Effect of ElectroSpark Process Parameters on the WE43 Magnesium Alloy Deposition Quality

Abstract

1. Introduction

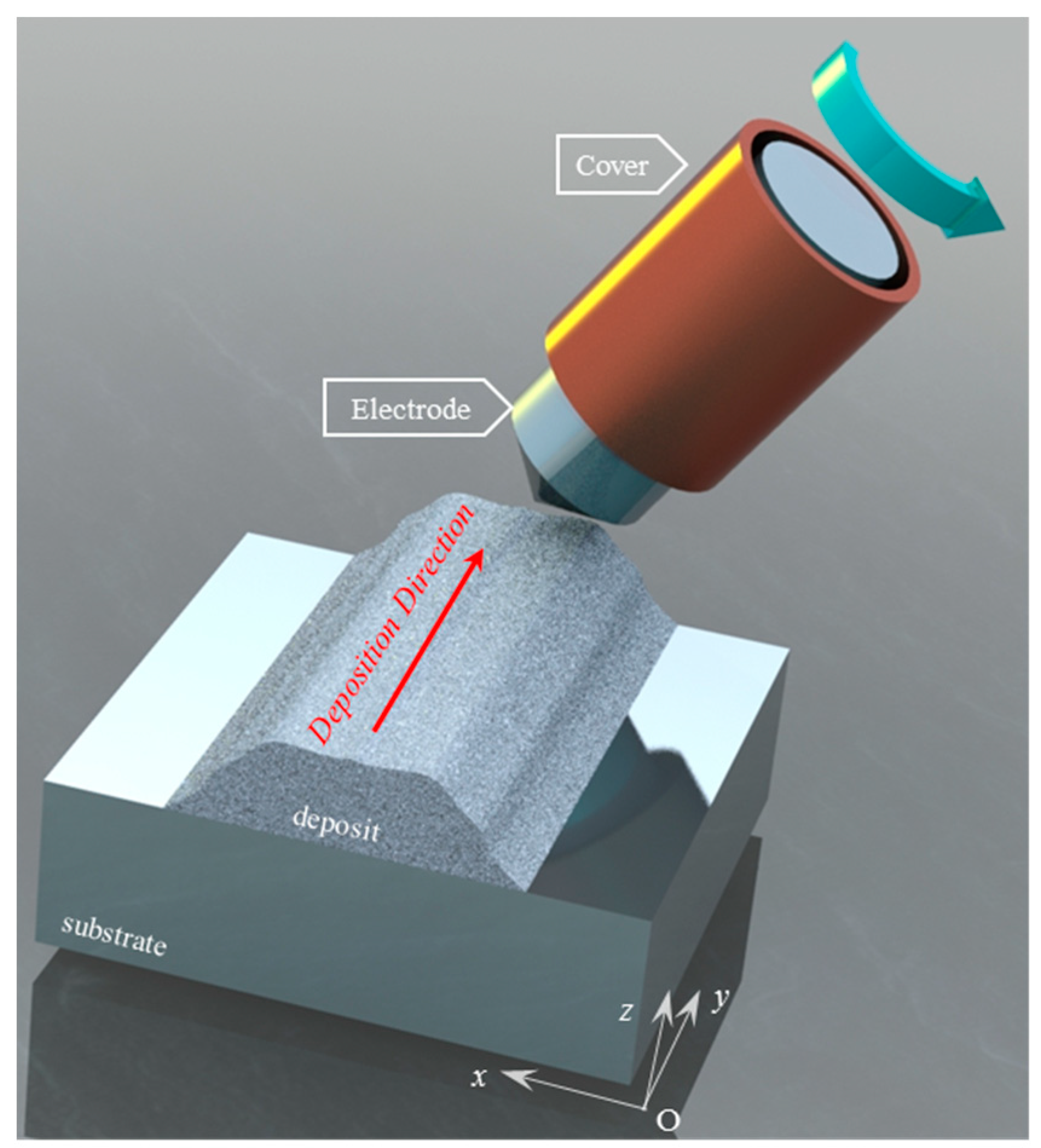

2. Experimental Details

2.1. Materials and Processing

2.2. Metallographic Characterization and Stereological Studies

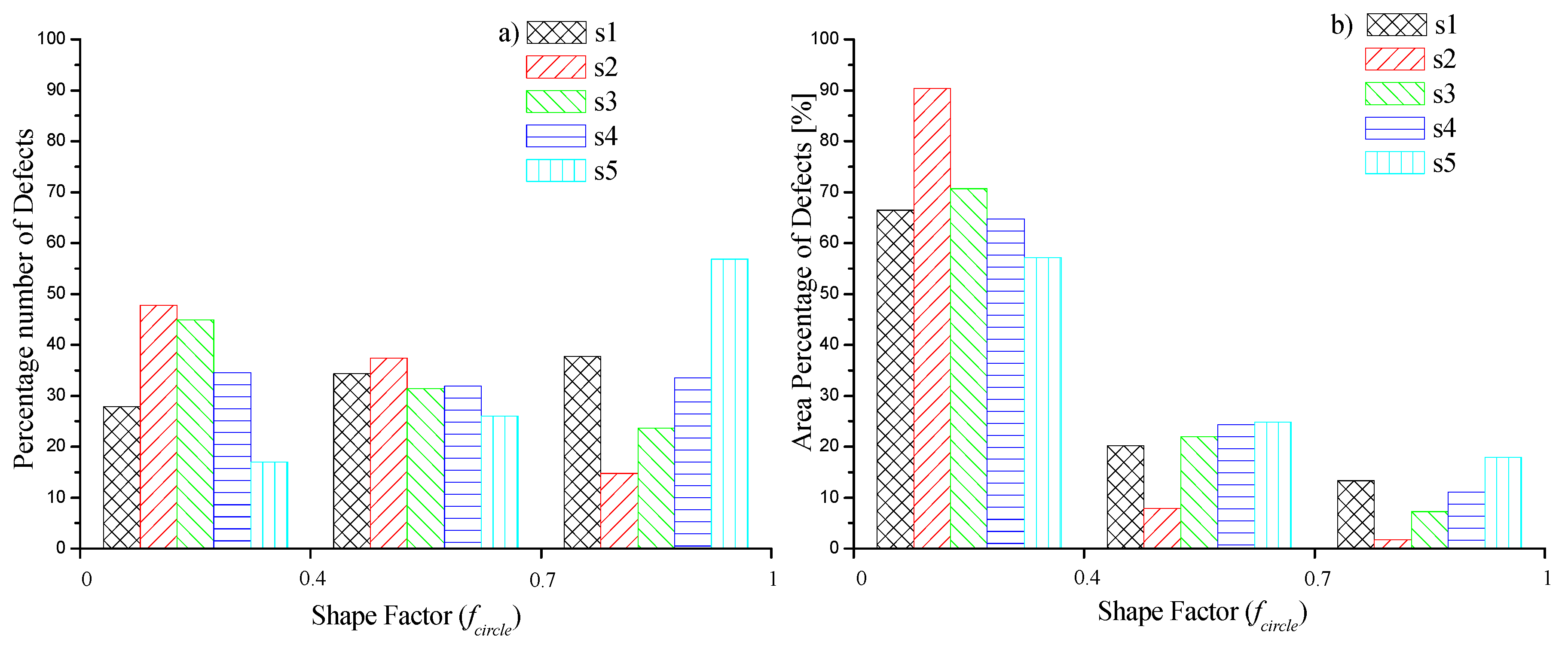

- laminar shaped defects or cracks (0 < fcircle < 0.4),

- random shaped defects (0.4 < fcircle < 0.7)

- spherical shaped defects (0.7 < fcircle < 1).

