Cutting Blade Measurement of an Ultrasonic Cutting Machine Using Multi-Step Detection

Abstract

1. Introduction

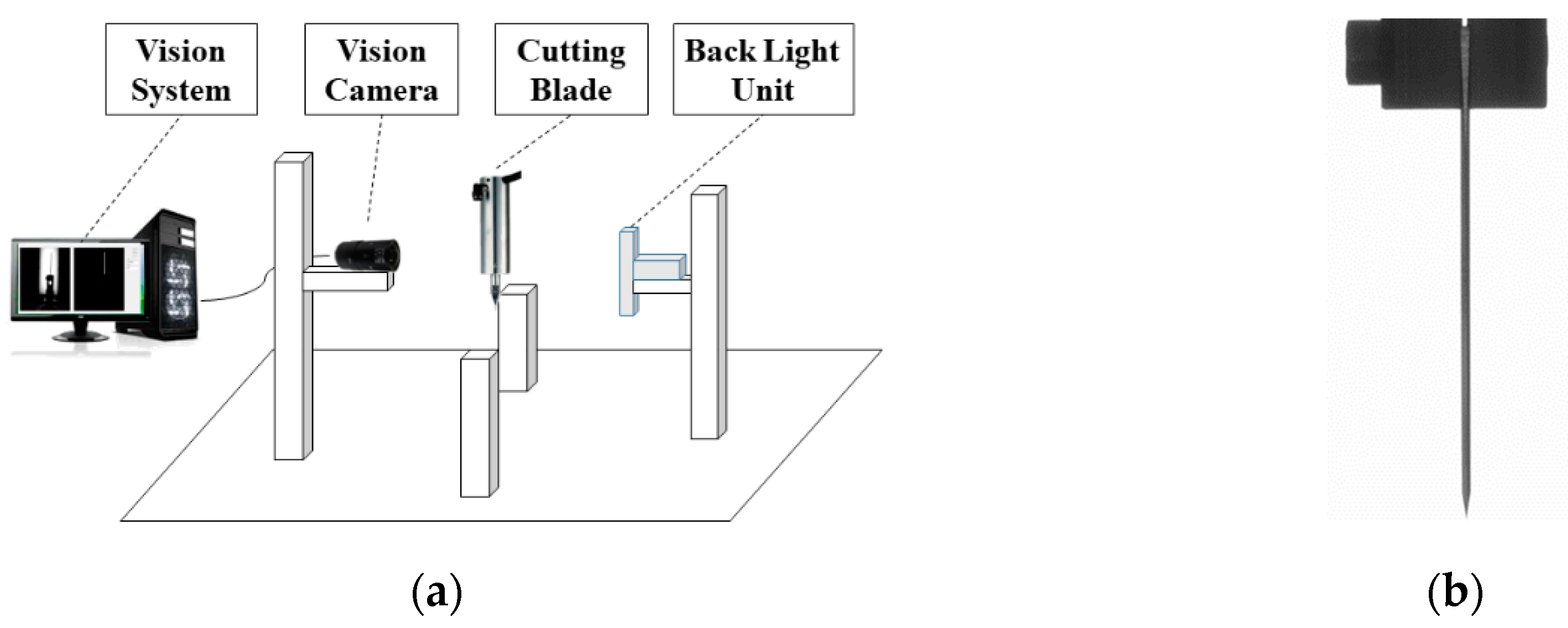

2. Cutting Blade Measurement System

2.1. System Configuration

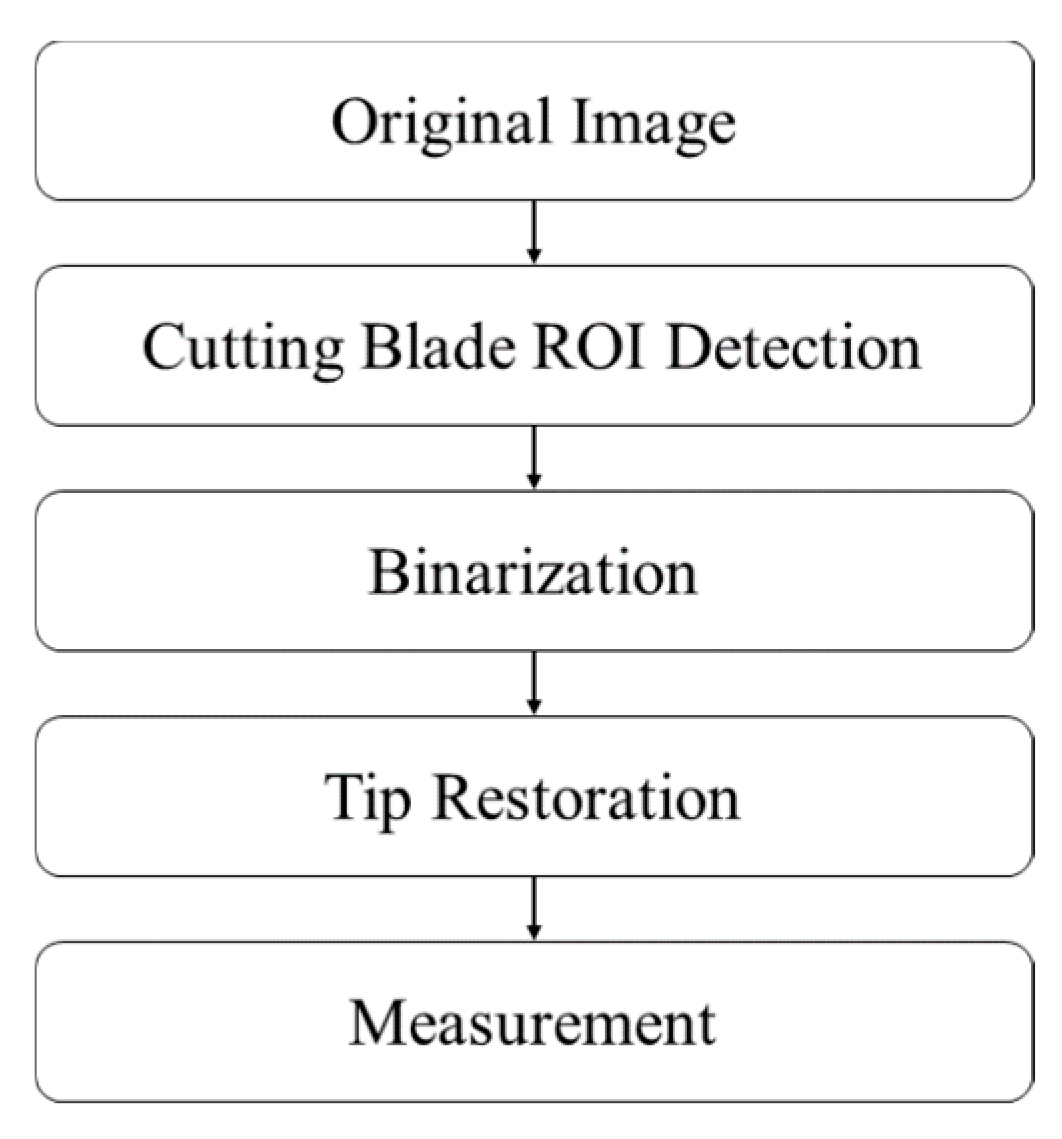

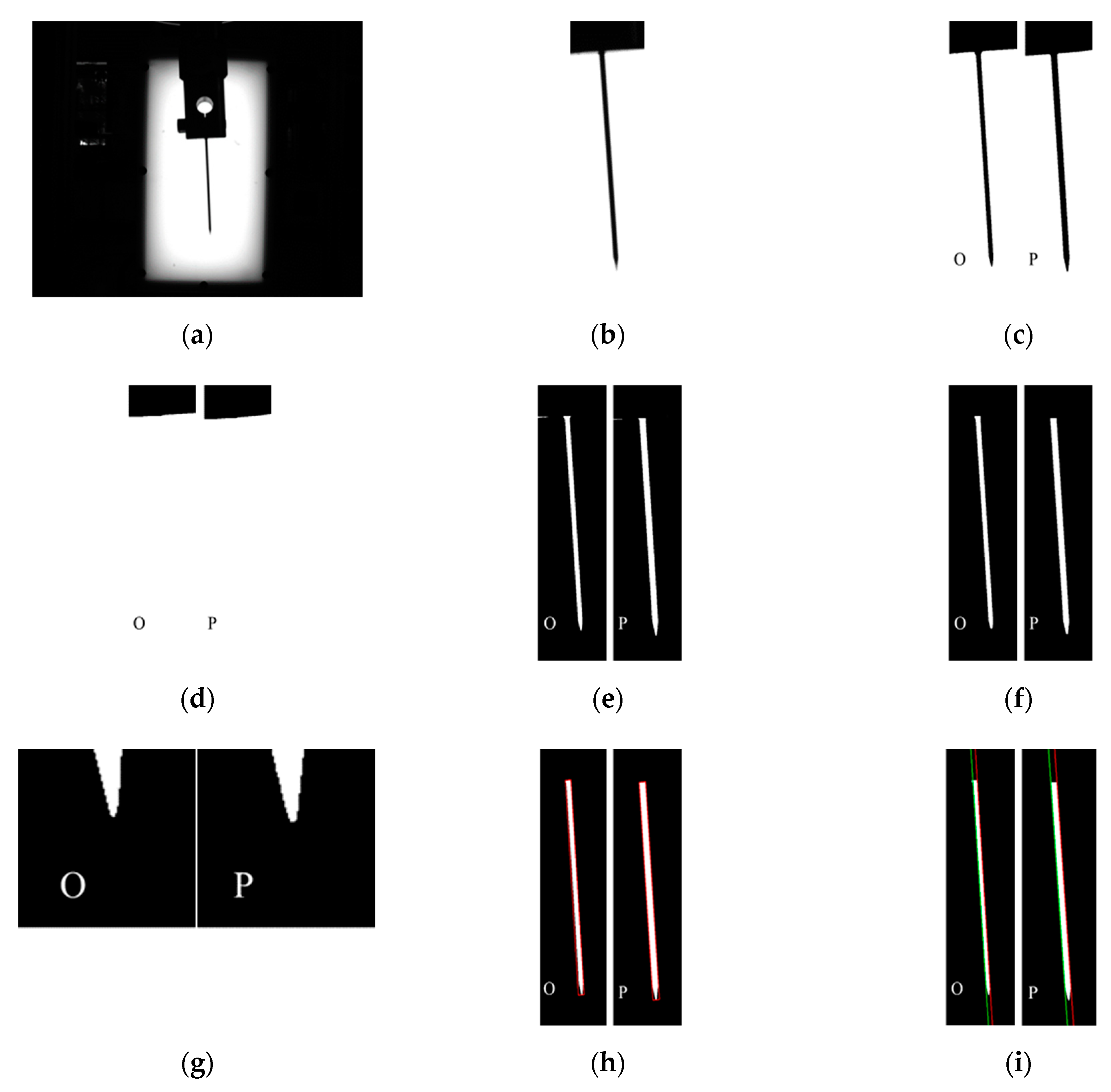

