Performance and Reinforcement Mechanism of Modified Asphalt Binders with Nano-Particles, Whiskers, and Fibers

Abstract

:1. Introduction

2. Material and Methods

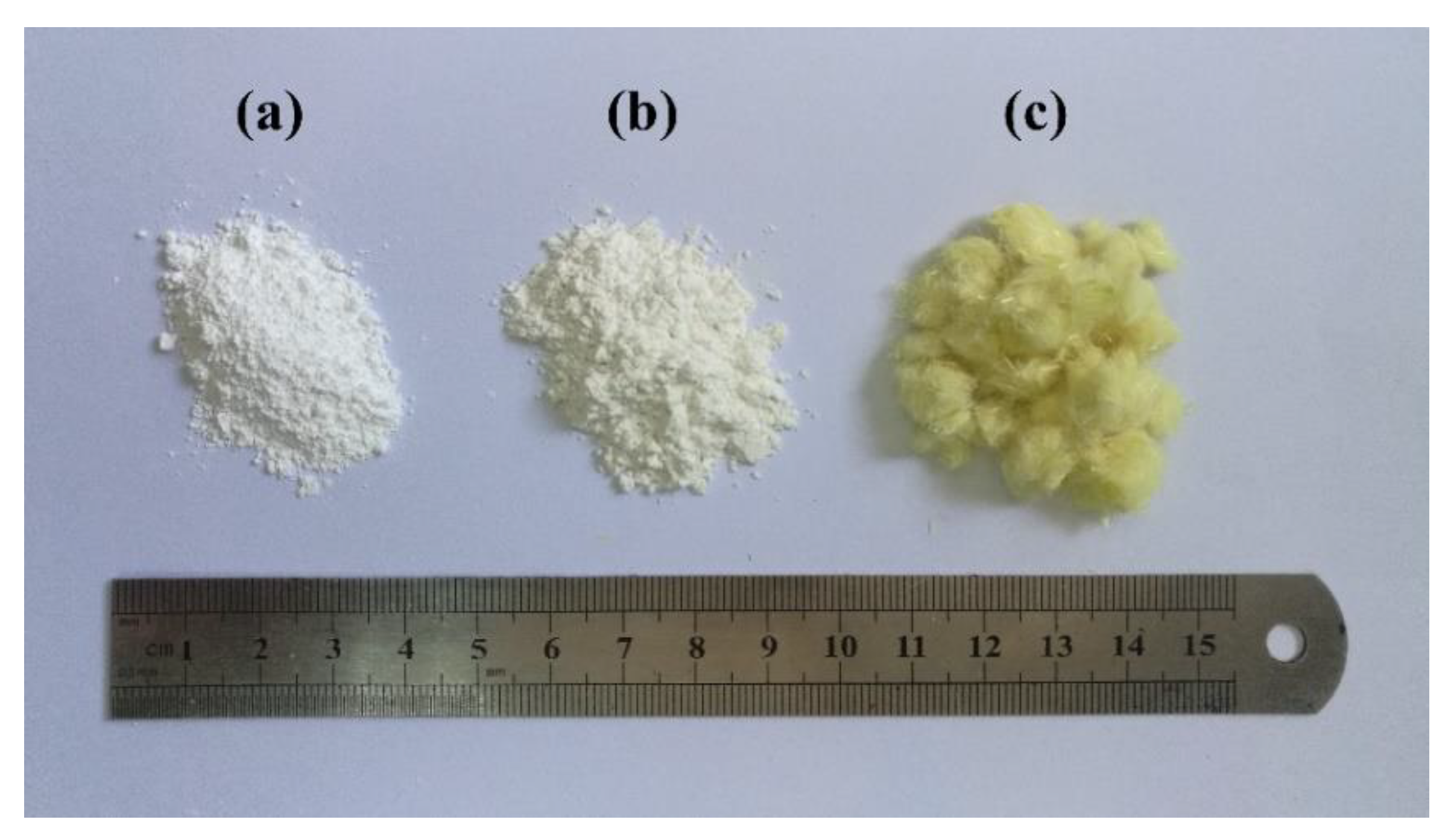

2.1. Raw Materials

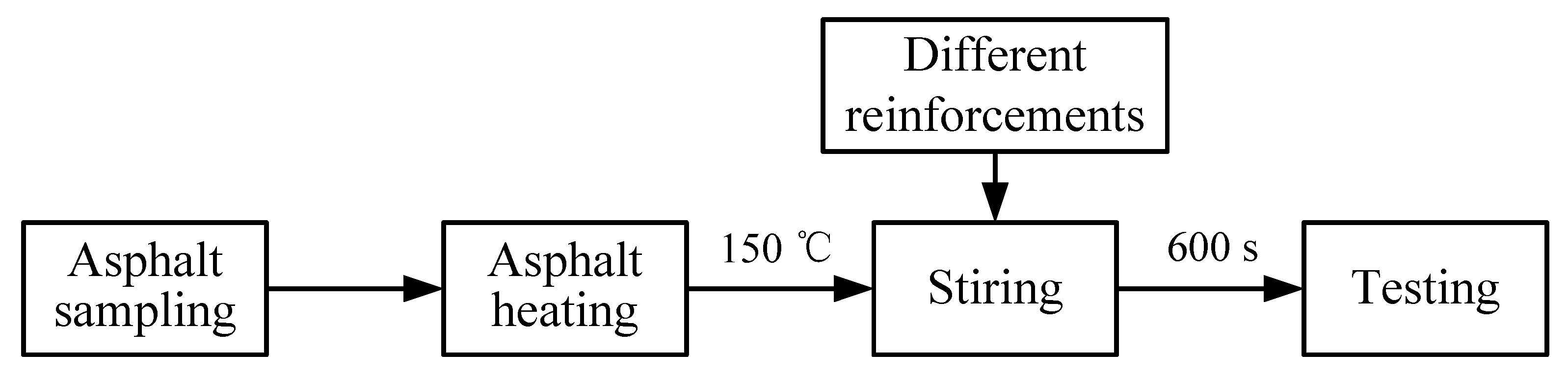

2.2. Preparation of Different Reinforcement-Modified Asphalt Binders

- (1)

- Asphalt was placed in an oven, heated to 150 °C, and placed in an electronic balance to weigh 200 g in a stainless-steel beaker.

- (2)

- The beaker containing the asphalt sample was placed in a constant temperature oil bath at 150 °C.

- (3)

- 4 g reinforcement was weighed with an electronic balance (2 wt% of asphalt sample).

- (4)

- The electric mixer was opened and the stirring speed was set to 350 rpm. The above-mentioned weighed reinforcement was gradually added to the asphalt. Stirring was continued until the reinforcement was evenly dispersed.

