Abstract

Layered silicates, as bitumen modifiers, have received increasing attention. The main objective of this study was to evaluate the influence of layered silicates on bitumen properties. For this study, montmorillonite (MMT), rectorite (REC), organic montmorillonite (OMMT), and organic rectorite (OREC) were selected. The layered structure type of layered silicates was characterized by SEM (scanning electron microscope) and XRD (X-ray diffraction diffractometer). Tests for determining high-temperature properties included viscosity, DSR (dynamic shear rheometer), and TG (thermogravimetry) tests, and studies for determining the low-temperature properties were conducted by BBR (bending beam rheometer) and DSC (differential scanning calorimetry) tests. Our results show that MMT, REC, OMMT, and OREC were all intercalated structures. OREC had the largest d001 interlayer space, followed by REC, OMMT, and MMT. OREC improved the high-temperature property of virgin bitumen more effectively than OMMT. Meanwhile, REC-modified bitumen exhibited a high-temperature property similar to OMMT-modified bitumen. When compared with REC and OREC, MMT and OMMT were less efficient in reducing the low-temperature properties of virgin bitumen, and OMMT was the least efficient. Therefore, it can be concluded that the nature of pristine layered silicates has a great impact on the high- and low-temperature properties of bitumen. Moreover, organic treatment can simultaneously improve the high- and low-temperature properties of layered silicate-modified bitumens.

1. Introduction

Bitumen pavement has been extensively employed in China, in view of its excellent properties such as low noise and good driving comfort [1]. In response to pavement distresses caused by the increasing traffic volume, loads, and other factors in early service conditions, virgin bitumen is usually required to be modified [2]. Polymers are the most commonly used modifier in bitumen, which mainly contain rubbers (e.g., styrene-butadiene rubber (SBR), chloroprene rubber (CR)), thermoplastic elastomers (e.g., styrene-butadiene-styrene (SBS)), thermoplastic resin (e.g., poluethylene (PE), ethylene-vinyl acetate (EVA)), and thermosetting resin (e.g., epoxy (EP)) [3,4,5,6]. In most cases, bitumen properties are dramatically improved by adding a small amount of polymers. However, there are also some deficiencies such as the easy aging and degradation of polymers in the bitumen matrix, and the poor storage stability of polymer-modified bitumens, which results from the physical coexistence between them [7,8].

In order to overcome these defects, many novel bitumen modifiers have appeared in recent years, and among them, layered silicates have been paid much attention to [9,10,11,12]. As it is well known, layered silicates are characterized by being one dimension smaller than 100 nm in the dispersed phase [13,14]. It is their small size and large specific surface area that endows them with surface effect, size effect, and barrier effect [12,14,15]. Hence, layered silicates with a small content, in general, largely improve bitumen properties [12,14]. Additionally, they have layered nanostructures in which there are exchangeable cations [16]. Bitumen molecules are able to insert interlayers [9,17,18]. It is these characteristics that make bitumen molecules effectively blocked, thereby improving the high-temperature stability and aging resistance of virgin bitumen [19,20].

The layered silicate chiefly consists of montmorillonite, rectorite, vermiculite, hectorte, saponite, and kaolinite [21,22,23,24]. Generally, before incorporation into the bitumen matrix, the hydrophilic layered silicate is converted into an organophilic material by selecting an appropriate organic reagent to react with exchangeable cations, which improves the compatibility of the layered silicate with bitumen [25]. In addition, the interlayer space of the pristine layered silicates is expanded [20,26,27]. Most studies have been conducted regarding montmorillonite (MMT) as a bitumen modifier [18,28,29], the main reason of which is that MMT is a 2:1 layered smectite clay with two silica tetrahedral sheets sandwiching an alumina octahedral sheet [29,30]. There exists a large amount of exchangeable cations (i.e., cation exchange capacity) between the 2:1 layers. Many organic reagent molecules can enter the MMT interlayers, thereby endowing MMT with excellent lipophilicity and great expansibility [30,31,32]. Therefore, organic montmorillonite (OMMT) particles with a large specific surface area are capable of effectively blocking the thermal motion of bitumen molecules, leading to the excellent thermal stability and aging resistance of OMMT-modified bitumen [17,33]. By comparison, rectorite (REC) has a layered structure similar to MMT, which is composed of alternate pairs of a non-expansible dioctahedral mica-like layers and expansible dioctahedral montmorillonite-like layers, in a 1:1 ratio [24,31,34]. The exchangeable cations only lie in the interlayers of a 2:1 montmorillonite-like layer, which determines that REC, in most cases, has a lower cation exchange capacity than MMT. Nevertheless, the size (including the interlayer space and layer aspect ratio) of REC particles are larger than those of MMT [24,35]. As a result, these differences in nature between MMT and REC possibly have an influence on bitumen properties.