2.3. Mechanical Properties Measurement: Vickers Micro-Hardness

3. Results and Discussion

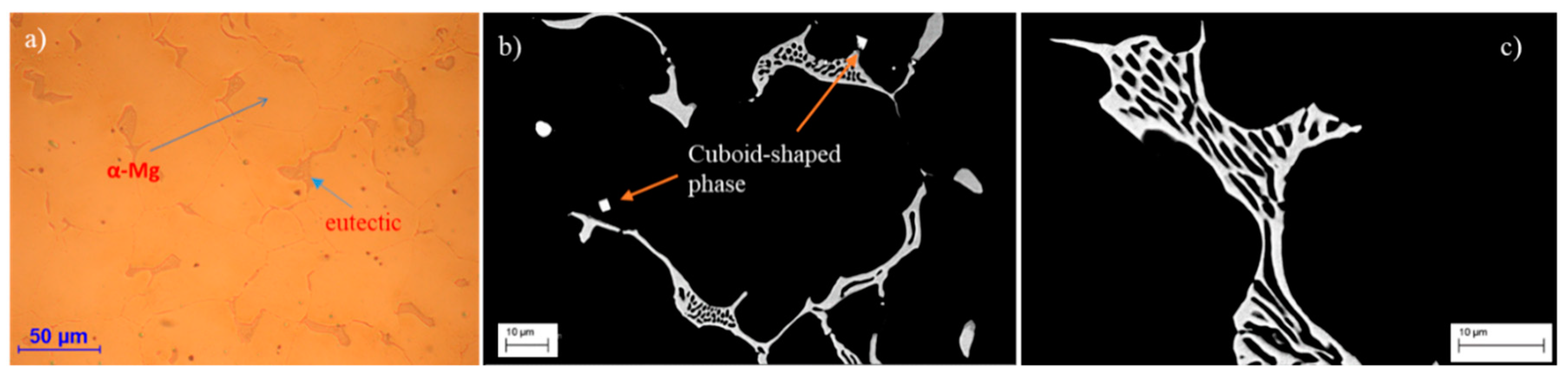

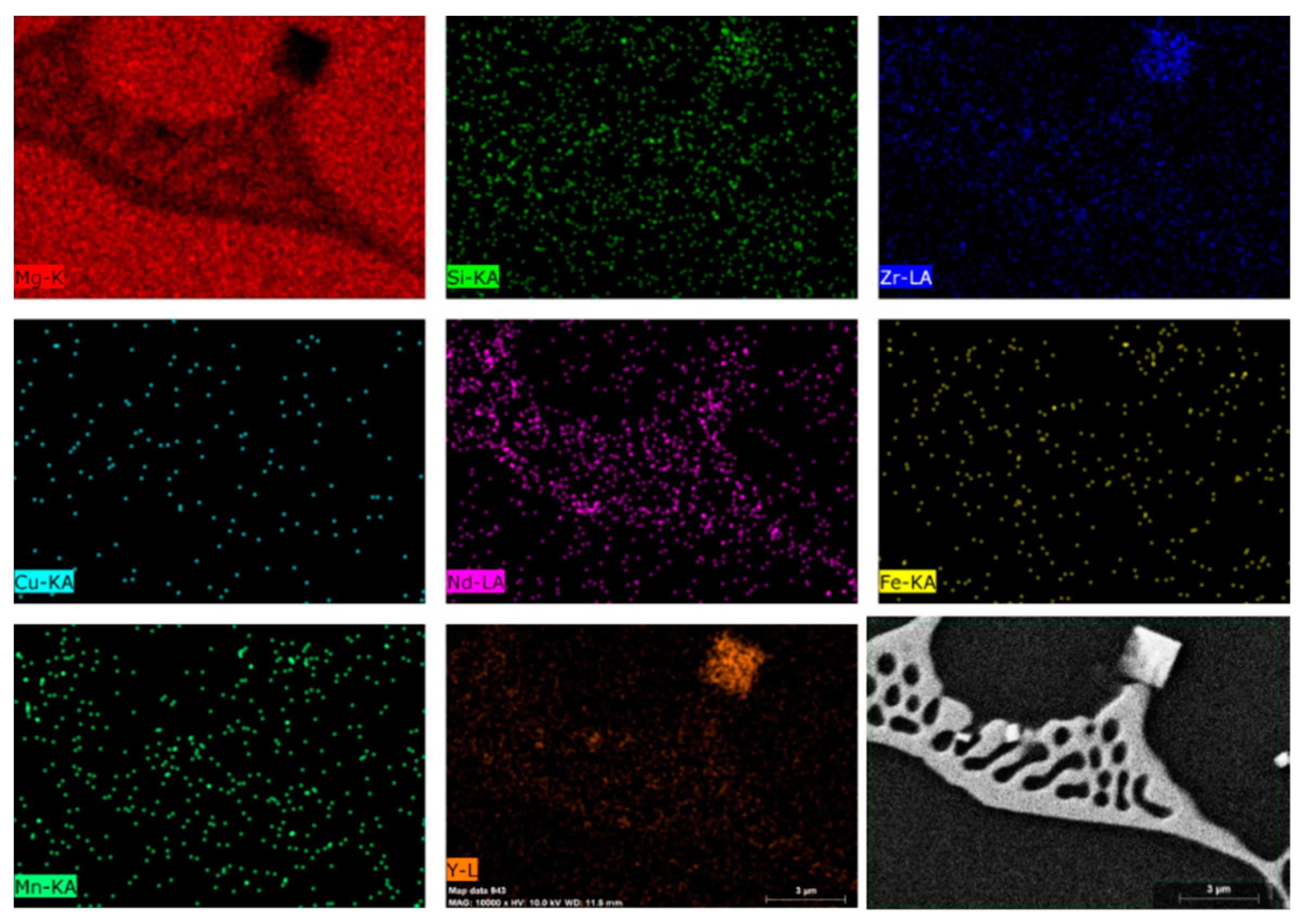

3.1. Microstructure of WE43 Base Material

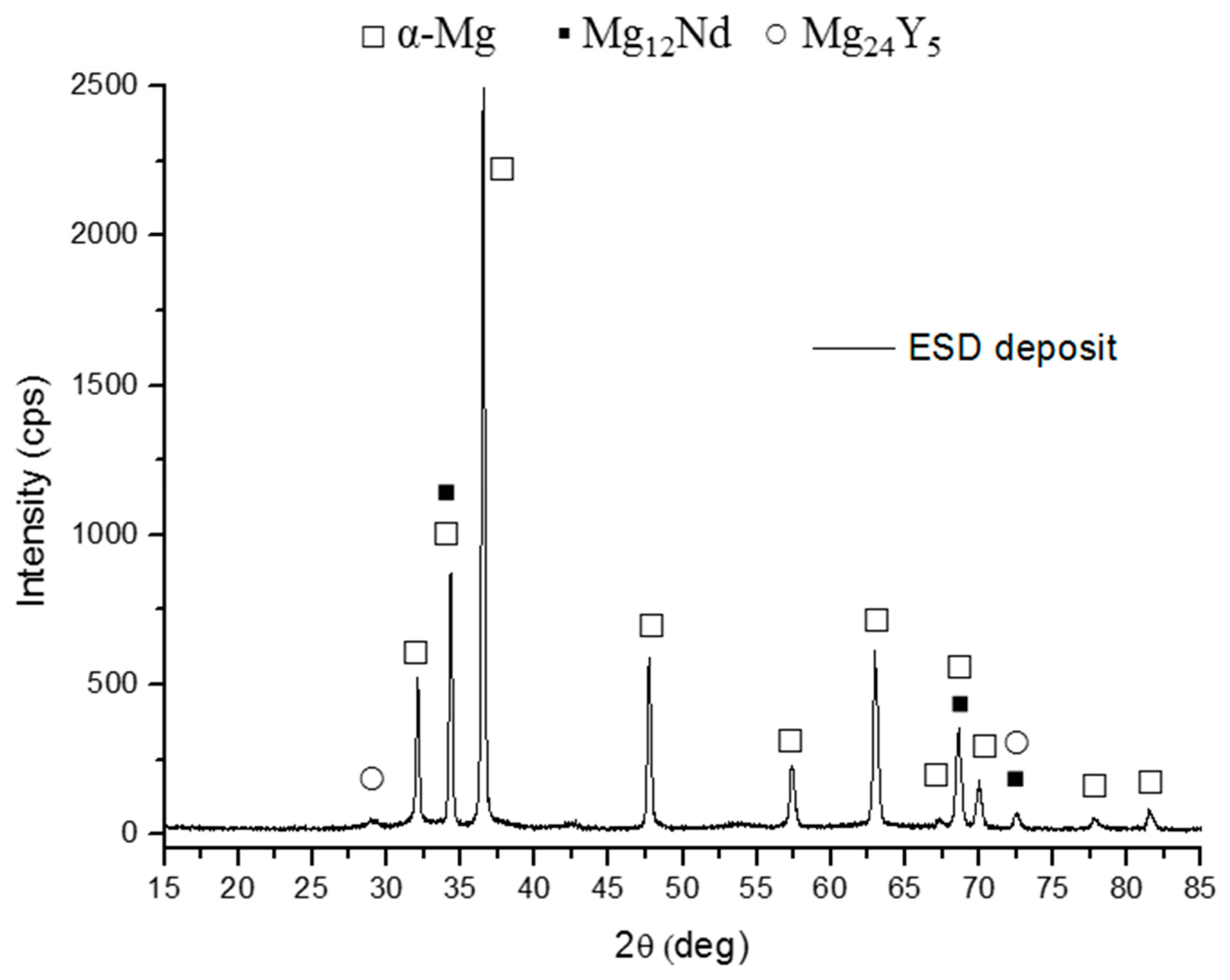

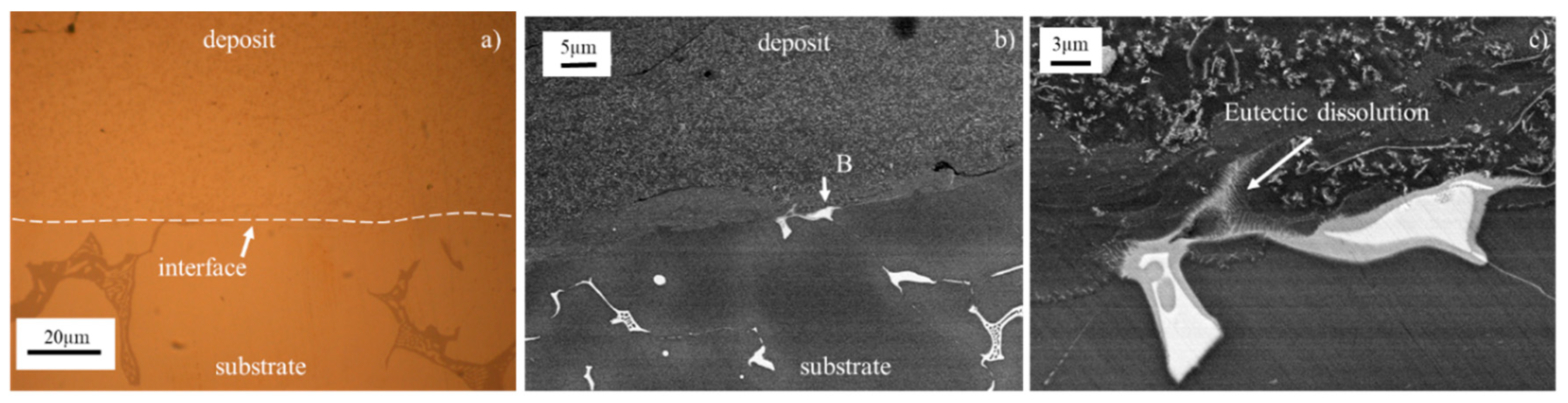

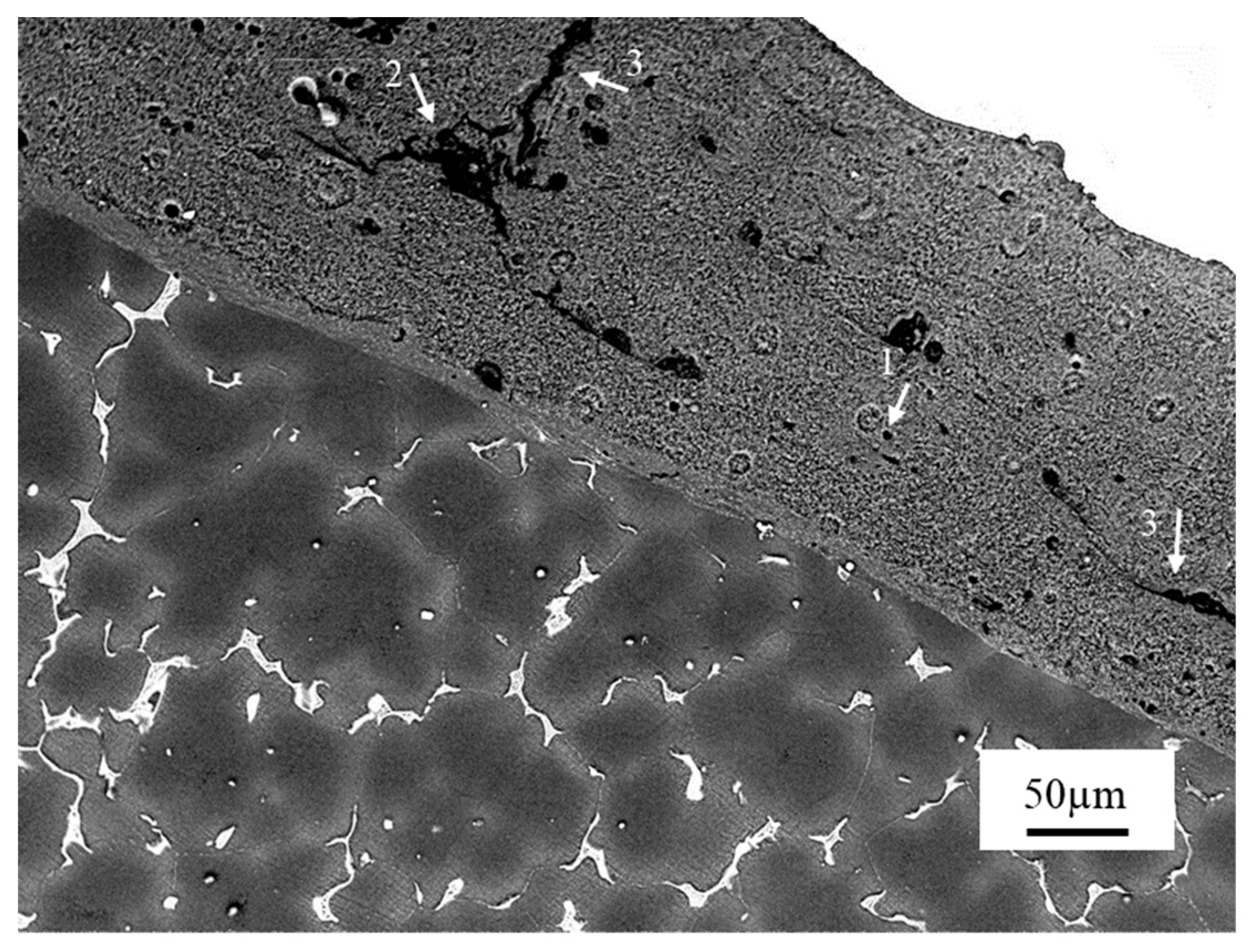

3.2. Microstructure of the Deposits

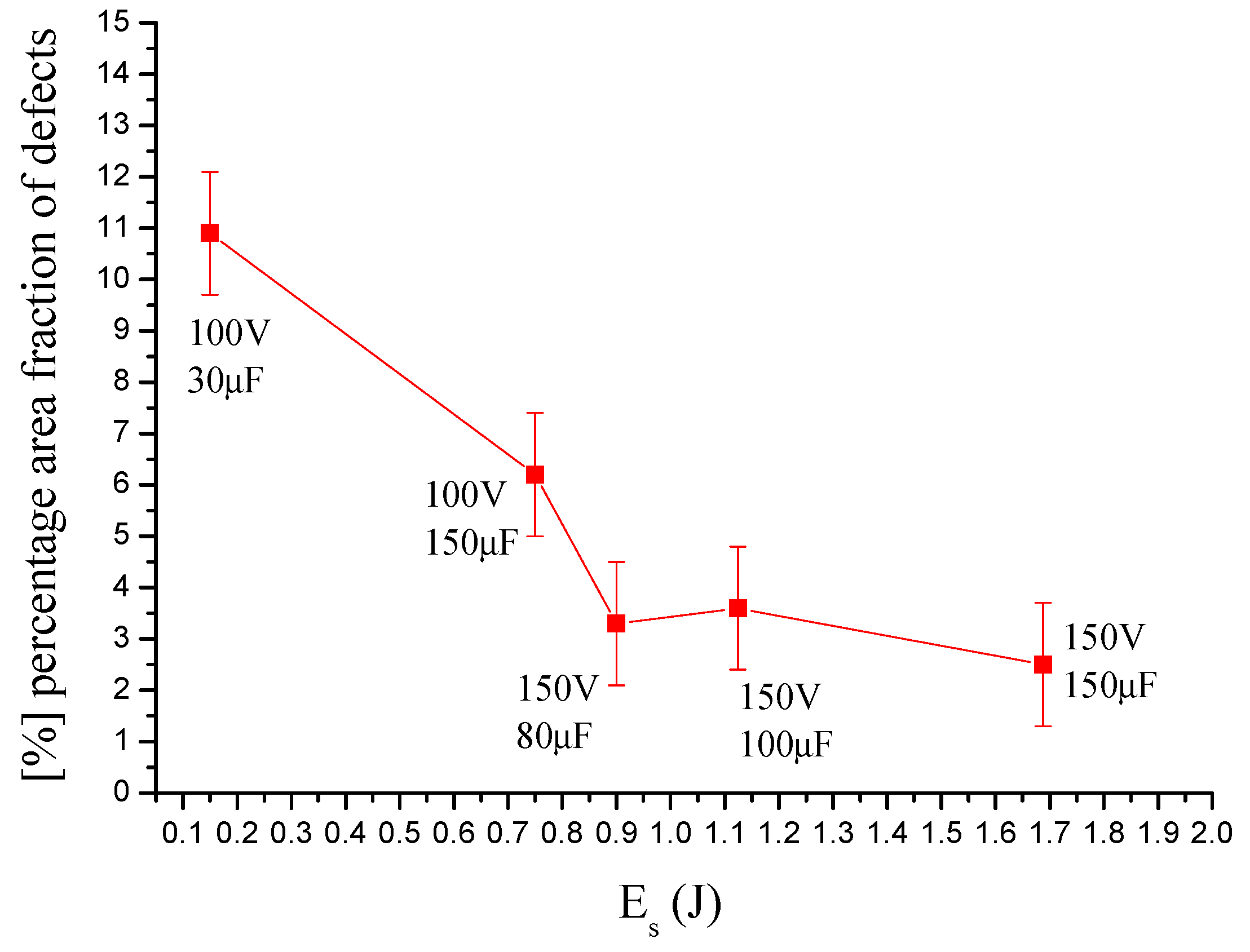

3.3. Analysis of Defects of WE43 Deposits

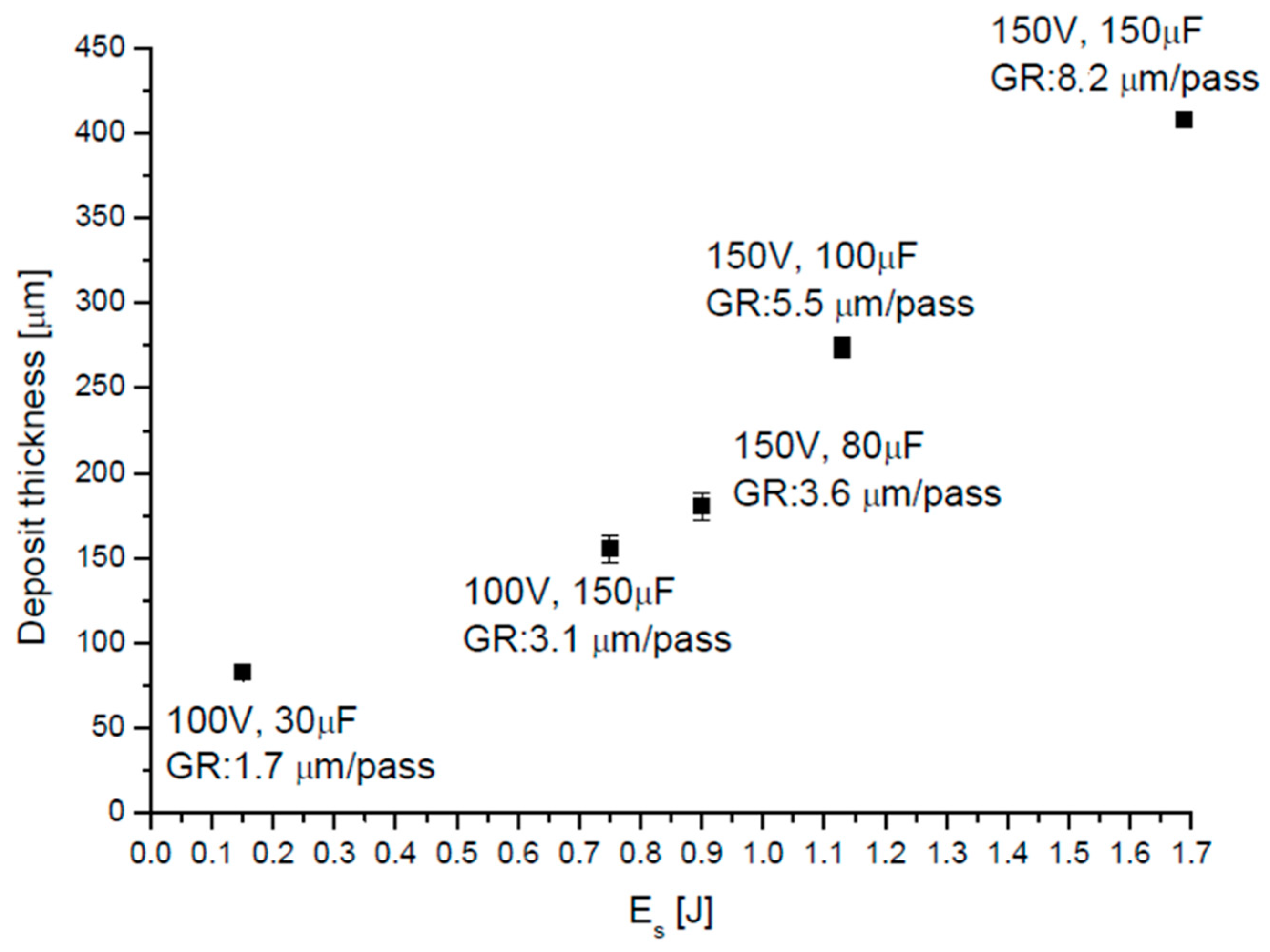

3.4. Effect of the Electric Parameters on Mechanical Properties and Thickness of Deposits

