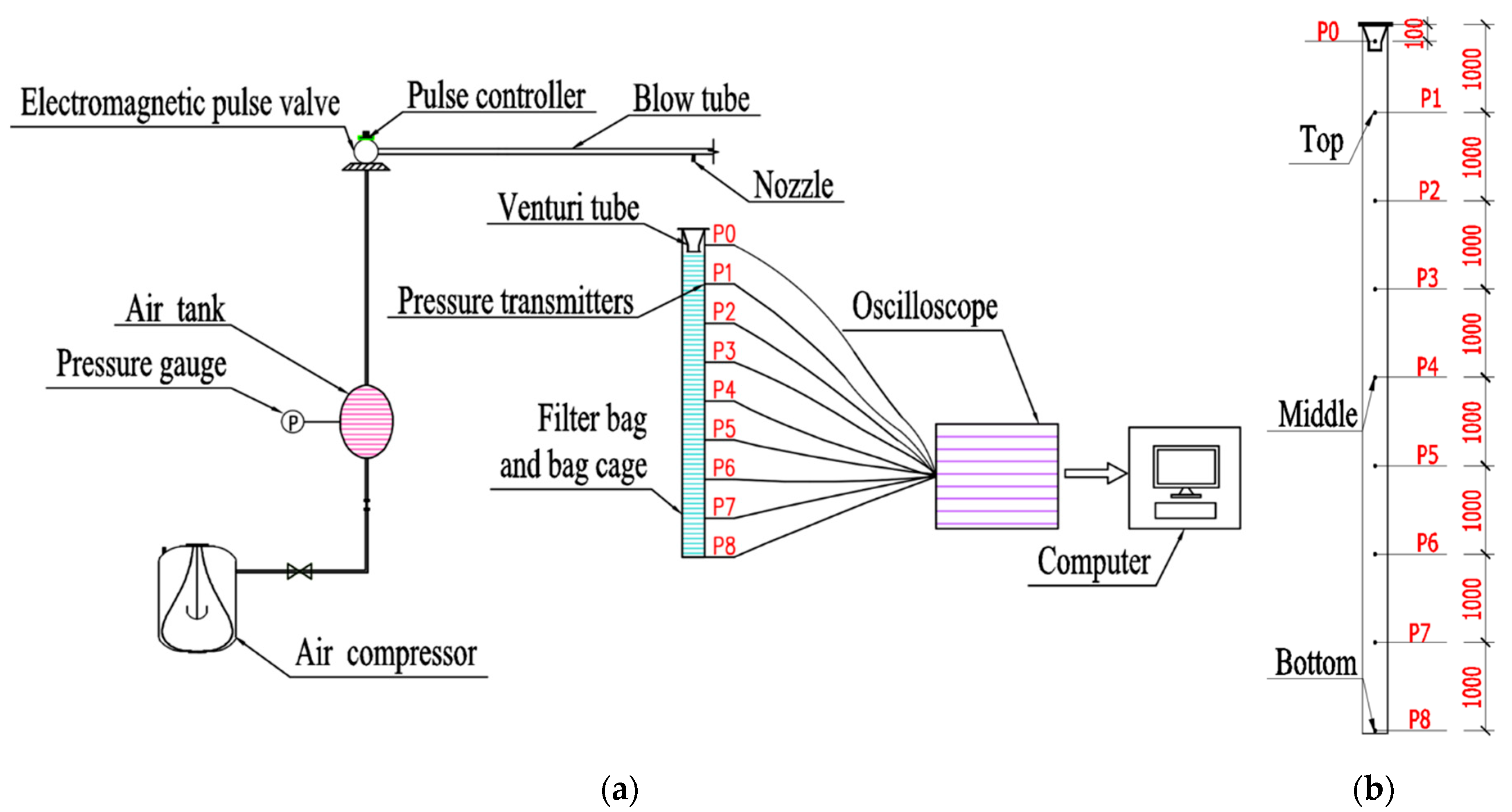

3.1. Effect of Pulsing Air Pressure and Pulsing Air Injection Time on the Cleaning Performance of the Filter Bag

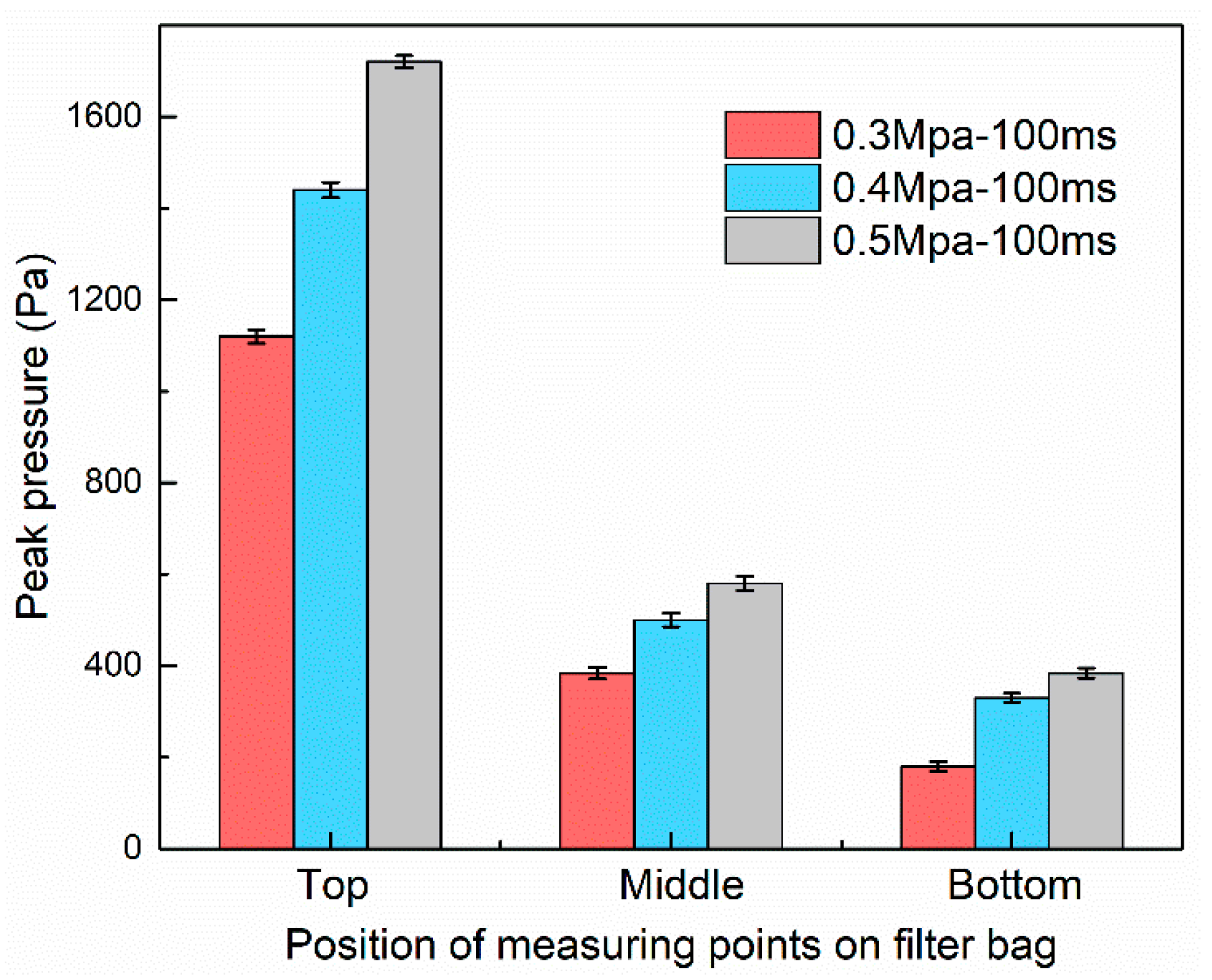

Figure 5 shows the peak pressure distribution of the airflow in the filter bag under different pulsing air pressure values (0.3, 0.4, and 0.5 MPa) at a pulsing air injection time of 100 ms. According to the data, the peak pressure (

) on the side wall of the filter bag increased with increasing pulsing air pressure values (