Zhang et al. [36,37] have reported on the microstructures, aging properties, and flame retardancy of OMMT and organic rectorite (OREC)-modified bitumens. It was found that the thermal aging resistance of bitumen chiefly relied on the nature of its layered silicates. Nevertheless, there has been little research at present regarding the effect of their nature on the high and low temperature property of bitumen. Therefore, a comparison should be made.

The main work in this study was to evaluate the influence of MMT, REC, OMMT, and OREC on bitumen properties. First, the nature of MMT, REC, OMMT, and OREC was analyzed. The high- and low-temperature properties of these layered silicate-modified bitumens were then investigated, mainly to identify the difference in the nature of these layered silicates, which further provides guidance for selecting a layered silicate that is suitable for the bitumen matrix.

2. Materials and Methods

2.1. Materials

The SK-90# virgin bitumen (penetration: 8.98 mm; softening point: 45.6 °C; ductility at 15 °C: 121 cm) was applied in this research. The pristine MMT and REC were supplied by the Fenghong Clay Chemical Factory, China and Shunhehuatao Co., Ltd, Hubei, China, respectively, and their purities were all greater than 95%. The dodecyl trimethyl ammonium chloride was selected as the organic reagent in this study, which was provided by the Sinopharm Chemical Reagent Co., Ltd., Shanghai, China.

2.2. Preparation Procedures

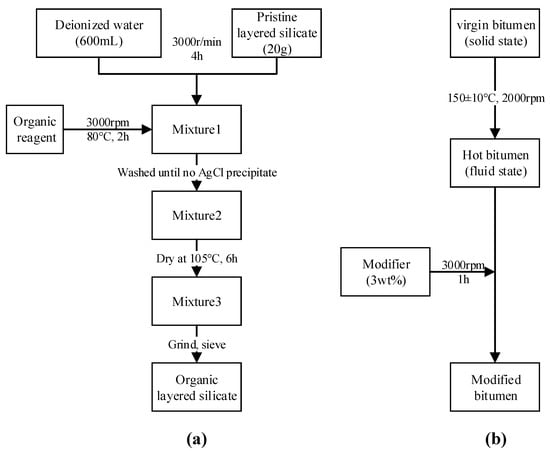

The preparation procedures of organic layered silicates are shown in Figure 1a. Layered silicate-modified bitumens are prepared by the melt blending method, as displayed in Figure 1b.

Figure 1.

The preparation process of samples: (a) Organic layered silicates; (b) modified bitumens.

2.3. Methods

The Brookfield viscosity test was performed by a NDJ-1F viscometer (made in China), in accordance with ASTM D4402. The test was conducted at 120 °C, 135 °C, 150 °C, and 165 °C.

In terms of ASTM D7175, the rutting resistance factor at 64 °C was measured via a dynamic shear rheometer (MCR-102 type, Anton Paar company, Graz, Austria). The test was carried out at 10 rad/s using two 25-mm plates with a 1-mm gap between them.

A bending beam rheometer was employed to test the low-temperature creep characteristics of the bitumen specimens, according to ASTM D6648. A bitumen beam with a standard size (length: 125 mm; width: 6.25 mm; height: 12.5 mm) was prepared in a mold. Before the test, the beam was removed from the mold and then placed in the test bath at –18 °C for 60 ± 5 min. In this test a 100 g-weight was applied to the beam for 240 s.

A JSM-6360LV SEM (JEOL company, Tokyo, Japan) was followed to observe the microstructure of the untreated and treated layered silicates. The acceleration voltage was 20 kV, and the magnification was 20,000.

The XRD spectra of layered silicate-modified bitumens were obtained using a Shimadzu XRD-6000 diffractometer (Cu-Kα radiation, λ = 0.154 nm; 30 mA, 40 kV). The diffractive angle (2θ) was from 3° to 10° with 0.02° steps. The interlayer space was calculated by the Bragg equation (λ = 2dsinθ).

The TG analysis of the layered silicate-modified bitumens was conducted on a SYQ-600 thermal analyzer (TA Instruments, United States). Approximately 10-mg samples were heated from 30 °C to 600 °C under a nitrogen atmosphere with a 10 °C/min heating rate and a 50 mL/min flow rate.