4. Conclusions

- The deposits’ microstructure was very fine grained due to the rapid solidification process. The XRD patterns of the coating and starting material are similar.

- The coatings’ thickness increases significantly with the spark pulse-energy.

- In the coating/substrate interface of WE43 alloy deposit a partial dissolution of the eutectic structures has been observed. In addition, the substrate micro hardness close to the coating interface does not change with process parameters, indicating that the heat input of the process does not alter significantly the substrate microstructure.

- The deposits cross-section exhibit several discontinuities that occur as voids. With increasing of the heat input the percentage of defectiveness was reduced. Particularly with increasing of the spark energy the laminar shape defects are reduced.

- The average micro-hardness values of the deposits are lower than that of the substrate and ddistributed in a small range (49–60 HV). The coatings micro-hardness values reflect the trend of the defectiveness.

Author Contributions

Funding

Conflicts of Interest

References

- Paydas, H.; Mertens, A.; Carrus, R.; Lecomte-Beckers, J.; Tchuindjang, T. Laser cladding as repair technology for Ti–6Al–4V alloy: Influence of building strategy on microstructure and hardness. Mater. Des. 2015, 85, 497–510. [Google Scholar] [CrossRef]

- Felix, L.M.; Kwan, C.C.; Zhou, N.Y. The Effect of Pulse Energy on the Defects and Microstructure of Electro-Spark-Deposited Inconel 718. Metall. Mater. Trans. A 2019, 50, 4223–4231. [Google Scholar] [CrossRef]

- Cao, T.; Lei, S.; Zhang, M. The friction and wear behavior of Cu/Cu-MoS2 self-lubricating coating prepared by electrospark deposition. Surf. Coat. Technol. 2015, 270, 24–32. [Google Scholar] [CrossRef]

- Feldshteina, E.E.; Kardapolova, M.K.; Gaida, R.; Khorodyski, B.; Kaval’chuk, O.V. Tribological Properties of ElectrosparkDeposited and Further Laser Hardened Coatings. J. Frict. Wear 2013, 34, 137–141. [Google Scholar] [CrossRef]

- Renna, G.; Leo, P.; Cerri, E.; Zanon, G.P. Thermal shock behaviour of CoCrAlTaY coatings on a Ni-base superalloy. Metall. Ital. 2015, 107, 33–41. [Google Scholar]

- Brandt, M. Laser Additive Manufacturing: Materials, Design, Technologies, and Applications; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar]

