A Two-Stage Building Information Modeling Based Building Design Method to Improve Lighting Environment and Increase Energy Efficiency

Abstract

1. Introduction

1.1. Daylight for Indoor Illumination

1.2. Barriers of Making a Good Building Design

- (1)

- Most of the designers are not experts in the area of building physics, thus they are not able to calculate the quantity of energy consumption and the levels of thermal and lighting performance of their building designs [31]. To solve this problem, designers have to follow the standards of the green building handbooks, such as Leadership in Energy and Environmental Design (LEED) and Building Research Establishment Environmental Assessment Method (BREEAM). However, the standards in these handbooks are the minimum thresholds for general buildings, thus they cannot fulfill the requirements of each specific building, which leads to the incomplete optimization on building performance [32].

- (2)

- In order to procure reliable and accurate optimization results quickly, simulation tools for thermal performance and lighting performance are necessary. Since designers do not understand every parameters of building physics and structure, they do not know how to preset the reasonable parameter values and operate the software successfully [33,34]. In addition, it will take a long time for designers to learn how to operate the simulation software, which is not only a burden for them, but also slows down the design work.

1.3. Objectives

- (1)

- The first objective was to improve the lighting environment in buildings by fully using daylight instead of artificial lighting and by applying an appropriate lighting control system.

- (2)

- The second objective was maximizing energy savings by optimizing the initial building design.