The glass transition temperature (Tg) of the bitumen specimens was determined by a differential scanning calorimeter (2910 type, TA company, United States). The test ranged from –40 °C to 20 °C at a heating rate of 10 °C/min and a flow rate of 50 mL/min.

3. Results and Discussion

3.1. Structural Characterization

3.1.1. SEM

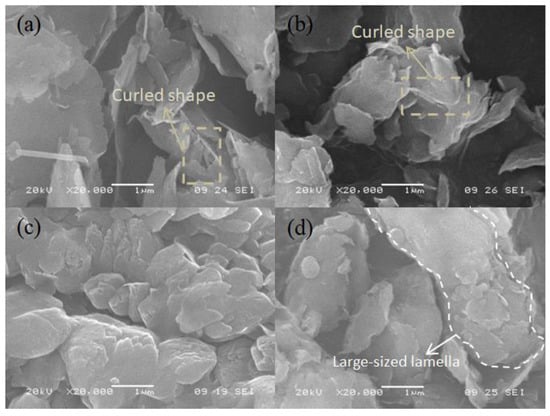

Figure 2 presents the SEM image that demonstrates the morphology of the untreated and treated layered silicates, where the layered structure between them can be compared. For MMT and REC, their platelet edges were generally curled, and the layered structures were unclear in Figure 2a,b, chiefly because of the irregular edges. After organic modification, layered structures were clearly observed; meanwhile, platelet edges were found to be regular without any remarkable curls. This demonstrates that the organic reagent embellishes irregular edges. More precisely, organic reagent molecules are able to form tight ion pairs with the layered silicates by adsorbing negative charges that exist on the surface, as well as to enter interlayers of the layered silicates through the reaction with exchangeable cations [17,21]. By comparing Figure 2c,d, it can be obtained that OREC had a larger-sized platelet than OMMT. Furthermore, both OMMT and OREC exhibited an intercalated structure without an exfoliated platelet, which can be further validated by the XRD test.

Figure 2.

The microstructure of untreated and treated layered silicates: (a) Montmorillonite (MMT); (b) rectorite (REC) [17]; (c) organic montmorillonite (OMMT); (d) organic rectorite (OREC).

3.1.2. XRD

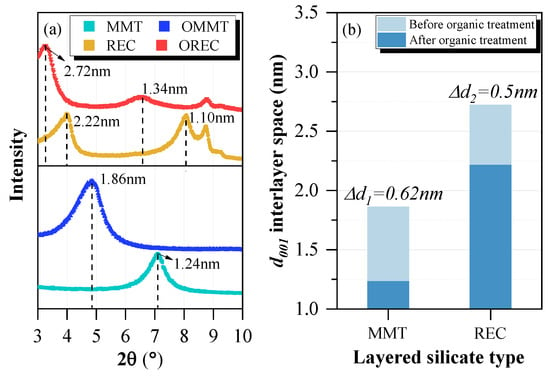

The XRD test result for the untreated and treated layered silicates is shown in Figure 3. It can be seen that in Figure 3a, the layered silicates all had the intercalated structure with different d001 interlayer spaces, where REC had a remarkably larger d001 interlayer space as compared to MMT, irrespective of the organic treatment. This is ascribed to the nature of the pristine layered silicate. Moreover, Figure 3a also shows that the d002 interlayer space of REC was 1.10 nm, which increased to 1.34 nm after the organic treatment. From Figure 3b, MMT had a greater increment in d001 value than REC, which can be attributed to the nature of the layered silicates. As mentioned in the Introduction, MMT has a larger cation exchange capacity than REC. As a result, more organic reagent molecules can insert MMT interlayers through the cation exchange reaction, and correspondingly, the interlayer space of MMT is largely increased.

Figure 3.

The XRD test result for untreated and treated layered silicates: (a) Diffraction angle; (b) interlayer space (d001).

