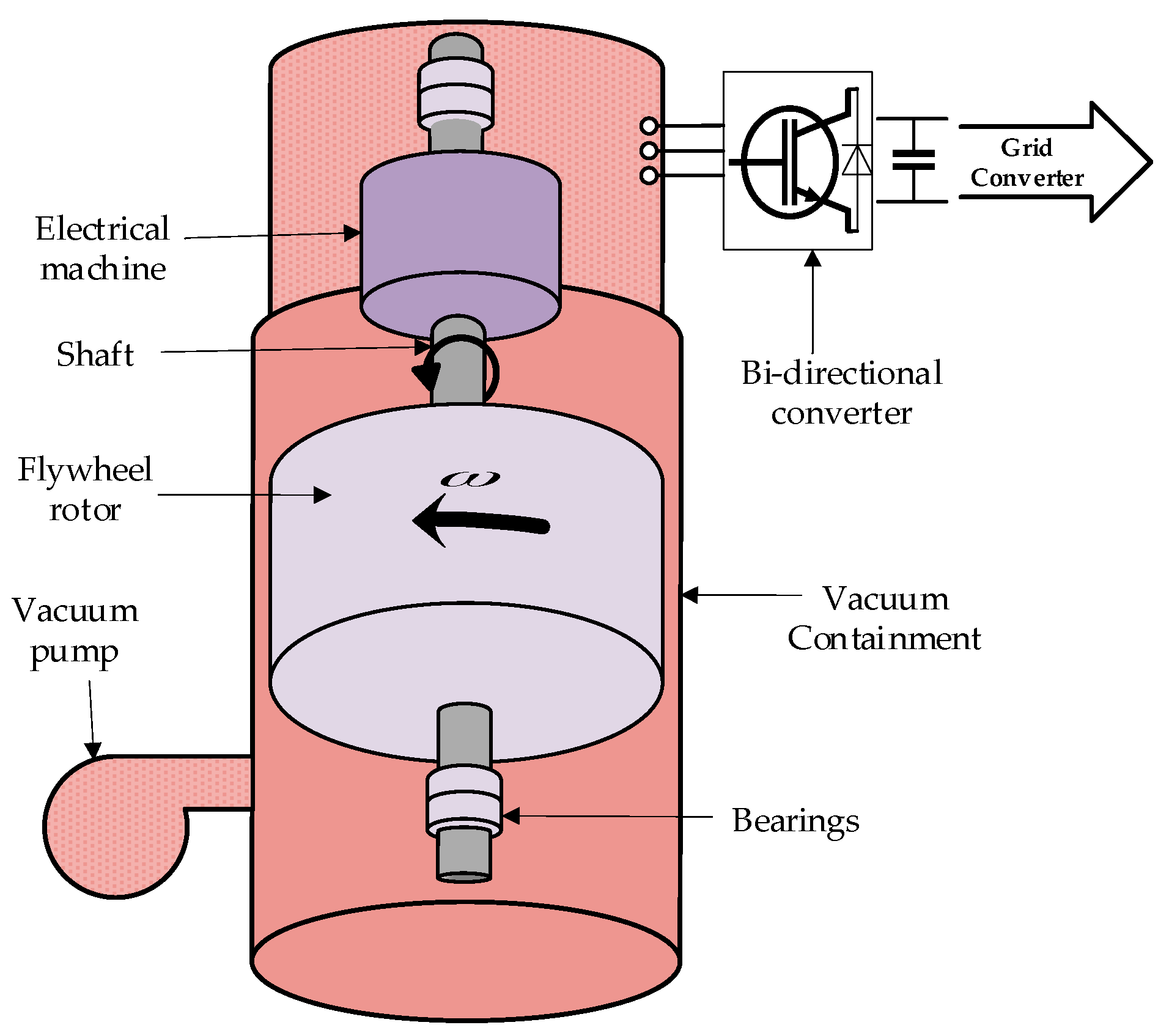

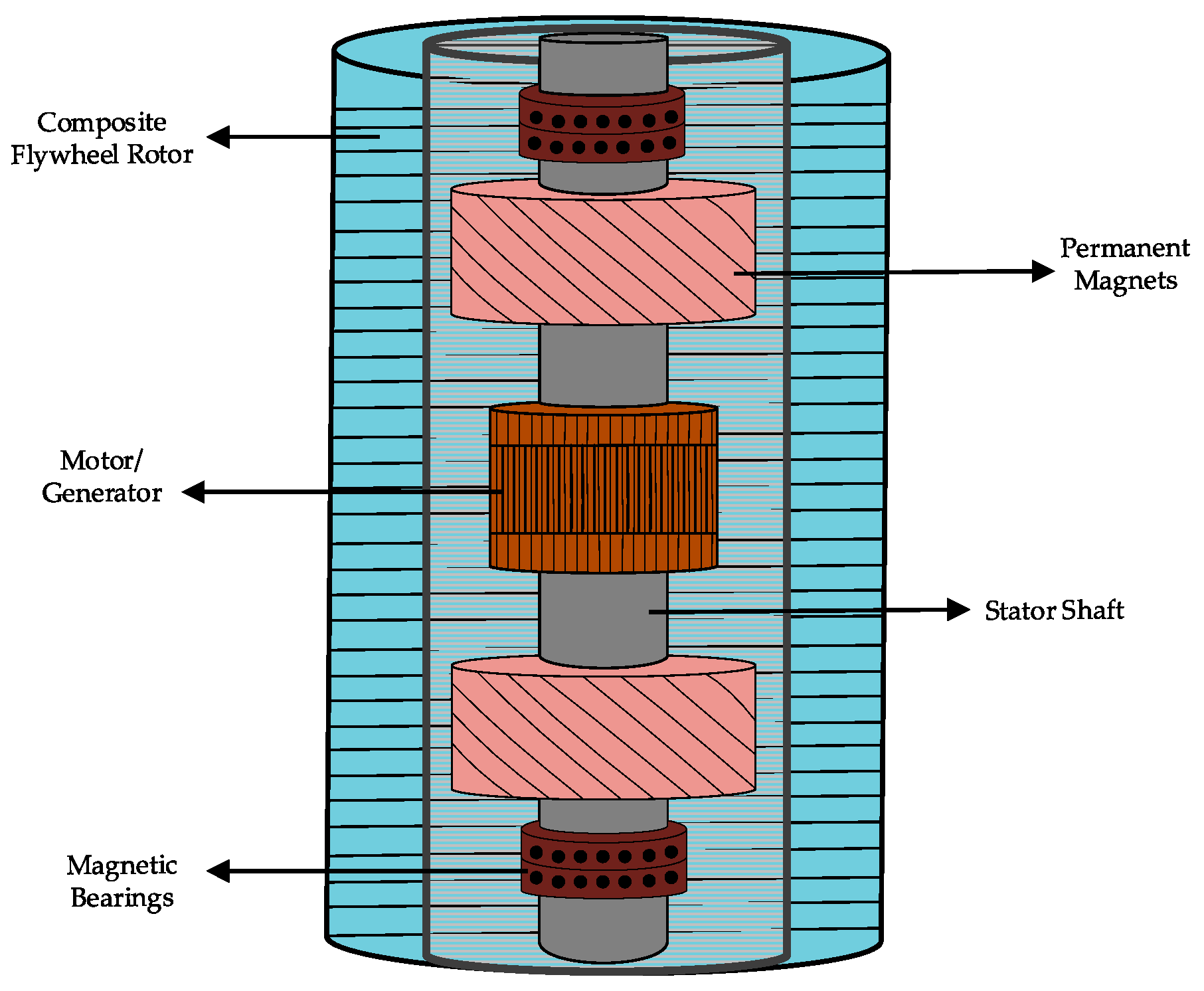

2.2. Components of FESS

2.2.1. Flywheel Rotor

2.2.2. Electric Machines

2.2.3. Bearing Systems

2.2.4. Power Electronics Interface

2.2.5. Containment

3. Loss Calculation of IM Driven FESS

3.1. SCIM-FESS Design and Parameters

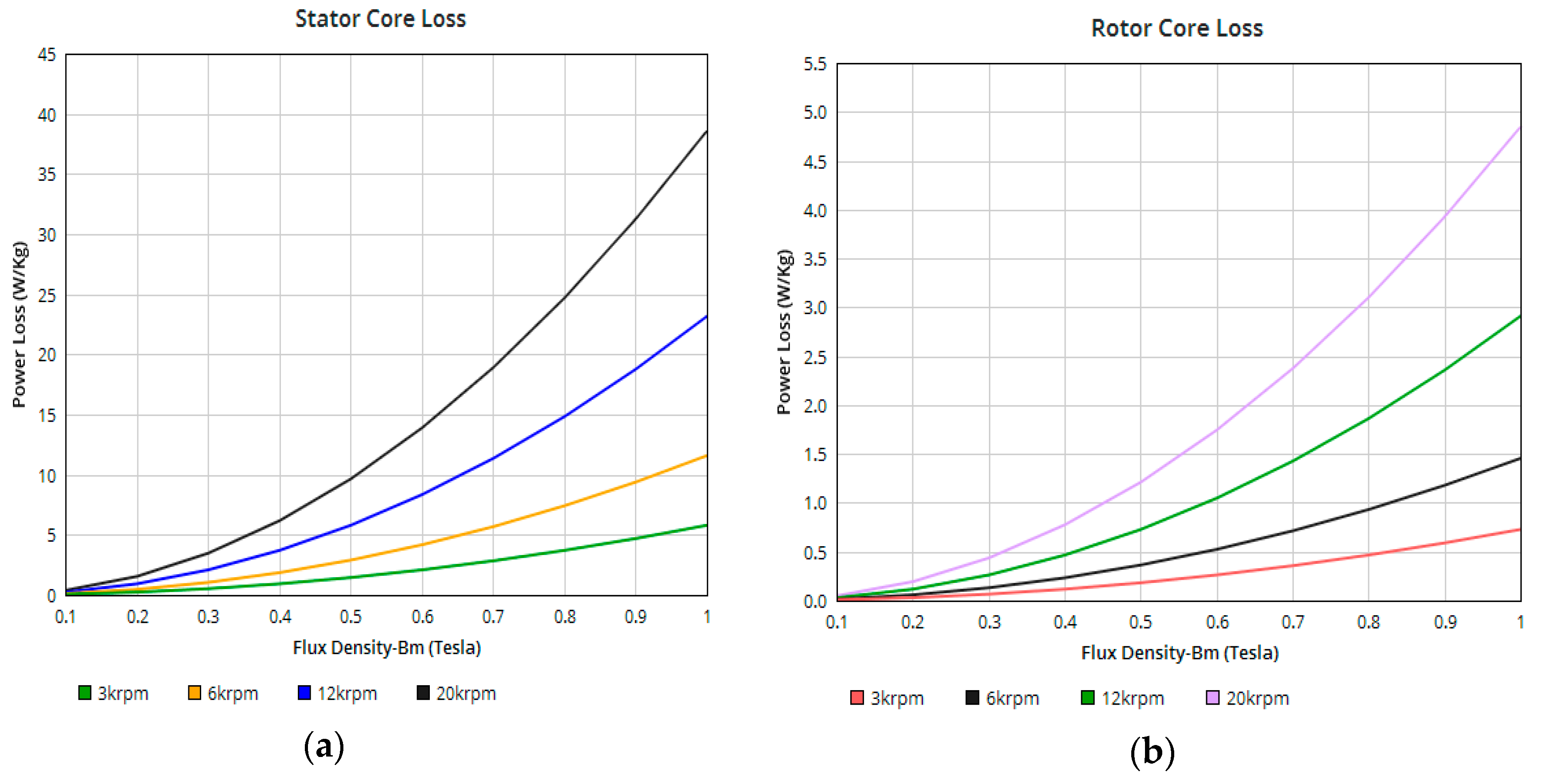

3.2. Electrical Losses

3.3. Mechanical Losses

3.3.1. Windage Loss

3.3.2. Bearing Losses

3.3.3. Stray Losses

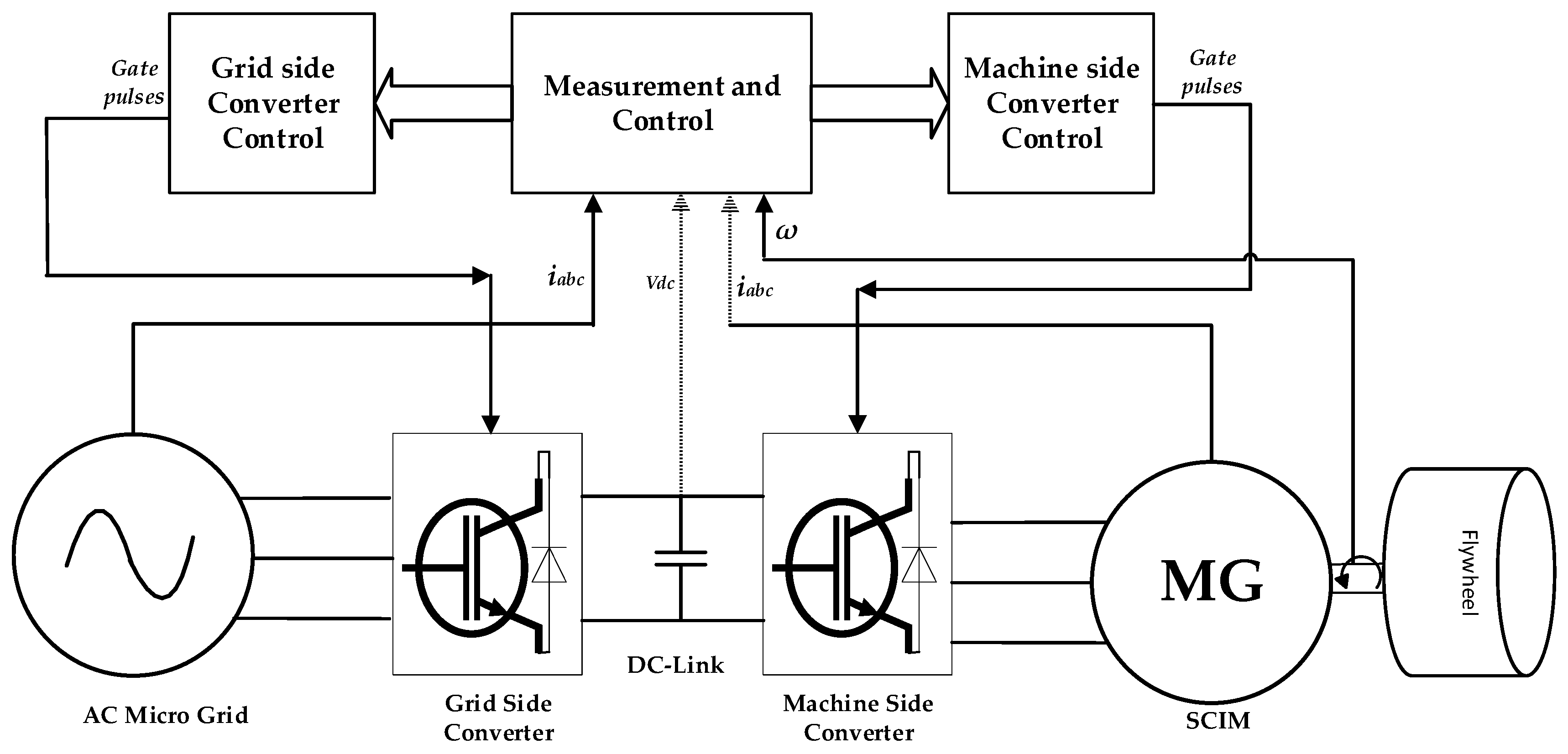

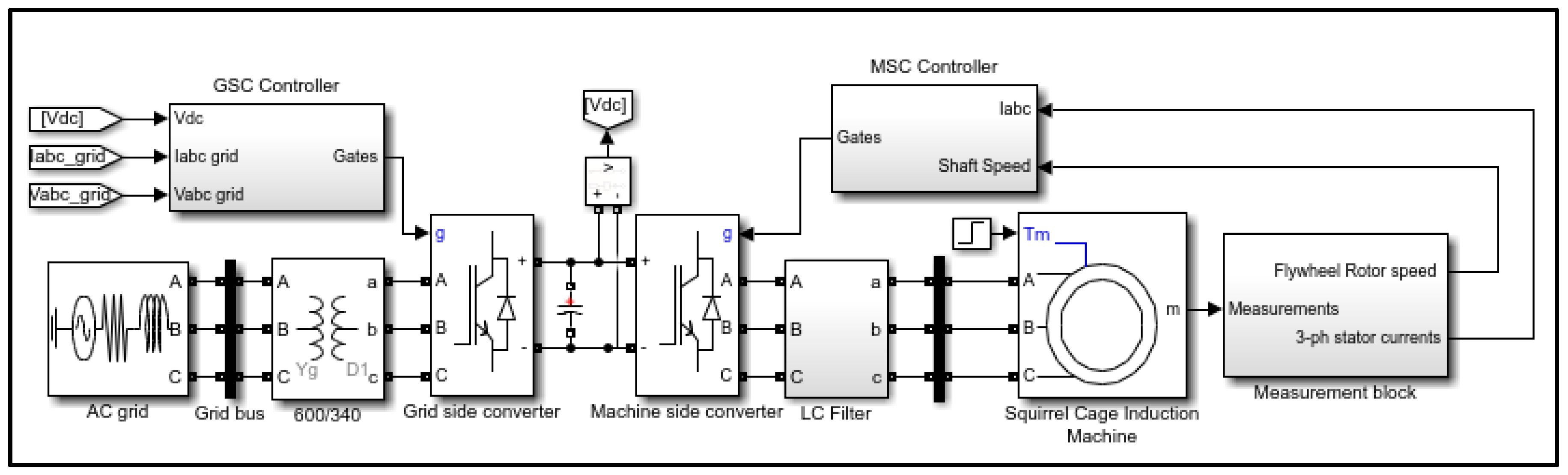

4. Design and Control of SCIM-FESS

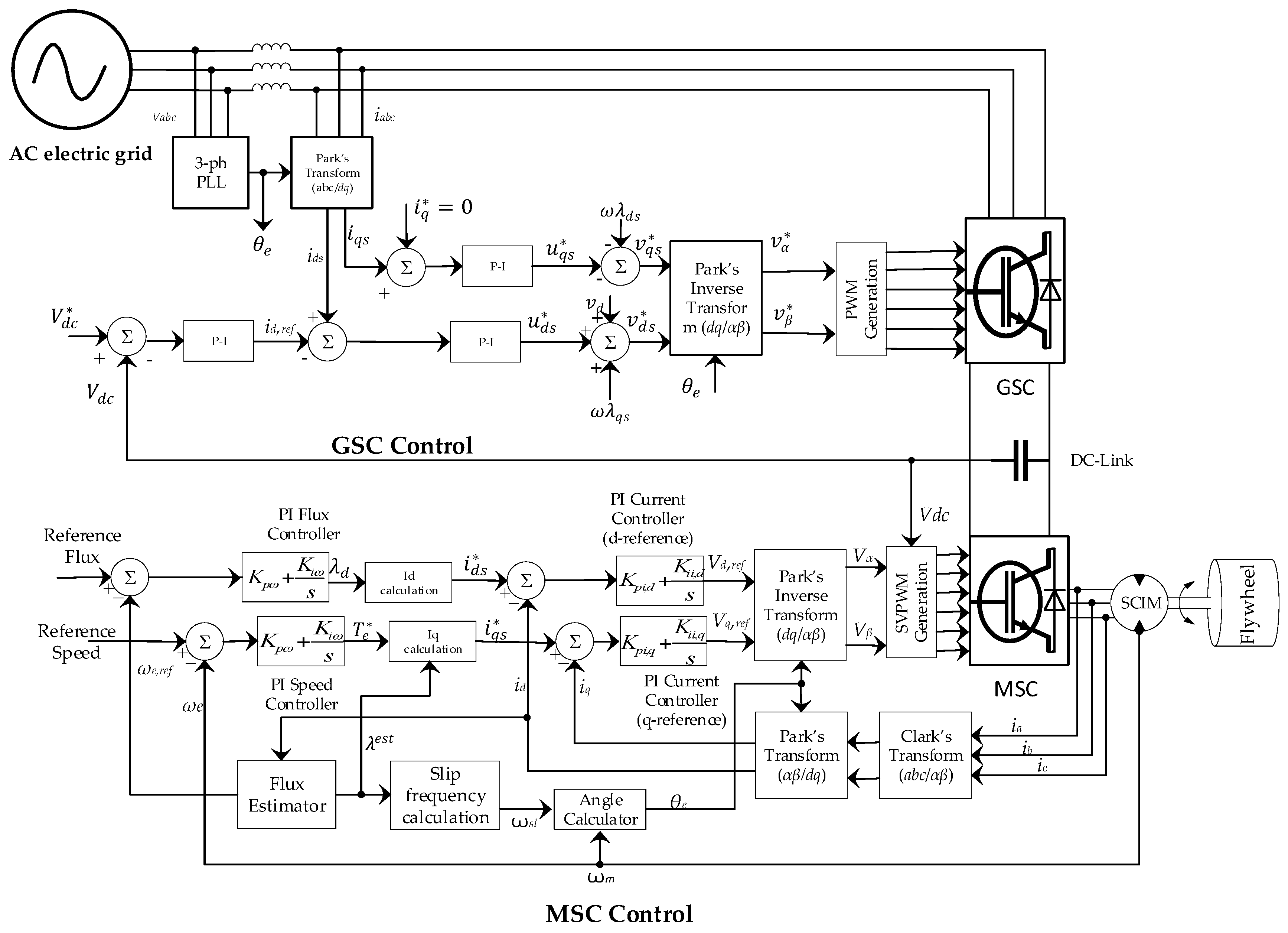

4.1. Control Structure of SCIM-FESS

4.1.1. Machine Side Converter Control

4.1.2. Grid Side Converter Control

5. Results and Analysis

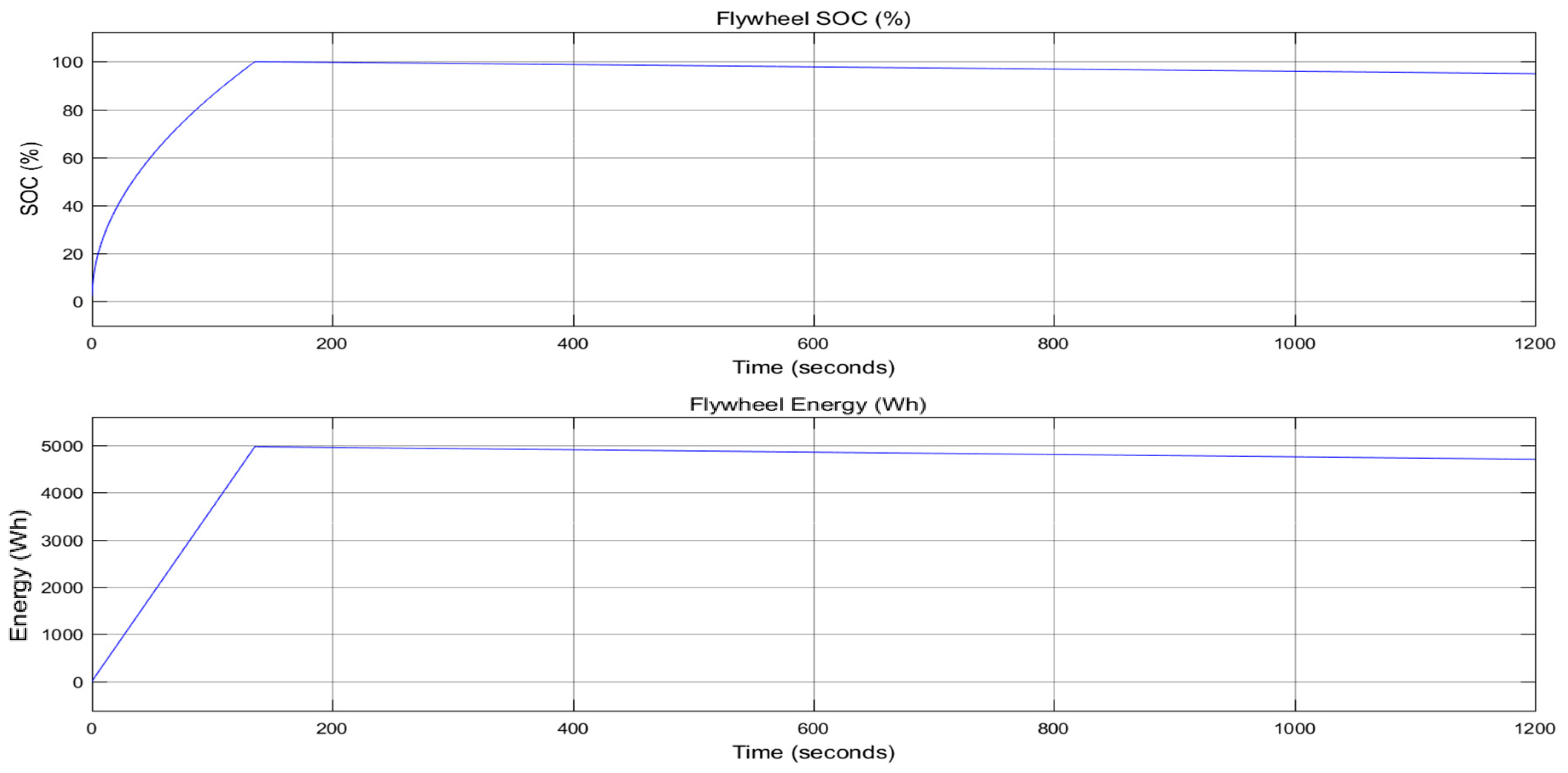

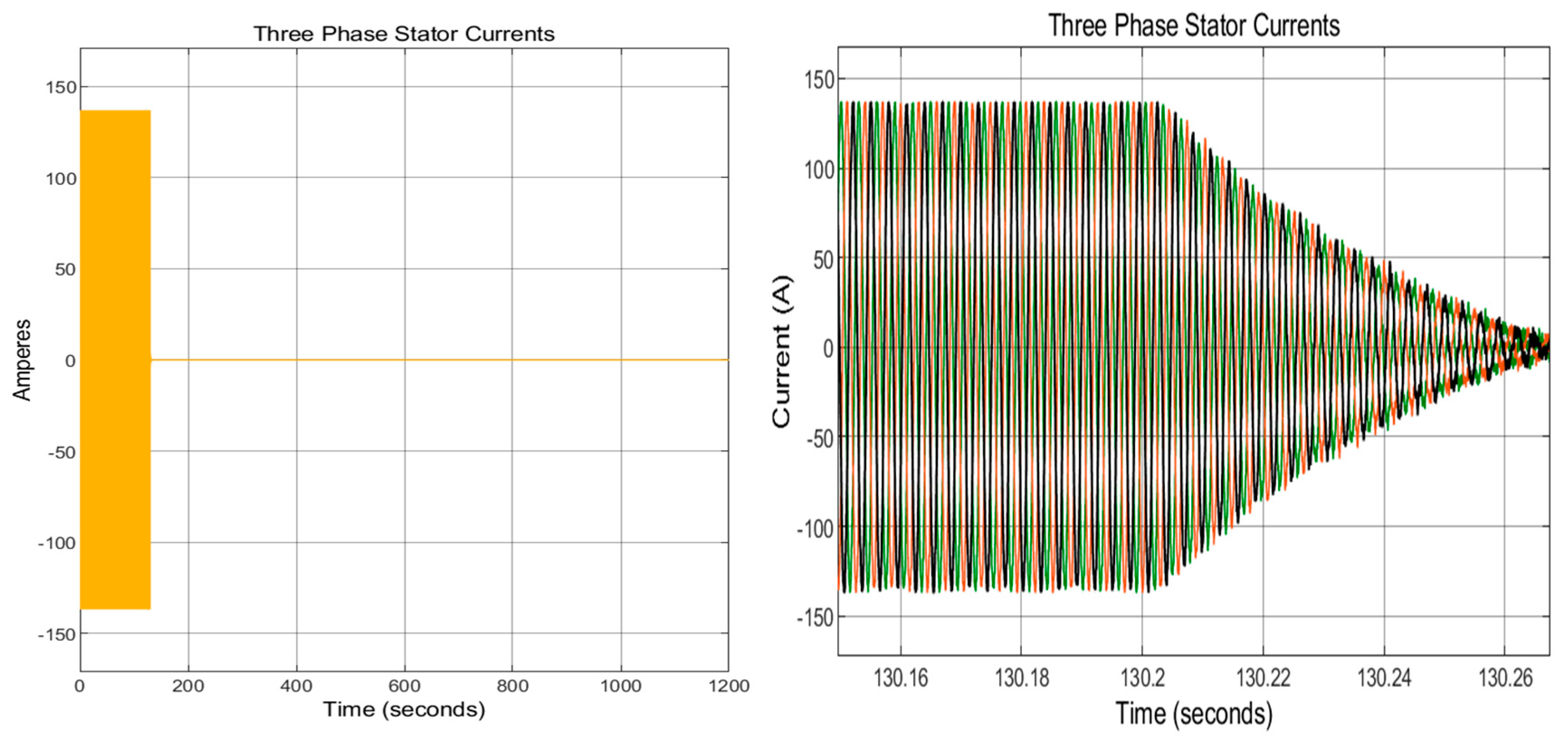

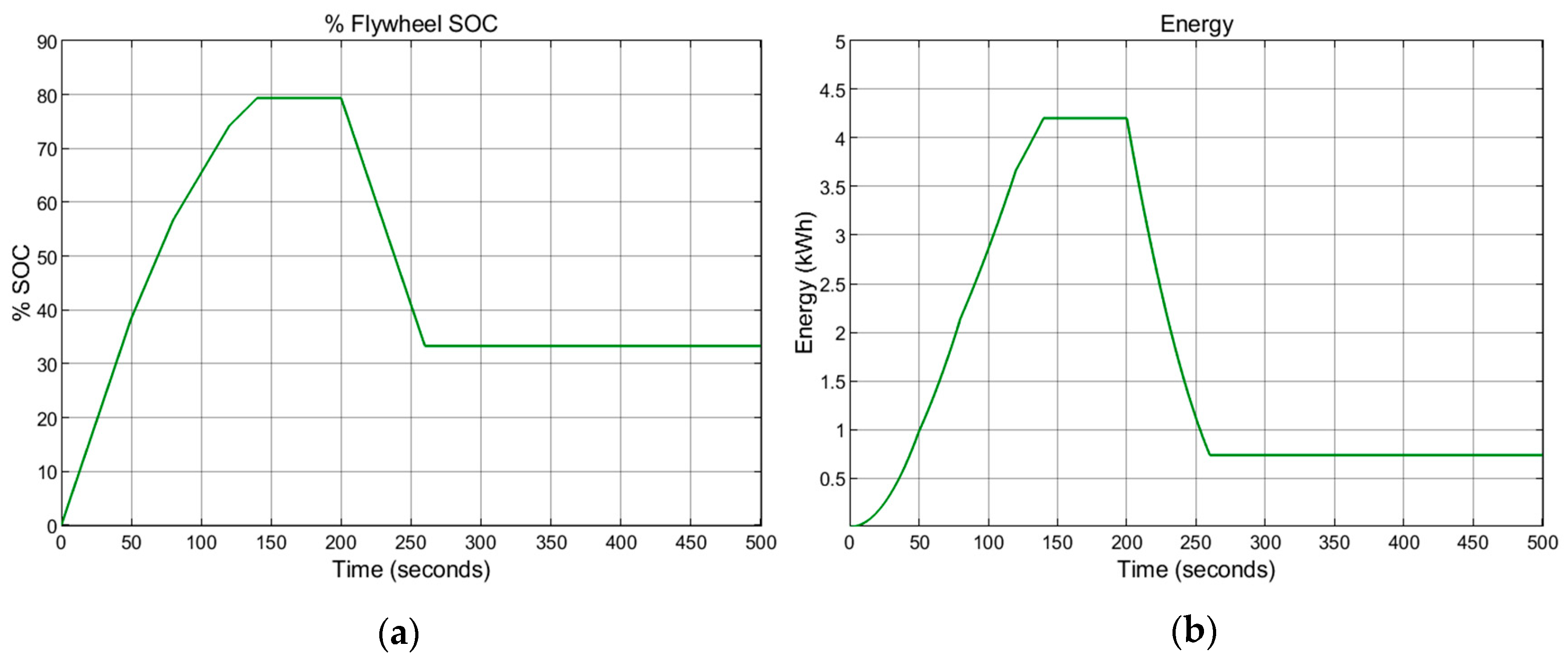

5.1. Acceleration Mode

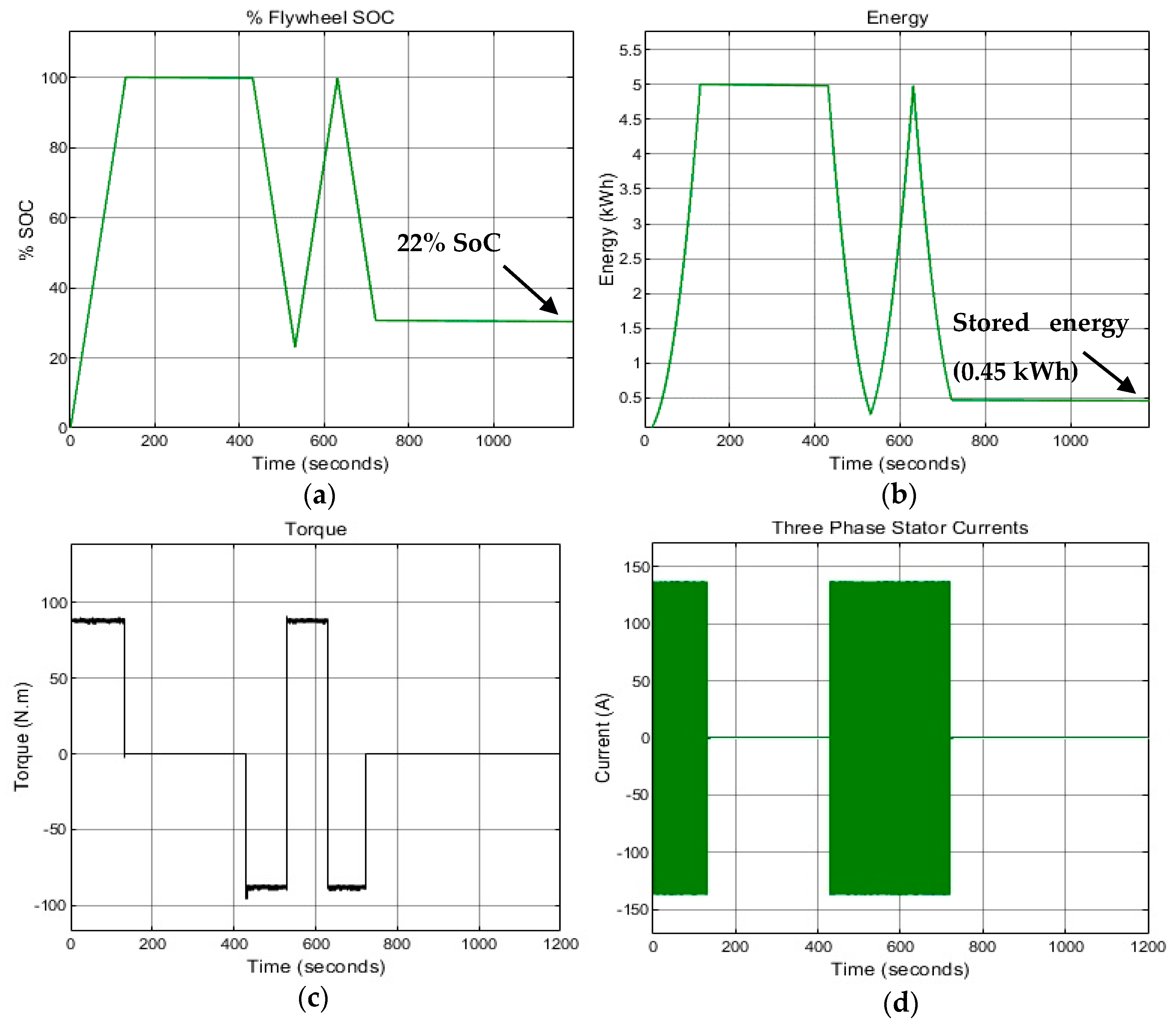

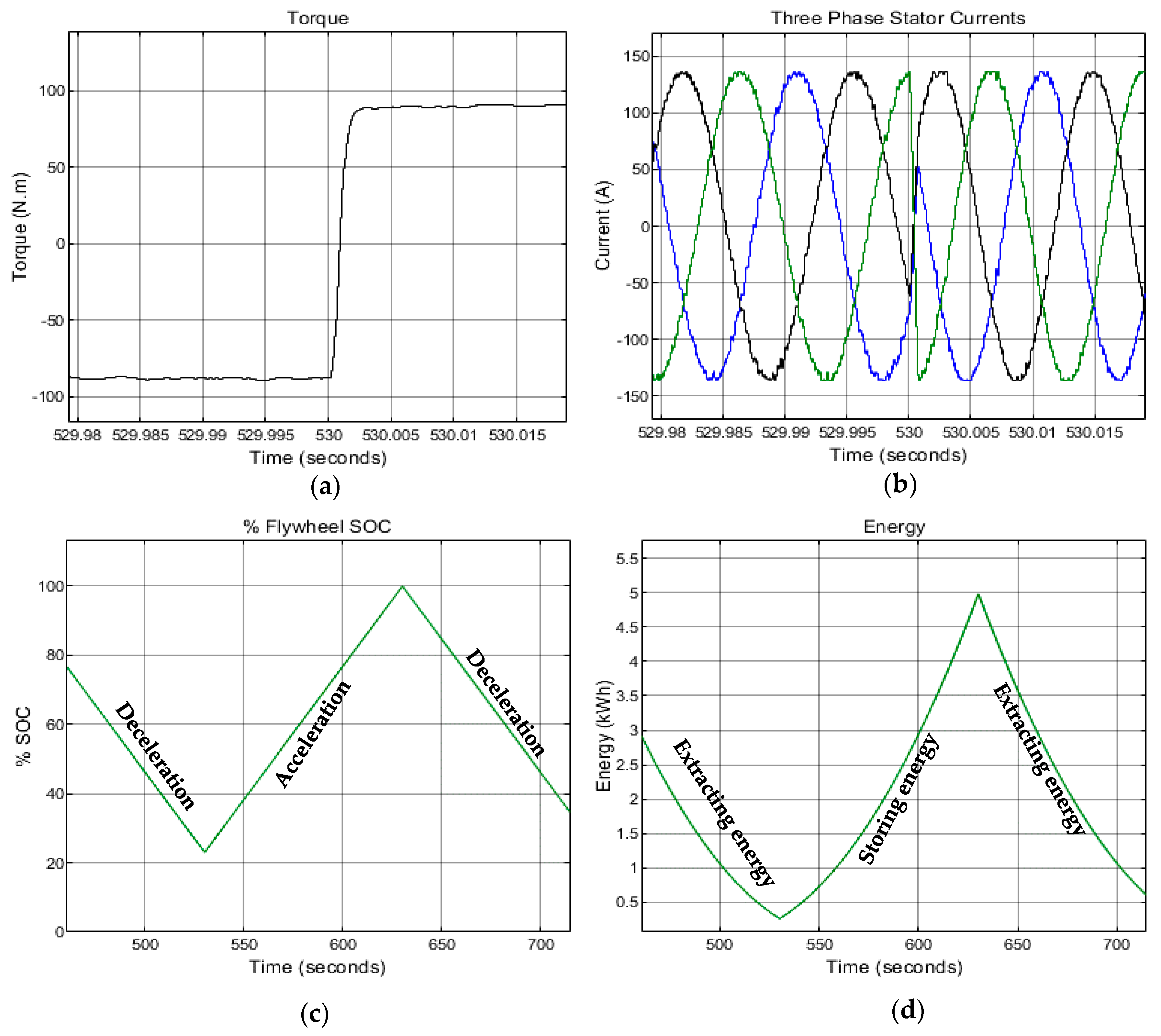

5.2. Deceleration-Acceleration Mode at Constant Torque

