Experimental Investigation of Force Response, Efficiency, and Wear Behaviors of Polycrystalline Diamond Rock Cutters

Abstract

:1. Introduction

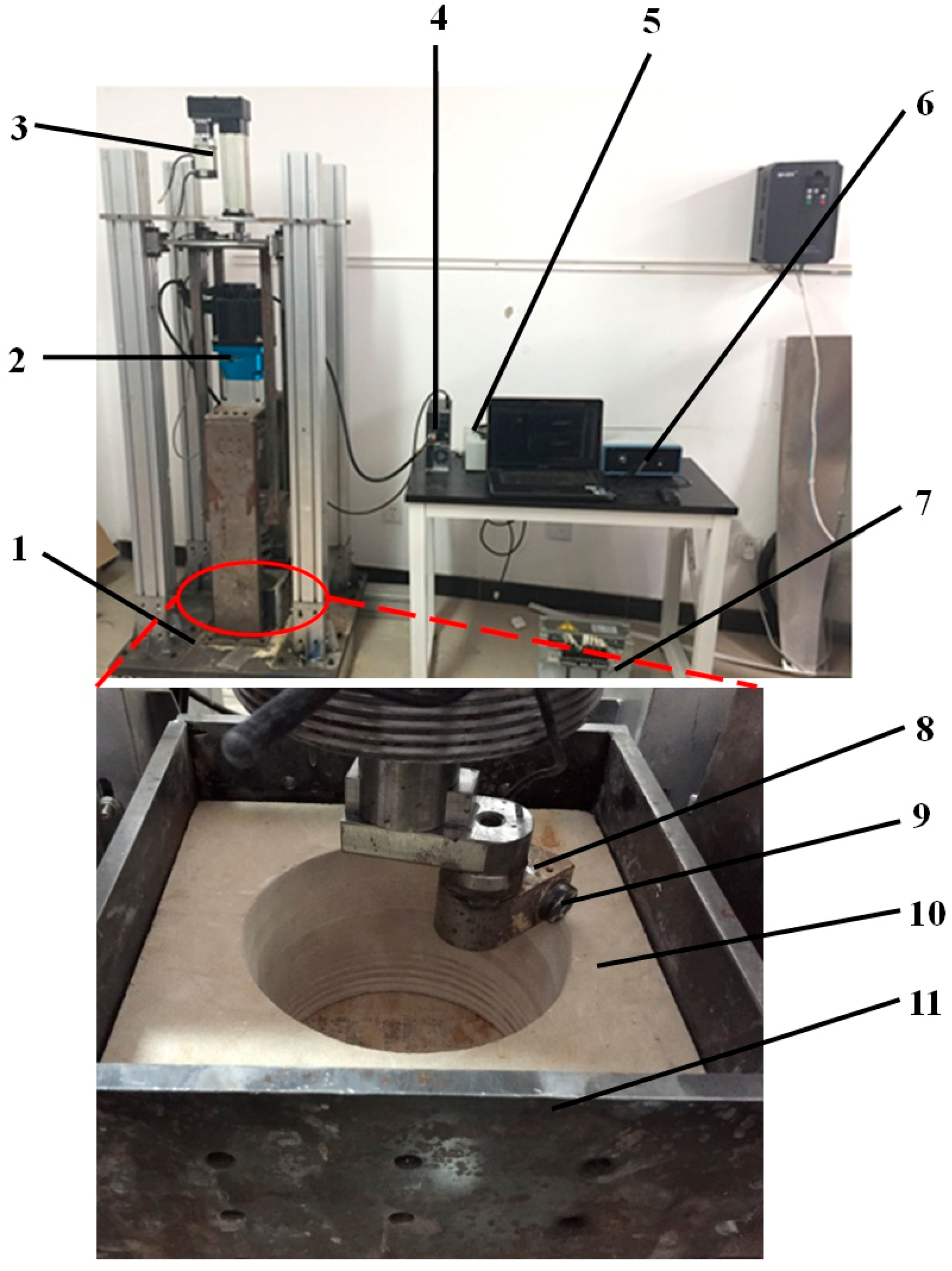

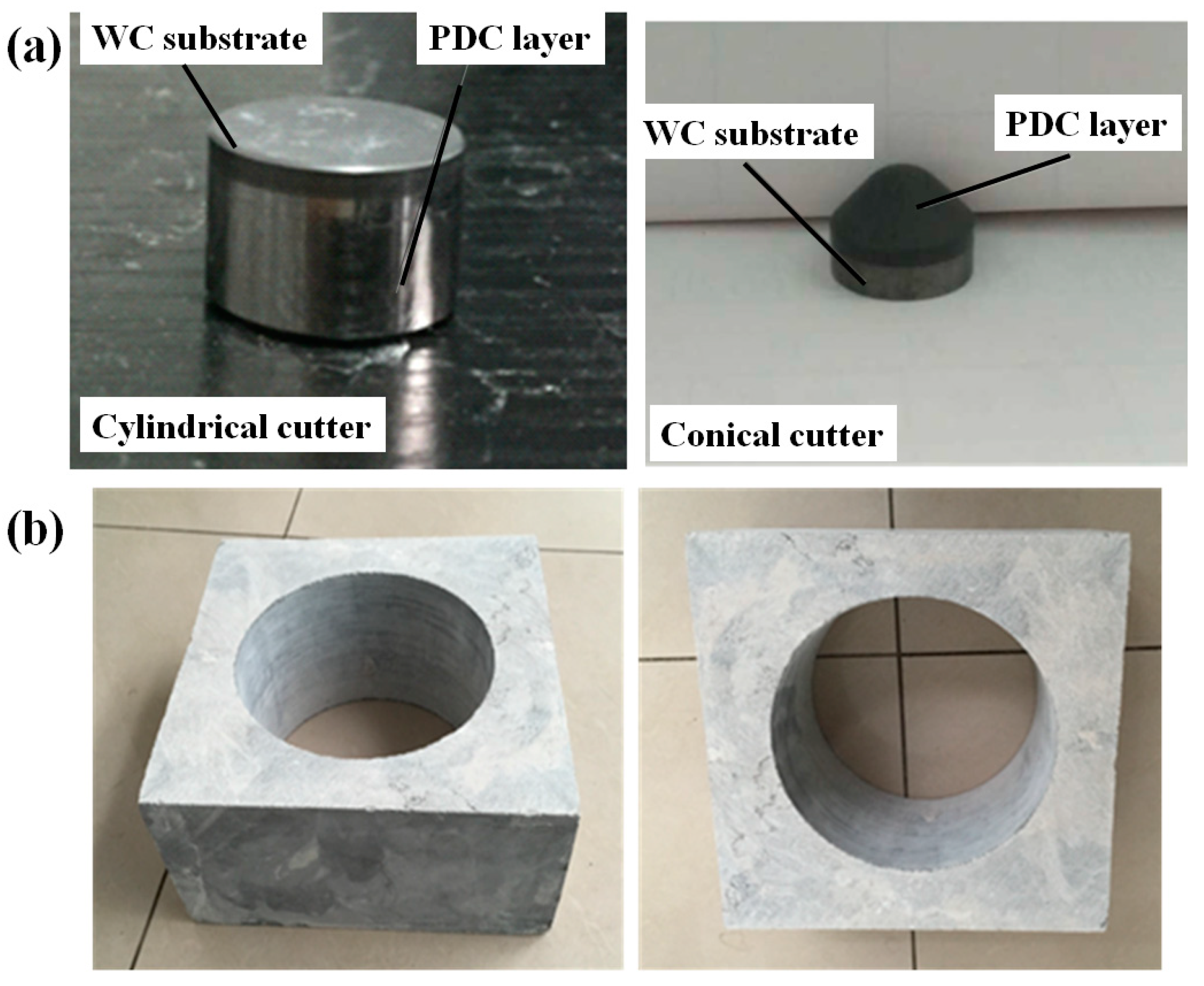

2. Experimental Details

3. Results and Discussion

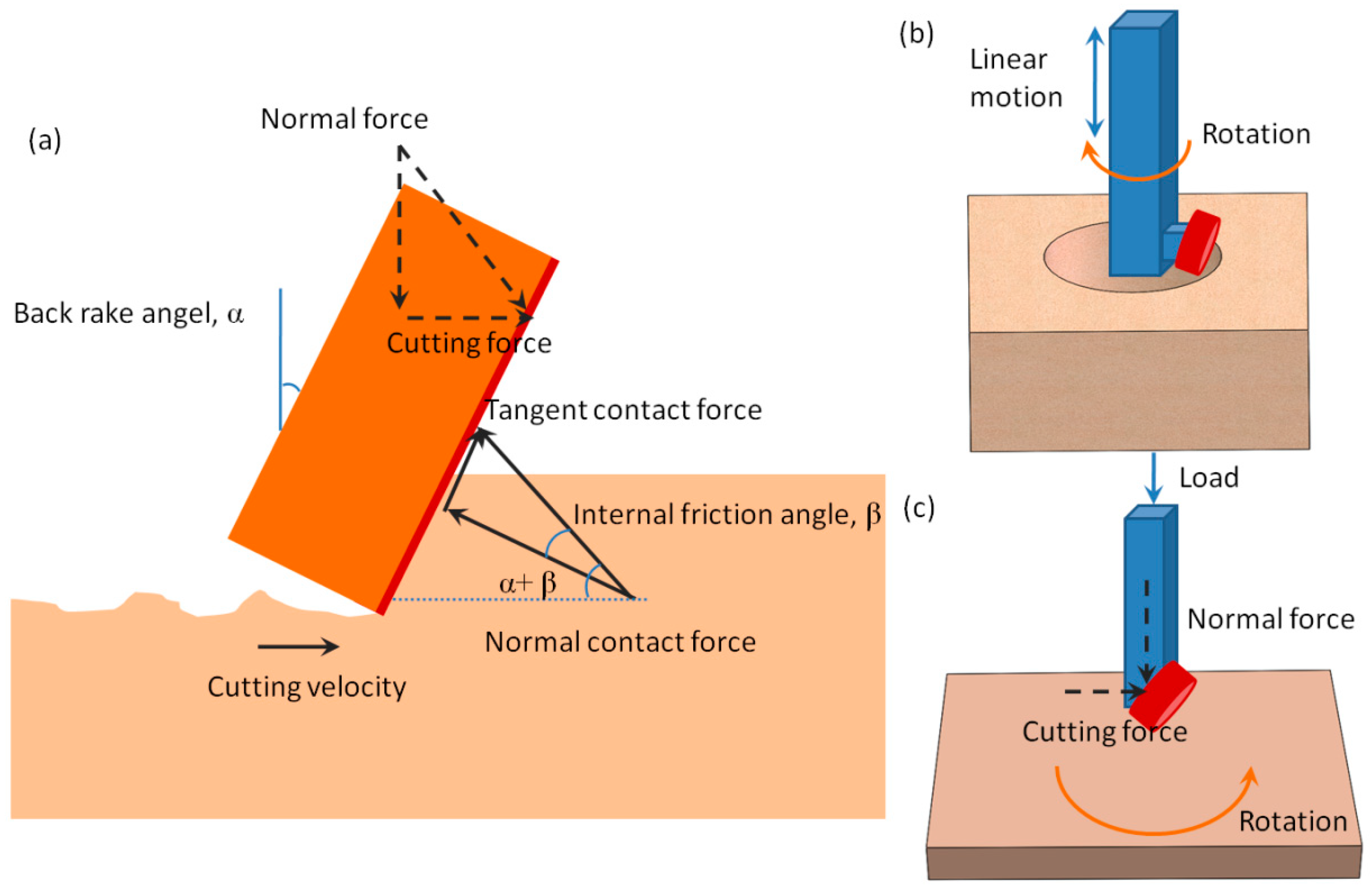

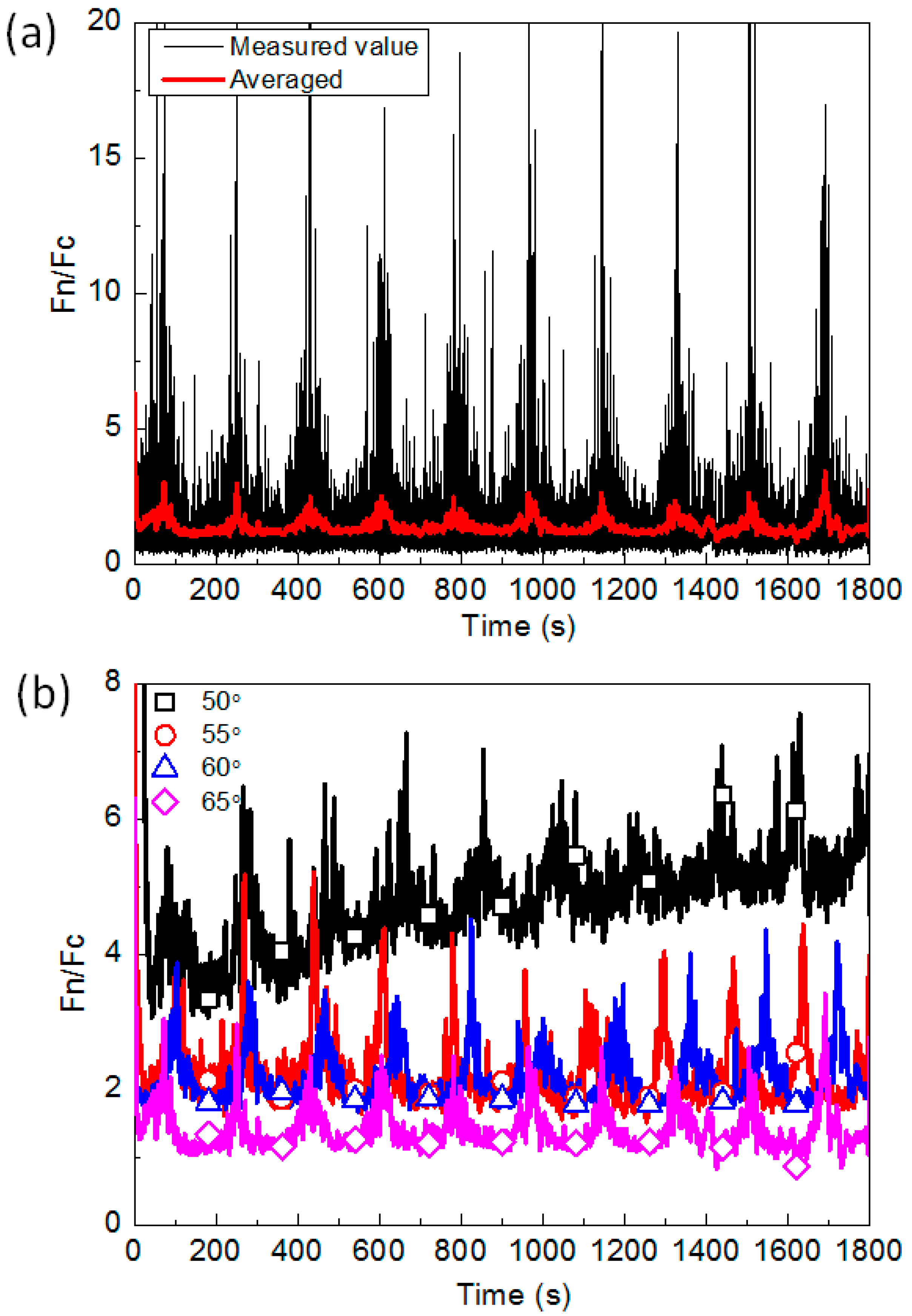