3.2. High-Temperature Property Analysis

3.2.1. Viscosity

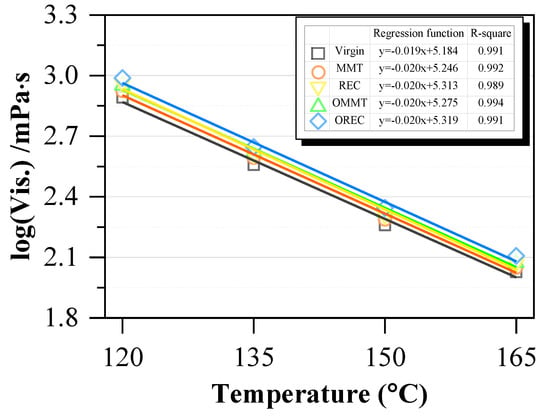

Aiming at investigating the effect of the layered silicate type on the flowability and high-temperature properties of virgin bitumen, the viscosity of all bitumen specimens at four high temperatures (120 °C, 135 °C, 150 °C, and 165 °C) is provided (Figure 4). As expected, viscosity increased with the incorporation of the modifiers, which can be attributed to the restriction of the modifiers on the motion of the bitumen molecules [29,33,36]. With respect to the modifier type, regardless of the test temperature, OREC endowed the virgin bitumen with the largest viscosity, contrary to MMT, and there was a similar viscosity for the REC-modified bitumen and the OMMT-modified bitumen, which is probably related to the specific surface area of the layered silicates in the bitumen matrix [17,36]. In detail, OREC is characterized by the largest interlayer space (obtained from Figure 4) and aspect ratio amongst these four silicates. Therefore, OREC has the largest specific surface area to hinder the motion of the bitumen molecules (or the flowability of bitumen) most effectively. However, although organophilic OMMT has a smaller aspect ratio and interlayer space than hydrophilic REC, it has a better compatibility with bitumen due to the organic treatment, which helps to enhance the specific surface area of OMMT particles in the bitumen matrix [17,18]. Additionally, it can also be noted that, in Figure 4, the temperature dependency of the viscosity was obvious, as the viscosity reduced nearly linearly with the temperature. The viscosity at other temperatures can be predicted based on the linear regression functions listed in this figure.

Figure 4.

The viscosity result for the bitumen samples at various temperatures.

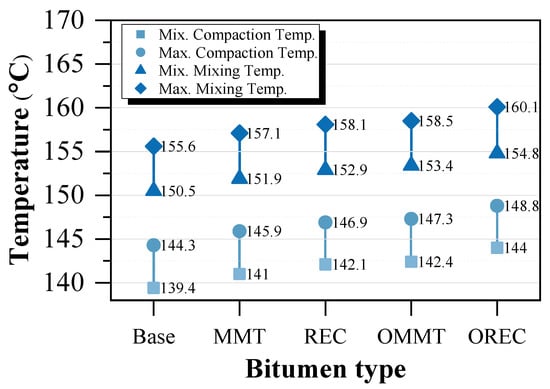

To ensure uniform mixing and effective compaction of the bitumen mixture, as well as to prevent the aging caused by too high temperatures, the bitumen pavement construction needs to control the construction temperature (including the mixing and compaction temperatures) of the bitumen mixture within an appropriate range. According to the Superpave specification [38], the mixing and compaction temperatures of these bitumens are obtained, as displayed in Figure 5. It can be seen that the modification promoted an increase in the mixing and compaction temperatures. Among these layered silicates, OREC endowed bitumen with the highest mixing temperature, followed by OMMT, REC, and MMT. Similar trends could be found for compaction temperature results. Significantly, the results in Figure 5 provide guidance for practical construction.

Figure 5.

The construction temperature of the bitumen specimens.

3.2.2. DSR

Rutting resistance factor (G*/sinδ), estimated by the DSR test, evaluates the permanent deformation of a viscoelastic material at high temperatures. Generally speaking, the large G*/sinδ value correlates with a better permanent deformation resistance. So, it can be obtained that, in Figure 6, the OREC-modified bitumen with the largest G*/sinδ value presents the best high-temperature permanent deformation resistance. This can also be ascribed to the strongest restriction of OREC on the motion of bitumen molecules. The comparison between pristine and organic-layered silicates shows that the organic treatment of MMT caused a greater increment in the G*/sinδ value than that of REC, which results from the larger cation exchange capacity of MMT. Interestingly, the G*/sinδ value of REC-modified bitumen was similar to that of OMMT-modified bitumen, suggesting that the REC-modified bitumen has almost the same permanent deformation resistance as OMMT-modified bitumen. As a consequence, it can be concluded that the nature of the layered silicate has an effect on the high-temperature properties of layered silicate-modified bitumen.

Figure 6.

The G*/sinδ result at 64 °C for bitumen specimens.

