1. Introduction

Global warming is considered one of the greatest challenges worldwide. International environmental agreements have been developed in response to climate change since the 1970s. The construction industry is considered to be one of the main contributors to global warming. According to the Intergovernmental Panel on Climate Change (IPCC) report [

1], not only is the construction industry responsible for about 40% of global energy consumption, it is also responsible for 30% of global greenhouse gas emissions per annum. Furthermore, it is common for most countries to construct high-rise buildings and larger-sized facilities, due to the rapid growth of population, and scarcity of land in urban areas [

2,

3,

4]. Since high-rise and larger-sized buildings and structures consume greater amounts of energy and materials per unit area, the total energy and carbon dioxide emissions associated with the construction industry are expected to grow. For example, it is reported that in South Korea, over 40% of the energy consumption and annual CO

2 equivalent emissions are related to the construction industry [

5,

6,

7]. From the perspective of sustainable development, it is undoubtable that reducing energy consumption and carbon dioxide emissions from the construction industry would be one of the most sustainable measures [

8,

9,

10,

11,

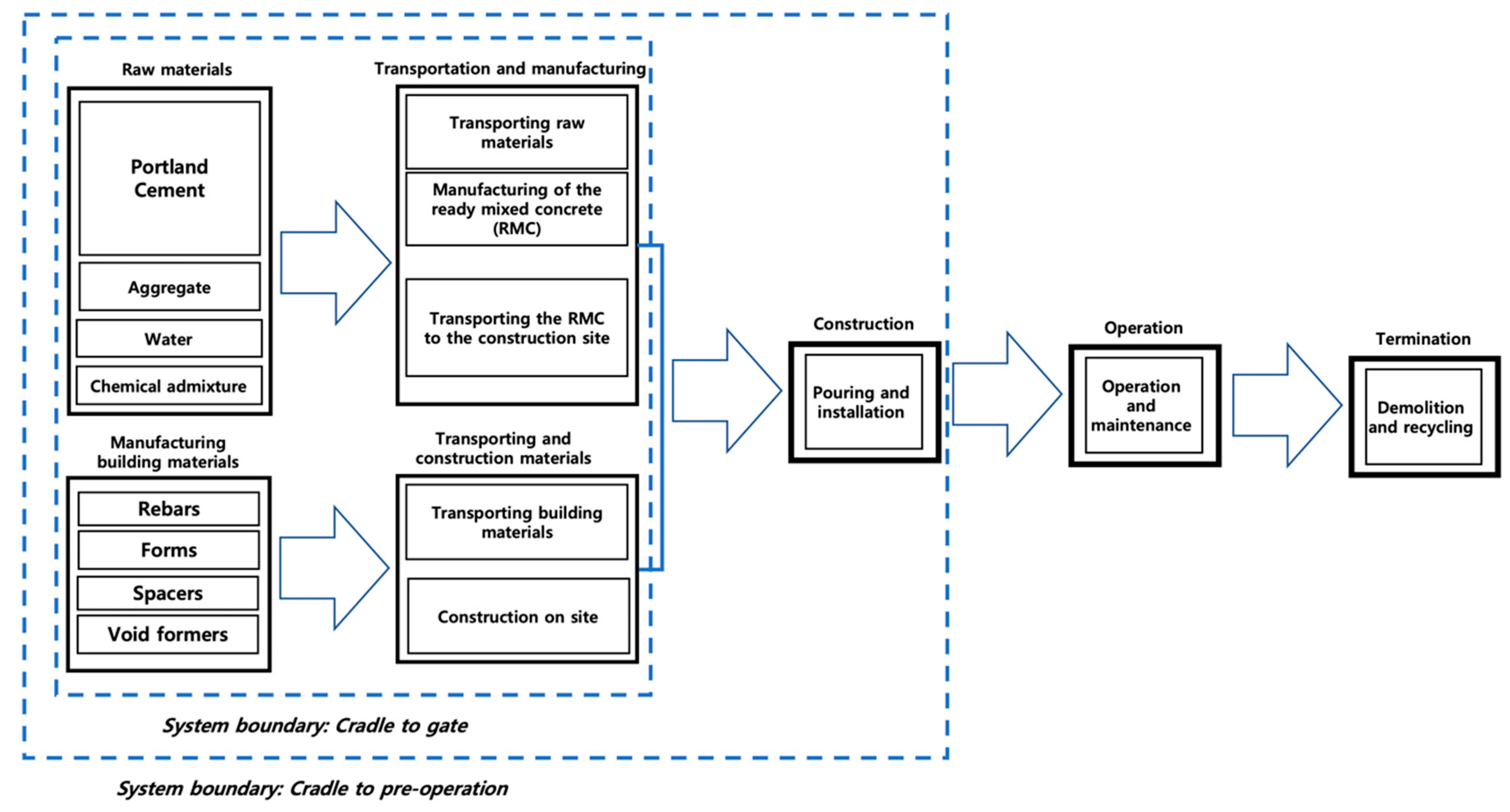

12]. Likewise, the construction industry has been exploring various approaches to mitigate the impacts of carbon dioxide emissions over the entire life cycle of buildings, which includes the manufacturing of building materials, transporting of the building materials, construction and installation, operation and maintenance, and eventual demolition [

12,

13,

14].