2.3. Experiment Methods and Evaluation Indexes

2.3.1. Conventional Indicator Tests

2.3.2. Dynamic Shear Rheology Test (DSR)

2.3.3. Scanning Electron Microscope (SEM)

3. Results and Discussion

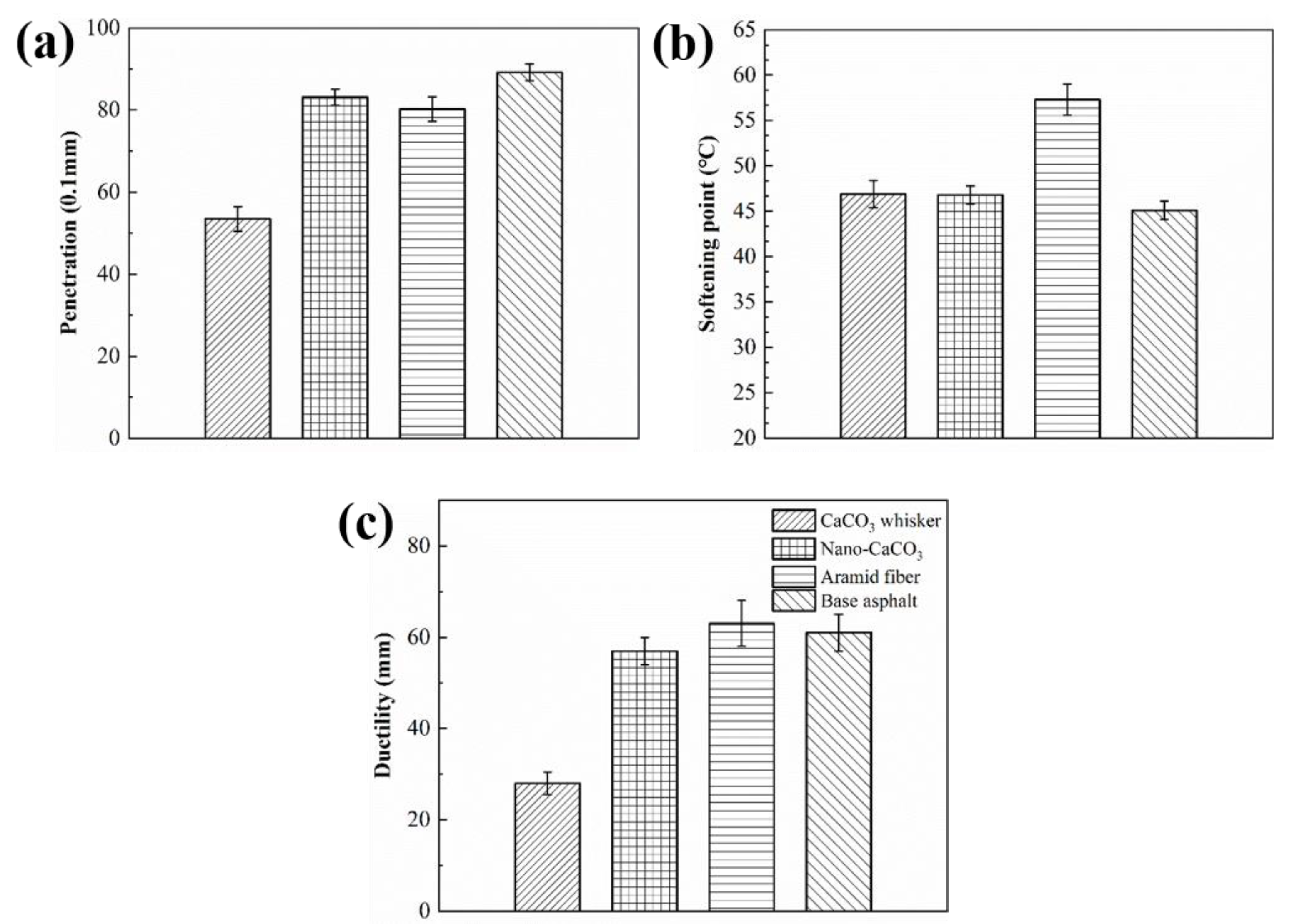

3.1. Conventional Technical Performances of the Modified Asphalt Binders

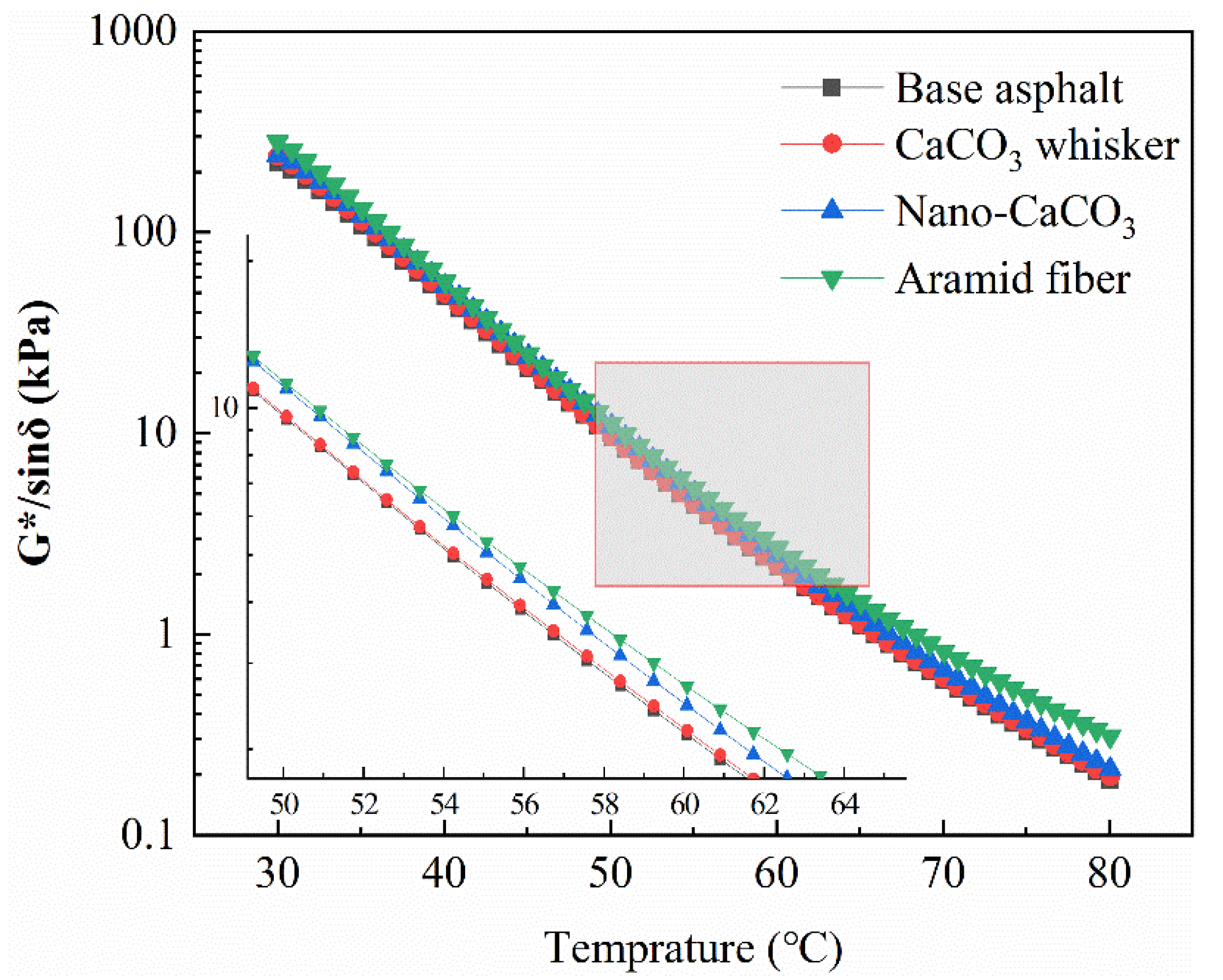

3.2. Rheological Properties of the Modified Asphalt Binders

3.2.1. Temperature Sweep Test

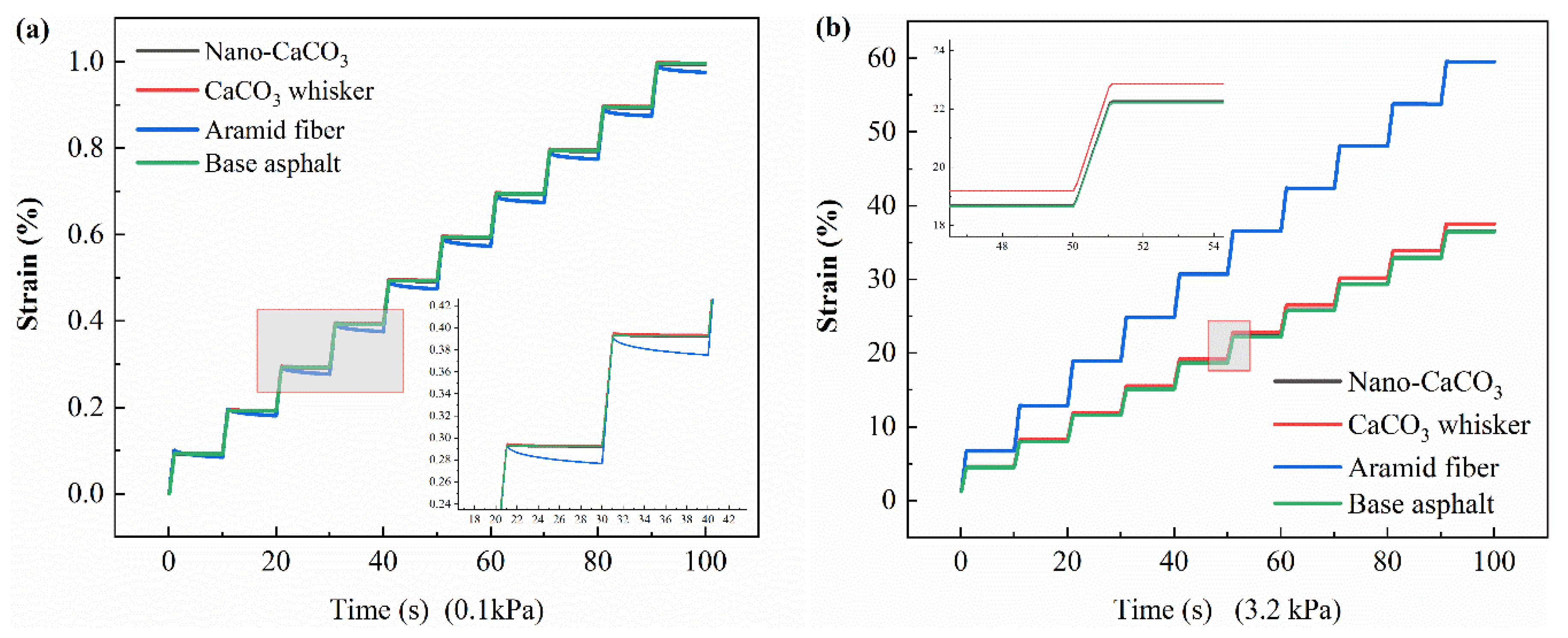

3.2.2. Multiple Stress Creep Recovery (MSCR) Test

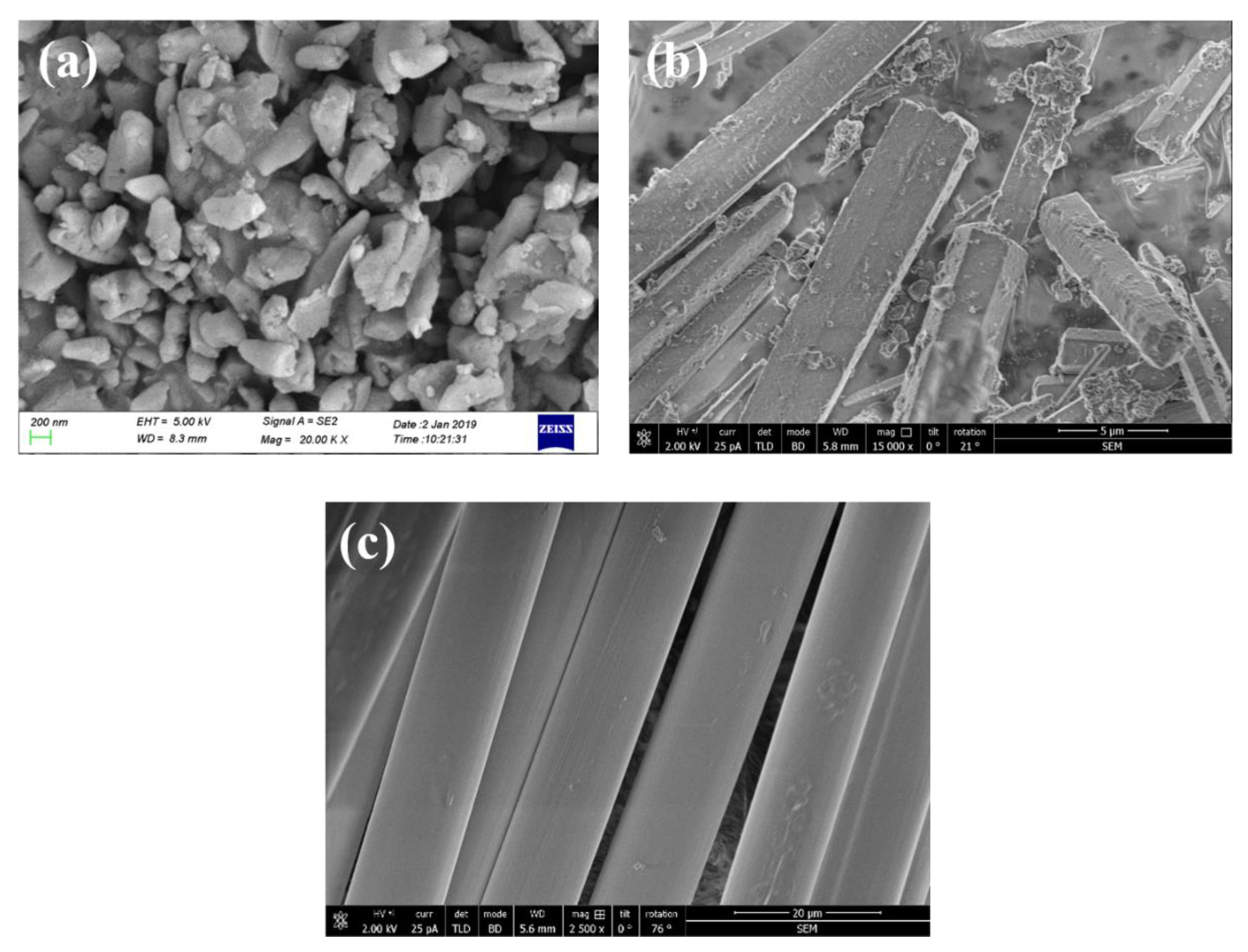

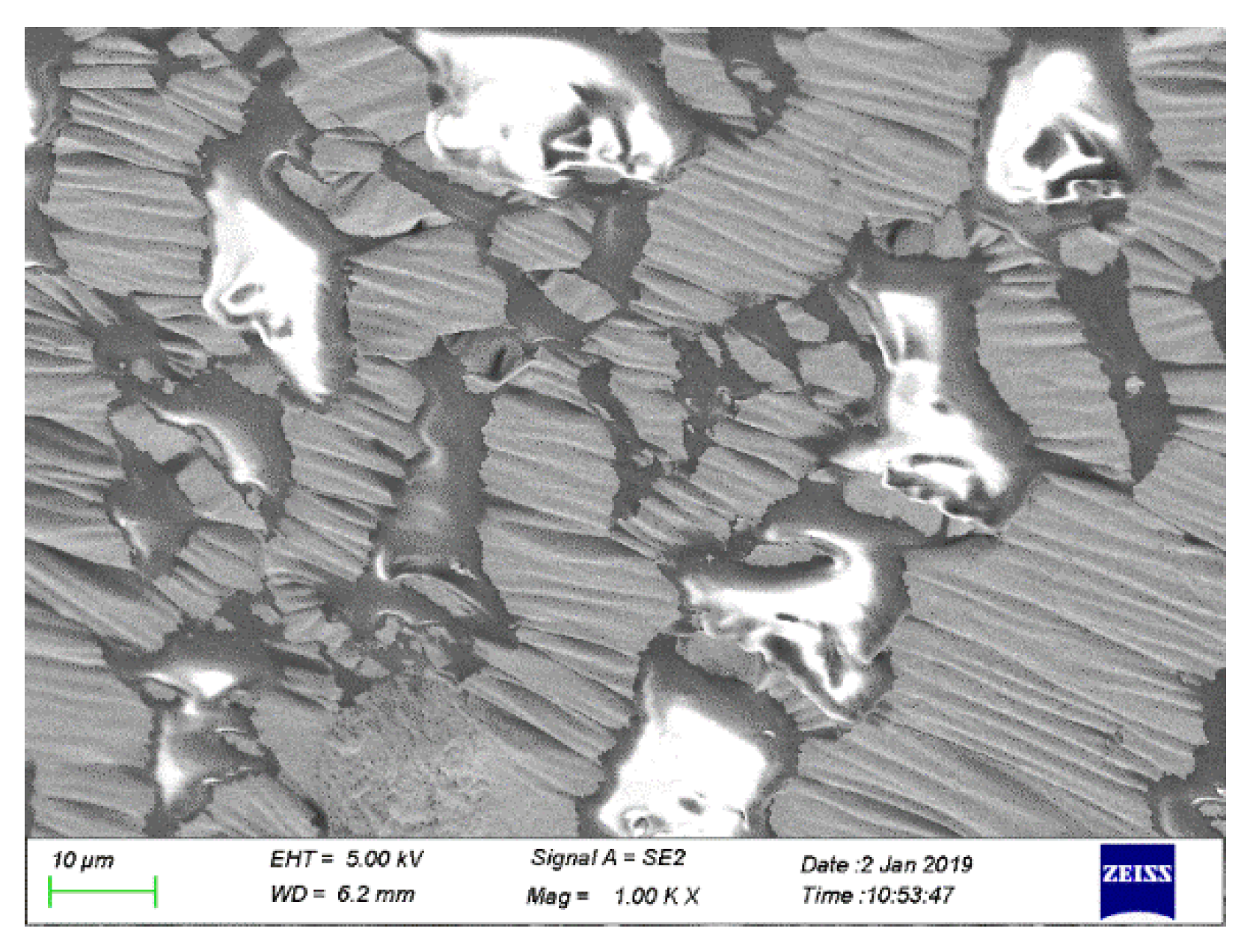

3.3. SEM Results of the Reinforcements and Interfaces

3.4. Reinforcement Mechanisms

3.4.1. Reinforcement Mechanism of Nano-CaCO3-Modified Asphalt Binder

3.4.2. Reinforcement Mechanism of CaCO3 Whiskers-Modified Asphalt Binder