3.2.3. TG

The TG test is regarded as an effective way to evaluate the thermal stability and to subsequently assess the high-temperature property of a material. In this study, the TG test results for all bitumens are illustrated in Figure 7. According to Figure 7, no matter if it is virgin bitumen or modified bitumen, the mass gradually decreased along in correlation to the rising temperature. Two parameters were utilized when quantitatively comparing the thermal stability between these bitumens, namely the mass loss at 160 °C (which is the highest construction temperature among the bitumens in Figure 5), and the final residual mass, the results shown in Figure 8. Regarding mass loss at 160 °C, the ranking was: Virgin bitumen > MMT-modified bitumen > REC-modified bitumen > OMMT-modified bitumen > OREC-modified bitumen. Obviously, the existence of the layered silicates gives an improvement in thermal stability due to the reduction of mass loss. Among these layered silicates, the OREC restricts the volatilization of some of the bitumen components most effectively, because of its largest specific surface area. Although the REC-modified bitumen exhibited a relatively large mass loss at 160 °C with respect to OMMT-modified bitumen, the increment was slight. This can suggest that the REC-modified bitumen has a similar thermal stability to the OMMT-modified bitumen. It can be noted that, in Figure 8a, the organic treatment to MMT caused a greater decrement in mass loss, the reason of which can be explained by the cation exchange capacity difference. In summary, the mass loss results further verify the effects of layered silicates on the high-temperature properties of bitumen.

Figure 7.

The TG result for bitumen samples: (a) Virgin bitumen; (b) MMT-modified bitumen; (c) REC-modified bitumen; (d) OMMT-modified bitumen; (e) OREC-modified bitumen.

Figure 8.

The analysis results for Figure 7: (a) Mass loss at 160 °C; (b) final residual mass.

On the other hand, in terms of final residual mass, the REC- and OREC-modified bitumens were dramatically greater than MMT and OMMT bitumens, indicating that the larger aspect ratios and interlayer spaces of REC and OREC are able to hinder the bitumen mass loss more obviously at 600 °C. Therefore, when considering the selection of pristine layered silicates, REC is probably more conductive to bitumen high-temperature properties than MMT.

3.3. Low-Temperature Property Analysis

3.3.1. BBR

The bending beam rheometer test (BBR) can evaluate the creep characteristics of bitumen at low-temperatures, mainly by creep stiffness (S) and creep rate (m-value). In general, a larger S value implies more tensile stress, and a smaller m-value corresponds to less stress relaxation. So, the small S value and large m-value are desirable for bitumen. From Figure 9, the incorporation of layered silicates significantly enhanced the S value while reducing the m-value, demonstrating that layered silicates are deficient in the low-temperature cracking-resistance of bitumen, which has been reported [18]. Among these modified bitumens, the REC-modified bitumen had the largest S value, followed by OREC-modified bitumen, MMT-modified bitumen, and OMMT-modified bitumen which ranked lowest. The opposite trend was found for m-value results. It is evident that REC impairs the low-temperature properties of virgin bitumen more obviously than MMT, regardless of organic treatment. This is likely due to the relatively great size (including the interlayer space and aspect ratio) of pristine REC, leading to stiffness of bitumen at low temperatures. Furthermore, in comparison with pristine layered silicate, the organic REC is less efficient at decreasing the low-temperature cracking resistance of bitumen, and OMMT exhibits even less efficiency than the OREC. Therefore, it can be concluded that, organic treatment to pristine layered silicate helps in the low-temperature cracking resistance of layered silicate-modified bitumen.

Figure 9.

(a,b) The S and m-value results at –18 °C for bitumen samples.

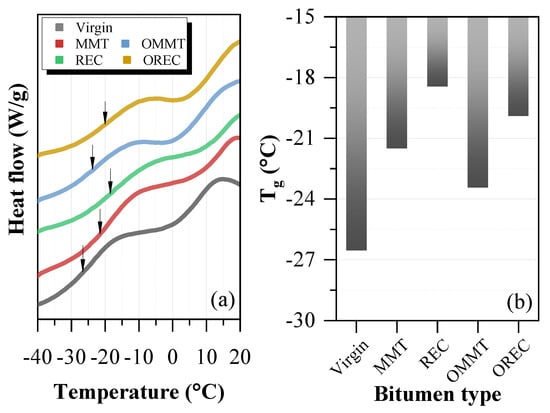

3.3.2. DSC

Cao et al. [39] and Zhang et al. [40] reported that there is a tight link between the glass transition temperature (Tg) gained by the differential scanning calorimetry (DSC) test and the low-temperature property for bitumen. That is to say, the lower Tg causes the greater fracture energy, which reflects better low-temperature cracking resistance. On the whole, the Tg is gained from the inflection point of the curve corresponding to the first scan, as seen in Figure 10a [40,41]. Figure 10b compares the Tg value amongst these bitumens. It is observed that in Figure 10b, the existence of layered silicates caused an increase in Tg, which indicates a negative effect of the layered silicates on the low-temperature cracking resistance of bitumen. Moreover, the comparison of these modified bitumens shows that MMT endowed virgin bitumen with a higher Tg than REC, regardless of the organic modification. Therefore, it can be concluded that, although the layered silicate has an adverse effect on the low-temperature cracking resistance of bitumen, MMT exhibits a relatively small impact as compared to REC, which is consistent with the discussion of the BBR results.

