Experimental and CFD Simulation Studies on Bell-Type Air Nozzles of CFB Boilers

Abstract

:1. Introduction

2. Experimental Research

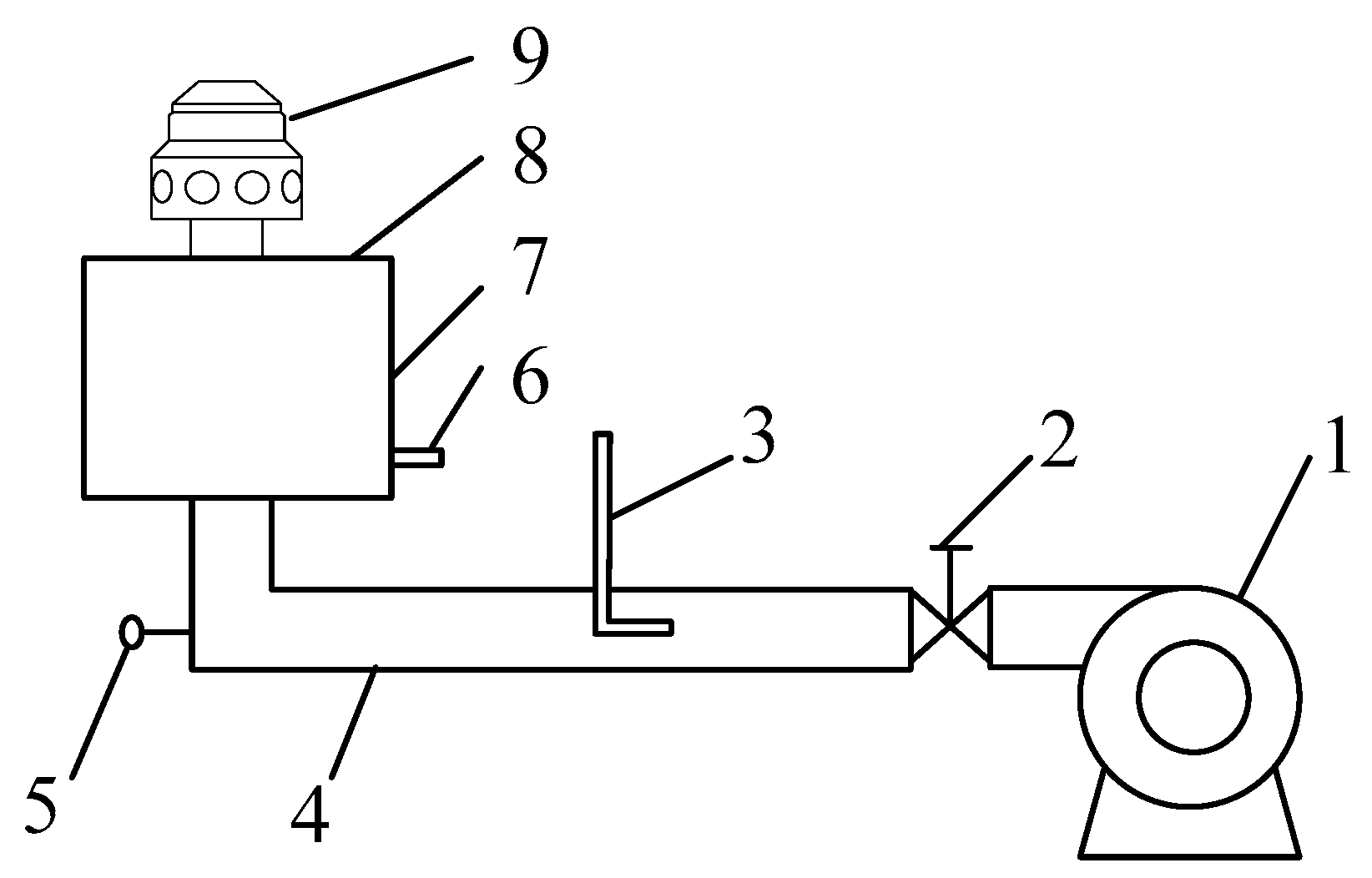

2.1. Cold-State Experiment Rig

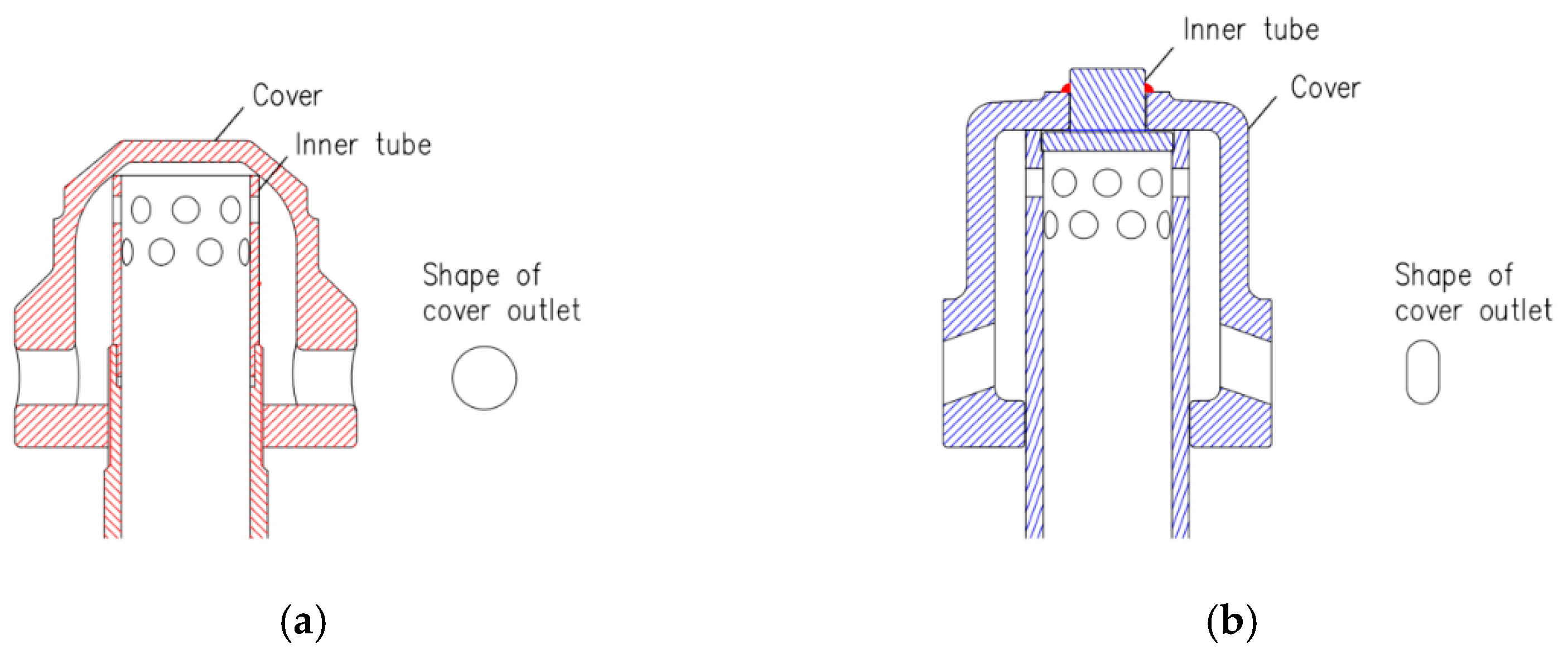

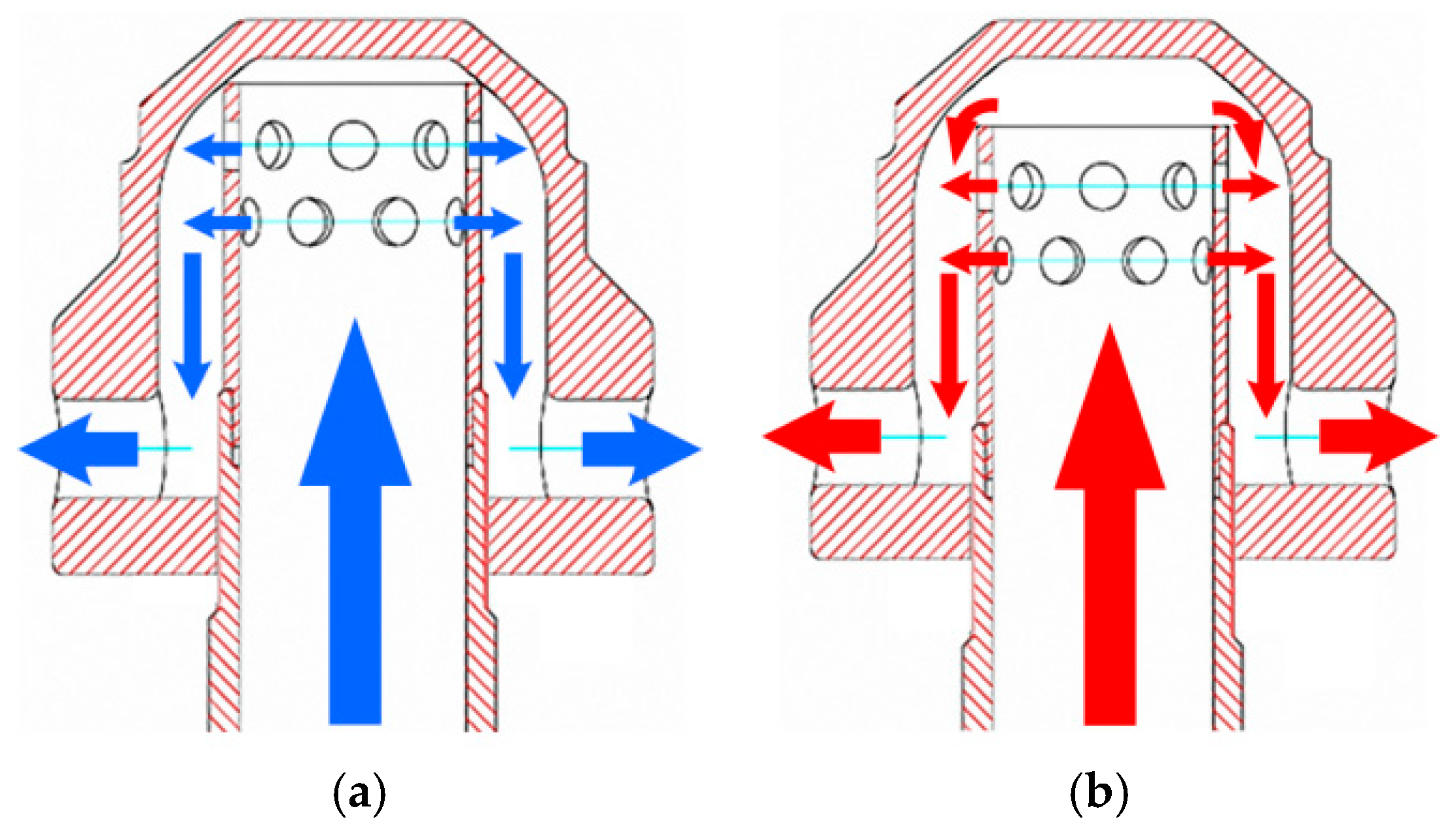

2.2. Structure of Air Nozzles

3. Numerical Simulation

3.1. Numerical Method

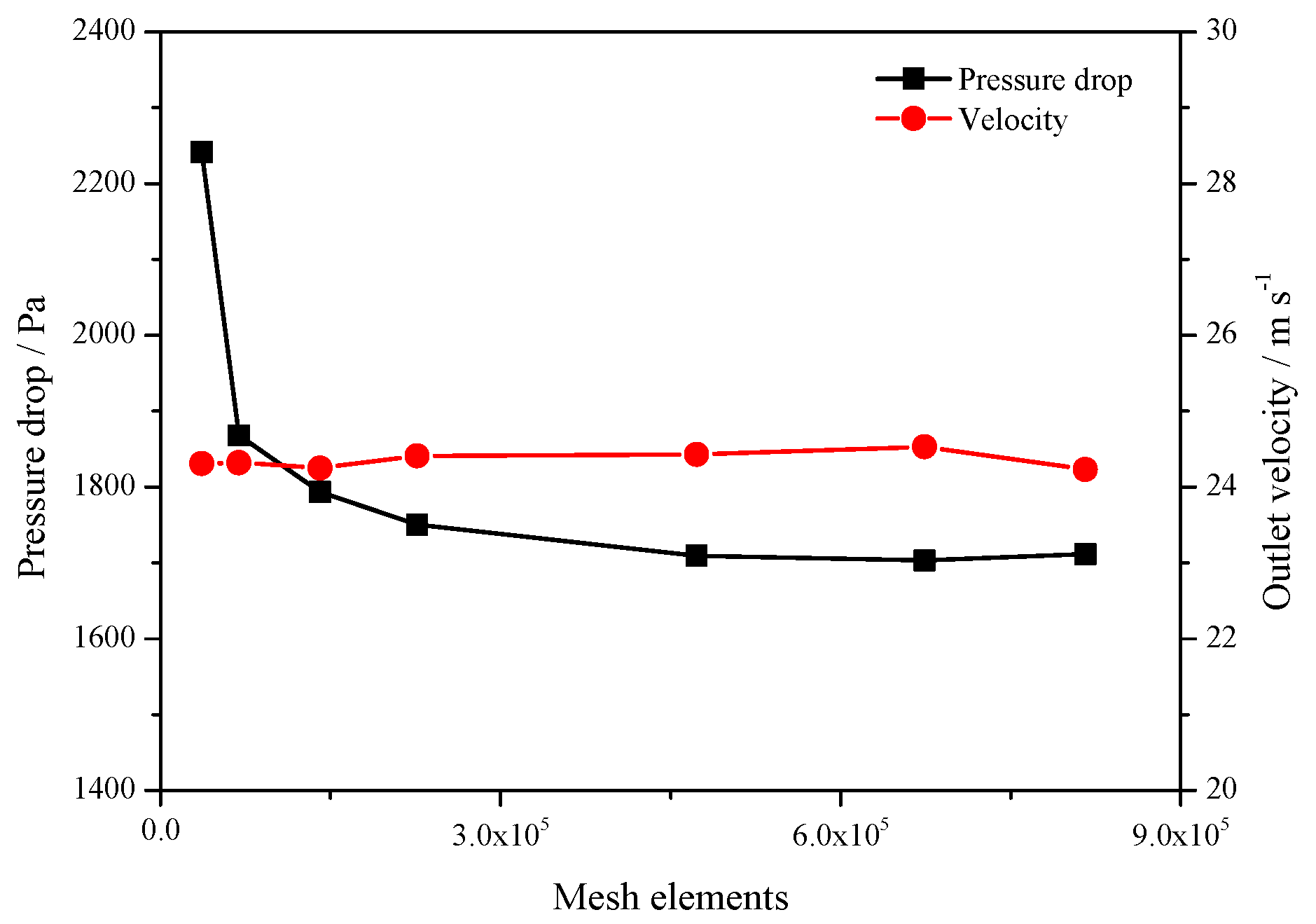

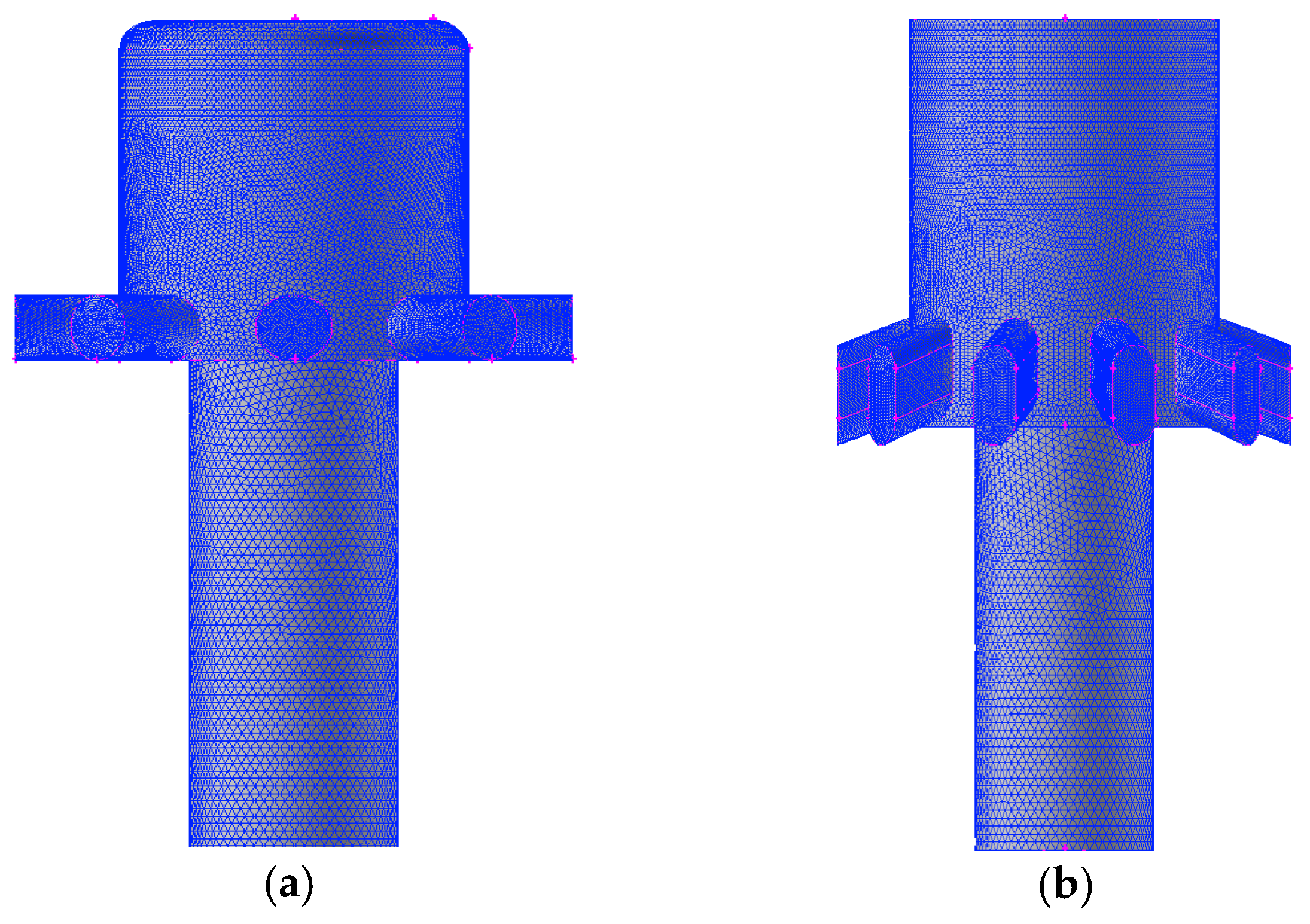

3.2. Computational Mesh

3.3. Boundary Conditions

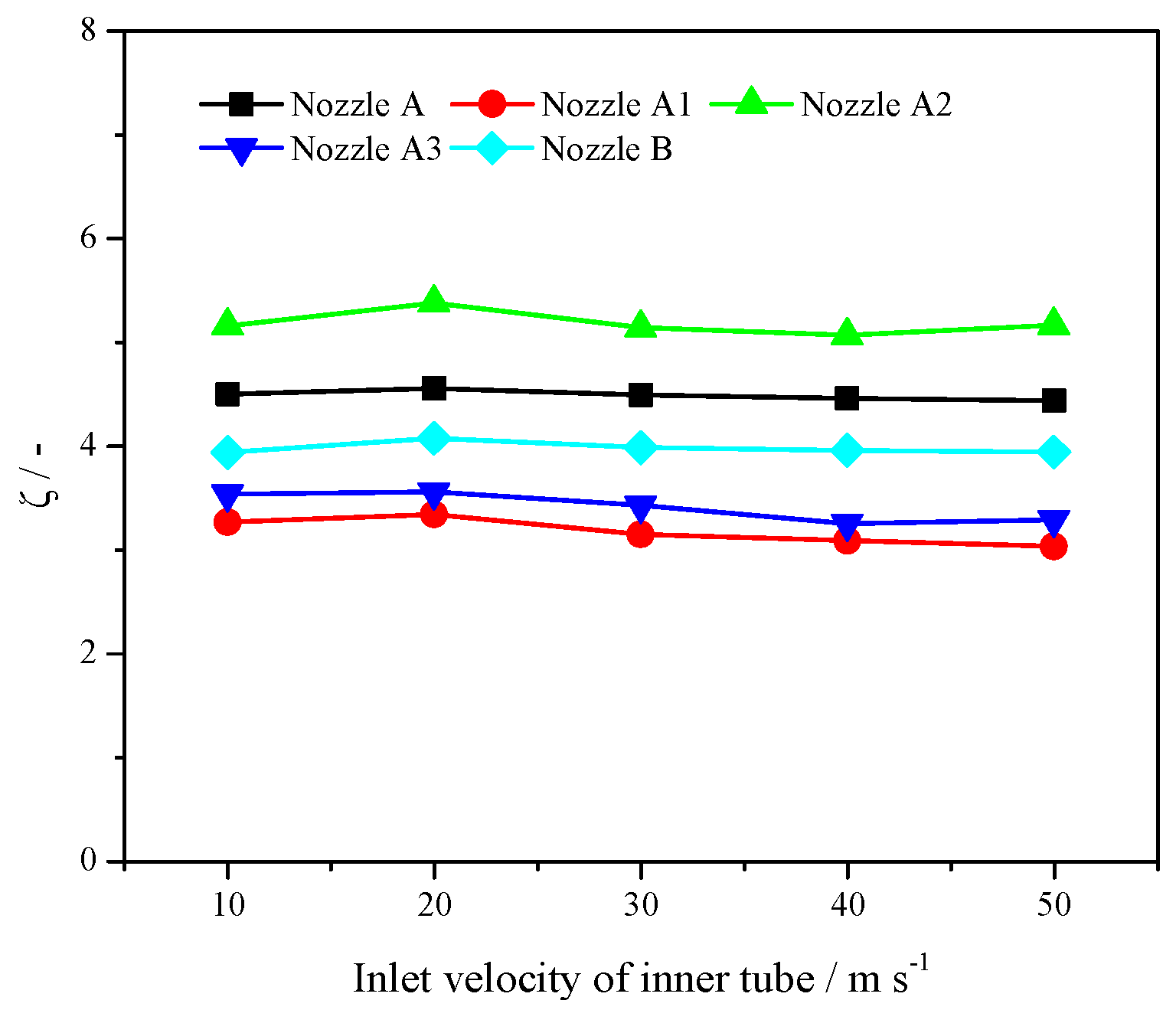