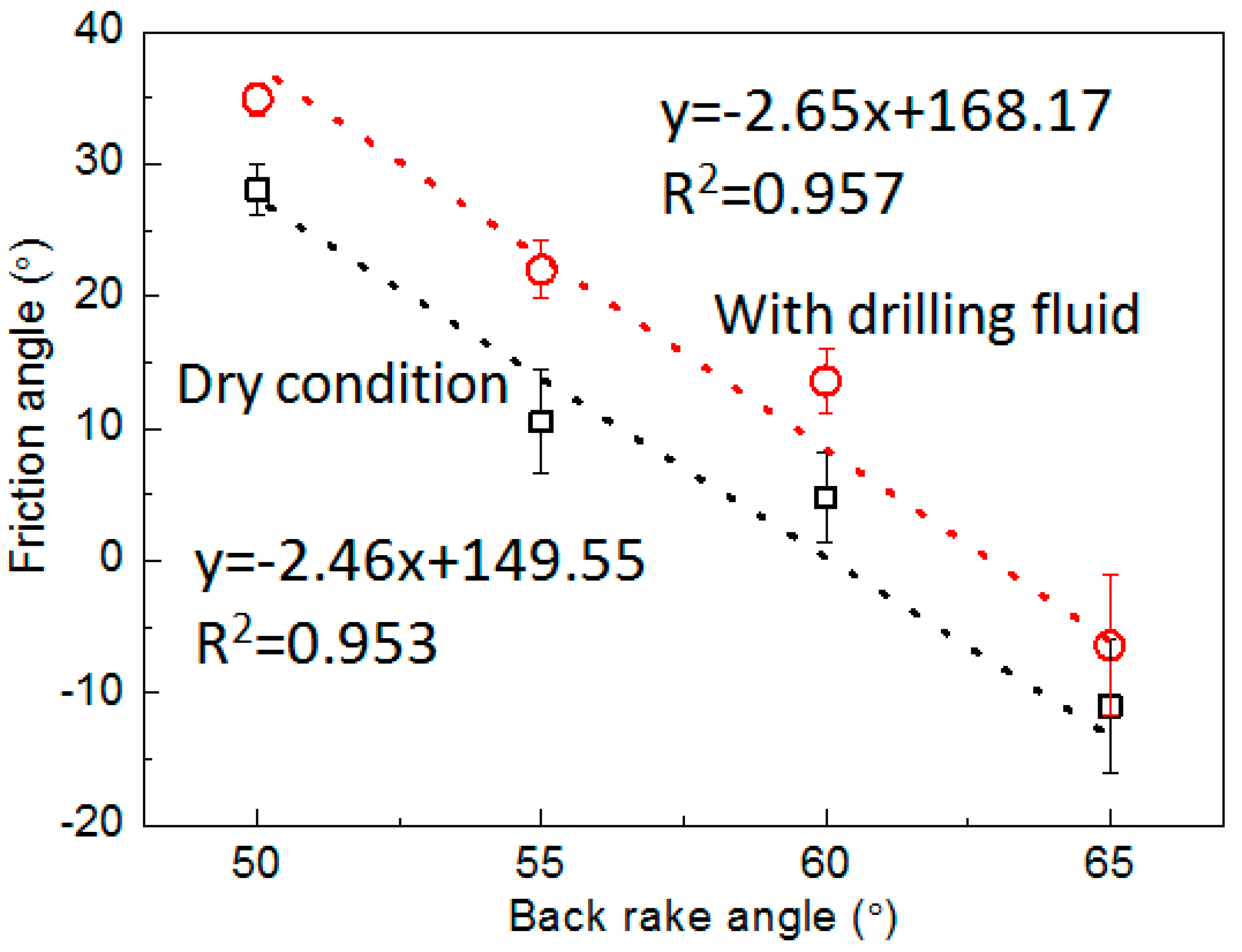

3.1. Friction Angle

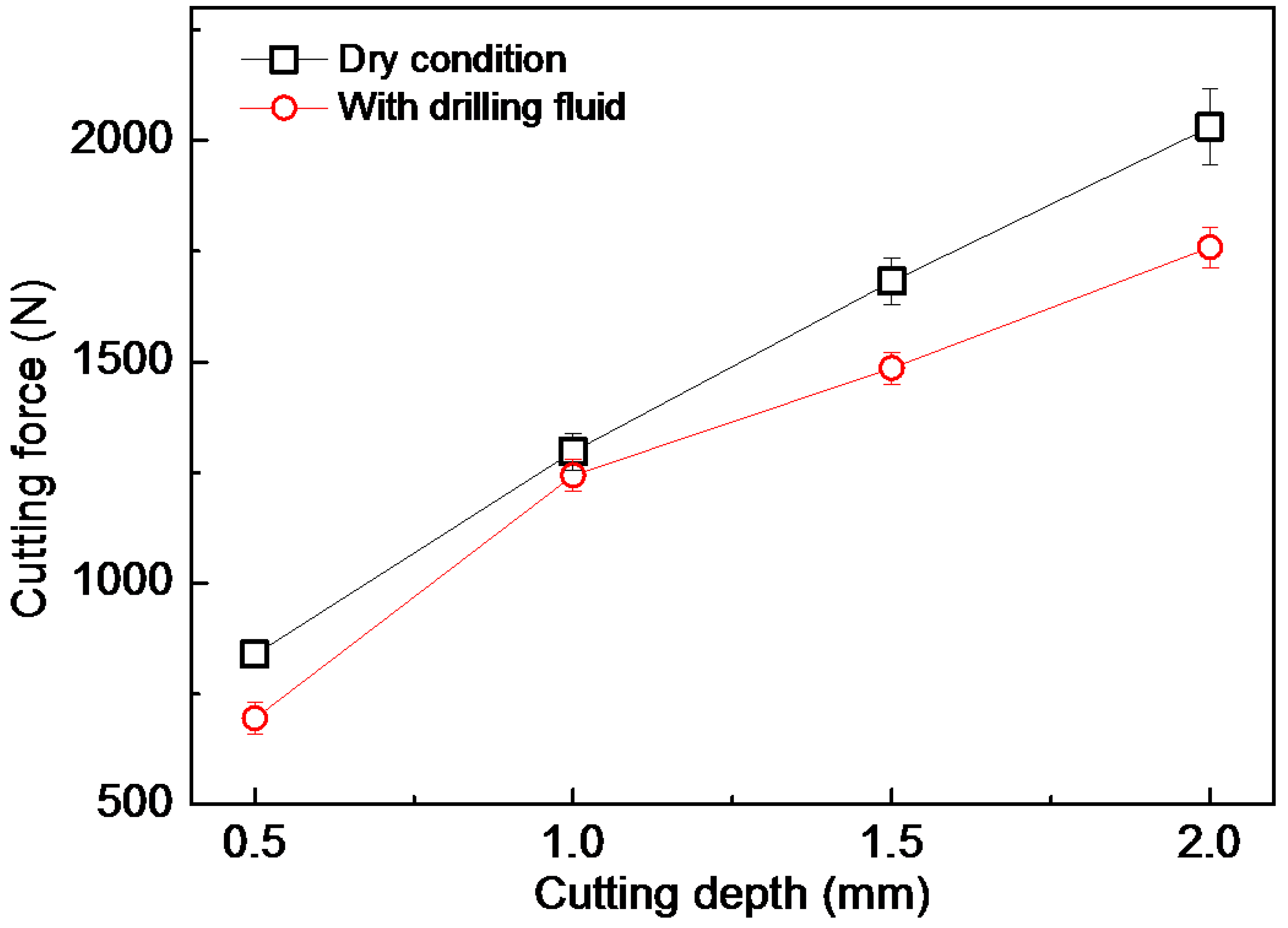

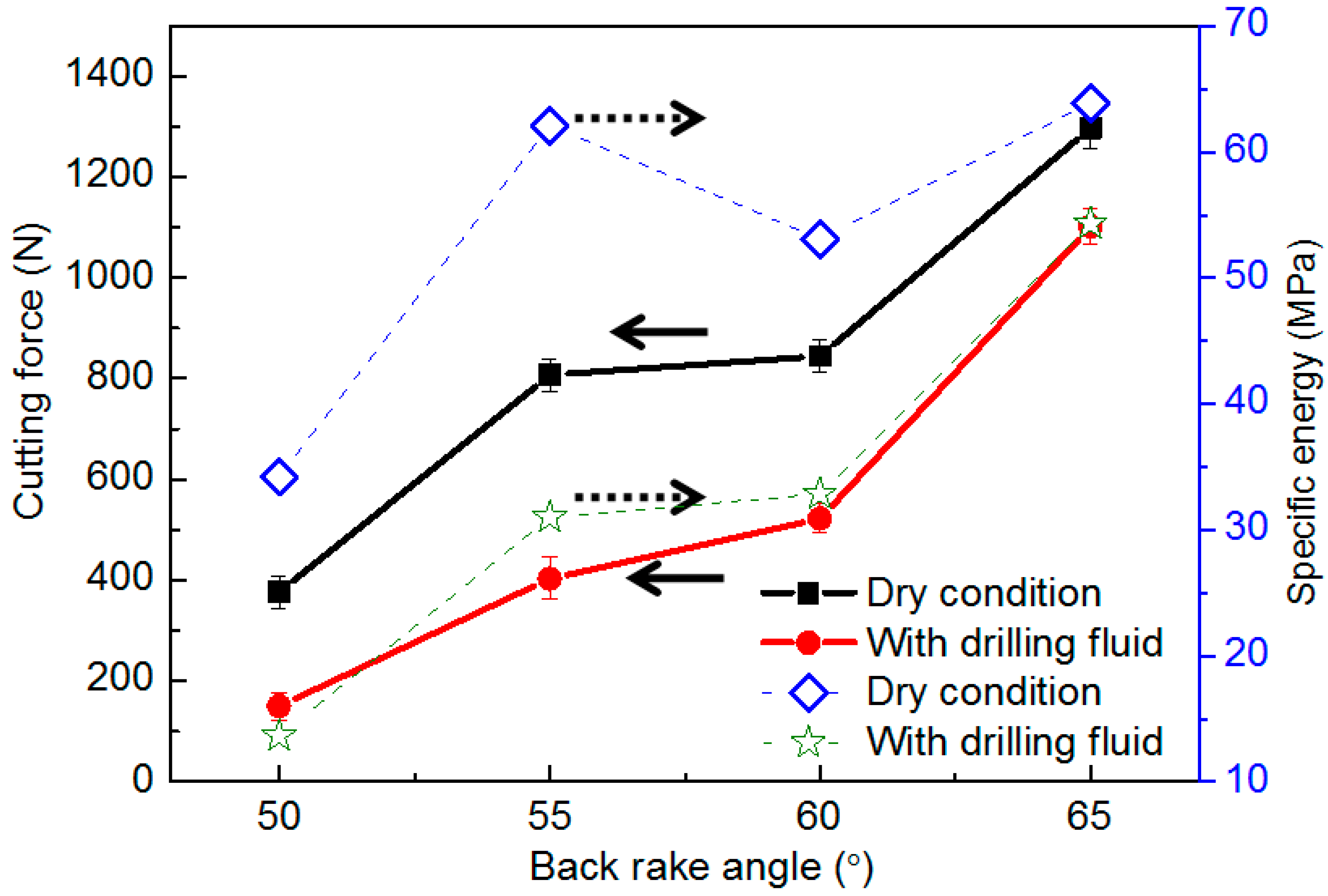

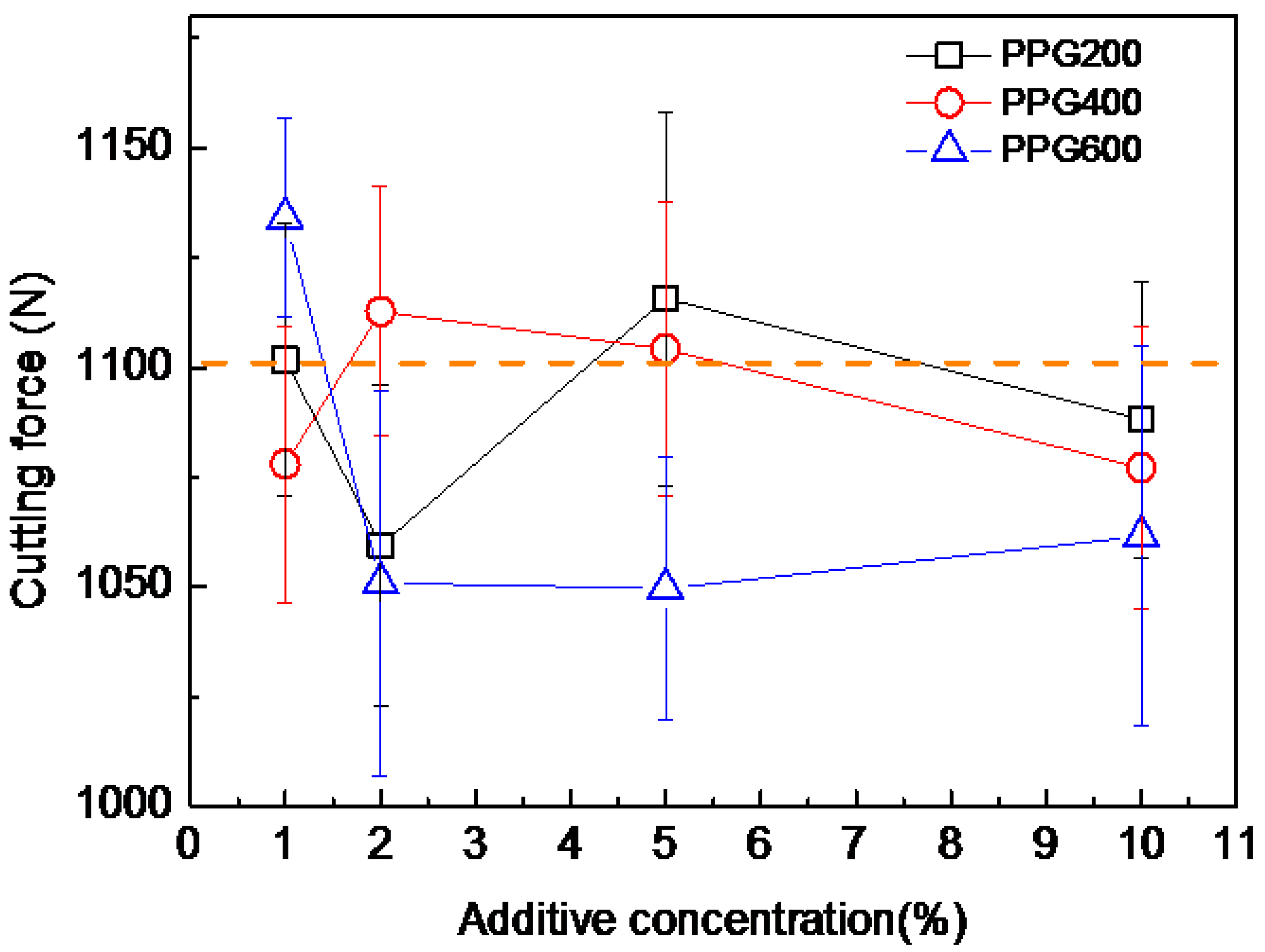

3.2. Cutting Force and Specific Energy

3.3. Wear Behaviors

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Warren, T.; Sinor, L. PDC bits: What’s needed to meet tomorrow’s challenge. In