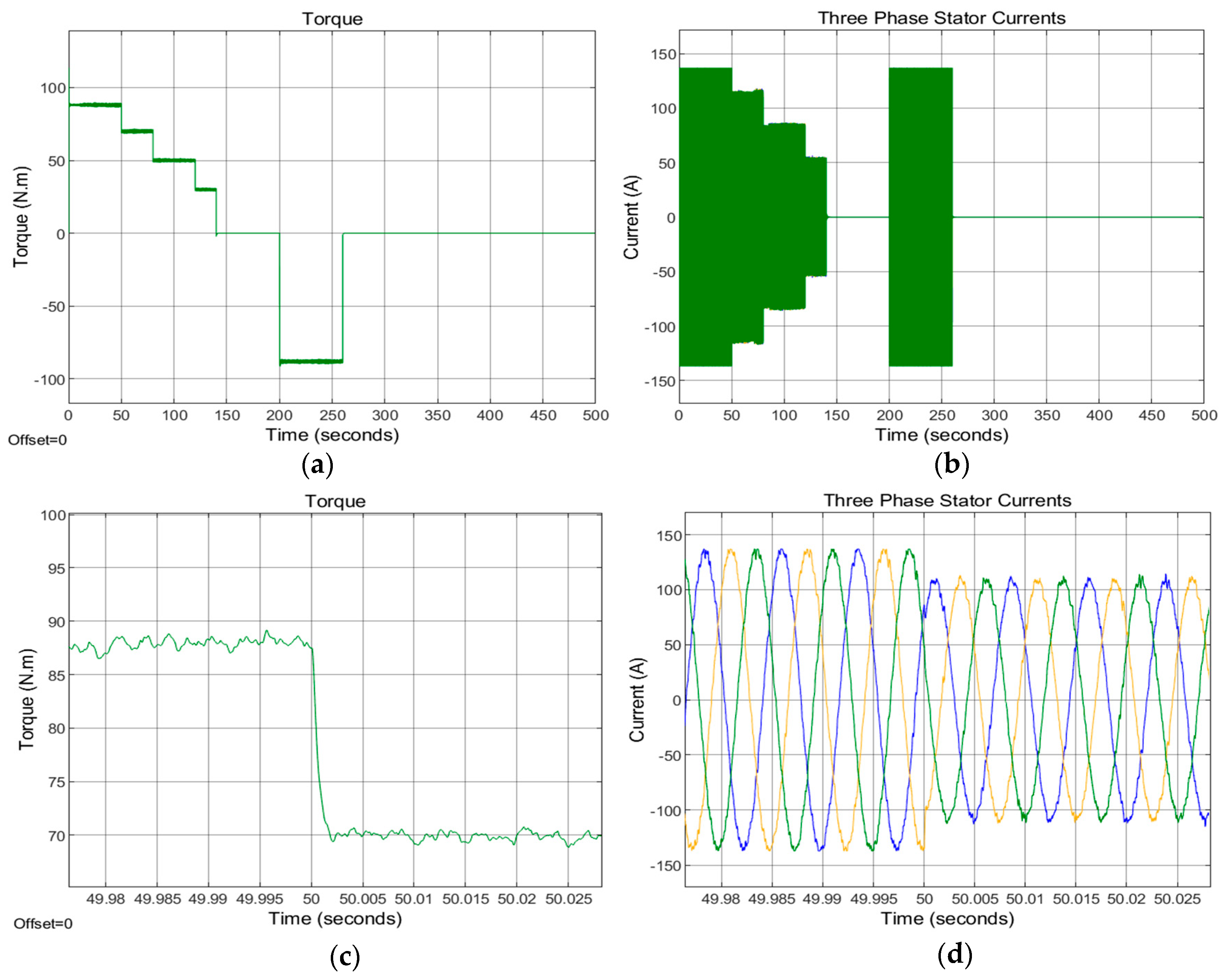

5.3. Deceleration-Acceleration Mode at Variable Torque

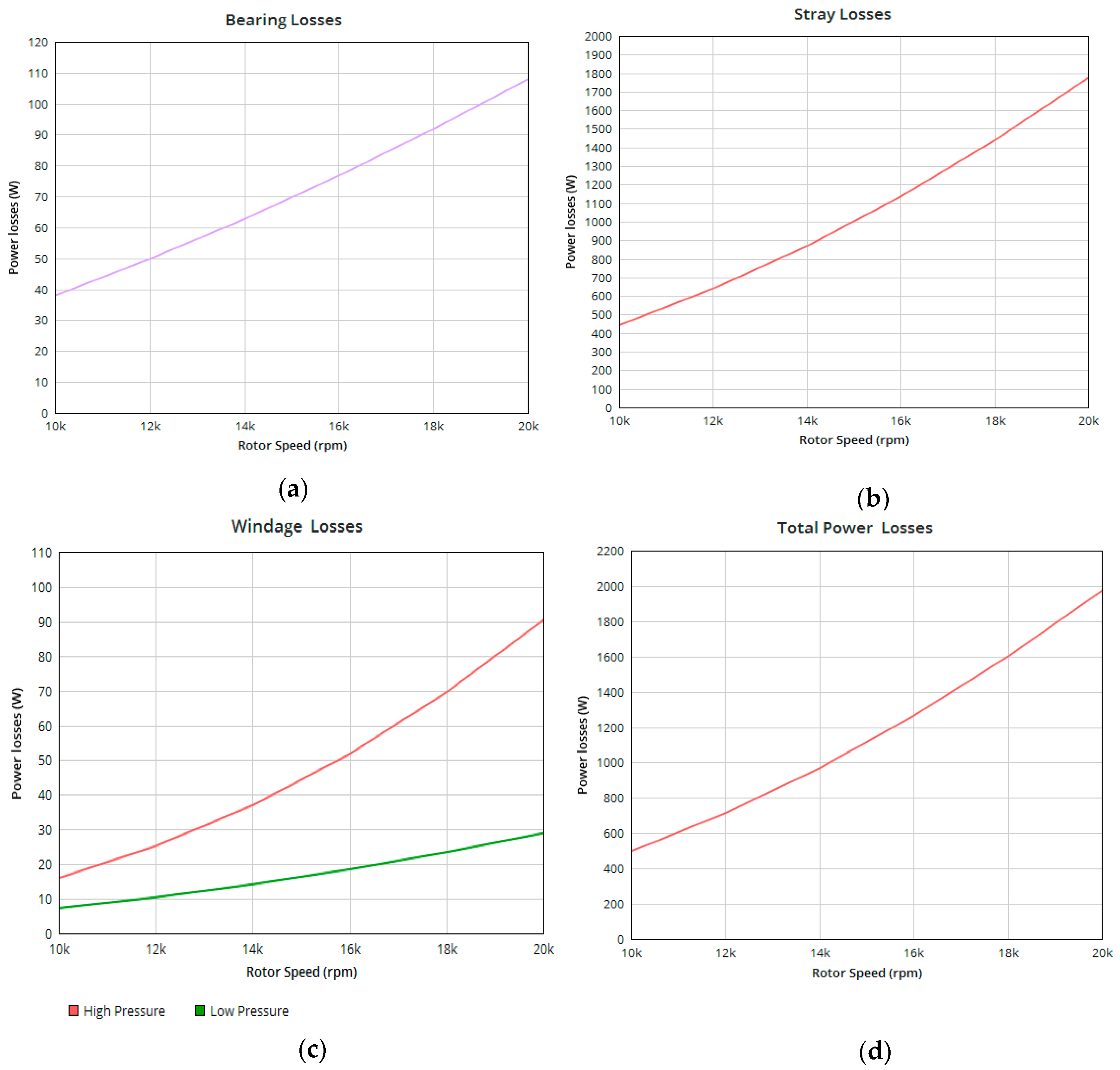

5.4. SCIM-FESS Losses

6. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hadjipaschalis, I.; Poullikkas, A.; Efthimiou, V. Overview of current and future energy storage technologies for electric power applications. Renew. Sustain. Energy Rev. 2009, 13, 1513–1522. [Google Scholar] [CrossRef]

- Guney, M.S.; Tepe, Y. Classification and assessment of energy storage systems. Renew. Sustain. Energy Rev. 2017, 75, 1187–1197. [Google Scholar] [CrossRef]

- Amiryar, M.E.; Pullen, K.R.; Nankoo, D. Development of a High-Fidelity Model for an Electrically Driven Energy Storage Flywheel Suitable for Small Scale Residential Applications. Appl. Sci. 2018, 8, 453. [Google Scholar] [CrossRef]

- Sabihuddin, S.; Kiprakis, A.E.; Markus, M. A Numerical and Graphical Review of Energy Storage Technologies. Energies 2015, 8, 172–216. [Google Scholar] [CrossRef]