) and the peak pressure decreased from the top (1000 mm) to the bottom (8000 mm) in the bag. In addition, the attenuation range of the peak pressure in the upper half of the filter bag was significantly greater than that observed in the lower half. This occured because when the compressed airflow was ejected from the nozzle, it would move downward rapidly and induce a large amount of secondary airflow to enter the filter bag. The compressed airflow (the primary airflow) and the secondary airflow mixed to form the total cleaning airflow. The cleaning airflow expanded as it moved downward, thus increasing the air pressure in the space it passed through. Moreover, due to the air permeability of the filter bag, the cleaning airflow was continuously diffused to the outside of the filter bag. Furthermore, the cleaning airflow would rub against the filter bag in the downward movement process, which inevitably consumed a certain amount of energy. Therefore, the peak pressure on the filter bag decreased with the increase of the distance between the measuring points and the bag mouth. On the other hand, the greater the pulsing air pressure, the greater the kinetic energy of the cleaning airflow, the more the amount of the cleaning airflow diffused outside the filter bag, and the more intense the friction with the filter bag, so the peak pressure differed greatly on the upper part of the filter bag under different pulsing air pressure values. When the cleaning airflow moved to the lower half of the filter bag, the friction between the cleaning airflow and the filter bag was weakened due to the energy attenuation of the cleaning airflow so that the gap of the peak pressure on the lower part of the filter bag became smaller under the different pulsing air pressure values. Further analysis showed that, at a pulsing air pressure (

) of 0.5 Mpa, the peak pressure of the filter bag at the three measuring points was 53.57% (top), 51.04% (middle), and 113.33% (bottom) higher than that obtained with a pulsing air pressure of 0.3 MPa, respectively. A similar analysis comparing a pulsing air pressure of 0.4 MPa and 0.3 MPa indicated that the values were of 28.57% (top), 30.21% (middle), and 83.33% (bottom), correspondingly. However, when the pulsing air pressure was 0.4 MPa, the peak pressure at the three measuring points was only 16.28% (top), 13.79% (middle), and 14.06% (bottom) lower than that obtained at a pulsing air pressure of 0.5 MPa. This indicated that as the pulsing air pressure increased, the rate of increase in the peak pressure of the filter bag decreased.

Figure 6 shows that the peak pressure arrival time (

) decreased with an increase in the pulsing air pressure (

) at the three measuring points. In addition, at the “top” point, the peak pressure arrival time values obtained under the three different pulsing air pressures were almost the same. Moreover, with an increasing distance between the measuring points and the bag mouth, the difference between the peak pressure arrival time under the three pulsing air pressures increased. The peak pressure arrival time at the “bottom” point was 262 ms (0.3 MPa), 204 ms (0.4 MPa), and 202 ms (0.5 MPa); thus, when the pulsing air pressure was 0.3 MPa, the peak pressure arrival time at the lower part of the filter bag was significantly higher than that obtained at a pulsing air pressure of 0.4 and 0.5 MPa. This result was consistent with the regular pattern related to the influence of different pulsing air pressure values (

) on the peak pressure (

), namely, for long filter bags, when the cleaning airflow passed through the upper half of the filter bag, due to the very high airflow velocity, the time of the cleaning airflow reaching the “top” point was similar under different pulsing air pressures, which meant the peak pressure arrival time at the “top” point tended to be the same. However, in the lower half of the filter bag, under different pulsing air pressures, the energy attenuation of the cleaning airflow was different, so that the peak pressure arrival time values were different. In addition, when the pulsing air pressure was 0.4 MPa and 0.5 MPa, the difference between the peak pressure arrival time at the three measuring points was small. Additionally, it was observed that the higher the pulsing air pressure, the greater the consumption of compressed air, and the higher the energy consumption of the cleaning bag. Moreover, high pulsing air pressure values caused excessive cleaning of the filter bag, destroying the initial layer of dust cake and reducing the filtration efficiency of the filter bag. Therefore, when selecting the pulsing air pressure, the relationship between the cleaning effect, the energy consumption of the pulse jet cleaning device, and the filtration efficiency of the filter bag should be systematically considered. In this investigation, a pulsing air pressure value of 0.4 MPa was selected to carry out the follow-up experimental study.