2.2. Detection Algorithm

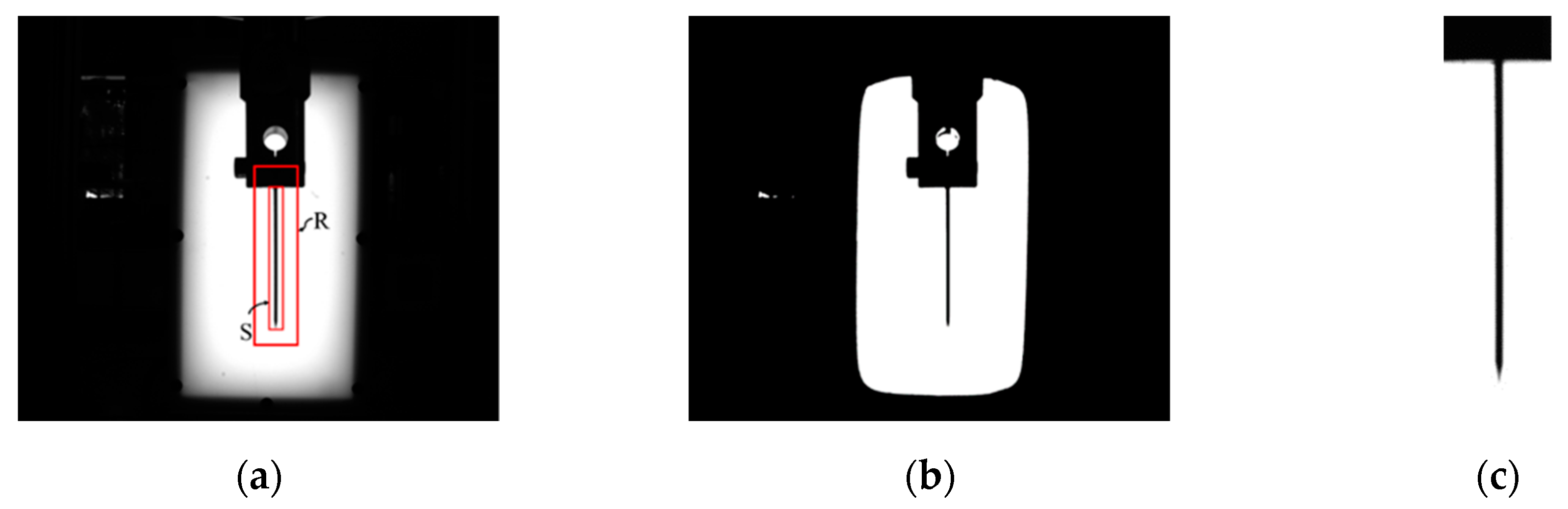

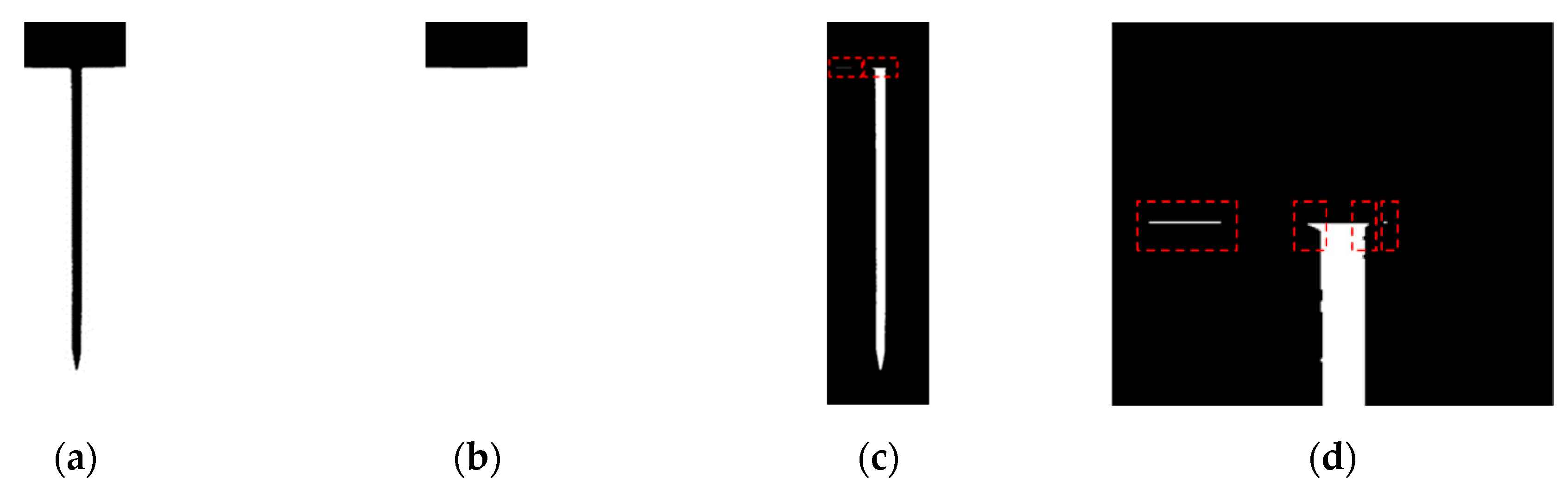

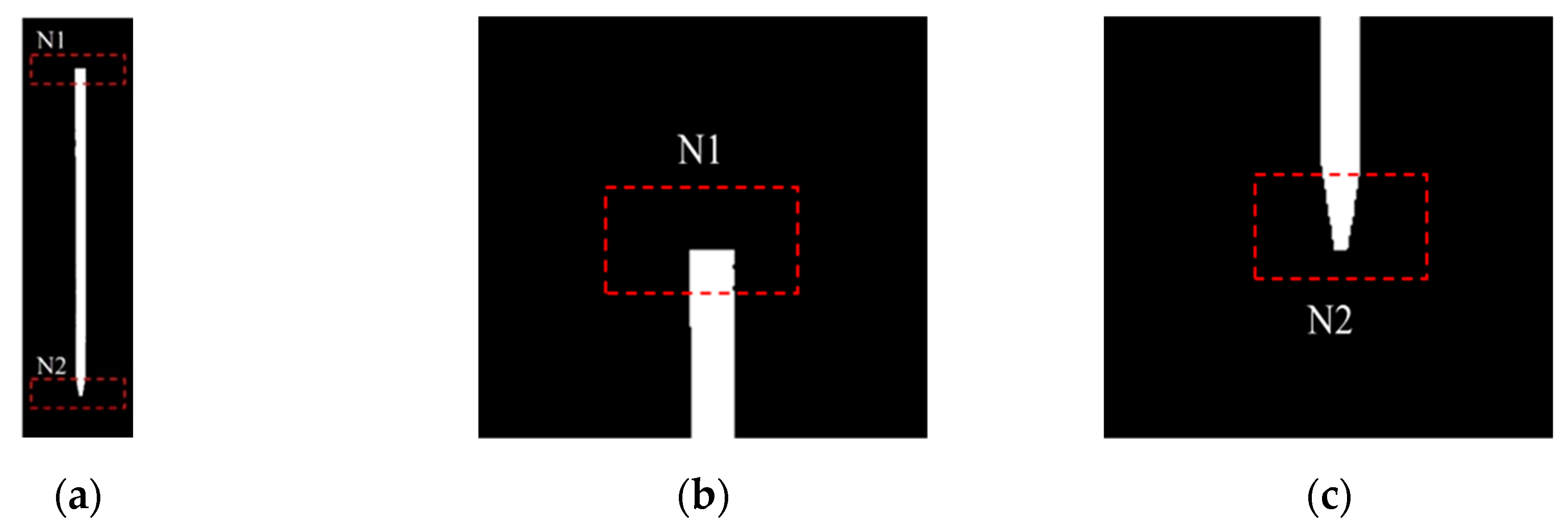

2.3. ROI Detection

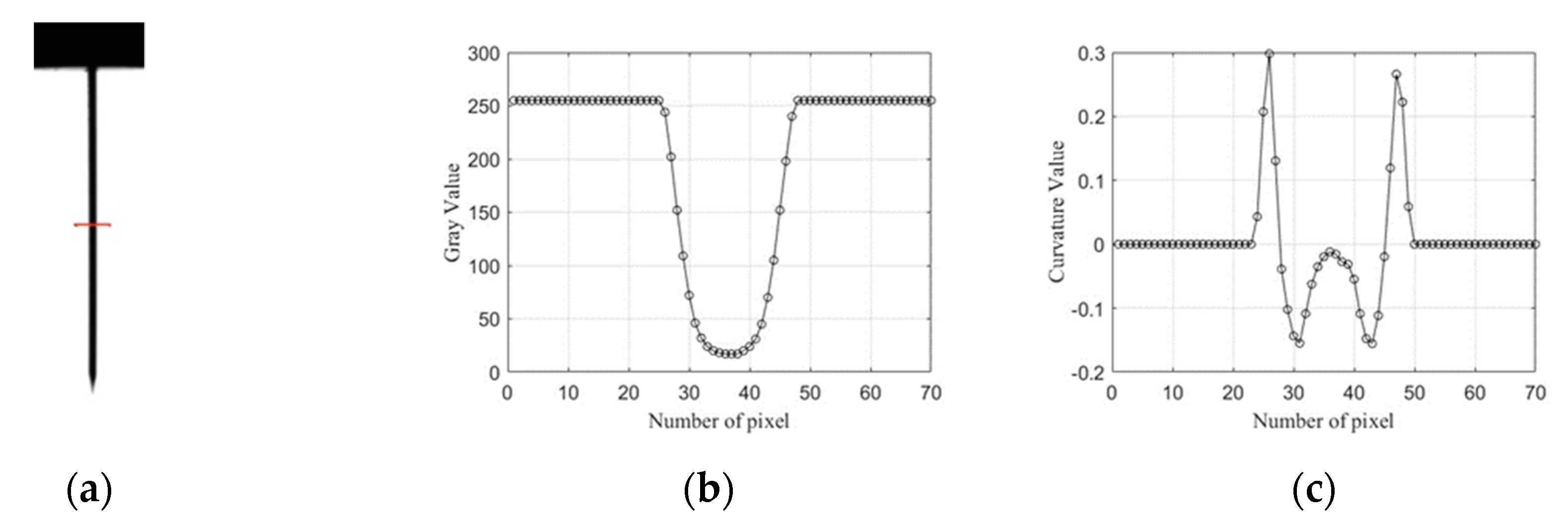

3. Curvature-Based Binarization Method

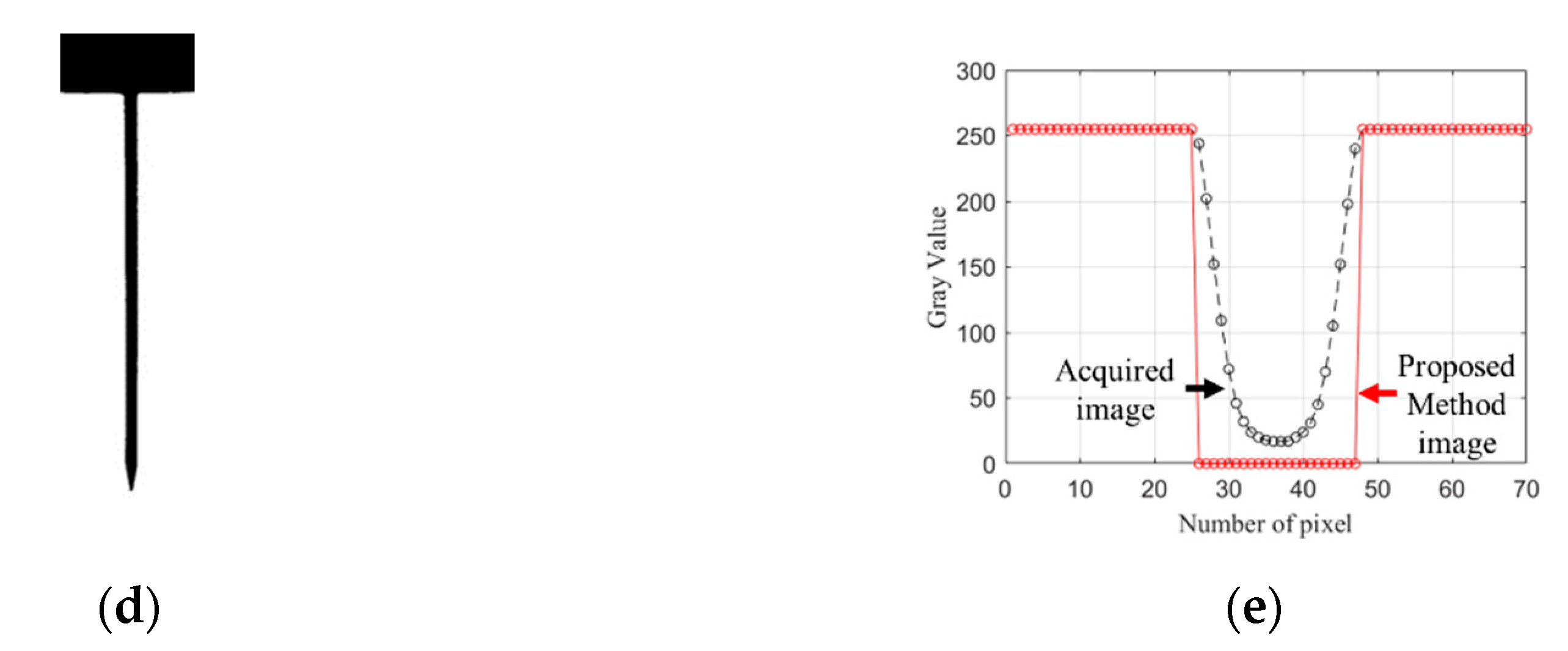