3.4.3. Reinforcement Mechanism of Aramid Fibers-Modified Asphalt Binder

4. Conclusions

- (1)

- The reinforcements with the same amount have different reinforcing effects on the composite due to different morphology. The nano-CaCO3 particles, CaCO3 whiskers, and aramid fibers could improve the high-temperature performance of asphalt, but the reinforcement mechanisms were different.

- (2)

- The nano-CaCO3 particles improved the high-temperature performance of asphalt through the diffusion-enhancing mechanism.

- (3)

- The mechanism of CaCO3 whiskers-reinforced asphalt is more similar to the mechanism of particle-reinforced composites. The CaCO3 whiskers improved the high-temperature performance of asphalt, but reduced plasticity and toughness. In addition, since the CaCO3 whiskers themselves are highly dense, they are easily cohesive and precipitated, and thus the prepared modified asphalt has poor stability.

- (4)

- The aramid fibers fully exert the reinforcing and toughening fiber effect in asphalt and have the best modification effect.

Author Contributions

Funding

Conflicts of Interest

References

- Ding, X.; Ma, T.; Huang, X. Discrete-element contour-filling modeling method for micromechanical and macromechanical analysis of aggregate skeleton of asphalt mixture. J. Transp. Eng. Part B Pavements 2018, 145, 04018056. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Qian, G.; Zheng, J.; Zhang, Y. Three-dimensional simulation of aggregate and asphalt mixture using parameterized shape and size gradation. J. Mater. Civ. Eng. 2019, 31, 04019004. [Google Scholar] [CrossRef]

