1. Introduction

Pineapple is a tropical fruit rich in nutrients; it is highly valued in international markets because of the fabrication of agro-industrial products and because it can be planted all year long with good irrigation systems. This tropical fruit was second place in worldwide production at 28% in 2017, along with mango, avocado and papaya, it had an average annual growth of 3.6%; Costa Rica is its main exporter [

1].

The use of this fruit leads to different products such as dried pineapple, juice, nectar, pulp, frozen pineapple, gelatin, marmalades, candy and vinegar [

2]. The fruit is made up of pulp, its most useful part, and a rind, crown and core, which are waste. This waste makes up 65% to 67% of the total weight of each pineapple produced [

2,

3].

Therefore, direct dumping of this organic waste leads to multiple different negative environmental impacts such as soil and water pollution through the filtration of leachates it generates [

4]. To avoid this, waste may be reused or submitted to physical, chemical, biological, thermal or mixed treatments, among which we can find feeding animals, crushing, composting, anaerobic digestion and vermicomposting.

Of the treatments mentioned, vermicomposting is presented as a viable alternative to degradation and stabilization of organic matter, as it results in excellent quality humus that provides immediate results due to the fact that plants absorb its nutrients faster [

5]. Because this is an affordable and sustainable option for the use of the aforementioned organic waste and a practice that seeks better organic matter content, it is one of the best options as a substitute for conventional fertilizers that can be harmful to soil [

6].

The literature consulted shows few studies on treatment of pineapple waste, especially through the vermicomposting process [

7]; what is referred to as waste in these cases consists of pineapple rinds, but not crowns and cores. Not enough information has been reported on the pre-composting process for this type of waste and even though there are some studies on vermicomposting that include all pineapple waste, it is necessary to study the different mixtures available along with other types of waste so as to enrich and balance nutrients, thus verifying the feasibility of the degradation process for this fruit.

Taking all this into account, the main objective of this research is to determine operational conditions for the degradation of different mixtures of pineapple waste along with other materials through pre-composting and vermicomposting at laboratory level.

2. Materials and Methods

2.1. Characteristics of the Substrate

2.1.1. Pre-Composting

The substrate was made up of pineapple waste (rinds, crowns and cores) only, however, by separation from other waste (vegetable waste from lettuce, chard, cabbage, spinach, celery, cress, broccoli and egg shells), which is called “load material” for this work.

2.1.2. Vermicomposting

The substrate was made up of pineapple waste and load material that was obtained from markets, bakeries and restaurants in the study area. For this research, 10 kg of pineapple were used, finely chopped to make degradation easier [

5,

8] and 10 kg of vegetable waste was added along with 1 kg of eggshells as loading material [

9]. Vegetable waste was also chopped and the eggshells were washed with soap and water and were allowed to dry in sunlight for 24 h [

10] and were later crushed in a sealed bag with a rolling pin.

2.2. Pre-Composting Process

A 11.4 L plastic vessel was used as a reactor and it was perforated at the bottom to allow the filtration of the leachate, which was collected in a second vessel. The upper part of the reactor was covered with a mosquito net to avoid the presence of insects and rodents.

For the development of the pre-composted material, the diced pineapple waste was kept in a reactor during a previously decided span of 30 days, which is a function of the material’s characteristics so as to be able to go on to the process of vermicomposting. The reactor’s operation type was intermittent, that is to say, the material was added and mixed in perfectly, allowing it enough time for the reaction to take place [

11]. Every third day, the waste was sprayed with clean water to maintain it within the required range of humidity [

12]; to assure this, the ‘fist test’ was used [

13]. This is a practical method that involves taking a sample of the substrate in your hand and squeezing, no water must come out from in between your fingers, and you should be left with a brittle lump in your hand. The reactor was placed at an approximate 5% inclination to make drainage of the leachate towards its container easier.

Waste was mixed every three days to allow it to aerate and to avoid compacting the homogenized substrate sample [

8], every week changes were observed in the sample’s physical conditions. The reactor used to treat the load material was also a plastic container with a diameter of 70 cm and a height of 17 cm. The bottom of this vessel also had perforations to allow the filtration of the leachate, which was collected in another plastic vessel beneath it. As with the pineapple, netting was placed over the top. Pre-composting of the load material took place three days before it was incorporated in the vermicomposting process due to the high rate of degradation of the vegetable waste used [

14].

2.3. Vermicomposting Process

For these process four reactors were used. These were plastic vessels with the dimensions 32 cm long, 9 cm wide and 20 cm high, with a total volume of 5.76 L. The bottoms of these vessels were perforated as well to allow the escape of leachates that were collected in other containers with netting covers.

A first layer of soil was added to each of the four reactors [

15]; this layer was 1 kg and was distributed 3 cm deep. Afterwards the mixtures of pineapple waste (PW) and load material (LM) were prepared and weighed with the following proportions.

Afterwards, the pineapple waste layer and the load material were added to each reactor, at a depth of approximately 5 cm, depending on the necessary amounts in each reactor to comply with the aforementioned proportions for the mixes.

Earthworms (

Eisenia foetida) were added to reactors M1, M2 and M3, with the exception of reactor CR, due to its use as a control sample. In addition, for each reactor 3 kg of waste were included. The number of earthworms necessary was then calculated approximately 60 days from the start of the process; each earthworm has an estimated weight of 0.75 g and taking into account that each earthworm can degrade its own approximate weight in waste per day [

16]; this resulted in an amount of 50 earthworms per reactor. The waste was then mixed manually to assure homogenization [

8], it was sprayed every third day to maintain an adequate degree of humidity in the reactors, using the “fist test” as in the pre-composting process. Every three days the substrate was manually mixed for aeration, which assured the earthworms were feeding uniformly on the organic waste. This operation in the reactors was intermittent, as during the pre-composting process.

2.4. Physicochemical Parameters and Sensory Specifications

During the pre-composting and vermicomposting processes temperature, pH, humidity, organic matter, total organic carbon and total nitrogen were determined in triplicate and the sensory characteristics (colour and smell) were also registered at the beginning, during and at the end of the process as per local norm, that establishes vermicompost (worm casting)—specifications and test methods [

17,

18,

19].

2.5. Statistical Analysis

Data generated (organic matter, total organic carbon and total nitrogen) were subjected to analysis of variance (ANOVA) and pair wise comparison using the Tukey test (p < 0.05). The JMP 8.0 Software Package program was used.