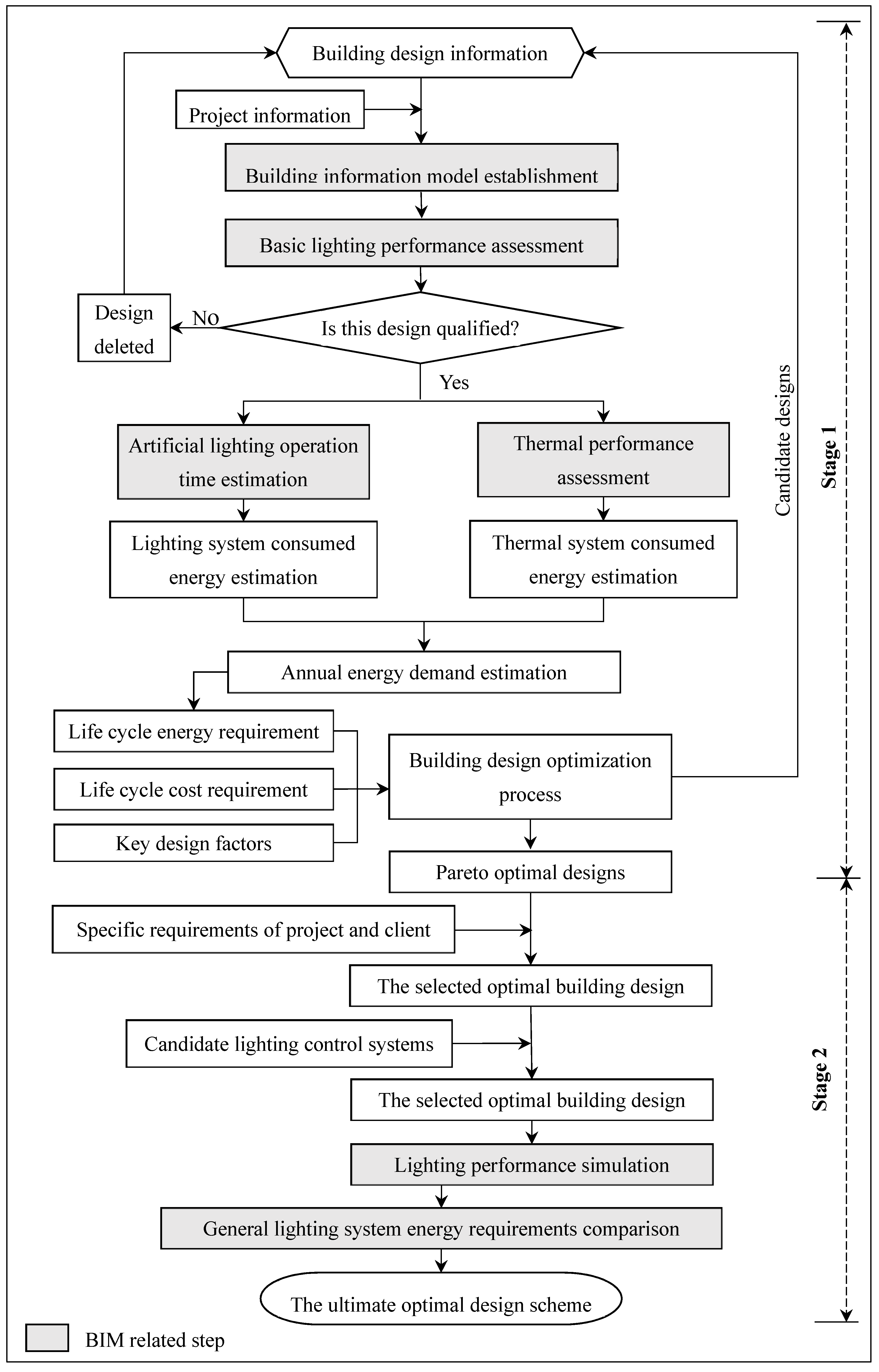

2. Two-Stage Building Information Modeling (BIM) Based Lighting Design Method

2.1. Stage 1: Building Desing Optimziation

2.1.1. Building performance simulation

2.1.2. Building Design Optimization

2.2. Stage 2: Lighting Control System Selection

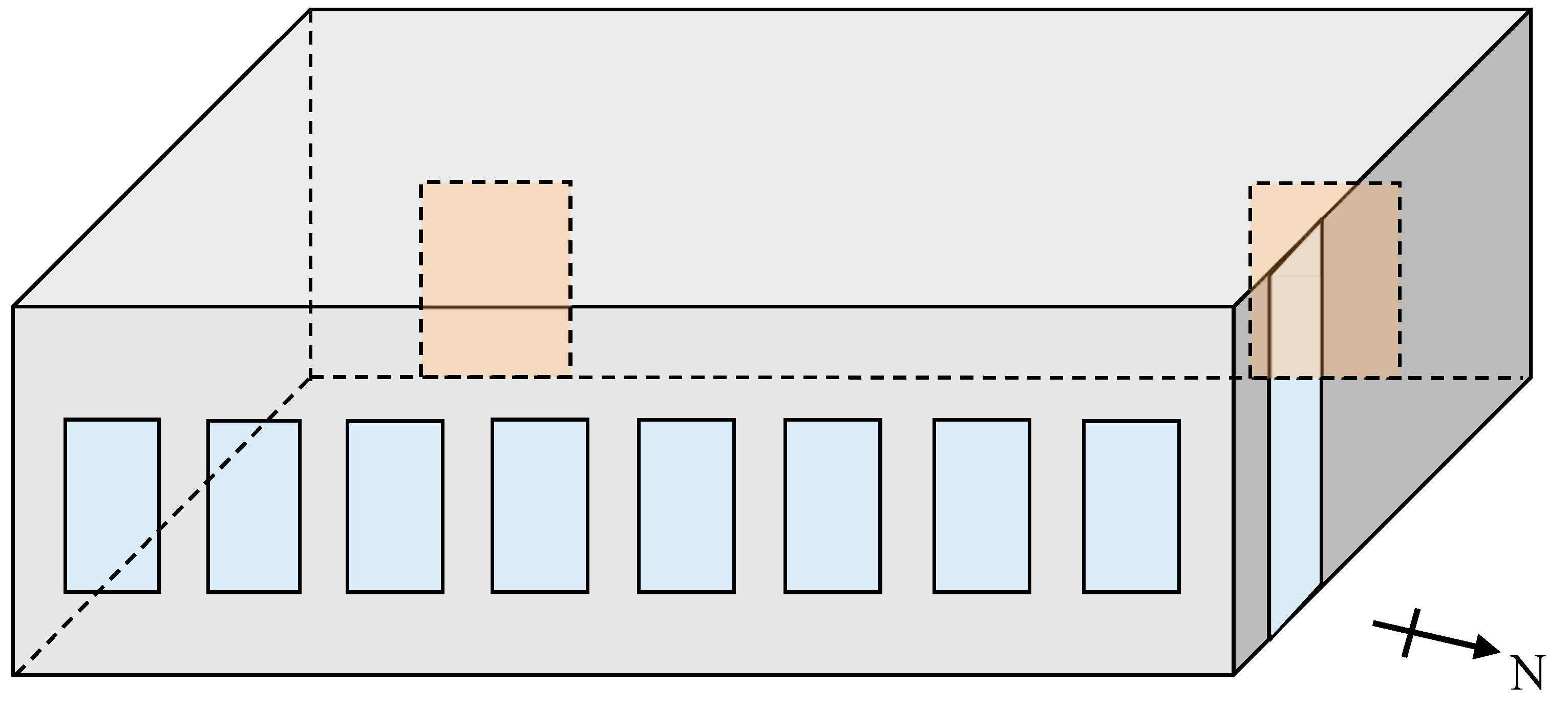

3. Case Study

4. Discussion

5. Conclusion

Author Contributions

Funding

Conflicts of Interest

References

- Shaikh, P.H.; Nor, N.B.M.; Nallagownden, P.; Elamvazuthi, I.; Ibrahim, T. A review on optimized control systems for building energy and comfort management of smart sustainable buildings. Renew. Sustain. Energy Rev. 2014, 34, 409–429. [Google Scholar] [CrossRef]

- Rebitzer, G. Integrating life cycle costing and life cycle assessment for managing costs and environmental impacts in supply chains. In Cost Management in Supply Chains; Physica: Heidelberg, Germany, 2002; pp. 128–146. [Google Scholar]

- Wei, Y.; Zhang, X.; Shi, Y.; Xia, L.; Pan, S.; Wu, J.; Han, M. A review of data-driven approaches for prediction and classification of building energy consumption. Renew. Sustain. Energy Rev. 2018, 82, 1027–1047. [Google Scholar] [CrossRef]

- Futrell, B.J.; Ozelkan, E.C.; Brentrup, D. Bi-objective optimization of building enclosure design for thermal and lighting performance. Build. Environ. 2015, 92, 591–602. [Google Scholar] [CrossRef]

- Yoon, Y.R.; Moon, H.J. Energy consumption model with energy use factors of tenants in commercial buildings using Gaussian process regression. Energy Build. 2018, 168, 215–224. [Google Scholar] [CrossRef]