- Darjani, S.; Koplik, J.; Pauchard, V. Extracting the equation of state of lattice gases from random sequential adsorption simulations by means of the gibbs adsorption isotherm. Phys. Rev. E 2017, 96, 052803. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Ivanov, S.; Mozaffari, S.; Shanaiah, N.; Karim, A.M. Palladium acetate trimer: Understanding its ligand-induced dissociation thermochemistry using isothermal titration calorimetry, x-ray absorption fine structure, and 31p nuclear magnetic resonance. Organometallics 2019, 38, 451–460. [Google Scholar] [CrossRef]

- Li, R.; Wang, C.; Wang, P.; Pei, J. Preparation of a novel flow improver and its viscosity-reducing effect on bitumen. Fuel. 2016, 181, 935–941. [Google Scholar] [CrossRef]

- Mozaffari, S.; Tchoukov, P.; Mozaffari, A.; Atias, J.; Czarnecki, J.; Nazemifard, N. Capillary driven flow in nanochannels–Application to heavy oil rheology studies. Colloids Surf. A Physicochem. Eng. Asp. 2016, 513, 178–187. [Google Scholar] [CrossRef]

- Ali, S.I.A.; Abdulwahid, R.; Eidan, M.L.; Yusoff, N.I.M. Evaluation of moisture and ageing effects on calcium carbonite nanoparticles modified asphalt mixtures. Int. J. Eng. Res. Afr. 2018, 34, 40–47. [Google Scholar]

- Han, N.F.; Zhou, D.J.; Tang, X.D. Effect of nano calcium carbonate and montmorillonite on properties of styrene-butadiene-styrene copolymer modified asphalt. Appl. Mech. Mater. 2011, 99–100, 1035–1038. [Google Scholar] [CrossRef]

- Hamedi, G.H.; Nejad, F.M.; Oveisi, K. Investigating the effects of using nanomaterials on moisture damage of hma. Road Mater. Pavement Des. 2015, 16, 536–552. [Google Scholar] [CrossRef]

- Hao, X.H.; Zhang, A.Q.; Yang, W. Study on the performance of nano calcium carbonate modified asphalt concrete ac-13. Adv. Mater. Res. 2012, 450–451, 503–507. [Google Scholar] [CrossRef]

