Third-Body and Dissipation Energy in Green Tribology Film

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Experiment

2.1. Preparation of HPMC Composites

2.2. Friction and Wear Tests

3. Results and Discussion

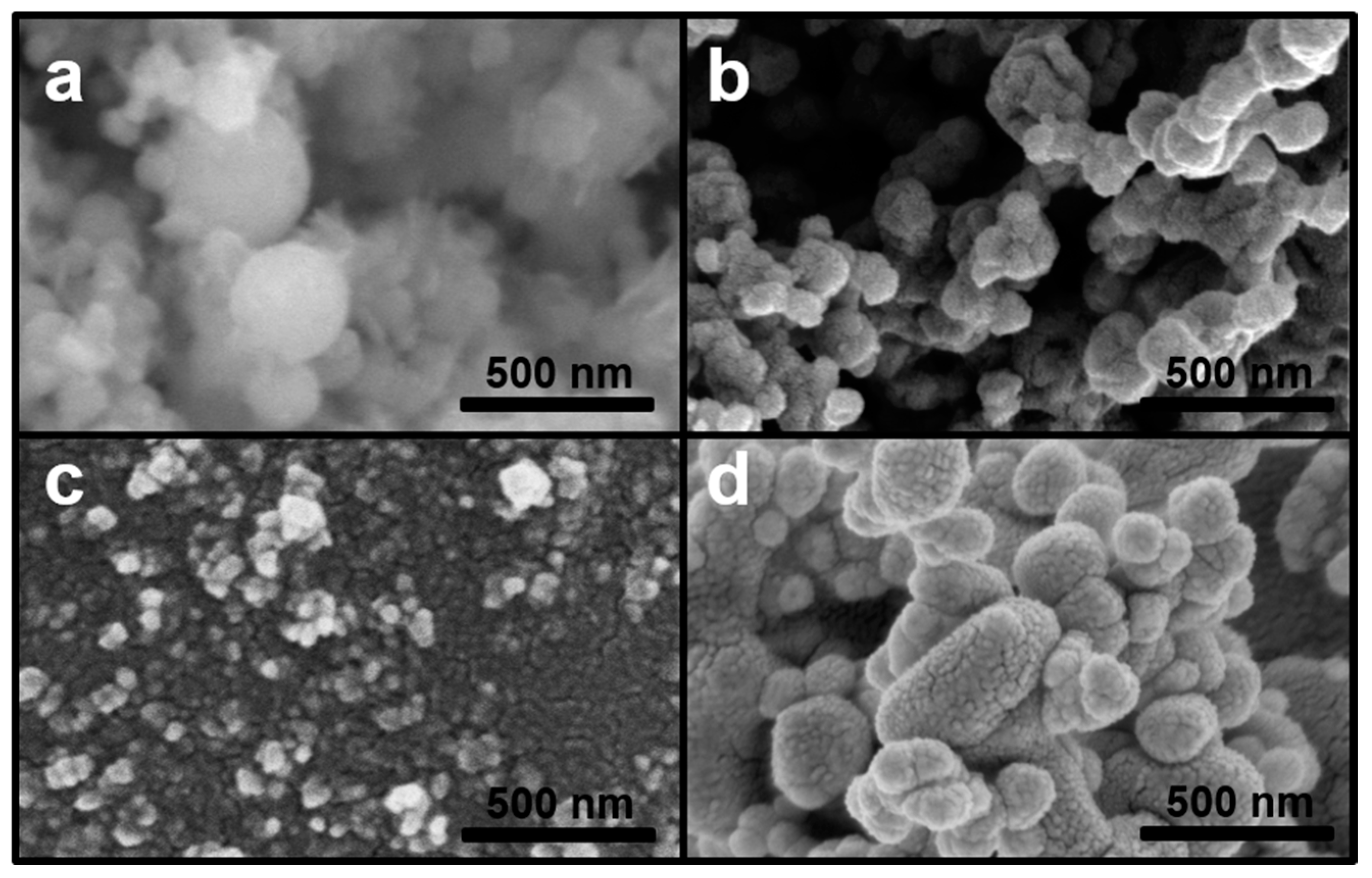

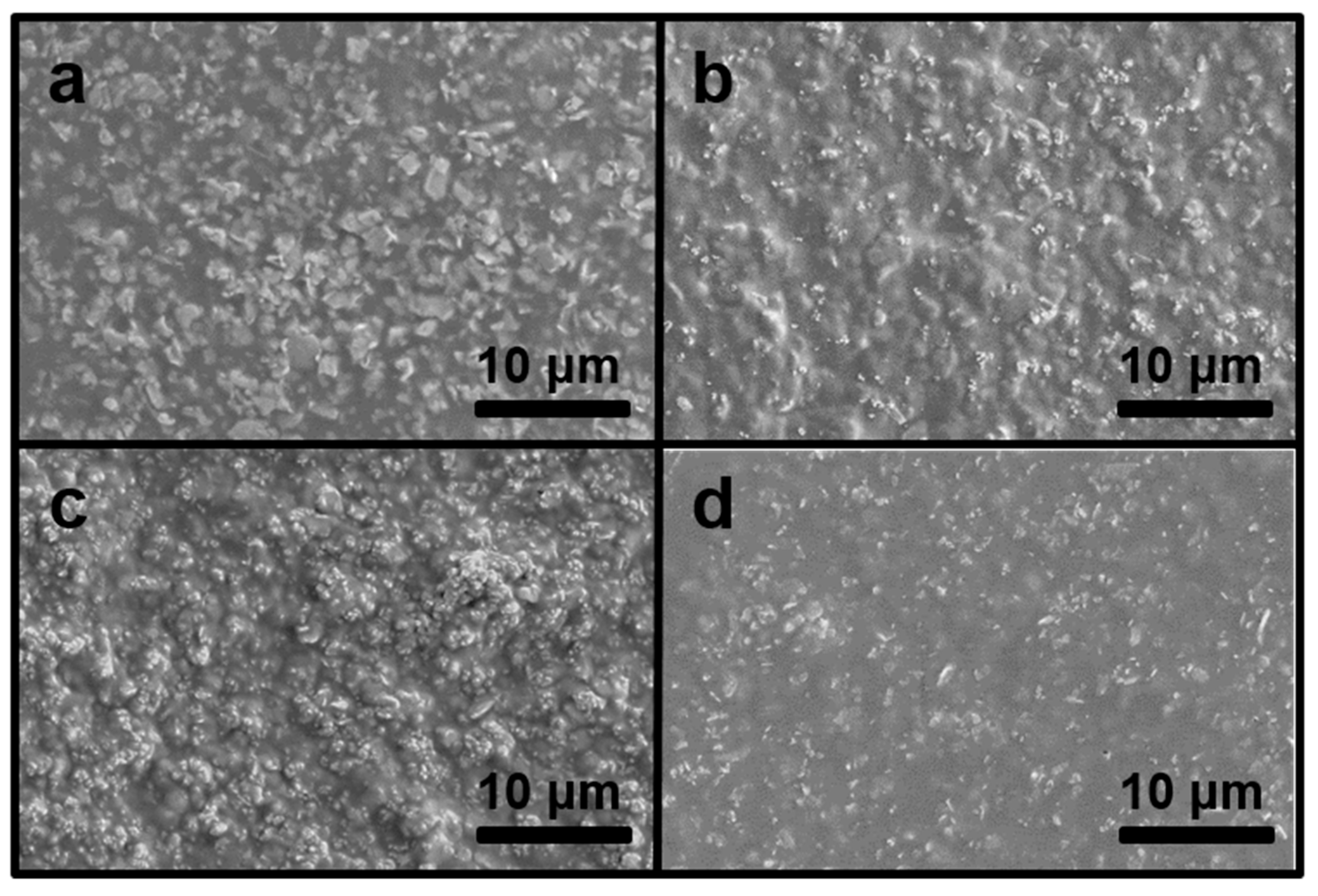