- Lim, Y.W.; Kandar, M.Z.; Ahmad, M.H.; Ossen, D.R.; Abdullah, A.M. Building façade design for daylighting quality in typical government office building. Build. Environ. 2012, 57, 194–204. [Google Scholar] [CrossRef]

- Zain-Ahmed, A.; Sopian, K.; Othman, M.Y.H.; Sayigh, A.A.M.; Surendran, P.N. Daylighting as a passive solar design strategy in tropical buildings: A case study of Malaysia. Energy Convers. Manag. 2002, 43, 1725–1736. [Google Scholar] [CrossRef]

- Hwang, T.; Kim, J.T. Effects of indoor lighting on occupants’ visual comfort and eye health in a green building. Indoor Built Environ. 2011, 20, 75–90. [Google Scholar] [CrossRef]

- Shishegar, N.; Boubekri, M. Natural light and productivity: Analyzing the impacts of daylighting on students’ and workers’ health and alertness. In Proceedings of the International Conference on Health, Biological and Life Science (HBLS-16), Istanbul, Turkey, 18–19 April 2016. [Google Scholar]

- Cammarano, S.; Pellegrino, A.; Lo Verso, V.R.M.; Aghemo, C. Dayligting design for energy saving in a building global energy simulation context. Energy Procedia 2015, 78, 364–369. [Google Scholar] [CrossRef]

- Al-Khatatbeh, B.J.; Ma’bdeh, S.N. Improving visual comfort and energy efficiency in existing classrooms using passive daylighting techniques. Energy Procedia 2017, 136, 102–108. [Google Scholar] [CrossRef]

- Krarti, M.; Erickson, P.M.; Hillman, T.C. A simplified method to estimate energy savings of artificial lighting use for daylighting. Build. Environ. 2005, 40, 747–754. [Google Scholar] [CrossRef]

- Ochoa, C.E.; Aries, M.B.C.; van Loenen, E.J.; Hensen, J.L.M. Considerations on design optimization criteria for windows providing low energy consumption and high visual comfort. Appl. Energy 2012, 95, 238–245. [Google Scholar] [CrossRef]