Figure 10.

The differential scanning calorimetry (DSC) test result for bitumen specimens: (a) Determination of Tg; (b) Tg result.

4. Conclusions

The effect of layered silicates on the high- and low-temperature properties of bitumen was studied. Based on the test results and discussion, the main conclusions can be drawn as follows:

- (1)

- MMT, REC, OMMT, and OREC are all intercalated structures, wherein OREC has the largest interlayer space, followed by REC, OMMT, and MMT.

- (2)

- OREC endowed virgin bitumen with the best high-temperature property, contrary to MMT, and REC-modified bitumen has a similar high-temperature property to OMMT-modified bitumen. Therefore, organic treatment is conductive to the high temperature of layered silicate-modified bitumens, and REC (OREC), with a larger interlayer space and aspect ratio, restricts the motion of bitumen molecules more significantly than MMT (OMMT).

- (3)

- Compared with REC and OREC, MMT and OMMT have a smaller interlayer space and aspect ratio, and are less efficient in reducing the low-temperature property of virgin bitumen, and OMMT is the least efficient.

- (4)

- The nature of layered silicates largely affects the high and low-temperature properties of bitumen; however, this investigation is limited to one bitumen source rather than various sources, and thus further research is required.

Author Contributions

For research articles with several authors, a short paragraph specifying their individual contributions must be provided. The following statements should be used “conceptualization, M.J., Z.Z. and L.W.; methodology, M.J., L.W. and X.W.; validation, Z.Z.; formal analysis, M.J.; investigation, M.J., L.W.; resources, Z.Z. and Z.M.; data curation, M.J., J.L. and D.Y.; writing—original draft preparation, M.J.; writing—review and editing, J.L. and D.Y.; visualization, Z.M.; funding acquisition, Z.Z.”, please turn to the CRediT taxonomy for the term explanation. Authorship must be limited to those who have contributed substantially to the work reported.

Funding

This research was funded by the Shaanxi Provincial Communication Construction Group (No. 17-06K), the National Natural Science Foundation of China (NSFC) (Grant No. 51208043) and the Fundamental Research Funds for the Central Universities of Chang’an University (No. 300102218523).

Conflicts of Interest

The authors declare no conflict of interest. There are no any personal circumstances or interest that may be perceived as inappropriately influencing the representation or interpretation of reported research results. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results

Abbreviations

Abbreviations are listed in the order in which they appear in the paper.

| MMT | montmorillonite |

| OMMT | organic montmorillonite |

| REC | rectorite |

| OREC | organic rectorite |

| DSR | dynamic shear rheometer |

| TG | thermogravimetry |

| BBR | bending beam rheometer |

| DSC | differential scanning calorimetry |

| SBR | styrene-butadiene rubber |

| CR | chloroprene rubber |

| SBS | styrenebutadiene-styrene copolymers |

| PE | poluethylene |

| EVA | ethylene-vinyl acetate |

| EP | epoxy |

| VMT | vermiculite |

| SEM | scanning electron microscope |

| XRD | X-ray diffraction |

| Tg | glass transition temperature |

| d001 | interlayer space |

| G*/sinδδ | rutting resistance factor |

| S | creep stiffness |

| m-value | creep rate |

| Ml | mass loss |

| Rm | residual mass |

References

- Jiang, W.; Xiao, J.; Yuan, D.; Lu, H.; Xu, S.; Huang, Y. Design and experiment of thermoelectric asphalt pavements with power-generation and temperature-reduction functions. Energy Build. 2018, 169, 39–47. [Google Scholar] [CrossRef]

- Guo, W.; Guo, X.; Chen, W.; Li, Y.; Sun, M.; Dai, W. Laboratory Assessment of Deteriorating Performance of Nano Hydrophobic Silane Silica Modified Asphalt in Spring-Thaw Season. Appl. Sci. 2019, 9, 2305. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Non-Newtonian Behaviors of Crumb Rubber-Modified Bituminous Binders. Appl. Sci. 2018, 8, 1760. [Google Scholar] [CrossRef]

- Li, X.; Pei, J.; Shen, J.; Li, R. Experimental Study on the High-Temperature and Low-Temperature Performance of Polyphosphoric Acid/Styrene-Butadiene-Styrene Composite-Modified Asphalt. Adv. Mater. Sci. Eng. 2019, 2019, 16. [Google Scholar]