- Mohamad, F.; Teh, J.; Lai, C.-M.; Chen, L.-R. Development of Energy Storage Systems for Power Network Reliability: A Review. Energies 2018, 11, 2278. [Google Scholar] [CrossRef]

- Breeze, P. An Introduction to Energy Storage Technologies. In Power System Energy Storage Technologies; Elsevier BV: Amsterdam, The Netherlands, 2018; pp. 1–11. [Google Scholar]

- Hittinger, E.; Whitacre, J.; Apt, J. What properties of grid energy storage are most valuable? J. Power Sources 2012, 206, 436–449. [Google Scholar] [CrossRef]

- Bender, D. Flywheels. In Proceedings of the Electrical Energy Storage Techniques, System Surety Engineering, Sandia National Laboratories, Livermore, CA, USA, 17 February 2016; pp. 183–201. [Google Scholar]

- Thoolen, F. Development of an Advanced High Speed Flywheel Energy Storage System Eindhoven; Technische Universiteit Eindhoven: Eindhoven, The Netherlands, 1993. [Google Scholar]

- Maass, D. Integral Composite Flywheel Rim and Hub. U.S. Patent No. 5,784,926, 28 July 1998. [Google Scholar]

- Hedlund, M.; Kamf, T.; De Santiago, J.; Abrahamsson, J.; Bernhoff, H. Reluctance Machine for a Hollow Cylinder Flywheel. Energies 2017, 10, 316. [Google Scholar] [CrossRef]

- Krack, M.; Secanell, M.; Mertiny, P. Rotor Design for High-Speed Flywheel Energy Storage Systems. In Energy Storage in the Emerging Era of Smart Grids; IntechOpen: London, UK, 2011; pp. 41–68. [Google Scholar]

- Bolund, B.; Bernhoff, H.; Leijon, M. Flywheel energy and power storage systems. Renew. Sustain. Energy Rev. 2007, 11, 235–258. [Google Scholar] [CrossRef]

- Arani, A.K.; Karami, H.; Gharehpetian, G.; Hejazi, M. Review of Flywheel Energy Storage Systems structures and applications in power systems and microgrids. Renew. Sustain. Energy Rev. 2017, 69, 9–18. [Google Scholar] [CrossRef]

- Wicki, S.; Hansen, E.G. Clean energy storage technology in the making: An innovation systems perspective on flywheel energy storage. J. Clean. Prod. 2017, 162, 1118–1134. [Google Scholar] [CrossRef]

- Ibrahim, H.; Ilinca, A.; Perron, J. Energy storage systems—Characteristics and comparisons. Renew. Sustain. Energy Rev. 2008, 12, 1221–1250. [Google Scholar] [CrossRef]