Proceedings of the University of Tulsa Centennial Petroleum Engineering Symposium, Tulsa, Oklahoma, 29–31 August 1994. [Google Scholar]

- Menand, S.; Gerbaud, L.; Dourfaye, A. PDC bit technology improvements increase efficiency, bit life. Drill. Contract. 2005, 61, 52–54. [Google Scholar]

- Bellin, F.; Dourfaye, A.; King, W.; Thigpen, M. The current state of PDC bit technology. World Oil 2010, 231, 9. [Google Scholar]

- Che, D.; Ehmann, K. Experimental study of force responses in polycrystalline diamond face turning of rock. Int. J. Rock Mech. Min. Sci. 2014, 72, 80–91. [Google Scholar] [CrossRef]

- Hareland, G.; Nygaard, R.; Yan, W.; Wise, J. Cutting efficiency of a single PDC cutter on hard rock. J. Can. Pet. Technol. 2009, 48, 60–65. [Google Scholar] [CrossRef]

- Rafatian, N.; Miska, S.Z.; Ledgerwood, L.W.; Yu, M.; Ahmed, R. Experimental study of MSE of a single PDC cutter under simulated pressurized conditions. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Amsterdam, The Netherlands, 17–19 March 2009. [Google Scholar]

- Akbari, B.; Miska, S. The effects of chamfer and back rake angle on PDC cutters friction. J. Nat. Gas Sci. Eng. 2016, 35, 347–353. [Google Scholar] [CrossRef]

- Che, D.; Ehmann, K. Polycrystalline diamond turning of rock. In Proceedings of the ASME 2013 International Manufacturing Science and Engineering Conference Collocated with the 41st North American Manufacturing Research Conference, Madison, WI, USA, 10–14 June 2013. [Google Scholar]

- Raymond, D.W. PDC bits demonstrate benefit over conventional hard-rock drill bits. In Transactions-Geothermal Resources Council; Geothermal Resources Council: Davis, CA, USA, 2001; pp. 125–132. [Google Scholar]

- Bybee, K. New bit design and cutter technology extend PDC applications to hard-rock drilling. J. Pet. Technol. 2005, 57, 63–64. [Google Scholar] [CrossRef]