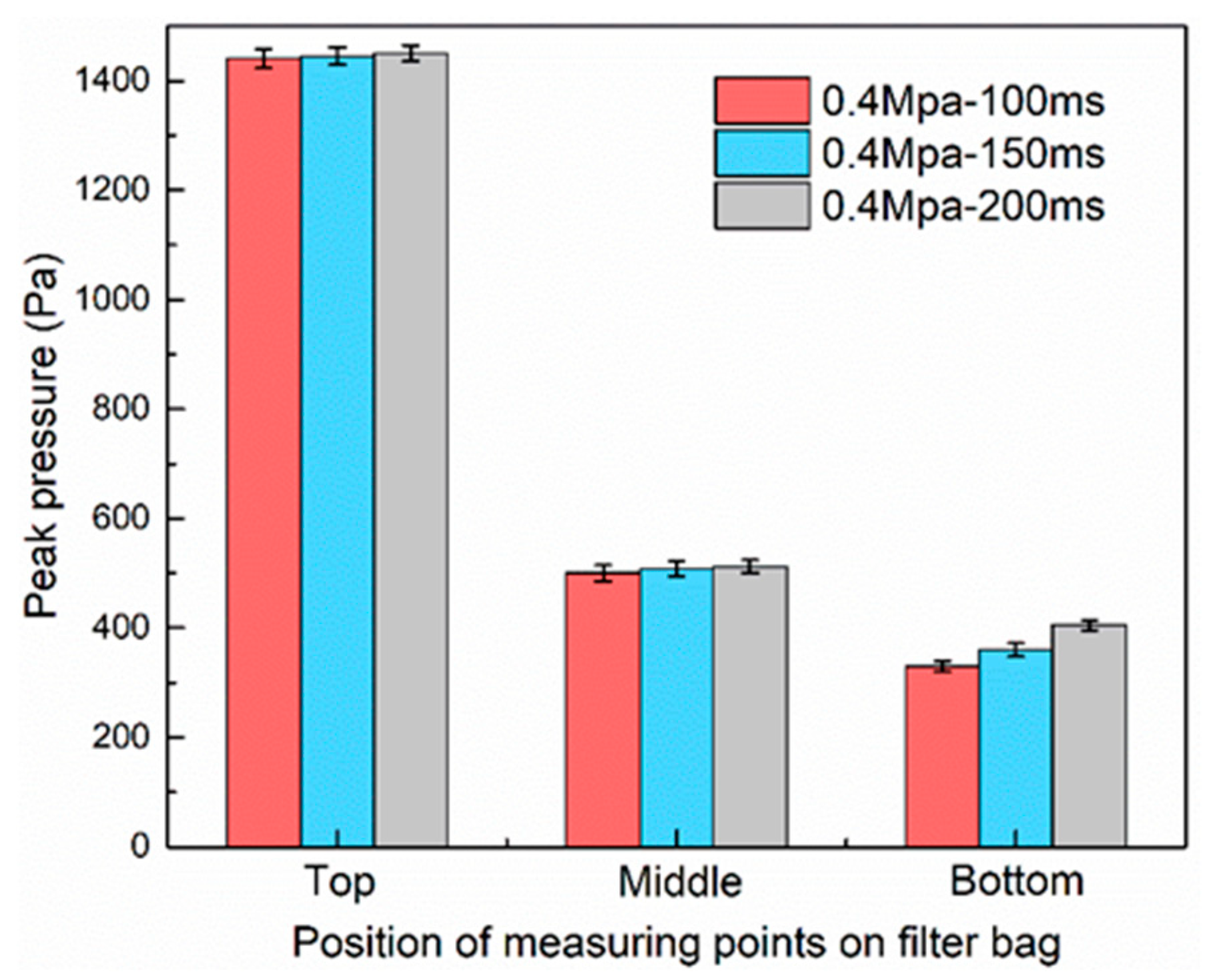

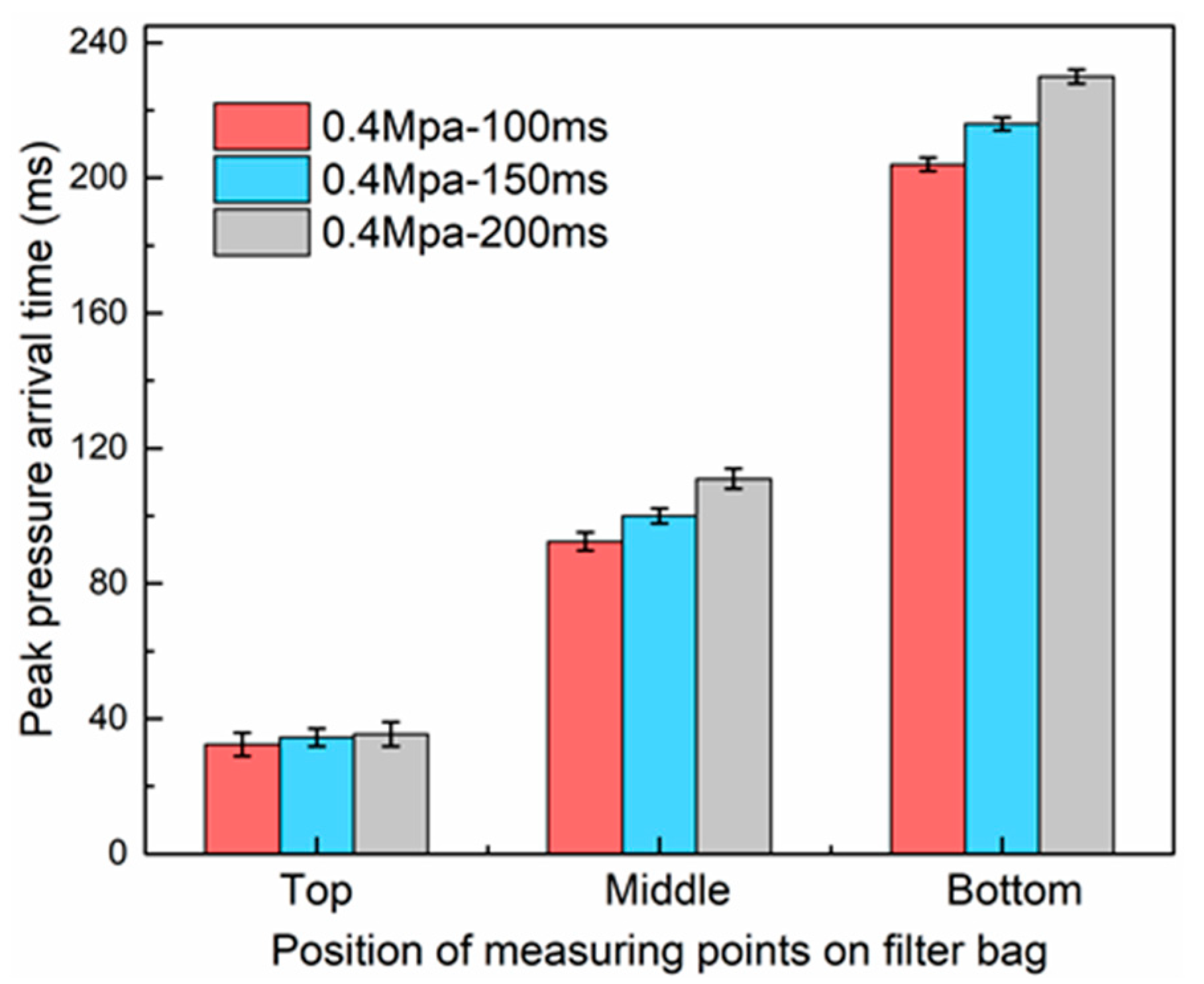

According to

Figure 7, at a constant pulsing air pressure (

) value of 0.4 Mpa, the effect of different pulsing air injection times (100, 150, and 200 ms) on the peak pressure was not significant. This figure shows that applying the three injection times previously mentioned, the peak pressure of the filter bag was similar in the two measuring points labeled as “top” and “middle”, respectively. However, these values were significantly different at the measuring point labeled as “bottom”. On the other hand,

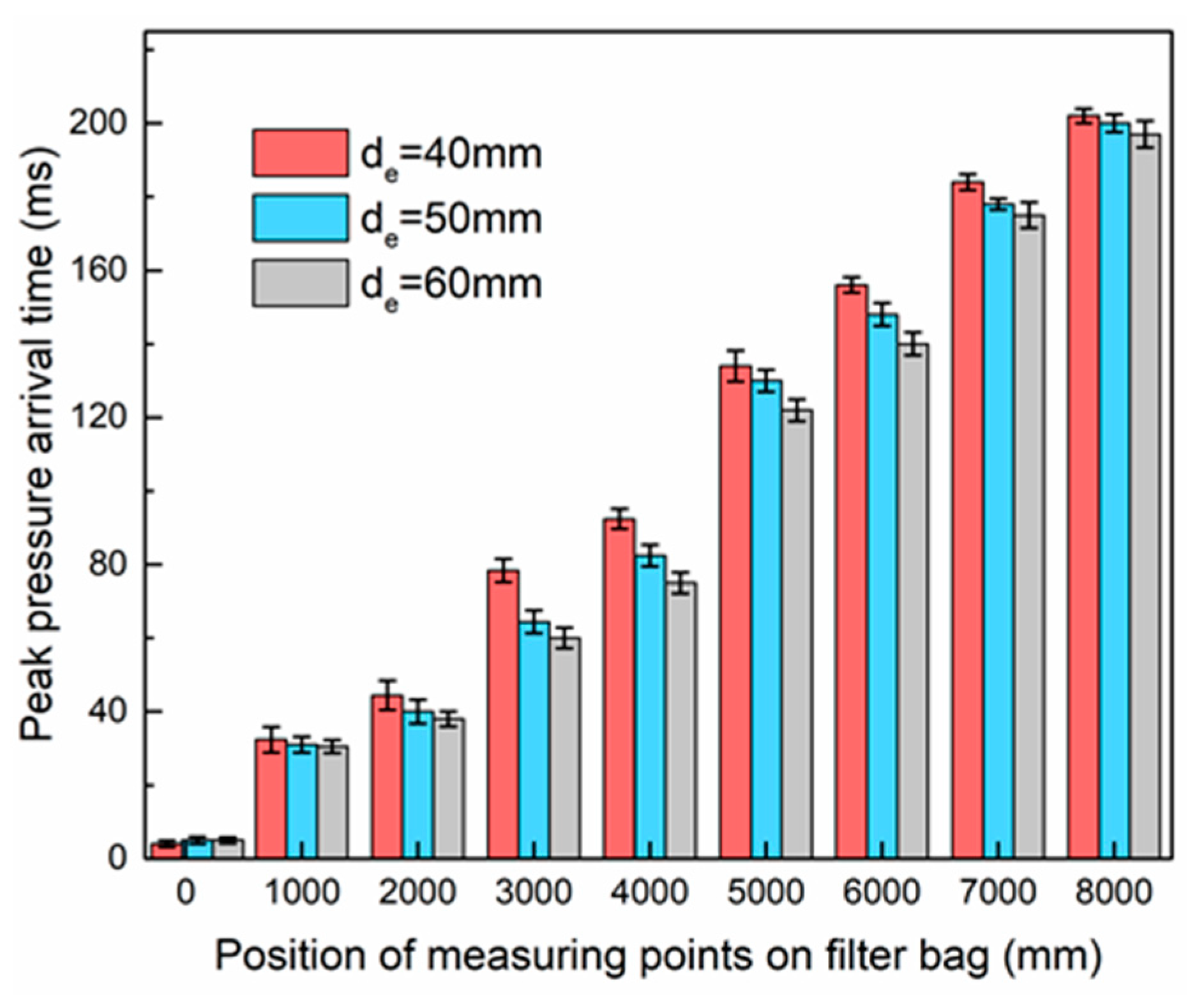

Figure 8 shows that the peak pressure arrival time (

) increased with increasing pulsing air injection time values

, and the difference between the peak pressure arrival time (

) at the same measuring point increased when the distance between the measuring points and the bag mouth increased. This indicates that the influence of the pulsing air injection time