4. Results and Discussion

4.1. Cold-State Experiment

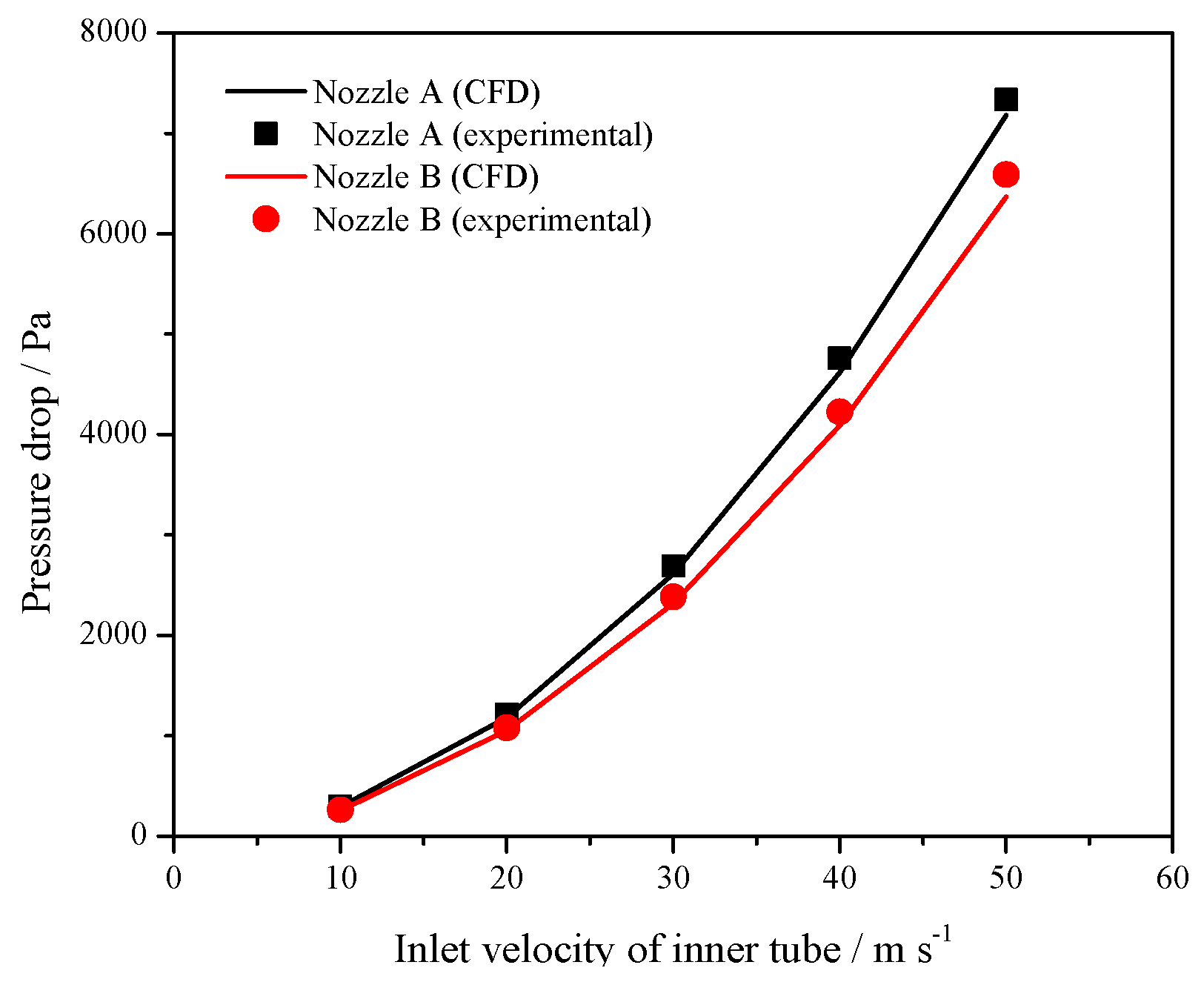

4.2. Simulation Validation

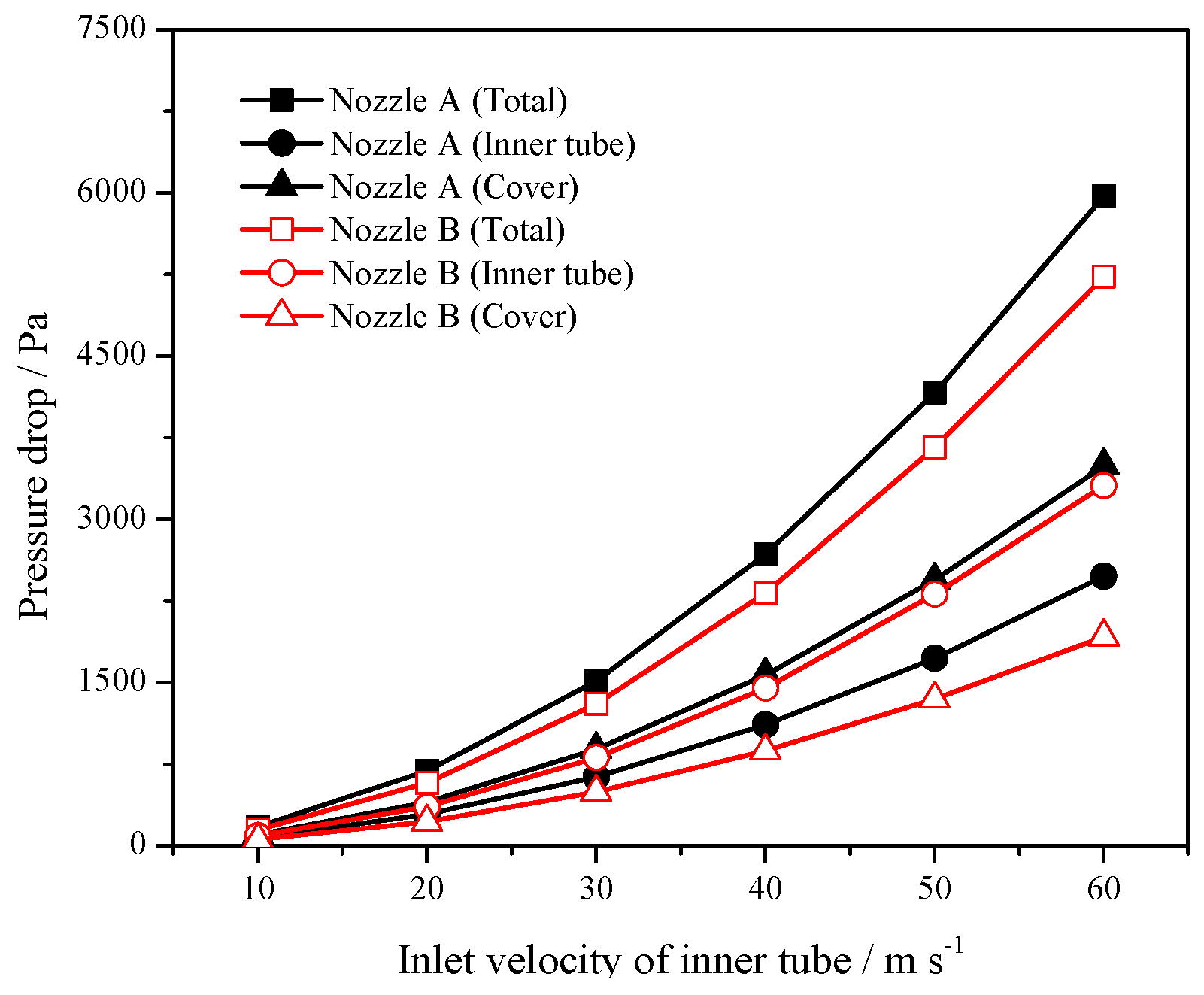

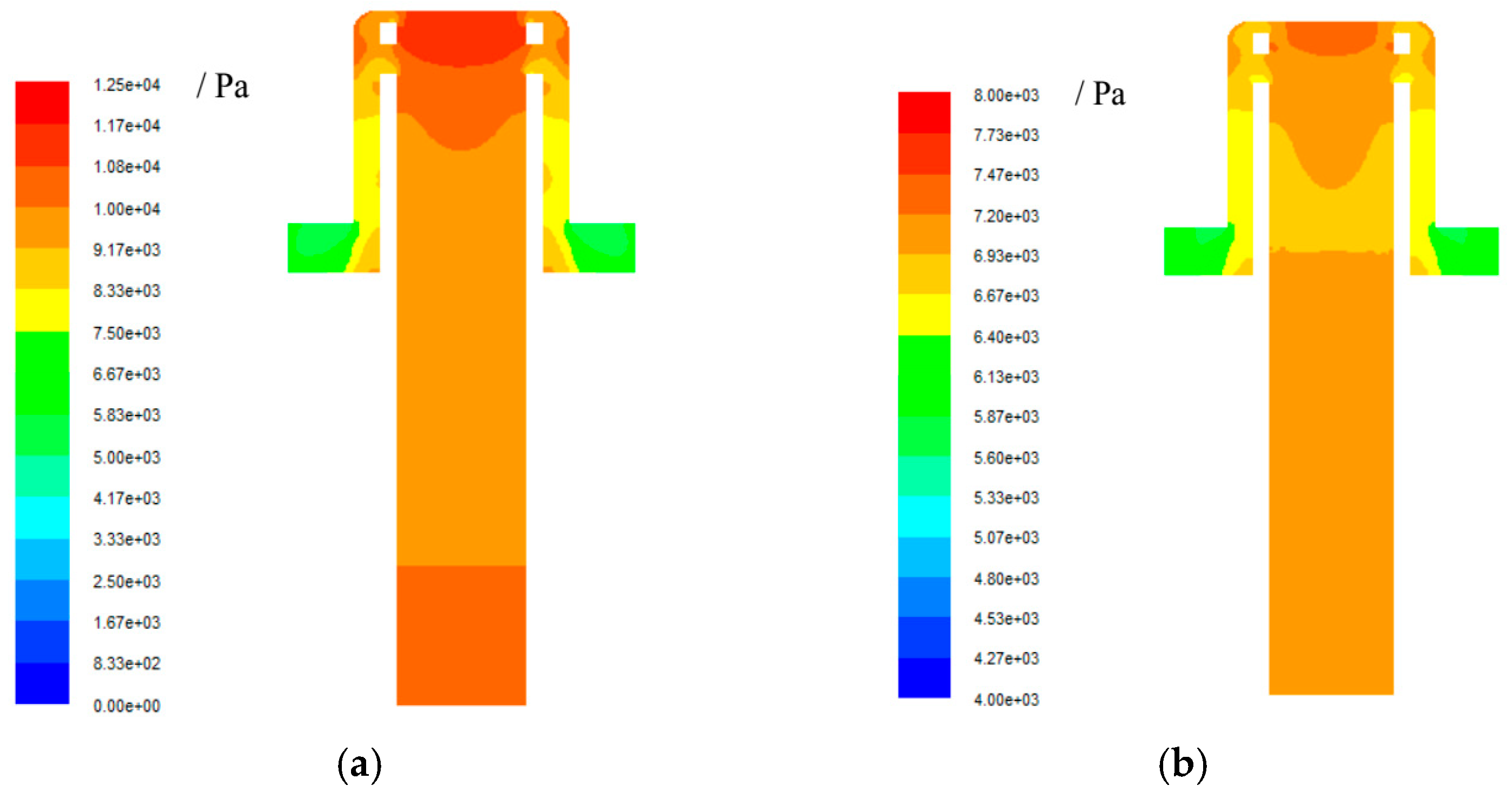

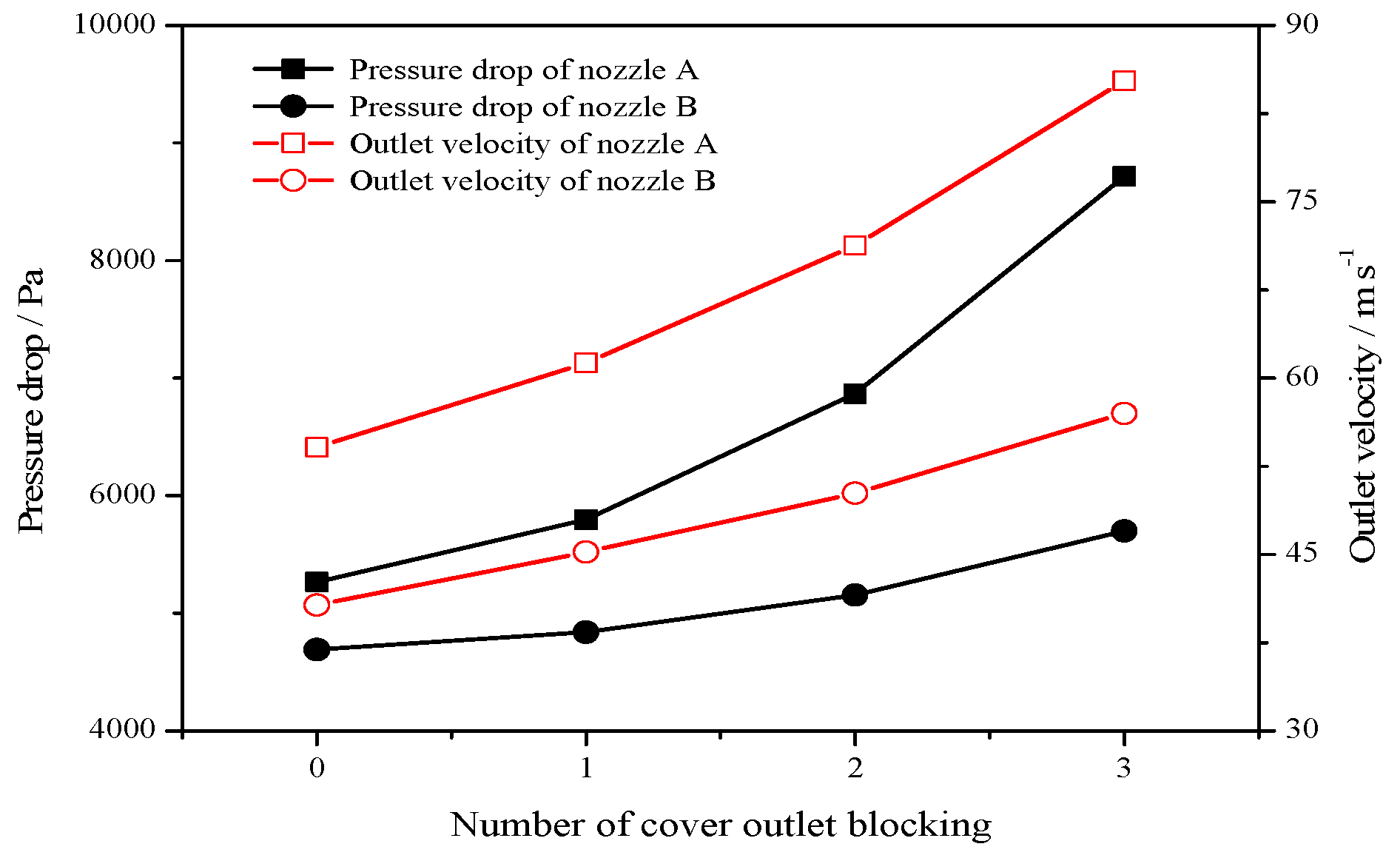

4.3. Pressure Drop Characteristics

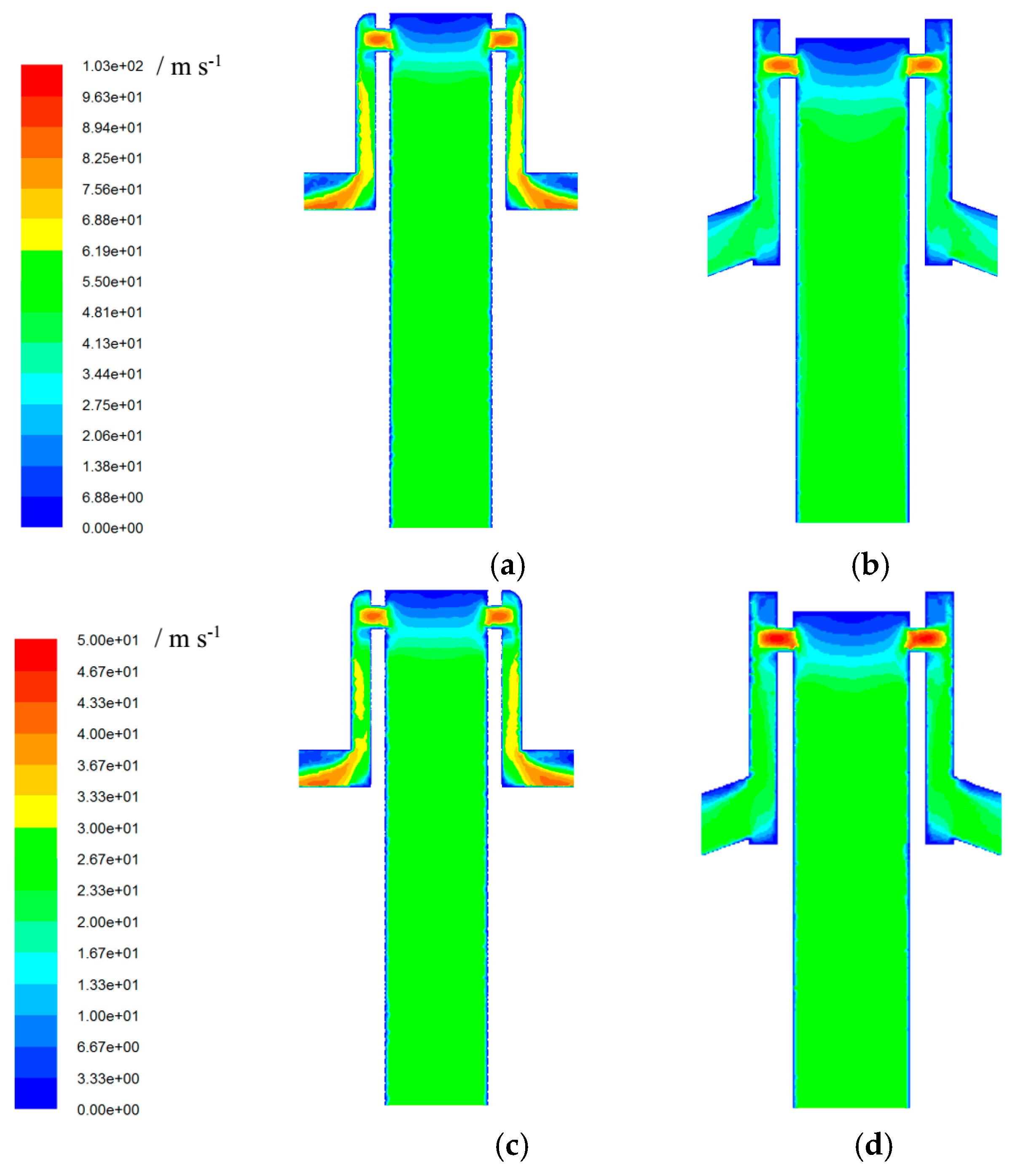

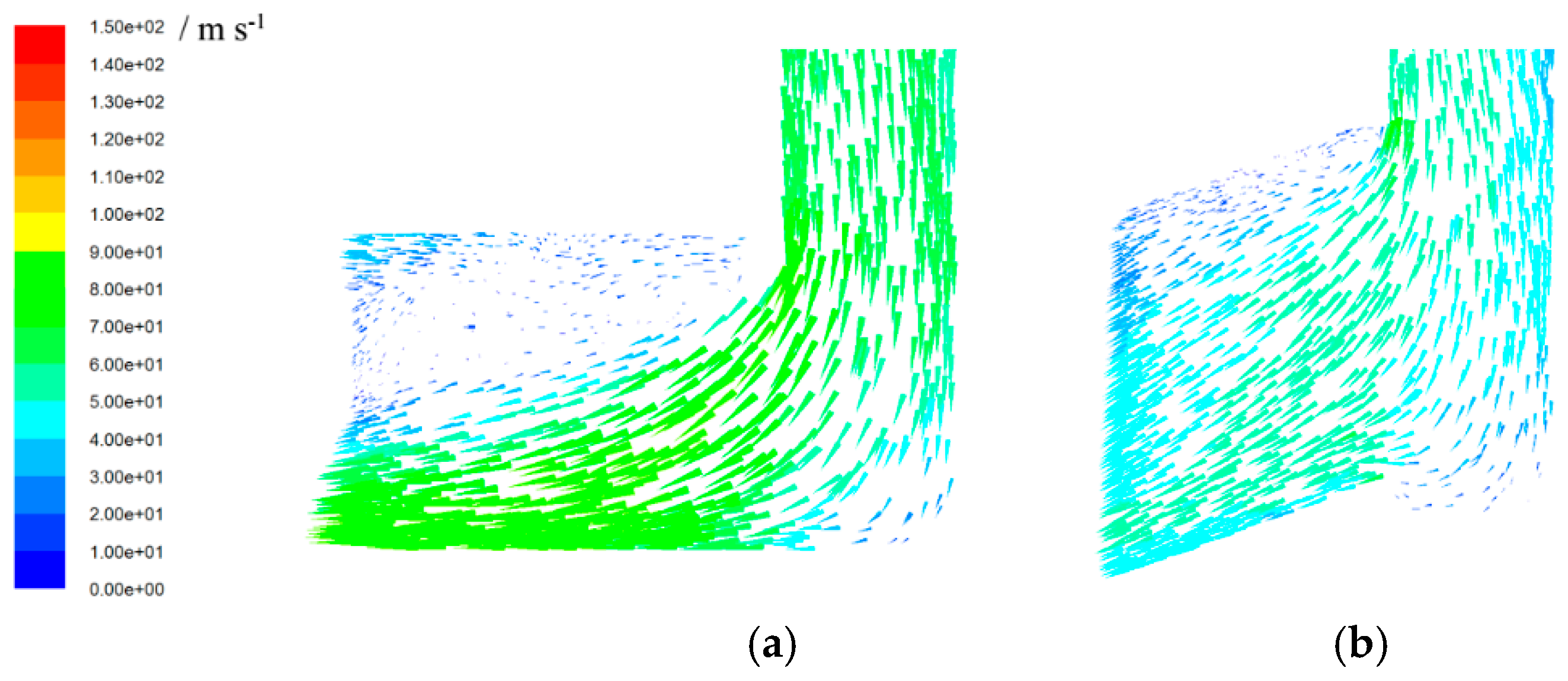

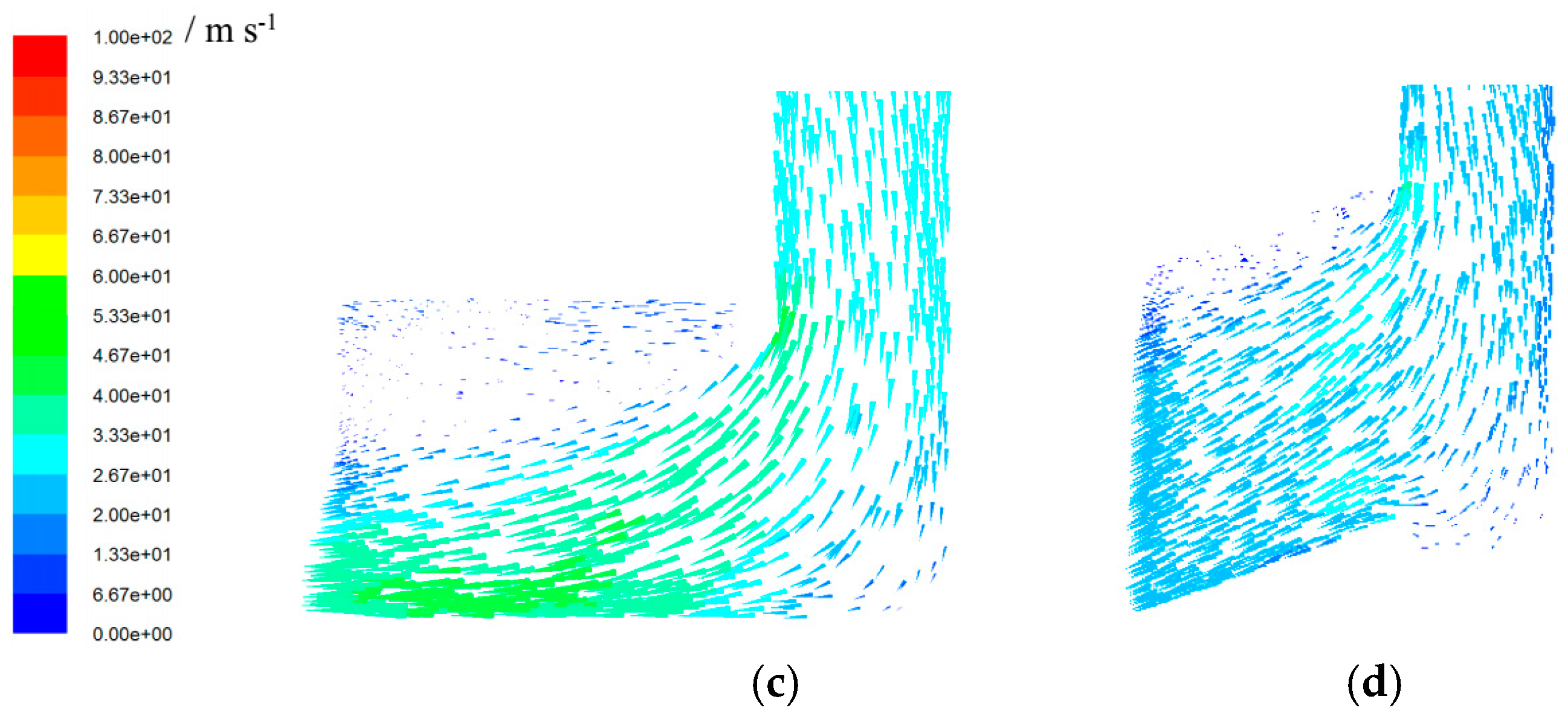

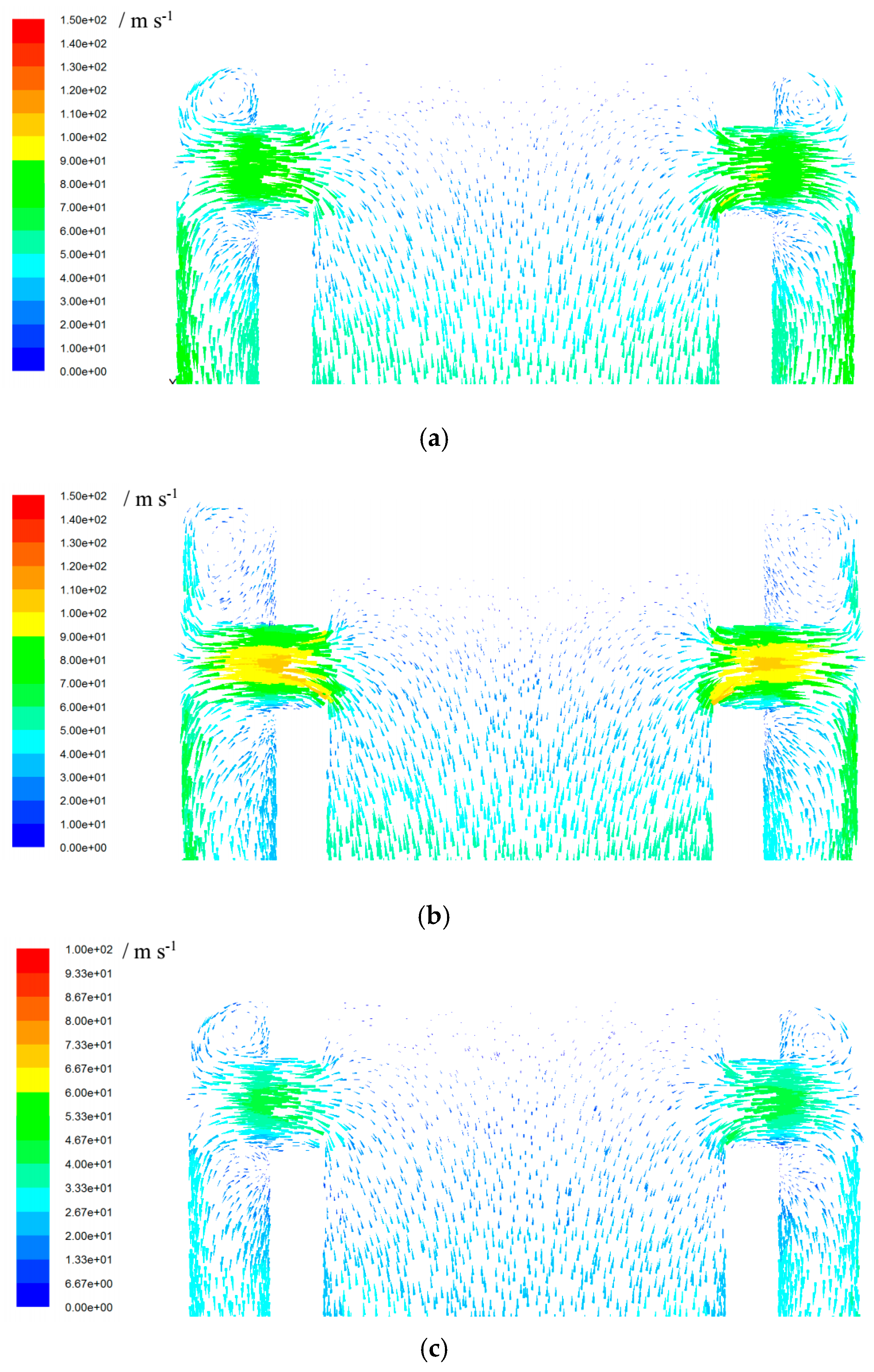

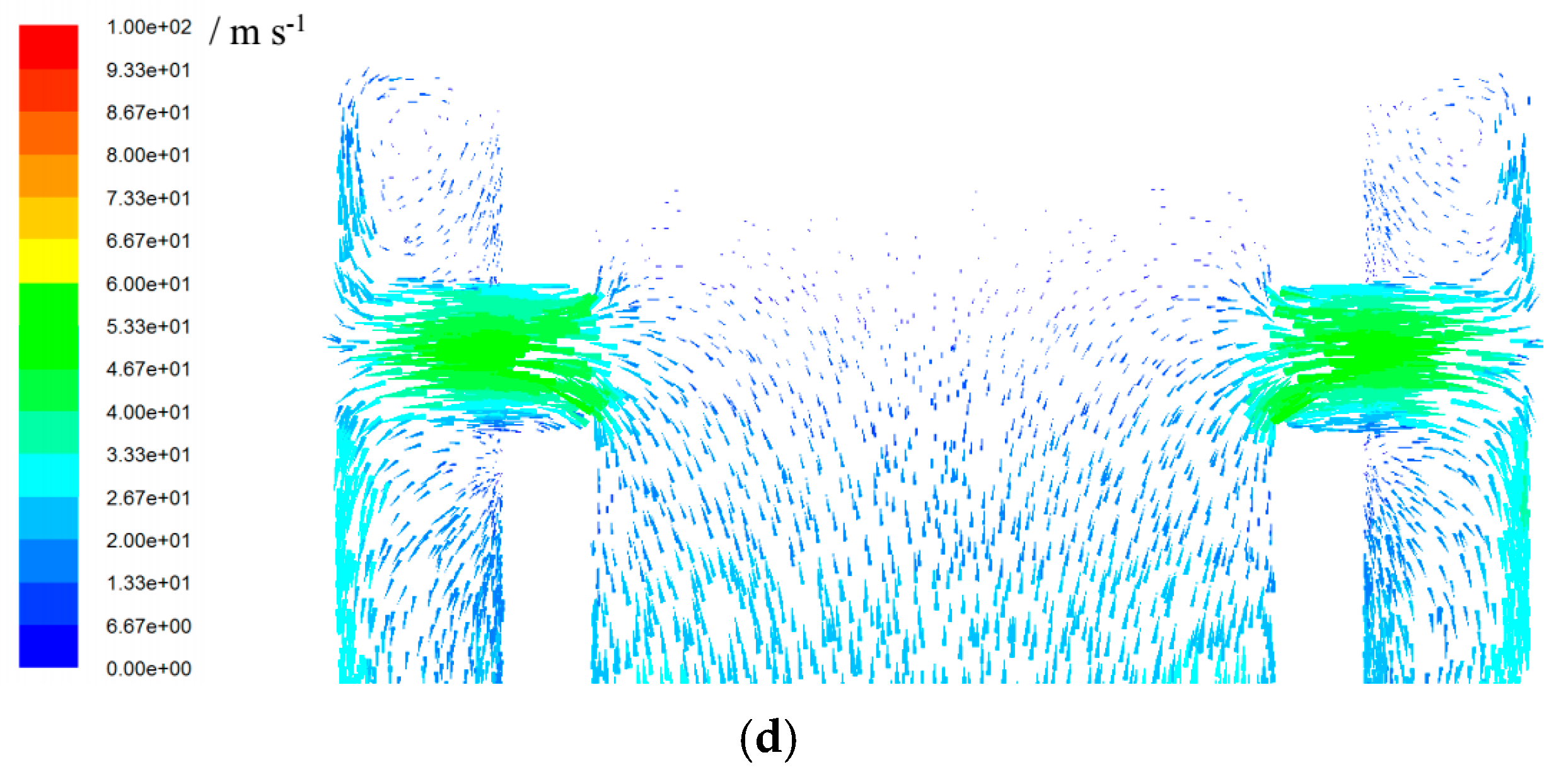

4.4. Flow Characteristics

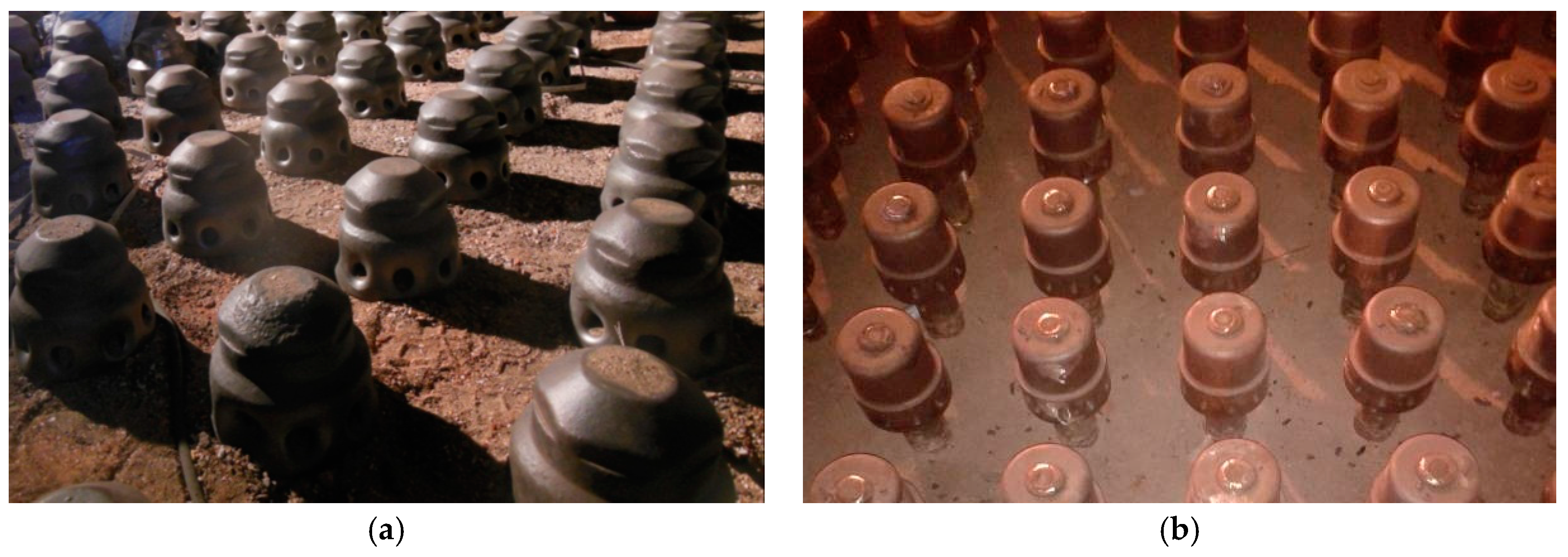