The reduction of carbon dioxide emissions in the construction industry has a unique characteristic compared to other manufacturing or service industries. Due to the relatively long life span of buildings of over 30 years, the mainstay of reducing the carbon dioxide emissions in the construction industry is focused on the CO

2 emissions from the operation and maintenance stage of buildings [

14,

15,

16,

17,

18]. A number of studies have maintained that approximately 70% of the life cycle CO

2 is generated from the operation phase for a typical office building, whereas only about 25% of carbon dioxide emissions are from the pre-operation stage, and less than 5% is emitted from the demolition and other stages [

14,

18,

19]. Recent studies regarding carbon dioxide emissions in the construction industry [

3,

4,

19,

20,

21,

22] report that energy consumption and carbon dioxide emissions during the operation stage of a building are gradually decreasing, due to the newly developed technologies to enhance the energy efficiency and optimisation of heating, ventilation, and air conditioning (HVAC) systems. Even though the carbon dioxide emissions from the pre-operation stage are smaller than the CO

2 emissions from the operation and maintenance stage, various studies have tried to mitigate the occurrence of carbon dioxide in this phase. Furthermore, when the different time frames of life cycle are considered, the carbon dioxide emissions from the pre-operation stage might become more significant [

23]. As the service life of buildings is reducing to less than 30 years, the contribution of CO

2 emissions from pre-operational stages would become larger at up to 50% [

21,

23]. As a consequence of the decreased carbon dioxide emissions from the operational and maintenance stage of buildings, the embodied carbon that is generated from manufacturing building materials to the construction stage becomes more significant, and from an entire life cycle perspective, has more potential to be mitigated [

14,

18,

24,

25,

26,

27].

Recent research in terms of carbon dioxide emissions from the pre-operational stage has focused on various aspects of the building to mitigate their impacts. Numerous studies have claimed that the CO

2 emissions from building material production are the most dominant contributor during this phase [

24,

27,

28,

29,

30]. As building material production is the main source of carbon dioxide emissions, various approaches are being taken to alleviate the impacts from building materials. According to Goverse et al. [

31], replacing building materials to low embodied carbon materials in Dutch residential buildings might achieve almost 50% reduction of carbon dioxide emissions, compared to the traditional method. Likewise, one of the most effective and prevalent approaches to lower the emissions of carbon dioxide emissions in the construction stage is the application of high-strength building materials. High-strength building materials not only lessen the input amount of building materials, but also enhance the durability of the entire structure or building [

6]. Moreover, the strengthening of building materials would be beneficial to prolong the lifespan of buildings from the whole life cycle perspective. Tae et al. [

6], for example, maintained that high-strength concrete would make it possible to reduce the emissions of carbon dioxide, owing to the quantity reduction of concrete and rebars, as well as the extension of building life span. In a similar vein, Cho and Na [

32] indicated that the utilisation of high-strength rebars would contribute to reduction of the carbon dioxide emissions regardless of the structural type of office buildings in South Korea, even though the amounts of splice and development in reinforcement were slightly increased.

Along with the utilisation of high-strength building materials, it is important to produce building materials with high recycling potential to mitigate the emissions of carbon dioxide. For instance, Gao et al. [

33] studied three buildings with different recycling ratio of building materials. The results indicated that approximately 25% of CO

2 could be decreased with the maximum recycling ratio. Moreover, Quack [

34] maintained that from a theoretical perspective, about 12% CO

2 emissions reduction would be achieved, when the recycling rate increased to 100%. While various studies have claimed the usefulness of increasing the recycling ratio for building materials production, application of by-products is also suggested to mitigate the environmental impacts from building materials. As stated in the previous section, enhancement of material strength is a practical method to reduce the carbon dioxide emissions to a certain extent. According to Tae et al. [

6], high-strength concrete of more than 24 MPa compressive strength would have a negative consequence, compared to high-strength concrete of less than 24 MPa. In order to deal with this matter, the authors suggested that applying industrial by-products, such as fly ash or blast furnace slag, would not only enhance the strength of concrete, but also reduce fuel consumption during the manufacturing of the concrete.

While a number of studies have considered replacing conventional building materials by alternative ones, approaches to the design of structural systems to mitigate the amount of building materials have been suggested. Structural systems are one of the core elements for the entire building to sustain the external forces, such as lateral loads, and service and permanent loads. According to Nadoushani and Akbarnezhad [

35], comprehensive assessment of embodied carbon and operating carbon during the structural design stage would be a significant factor to assess the life cycle carbon of a building. The authors indicated that the embodied carbon from steel structure buildings is less than that from reinforced concrete structure ones, but the operating carbon of steel structure buildings is higher than that of reinforced ones. Similarly, Baek et al. [

36] compared apartment buildings with different structural systems and building materials. Building materials, as well as design, would be one of the important factors to lower the carbon dioxide emissions during the construction phase. Likewise, optimal design of a building with high-strength building materials would result in superior performance in terms of carbon dioxide emissions and structural reliability [

26]. Therefore, selecting the structural design and building materials would make it possible to reduce carbon dioxide emissions during the construction phase.

As the efficient use of land and urbanisation has become prevalent in recent years, it is common to construct high-rise buildings in urban areas around the world. Slabs in a building not only provide occupants with a flat surface, but also transfer various loads, such as service and permanent loads, through beams, girders, and columns, to the ground. Furthermore, the self-weight of slabs in high-rise buildings would significantly grow as the height of a building increased. Given the significant role of slabs in a building, the main focus of research regarding slab systems is to corroborate the structural performance and reliability, such as the flexural, shear, and seismic performance [

37,

38,

39,

40]. Compared to studies on the structural performance of slabs, studies that evaluate the environmental impacts of slab systems are relatively scarce. For example, Ferreiro-Cabello et al. [

41] examined the carbon dioxide emissions from reinforced concrete slab of different thickness. The authors analysed the relationships amongst the distance between columns, the thickness of slabs, and the carbon dioxide emissions. However, this research only dealt with the conventional reinforced concrete slab system, rather than newly developed slab systems. In order to reduce the self-weight of slab systems, the flat plate slab and voided slab systems are applied to buildings for enhanced serviceability and ease of construction. Although the application of flat plate slab systems and the voided slab systems is prevalent, there is little research to compare and verify their environmental performance.