- Beste, U.; Jacobson, S. A new view of the deterioration and wear of WC/Co cemented carbide rock drill buttons. Wear 2008, 264, 1129–1141. [Google Scholar] [CrossRef]

- Beste, U.; Lundvall, A.; Jacobson, S. Micro-scratch evaluation of rock types—A means to comprehend rock drill wear. Tribol. Int. 2004, 37, 203–210. [Google Scholar] [CrossRef]

- Petrica, M.; Badisch, E.; Peinsitt, T. Abrasive wear mechanisms and their relation to rock properties. Wear 2013, 308, 86–94. [Google Scholar] [CrossRef]

- Hamade, R.; Manthri, S.; Pusavec, F.; Zacny, K.; Taylor, L.; Dillon, O.; Rouch, K.; Jawahir, I. Compact core drilling in basalt rock using PCD tool inserts: Wear characteristics and cutting forces. J. Mate. Process. Technol. 2010, 210, 1326–1339. [Google Scholar] [CrossRef]

- Huang, H.; Lecampion, B.; Detournay, E. Discrete element modeling of tool-rock interaction I: Rock cutting. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 1913–1929. [Google Scholar] [CrossRef]

- Menezes, P.L. Influence of rock mechanical properties and rake angle on the formation of rock fragments during cutting operation. Int. J. Adv. Manuf. Technol. 2017, 90, 127–139. [Google Scholar] [CrossRef]

- Che, D.; Han, P.; Guo, P.; Ehmann, K. Issues in Polycrystalline Diamond Compact Cutter–Rock Interaction from a Metal Machining Point of View—Part II: Bit Performance and Rock Cutting Mechanics. J. Manuf. Sci. Eng. 2012, 134, 064002. [Google Scholar] [CrossRef]

- Che, D.; Zhang, W.; Ehmann, K. Chip formation and force responses in linear rock cutting: An experimental study. J. Manuf. Sci. Eng. 2017, 139, 011011. [Google Scholar] [CrossRef]

- Ai, X. Technology and applications of air drilling. Pet. Drill. Tech. 2006, 34, 16. [Google Scholar]

- Xiao, H.; Liu, S.; Chen, Y.; Han, D.; Wang, D. Impacts of polypropylene glycol (PPG) additive and pH on tribological properties of water-based drilling mud for steel-steel contact. Tribol. Int. 2017, 110, 318–325. [Google Scholar] [CrossRef]

- Richard, T. Determination of Rock Strength from Cutting Tests. Ph.D. Thesis, University of Minnesota, Minneapolis, MN, USA, 1999. [Google Scholar]

- Jimenez, M.A.; Genolet, L.C.; Chavez, J.C.; Espin, D. Method for Treating Drilling Fluid Using Nanoparticles. U.S. Patent 6,579,832, 17 June 2003. [Google Scholar]

- Lee, L.; Patel, A.D.; Stamatakis, E. Glycol Based Drilling Fluid. U.S. Patent 6,291,405, 18 September 2001. [Google Scholar]

- Olofsson, J.; Bexell, U.; Jacobson, S. Tribofilm formation of lightly loaded self mated alumina contacts. Wear 2012, 289, 39–45. [Google Scholar] [CrossRef]

- Olofsson, J.; Lindberg, F.; Johansson, S.; Jacobson, S. On the role of tribofilm formation on the alumina drive components of an ultrasonic motor. Wear 2009, 267, 1295–1300. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, S.; Wang, D. Tribological Properties of Sliding Shale Rock–Alumina Contact in Hydraulic Fracturing. Tribol. Lett. 2016, 62, 20. [Google Scholar] [CrossRef]

| Shear Strength | Compressive Strength | Tensile Strength |

|---|---|---|

| 26.848 MPa | 146.9 MPa | 8.125 MPa |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, H.; Liu, S.; Tan, K. Experimental Investigation of Force Response, Efficiency, and Wear Behaviors of Polycrystalline Diamond Rock Cutters. Appl. Sci. 2019, 9, 3059. https://doi.org/10.3390/app9153059

Xiao H, Liu S, Tan K. Experimental Investigation of Force Response, Efficiency, and Wear Behaviors of Polycrystalline Diamond Rock Cutters. Applied Sciences. 2019; 9(15):3059. https://doi.org/10.3390/app9153059

Chicago/Turabian StyleXiao, Huaping, Shuhai Liu, and Kaiwen Tan. 2019. "Experimental Investigation of Force Response, Efficiency, and Wear Behaviors of Polycrystalline Diamond Rock Cutters" Applied Sciences 9, no. 15: 3059. https://doi.org/10.3390/app9153059

APA StyleXiao, H., Liu, S., & Tan, K. (2019). Experimental Investigation of Force Response, Efficiency, and Wear Behaviors of Polycrystalline Diamond Rock Cutters. Applied Sciences, 9(15), 3059. https://doi.org/10.3390/app9153059