4.5. Engineering Applications

5. Conclusions

- (1)

- For the bell-type air nozzle, results of the numerical simulation agree with those of the cold-state experiment.

- (2)

- This paper has conducted simulations for nozzle A and nozzle B at 100% load and 30% load under hot-state, the results indicating that the performance index of nozzle B is better than nozzle A.

- (3)

- The resistance coefficient of nozzle A will rise after the outer cover is blocked. The abrasion of the outer cover, the generation of a gap between the inner tube and the top of the outer cover, will reduce the resistance coefficient.

- (4)

- The small hole in the outlet of nozzle B is designed as a downward special shape, and the outlet velocity is evenly distributed. Therefore, the risk of the outer cover clogging is less than nozzle A.

- (5)

- The application results of a 480 t h−1 CFB boiler show that the air nozzle replacement rate is reduced from 34.5% within 5000 h to 2.6% after replacing nozzle A with nozzle B, and the service life of the air nozzle is significantly extended.

- (6)

- The related research is of great value for the design and working characteristics evaluation of the bell-type air nozzle. The new bell-type air nozzle has important engineering application potential.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| A | Inlet area of air nozzle (m2) |

| u | Inlet velocity of air nozzle (m s−1) |

| p | Ambient pressure (Pa) |

| Pinlet | Inlet pressure of air nozzle (Pa) |

| Poutlet | Outlet pressure of air nozzle (Pa) |

| ΔP | Pressure drop of air nozzle (Pa) |

| T | Air temperature (°C) |

| Q | Flow rate of air (m3 s−1) |