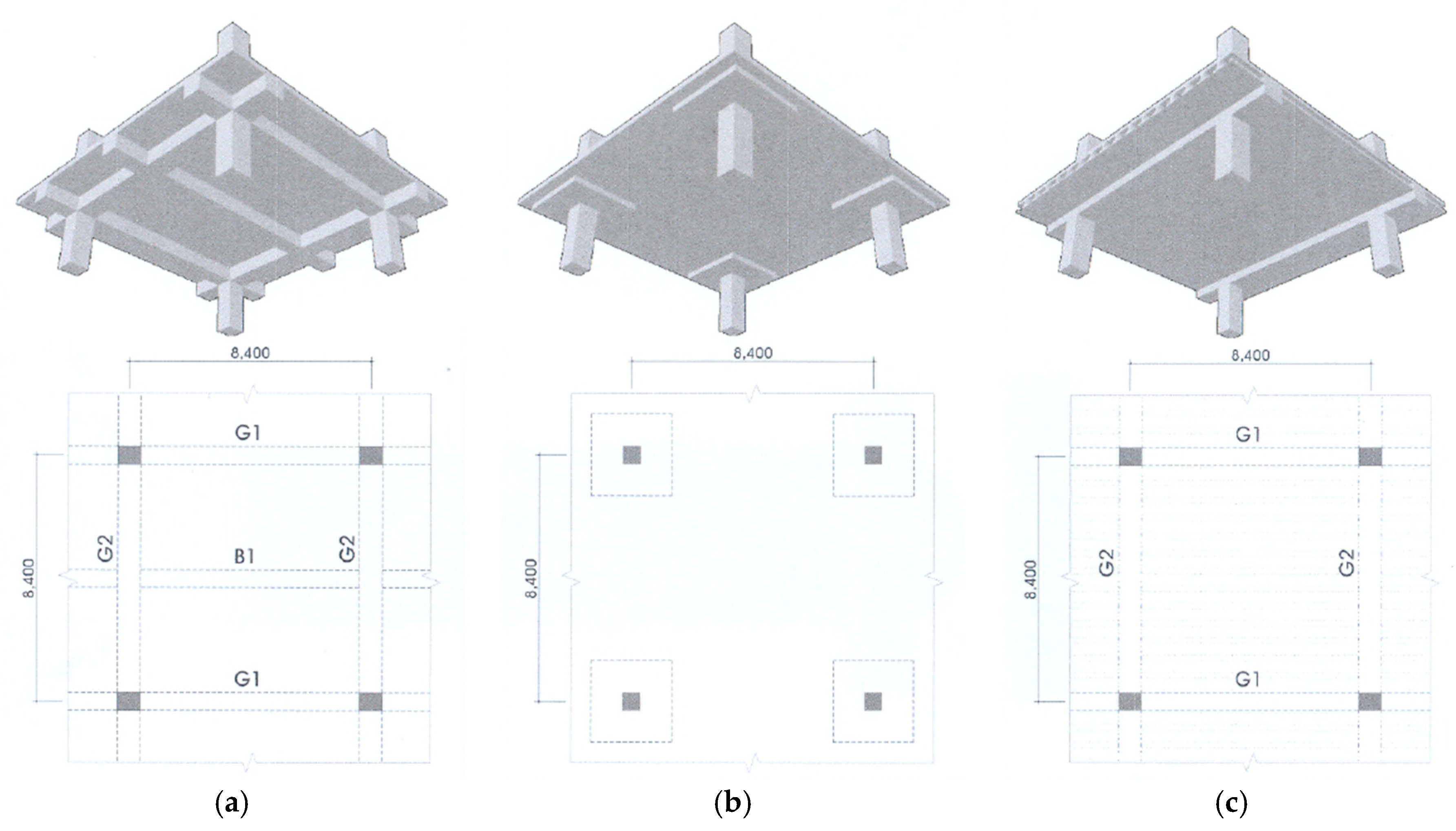

The purpose of this research is to assess the environmental performance of three different slab systems (i.e., the ordinary reinforced concrete slab, flat plate slab, and voided slab systems) during the construction phase (see

Figure 1). In this study, the process-based life cycle assessment (LCA) method was applied, in order to evaluate their level of performance. The comparison amongst the three slab systems was carried out for the following three stages: building material production before transportation to the construction site; transportation of the building materials to the construction site; and utilisation of construction equipment during the construction and installation. The analysed data were further discussed to illustrate the respective environmental performance of the ordinary reinforced concrete slab, flat plate slab, and voided slab systems during the construction phase.