3. Results and Discussion

3.1. Pre-Composting Process

3.1.1. Temperature

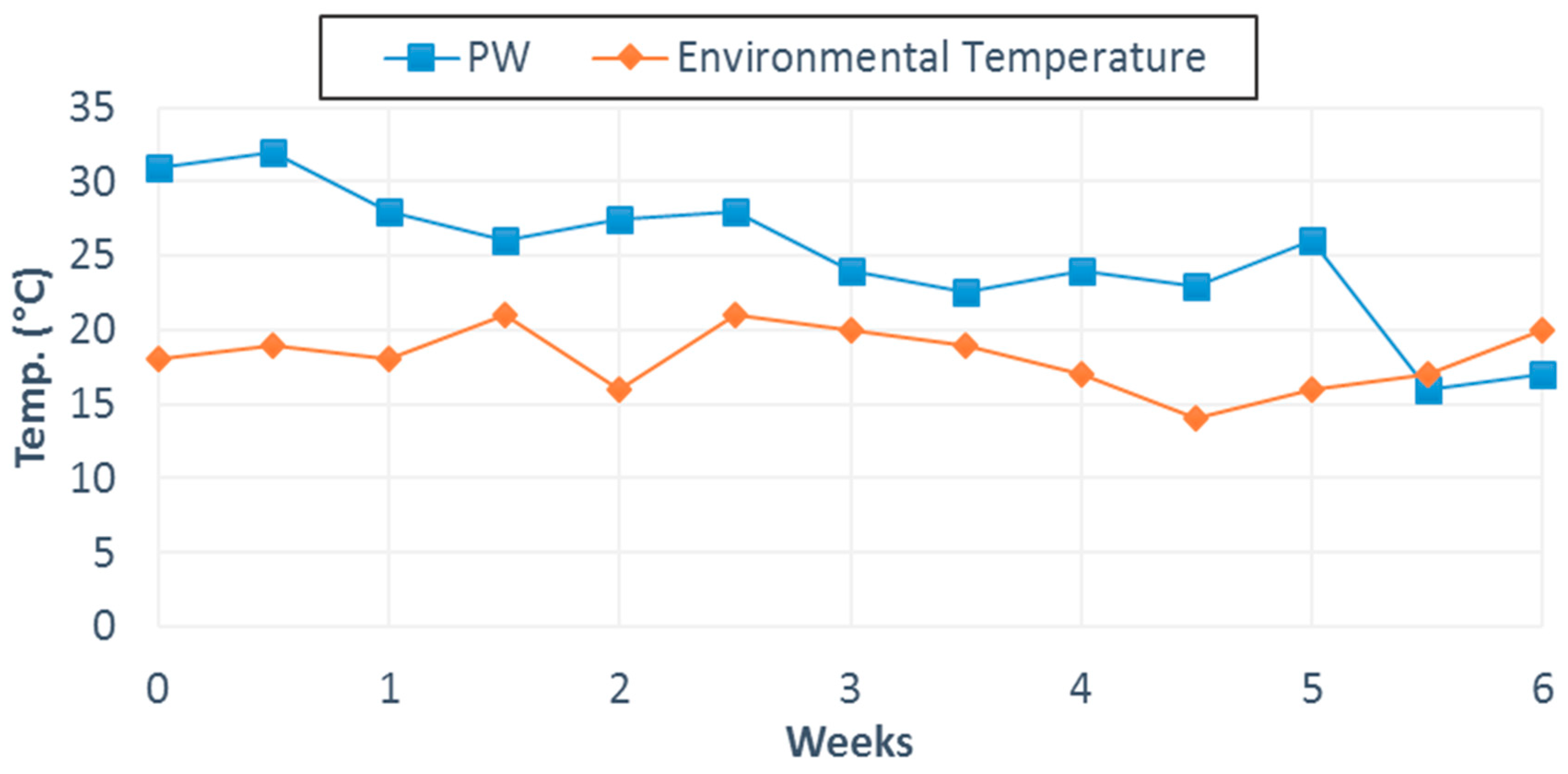

The temperature behavior of the pineapple waste, along with environmental temperatures in the 6 weeks that made up the pre-composting process can be observed in

Figure 1. An initial value of 30 °C can be observed; within the first few days this value increased to 31.5 °C, it later decreased to 27 °C between the first and second week. The waste’s temperature was maintained at an average with a gradient difference of 4 to 7 °C above environmental temperature (14 to 21 °C); this was caused by heat generated by the waste due to microbial activity [

20,

21]. Starting on the third week, waste temperature decreased toward values closer to environmental temperature, indicating a tendency toward stabilization, which is in agreement to what is reported by [

8,

22,

23], who state that during the last weeks of the process, the temperature decreases until it reaches environmental temperature. During the pre-composting process, temperature values of the waste were found within the range of 18 to 55 °C reported by Acosta et al. [

24] and Nair et al. [

25].

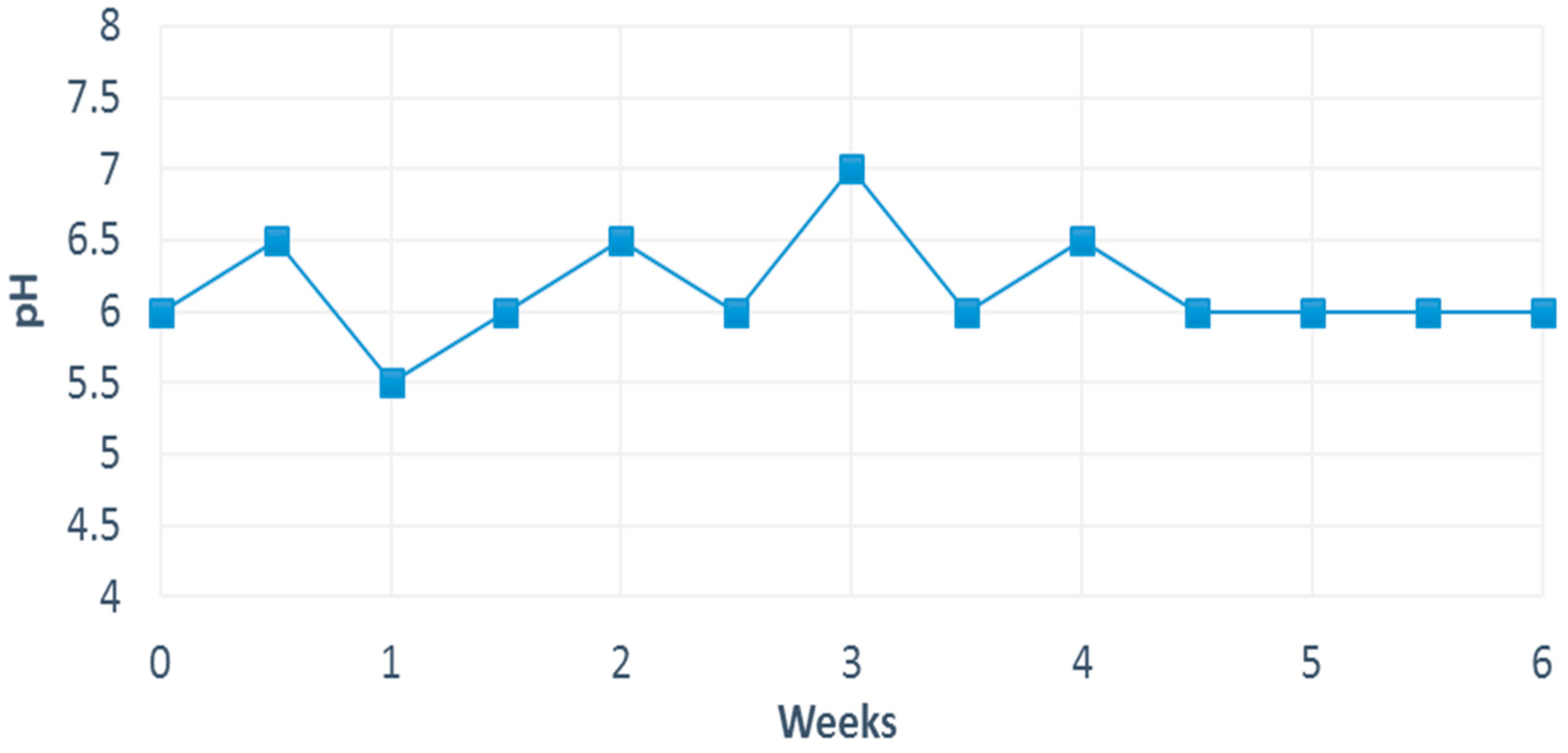

3.1.2. pH

Figure 2 shows pH behavior of the pineapple waste during pre-composting, and an initial value of 6 was observed. During the first days pH decreased to 5.5 due to the generation of organic acids and a consequent production of CO

2 [

20] and later increased to 7 as a result of the conversion of organic nitrogen to ammonium and ammonia, producing a certain degree of alkalinity to tend toward stabilization due to the fact that pH rises and the waste is alkanized to finally be stabilized in values close to neutral [

8], whereas other authors mention that a progressive alkalinization of the waste is produced, due to the loss of organic acids and the generation of ammonia originated from protein decomposition and in the last phase the pH tends to neutral values due to the formation of humic compounds which have buffer properties [

20].Throughout the pre-composting process, pH was maintained within the range of 5.5 to 8.5 [

8,

24,

26].