- Ashrafian, T.; Moazzen, N. The impact of glazing ratio and window configuration on occupants’ comfort and energy demand: The case study of a school building in Eskisehir, Turkey. Sustain. Cities Soc. 2019, 47, 1–14. [Google Scholar] [CrossRef]

- Reinhart, C.F.; Mardaljevic, J.; Rogers, Z. Dynamic daylight performance metrics for sustainable building design. Leukos 2006, 3, 7–31. [Google Scholar] [CrossRef]

- Hee, W.J.; Alghoul, M.A.; Bakhtyar, B.; Elayeb, O.K.; Shameri, M.A.; Alrubaih, M.S.; Sopian, K. The role of window glazing on daylighting and energy saving in buildings. Renew. Sustain. Energy Rev. 2015, 42, 323–343. [Google Scholar] [CrossRef]

- Huang, Y.C.; Lam, K.P.; Dobbs, G. A scalable lighting simulation tool for integrated building design. In Proceedings of the Third National Conference of IBPSA-USA, Berkeley, CA, USA, 30 July–1 August 2008. [Google Scholar]

- Lagios, K.; Niemasz, J.; Reinhart, G. Animated building performance simulation (ABPS)—Linking rhinoceros/Grasshopper with Radiance/Daysim. In Proceedings of the Forth National Conference of IBPSA-USA, New York, NY, USA, 11–13 August 2010. [Google Scholar]

- Kota, S.; Haberl, J.S.; Clayton, M.J.; Yan, W. Building information modeling (BIM)- based daylighting simulation and analysis. Energy Build. 2014, 81, 391–403. [Google Scholar] [CrossRef]

- Lee, J.W.; Jung, H.J.; Park, J.Y.; Lee, J.B.; Yoon, Y. Optimization of building window system in Asian regions by analyzing solar heat gain and daylighting elements. Renew. Energy 2013, 50, 522–531. [Google Scholar] [CrossRef]

- Mangkuto, R.A.; Rohmah, M.; Asri, A.D. Design optimization for window size, orientation, and wall reflectance with regard to various daylight metrics and lighting energy demand: A case study of buildings in the tropics. Appl. Energy 2016, 164, 211–219. [Google Scholar] [CrossRef]

- Zhai, Y.; Wang, Y.; Huang, Y.; Meng, X. A multi-objective optimization methodology for window design considering energy consumption, thermal environment and visual performance. Renew. Energy 2019, 134, 1190–1199. [Google Scholar] [CrossRef]

- Vera, S.; Uribe, D.; Bustamante, W.; Molina, G. Optimization of a fixed exterior complex fenestration system considering visual comfort and energy performance criteria. Build. Environ. 2017, 113, 163–174. [Google Scholar] [CrossRef]

- Zhang, A.; Bokel, R.; van den Dobbelsteen, A.; Sun, Y. Optimization of thermal and daylight performance of school buildings based on a multi-objective genetic algorithm in the cold climate of China. Energy Build. 2017, 139, 371–384. [Google Scholar] [CrossRef]

- Linhart, F.; Scartezzini, J. Minimizing lighting power density in office rooms equipped with Anidolic Daylighting Systems. Sol. Energy 2010, 84, 587–595. [Google Scholar] [CrossRef]

- Hua, Y.; Oswald, A.; Yang, X. Effectiveness of daylighting design and occupant visual satisfaction in a LEED Gold laboratory building. Build. Environ. 2011, 46, 54–64. [Google Scholar] [CrossRef]

- Li, D.H.W.; Lam, J.C. An investigation of daylighting performance and energy saving in a daylit corridor. Energy Build. 2003, 35, 365–373. [Google Scholar] [CrossRef]

- Yun, G.Y.; Kim, H.; Kim, J.T. Effects of occupancy and lighting use patterns on lighting energy consumption. Energy Build. 2012, 46, 152–158. [Google Scholar] [CrossRef]

- Li, D.H.W.; Lam, T.N.T.; Wong, S.L. Lighting and energy performance for an office using high frequency dimming controls. Energy Convers. Manag. 2006, 47, 1133–1145. [Google Scholar] [CrossRef]