- You, Z.; Mills-Beale, J.; Foley, J.M.; Roy, S.; Odegard, G.M.; Dai, Q.; Shu, W.G. Nanoclay-modified asphalt materials: Preparation and characterization. Constr. Build. Mater. 2011, 25, 1072–1078. [Google Scholar] [CrossRef]

- Eichhorn, S.J.; Dufresne, A.; Aranguren, M.; Marcovich, N.E.; Capadona, J.R.; Rowan, S.J.; Weder, C.; Thielemans, W.; Roman, M.; Renneckar, S. Review: Current international research into cellulose nanofibres and nanocomposites. J. Mater. Sci. 2010, 45, 1. [Google Scholar] [CrossRef]

- Li, R.; Yu, Y.; Zhou, B.; Guo, Q.; Li, M.; Pei, J. Harvesting energy from pavement based on piezoelectric effects: Fabrication and electric properties of piezoelectric vibrator. J. Renew. Sustain. Energy 2018, 10, 054701. [Google Scholar] [CrossRef]

- Li, R.; Pei, J.; Sun, C. Effect of nano-zno with modified surface on properties of bitumen. Constr. Build. Mater. 2015, 98, 656–661. [Google Scholar] [CrossRef]

- Sylenko, P.M.; Shlapak, A.M.; Petrovska, S.S.; Khyzhun, O.Y.; Solonin, Y.M.; Atuchin, V.V. Direct nitridation synthesis and characterization of si3n4 nanofibers. Res. Chem. Intermed. 2015, 41, 1–12. [Google Scholar] [CrossRef]

- Liu, F.; Darjani, S.; Akhmetkhanova, N.; Maldarelli, C.; Banerjee, S.; Pauchard, V. Mixture effect on the dilatation rheology of asphaltenes-laden interfaces. Langmuir 2017, 33, 1927–1942. [Google Scholar] [CrossRef] [PubMed]

- Mozaffari, S.; Tchoukov, P.; Atias, J.; Czarnecki, J.; Nazemifard, N. Effect of asphaltenes aggregation on rheological properties of diluted athabasca bitumen. Energy Fuels 2015, 29, 5595–5599. [Google Scholar] [CrossRef]

- Zhang, H.G.; Hao, P.W.; Wang, X.S. Indoor research of high-modulus asphalt concrete with the added calcium sulfate whisker. Appl. Mech. Mater. 2011, 94–96, 90–94. [Google Scholar] [CrossRef]

- Yang, Y.; Deng, Y. Mechanical properties of hybrid short fibers reinforced oil well cement by polyester fiber and calcium carbonate whisker. Constr. Build. Mater. 2018, 182, 258–272. [Google Scholar] [CrossRef]

- Cao, M.; Xu, L.; Zhang, C. Rheology, fiber distribution and mechanical properties of calcium carbonate (caco 3) whisker reinforced cement mortar. Compos. Part A 2016, 90, 662–669. [Google Scholar] [CrossRef]

- Li, R.; Dai, Y.; Wang, P.; Sun, C.; Pei, J. Evaluation of nano-zno dispersed state in bitumen with digital imaging processing techniques. J. Test. Eval. 2017, 46, 20160401. [Google Scholar] [CrossRef]

- Cai, J.M.; Panteki, J. Using Calcium Carbonate Whisker in Engineered Cementitious Composites. In Proceedings of the International Conference on Fracture Mechanics of Concrete and Concrete Structures, Berkeley, CA, USA, 22–25 May 2016. [Google Scholar]

- Xing, X.; Pei, J.; Li, R.; Tan, X. Effect and mechanism of calcium carbonate whisker on asphalt binder. Mater. Res. Express 2019, 6, 055306. [Google Scholar] [CrossRef]

- Li, M.; Yang, Y.; Liu, M.; Guo, X.; Zhou, S. Hybrid effect of calcium carbonate whisker and carbon fiber on the mechanical properties and microstructure of oil well cement. Constr. Build. Mater. 2015, 93, 995–1002. [Google Scholar] [CrossRef]

- Klinsky, L.M.G.; Kaloush, K.E.; Faria, V.C.; Bardini, V.S.S. Performance characteristics of fiber modified hot mix asphalt. Constr. Build. Mater. 2018, 176, 747–752. [Google Scholar] [CrossRef] [Green Version]

- Fazaeli, H.; Samin, Y.; Pirnoun, A.; Dabiri, A.S. Laboratory and field evaluation of the warm fiber reinforced high performance asphalt mixtures (case study karaj–chaloos road). Constr. Build. Mater. 2016, 122, 273–283. [Google Scholar] [CrossRef]

- Mirabdolazimi, S.M.; Shafabakhsh, G. Rutting depth prediction of hot mix asphalts modified with forta fiber using artificial neural networks and genetic programming technique. Constr. Build. Mater. 2017, 148, 666–674. [Google Scholar] [CrossRef]