3. Results and Discussion

3.1. Total Carbon Dioxide Emissions of Each Slab System

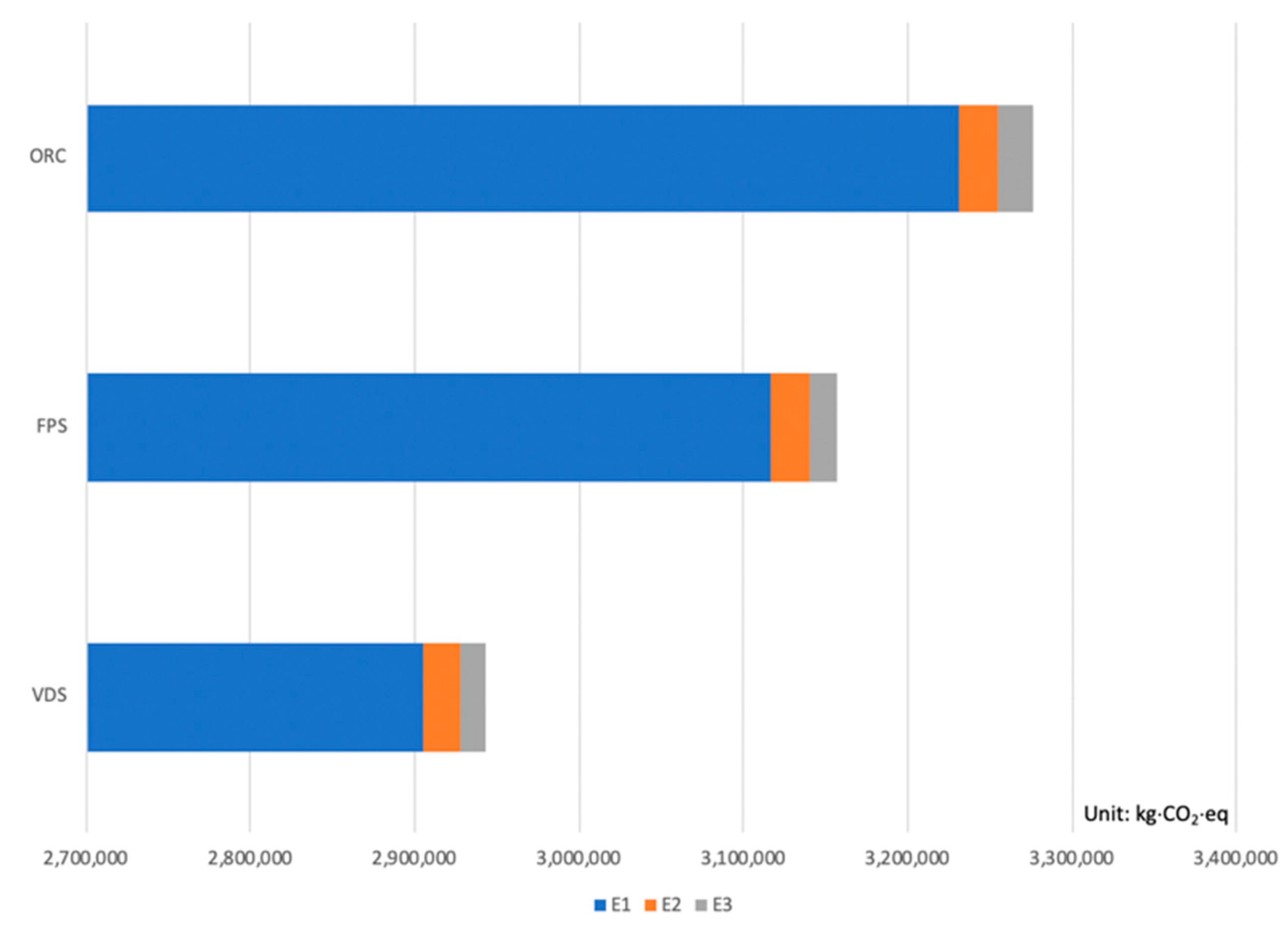

Table 5 summarises the estimated carbon dioxide emissions of alternative slab systems over the ordinary reinforced concrete slab during the construction phase, as well as the share of each life cycle (i.e., the manufacturing of building materials, transportation of building materials, and carbon dioxide emissions of construction equipment) in the total carbon dioxide emissions. The total carbon dioxide emissions during the construction phase of the ordinary reinforced concrete slab, flat plate slab, and the voided slab systems are 3275, 3157, and 2943 tons CO

2 eq. (equivalent to 242, 234, and 218 kg CO

2 eq./m

2), respectively. A reduction of 0.8 tons per 100 m

2 was achieved in the building with flat plate slab, which is approximately 3.6% less than the ordinary reinforced concrete slab. Likewise, 2.4 tons per 100 m

2 of carbon dioxide was reduced in the voided slab system, about 10.1% less CO

2 compared with the ordinary reinforced concrete slab.

The reduction of carbon dioxide emissions from the voided slab system indicated the highest reduction ratio amongst all three cases. The high reduction potential from the voided slab system might be attributed to the reduction of building materials, even though steel decking and void formers were additionally utilised in the voided slab system. In particular, high reduction of concrete and reinforcing bars would make it possible for the voided slab system to emit less carbon dioxide compared with the two alternatives of this study. In addition, the flat plate slab is frequently suggested as an alternative structural system for residential or commercial building in South Korea, since it would enhance the workability for construction workers and serviceability for occupants. In South Korea, it has been tabooed to apply a flat plate slab to buildings since the collapse of a department store building in 1995 [

51,

52]. However, flat plate slabs have been increasingly applied to commercial and residential buildings in recent years, because of the system’s advantages, such as simple formworks during the construction phase, and extended span for enhanced serviceability. As indicated in

Table 6, the carbon dioxide emissions of flat plate slab were reduced by about 3.5% over the ordinary reinforced concrete slab. Based on these results, when the environmental impact is considered to select the structural system in buildings, both flat plate slab and the voided slab system would be an alternative method to the ordinary reinforced concrete slab.

