1. Introduction

The use of renewable energy resources has grown as a result of the concerns about CO

2 emissions, dependence on fossil fuels, as well as climate change. Solar energy is a clean and practically infinite renewable resource, which could satisfy the global energy demand with only a small fraction of the solar radiation that reaches the surface of the Earth. Therefore, the development of new efficient ways to use solar energy at accessible costs is both a great scientific and technological opportunity [

1].

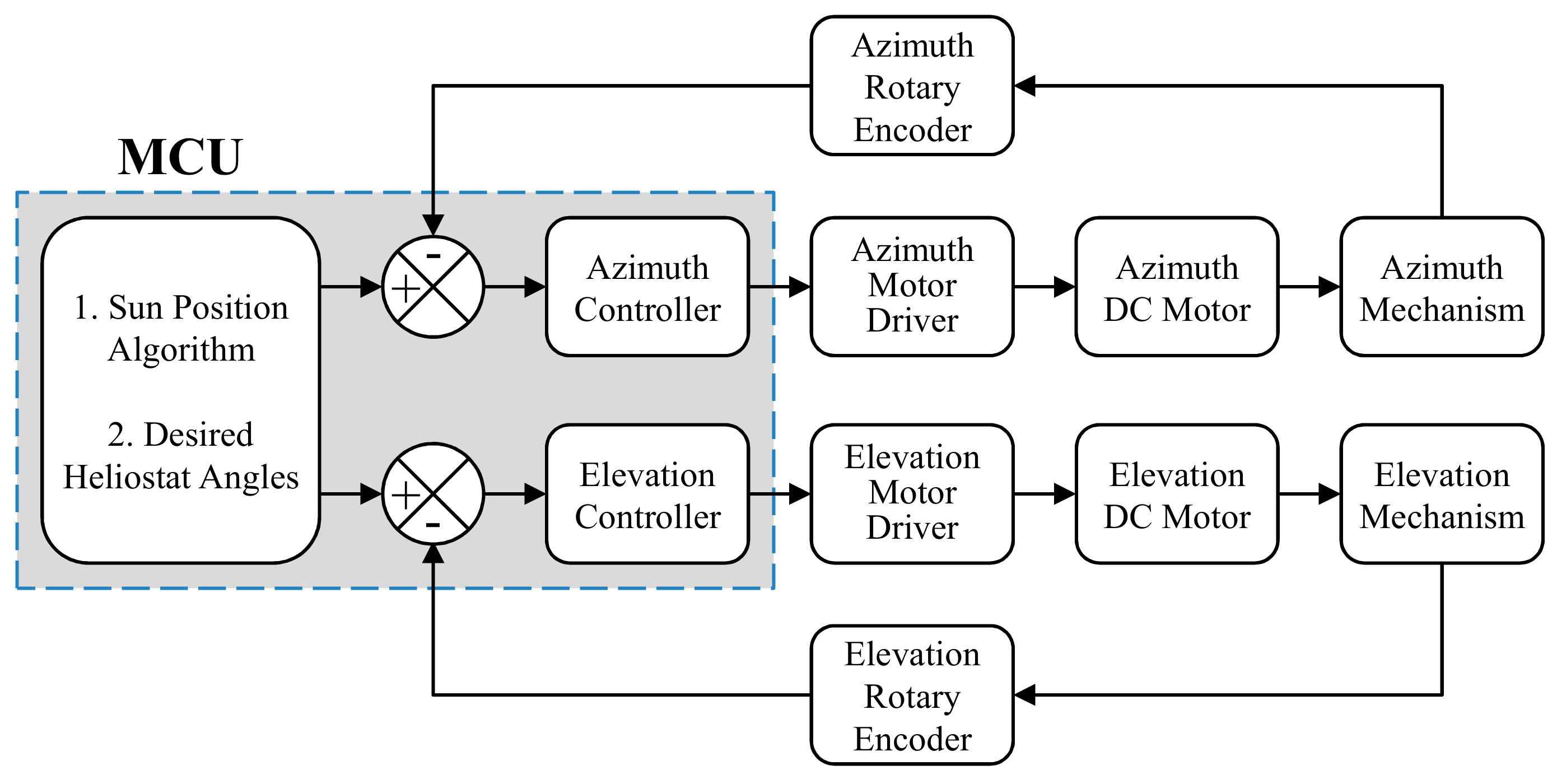

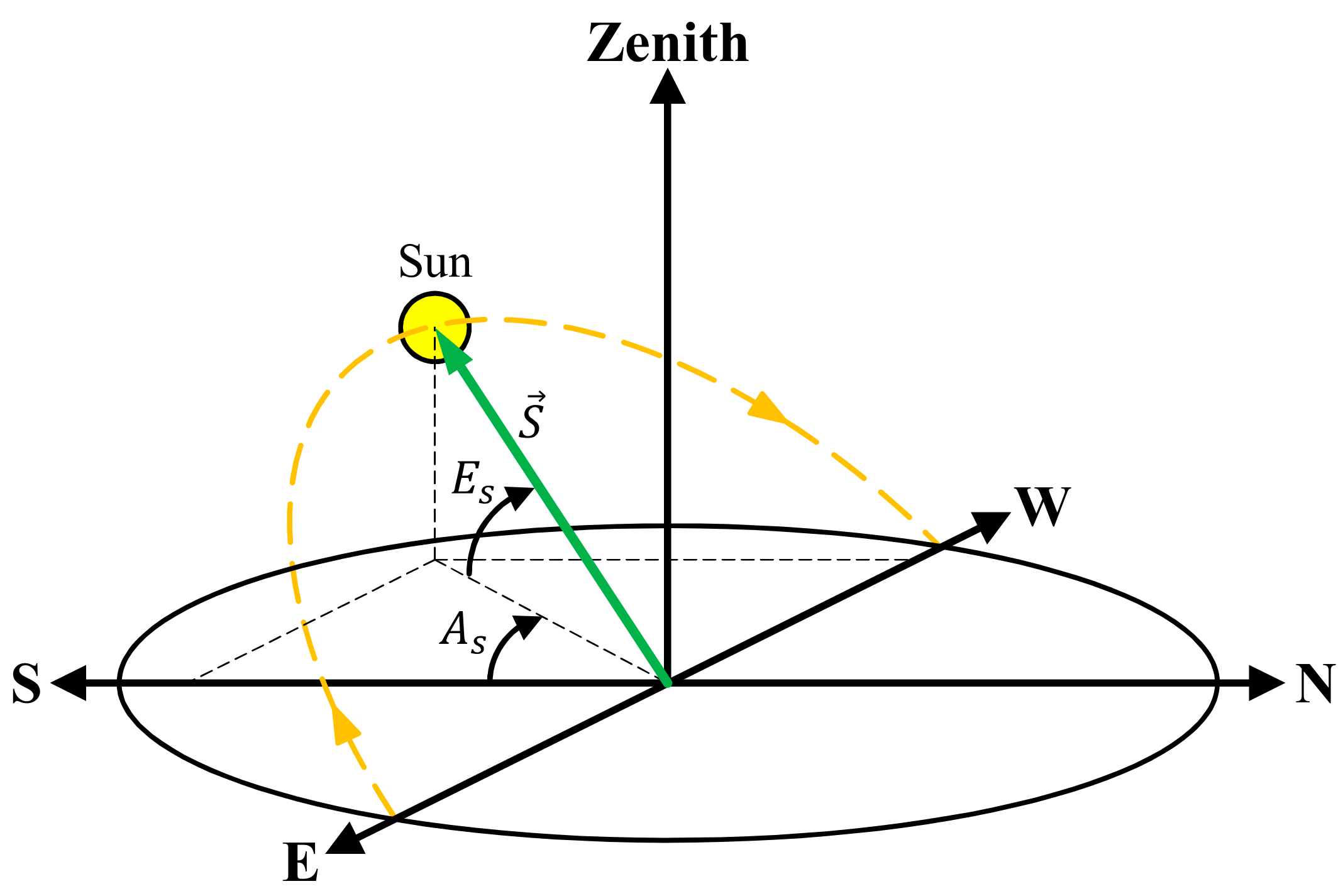

In high-concentration solar plants, it is necessary to have control systems that help to reduce losses in the concentration of solar radiation and to avoid damage to the operators and the facilities. In order to collect solar energy, it is necessary to know the position of the sun throughout the day. This can be achieved by using a solar tracker, which combines a mechanical structure with electronic feedback devices. Solar trackers are divided into single-axis or two-axis trackers. In single-axis solar trackers, the tracking system drives the rotation axis until the normal component of the mechanical structure and the solar vector are coplanar, whereas the double-axis solar trackers follow the sun in the horizontal and the vertical plane [

2]. The solar tracking systems are also divided into three classifications: the sensor driver systems (SDS), which determine the position of the sun using solar sensors, the microprocessor driver systems (MDS), which use an algorithm to determine the position of the sun using a microcontroller, and the combination of the first two methods [

3].