- Barile, C.; Casavola, C.; Pappalettera, G.; Pappalettere, C. Analysis of crack propagation in stainless steel by comparing acoustic emissions and infrared thermography data. Eng. Fail. Anal. 2015, 69, 35–42. [Google Scholar] [CrossRef]

- Mao, Y.; Li, Z.; Feng, K.; Guo, X.; Zhou, Z.; Wu, Y. Corrosion behavior of carbon film coated magnesium alloy with electroless plating nickel interlayer. J. Mater. Process. Technol. 2015, 219, 42–47. [Google Scholar] [CrossRef]

- Ermakova, E.N.; Sysoev, S.V.; Nikulina, L.D.; Tsyrendorzhieva, I.P.; Rakhlin, V.I.; Kosinova, M.L. Synthesis and characterization of organosilicon compounds as novel precursors for CVD processes. Thermochim. Acta 2015, 622, 2–8. [Google Scholar] [CrossRef]

- Campbell, F.C. Manufacturing Technology for Aerospace Structural Materials; Elsevier: Amsterdam, Netherlands, 2006. [Google Scholar]

- Turowska, A.; Adamiec, J. Mechanical properties of WE43 magnesium alloy joint at elevated temperature. Arch. Metall. Mater. 2015, 60, 2695–2701. [Google Scholar] [CrossRef]

- Kierzek, A.; Adamiec, J. Creep Resistance of WE43 Magnesium Alloy Joints Solid State Phenomena. Trans. Tech. Publ. 2012, 191, 177–182. [Google Scholar]

- Gupta, M.; Wong, W.L.E. Magnesium–based nanocomposites lightweight materials of the future. Mater. Charact. 2015, 105, 30–46. [Google Scholar] [CrossRef]

- Rashad, M.; Pan, F.; Lin, D.; Asif, M. High temperature mechanical behavior of AZ61 magnesium alloy reinforced with graphene nanoplatelets. Mater. Des. 2016, 89, 1242–1250. [Google Scholar] [CrossRef]

- Liu, J.; Yu, H.; Chen, C.; Weng, F.; Dai, J. Research and development status of laser cladding on magnesium alloys: A review. Opt. Lasers Eng. 2017, 93, 195–210. [Google Scholar] [CrossRef]

- McClelland, Z.; Avery, D.Z.; Williams, M.B.; Mason, C.J.T.; Rivera, O.G.; Leah, C.; Allison, P.G.; Jordon, J.B.; Martens, R.L.; Hardwick, N. Microstructure and Mechanical Properties of High Shear Material Deposition of Rare Earth Magnesium Alloys WE43. In Magnesium Technology; Springer: Switzerland, Germany, 2019; pp. 277–282. [Google Scholar]

- Kocurek, R.; Adamiec, J. The Repair Welding Technology of Casts Magnesium Alloy QE2. Solid State Phenom. 2014, 212, 81–86. [Google Scholar] [CrossRef]

- Carofalo, A.; Dattoma, V.; Nobile, R.; Panella, F.W.; Alfeo, G.; Scialpi, A.; Zanon, G.P. Mechanical Characterization of a Nickel-based Superalloy Repaired using MicroPlasma and ESD Technology. Procedia Eng. 2015, 109, 312–319. [Google Scholar] [CrossRef]

- Leo, P.; Renna, G.; Perulli, P.; Zanon, G.P.; Alfeo, G. Caratterizzazione microstrutturale e meccanica di rivestimenti in lega AA2024 ottenuti mediante electrospark deposition. In Proceedings of the 36° Conferenza Nazionale AIM, Parma, Italy, 21–23 September 2016. [Google Scholar]

- Cerri, E.; Renna, G.; Leo, P.; Zanon, G.P.; Alfeo, G. caratterizzazione di deposizioni di leghe leggere mediante electro spark deposition. In Proceedings of the 35° Conferenza Nazionale AIM, Bologna, Italy, 21–22 November 2014. [Google Scholar]

- Xiang, H.O.N.G.; Ke, F.E.N.G.; Tan, Y.F.; Wang, X.L.; Hua, T.A.N. Effects of process parameters on microstructure and wear resistance of TiN coatings deposited on TC11 titanium alloy by electrospark deposition. Trans. Nonferrous Met. Soc. China 2017, 27, 1767–1776. [Google Scholar]

- Frangini, S.; Masci, A. A study on the effect of a dynamic contact force control for improving electrospark coating properties. Surf. Coat. Technol. 2010, 204, 2613–2623. [Google Scholar] [CrossRef]

- Padgurskas, J.; Kreivaitis, R.; Rukuiža, R.; Mihailov, V.; Agafii, V.; Kriukiene, R.; Baltušnikas, A. Tribological properties of coatings obtained by electro-spark alloying C45 steel surfaces. Surf. Coat. Technol. 2017, 311, 90–97. [Google Scholar] [CrossRef]

- Xie, Y.J.; Wang, M.C. Microstructural morphology of electrospark deposition layer of a high gamma prime superalloy. Surf. Coat. Technol. 2006, 201, 691–698. [Google Scholar] [CrossRef]

- Champagne, V.; Pepi, M.; Edwards, B. Electrospark Deposition for the Repair of Army Main Battle Tank Components; Army Research Laboratory: Adelphi, MD, USA, 2006. [Google Scholar]

- Wang, W.F.; Wang, M.C.; Sun, F.J.; Zheng, Y.G.; Jiao, J.M. Microstructure and cavitation erosion characteristics of Al–Si alloy coating prepared by electrospark deposition. Surf. Coat. Technol. 2008, 202, 5116–5121. [Google Scholar] [CrossRef]

- Anisimov, E.; Khan, A.K.; Ojo, O.A. Analysis of Microstructure in Electro-Spark Deposited IN718 Superalloy. Mater. Charact. 2016, 119, 233–240. [Google Scholar] [CrossRef]