3.1.3. Humidity

Figure 3 shows humidity behavior during the pre-composting period, results initially showed a value of 80%; humidity was maintained between 79 and 82.8% during the process, which coincides with values reported by literature [

25,

27]. Humidity is an important control parameter in the process due to the fact that values outside of the reported range may generate anaerobiosis if it is excessive, whereas a lack of humidity inhibits the microorganisms involved in the pre-composting process [

8].

3.1.4. Organic Matter (OM)

The initial content of organic matter (OM) in the pineapple waste was 85.1% (

Table 1), similar to the 84.8% to 96.1% range for waste made up of banana peels and vegetables [

28]; the 82.8% to 90.2% for sugar cane bagasse [

29] and 82.6% for tomato cultivation waste [

30]. At the end of the process, OM content was reduced to 68.88% due to mineralization and carbon loss, therefore leading to a removal efficiency of 19.06%, due to the microorganisms’ adaptation phase for the degradation of substrate, which is characteristic of this type of preliminary treatment to waste. Additionally, the low removal could have taken place due to the pineapple crowns within the waste that are made up of a cellulosic material that is slow to degrade [

31]. Huang et al. [

28] obtained a final vlue of 39.1% of OM, for which the removal efficiency was 56.77%.

3.1.5. Total Organic Carbon (TOC)

The fresh waste’s initial TOC percentage was 49.36% (

Table 1), close to the 43.3% to 46% for vegetables and greens [

32] and between the 47.68% to 51.33% for rice straw and paper waste [

33]. At the end of pre-composting, the TOC value was 39.95%, therefore the removal percentage was 19.06%, similar to removal efficiencies determined by [

34,

35]. Other authors report that at the end of the process, they obtained TOC values within the range of 33.8% to 35.7%, with a removal efficiency of 21.93%, similar to the value obtained in this study. [

32]. The decrease in the carbon content was the result of the organic matter mineralization by the microorganisms [

36,

37,

38]. In the literature consulted a study which presented an initial value of 31. 8% for domestic and gardening waste was found and at the end of the pre-composting it reported a value of 27.1% having as a consequence a removal efficiency of 14.77% [

34].

3.1.6. Total Nitrogen (TN)

The pineapple waste’s initial total nitrogen concentration was 3.1% (

Table 1), similar to the 2.7% values for tomato waste [

30] and 2.38% for fruit and vegetable waste [

15]. At the end of the pre-composting process, the concentration obtained was 1.5%, and therefore TN removal was at 51.61%. This decrease was originated due to the dragging of TN in the leachate generated during the process. Pérez et al. [

35] and Lazcano et al. [

39] also found a reduction of TN within the pre-composting process.

3.1.7. Carbon/Nitrogen (C/N) Relation

Carbon/nitrogen (C/N) relation at the end of the pre-composting process was 26.63 (

Table 1) due to the low removal of organic carbon because it is a preliminary treatment. In a study of thermophilic pre-composting for domestic waste, Frederickson et al. [

40] found a C/N relation of 34. Furthermore, Nair et al. [

25] found values between 25 and 30 after a pre-composting of kitchen waste. The ideal initial relationship for the development of vermicomposting is in the range of 20 to 35 [

5]. Therefore, the C/N relation obtained in the pre-composting process has the required values to allow the waste to be processed through vermicomposting.

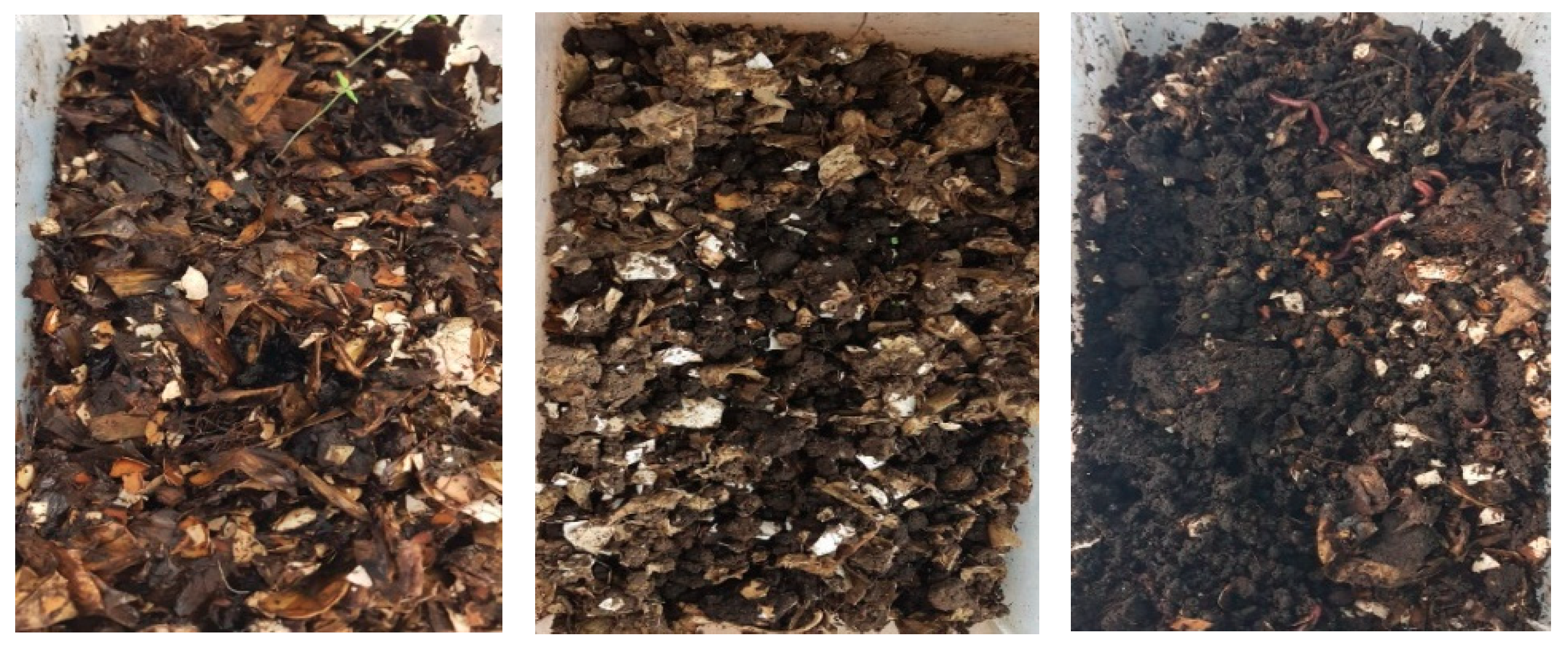

3.1.8. Sensory Characteristics of Pre-Composting

Figure 4 shows three images of pineapple waste during the pre-composting process, the original substrate was yellow to light brown in color, as time went by it turned to a dark brown color. These characteristics are in accordance with López and Sainz [

41] who have indicated that the end of the process leads to a dark colored organic matter originated by heat absorption due to its degradation. At the beginning of the experiment, pineapple waste gave off penetrating odors, with time these smells dissipated, leading to an odor free product at the end of the pre-composting process, it also presented a porous texture as in FAO [

8].