- Doulos, L.; Tsangrassoulis, A.; Topalis, F. Quantifying energy savings in daylight responsive systems: The role of dimming electronic ballasts. Energy Build. 2008, 40, 36–50. [Google Scholar] [CrossRef]

- Geyer, P. Systems modelling for sustainable building design. Adv. Eng. Inform. 2012, 26, 656–668. [Google Scholar] [CrossRef]

- Chen, X.; Yang, H.; Lu, L. A comprehensive review on passive design approaches in green building rating tools. Renew. Sustain. Energy Rev. 2015, 50, 1425–1436. [Google Scholar] [CrossRef]

- Negendahl, K. Building performance simulation in the early design stage: An introduction to integrated dynamic models. Autom. Constr. 2015, 54, 39–53. [Google Scholar] [CrossRef]

- Loonen, R.C.G.M.; Favoino, F.; Hensen, J.L.M.; Overend, M. Review of current status, requirements and opportunities for building performance simulation of adaptive facades. J. Build. Perform. Simul. 2017, 10, 205–223. [Google Scholar] [CrossRef]

- Sun, B.; Luh, P.B.; Jia, Q.; Jiang, Z.; Wang, F.; Song, C. Building energy management: Integrated control of active and passive heating, cooling, lighting, shading, and ventilation systems. IEEE Trans. Autom. Sci. Eng. 2013, 10, 588–602. [Google Scholar] [CrossRef]

- Jeon, J.; Lee, J.; Seo, J. Application of PCM thermal energy storage system to reduce building energy consumption. J. Therm. Anal. Calorim. 2013, 111, 279–288. [Google Scholar] [CrossRef]

- Wong, S.L.; Wan, K.K.W.; Lam, T.N.T. Artificial neural networks for energy analysis of office buildings with daylighting. Appl. Energy 2010, 87, 551–557. [Google Scholar] [CrossRef]

- Zitzler, K.; Deb, K.; Thiele, L. Comparison of multiobjective evolutionary algorithms: Empirical results. Evol. Comput. 2000, 8, 173–195. [Google Scholar] [CrossRef]

- Yu, W.; Li, B.; Jia, H.; Zhang, M.; Wang, D. Application of multi-objective genetic algorithm to optimize energy efficiency and thermal comfort in building design. Energy Build. 2015, 88, 135–143. [Google Scholar] [CrossRef]

- Evins, R. Multi-level optimization of building design, energy system sizing and operation. Energy 2015, 90, 1775–1789. [Google Scholar] [CrossRef]

- Kim, H.; Stumpf, A.; Kim, W. Analysis of an energy efficient building design through data mining approach. Automat. Constr. 2011, 20, 37–43. [Google Scholar] [CrossRef]

- Attia, S.; Gratia, E.; Herde, A.D.; Hensen Jan, L.M. Simulation-based decision support tool for early stages of zero-energy building design. Energy Build. 2012, 49, 2–15. [Google Scholar] [CrossRef]

- Pan, Y.; Yin, R.; Huang, Z. Energy modeling of two office buildings with data center for green building design. Energy Build. 2008, 40, 1145–1152. [Google Scholar] [CrossRef]

- Roisin, B.; Bodart, M.; Deneyer, A.; D’Herdt, P. Lighting energy savings in office using different control systems and their real consumption. Energy Build. 2008, 40, 514–523. [Google Scholar] [CrossRef]

- Galasiu, A.D.; Newsham, G.R.; Suvagau, C.; Sander, D.M. Energy saving lighting control systems for open-plan offices: A field study. Leukos 2007, 4, 7–29. [Google Scholar] [CrossRef]

- Inventory of Carbon and Energy, 2nd ed.; University of Bath: Bath, UK, 2011.