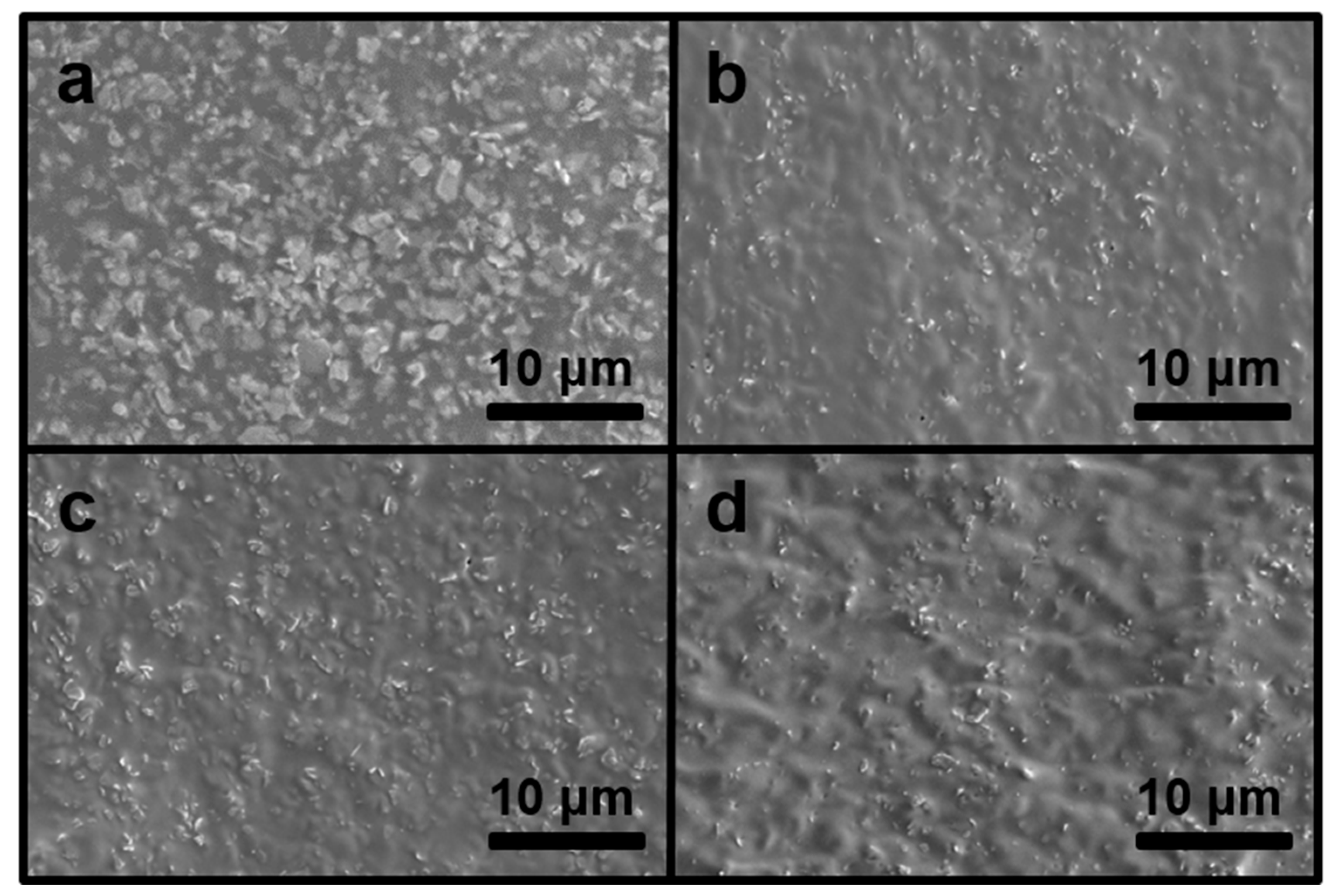

3.1. Observation of HPMC Composites

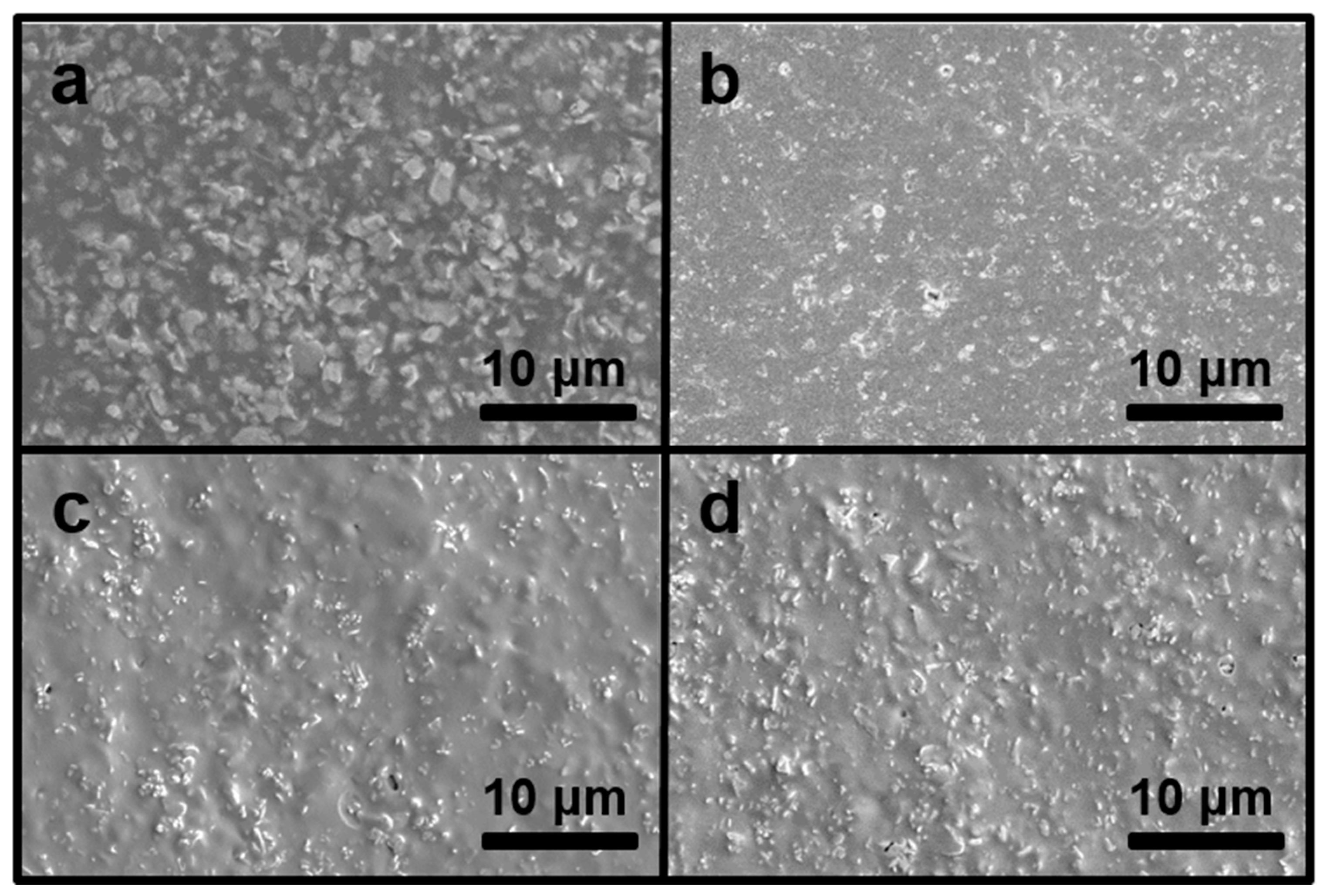

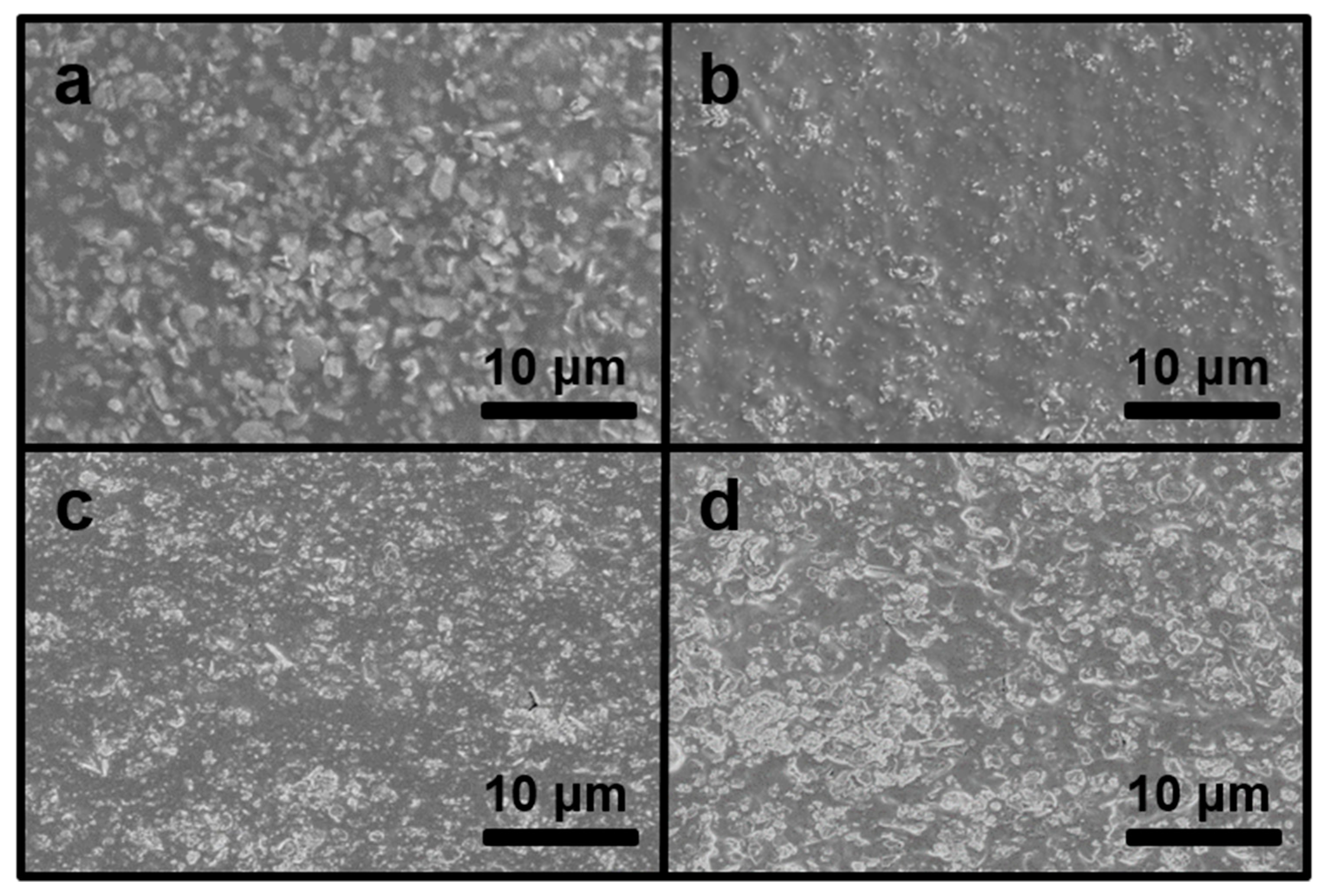