Dual-axis SDS sun trackers have been designed in order to drive photovoltaic (PV) systems. Seme et al. [

4] developed a dual-axis tracking system without using a microcontroller, producing more than 27% electric energy than a fixed system. Ahmed [

5] and Rao et al. [

6] implemented a dual-axis sun tracker on an 8051 MCU, using light dependent resistors (LDR) to sense the position of the sun and two stepper motors to orient a PV panel. Mishra et al. [

7] designed a solar tracking system based on Arduino UNO with a Bluetooth radio module to get a real-time measurement of the output voltage of the solar panel on a mobile app. Makhija et al. [

8] used an ATMega328 microcontroller, four LDRs, and two servo motors to build a sun tracker on a PV, increasing the output voltage 37% against a fixed PV. Flores-Hernández et al. [

9] developed a dual-axis solar tracker using a robotic sensor, allowing to reduce the energy consumption of the tracking system as well as adding multiple tracking systems using the same sensor.

Other works implemented MDS sun trackers. Chabuk et al. [

10] applied a dual-axis solar tracker based on an MCU, using a real-time clock (RTC) to obtain the time of the day and to determine the angle of movement of two stepper motors. Yang et al. [

11] developed an open-loop sun tracker controlled by a microprocessor AT89S52, using a GPS and an RTC to determine the geographical position coordinates (latitude and longitude) and the current date and time to obtain the sun position. Sidek et al. [

12] built a master-slave dual-axis solar tracking system using two slave microcontrollers to control the position of both axes, which are governed by a master microcontroller, obtaining an accuracy of 0.5° in the sun tracker with a maximum energy gain of 26.9% better than the fixed-tilted PV panel. Kumar.N and Subramaniam [

13] implemented an MDS sun tracker to orient a solar dish concentrator, calculating the sun position using an RTC and a solar position equation, thus obtaining 75% more average thermal energy compared to a fixed solar tracking system.

In central receiver systems, there are two-axis solar tracking reflectors called heliostats that concentrate the sunlight on a receiver located on top of a tower. Every heliostat uses a local control that guides the heliostat into the desired position by using two electric motors connected to reduction gears. A control algorithm modifies the angular position of the motors, allowing the mechanical structure to remain a stable position despite changes in the environmental conditions [

1]. Besides, a unique central control is used to communicate with the local controls through a wireless communication system. However, due to the limited bandwidth in wireless communication, it is difficult to control the orientation of each heliostat from the central control with a high update rate, which increases the possibility of errors. Therefore, every local control must calculate the sun position and the aim point in order to move the heliostat to the desired position, reducing the network traffic between the central and the local control, and increasing its autonomy [