3.2. Vermicomposting Process

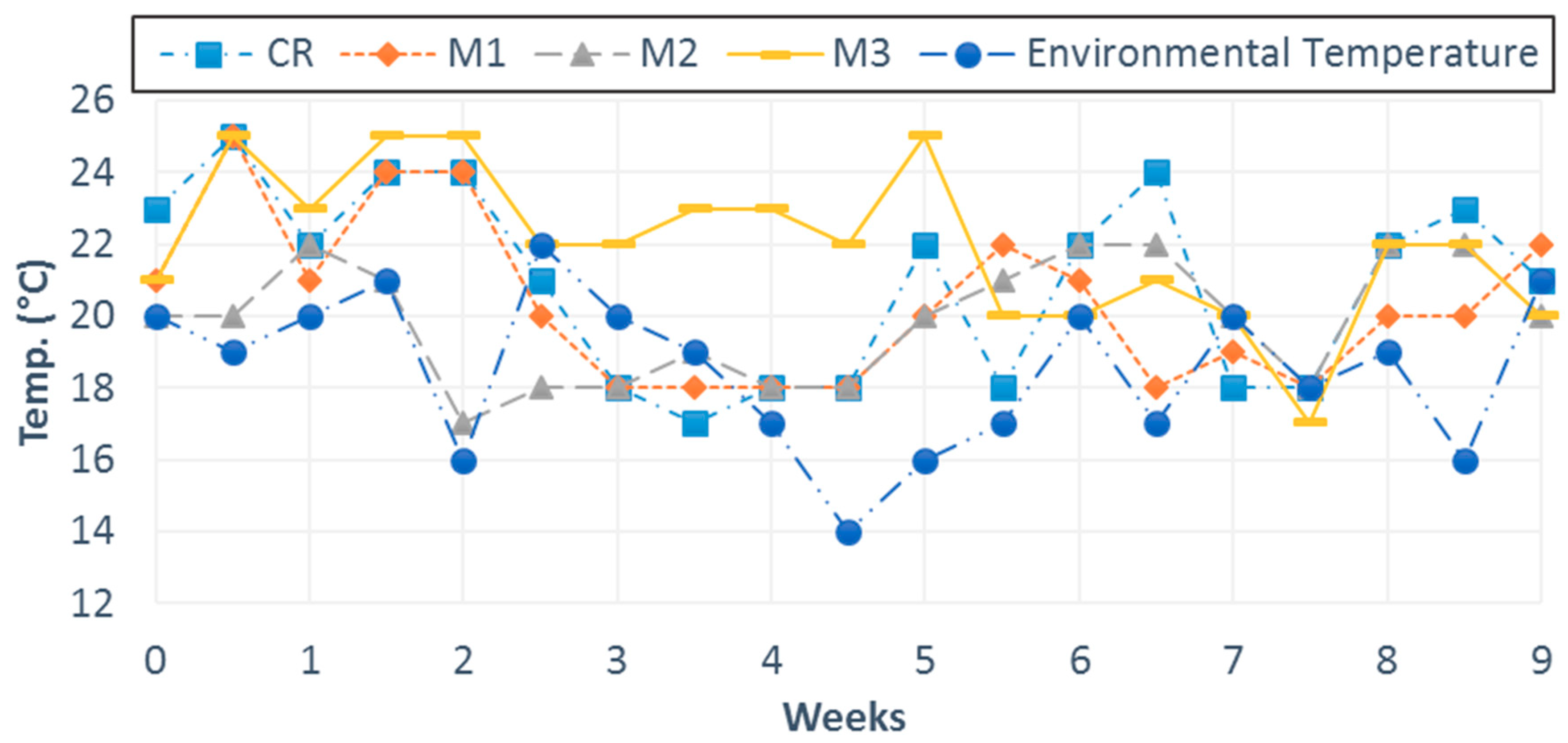

3.2.1. Temperature

Figure 5 shows temperature behavior during the 9 weeks of the experimental vermicomposting process; the initial temperature of the four mixes remained between 20 and 23 °C while environmental temperature presented an initial 20 °C value. The temperature range for this process was less than what was shown during pre-composting; this too coincided with information reported by Jack and Thies [

42], who mentioned the temperature during the pre-composting process is higher due to microorganisms generating heat.

Temperatures for this experiment were maintained between 15.5 and 25 °C and these values were found to be among the range where

Eisenia foetida can grow and reproduce from 12 to 35 °C as reported by various consulted authors [

5,

43,

44,

45,

46,

47,

48,

49,

50,

51,

52].

Environmental temperature (14 to 22 °C) was maintained beneath the temperatures registered in the waste mixes and was equaled at the end of the vermicomposting process, indicating its stabilization. Therefore, the variations and values registered for temperature during the process were favorable for earthworm development.

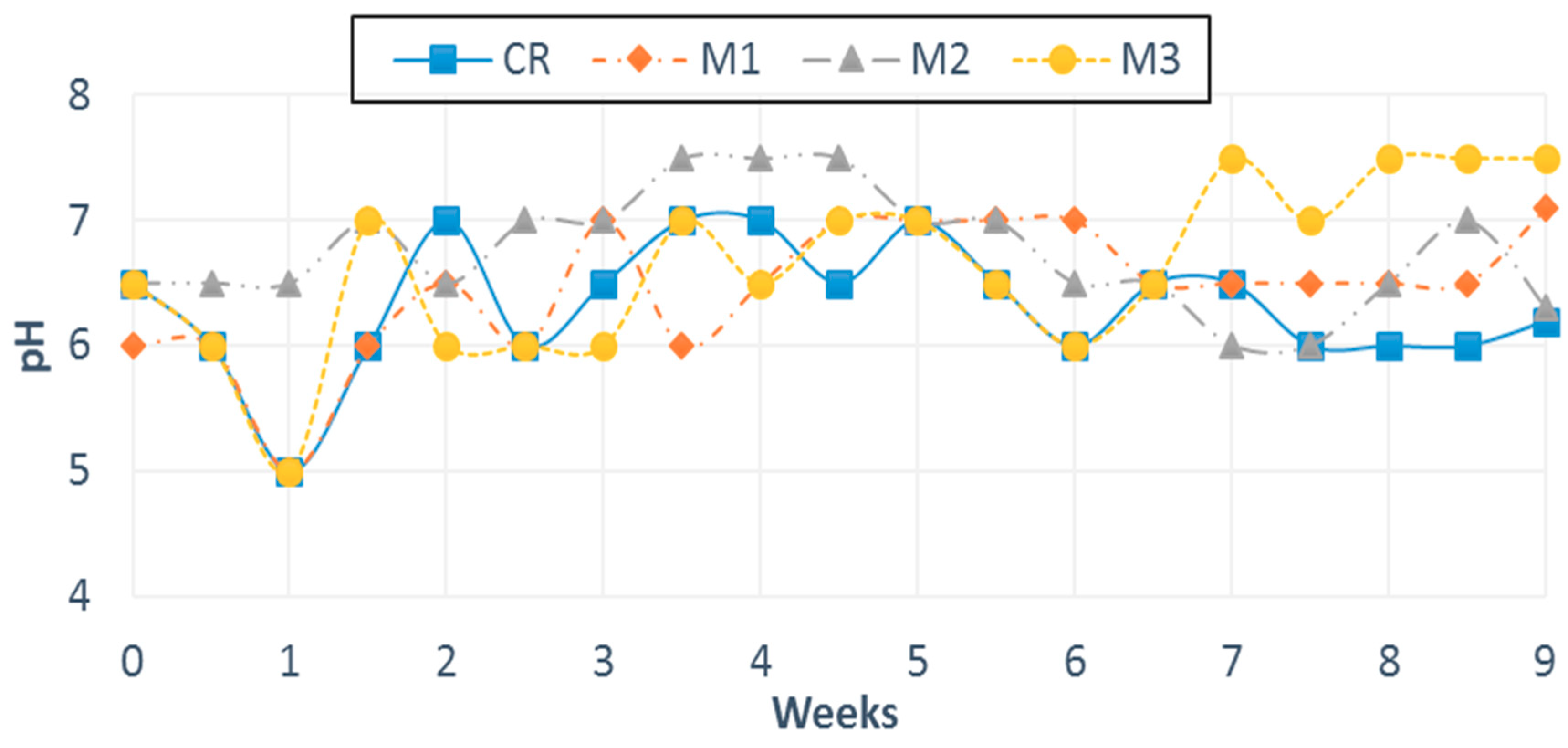

3.2.2. pH

pH behavior of the different pineapple waste mixtures during the vermicomposting process is shown in

Figure 6. The initial pH values for the reactors were 6.5 (CR); 6 (M1); 6.5 (M2) and 6.5 (M3) within a neutral range. pH levels dropped in all mixes except M2, which remained constant, during the first week. Later pH values increased, remaining above 6, which indicated a probable mineralization of protein process with the generation of ammonia [

32], to continue in a range between 6 to 7, as opposed to M2 that increased up to 7.5 between weeks 3 and 5 to drop down later. The last weeks the M3′s pH level increased to 7.5, whereas the rest remained between 6 and 7. pH values for all four reactors during the vermicomposting process remained within the 5 to 7.5 range, which coincided with other consulted studies [

38,

50,

53,

54,

55,

56]. Final pH values for reactors M1, M2 and M3 (7.1, 6.3, 7.5 respectively) were above that of the CR (6.2), possibly due to intestinal calcium found in the earthworms that can stabilize pH levels [

48]. Therefore, pH levels showed evidence of stability in the degradation process via vermicomposting [

57].