3.1. Image Binarization

3.2. Background Extraction

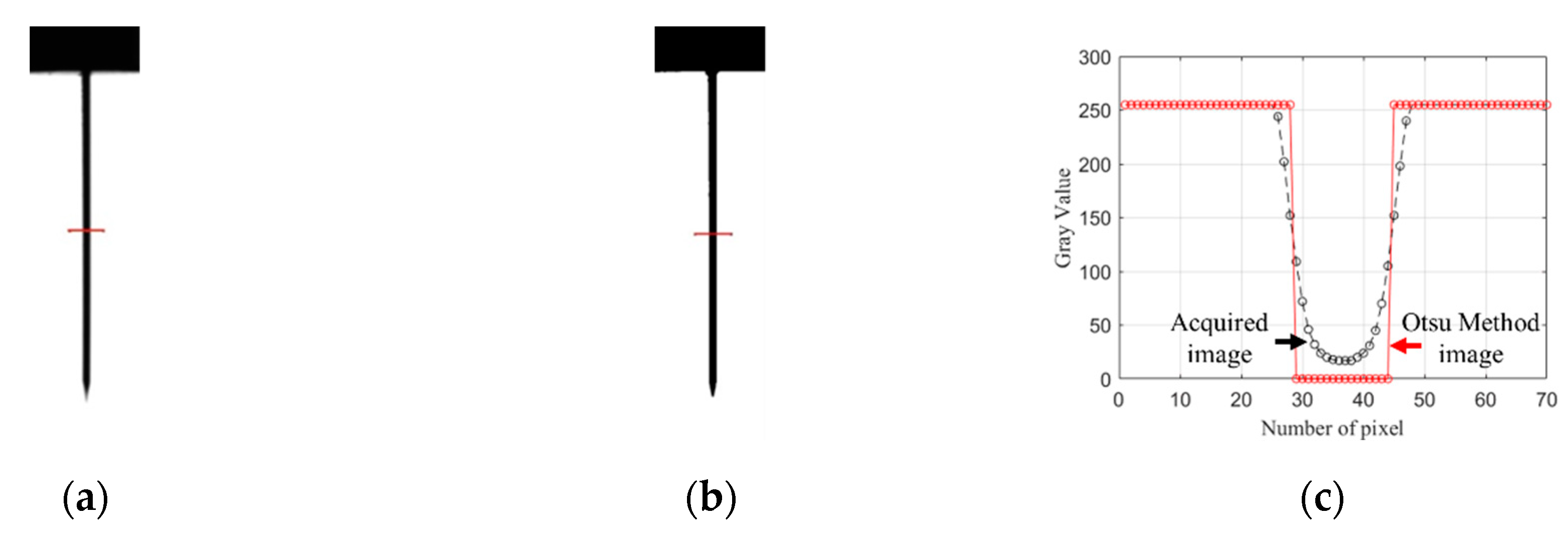

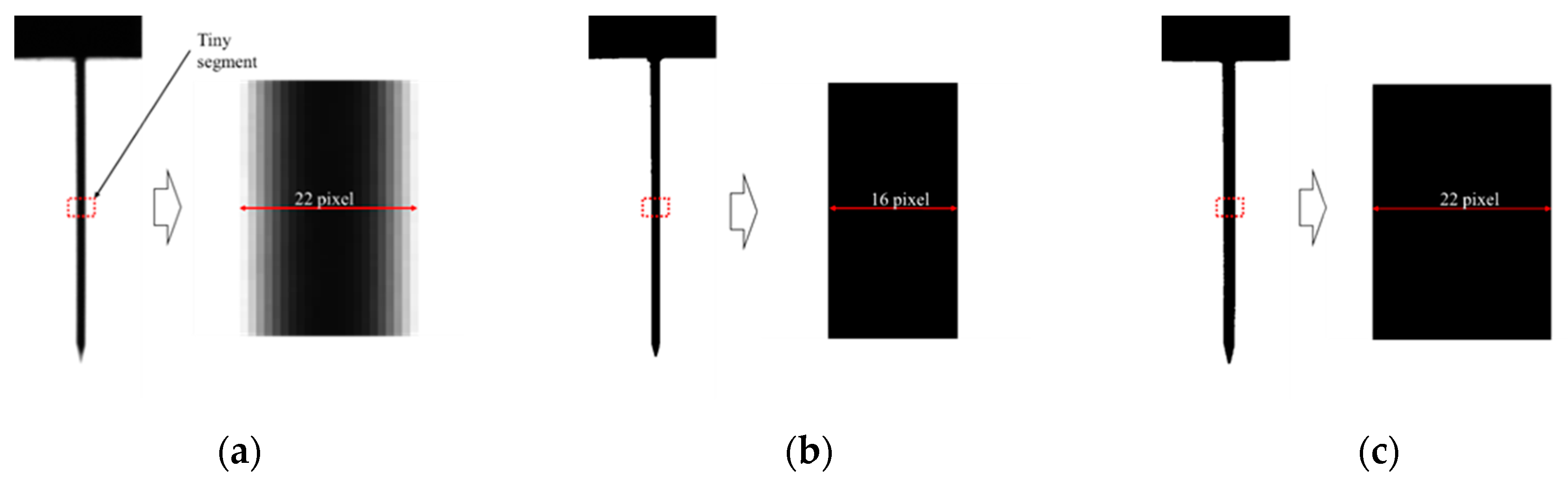

3.3. Restoration of Lost Data

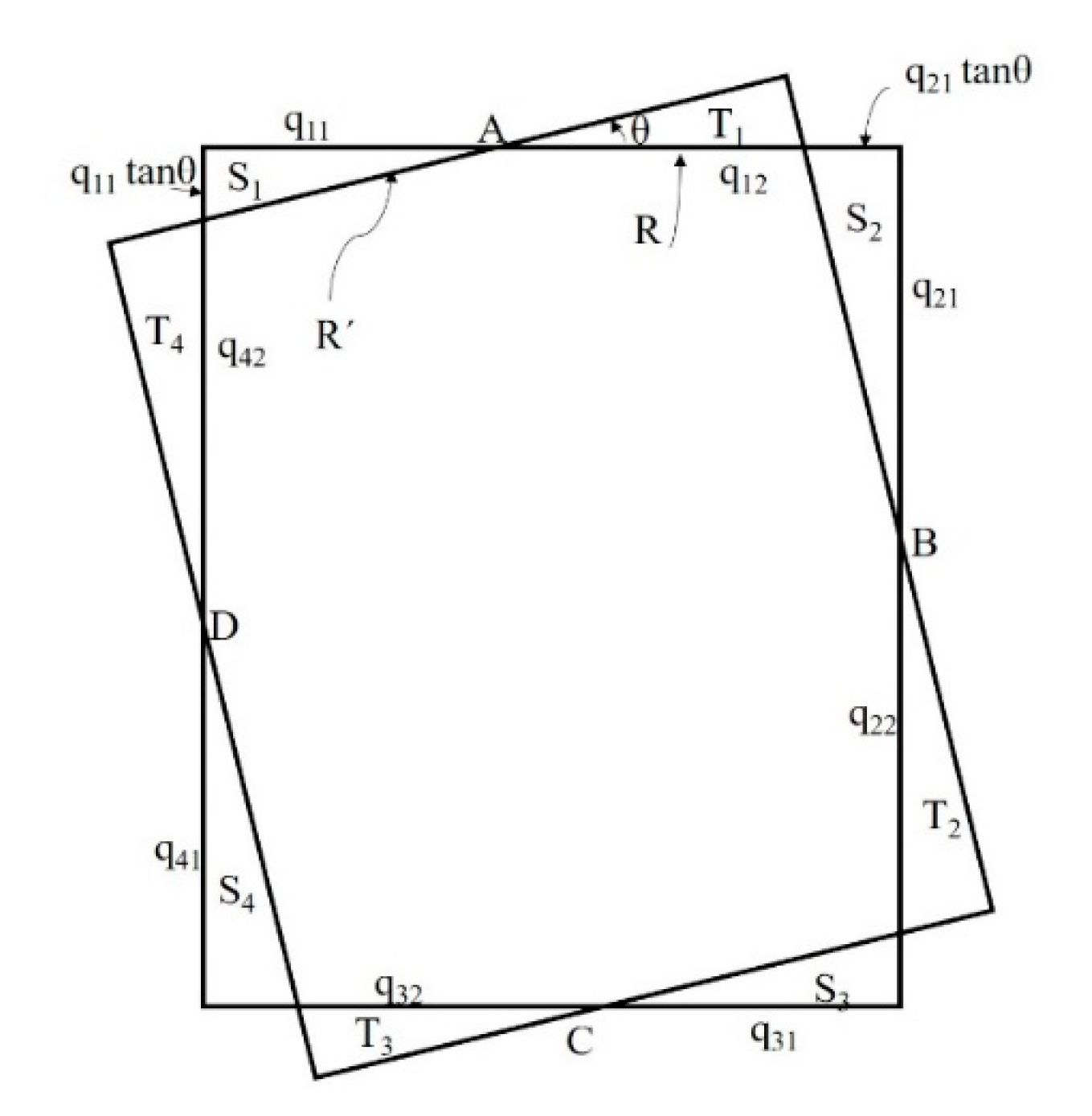

3.4. Cutting Blade Rotation Angle and Length Measurement