- Behnood, A.; Gharehveran, M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2019, 112, 766–791. [Google Scholar]

- Tsantilis, L.; Dalmazzo, D.; Baglieri, O.; Santagata, E. Effect of SBS molecular structure on the rheological properties of ternary nanomodified bituminous binders. Constr. Build. Mater. 2019, 222, 183–192. [Google Scholar] [CrossRef]

- Polacco, G.; Filippi, S.; Merusi, F.; Stastna, G. A review of the fundamentals of polymer-modified asphalts: Asphalt/polymer interactions and principles of compatibility. Adv. Colloid Interface 2015, 224, 72–112. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Jin, J.; Tan, Y.; Liu, R.; Lin, F.; Wu, Y.; Qian, G.; Wei, H.; Zheng, J. Structure characteristics of organic bentonite and the effects on rheological and aging properties of asphalt. Powder Technol. 2018, 329, 107–114. [Google Scholar] [CrossRef]

- Martinho, F.; Farinha, J. An overview of the use of nanoclay modified bitumen in asphalt mixtures for enhanced flexible pavement performances. Road Mater. Pavement 2017, 20, 671–701. [Google Scholar]

- Fang, C.; Yu, R.; Liu, S.; Li, Y. Nanomaterials Applied in Asphalt Modification: A Review. J. Mater. Sci. Technol. 2013, 29, 589–594. [Google Scholar] [CrossRef]

- Li, R.; Xiao, F.; Amirkhanian, S.; You, Z.; Huang, J. Developments of nano materials and technologies on asphalt materials—A review. Constr. Build. Mater. 2017, 143, 633–648. [Google Scholar] [CrossRef]

- Kiliaris, P.; Papaspyrides, C. Polymer/layered silicate (clay) nanocomposites: An overview of flame retardancy. Prog. Polym. Sci. 2010, 35, 902–958. [Google Scholar] [CrossRef]

- Xiao, F.; Guo, R.; Wang, J. Flame retardant and its influence on the performance of asphalt—A review. Constr. Build. Mater. 2019, 212, 841–861. [Google Scholar] [CrossRef]

- Wang, H.; Xie, H.; Wang, S.; Gao, Z.; Li, C.; Hu, G.; Xiong, C. Enhanced dielectric property and energy storage density of PVDF-HFP based dielectric composites by incorporation of silver nanoparticles-decorated exfoliated montmorillonite nanoplatelets. Compos. Pt. A-Appl. Sci. Manuf. 2018, 108, 62–68. [Google Scholar] [CrossRef]

- Zare-Shahabadi, A.; Shokuhfar, A.; Ebrahimi-Nejad, S. Preparation and rheological characterization of asphalt binders reinforced with layered silicate nanoparticles. Constr. Build. Mater. 2010, 24, 1239–1244. [Google Scholar] [CrossRef]

- Zhang, Z.; Jia, M.; Jiao, W.; Qi, B.; Liu, H. Physical properties and microstructures of organic rectorites and their modified asphalts. Constr. Build. Mater. 2018, 171, 33–43. [Google Scholar] [CrossRef]

- Jia, M.; Zhang, Z.; Wei, L.; Wu, X.; Cui, X.; Zhang, H.; Lv, W.; Zhang, Q. Study on properties and mechanism of organic montmorillonite modified bitumens: View from the selection of organic reagents. Constr. Build. Mater. 2019, 217, 331–342. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, H.; Wang, X.; Yu, J. Microstructures and thermal aging mechanism of expanded vermiculite modified bitumen. Constr. Build. Mater. 2013, 47, 919–926. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, C.; Yan, K.; Yu, J. Effect of Rectorite and Its Organic Modification on Properties of Bitumen. J. Mater. Civ. Eng. 2015, 27. [Google Scholar] [CrossRef]

- Pavlidou, S.; Papaspyrides, C. A review on polymer–layered silicate nanocomposites. Prog. Polym. Sci. 2008, 33, 1119–1198. [Google Scholar]

- Yin, X.; Gupta, V.; Du, H.; Wang, X.; Miller, J. Surface charge and wetting characteristics of layered silicate minerals. Adv. Colloid Interface 2012, 179–182, 43–50. [Google Scholar] [CrossRef] [PubMed]

- Sinha Ray, S.; Okamoto, M. Polymer/layered silicate nanocomposites: a review from preparation to processing. Prog. Polym. Sci. 2003, 28, 1539–1641. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Z.; Liu, F.; Xue, X. Synthesis and characterization of UV-curing epoxy acrylate coatings modified with organically modified rectorite. J. Coat. Technol. Res. 2016, 14, 107–115. [Google Scholar] [CrossRef]