on both the peak pressure (

) and the peak pressure arrival time (

) was not the same. This phenomenon may be explained by the fact that, at a constant value of the compressed pulsing air pressure, by increasing the pulsing air injection time, the amount of compressed air injected into the filter bag also increases; in addition, the peak pressure arrival time at the “top” measuring point was less than 40 ms, which was significantly smaller than the injection time of the compressed pulsing air set in the experiment. This indicates that the cleaning airflow pressure at the “top” measuring point had reached its peak value before the end of the pulsing air injection. Therefore, the compressed airflow injected between the peak pressure arrival time and the end of the pulsing airflow injection had no significant influence on the peak pressure and the peak pressure arrival time at the point labeled as “top”. On the other hand, with the increase of the injection time, the total flow volume of the primary airflow increased, which in turn increased the total flow volume of the secondary airflow and ultimately led to the increase of the total amount and duration of the cleaning airflow. Therefore, at the “bottom” point, the total amount of the cleaning airflow increased, leading to an increase in the refluxing of the cleaning airflow (this reflux was generated when the cleaning airflow reached the bottom of the bag), thereby causing the peak pressure to become larger. In addition, the increase of the refluxing lengthened the reflux action time of the cleaning air flow, which in turn increased the peak pressure arrival time. According to the test results, when the pulsing air pressure was constant, increasing the pulsing air injection time did not significantly increase the peak pressure; on the contrary, the peak pressure arrival time increased, which was not favorable for the cleaning process. Moreover, it increased the consumption of compressed air, also increasing energy consumption. In the follow-up test, the pulsing air injection time was set to 100 ms.