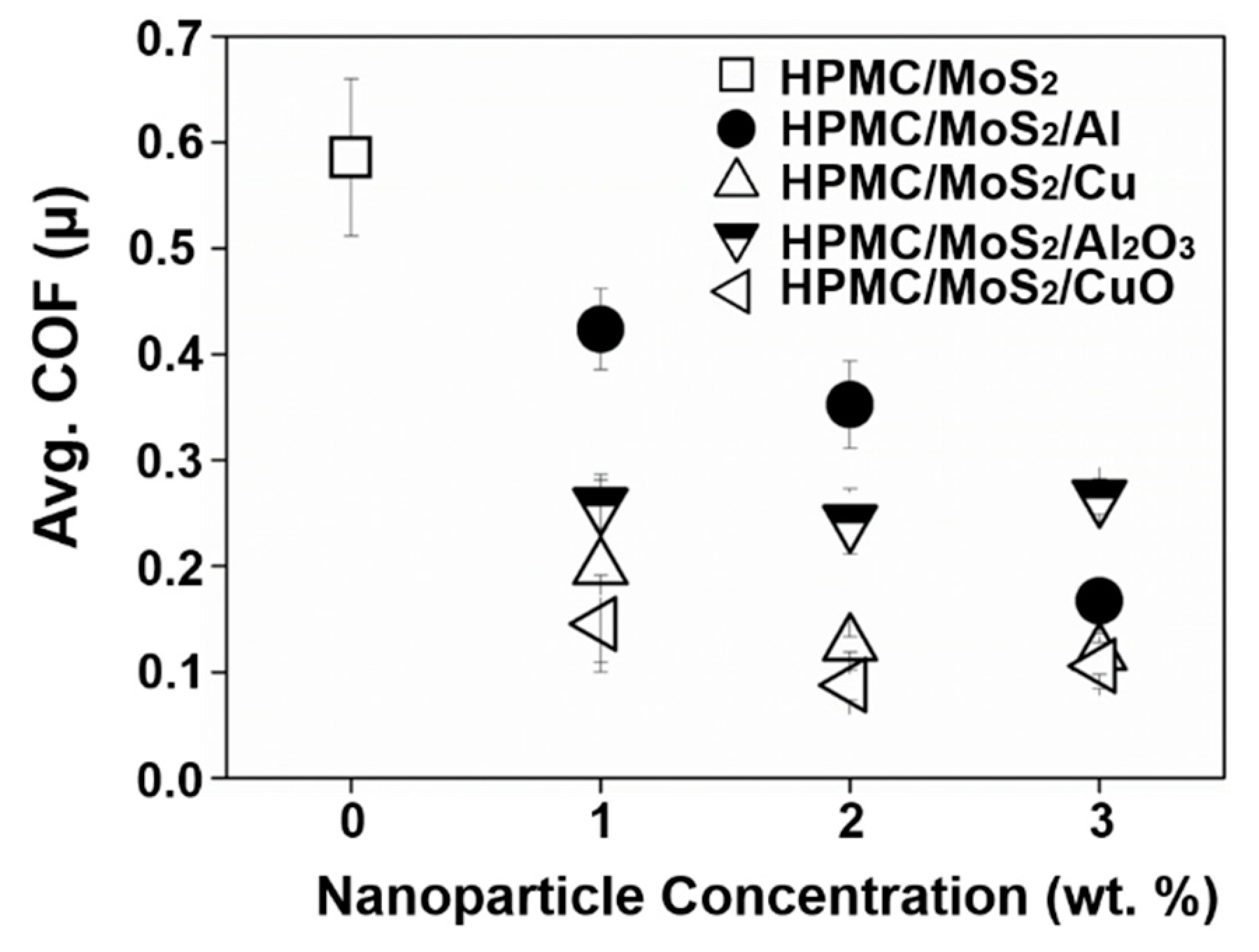

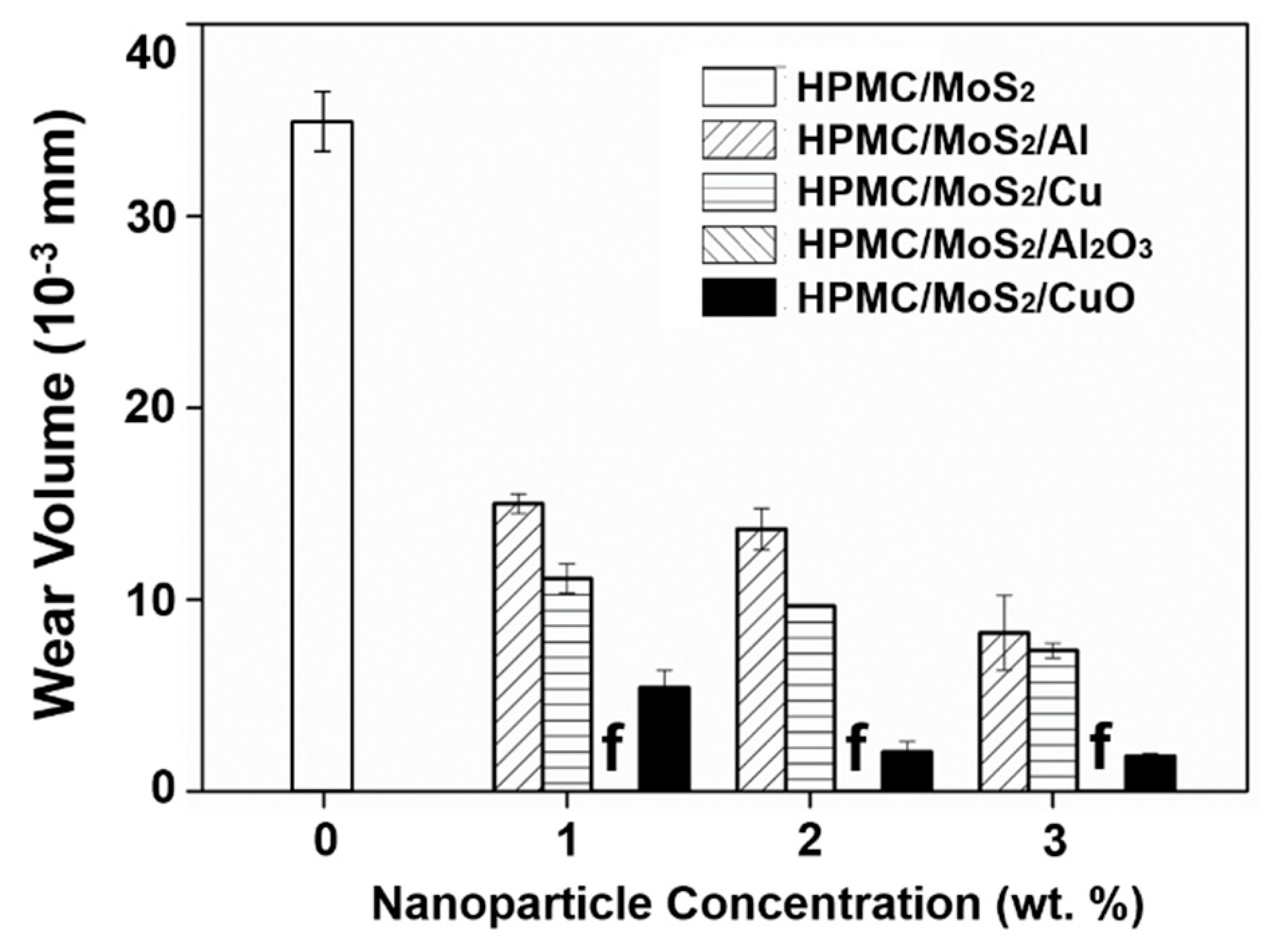

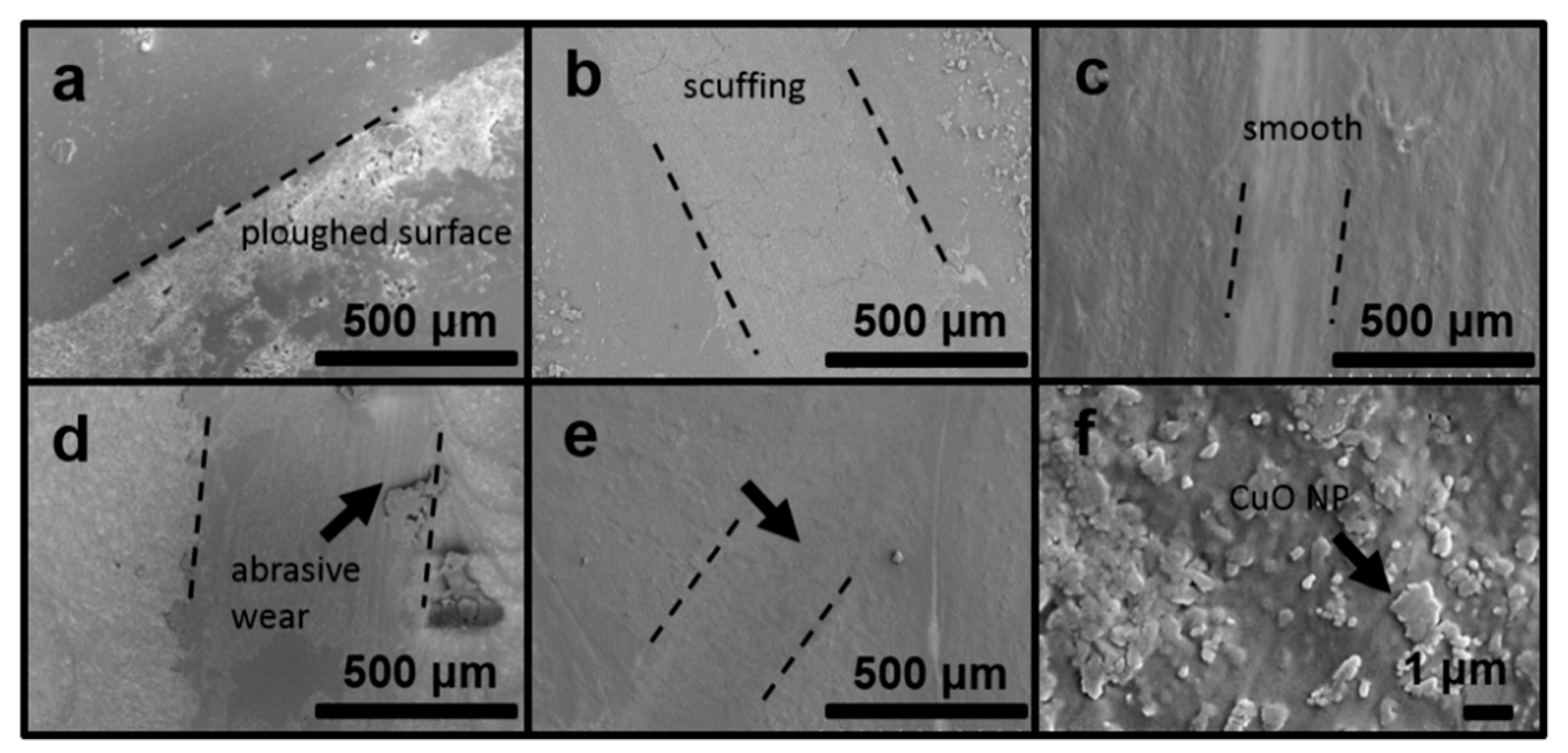