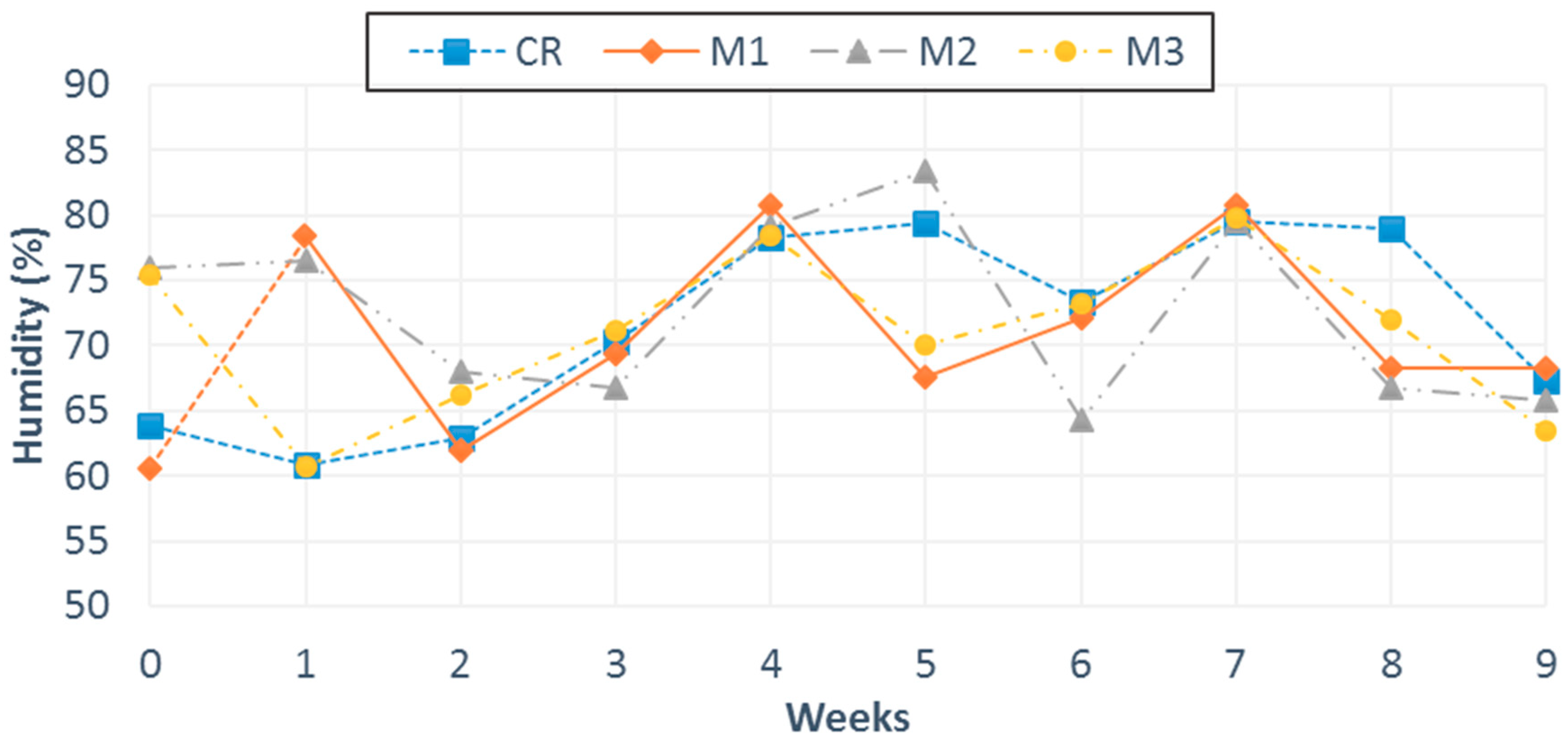

3.2.3. Humidity

Figure 7 shows humidity behavior in the four samples during the vermicomposting process, where it can be appreciated that it remained between 60% and 83.3%, which is within the 50% to 90% range reported by different authors [

5,

45,

48,

49,

50,

52,

56,

58,

59,

60]. If the humidity is above this range, undesirable anaerobic conditions are favored [

5]. Moisture is critical for the survival of earthworms because it facilitates the absorption of oxygen, in addition, this parameter is important because it evaporates easily inside the body cavity’s earthworm, especially in dry environments [

45,

49]. There is an important relationship between the humidity in organic waste and the growth rate of earthworms [

48].

3.2.4. Organic Matter

Initial values of OM content for all four mixtures were 57.89% (CR) and (M1); 51.46% (M2) and 52.84% (M3) (

Table 2). At the end of the process, final OM values were 31.39% (CR); 32.07%(M1); 32.73% (M2) and 31.39% (M3) (

Table 3) similar to values found for domestic waste within the range of 34.81 and 34.92% [

61], whereas for fruits and vegetables the reported value was of 41.9% [

62]. Based on the aforementioned data, percentages of removal for OM were 45.78% (CR); 44.60% (M1); 36.40% (M2) and 40.59% (M3) showing most of the removal in CR and M1. These values are similar to those reported in literature which are within a range of 30 to 56%, with OM removal percentages which are between 30 and 45% [

30,

49,

62,

63]. The OM contents at the beginning of the vermicomposting process were significantly different between reactors CR and M1 in comparison to reactors M2 and M3, although the final values of OM in all four reactors did not present significant differences. This implies that there was no effect in the reduction of OM due to the differences between the percentages of pineapple waste and the load material in each of the mixes.

3.2.5. Total Organic Carbon

Initial total organic carbon values were 33.58% (CR) and (M1); 29.85% (M2) and 30.65% (M3) (

Table 2); within the 25.45 to 56.07% range [

30,

33,

36,

61,

64,

65,

66]. At the end of the vermicomposting process TOC values were 18.21% (CR); 18.60% (M1); 18.98% (M2) and 18.21% (M3) (

Table 3). These values were found within the range reported in the literature which were 15.75 to 38% [

33,

53,

56,

61,

62,

65]. Based on the aforementioned data, TOC removal percentages in the vermicomposting process for the four mixes were 45.78% (CR) 44.60% (M1); 36.40% (M2) and 40.59% (M3), which coincides with consulted studies [

32,

33]. As is the case with the OM sample, initial TOC contents for all four reactors before the vermicomposting process showed significant differences between CR and M1 reactors with respect to M2 and M3, while final values were not significantly different from each other.