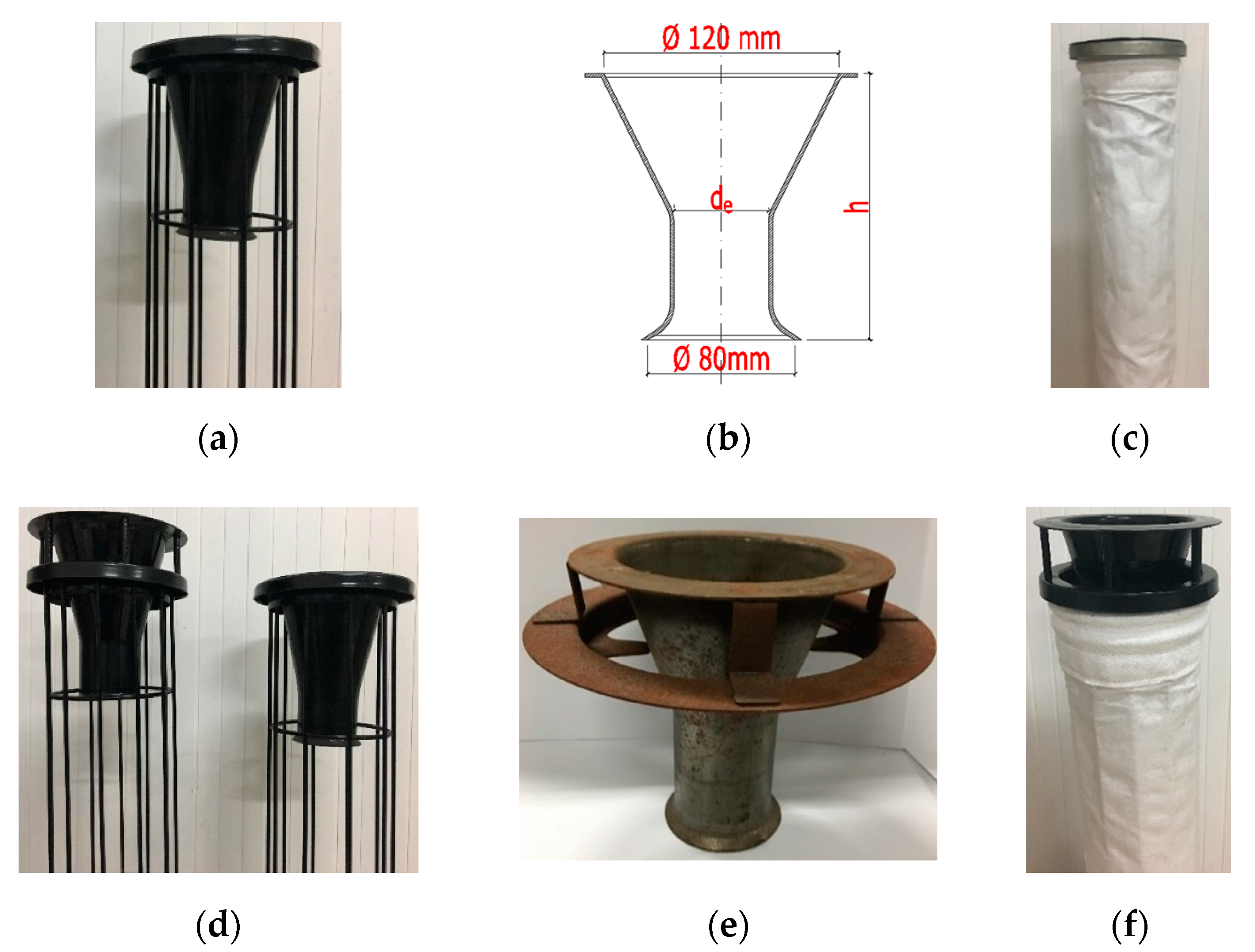

3.2. Effect of Venturi Length and Throat Diameter on the Cleaning Performance of the Filter Bag

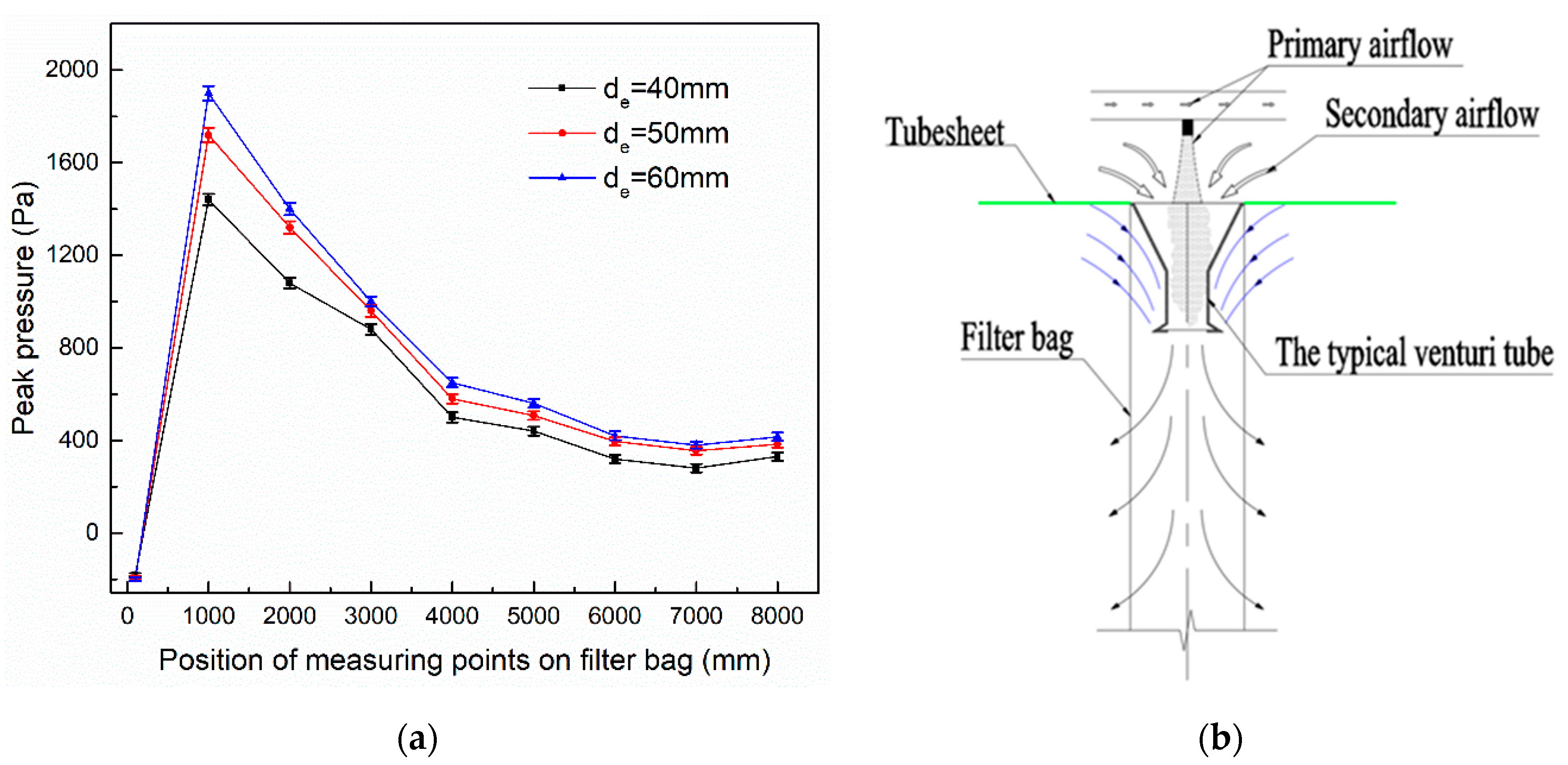

Figure 9a illustrates the variation of the peak pressure on the filter bag under different venturi throat diameters (40, 50, and 60 mm) at a pulsing air pressure of 0.4 Mpa, pulsing air injection time of 100 ms, and venturi length of 200 mm. The peak pressure in the point P0 was negative, later increasing until reaching a maximum value at the point P1. Subsequently, the peak pressure decreased with an increasing distance from the measuring point to the bag mouth. Finally, the peak pressure rose again at point P8. As shown in

Figure 9b, when the typical venturi-type tube was installed in the bag cage, the area near the bag mouth was in the “blind action zone” of the cleaning airflow (primary airflow and secondary airflow). In addition, when the cleaning airflow was ejected from the venturi tube, the airflow outside the filter bag near P0 would be induced to the inside, creating a negative pressure zone in the area near the bag mouth. It can be seen that the area near P0 is the one with the worst cleaning performance. This inference is consistent with the literature [

3,

20]. Since, in this point, the dust layer cannot be effectively cleaned, the filter material in this area loses its filtration ability. Thus, it should be considered that installing the typical venturi-type tube implies that the area near the filter bag mouth will exhibit low filtration performance. The maximum value of the peak pressure occurred at P1, which was consistent with the results of literature [

21,

22]. In the process of moving downward from the bag mouth, the cleaning airflow expanded and diffused outside the filter bag. Since the cleaning airflow could not be infinitely expanded, and the consumption and energy loss of the cleaning airflow accompanied the whole process, it was inevitable that there would be a maximum pressure on the side wall of the filter bag. After the maximum pressure occurred, the expansion effect of the cleaning airflow decreased and the energy attenuation increased. Later, the peak pressure on the filter bag decreased. The peak pressure at P8 was larger than that obtained at P7, which was likely caused by the refluxing of the cleaning airflow.

According to

Figure 9a and