3.2. Friction and Wear Properties of the HPMC Composites

3.3. Dissipation Energy Analysis of the HPMC Composites

4. Conclusions

- (1)

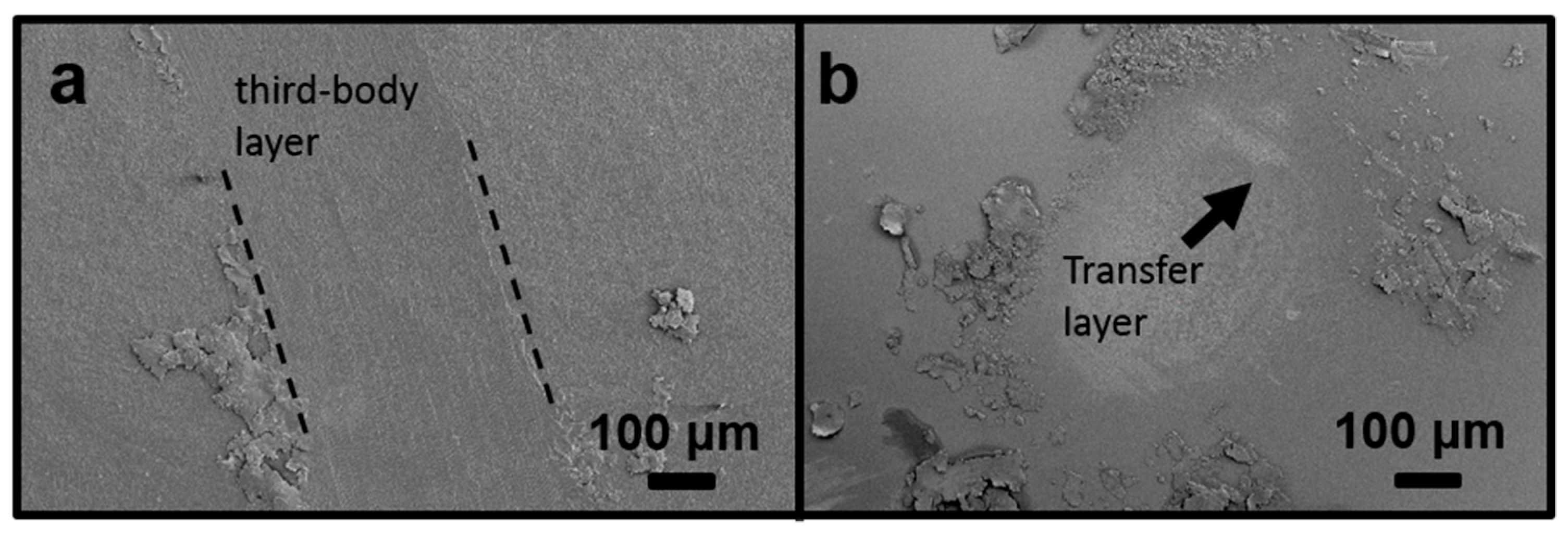

- MoS2 additive is beneficial for the formation of third-body layer, which is the main factor of improving tribology property of the composite.