- Jaskuła, P.; Stienss, M.; Szydłowski, C. Effect of polymer fibres reinforcement on selected properties of asphalt mixtures. Procedia Eng. 2017, 172, 441–448. [Google Scholar] [CrossRef]

- Peter, H.M.Y.; Beaumont, W.R.; Aramid Fibers, C.H.Z. Comprehensive Composite Materials II; Elsevier: Amsterdam, The Netherlands, 2018; pp. 187–217. [Google Scholar]

- Badeli, S.; Carter, A.; Doré, G.; Saliani, S. Evaluation of the durability and the performance of an asphalt mix involving aramid pulp fiber (apf): Complex modulus before and after freeze-thaw cycles, fatigue, and tsrst tests. Constr. Build. Mater. 2018, 174, 60–71. [Google Scholar] [CrossRef]

- Eskandarsefat, S.; Hofko, B.; Rossi, C.O.; Sangiorgi, C. Fundamental properties of bitumen binders containing novel cellulose-based poly-functional fibres. Compos. Part B Eng. 2019, 163, 339–350. [Google Scholar] [CrossRef]

- D’Angelo, J.A. The relationship of the mscr test to rutting. Road Mater. Pavement 2009, 10, 61–80. [Google Scholar] [CrossRef]

- Han, C.; Guo, T.; Nan, X.; Zhi, H.; Zhang, D. New research progress in cu-based composites. Mater. Rev. 2012, 26, 90–94. [Google Scholar]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction; John Wiley & Sons: New York, NY, USA, 2007; Volume 7. [Google Scholar]

| Test Indices | Measured Values |

|---|---|

| Penetration at 25 °C, 0.1 mm | 89.7 |

| Ductility at 10 °C, cm | 61 |

| Softening Point (Ring-and-Ball method), °C | 44.3 |

| Appearance | Average Particle Size (nm) | Calcium Carbonate Content (%) | Whiteness (%) | Moisture Content (%) | Decomposition Temperature (°C) |

|---|---|---|---|---|---|

| White powder | 10–100 | 98.5 | 95 | 0.15 | 530 |

| Diameter (μm) | Tensile Strength (MPa) | Decomposition Temperature (°C) | Density (g/cm3) | Average Length (μm) | Length-Diameter Ratio |

|---|---|---|---|---|---|

| 1–3 | 3000–6000 | 660 | 2.8 | 20–30 | 15–60 |

| Diameter (μm) | Specific Gravity (g/cm3) | Elastic Modulus (cN·dtex−1) | Decomposition Temperature (°C) | Breaking Elongation (%) | Fracture Stress (GPa) |

|---|---|---|---|---|---|

| 3–5 | 1.44 | 410–710 | 430–550 | 3.6 | 2.76 |

| Asphalt | 0.1 kPa | 3.2 kPa | ||||||

|---|---|---|---|---|---|---|---|---|

| R/% | Error % | Jnr/ kPa−1 | Error % | R/% | Error % | Jnr/ kPa−1 | Error % | |

| Nano-CaCO3-modified asphalt | 1.15 | 5.2 | 0.92 | 11.8 | 0.05 | 7.3 | 1.03 | 10.8 |

| CaCO3 whisker-modified asphalt | 2.08 | 3.6 | 0.93 | 12.6 | 0.03 | 6.7 | 1.06 | 13.9 |

| Aramid-modified asphalt | 14.34 | 4.3 | 0.88 | 14.7 | 0.65 | 5.9 | 1.69 | 8.4 |

| Base asphalt | 0.93 | 5.1 | 0.93 | 9.8 | 0.02 | 6.4 | 1.03 | 7.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, X.; Pei, J.; Shen, C.; Li, R.; Zhang, J.; Huang, J.; Hu, D. Performance and Reinforcement Mechanism of Modified Asphalt Binders with Nano-Particles, Whiskers, and Fibers. Appl. Sci. 2019, 9, 2995. https://doi.org/10.3390/app9152995

Xing X, Pei J, Shen C, Li R, Zhang J, Huang J, Hu D. Performance and Reinforcement Mechanism of Modified Asphalt Binders with Nano-Particles, Whiskers, and Fibers. Applied Sciences. 2019; 9(15):2995. https://doi.org/10.3390/app9152995

Chicago/Turabian StyleXing, Xiangyang, Jianzhong Pei, Chenchen Shen, Rui Li, Jiupeng Zhang, Jianyou Huang, and Dongliang Hu. 2019. "Performance and Reinforcement Mechanism of Modified Asphalt Binders with Nano-Particles, Whiskers, and Fibers" Applied Sciences 9, no. 15: 2995. https://doi.org/10.3390/app9152995

APA StyleXing, X., Pei, J., Shen, C., Li, R., Zhang, J., Huang, J., & Hu, D. (2019). Performance and Reinforcement Mechanism of Modified Asphalt Binders with Nano-Particles, Whiskers, and Fibers. Applied Sciences, 9(15), 2995. https://doi.org/10.3390/app9152995