- Asif, M.; Davidson, A.; Muneer, T. Embodied energy analysis of aluminium-clad windows. Build. Serv. Eng. Res. Technol. 2001, 22, 195–199. [Google Scholar] [CrossRef]

- Syrrakou, E.; Papaefthimiou, S.; Yianoulis, P. Eco-efficiency evaluation of a smart window prototype. Sci. Total Environ. 2006, 359, 267–282. [Google Scholar] [CrossRef] [PubMed]

- Prakash, O.; Kumar, A. Annual Performance of a modified greenhouse dryer under passive mode in no-load conditions. Int. J. Green Energy 2015, 12, 1091–1099. [Google Scholar] [CrossRef]

- Chen, T.Y.; Burnett, J.; Chau, C.K. Analysis of embodied energy use in the residential building of Hong Kong. Energy 2001, 26, 323–340. [Google Scholar] [CrossRef]

- Hammond, G.P.; Jones, C.I. Embodied energy and carbon in construction materials. Proc. Inst. Civ. Eng.-Energy 2008, 161, 87–98. [Google Scholar] [CrossRef]

| Design Factor | Variable Description |

|---|---|

| Window-to-wall ratio | 0.19 |

| Glazing type | 6 mm double clear float glass with 6 mm air gap |

| Wall type | 300 mm reinforced concrete wall + 50 mm EPS board +30 mm cement and sand (1:3) screed + 10 mm plaster |

| Artificial light type | T8 fluorescent light, 30W |

| Decision Variable | Content | Unit Cost (CNY/mq) | Energy Intensity (MJ/mq) | |

|---|---|---|---|---|

| Window-to-wall ratio | γ | (0, 0.9) | ||

| Glazing type | G1 | 6 mm clear glass +12 mm argon gap +6 mm clear glass | 400 | 1345.84 |

| G2 | 6 mm low-e glass +12 mm argon gap +6 mm clear glass | 700 | 1937.60 | |

| G3 | 6 mm tint glass +6 mm argon gap +6 mm clear glass | 500 | 1549.60 | |

| Wall type | W1 | 300 mm reinforced concrete wall +50 mm Polystyrene (EPS) board +10 mm cement and sand (1:3) screed +10 mm plaster | 143.67 | 564.50 |

| W2 | 300 mm aerated concrete block wall +50 mm EPS board +10 mm cement and sand (1:3) screed +10 mm plaster | 125 | 370.40 | |

| W3 | 300 mm lightweight concrete block wall +50 mm EPS board +10 mm cement and sand (1:3) screed +10 mm plaster | 114.68 | 370.70 | |