- (2)

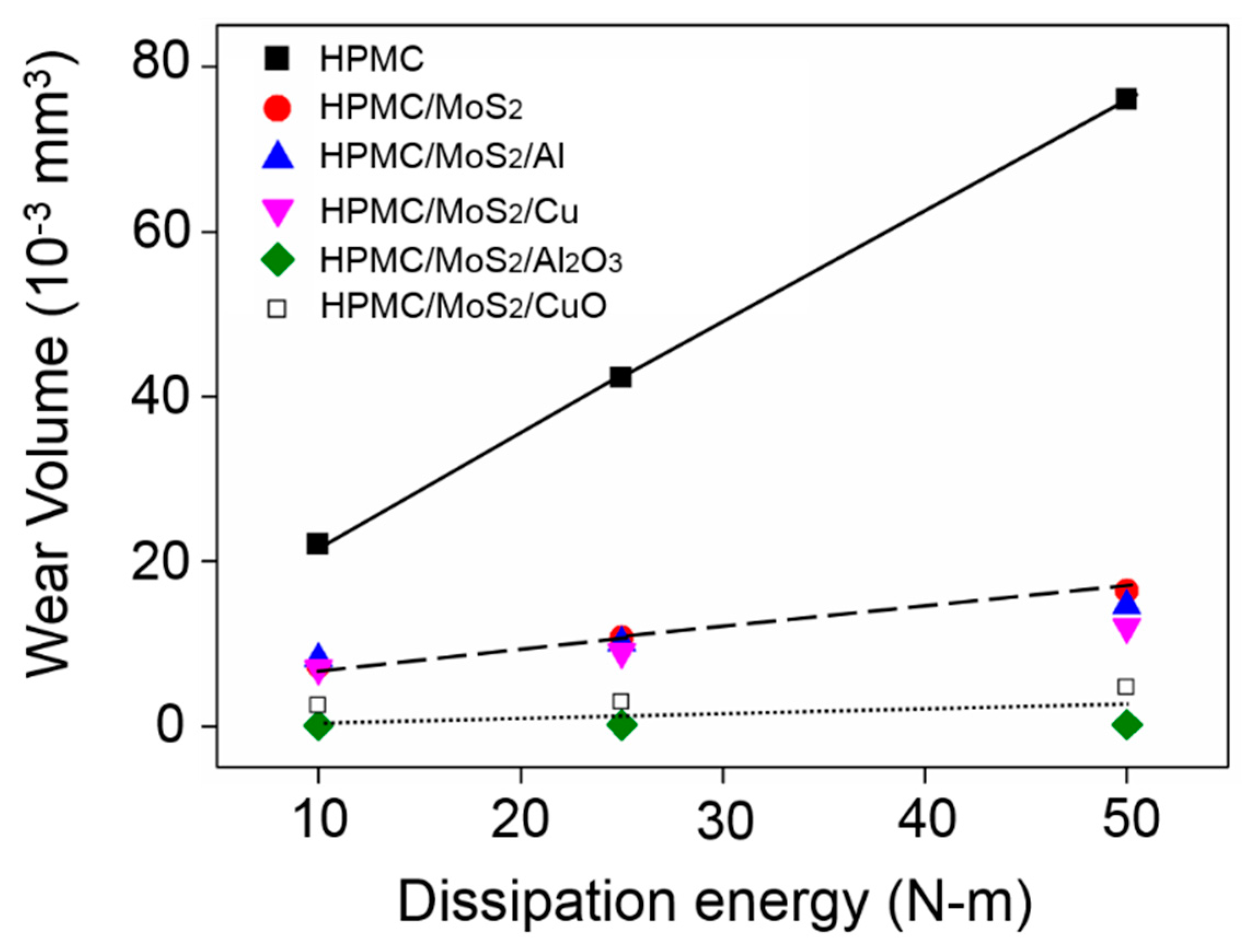

- In the dissipation energy observation, different slopes represent different wear mechanism. The lower the slope, more lubricating factors are involved in the wear process. The dissipation energy analysis can be used as a simple method to determine wear mechanisms in the wear system.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, S.W. Green tribology: Fundamentals and future development. Friction 2013, 1, 186–194. [Google Scholar] [CrossRef] [Green Version]

- Nosonovsky, M.; Bhushan, B. Green Tribology: Principles, research areas and challenges. Philos. Trans. R Soc. A 2010, 368, 4677–4694. [Google Scholar] [CrossRef] [PubMed]

- Kharissova, O.V.; Dias, H.R.; Kharisov, B.I.; Pérez, B.O.; Pérez, V.M.J. The greener synthesis of nanoparticles. Trends Biotechnol. 2013, 31, 240–248. [Google Scholar] [CrossRef] [PubMed]

- Kaviya, S.; Santhanalakshmi, J.; Viswanathan, B. Green synthesis of silver nanoparticles using Polyalthia longifolia leaf extract along with D-sorbitol: Study of antibacterial activity. J. Nanotechnol. 2011, 2011, 152970. [Google Scholar] [CrossRef] [PubMed]

- Alves, S.M.; Barros, B.S.; Trajano, M.F.; Ribeiro, K.S.B.; Moura, E. Tribological behavior of vegetable oil-based lubricants with nanoparticles of oxides in boundary lubrication conditions. Tribol. Int. 2013, 65, 28–36. [Google Scholar] [CrossRef]

- Quinchia, L.A.; Delgado, M.A.; Reddyhoff, T.; Gallegos, C.; Spikes, H.A. Tribological studies of potential vegetable oil-based lubricants containing environmentally friendly viscosity modifiers. Tribol. Int. 2014, 69, 110–117. [Google Scholar] [CrossRef]

- Rastogi, V.; Samyn, P. Bio-based coatings for paper applications. Coatings 2015, 5, 887–930. [Google Scholar] [CrossRef]

- Shi, S.C.; Huang, T.F. Raman study of HPMC biopolymer transfer layer formation under tribology test. Opt. Quantum Electron. 2016, 48, 532. [Google Scholar] [CrossRef]