3.5. Cutting Blade Thickness Measurement

3.6. Abnormalities’ Inspection in the Cutting Blade

4. Experimental Results and Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Seo, J.S.; Lee, Y.J.; Kim, J.W.; Park, D.S. Design Improvement and Performance Evaluation of 20kHz Horn for Ultrasonic Cutting. J. Korean Soc. Manuf. Process Eng. 2013, 12, 135–140. [Google Scholar]

- Ji, S.; Yuan, J.; Wan, Y.; Zhang, X.; Bao, G.; Zhang, L.; Zhang, L. Method of monitoring wearing and breakage states of cutting tools based on Mahalanobis distance features. J. Mater. Process. Technol. 2002, 129, 114–117. [Google Scholar] [CrossRef]

- Furferi, R.; Governi, L.; Puggelli, L.; Servi, M.; Volpe, Y. Machine Vision System for Counting Small Metal Parts in Electro-Deposition Industry. Appl. Sci. 2019, 9, 2418. [Google Scholar] [CrossRef]

- Wen, S.; Chen, Z.; Li, C. Vision-Based Surface Inspection System for Bearing Rollers Using Convolutional Neural Networks. Appl. Sci. 2018, 8, 2565. [Google Scholar] [CrossRef]

- Jung, Y.; Park, K.-H. O-ring Size Measurement Based on a Small Machine Vision Inspection Equipment. J. Korea Ind. Inf. Syst. Res. 2014, 19, 41–52. [Google Scholar]