Figure 10, with an increase in the venturi throat diameter, the peak pressure on the filter bag increased and the peak pressure arrival time decreased. This indicates that a better cleaning effect can be obtained by increasing the throat diameter of the venturi. This may be explained by the fact that the smaller the venturi throat diameter, the greater the resistance of the clearing airflow (the primary airflow + the secondary airflow) passing through the venturi, which led to the greater energy loss of the cleaning airflow, thus making the peak pressure smaller and the peak pressure arrival time greater.

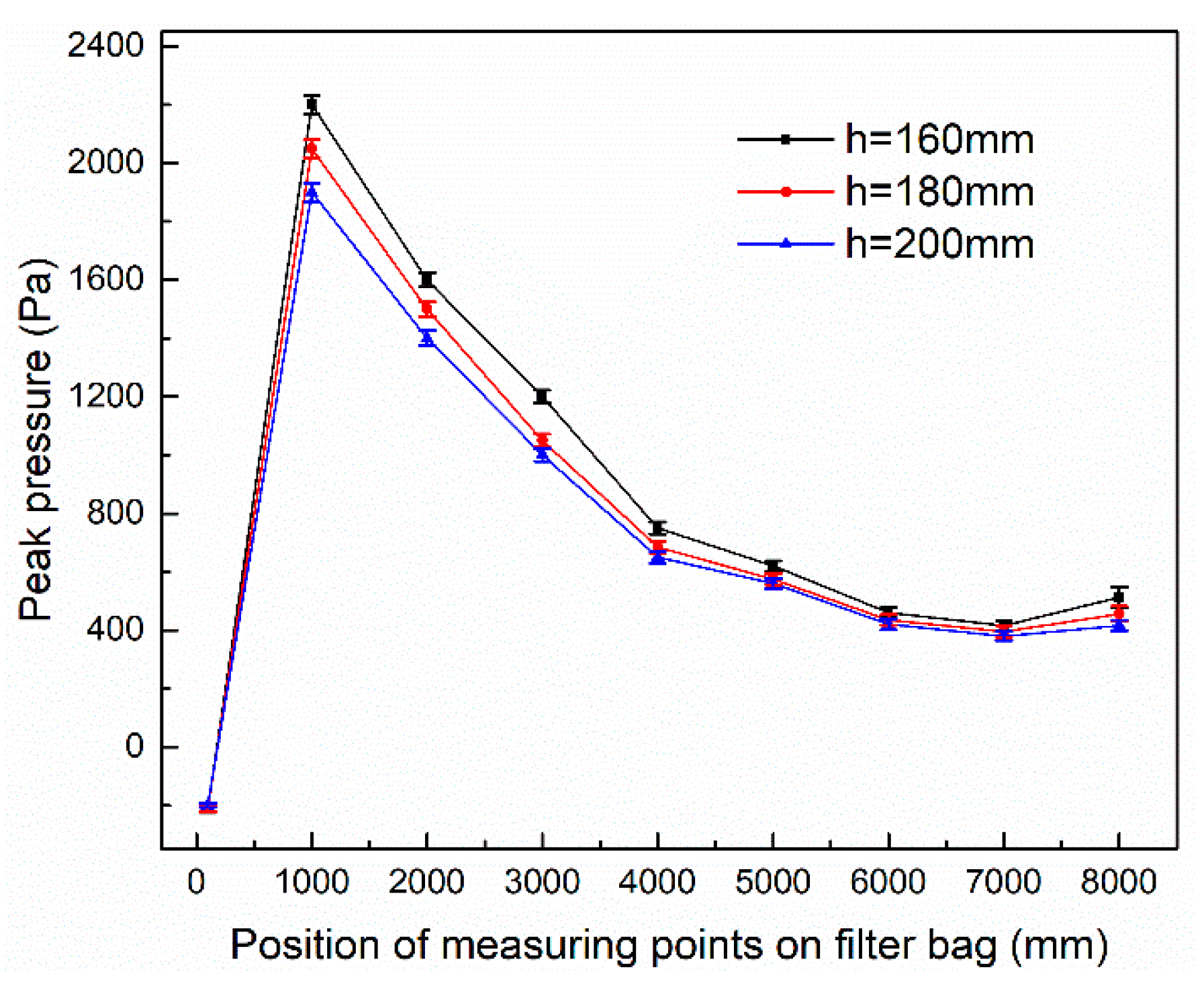

Figure 11 and

Figure 12 show the influence of different venturi lengths (160, 180, and 200 mm) on the peak pressure and the peak pressure arrival time, respectively. Experiments were run at a pulsing air pressure of 0.4 MPa, pulsing air injection time of 100 ms, and a venturi throat diameter of 60 mm. According to the results, as venturi tube length decreases, the peak pressure increases; however, the peak pressure arrival time decreases. This suggests that it is possible to improve the cleaning effect by reducing the length of the venturi tube. In addition, when reducing the venturi length, a larger effect was observed on the peak pressure in the upper half of the filter bag, compared to that in the second half. On the contrary, a more significant effect was observed in the lower half of the bag for the peak pressure arrival time under the same reduced-venturi length condition. This occurred because, for the cleaning airflow, the venturi tube is a resistance component. The longer the venturi tube, the longer the distance the cleaning airflow moves in the tube, and the greater the energy loss of the cleaning airflow. Thus, the peak pressure on the filter bag decreases and the peak pressure arrival time increases. In addition, according to the test results, when the cleaning pressure in point P4 (4000 mm) reached its peak value, the injection of compressed pulsing air was not finished (100 ms). This indicates that the increase of the cleaning pressure on the upper part of the filter bag was within the time range of the continuous action of the compressed air, which made the velocity of the cleaning airflow in the upper part of the filter bag very large, so that the time for the the cleaning airflow to reach the P0~P4 point under different venturi tube lengths was almost the same. Thus, the peak pressure for the upper half of the filter bag with different venturi tube lengths was reached at the same time, but the peak pressure was quite different (especially for P1). For the lower half of the filter bag, the longer the length of the venturi tube, the greater the energy loss of the cleaning airflow, and the longer the time for the cleaning airflow to reach the P5~P8 point, which made the peak pressure smaller and the peak pressure arrival time greater.