3.2.6. Total Nitrogen

Initial concentrations for all four mixtures at the beginning of the vermicomposting process were 4.25% (CR) and (M1); 3.5% (M2) and 3.7% (M3) (

Table 2), which coincided with various authors [

32,

33,

59,

61,

62,

65]. At the end, concentrations were 1.5% (CR); 1.9% (M1); 1.2% (M2) and 2.2% (M3) (

Table 3). The aforementioned concentrations were found to be within the range established by local norm for earthworm hummus from 1 to 4% [

54]. Likewise, they are among the values from 1.2% and 4.2% obtained by multiple authors [

32,

33,

59,

61,

62,

65,

67]. In all the mixes TN decreased, which was also reported by different authors [

56,

62,

64]. This decrease in TN concentration was related to nutrient loss through the leachate as reported by Huang et al. [

15]. This TN decrease may also have presented itself due to the de-nitrification process that occurred within the earthworm’s digestive tract [

28] as well as ammonium volatilization [

36]. According to the aforementioned data, removal percentages of TN during the vermicomposting process for all four mixes were 64.71% (CR); 55.29% (M1); 65.71% (M2) and 40.54% (M3). Initial concentrations of TN in the CR and M1 reactors presented significant differences in comparison to reactors M2 and M3, the final concentrations were significantly different between all four reactors. The highest value was M3 with a 2.2 + 0.03 concentration followed by M1 with 1.9 + 0.04.

3.2.7. C/N Relation

Final values for the C/N relationship in the four mixes were 12.14 (CR), 9.79 (M1), 15.81 (M2) and 8.28 (M3). These values resulted under 20, as per local norm for earthworm compost [

54], they also supported what has been reported by different authors [

30,

32,

33,

53,

56,

61,

64,

68,

69,

70,

71]. Iglesias and Pérez [

72] concluded a C/N relation beneath 20 can be considered a necessary condition for compost maturity, but values under 12 are more adequate to guarantee the degree of maturity.

3.2.8. Sensory Characteristics of Vermicomposting

Figure 8 shows the different shades observed in one of the mixes at the beginning, during and at the end of the vermicomposting process. In the literature a large size of particle is reported at the beginning of the vermicomposting, whereas at the end of the process it has a fine consistency, with loose, granular and uniform structure [

9,

46]. The literature mentioned that throughout the vermicomposting process the soil color darkened [

5,

23,

46,

51,

55,

73]. During the last weeks the odor was imperceptible as has been reported in the literature. [

5,

18,

23,

46,

51].

4. Conclusions

In this research, it was demonstrated that the substrate degradation of pineapple waste (rinds, crowns and cores) was feasible and favorable through the vermicomposting process, as evidenced by the final characteristics of the vermicompost.

Removal percentages of total organic matter and organic carbon in the pre-composting of the pineapple waste were low, but similar to values reported by different studies, likely due to the adaptation of microorganisms to the type of substrate for degradation.

Vermicomposting was as an adequate process for degradation of pineapple waste, due to the load material made up of vegetables and eggshells, which allowed for the balance of the nutrients required by microorganisms and earthworms. All four mixes showed characteristics of OM, TOC, TN and the C/N relation of a quality vermicompost; however, the M3 reactor was the best option. Therefore, future research will need to analyze in depth the behaviour of this kind of agro-industrial waste and the chemical routes in their degradation as well as test new mixes.

Author Contributions

Conceptualization, E.C.-G, M.R.G.-D., L.D.M.-S; methodology, L.D.M.-S; formal analysis, L.D.M.-S; writing—original draft preparation, E.C.-G.; writing—review and editing, E.C.-G, M.R.G.-D., L.D.M.-S; resources, E.C.-G.; validation, L.D.M.-S.; supervision, M.R.G.-D.; data curation, M.P.S.-C.; project administration, E.C.-G.; investigation M.P.S.-C.

Funding

This research was funded by Facultad de Ingeniería Civil, Xalapa, Universidad Veracruzana.

Conflicts of Interest

The authors declare no conflict of interest.

References

- FAO. Perspectivas Mundiales de las Principales Frutas Tropicales. Perspectivas, retos y Oportunidades a corto plazo en un Mercado Global Pujante. Organización de las Naciones Unidas para la Alimentación y la Agricultura. 2017. Available online: http://www.fao.org/fileadmin/templates/est/COMM_MARKETS_MONITORING/Tropical_Fruits/Documents/Tropical_Fruits_Spanish2017.pdf (accessed on 20 April 2019).

- FAO. Pineapple Post-Havest Operations. Organización de las Naciones Unidas para la Alimentación y la Agricultura. Available online: http://www.fao.org/3/a-ax438e.pdf (accessed on 20 April 2019).

- Sánchez, M.; Ahuja, S.; Acevedo, R. Producción de Piña Cayena Lisa y MD2 (Ananas comosus L.) en condiciones de Loma Bonita, Oaxaca. Cienc. Biol. Agron. 2005, 1, 100–110. [Google Scholar]

- SEMARNAT. Guía para la Gestión Integral de los Residuos Sólidos Municipales; Secretaría de Medio Ambiente y Recursos Naturales: México City, México, 2001; ISBN 968-817-498-X. [Google Scholar]

- Ruíz, M.M. Taller de Elaboración de Lombricomposta. 2011. Available online: http://www.ibero.mx/web/filesd/publicaciones/taller-de-lombricomposta.pdf (accessed on 8 January 2019).

- Castillo, B.E.; López, G.R.C. Planta de lombricomposteo “Beneficio de mejora de suelo en zona de trabajo ejidal”. In Estudios Agrarios; Universidad Autónoma Metropolitana-Xochimilco: Xochimilco, Mexico, 2010; pp. 133–161. [Google Scholar]

- Mainoo, N.O.K.; Barrington, S.; Whalen, J.K.; Sampedro, L. Pilo-scale vermicomposting of pineapple wastes with earthworms native to Accra, Ghana. Bioresour. Technol. 2009, 100, 5872–5875. [Google Scholar] [CrossRef] [PubMed]

- FAO. Manual de Compostaje del Agricultor: Experiencias en América Latina; Organización de las Naciones Unidas para la Alimentación y la Agricultura: Santiago, Chile, 2013; ISBN 978-92-5-307844-8. [Google Scholar]

- Moreno, C.J.; Moral, H.R. Compostaje; Mundi Prensa Libros S. A.: Madrid, España, 2008; ISBN 978-84-8476-346-8 84-8476-346-3. [Google Scholar]

- Castro, A.R.; Cova, L.J.; García, D.E.; Medina, M.G. Efecto de la cáscara de huevo en la producción de cápsulas de la lombriz roja (Eisenia andrei). Zootecn Trop. 2007, 25, 135–142. [Google Scholar]

- Barba, J.A.; Clausell, T.C. Reactores Químicos y Bioquímicos; Universitat Jaume I.: Castello de la Plana, España, 2014; ISBN 978-8-469-59787-3. [Google Scholar]

- García, G.C.; Félix, H.J.A. Manual para la Producción de Abonos Orgánicos y Biorracionales; Fundación produce Sinaloa, A.C.: Sinaloa, Mexico, 2014; ISBN 978-607-8347-33-9. [Google Scholar]

- Restrepo, J.R. Manual Práctico: El A, B, C, de la Agricultura Orgánica y Harinas de Rocas; SIMAS: Managua, Nicaragua, 2007; ISBN 978-99924-55-27-2. [Google Scholar]

- Arvanitoyannis, I.S.; Varzakas, T.H. Vegetable Waste Treatment: Comparison and Critical Presentation of Methodologies. Crit. Rev. Food Sci. Nutr. 2008, 48, 205–247. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.; Li, F.; Wei, Y.; Fu, X.; Chen, X. Effects of earthworms on physicochemical properties and microbial profiles during vermicomposting of fresh fruit and vegetable wastes. Bioresour. Technol. 2014, 170, 45–52. [Google Scholar] [CrossRef] [PubMed]

- Villar, I.; Alves, D.; Pérez, D.D.; Mato, S. Changes in microbial dynamics during vermicomposting of fresh and composted sewage sludge. Waste Manag. 2016, 48, 409–417. [Google Scholar] [CrossRef] [PubMed]