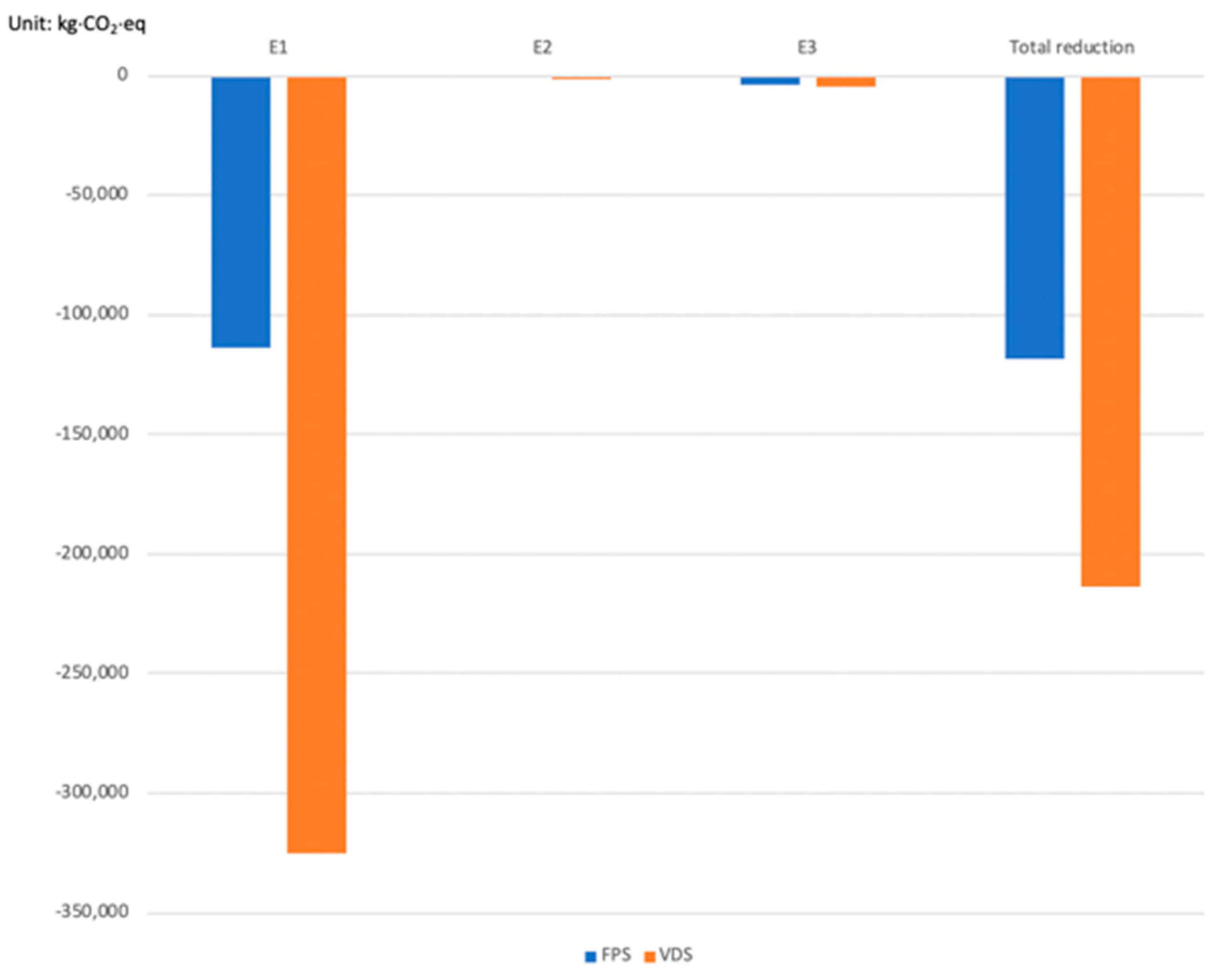

Table 6 summarises the reduced amount of carbon dioxide emissions and the reduction ratio of the flat plate slab and voided slab system over the ordinary reinforced concrete slab. Columns 4 and 5 in

Table 5 present the reduction ratio of each emissions source to the total carbon dioxide emissions reduction brought by the application of flat plate slab and the voided slab system. A total of 3.52% and 10.07% of the carbon dioxide emissions reduction are due to the manufacturing of building materials (

E1); 3.91% and 7.07% of reduction are due to the transporting of building materials to the construction site (

E2); and 3.62% and 10.14% of carbon dioxide emissions were reduced in the construction equipment usage on site (

E3). Amongst the three cases, the manufacturing of building materials contributed the largest proportion of carbon dioxide emissions reduction (see

Figure 4):

In the current study, the reductions of carbon dioxide emissions from the transporting of building materials to the construction site were 3.91% and 7.07% for the flat plate slab and the voided slab systems, respectively. Moreover, 18.43% and 24.10% reduction of the carbon dioxide emissions for flat plate slab and the voided slab systems, respectively, were achieved by the utilisation of construction equipment on site.

Table 6 shows that the major contributor of reduction of the total carbon dioxide emissions was manufacturing of the building materials in all cases. On the other hand, the largest reduction ratio was shown in the utilisation of construction equipment on site for the flat plate slab and the voided slab systems.

From the perspective of the reduction in each emissions source when replacing the ordinary reinforced concrete slab by alternative methods, columns 4 and 5 in

Table 6 indicate that the voided slab system would be the most beneficial approach to the reduction of CO

2, compared to the ordinary reinforced concrete slab method. In the case of the voided slab system, a reduction of 10.07% of the emissions from the manufacturing of building materials, 7.07% of the emissions from the transporting of building materials, and 24.10% of the utilisation of construction equipment were indicated when replacing the ordinary reinforced concrete slab by the voided slab system. Similarly, 3.52%, 3.91%, and 18.43% of reduction for the manufacturing of building materials, transporting of building materials to the construction site, and utilisation of construction equipment, respectively, were noted from the adoption of the flat plate slab system. Based on these results, the most effective method to mitigate the impact of the carbon dioxide emissions from the slab system of buildings would be the voided slab system as indicated in

Figure 5.