- Siepmann, J.; Peppas, N.A. Modeling of drug release from delivery systems based on hydroxypropyl methylcellulose (HPMC). Adv. Drug Deliv. Rev. 2012, 64, 163–174. [Google Scholar] [CrossRef]

- de Moura, M.R.; Aouada, F.A.; Avena-Bustillos, R.J.; McHugh, T.H.; Krochta, J.M.; Mattoso, L.H. Improved barrier and mechanical properties of novel hydroxypropyl methylcellulose edible films with chitosan/tripolyphosphate nanoparticles. J. Food Eng. 2009, 92, 448–453. [Google Scholar] [CrossRef]

- Shi, S.C.; Su, C.C. Corrosion inhibition of high speed steel by biopolymer HPMC derivatives. Materials 2016, 9, 612. [Google Scholar] [CrossRef] [PubMed]

- Fahs, A.; Brogly, M.; Bistac, S.; Schmitt, M. Hydroxypropyl methylcellulose (HPMC) formulated films: Relevance to adhesion and friction surface properties. Carbohydr. Polym. 2010, 80, 105–114. [Google Scholar] [CrossRef]

- Shi, S.C.; Huang, T.F.; Wu, J.Y. Preparation and tribological study of biodegradable lubrication films on Si substrate. Materials 2015, 8, 1738–1751. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.C.; Wu, J.Y.; Peng, Y.Q. Transfer layer formation in MoS2/hydroxypropyl methylcellulose composite. Wear 2018, 408, 208–213. [Google Scholar] [CrossRef]

- Shi, S.C. Tribological performance of green lubricant enhanced by sulfidation IF-MoS2. Materials 2016, 9, 856. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.C.; Huang, T.F. Self-healing materials for ecotribology. Materials 2017, 10, 91. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.C.; Huang, T.F. Effects of temperature and humidity on self-healing behaviour of biopolymer hydroxylpropyl methylcellulose for ecotribology. Surf. Coat. Technol. 2018, 350, 997–1002. [Google Scholar] [CrossRef]

- Shi, S.C.; Wu, J.Y.; Huang, T.F. Raman, FTIR, and XRD study of MoS2 enhanced hydroxypropyl methylcellulose green lubricant. Opt. Quantum Electron. 2018, 48, 474. [Google Scholar] [CrossRef]

- Shi, S.C.; Wu, J.Y. Deagglomeration and tribological properties of MoS2/hydroxypropyl methylcellulose composite thin film. Surf. Coat. Technol. 2018, 350, 1045–1049. [Google Scholar] [CrossRef]

- Shi, S.C.; Wu, J.Y. Enhancement mechanism for carbohydrate polymer green lubricant. Polym. Polym. Compos. 2018, 26, 85–90. [Google Scholar] [CrossRef]

- Shi, S.C.; Wu, J.Y. Parameter effect on tribology performance of biopolymer composite green lubricant. Sens. Mater. 2017, 29, 1491–1496. [Google Scholar]

- Shi, S.C.; Wu, J.Y. MoS2 additives for enhancing tribological performance of hydroxypropyl methylcellulose biopolymer. Smart Sci. 2017, 5, 167–172. [Google Scholar] [CrossRef]

- Ramalho, A.; Miranda, J. The relationship between wear and dissipated energy in sliding systems. Wear 2006, 260, 361–367. [Google Scholar] [CrossRef] [Green Version]

| Solution Type | Weight of Solute (g) | Weight of Solvent (g) | ||

|---|---|---|---|---|

| HPMC | MoS2 | DI Water | Ethanol | |

| HPMC/MoS2 | 1 | 0.5 | 1.8 | 7.2 |

| HPMC/MoS2/ nanoparticle solution | ||||

| Solution type | Nanoparticle (g) | Ethanol (g) | Span80 (g) | HPMC/MoS2(g) |

| 1 wt.% | 0.2 | 9.2 | 0.1 | 10.5 |

| 2 wt.% | 0.4 | 8.9 | 0.2 | 10.5 |

| 3 wt.% | 0.6 | 8.6 | 0.3 | 10.5 |

| Nanoparticle (NP) | Surface Roughness, Ra (μm) | |||

|---|---|---|---|---|

| HPMC/MoS2 | HPMC/MoS2/ NP 1 wt.% | HPMC/MoS2/ NP 2 wt.% | HPMC/MoS2/ NP 3 wt.% | |

| Al | 1.96 ± 0.01 | 2.12 ± 0.04 | 2.35 ± 0.05 | 2.45 ± 0.11 |

| Cu | 2.19 ± 0.15 | 2.11 ± 0.07 | 2.63 ± 0.19 | |

| Al2O3 | 2.27 ± 0.01 | 1.61 ± 0.13 | 1.66 ± 0.16 | |

| CuO | 2.14 ± 0.09 | 2.13 ± 0.07 | 2.24 ± 0.01 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, S.-C.; Pek, S.-S. Third-Body and Dissipation Energy in Green Tribology Film. Appl. Sci. 2019, 9, 3787. https://doi.org/10.3390/app9183787

Shi S-C, Pek S-S. Third-Body and Dissipation Energy in Green Tribology Film. Applied Sciences. 2019; 9(18):3787. https://doi.org/10.3390/app9183787

Chicago/Turabian StyleShi, Shih-Chen, and Shia-Seng Pek. 2019. "Third-Body and Dissipation Energy in Green Tribology Film" Applied Sciences 9, no. 18: 3787. https://doi.org/10.3390/app9183787

APA StyleShi, S.-C., & Pek, S.-S. (2019). Third-Body and Dissipation Energy in Green Tribology Film. Applied Sciences, 9(18), 3787. https://doi.org/10.3390/app9183787