| ζ | Resistance coefficient of air nozzle (−) |

| ρ | Density of air (kg m−3) |

| ρ0 | Density of air under standard condition (kg m−3) |

References

- Leckner, B. Fluidized bed combustion: Mixing and pollutant limitation. Prog. Energy Combust. Sci. 1998, 24, 31–61. [Google Scholar] [CrossRef]

- Basu, P. Combustion of coal in circulating fluidized-bed boilers: A review. Chem. Eng. Sci. 1999, 54, 5547–5557. [Google Scholar] [CrossRef]

- Rydén, M.; Hanning, M.; Corcoran, A.; Lind, F. Oxygen Carrier Aided Combustion (OCAC) of Wood Chips in a Semi-Commercial Circulating Fluidized Bed Boiler Using Manganese Ore as Bed Material. Appl. Sci. 2016, 6, 347. [Google Scholar] [CrossRef]

- Yue, G.; Cai, R.; Lu, J.; Zhang, H. From a CFB reactor to a CFB boiler—The review of R&D progress of CFB coal combustion technology in China. Powder Technol. 2017, 316, 18–28. [Google Scholar]

- Yue, G.; Lu, J.; Yang, H.; Su, H. Research on supercritical circulating fluidized bed boiler. In Proceedings of the 11th International Conference on Fluidized Bed Technology, Beijing, China, 4–17 May 2014; pp. 541–550. [Google Scholar]