- Arghandeh, R.; Pipattanasomporn, M.; Rahman, S. Flywheel Energy Storage Systems for Ride-through Applications in a Facility Microgrid. IEEE Trans. Smart Grid 2012, 3, 1955–1962. [Google Scholar] [CrossRef]

- Schmidt, O.; Melchior, S.; Hawkes, A.; Staffell, I. Projecting the Future Levelized Cost of Electricity Storage Technologies. Joule 2019, 3, 81–100. [Google Scholar] [CrossRef]

- Shuhei, K.; Miao-miao, C.; Hideo, S.; Ryuichi, S. Semiconductor Power Converterless Voltage Sag Compensator and UPS Using a Flywheel Induction Motor and an Engine Generator. In Proceedings of the Power Conversion Conference, Nagoya, Japan, 2–5 April 2007. [Google Scholar]

- Kimura, N.; Sonoda, M.; Morizane, T.; Taniguchi, K.; Kurokawa, F. Emergency power supply using flywheel and doubly fed induction generator. In Proceedings of the 31st International Telecommunications Energy Conference (INTELEC), Incheon, Korea, 18–22 October 2009; pp. 1–6. [Google Scholar]

- Lashway, C.R.; Elsayed, A.T.; Mohammed, O.A. DC voltage ripple quantification for a flywheel-battery based Hybrid Energy Storage System. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 20–24 March 2016; pp. 1267–1272. [Google Scholar]

- McGroarty, J.; Schmeller, J.; Hockney, R.; Polimeno, M. Flywheel energy storage system for electric start and an all-electric ship. In Proceedings of the IEEE Electric Ship Technologies Symposium, Philadelphia, PA, USA, 27 July 2005; pp. 400–406. [Google Scholar]

- Zhao, B.; Zhang, X.; Chen, J. Integrated microgrid laboratory system. In Proceedings of the IEEE Power & Energy Society General Meeting, Vancouver, BC, Canada, 21–25 July 2013; p. 1. [Google Scholar]

- Amiryar, M.E.; Pullen, K.R. Assessment of the Carbon and Cost Savings of a Combined Diesel Generator, Solar Photovoltaic, and Flywheel Energy Storage Islanded Grid System. Energies 2019, 12, 3356. [Google Scholar] [CrossRef]

- Faraji, F.; Majazi, A.; Al-Haddad, K. A comprehensive review of Flywheel Energy Storage System technology. Renew. Sustain. Energy Rev. 2017, 67, 477–490. [Google Scholar]