- SEMARNAT. Norma Oficial Mexicana NOM-02-RECNAT-2000. In Establece las Especificaciones de Fertilidad, Salinidad y Clasificación de Suelos. Estudios, Muestreo y Análisis; Secretaría de Medio Ambiente y Recursos Naturales, Diario Oficial de la Federación: México City, México, 2002. [Google Scholar]

- SCFI. Norma Mexicana NMX-F-066-S-1978. In Determinación de Cenizas en Alimentos; Secretaría de Comercio y Fomento Industrial, Diario Oficial de la Federación: México City, México, 1978. [Google Scholar]

- SEDUE. Norma Mexicana NMX-AA-24-1984. In Protección al Ambiente-Contaminación del Suelo-Residuos Sólidos Municipales-Determinación de Nitrógeno Total; Secretaría de Desarrollo Urbano y Ecología, Diario Oficial de la Federación: México City, México, 1992. [Google Scholar]

- Bueno, M.P.; Díaz, B.M.J.; Cabrera, C.F. Capítulo 4. Factores que Afectan al Proceso de Compostaje. 2008. Available online: http://digital.csic.es/bitstream/10261/20837/3/Factores%20que%20afectan%20al%20proceso%20de%20compostaje.pdf (accessed on 1 June 2019).

- Yadav, A.; Garg, V.K. Biotransformation of bakery industry sludge into valuable product using vermicomposting. Bioresour. Technol. 2019, 274, 512–517. [Google Scholar] [CrossRef]

- Lopes, F.L.; Lopes, S.W.T.; Milori, D.M.B.P.; Luiz, S.M.; Martín, N.L. Characterization of organic matter from composting of different residues by physicochemical and spectroscopic methods. Bioresour. Technol. 2010, 101, 1927–1936. [Google Scholar]

- Díaz, E. Guía de Lombricultura: Una alternativa de Producción; Agencia de Desarrollo Económico y Comercio Exterior: La Rioja, Spain, 2002; p. 57. [Google Scholar]

- Acosta, D.C.M.; Solís, P.O.; Villegas, T.O.G.; Cardoso, V.L. Precomposteo de residuos orgánicos y su efecto en la dinámica poblacional de Eisenia foetida. Agron. Costarric. 2013, 37, 127–139. [Google Scholar]

- Nair, J.; Sekiozoic, V.; Anda, M. Effect of pre-composting on vermicomposting of kitchen waste. Bioresour. Technol. 2005, 97, 2091–2095. [Google Scholar] [CrossRef]

- Cabildo, M.M.P.; Claramunt, V.R.M.; Cornago, R.M.P.; Escolástico, L.C.; Esteban, S.S.; Farrán, M.M.A.; García, F.M.A.; López, G.C.; Pérez, E.J.; Pérez, T.M.; et al. Tratamiento de la materia orgánica. In Compostaje en Reciclado y Tratamiento de Residuos; UNED, Ciencias Ambientales: Madrid, Spain, 2008; pp. 141–165. [Google Scholar]

- Zhu, N. Composting of high moisture content swine manure with corncob in a pilot-scale aerated static bin system. Bioresour. Technol. 2006, 97, 1870–1875. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.; Xia, H.; Li, F.; Wei, Y.; Cui, G.; Fu, X.; Chen, X. Optimal growth condition of earthworms and their vermicompost features during recycling of five different fresh fruit and vegetable wastes. Environ. Sci. Pollut. Res. 2016, 23, 13569–13575. [Google Scholar] [CrossRef] [PubMed]

- Méndez, M.A.; Robles, C.; Ruiz, V.J.; Castañeda, H.E. Compostaje de residuos agroindustriales inoculados con hongos lignocelulósicos y modificación de la relación C/N. Rev. Mex. Cienc. Agríc. 2018, 9, 271–280. [Google Scholar]

- Fornes, F.; Mendoza, H.D.; García, F.R.; Abad, M.; Belda, R.M. Composting versus vermicomposting: A comparative study of organic matter evolution through straight and combined processes. Bioresour. Technol. 2012, 118, 296–305. [Google Scholar] [CrossRef] [PubMed]

- Ramos, M.; Sánchez, M.; Rojas, M.; Mora, R. Structural, physicochemical and functional properties of industrial residues of pineapple (Ananas comosus). Cellul. Chem. Technol. 2013, 48, 633–641. [Google Scholar]

- Fernández, G.M.J.; Romero, E.; Nogales, R. Feasibility of vermicomposting for vegetable greenhouse waste recycling. Bioresour. Technol. 2010, 101, 9654–9660. [Google Scholar] [CrossRef]

- Sharma, K.; Garg, V.K. Comparative analysis of vermicompost quality produced from rice straw and paper waste employing earthworm Eisenia fetida (Sav.). Bioresour. Technol. 2018, 208, 708–715. [Google Scholar] [CrossRef]

- Suleiman, H.; Rorat, A.; Grobelak, A.; Grosser, A.; Milczarek, M.; Plytycz, B.; Kacprzak, M.; Vandenbulcke, F. Determination of the performance of vermicomposting process applied to sewage sludge by monitoring of the compost quality and immune responses in three earthworm species: Eisenia fetida, Eisenia Andrei and Dendrobaena veneta. Bioresour. Technol. 2017, 241, 103–112. [Google Scholar] [CrossRef]

- Pérez, G.E.A.; Lagunez, Z.J.; Corona, H.J.; Barajas, A.M. Growth and reproductive potential of Eisenia foetida (Sav) on various zoo animal dungs after two methods of pre-composting followed by vermicomposting. Waste Manag. 2017, 64, 67–78. [Google Scholar] [CrossRef]

- Favoretto, L.P.; Ademola, A.E.; Abosede, O.O.; Vinicius, B.A.; Oliveria, R.M.O. Chemical study of vermicomposted agroindustrial wastes. Recycl. Org. Waste Agric. 2016, 5, 55–63. [Google Scholar]

- Huang, G.F.; Wong, J.W.C.; Wu, Q.T.; Nagar, B.B. Transformation of organic matter during co-composting of pig manure with sawdust. Bioresour. Technol. 2006, 97, 1834–1842. [Google Scholar] [CrossRef] [PubMed]

- Bhat, S.A.; Singh, J.; Vig, A.P. Potential utilization of bagasse as feed material for earthworm Eisenia fetida and production of vermicompost. Springerplus 2015, 4, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Lazcano, C.; Gómez, B.M.; Domínguez, J. Comparison of the effectiveness of composting and vermicomposting for the biological stabilization of cattle manure. Chemosphere 2008, 72, 1013–1019. [Google Scholar] [CrossRef]

- Frederickson, J.; Howell, G.; Hobson, A.M. Effect of pre-composting and vermicomposting on compost characteristics. Eur. J. Soil. Biol. 2007, 43, S320–S326. [Google Scholar] [CrossRef]

- López, E.; Sainz, J. Gestión de Residuos Orgánicos de uso Agrícola. Santiago de Compostela; Servizo de Publicación e Intercambio Científico: Galicia, España, 2011; ISBN 978-84-9887-822-6. [Google Scholar]

- Jack, A.; Thies, J.E. Compost and vermicompost as amendments promoting Soil Health. Biol. Approaches Sustain. Soil Syst. 2006, 31, 453–466. [Google Scholar]

- Kendie, A.H. Effects of Carbon to Nitrogen Ratio on Vermicomposting of Rice Husk and Cow Dung with Fresh Biosolid. Master’s Thesis, Mekelle University, Mekele, Etiopia, 2009. [Google Scholar]