- Basu, P. Circulating Fluidized Bed Boilers: Design, Operation and Maintenance; Springer International Publishing AG: Cham, Switzerland, 2015. [Google Scholar]

- Huang, Z. Optimization Technologies of Circulating Fluidized Bed Boiler; China Electric Power Press: Beijing, China, 2019. [Google Scholar]

- Sun, Z.; Jin, B.; Zhang, M.; Liu, R.; Zhang, Y. Experimental study on cotton stalk combustion in a circulating fluidized bed. Appl. Energy 2008, 85, 1027–1040. [Google Scholar] [CrossRef]

- Zeng, B.; Lu, X.; Gan, L.; Shu, M. Development of a novel fluidized bed ash cooler for circulating fluidized bed boilers: Experimental study and application. Powder Technol. 2011, 212, 151–160. [Google Scholar] [CrossRef]

- Whitehead, A.; Dent, D. Influence of distributor pressure drop uniformity on large fluidized-bed systems. AIChE J. 1982, 28, 169–172. [Google Scholar] [CrossRef]

- Qureshi, E.; Creasy, D. Fluidised bed gas distributors. Powder Technol. 1979, 22, 113–119. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, Y.; Meng, A. Design and application of novel horizontal circulating fluidized bed boiler. In Proceedings of the 20th International Conference on Fluidized Bed Combustion, Xi’an, China, 18–21 May 2009; pp. 206–211. [Google Scholar]

- Yue, G.; Lu, J.; Zhang, H.; Yang, H.; Zhang, J.; Liu, Q.; Li, Z.; Joos, E.; Jaud, P. Design theory of circulating fluidized bed boilers. In Proceedings of the 18th International Fluidized Bed Combustion Conference, Toronto, Canada, 22–25 May 2005; pp. 18–21. [Google Scholar]

- Huang, Z.; Xiao, P.; Jiang, J.; Sun, X. Optimal Retrofit of Domestic 200 MW CFB Boilers Air Nozzle. In Proceedings of the CSEE, Wuhan, China, 21–22 August 2011; Volume 31, pp. 183–186. [Google Scholar]

- Mirek, P.; Mirek, J.; Sekret, R.; Nowak, W. Nozzles in CFB Boilers, Circulated Fluidized Bed Technology VIII; International Academic Publishers/World Publishing Corporation: Hangzhou, China, 2005; pp. 877–884. [Google Scholar]

- Mirek, P.; Nowak, W. The influence of air distributor’s geometry on combustion conditions in large—Scale CFB boiler. Arch. Thermodyn. 2008, 29, 37–44. [Google Scholar]

- Mirek, P. Designing of primary air nozzles for large—Scale CFB boilers in a combined numerical—Experimental approach. Chem. Eng. Proc. Process Intensif. 2011, 50, 694–701. [Google Scholar] [CrossRef]

- Yang, H.; Huang, Z.; Yue, G.; Lu, J. Characteristics of a Float Nozzle Designed for CFB Boilers. Chem. Eng. Technol. Indust. Chem. 2007, 30, 1398–1400. [Google Scholar] [CrossRef]

- Johnsson, F.; Larsson, G.; Leckner, B. Pressure and flow fluctuations in a fluidized bed—Interaction with the air—Feed system. Chem. Eng. Sci. 2002, 57, 1379–1392. [Google Scholar] [CrossRef]

- Depypere, F.; Pieters, J.; Dewettinck, K. CFD analysis of air distribution in fluidized bed equipment. Powder Technol. 2004, 145, 176–189. [Google Scholar] [CrossRef]

- Dhotre, M.; Joshi, J. Design of a gas distributor: Three—Dimensional CFD simulation of a coupled system consisting of a gas chamber and a bubble column. Chem. Eng. J. 2007, 125, 149–163. [Google Scholar] [CrossRef]

- Hughes, T. Scale Model Testing of JEA Northside Units 1 and 2 Primary Air Distribution System and Windbox. Ph.D. Thesis, Tennessee Technological University, Cookeville, TN, USA, 2013. [Google Scholar]

- Tong, J.C.; Sparrow, E.M.; Abraham, J.P. Geometric strategies for attainment of identical outflows through all of the exit ports of a distribution manifold in a manifold system. Appl. Therm. Eng. 2009, 29, 3552–3560. [Google Scholar] [CrossRef]

- Bhasker, C. Simulation of air flow in the typical boiler windbox segments. Adv. Eng. Softw. 2002, 33, 793–804. [Google Scholar] [CrossRef]

- Sekret, W.; Nowak, W. Analysis of the bottom part of a large technical scale circulating fluidized bed boiler. Arch. Thermodyn. 2006, 27, 31–52. [Google Scholar]

- Mirek, P.; Klajny, M. Air nozzle design criteria for protection against the backflow of solids in CFB boilers. Appl. Therm. Eng. 2018, 141, 503–515. [Google Scholar] [CrossRef]

- Speziale, C.; Thangam, S. Analysis of an RNG based turbulence model for separated flows. Int. J. Eng. Sci. 1992, 30, 1379-IN4. [Google Scholar] [CrossRef]

- Smith, L.; Reynolds, W. On the Yakhot—Orszag renormalization group method for deriving turbulence statistics and models. Phys. Fluids A Fluid Dyn. 1992, 4, 364–390. [Google Scholar] [CrossRef]

- Serrano, J.R.; Novella, R.; Gomez-Soriano, J.; Martínez, P.J. Computational Methodology for Knocking Combustion Analysis in Compression-Ignited Advanced Concepts. Appl. Sci. 2018, 8, 1707. [Google Scholar] [CrossRef]

- Tan, P.; Sha, Y.; Bai, X.; Tu, D.; Ma, J.; Huang, W.; Fang, Y. A Performance Test and Internal Flow Field Simulation of a Vortex Pump. Appl. Sci. 2017, 7, 1273. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, D.; Zhang, D.; Xie, Y. Investigation on Unsteady Flow Characteristics of a SCO2 Centrifugal Compressor. Appl. Sci. 2017, 7, 310. [Google Scholar] [CrossRef]

- Paqnneerselvam, R.; Savithri, S.; Surender, G. CFD simulation of hydrodynamics of gas—Liquid—Solid fluidised bed reactor. Chem. Eng. Sci. 2009, 64, 1119–1135. [Google Scholar] [CrossRef]

- Pei, P.; Wu, G.; Zhang, K.; Yu, B.; Jiang, J.; Wen, D. CFD simulation of jet behaviors in a binary gas—solid fluidized bed comparisons with experiments. Front. Chem. Eng. China 2010, 4, 242–249. [Google Scholar] [CrossRef]

| Description | Units | Nozzle A | Nozzle B | |

|---|---|---|---|---|

| Inner tube | Internal diameter | mm | 60 | 60 |

| External diameter | mm | 76 | 76 | |

| Number of orifices | - | 16 | 16 | |

| Diameter of orifice | mm | 15 | 13.5 | |

| Cover | Internal diameter | mm | 103 | 105 |

| External diameter | mm | 159 | 159 | |

| Number of outlets | - | 8 | 10 | |

| Diameter of outlet | mm | 22.5 | 23 * | |

| Angle of outlet | - | horizontal | 20° | |

| Fixed method with inner tube | - | threaded | welding | |

| Model | Setting |

|---|---|

| Viscous | RNG k-ε |

| Inlet of inner tube | Velocity-inlet |

| Outlets of cover | Pressure-outlet |

| Wall function | Standard wall function |

| Momentum | Second order upwind |

| Pressure-velocity coupling | SIMPLE |

| Description | Units | Nozzle A (100% Load) | Nozzle A (30% Load) | Nozzle B (100% Load) | Nozzle B (30% Load) |

|---|---|---|---|---|---|

| Pressure drop | Pa | 5265 | 1253 | 4691 | 1110 |

| Inlet velocity | m s−1 | 56.5 | 27.1 | 56.5 | 27.1 |

| Outlet velocity | m s−1 | 54.1 | 25.8 | 40.7 | 19.3 |

| Air temperature | °C | 200 | 180 | 200 | 180 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Deng, L.; Che, D. Experimental and CFD Simulation Studies on Bell-Type Air Nozzles of CFB Boilers. Appl. Sci. 2019, 9, 3805. https://doi.org/10.3390/app9183805

Huang Z, Deng L, Che D. Experimental and CFD Simulation Studies on Bell-Type Air Nozzles of CFB Boilers. Applied Sciences. 2019; 9(18):3805. https://doi.org/10.3390/app9183805

Chicago/Turabian StyleHuang, Zhong, Lei Deng, and Defu Che. 2019. "Experimental and CFD Simulation Studies on Bell-Type Air Nozzles of CFB Boilers" Applied Sciences 9, no. 18: 3805. https://doi.org/10.3390/app9183805

APA StyleHuang, Z., Deng, L., & Che, D. (2019). Experimental and CFD Simulation Studies on Bell-Type Air Nozzles of CFB Boilers. Applied Sciences, 9(18), 3805. https://doi.org/10.3390/app9183805