3.2. Carbon Dioxide Emissions from the Manufacturing of Building Materials

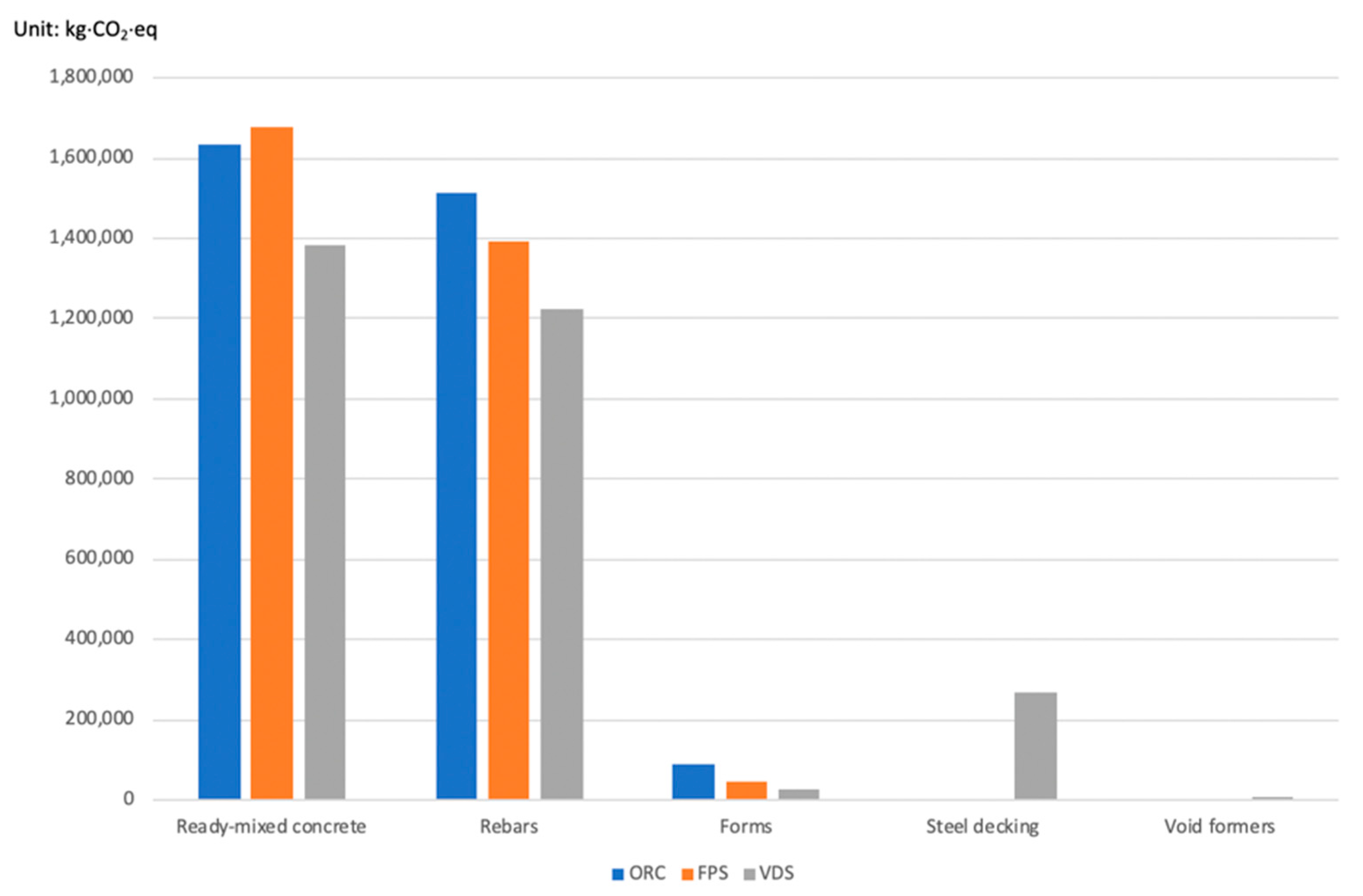

As the largest source of total carbon dioxide emissions amongst the three different types of slab system, the CO

2 emissions from each building material varied from its input amount.

Table 7 and

Table 8 show the carbon dioxide emissions per square meter of each building material. The building materials used in the three cases were divided into permanent and temporary materials. Concrete, reinforcement rebars, steel decking, and void formers were categorised into permanent materials that were integrated with the slab. Temporary materials were auxiliary materials that were removed when the construction work was finished. In this study, forms were the only temporary materials, and were reused 7 times for concreting and moulding work.

The carbon dioxide emissions of building materials generated approximately 238, 231, and 215 kg CO2 eq./m2 for the ordinary reinforced concrete slab, flat plate slab, and voided slab systems, respectively. In all cases, ready-mixed concrete is the largest contributor of carbon dioxide emissions during the manufacturing of building material stage. Specifically, the contribution percentage of each material in the ordinary reinforced concrete slab system is 50.7% for ready-mixed concrete, 46.9% for reinforcing bars, and 2.4% for forms. The flat plate slab system indicated similar proportions to the ordinary reinforced concrete slab system, and accounts for 53.9% of ready-mixed concrete, 44.7% of rebars, and 1.4% of forms, respectively. Additionally, the proportions of materials for the voided slab system are 47.6% for ready-mixed concrete, 42.1% for rebars, 1.0% for forms, 9.2% for steel decking, and 0.1% for void formers. In the voided slab system, the steel decking was the third largest carbon dioxide emissions source.

Table 8 shows that the carbon dioxide reduction in the voided slab system was the largest amount of carbon dioxide reduction amongst all the three slab systems. A total of 113,741 and 325,381 kg CO

2 eq. in reduction of carbon dioxide emissions were contributed by the flat plate slab and the voided slab systems, compared to the ordinary reinforced concrete slab system (see

Table 8). These amounts yielded approximately 3.5% and 10.1% in reduction compared to the ordinary reinforced concrete slab in this study. Comparisons of the three slab systems indicate that the reinforcing bars and forms were significant building materials to mitigate the emissions of carbon dioxide in the flat plate slab and the voided slab systems. In particular, reinforcing bars in the flat plate slab and voided slab systems were the main contributor to lowering the carbon dioxide emissions during the manufacturing of building materials stage. Totals of 119,290 and 280,072 kg CO