| Artificial light type | L1 | T8 fluorescent light, 30W | 50 | |

| L2 | T5 fluorescent light, 14W | 38 | ||

| L3 | T8 LED light, 18W | 65 |

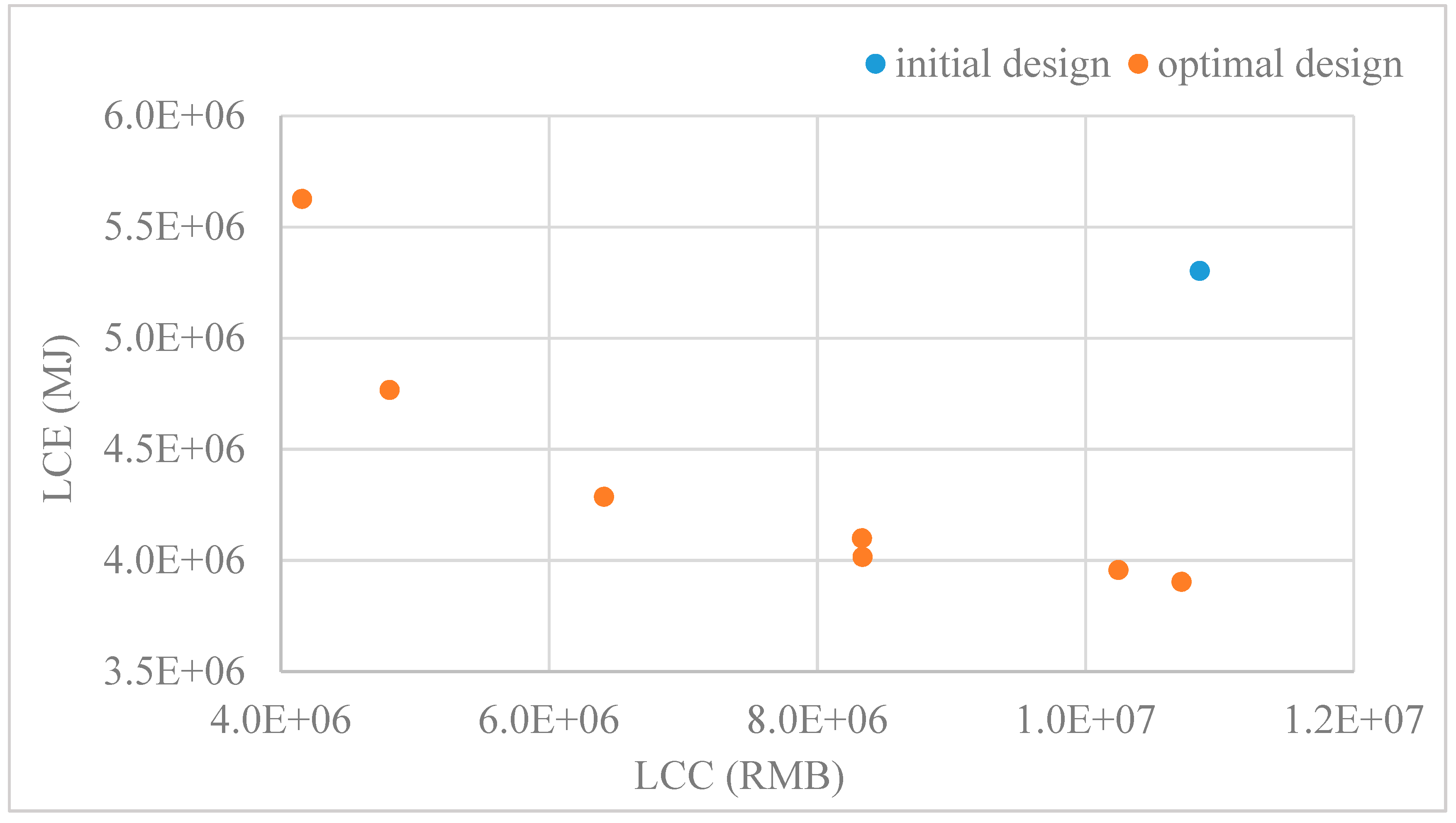

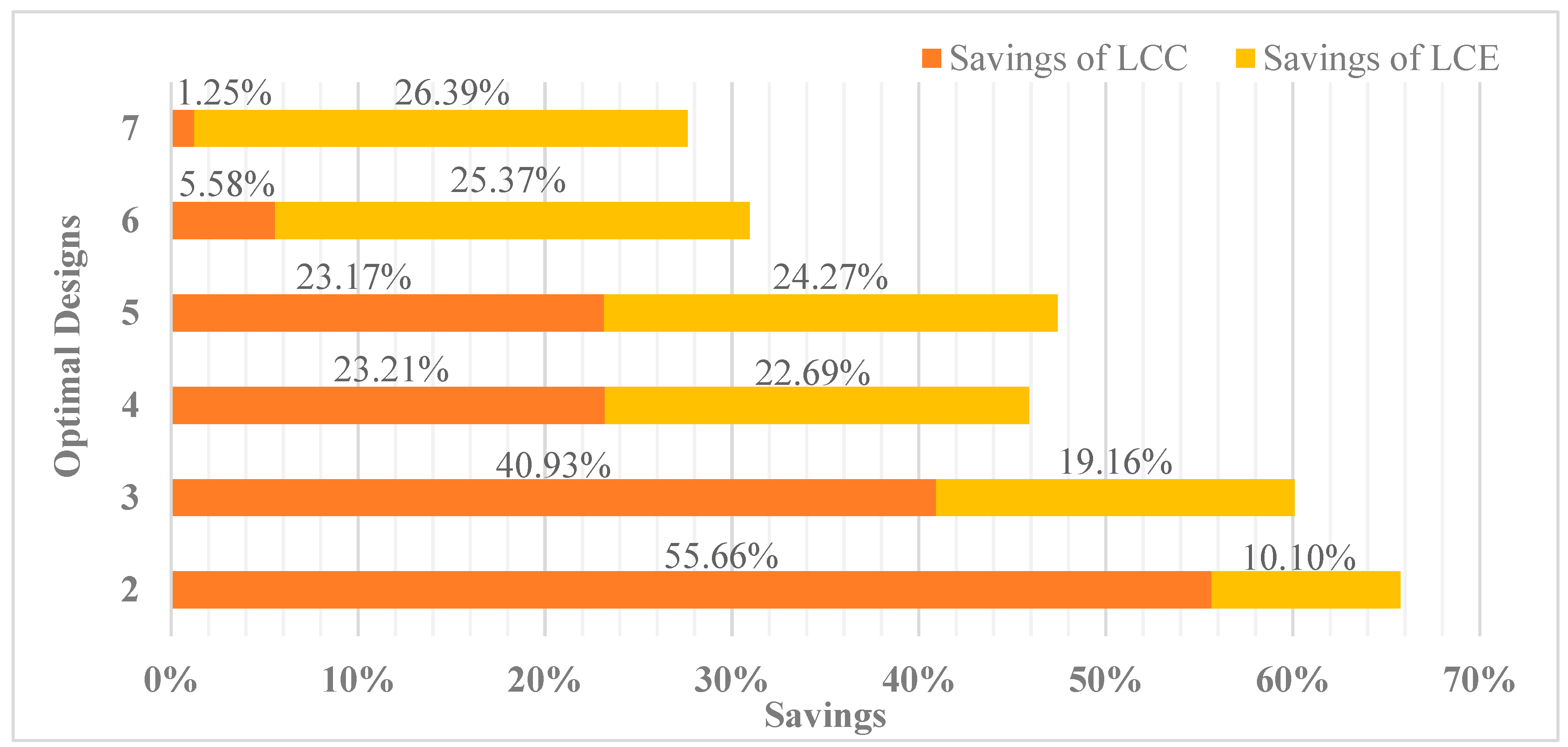

| No. | Window-to-Wall Ratio | Glazing Type | Wall Type | Artificial Light Type | LCC (CNY ¥) | LCE (MJ) |

|---|---|---|---|---|---|---|

| 1 | 0.900 | 1 | 1 | 2 | 4,158,961.07 | 5,624,928.382 |

| 2 | 0.748 | 2 | 2 | 1 | 4,811,119.35 | 4,765,746.660 |

| 3 | 0.201 | 3 | 3 | 2 | 6,410,224.77 | 4,285,789.883 |

| 4 | 0.139 | 2 | 3 | 2 | 8,332,691.86 | 4,098,387.582 |

| 5 | 0.137 | 1 | 3 | 2 | 8,336,950.97 | 4,014,879.593 |

| 6 | 0.100 | 2 | 2 | 2 | 10,245,469.86 | 3,956,413.052 |

| 7 | 0.085 | 1 | 2 | 2 | 10,716,024.16 | 3,902,559.339 |

| Lighting Control Mode | LCC (CNY ¥) | LCE (MJ) |

|---|---|---|

| MLS | 8,429,845.70 | 4,068,169.843 |

| ALS | 8,364,098.08 | 4,015,142.393 |

| ALD | 8,384,345.69 | 4,028,560.143 |

| Design Scheme | LCC (CNY ¥) | Saving of LCC | LCE (MJ) | Saving of LCE |

|---|---|---|---|---|

| Initial | 10,851,157.42 | - | 5,301,347.349 | - |

| Ultimate optimal | 8,364,098.08 | 22.92% | 4,015,142.393 | 24.26% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Ning, X. A Two-Stage Building Information Modeling Based Building Design Method to Improve Lighting Environment and Increase Energy Efficiency. Appl. Sci. 2019, 9, 4076. https://doi.org/10.3390/app9194076

Liu S, Ning X. A Two-Stage Building Information Modeling Based Building Design Method to Improve Lighting Environment and Increase Energy Efficiency. Applied Sciences. 2019; 9(19):4076. https://doi.org/10.3390/app9194076

Chicago/Turabian StyleLiu, Sha, and Xin Ning. 2019. "A Two-Stage Building Information Modeling Based Building Design Method to Improve Lighting Environment and Increase Energy Efficiency" Applied Sciences 9, no. 19: 4076. https://doi.org/10.3390/app9194076

APA StyleLiu, S., & Ning, X. (2019). A Two-Stage Building Information Modeling Based Building Design Method to Improve Lighting Environment and Increase Energy Efficiency. Applied Sciences, 9(19), 4076. https://doi.org/10.3390/app9194076