- Recheis, M.; Fulmek, P.; Wegleiter, H.; Schweighofer, B. Rotor Losses in a Switched Reluctance Motor—Analysis and Reduction Methods. EPJ Web Conf. 2013, 40, 17008. [Google Scholar]

- Torrey, D. Switched reluctance generators and their control. IEEE Trans. Ind. Electron. 2002, 49, 3–14. [Google Scholar] [CrossRef]

- Memon, A.A.; Shah, S.A.A.; Shah, W.; Baloch, M.H.; Kaloi, G.S.; Mirjat, N.H. A Flexible Mathematical Model for Dissimilar Operating Modes of a Switched Reluctance Machine. IEEE Access 2018, 6, 9643–9649. [Google Scholar] [CrossRef]

- Soomro, A.; Amiryar, M.E.; Pullen, K.R.; Nankoo, D. Comparison of performance and controlling schemes of synchronous and induction machines used in flywheel enregy storage systems. Energy Procedia 2018, 151, 100–110. [Google Scholar] [CrossRef]

- Amodeo, S.J.; León, A.E.; Chiacchiarini, H.G.; Solsona, J.A.; Busada, C.A. Non linear Control Strategies of a Flywheel driven by a Synchronous Homopolar Machine. In Proceedings of the IEEE International Symposium on Industrial Electronics, Vigo, Spain, 4–7 June 2007. [Google Scholar]

- Severson, E.; Nilssen, R.; Undeland, T.; Mohan, N. Magnetic Equivalent Circuit Modeling of the AC Homopolar Machine for Flywheel Energy Storage. IEEE Trans. Energy Convers. 2015, 30, 1670–1678. [Google Scholar] [CrossRef]

- Cárdenas, R.; Pena, R.; Asher, G.; Clare, J. Control strategies for enhanced power smoothing in wind energy systems using a flywheel driven by a vector-controlled induction machine. IEEE Trans. Ind. Electron. 2001, 48, 625–635. [Google Scholar] [CrossRef]

- Cimuca, G.; Breban, S.; Radulescu, M.M.; Saudemont, C.; Robyns, B. Design and Control Strategies of an Induction-Machine-Based Flywheel Energy Storage System Associated to a Variable-Speed Wind Generator. IEEE Trans. Energy Convers. 2010, 25, 526–534. [Google Scholar] [CrossRef]

- Kato, S.; Cheng, M.-M.; Sumitani, H.; Shimada, R. Flywheel size design considerations and experimental verification using a 50-kW system for voltage sag compensator with flywheel induction motor. Electr. Eng. Jpn. 2012, 181, 36–44. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Park, K.-S.; Jeong, Y.-S. Comparison of harmonic compensation based on wound/squirrel-cage rotor type induction motors with flywheel. In Proceedings of the Third International Power Electronics and Motion Control Conference (IPEMC), Beijing, China, 15–18 August 2000. [Google Scholar]

- Zhang, J.; Chen, Z.; Cai, L.; Zhao, Y. Flywheel energy storage system design for distribution network. In Proceedings of the IEEE Power Engineering Society Winter Meeting, Singapore, 23–27 January 2000. [Google Scholar]

- Cimuca, G.; Saudemont, C.; Robyns, B.; Radulescu, M. Control and Performance Evaluation of a Flywheel Energy-Storage System Associated to a Variable-Speed Wind Generator. IEEE Trans. Ind. Electron. 2006, 53, 1074–1085. [Google Scholar] [CrossRef]

- Suzki, Y.; Koyanagi, A.; Kobarashi, M.; Shimada, R. Noverl applicaiton of the flywheel energy storage system. Energy 2005, 30, 2128–2143. [Google Scholar] [CrossRef]

- Arani, A.A.K.; Zaker, B.; Gharehpetian, G.B. Induction machine-based flywheel energy storage system modeling and control for frequency regulation after micro-grid islanding. Int. Trans. Electr. Energy Syst. 2017, 27, e2356. [Google Scholar] [CrossRef]

- Park, J.-D. Simple flywheel energy storage using squirrel-cage induction machine for DC bus microgrid systems. In Proceedings of the 36th Annual Conference on IEEE Industrial Electronics Society (IECON), Glendale, AZ, USA, 7–10 November 2010; pp. 3040–3045. [Google Scholar]

- Kim, S.-H. Electric Motor Control; Elsevier Science: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Shelke, R.; Dighole, D. A Review paper on Dual Mass Flywheel system. Int. J. Sci. Eng. Technol. Res. 2016, 5, 326–331. [Google Scholar]

- Aneke, M.; Wang, M. Energy storage technologies and real life applications—A state of the art review. Appl. Energy 2016, 179, 350–377. [Google Scholar] [CrossRef]

- Hasan, N.S.; Hassan, M.Y.; Majid, M.S.; Rahman, H.A. Review of storage schemes for wind energy systems. Renew. Sustain. Energy Rev. 2013, 21, 237–247. [Google Scholar] [CrossRef]

- Bitterly, J.G. Flywheel technology past, present, and 21st Century projections. IEEE Aerosp. Electron. Syst. Mag. 1998, 13, 13–18. [Google Scholar] [CrossRef]

- Mears, L.; Gotschall, H.; Kamath, H.H. EPRI-DOE Handbook of Energy Storage for Transmission and Distribution Applications; Electric Power Research Insttute, Inc.: Palo Alto, CA, USA; U.S Department of Energy: Washington, DC, USA, 2003.

- Sebastian, R.; Alzola, R.P. Flywheel energy storage systems: Review and simulation for an isolated wind power system. Renew. Sustain. Energy Rev. 2012, 16, 6803–6813. [Google Scholar] [CrossRef]

- Truong, L.; Wolff, F.; Dravid, N. Simulation of flywheel electrical system for aerospace applications. In Proceedings of the 35th Intersociety Energy Conversion Engineering Conference and Exhibit, Las Vegas, NV, USA, 24–28 July 2000. [Google Scholar]

- Kan, H.; Chau, K.; Cheng, K.M. Development of doubly salient permanent magnet motor flywheel energy storage for building integrated photovoltaic system. In Proceedings of the Sixteenth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Anaheim, CA, USA, 4–8 March 2001. [Google Scholar]

- Reiner, G.; Wehlau, N. Concept of a 50 MW/650 MJ power source based on industry-established MDS flywheel units. In Proceedings of the 28th IEEE International Conference on Plasma Science and 13th IEEE International Pulsed Power Conference, Las Vegas, NV, USA, 17–22 June 2001. [Google Scholar]

- Holm, S.R. Modelling and Optimization of Permanent Magnet Machine in a Flywheel. Ph.D. Thesis, Delf University of Technology, Delf, The Netherland, 2003. [Google Scholar]

- Zhu, Z.Q.; Howe, D. Electrical Machines and Drives for Electric, Hybrid, and Fuel Cell Vehicles. Proc. IEEE 2007, 95, 746–765. [Google Scholar] [CrossRef]

- Amiryar, M.E.; Pullen, K.R. A Review of Flywheel Energy Storage System Technologies and Their Applications. Appl. Sci. 2017, 7, 286. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, J. Flywheel energy storage—An upswing technology for Energy Sustainability. Energy Build. 2006, 39, 599–604. [Google Scholar] [CrossRef]

- Sotelo, G.; De Andrade, R.; Ferreira, A. Magnetic Bearing Sets for a Flywheel System. IEEE Trans. Appl. Supercond. 2007, 17, 2150–2153. [Google Scholar] [CrossRef]

- Ren, M.; Shen, Y.; Li, Z.; Nonami, K. Modeling and Control of a Flywheel Energy Storage System Using Active Magnetic Bearing for Vehicle. In Proceedings of the International Conference on Information Engineering and Computer Science, Wuhan, China, 19–20 December 2009; pp. 1–5. [Google Scholar]

- Zhang, C.; Tseng, K.J. A Novel Flywheel Energy Storage System With Partially-Self-Bearing Flywheel-Rotor. IEEE Trans. Energy Convers. 2007, 22, 477–487. [Google Scholar] [CrossRef]

- Qiu, Y.; Ding, H. Flywheel Energy Storage System with PermanentMagnetic Bearing and Spiral Groove Bearing. In Proceedings of the 8th International Conference on Mechanical and Intelligent Manufacturing Technologies, Cape Town, South Africa, 3–6 February 2017. [Google Scholar]

- Ruddell, A. Investigation on Storage Technologies for Intermittent Renewable Energies: Evaluation and Recommended R&D Strategy; CCLRC-Rutherford Appleton Laboratory Chilton: Didcot, UK, 2003. [Google Scholar]

- Alias, A.; Rahim, N.A.; Hussain, M.A. Bidirectional three phase power converter. In Proceedings of the IEEE Conference on Clean Energy and Technology (CET), Kuala Lumpur, Malaysia, 27–29 June 2011; pp. 337–341. [Google Scholar]

- Oliveira, J.G.; Schettino, H.; Gama, V.; Carvalho, R.; Bernhoff, H. Implementation and Control of an AC/DC/AC Converter for Double Wound Flywheel Application. Adv. Power Electron. 2012, 2012, 604703. [Google Scholar] [CrossRef][Green Version]