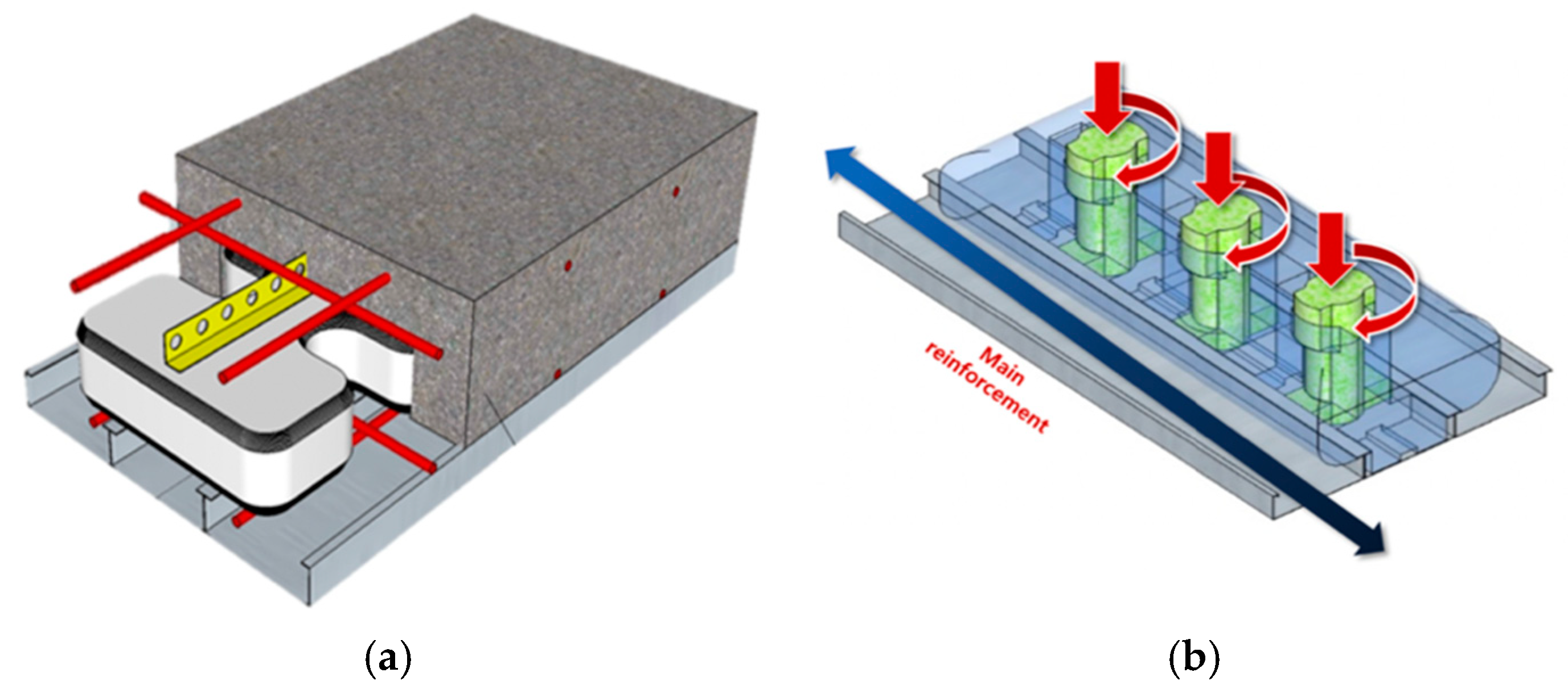

2 eq. for the flat plate slab and voided slab systems, respectively, were reduced in rebars amongst all the building materials. Moreover, a reduction of 249,656 kg CO

2 eq. in ready-mixed concrete was contributed by the voided slab system over the ordinary reinforced concrete slab. In the voided slab system, the hollow parts were filled with light-weight void formers, which were made by Expanded Polystyrene (EPS). Since the void formers were relatively lighter than the other materials, it would make it possible to not only reduce the carbon dioxide emissions, but also to lower the weight of the slab itself. On the other hand, a slight increase of 47,518 kg CO

2 eq. in the ready-mixed concrete was indicated in the flat plate slab system. It is considered that this might be caused by the additional structural members, such as drop panels to enhance the nominal shear strength of flat plate slab at the critical section around the columns. Consequently, the voided slab system would have the least environmental impact compared to the other slab systems, even though it has additional building material, such as steel decking and void formers (see

Figure 6).

3.3. Carbon Dioxide Emissions during Transporting of the Building Materials

Carbon dioxide emissions associated with transporting building materials from the manufacturer’s location to the construction site were calculated based on the fuel efficiency of each vehicle, and the distance between the manufacturing place and the construction site. The total carbon dioxide emissions from the transporting building materials were 24,381, 23,428, and 22,657 kg CO2 eq. for the ordinary reinforced concrete slab, flat plate slab, and voided slab systems, respectively. As to the lower total CO2 emissions in the voided slab system, which involves two more types of transportation than the other slab systems, the emissions of CO2 from transporting building materials were less than those of the ordinary reinforced concrete slab and flat plate slab systems. In this study, it was interesting that the carbon dioxide emissions for transporting the void formers were larger than for the forms, even though the unit weight of void former (i.e., approximately 1.6 kg/void former) was relatively lighter than that of the other building materials. This was attributed to the height of void formers being 0.9 m, which required more vehicles to convey them to the construction site. Due to the road traffic act in South Korea, the maximum clearance of each vehicle was 4.5 m, so the number of lorries for the void formers was larger than for the other materials.

In this study, the emissions of carbon dioxide from the transporting of building materials were calculated by two different approaches. The first method was to compute the CO

2 emissions based on the fuel efficiency of vehicle type, and the distance of location between the manufacturer and the construction site. The other approach was to determine the carbon dioxide emissions for transportation based on the operating time of vehicles by the vehicle logs of operation.

Table 9 shows that the emissions of carbon dioxide had slightly different value, depending upon the calculation methods. For ready-mixed concrete, the CO

2 emissions from calculation by vehicle operation time indicate more than the former method. The distance from ready-mixed concrete supplier to the construction site was 25 km, which was relatively shorter than that of the other building materials. However, the transporting time for the ready-mixed concrete was influenced by traversing the central district area, and it would waste more time to convey the building materials, compared to the others in this study. Moreover, the transporting quantity of the ready-mixed concrete was unable to be altered, since it was delivered by the standardised size of lorries (i.e., the Ready-mixed concrete mixer capacity is 5 m

3 in standardised size). On the other hand, different sized vehicles were able to be used flexibly for other building materials, depending upon the situation at the construction site.

3.4. Carbon Dioxide Emissions from the Utilisation of Construction Equipment on Site

The construction equipment used in this study were concrete pump trucks and vibrators for ready-mixed concrete, and cranes for the lifting and loading of rebars, forms, steel decking, and void formers on site. The reductions in the amount of total carbon dioxide emissions from the utilisation of construction equipment replacing the ordinary reinforced concrete slab by the flat plate slab and the voided slab systems were 3758 and 4913 kg CO

2 eq., respectively (see

Table 10). The carbon dioxide emissions from utilising construction equipment were reduced by 3.6% and 10.1% for the flat plate slab and voided slab systems, respectively. The lowering of carbon dioxide for the flat plate slab and voided slab systems is associated with the reduction in the amount of ready-mixed concrete. In high-rise buildings, the utilisation of concrete pump trucks would be inevitable to convey ready-mixed concrete to the upper floors. In addition, the use of vibrators in concrete work is indispensable during the concrete pouring and curing steps to remove internal bubbles, and to prevent material segregation.