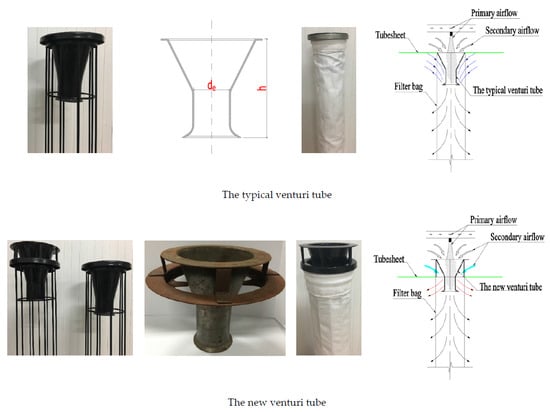

3.3. Effect of the New Venturi-Type on the Cleaning Performance of the Filter Bag

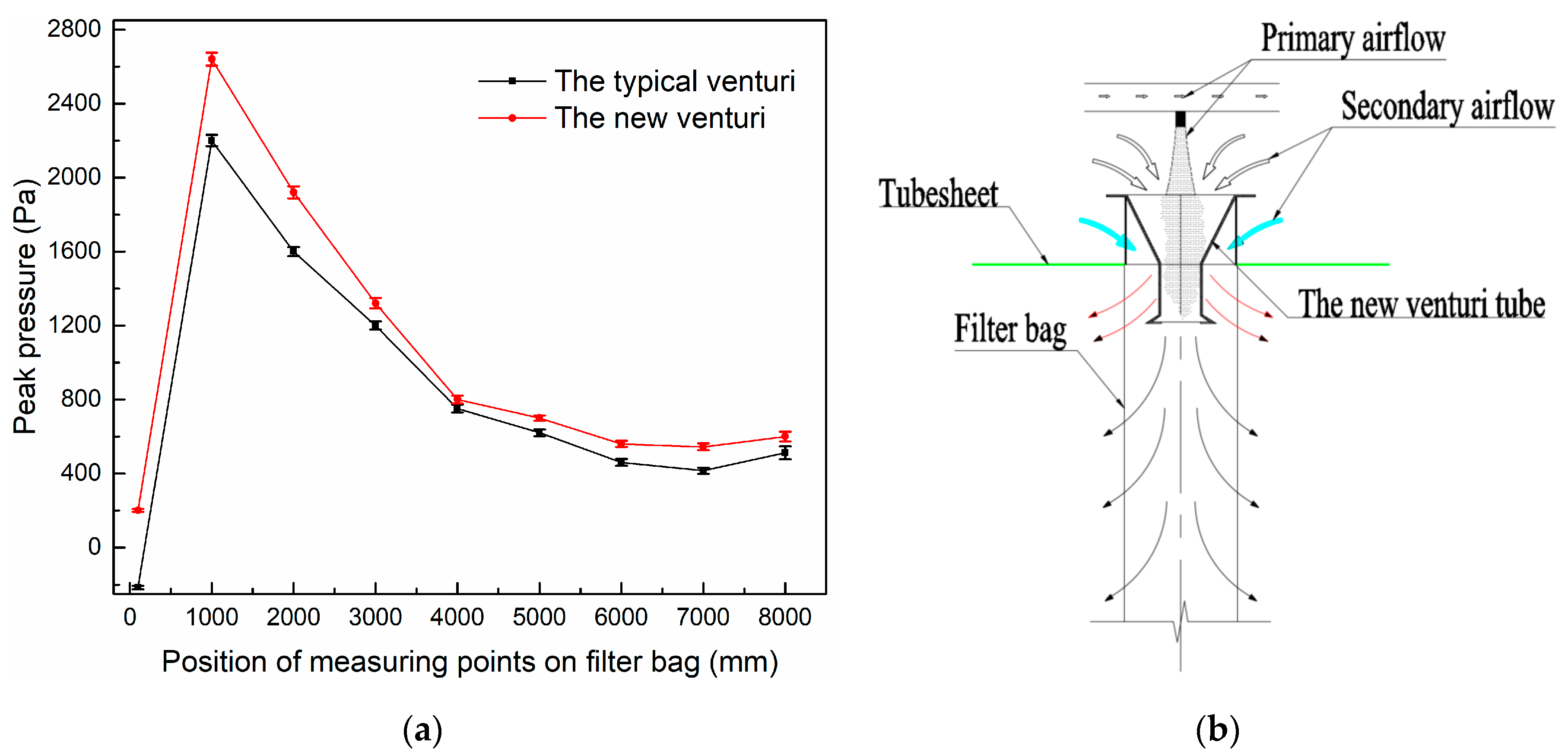

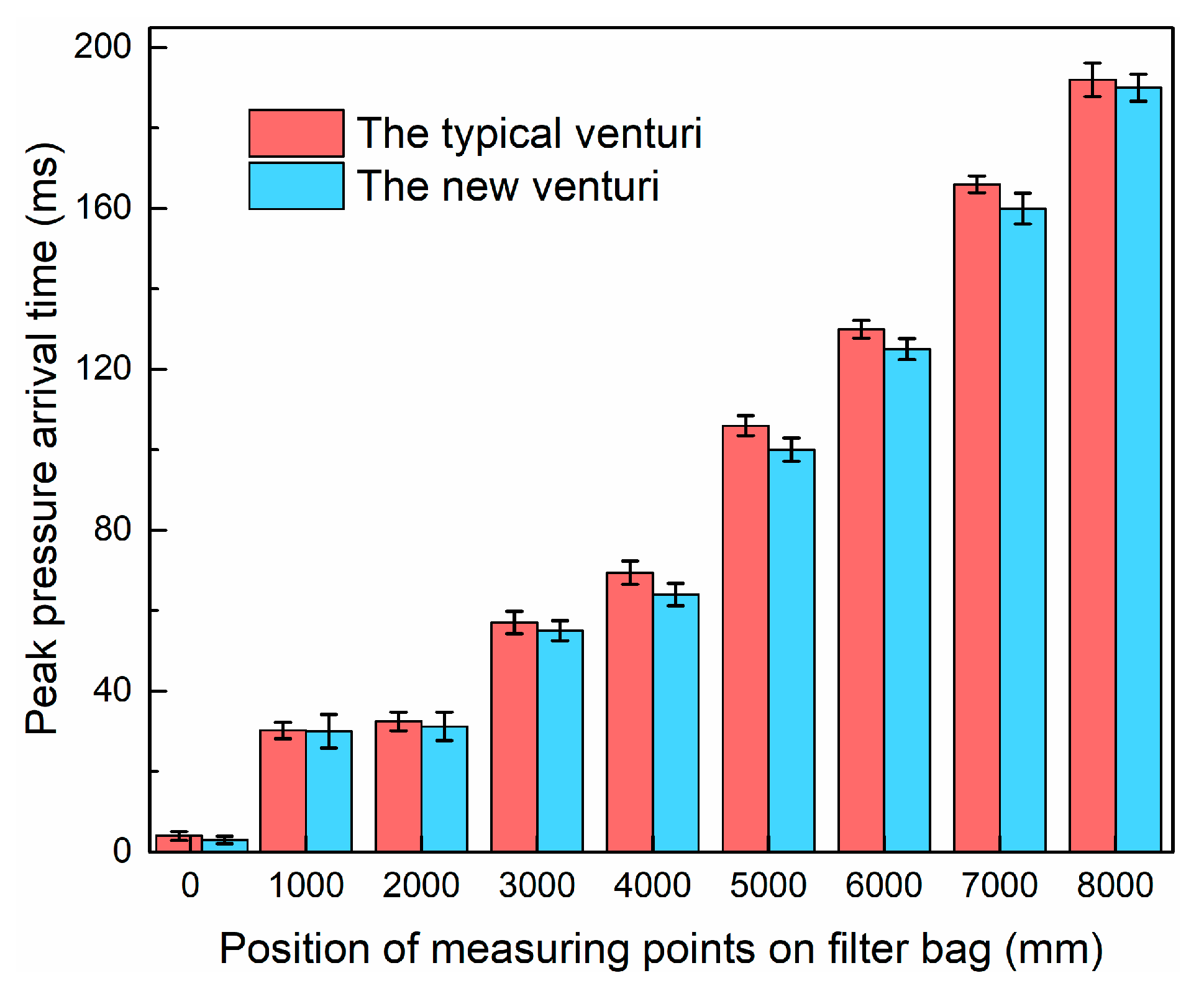

Figure 13a and

Figure 14 display the results for the effects of two types of venturi tubes on the cleaning performance of the filter bags. Experiments were performed at a pulsing air pressure of 0.4 MPa, a pulsing air injection time of 100 ms, and a venturi throat diameter and length of 60 mm and 160 mm, respectively. Data showed that, when using the new venturi tube and for every measuring point, the peak pressure was higher and the peak pressure arrival time was shorter compared to the values obtained when using the typical venturi tube. The filter bag with the new venturi displayed a positive peak pressure at P0 (200 Pa). It is obvious that this new tube had an effect on the peak pressure in the area near the filter bag mouth. Since the new venturi was placed at a higher height compared to that for the typical venturi (as shown in

Figure 2), when a compressed airflow (primay airflow) was injected into the new venturi, two streams of secondary airflow near the bag mouth were generated. As shown in

Figure 13b, the secondary airflow that is above the inlet enters the venturi, mixes itself with the primary airflow, and is later ejected. On the other hand, the secondary airflow that is below the venturi inlet enters the filter bag through the side of the venturi, and later mixes itself with the cleaning airflow at the venturi outlet. Therefore, when the new venturi was installed, the area near the bag mouth was impacted from the inside to the outside of the bag by the secondary airflow. This produced a positive peak pressure in P0. In addition, given that in the new venturi the secondary airflow was larger than that in the typical venturi, the peak pressure observed at P1 in the filter bag adapted with the new venturi was significantly higher than that where the typical type venturi was installed. In this case, the value increased by about 440 Pa. Data also demonstrated that, when the flow rate of the secondary airflow increased, the new venturi did not extend the action time of the secondary airflow on the lower half of the filter bag. This effect was different to that obtained when the pulsing air injection time was increased. Therefore, the peak pressure arrival time on the filter bag with the new venturi was shorter than that observed when using the typical venturi-type (See

Figure 14).