- Enrique, P.D.; Jiao, Z.; Zhou, N.Y. Effect of Direct Aging on Heat-Affected Zone and Tensile Properties of Electrospark-Deposited Alloy 718. Met. Mater. Trans. A 2019, 50, 285–294. [Google Scholar] [CrossRef]

- Cadney, S.; Brochu, M. Formation of amorphous Zr41.2Ti13.8Ni10Cu12.5Be22.5 coatings via the ElectroSpark Deposition process. Intermetallics 2008, 16, 518–523. [Google Scholar] [CrossRef]

- Hasanabadi, M.F.; Ghaini, F.M.; Ebrahimnia, M.; Shahverdi, H.R. Production of amorphous and nanocrystalline iron based coatings by electro-spark deposition process. Surf. Coat. Technol. 2015, 270, 95–101. [Google Scholar] [CrossRef]

- Leo, P.; Renna, G.; Casalino, G. Study of the Direct Metal Deposition of AA2024 by ElectroSpark for Coating and Reparation Scopes. Appl. Sci. 2017, 7, 945. [Google Scholar] [CrossRef]

- Renna, G.; Leo, P.; Casalino, G.; Cerri, E. Repairing 2024 Aluminum Alloy via Electrospark Deposition Process: A Feasibility Study. Adv. Mater. Sci. Eng. 2018, 1–11. [Google Scholar] [CrossRef]

- Enrique, P.D.; Jiao, Z.; Zhou, N.Y.; Toyserkan, E. Effect of microstructure on tensile properties of electrospark deposition repaired Ni-superalloy. Mater. Sci. Eng. A 2018, 729, 268–275. [Google Scholar] [CrossRef]

- Brochu, M.; Heard, D.W.; Milligan, J.; Cadney, S. Bulk nanostructure and amorphous metallic components using the electrospark welding process. Assem. Autom. 2010, 30, 248–256. [Google Scholar] [CrossRef]

- Avedesian, M.M.; Baker, H. Magnesium and Magnesium Alloys; ASM Handbook: Cleveland, OH, USA, 1999. [Google Scholar]

- Ascencio, M.; Pekguleryuz, M.; Omanovic, S. An investigation of the corrosion mechanisms of WE43 Mg alloy in a modified simulated body fluid solution: The influence of immersion time. Corros. Sci. 2014, 87, 489–503. [Google Scholar] [CrossRef]

- Verbitchi, V.; Ciuca, C.; Cojocaru, R. Electro-Spark Coating with Special Materials. Nonconv. Technol. Rev. 2011, 1, 57–62. [Google Scholar]

- Staia, M.H.; Fragiel, A.; Cruz, M.; Carrasquero, E.; Campillo, B.; Perez, R.; Constantino, M.; Sudarshan, T.S. Characterization and wear behavior of pulsed electrode surfacing coatings. Wear 2001, 251, 1051–1060. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, Y.H. Surface modification of resistance welding electrode by electro-spark deposited composite coatings: Part I. Coating characterization Surf. Coat. Technol. 2006, 201, 1503–1510. [Google Scholar] [CrossRef]

- Reynold, J.L.; Holdren, R.L.; Brown, L.E. Electro-Spark Deposition. Adv. Mater. Processes 2003, 161, 35–37. [Google Scholar]

- Heard, D.W.; Brochu, M. Development of a nanostructure microstructure in the Al–Ni system using the electrospark deposition process. J. Mater. Process. Technol. 2010, 210, 892–898. [Google Scholar] [CrossRef]

| Zn | Fe | Si | Cu | Mn | Y | Nd | Zr | Mg | Other | |

|---|---|---|---|---|---|---|---|---|---|---|

| WE43 | 0.203 | 0.0071 | 0.005 | 0.009 | < 0.0001 | 3.963 | 2.388 | 0.409 | Bal. | < 0.2 |

| Sample | Voltage [V] | Capacitance [µF] | Es [J] |

|---|---|---|---|

| s1 | 100 | 30 | 0.15 |

| s2 | 100 | 150 | 0.75 |

| s3 | 150 | 80 | 0.9 |

| s4 | 150 | 100 | 1.13 |

| s5 | 150 | 150 | 1.69 |

| Sample | s1 | s2 | s3 | s4 | s5 |

|---|---|---|---|---|---|

| HV of deposits | 49 ± 3.5 | 58 ± 5 | 60.1 ± 4.6 | 60 ± 5 | 59.5 ± 3.2 |

| HV at 100 µm far from the interface | 75 ± 2 | 73.5 ± 1 | 73 ± 1 | 72 ± 3 | 74.3 ± 1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Renna, G.; Leo, P.; Casavola, C. Effect of ElectroSpark Process Parameters on the WE43 Magnesium Alloy Deposition Quality. Appl. Sci. 2019, 9, 4383. https://doi.org/10.3390/app9204383

Renna G, Leo P, Casavola C. Effect of ElectroSpark Process Parameters on the WE43 Magnesium Alloy Deposition Quality. Applied Sciences. 2019; 9(20):4383. https://doi.org/10.3390/app9204383

Chicago/Turabian StyleRenna, Gilda, Paola Leo, and Caterina Casavola. 2019. "Effect of ElectroSpark Process Parameters on the WE43 Magnesium Alloy Deposition Quality" Applied Sciences 9, no. 20: 4383. https://doi.org/10.3390/app9204383

APA StyleRenna, G., Leo, P., & Casavola, C. (2019). Effect of ElectroSpark Process Parameters on the WE43 Magnesium Alloy Deposition Quality. Applied Sciences, 9(20), 4383. https://doi.org/10.3390/app9204383