- Tsantilis, L.; Baglieri, O.; Santagata, E. Low-temperature properties of bituminous nanocomposites for road applications. Constr. Build. Mater. 2018, 171, 397–403. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, H.; Zhu, C.; Zhao, B. Rheological examination of aging in bitumen with inorganic nanoparticles and organic expanded vermiculite. Constr. Build. Mater. 2015, 101, 884–891. [Google Scholar] [CrossRef]

- Papatzani, S.; Paine, K. From Nanostructural Characterization of Nanoparticles to Performance Assessment of Low Clinker Fiber–Cement Nanohybrids. Appl. Sci. 2019, 9, 1938. [Google Scholar] [CrossRef]

- Yu, J.; Feng, P.; Zhang, H.; Wu, S. Effect of organo-montmorillonite on aging properties of asphalt. Constr. Build. Mater. 2009, 23, 2636–2640. [Google Scholar] [CrossRef]

- Vargas, M.; Moreno, L.; Montiel, R.; Manero, O.; Vázquez, H. Effects of montmorillonite (Mt) and two different organo-Mt additives on the performance of asphalt. Appl. Clay Sci. 2017, 139, 20–27. [Google Scholar] [CrossRef]

- Li, Y.; Tian, G.; Dong, G.; Bai, S.; Han, X.; Liang, J.; Meng, J.; Zhang, H. Research progress on the raw and modified montmorillonites as adsorbents for mycotoxins: A review. Appl. Clay Sci. 2018, 163, 299–311. [Google Scholar] [CrossRef]

- Huang, Y.; Ma, X.; Liang, G.; Yan, Y.; Wang, S. Adsorption behavior of Cr(VI) on organic-modified rectorite. Chem. Eng. J. 2008, 138, 187–193. [Google Scholar]

- Bee, S.L.; Abdullah, M.A.A.; Bee, S.T.; Sin, L.T.; Rahmat, A.R. Polymer nanocomposites based on silylated-montmorillonite: A review. Prog. Polym. Sci. 2018, 85, 57–82. [Google Scholar]

- Yu, J.; Zeng, X.; Wu, S.; Wang, L.; Liu, G. Preparation and properties of montmorillonite modified asphalts. Mat. Sci. Eng. A-Struct. 2007, 447, 233–238. [Google Scholar] [CrossRef]

- Lu, Y.; Chang, P.; Zheng, P.; Ma, X. Rectorite–TiO2–Fe3O4 composites: Assembly, characterization, adsorption and photodegradation. Chem. Eng. J. 2014, 255, 49–54. [Google Scholar] [CrossRef]

- Tu, H.; Li, D.; Yi, Y.; Liu, R.; Wu, Y.; Dong, X.; Shi, X.; Deng, H. Incorporation of rectorite into porous polycaprolactone/TiO2 nanofibrous mats for enhancing photocatalysis properties towards organic dye pollution. Compos. Commun. 2019, 15, 58–63. [Google Scholar]

- Zhang, H.; Tan, B.; Xu, H.; Yan, K. Microstructures and Thermal Aging Properties of Layered Silicate Modified Bitumens. Petrol. Sci. Technol. 2014, 32, 1697–1703. [Google Scholar]

- Zhang, H.; Shi, C.; Han, J.; Yu, J. Effect of organic layered silicates on flame retardancy and aging properties of bitumen. Constr. Build. Mater. 2013, 40, 1151–1155. [Google Scholar] [CrossRef]

- AASHTO. AASHTO Designation: T 316–02: Standard Method of Test for Viscosity Determination of Asphalt Binder Using Rotational Viscometer; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2002. [Google Scholar]

- Cao, L.; Tan, Y.; Dong, Z.; Cun, L. Evaluation for Low Temperature Performance of SBS Modified Asphalt Using Glass Transition Temperature. China J. Highway Transport. 2006, 19, 1–6. [Google Scholar]

- Zhang, L.; Tan, Y.; Hussain, B. Relationship between glass transition temperature and low temperature properties of oil modified binders. Constr. Build. Mater. 2016, 104, 92–98. [Google Scholar]

- Lin, P.; Huang, W.; Tang, N.; Xiao, F.; Li, Y. Understanding the low temperature properties of Terminal Blend hybrid asphalt through chemical and thermal analysis methods. Constr. Build. Mater. 2018, 169, 543–552. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).