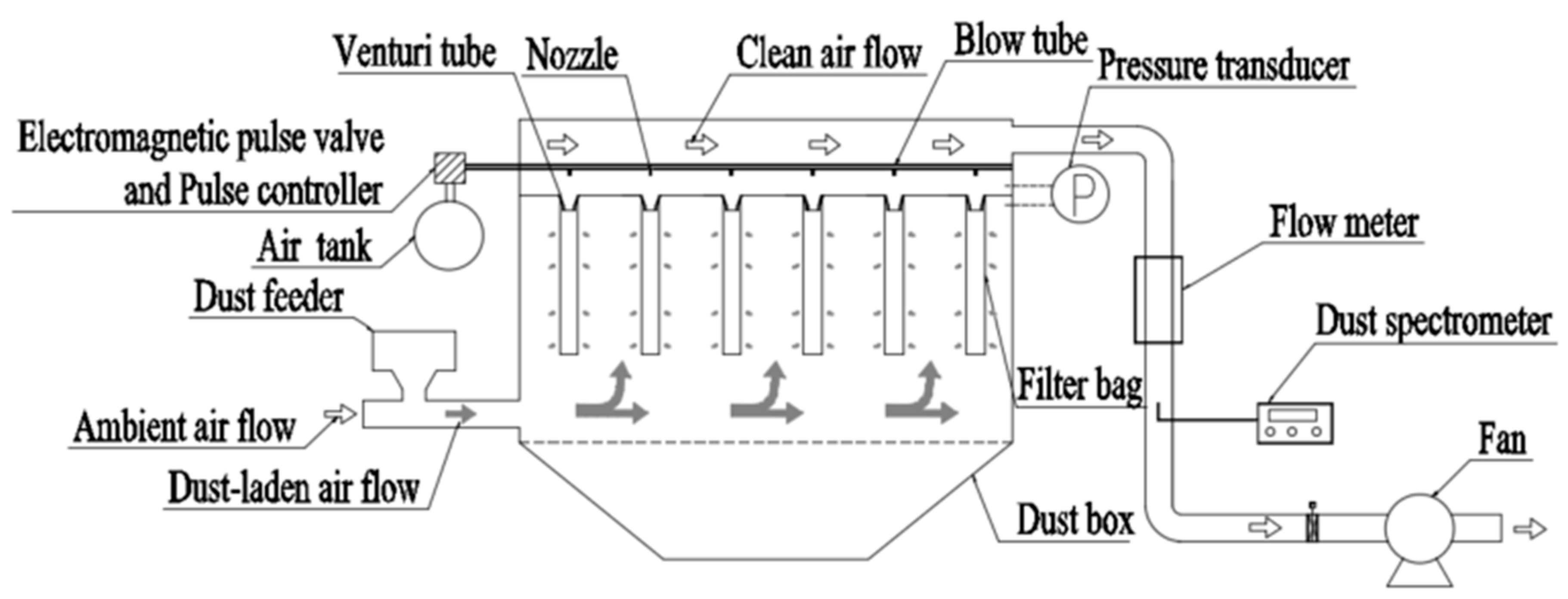

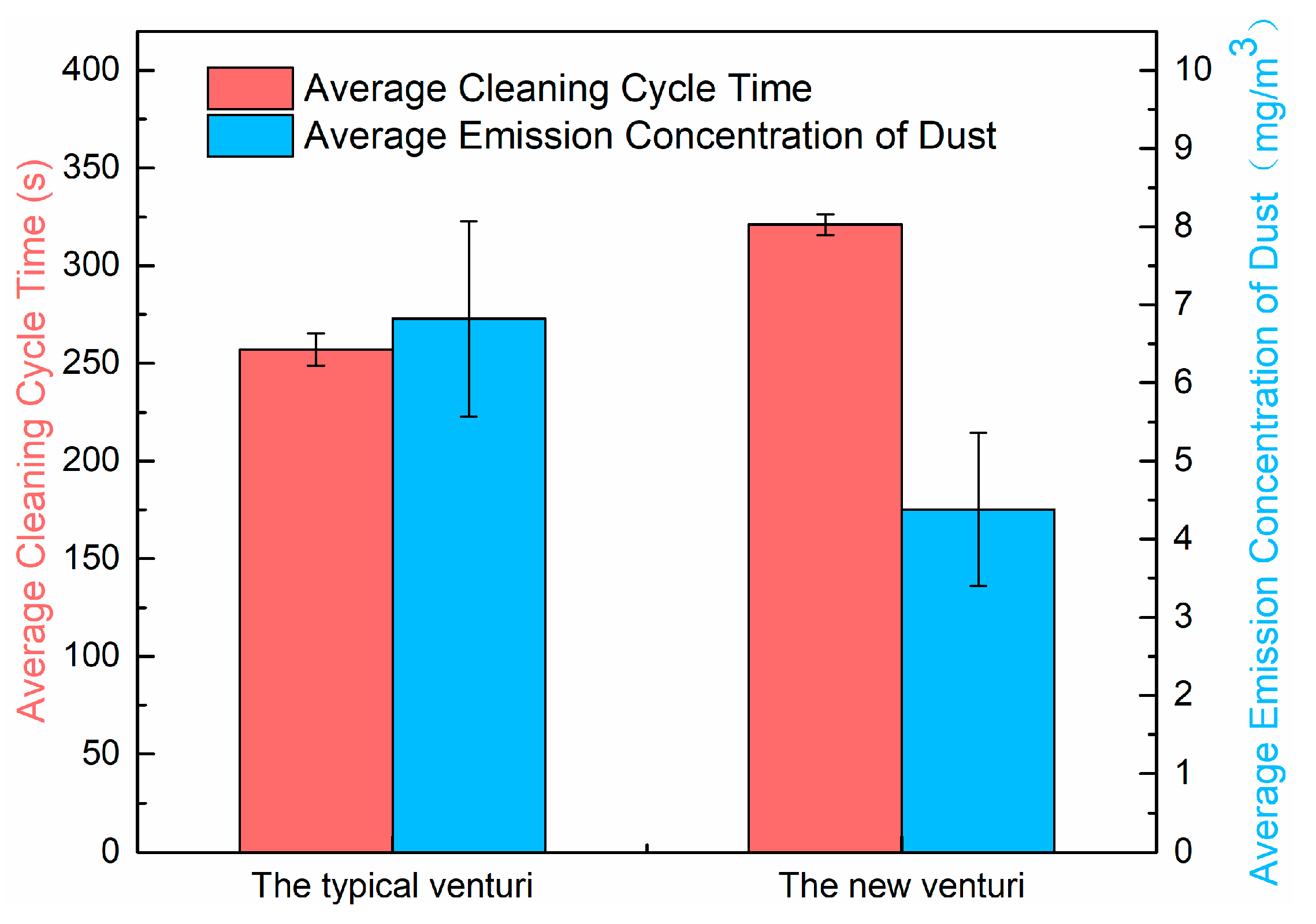

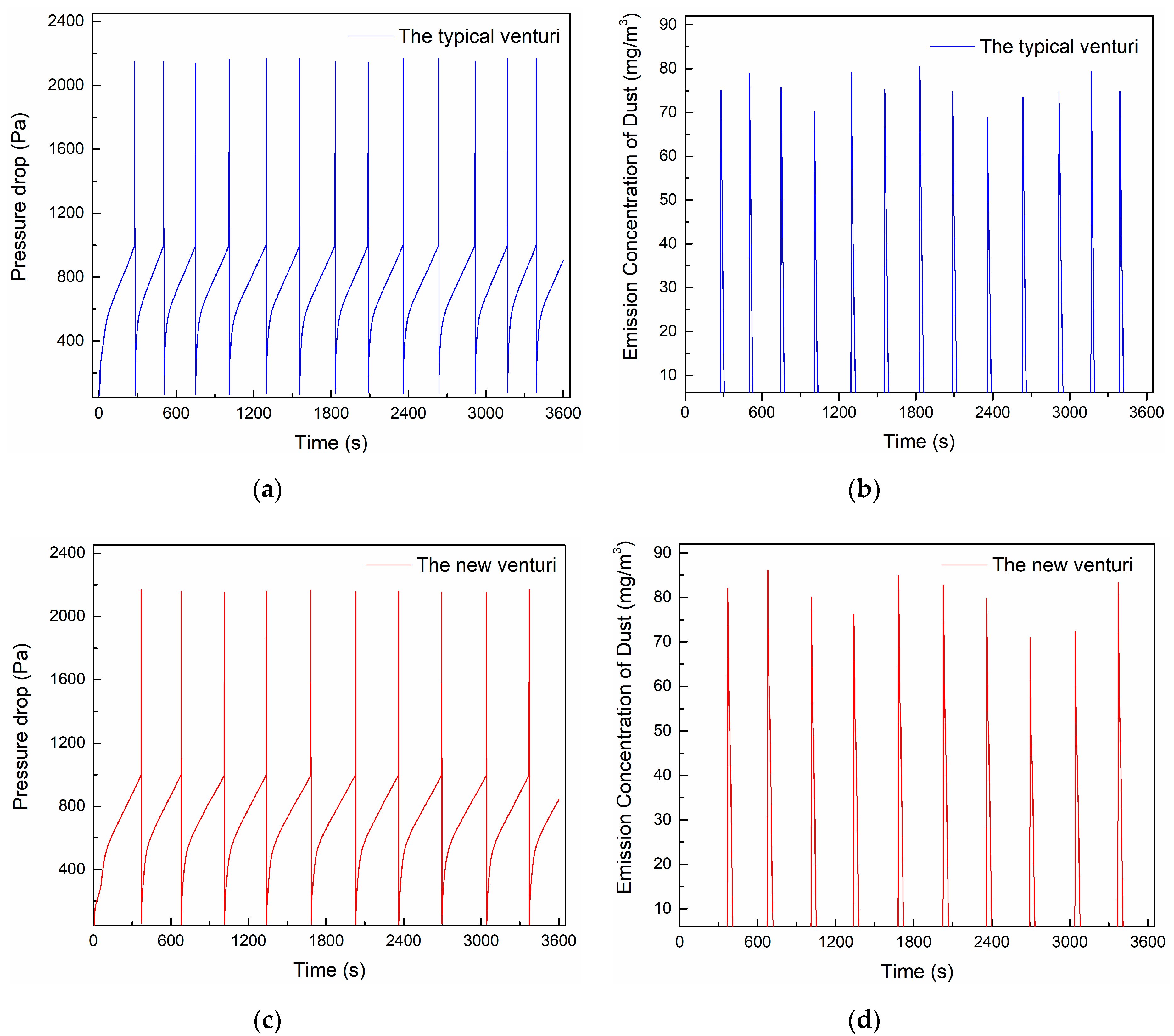

3.4. Effect of the New Venturi-type on the Baghouse Cleaning Performance

Experimental results for the cleaning cycle time and dust emission concentration of baghouses adapted with the typical or the new venturi tubes are shown in

Figure 15. In these experiments, the pulsing air pressure was set to 0.4 MPa and the pulsing air injection time to 100 ms. According to the data, the average cleaning cycle time of the baghouse with the new venturi (321 s) was significantly longer than that of the baghouse with the typical one (257 s). The test conditions of the two groups were identical, which indicated that the baghouse adapted with the new venturi displayed better dust cleaning performance. In this new tube, the cleaning airflow was more efficient in removing the dust cake deposited on the filter bag. Therefore, after dust cleaning, the baghouse installed with the new venturi displayed lower resistance, and the cleaning cycle time increased. Thus, compared to the baghouse with the typical venturi, the one with the new venturi tube showed longer cleaning cycle time, less compressed air consumption, and lower dust cleaning energy consumption during the same filtration time. In addition, the average dust emission concentration was lower in the new venturi baghouse (4.38 mg/m

3), compared to the typical one (6.82 mg/m

3). These results may indicate that the new venturi baghouse displayed a better control effect on dust emission. A potential explanation for this phenomenon is as follows: the cleaning airflow might have destroyed the dust cake deposited on the filter bag. In consequence, the filter bag was exposed to the dust-laden airflow. Shortly after the cleaning and before the dust cake was redeposited again, an instantaneous peak of the dust emission concentration occurred [

23,

24,

25]. During the 1-h test period, the baghouse with the typical venturi showed a shorter cleaning cycle and more bag cleaning times (as shown in

Figure 16). Additionaly, the number of peak values for the dust emission concentrations, the dust leakage quantity, and the dust emission concentration were higher. Additionally, in the new venturi-type design, the dust cleaning pressure in the area near the mouth of the filter bag was changed into a positive one. This allowed a more effective removal of the dust cake deposited near the mouth of the filter bag (

Figure 13b). Thus, compared to the baghouse adapted with the typical venturi-type (as shown in

Figure 9b), the former displayed a larger filtration area. This was one of the reasons for the low dust emission concentration of the baghouse installed with the new venturi.