- Gómez, R.S.; Ángeles, M.L.; Nuñez, H.G.; Figueroa, V.U. Metodologías para la Elaboración de Compostas y Lombricompostas de Excretas de Ganado de Leche; Centro de Investigación disciplinaria en fisiología y Mejoramiento Animal (INIFAP): Coyoacán, Mexico, 2013; ISBN 978-607-37-0219-5. [Google Scholar]

- Othman, N.; Irwan, J.M.; Roslan, M.A. Vermicomposting of food waste. Int. J. Integr. Eng. 2012, 4, 39–48. [Google Scholar]

- Gabriel, P.; Loza, M.M.; Mamani, F.; Sainz, H. Effect of the californian red worm (Eisenia foetida) during the composteo and vermicomposteo in properties of the Experimental Station of the Academic Rural Unit Carmen Pampa. J. Selva Andin. Res. Soci. 2011, 2, 24–39. [Google Scholar]

- Durán, L.; Henríquez, C. Crecimiento y reproducción de la lombriz roja (Eisenia foetida) en cinco sustratos orgánicos. Agron. Costarric. 2009, 33, 275–281. [Google Scholar]

- Domínguez, J. State of the Art and New Perspectives on Vermicomposting Research. In Earthworm Ecology, 2nd ed.; Edwards, C.A., Ed.; CRC Press LLC.: Boca Raton, FL, USA, 2004; pp. 401–424. [Google Scholar]

- Gupta, R.; Garg, V.K. Vermitechnology for Organic Waste Recycling. In Current Developments in Biotechnology and Bioengineering: Solid Waste Management; Elsevier: Amsterdam, The Netherlands, 2017; pp. 83–112. [Google Scholar]

- Ávila, H.B.A. Transferencia de la Técnica de Manejo y Producción a Base de Pulpa de Café, con Pequeños Caficultores de la Aldea Los Coles, San Pedro Necta, Huehuetenango. Ph.D. Thesis, Universidad de San Carlos de Guatemala, Huehuetenango, Guatemala, 2010. [Google Scholar]

- Manyuchi, M.M.M.; Phiri, A.; Chirinda, N.; Muredzi, P.; Govhaand, J.; Sengudzwa, T. Vermicomposting of waste corn pulp blended with cow dung using Eisenia foetida. World Acad. Sci. Eng. Technol. 2012, 68, 1306–1309. [Google Scholar]

- Domínguez, J.; Gómez, B.M. Ciclos de vida de las lombrices de tierra aptas para el vermicompostaje. Acta Zool. Mex. Número Espec. 2010, 2, 309–320. [Google Scholar] [CrossRef]

- Swarnam, T.P.; Velmurugan, A.; Pandey, S.K.; Dam, R.S. Enhancing nutrient recovery and compost maturity of coconut husk by vermicomposting technology. Bioresour. Technol. 2016, 207, 76–84. [Google Scholar] [CrossRef] [PubMed]

- SCFI. Norma Mexicana NMX-FF-109-SCFI-2007. In Humus de Lombriz (lombricomposta)—Especificaciones y Métodos de Prueba; Secretaría de Comercio y Fomento Industrial, Diario Oficial de la Federación: México City, México, 2008. [Google Scholar]

- Rodríguez, G.Q.; Armenta, B.A.D.; Valenzuela, W.Q.; Camacho, J.R.B.; Esparza, H.M.L. Evaluación sustratos orgánicos para la producción de lombricomposta con Eisenia foetida. Nat. Desarro. 2003, 1, 3–9. [Google Scholar]

- Majlessi, M.; Eslami ANajafi, H.S.; Mirshafieean, S.; Babaii, S. Vermicomposting of food waste: Assessing the stability and maturity. Iran. J. Environ. Health Sci. Eng. 2012, 9, 25. [Google Scholar] [CrossRef] [PubMed]

- Villegas, C.V.M.; Laines, C.J.R. Vermicompostaje: Avances y estrategias en el tratamiento de residuos sólidos orgánicos. Rev. Mex. Cienc. Agríc. 2017, 8, 393–406. [Google Scholar]

- Sutar, S. Vermicomposting of pressmud from sugar industry. Int. J. Innov. Eng. Res. Technol. 2015, 2, 1–10. [Google Scholar]

- Raza, S.T.; Bo, Z.; Ali, Z.; Liang, T.J. Vermicomposting by Eisenia fetida is a Sustainable and Eco-Friendly Technology for Better Nutrient Recovery and Organic Waste Managment in Upland Areas of China. Zool. Soc. Pak. 2019, 51, 1027–1034. [Google Scholar]

- Gupta, C.; Prakach DGupta, S.; Azucena, N.M. Chapter 15: Role of vermicomposting in agricultural waste management. In Sustainable Green Technologies for Environmental Management; Department of Zoology, RGPG College, Meerut: Uttar Pradesh, India, 2019; pp. 283–295. [Google Scholar]

- Suthar, S.; Singh, S. Vermicomposting of domestic waste by using two epigeic earthworms (Perionyx excavates and Perionyx sansibaricus). Int. J. Environ. Sci. Technol. 2007, 5, 99–106. [Google Scholar] [CrossRef]

- Huang, K.; Xia, H.; Cui, G.; Li, F. Effects of earthworms on nitrification and ammonia oxidizers in vermicomposting systems for recycling of fruit and vegetable wastes. Sci. Total Environ. 2017, 578, 337–345. [Google Scholar] [CrossRef]

- Bhandarkar, B.A.; Kakde, S.A.; Donar, S.K.; Sayyed, A.S. Vermicomposting from bagasse by using Eudilus Eugenia. Int. J. Res. Eng. Technol. 2014, 3, 14–19. [Google Scholar]

- Chhotu, D.J.; Fulekar, M.H. Vermicomposting of vegetable waste: A bio-physicochemical process based on hydro-operating biorreactor. Afr. J. Biotechnol. 2008, 7, 3723–3730. [Google Scholar]

- Mohan, S.M. Biodegradation of Garden Waste, Market Waste Using Eisenia fetida and Eudrilus Eugenia and Assessment of Manure Quality on Tomato. J. Inst. Eng. India Ser. A 2014, 95, 75–82. [Google Scholar] [CrossRef]

- Kumar, R.; Verma, D.; Singh, B.L.; Kumar, U. Composting of sugar-cane waste bye- products throught treatment with microorganisms and subsequent vermicomposting. Bioresour. Technol. 2010, 101, 6707–6711. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, J.; Sánchez, H.J.; Lores, M. Vermicomposting of Winemaking By-Products. In Handbook of Grape Processing By-Products; Academic Press: Vienna Austria, 2017; pp. 55–78. [Google Scholar]

- Kohli, R.; Hussain, M. Management of flower waste by vermicomposting. In Proceedings of the Internationl Conference on Global Trends in Engineering Technology Management, Jalgaon, India, 4–6 January 2016; pp. 34–38. [Google Scholar]

- Tognetti, C.; Laos, F.; Mazzarino, M.J.; Hernández, M.T. Composting vs. Vermicomposting: A comparison of End Product Quality. Compost Sci. Util. 2005, 13, 6–13. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Q.; Zhang, Y.; Chen, J.; Zhang, D.; Tong, J. Changes in fibrolytic enzyme activity during vermicomposting of maize stover by an anecic earthworm Amynthas hupeiensis. Polym. Degrad. Stabil. 2015, 120, 169–177. [Google Scholar] [CrossRef]

- Singh, A.; Sharma, S. Composting of a crop residue through treatment with microorganisms and subsequent vermicomposting. Bioresour. Technol. 2002, 85, 107–111. [Google Scholar] [CrossRef]

- Iglesias, J.E.; Pérez, G.V. Determination of maturity indices for city refuse composts. Agric. Ecosyst. Environ. 1992, 38, 331–343. [Google Scholar] [CrossRef]

- Warman, P.R.; AngLopez, M.J. Vermicomposting derived from different feedstocks as a plant growth medium. Bioresour. Technol. 2010, 101, 4479–4483. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).