- Lee, J.-J.; Lee, K.-H.; Chung, C.-D.; Park, K.-H.; Park, Y.-B.; Lee, B.-G. Pattern Elimination Method Based on Perspective Transform for Defect Detection of TFT-LCD. J. Korea Multimed. Soc. 2012, 15, 784–793. [Google Scholar] [CrossRef]

- He, J.; Shi, L.; Xiao, J.; Cheng, J.; Zhu, Y. Size Detection of Firebricks Based on Machine Vision Technology. In Proceedings of the 2010 International Conference on Measuring Technology and Mechatronics Automation, Changsha, China, 13–14 March 2010; pp. 394–397. [Google Scholar]

- Xiang, R.; He, W.; Zhang, X.; Wang, D.; Shan, Y. Size measurement based on a two camera machine vision system for the bayonets of automobile brake pads. J. Int. Meas. Confed. 2018, 122, 106–116. [Google Scholar] [CrossRef]

- Choi, H.H.; Yun, B.J. Contrast Enhancement for the Captured Image by Estimating Local Illumination. Opt. Rev. 2011, 18, 389–393. [Google Scholar] [CrossRef]

- Lee, H.Y.; Kim, T.H.; Park, K.H. Target Extraction in Forward-Looking Infrared Images Using Fuzzy Thresholding via Local Region Analysis. Opt. Rev. 2011, 18, 383–388. [Google Scholar] [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray Level Histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Boccardi, S.; Carlomagno, G.M.; Simeoli, G.; Russo, P.; Meola, C. Evaluation of impact-affected areas of glass fibre thermoplastic composites from thermographic images. Meas. Sci. Technol. 2016, 27, 075602. [Google Scholar] [CrossRef]

- Kim, T.-H.; Kim, S.-W.; Ryu, C.-H.; Yun, B.-J.; Kim, J.-H.; Choi, B.-J.; Park, K.-H. ECG Signal Compression using Feature Points based on Curvature. J. Korea Inst. Intell. Syst. 2010, 20, 624–630. [Google Scholar] [CrossRef]

- Lamiroy, B.; Gaucher, O.; Fritz, L. Robust Circle Detection. In Proceedings of the 9th International Conference on Document Analysis and Recognition, Parana, Brazil, 23–26 September 2007; pp. 526–530. [Google Scholar]

- Freeman, H.; Shapira, R. Determining the Minimum-Area Encasing Rectangle for an Arbitrary Closed Curve. Commun. ACM 1974, 18, 409–413. [Google Scholar] [CrossRef]

- Fischler, M.A.; Bolles, R.C. Random Sample Consensus: A Paradigm for Model Fitting with Applications to Image Analysis and Automated Cartography. Commun. ACM 1981, 24, 381–395. [Google Scholar] [CrossRef]

- Lei, Z.; Gao, J.; Wang, Z. Size Measurement Technology of Seals. In Proceedings of the 2010 3rd International Conference on Computer Science and Information Technology, Chengdu, China, 9–11 July 2010; pp. 222–225. [Google Scholar]

| Original | Thickness | 0.6 mm | |||

|---|---|---|---|---|---|

| Length | 25 mm | ||||

| Real Angle | Measured Angle | Otsu Method [mm] | Proposal Method [mm] | ||

| Thickness | Length | Thickness | Length | ||

| 0° | 0° | 0.4290 | 24.6400 | 0.6006 | 24.9550 |

| 2.20° | 2.186° | 0.4573 | 24.7071 | 0.6002 | 24.9889 |

| 3.40° | 3.367° | 0.4425 | 24.7378 | 0.6138 | 25.0209 |

| −2.4° | −2.444° | 0.4286 | 24.6843 | 0.6000 | 24.9585 |

| Mean | 0.4393 | 24.6923 | 0.6036 | 24.9808 | |

| Standard deviation | 0.00018 | 0.00169 | 0.00004 | 0.00094 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, T.-G.; Ahmad, S.F.; Yun, B.-J.; Kim, H.D. Cutting Blade Measurement of an Ultrasonic Cutting Machine Using Multi-Step Detection. Appl. Sci. 2019, 9, 3338. https://doi.org/10.3390/app9163338

Kim T-G, Ahmad SF, Yun B-J, Kim HD. Cutting Blade Measurement of an Ultrasonic Cutting Machine Using Multi-Step Detection. Applied Sciences. 2019; 9(16):3338. https://doi.org/10.3390/app9163338

Chicago/Turabian StyleKim, Tae-Gu, Sheikh Faisal Ahmad, Byoung-Ju Yun, and Hyun Deok Kim. 2019. "Cutting Blade Measurement of an Ultrasonic Cutting Machine Using Multi-Step Detection" Applied Sciences 9, no. 16: 3338. https://doi.org/10.3390/app9163338

APA StyleKim, T.-G., Ahmad, S. F., Yun, B.-J., & Kim, H. D. (2019). Cutting Blade Measurement of an Ultrasonic Cutting Machine Using Multi-Step Detection. Applied Sciences, 9(16), 3338. https://doi.org/10.3390/app9163338