- Elserougi, A.; Massoud, A.; Ahmed, S. Flywheel energy storage system based on boost DC-AC converter. In Proceedings of the IET Conference on Renewable Power Generation (RPG), Edinburgh, UK, 6–8 September 2011; p. 241. [Google Scholar]

- Babuska, V.; Beatty, S.M.; deBlonk, B.J.; Fausz, J.L. A Review of Technology Developments in Flywheel Attitude Control and Energy Transmission Systems. In Proceedings of the IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 6–13 March 2004. [Google Scholar]

- Popescu, M.; McGilp, M.I.; Miller, T.J.E.; Dellinger, S.J.; Heideman, R.J.; Ionel, D.M. Computation of Core Losses in Electrical Machines Using Improved Models for Laminated Steel. IEEE Trans. Ind. Appl. 2007, 43, 1554–1564. [Google Scholar]

- Roy, R.; Prabhakar, K.K.; Kumar, P. Core-loss calculation in different parts of Induction Machine. IET Electr. Power Appl. 2017, 11, 11. [Google Scholar] [CrossRef]

- Cogent Power Inc. Typical data for SURA® M470-50HP. Cogent Power. Available online: https://cogent-power.com/cms-data/downloads/m470-50hp.pdf (accessed on 30 July 2019).

- Pyrhnen, J.; Jokinen, T.; Hrabovcov, V. Design of Rotating Electrical Machines; Wiley: Chichester, UK, 2008. [Google Scholar]

- Liu, H.-P.; Werst, M.; Hahne, J.J.; Bogard, D. Prediction of Windage Losses of an Enclosed High Speed Composite Rotor in Low Air Pressure Environments. Heat Transf. 2003, 1, 15–23. [Google Scholar]

- Harris, T.A.; Kotzalas, M.N. Rolling Bearing Analysis; Taylor & Francis Group LLC: Boca Raton, FL, USA, 2007. [Google Scholar]

- Tu, M. Validation and Modeling of Power Losses of NJ 406 Cylindrical Roller Bearings. Master’s Thesis, KTH Industrial Engineering and Management, Stockholm, Sweden, 2016. [Google Scholar]

- SKF. Bearing Friction, Power Loss and Starting Torque. Available online: https://www.skf.com/uk/products/bearings-units-housings/principles/bearing-selection-process/operating-temperature-and-speed/friction-powerloss-startingtorque/index.html (accessed on 2 April 2019).

- Davis, R.W. Notes on Induction Motor Losses. Am. Inst. Electr. Eng. 1913, 32, 363–367. [Google Scholar] [CrossRef]

- Tamura, J. Calculation Method of Losses and Efficiency of Wind Generators. In Waste Energy for Life Cycle Assessment; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2012; pp. 25–51. [Google Scholar]

- Feng, J.; Gongbao, W.; Lijun, F.; Yaqiao, Y.; Ruitian, W.; Zhen, X. Controller design of flywheel energy storage systems in microgrid. In Proceedings of the 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014; pp. 2821–2826. [Google Scholar]

- Amezquita-Brooks, L.; Liceaga-Castro, J.; Liceaga-Castro, E. Speed and Position Controllers Using Indirect Field-Oriented Control: A classical Control Approach. IEEE Trans. Ind. Electron. 2014, 61, 1928–1943. [Google Scholar] [CrossRef]

- Sun, H.; Ren, Y.; Li, H.; An, Z.; Liu, J.; Hu, H.; Liu, H. DFIG wind power generation based on back-to-back PWM converter. In Proceedings of the International Conference on Mechatronics and Automation, Changchun, China, 9–12 August 2009; pp. 2276–2280. [Google Scholar]

- Diaz-Gonzalez, F.; Sumper, A.; Gomis-Bellmunt, O. Energy Storage in Power Systems; John Wiley & Sons Ltd.: Chichester, UK, 2016. [Google Scholar]

- Sheng, X. Design and Prototyping of a Low-Speed Flywheel System for Automotive Brake Energy Recovery. Undergraduate Honors Thesis, The Ohio State University, Columbus, OH, USA, 2012. [Google Scholar]

- Chapman, S.J. Elecrical Machinery Fundamentals; McGraw-Hill Inc.: New York, NY, USA, 1991. [Google Scholar]

| SCIM | PMSM | SRM | |

|---|---|---|---|

| Advantages | Rugged construction | Simple rotor design | Robust simple structure |

| No risk of demagnetization | High power, high load and high torque density | High power density | |

| Low cost | Easy to install and maintain due to smaller size | Low cost | |

| High efficiency (93.4%) | Very high efficiency (95.5%) | High efficiency (93%) | |

| No idling losses due to its lower rotor magnetic field at zero torque value, consequently this reduces a total electrical loss of IM | No field winding losses due to use of permanent magnets | No idling losses | |

| High torque and high power capability | Suitable to operate in low pressure vacuum with negligible rotor losses | Wide speed range | |

| Drawbacks | Difficult mechanical design for high speed applications | Risk of sudden demagnetization | Significant rotor eddy current losses due to the time varying magnetic field |

| Difficult to operate in absolute vacuum due to complex heat transfer system | Due to use of permanent magnets, PMSM have low tensile strength | High torque and current ripples | |

| Limited speed and larger volume | High cost | Difficult to regulate speed | |

| Copper losses in electromagnets during field excitation due to high inrush currents | Idling losses at zero torque due to presence of magnetic field | High losses due to need of excitation |

| Parameter | Value |

|---|---|

| Stator Resistance | 11.85 mΩ |

| Rotor Resistance | 9.29 mΩ |

| Stator leakage inductance | 0.2027 mH |

| Rotor leakage inductance | 0.2027 mH |

| Mutual Inductance | 9.295 mH |

| Rated magnetic flux | 0.75 Weber |

| Power rating | 100 kW |

| Nominal torque | 90 N·m |

| Maximum speed | 20 krpm |

| Minimum speed | 10 krpm |

| Switching frequency | 20 kHz |

| DC bus voltage | 600 V |

| Air density () | 0.0011 kg/m3 |

| Air dynamic viscosity | 1.91 × 10−5 kg/m·s |

| Flywheel rotor outer diameter | 0.4 m |

| Shaft diameter | 0.025 m |

| Bearing design factor | 0.0005 |

| Kinematic oil viscosity | 130 × 106 m2/s |

| Lamination thickness (t) | 0.15 mm |

| Conductivity of electrical steel () | 2.08 × 106 Siemens/m |

| Density of electrical steel () | 7650 kg/m3 |

| Bm (T) | W/kg at 50 Hz | W/kg at 100 Hz | W/kg at 200 Hz | W/kg at 400 Hz |

|---|---|---|---|---|

| 0.1 | 0.03 | 0.07 | 0.23 | 0.58 |

| 0.2 | 0.13 | 0.29 | 0.84 | 2.14 |

| 0.3 | 0.26 | 0.61 | 1.71 | 4.37 |

| 0.4 | 0.43 | 1.00 | 2.78 | 7.17 |

| 0.5 | 0.63 | 1.46 | 4.03 | 10.6 |

| 0.6 | 0.85 | 1.98 | 5.48 | 14.7 |

| 0.7 | 1.09 | 2.55 | 7.12 | 19.6 |

| 0.8 | 1.34 | 3.19 | 9.02 | 25.4 |

| 0.9 | 1.62 | 3.91 | 11.2 | 32.4 |

| 1 | 1.94 | 4.71 | 13.7 | 40.6 |

| Bearing Type | Nominal Contact Angle (Degrees) | z | y |

|---|---|---|---|

| Radial deep-groove | 0 | 0.0004–0.0006 | 0.55 |

| Thrust | 90 | 0.0008 | 0.33 |

| Double-row self-aligning | 10 | 0.0003 | 0.4 |

| Angular-contact | 30–40 | 0.001 | 0.33 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soomro, A.; Amiryar, M.E.; Nankoo, D.; Pullen, K.R. Performance and Loss Analysis of Squirrel Cage Induction Machine Based Flywheel Energy Storage System. Appl. Sci. 2019, 9, 4537. https://doi.org/10.3390/app9214537

Soomro A, Amiryar ME, Nankoo D, Pullen KR. Performance and Loss Analysis of Squirrel Cage Induction Machine Based Flywheel Energy Storage System. Applied Sciences. 2019; 9(21):4537. https://doi.org/10.3390/app9214537

Chicago/Turabian StyleSoomro, Abid, Mustafa E. Amiryar, Daniel Nankoo, and Keith R. Pullen. 2019. "Performance and Loss Analysis of Squirrel Cage Induction Machine Based Flywheel Energy Storage System" Applied Sciences 9, no. 21: 4537. https://doi.org/10.3390/app9214537

APA StyleSoomro, A., Amiryar, M. E., Nankoo, D., & Pullen, K. R. (2019). Performance and Loss Analysis of Squirrel Cage Induction Machine Based Flywheel Energy Storage System. Applied Sciences, 9(21), 4537. https://doi.org/10.3390/app9214537