Moreover, the use of cranes was one of the significant factors to load and lift heavy building materials from the transporting vehicles to the upper floors. In the ordinary reinforced concrete slab, the large number of beams and girders was attributed to be the main factor to the use of a large volume of forms. For this reason, the emissions of carbon dioxide from cranes were higher for this slab system than for the other two slab systems (see

Table 10). Similarly, in the voided slab system, the cranes were used to lift steel decking and the void formers. However, the emissions of carbon dioxide were less than for the two other methods, since the weights of both building materials (steel decking and void formers) were lighter than that of the forms in this study. Based on the results, in the emissions of carbon dioxide from the use of construction equipment, as the height of the building increased, it was inevitable to utilise concrete pump trucks and cranes. Hence, it would be important to minimise the lead time and intervals between activities during the construction work. For example, an effective strategy to reduce time waste during the construction process would be the adopting of principles and practices of lean construction [

53,

54,

55].

3.5. Discussion

In this study, the variations of carbon dioxide emissions amongst the different slab systems were dependent upon reinforcing bars. The reason for the variance of reinforcing bars in the slab systems was that the application of rebars is due to the design requirements and standards [

49,

50]. Reinforcing bars are the most significant element in reinforced concrete structures to reduce vulnerability by increasing tensile strength. In particular, numerous beams and girders of reinforcement bars are embedded into the ordinary reinforced concrete slab. Beams and girders would distribute service and permanent loads of the slab, as well as resist external forces in a structure. However, the flat plate slab and voided slab systems would require lesser amounts of reinforcing bars over the ordinary reinforced concrete slab, as in both cases, the number of beams and girders were reduced. In particular, the decreased number of beams and girders in the flat plate slab and voided slab systems might not only require less quantity of rebars, but also a lesser amount of forms, which during the manufacturing of building materials would make it possible to reduce the carbon dioxide emissions.

Meanwhile, approximately 270,000 and 1400 kg CO2 eq. for steel decking and void formers, respectively, were attributed to the voided slab system. The total amount of carbon dioxide generated from steel decking and void formers was almost the same as the emissions from reinforcing bars. In the case of the voided slab system, the total amount of carbon dioxide emissions was reduced by approximately 10%, even though the CO2 generated from steel decking was quite large. Based on these results, ready-mixed concrete was the most significant factor in determining the overall reduction of carbon dioxide emissions in the different slab systems. Therefore, further design optimisation would be able to reduce the total carbon dioxide emissions of the building materials. Moreover, the application of high-strength materials, such as high-strength concrete and rebars, as well as recycled materials and by-products, would be a useful approach to mitigate the environmental impacts from building materials.

Table 5 shows that the carbon dioxide emissions from the transport of building materials were determined by the distance between the location of manufacturers and the construction site. Consequently, a potential way to reduce the carbon dioxide emissions from transporting the building materials would be in selecting the manufacturer who was proximate to the construction site. Moreover, the utilisation of imported building materials was beneficial to the economic perspective, which would reduce the cost of construction. However, the environmental loads from such material would have more environmental impact, compared to the domestically produced one. In this regard, further research to compare the domestic and imported building materials should be carried out to verify the influences, since the spatial restrictions are disappearing.

4. Conclusions

It is recognised that construction projects emit substantial volumes of carbon dioxide emissions. Various construction methods and alternatives have been suggested to minimise the emissions of carbon dioxide during construction work. A structural system of a building is a significant factor to not only sustain the entire building from external forces, but also to determine the quantities of building materials. Previous studies regarding structural systems have mainly focused on the structural performance, such as the flexural or shear capabilities of structures, and optimal design for workability during the construction stage, rather than the evaluation of environmental impacts by different structural systems. The purpose of this study was to evaluate the carbon dioxide emissions of different slab systems as a means of mitigating the environmental impacts of a high-rise commercial building project in South Korea.

The total carbon dioxide emissions of the three slab systems during the construction phase are comprised of the manufacturing of building materials, transporting of building materials to the construction site, and carbon dioxide emissions from the energy consumption of construction equipment. The results show the total CO2 emissions of 3275, 3157, and 2943 tons CO2 eq., which are equivalent to 242, 234, and 218 kg CO2 eq., for the ordinary reinforced concrete slab, flat plate slab, and voided slab systems, respectively. The manufacturing of building materials is the main contributor of CO2 emissions, which indicate 3,230,945, 3,117,203, and 2,905,564 kg CO2 eq., respectively. Based on the results, approximately 3.7% and 10.1% reduction of carbon dioxide emissions would be achieved by replacing the ordinary reinforced concrete slab by the flat plate slab and the voided slab systems, respectively. In this context, the voided slab system would be able to achieve the most carbon dioxide reduction amongst three different slab system of this study.

Comparing the building materials in the three slab systems, the reinforcing bars and forms were significant building materials to reduce the CO2 emissions in the flat plate slab and voided slab systems. In this study, reinforcing bars were the main contributor to lowering the carbon dioxide emissions in the flat plate slab and voided slab systems. Moreover, the emissions of carbon dioxide from transporting building materials were relatively small, compared to the manufacturing of building materials. However, it is recommended that the selection of location of material providers would contribute to lowering the CO2 emissions from this stage. Based on the results of this study, the reduction potential of the voided slab system is the greatest amongst all the three different slab systems. Moreover, replacing the ordinary reinforced concrete slab system by alternative methods would make it possible to reduce the carbon dioxide emissions during the construction phase in building projects.

While this study was carried out on the evaluation and comparison of the carbon dioxide emissions from an actually designed building in South Korea, there is a limitation that should be addressed in future research. In order to verify the practicability and expand the applicability of the voided slab system in building projects, more cases need to be investigated in future studies. Moreover, life cycle assessment of the flat plate slab and voided slab systems during the operation and maintenance phases should be performed from the whole life cycle perspective of a building.