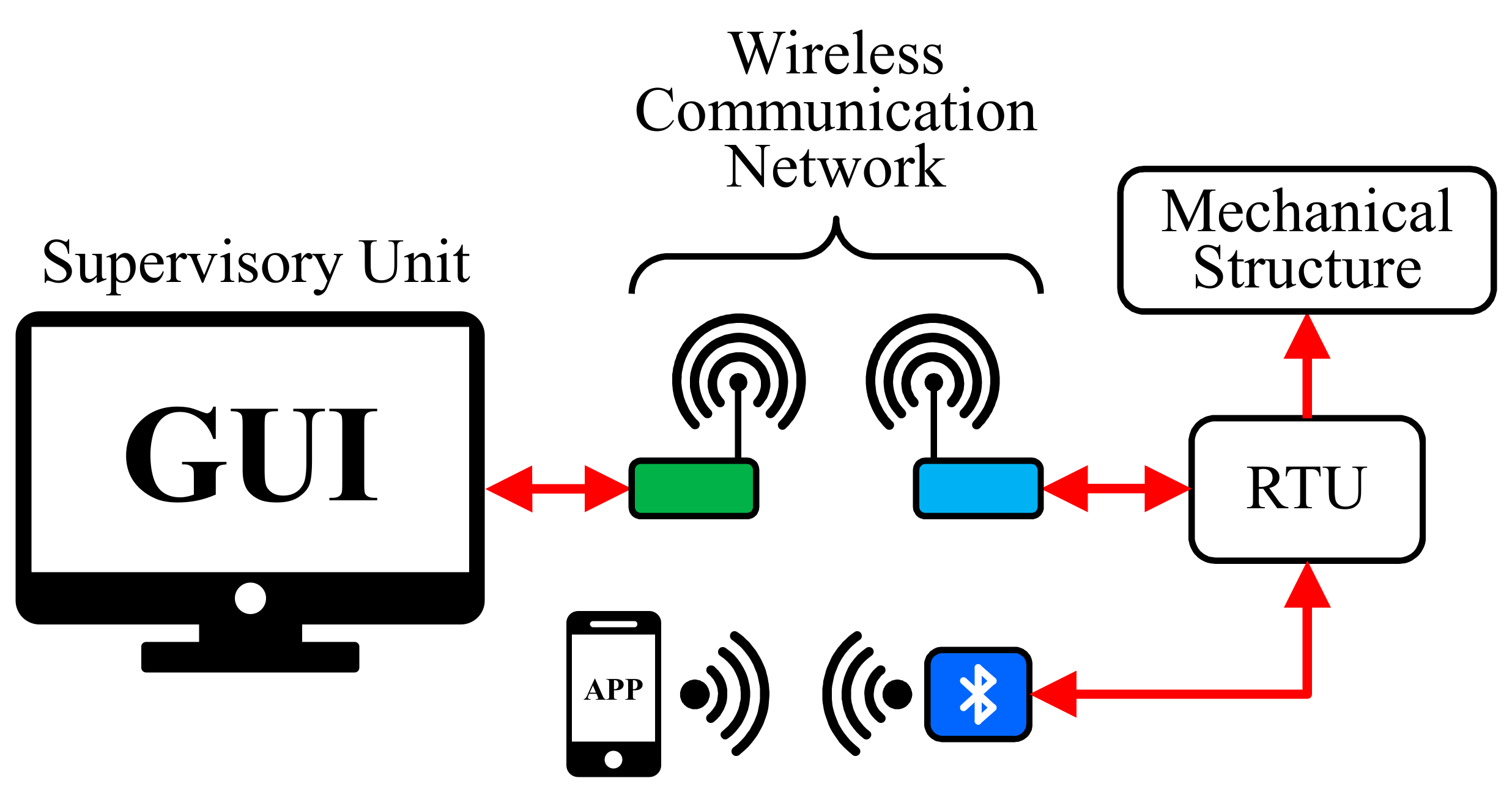

14]. A SCADA system integrates the information received from the local controllers (also called remote terminal units), by using a supervisory unit (SU) embedded into a computer, in order to analyze the data, supervise the process, and make decisions by using a human-machine interface [

1].

Some heliostat control systems have been presented in the literature. Loudadi and El Omari [

15] developed a heliostat control by using Java language on a computer, which calculates the angles of the position of the sun and the heliostat, sending them via Bluetooth to a microcontroller-based card, in order to control a 0.16 m

2 heliostat by using two low-power DC motors. The heliostat sends its actual position to the computer, which compares it with the calculated values and corrects the position of the heliostat if there is a difference between the values. Pışırır and Bıngöl [

16] developed a heliostat control in an embedded system using an industrial computer model ARK 1388V, which performs all the tasks of the heliostat. The control system orients a 1 m

2 heliostat by using two stepper motors, a programmable controller, and a driver circuit. The system moves the heliostat every four minutes, by using the previous and new position of the heliostat in order to calculate the step number of the motors. Gross et al. [

17] developed a control system with a graphical user interface (GUI) to monitor a field of heliostats, allowing to control multiple receivers and types of heliostats in a single application. The system can be updated by adding new heliostats in the field and more than one receiver.

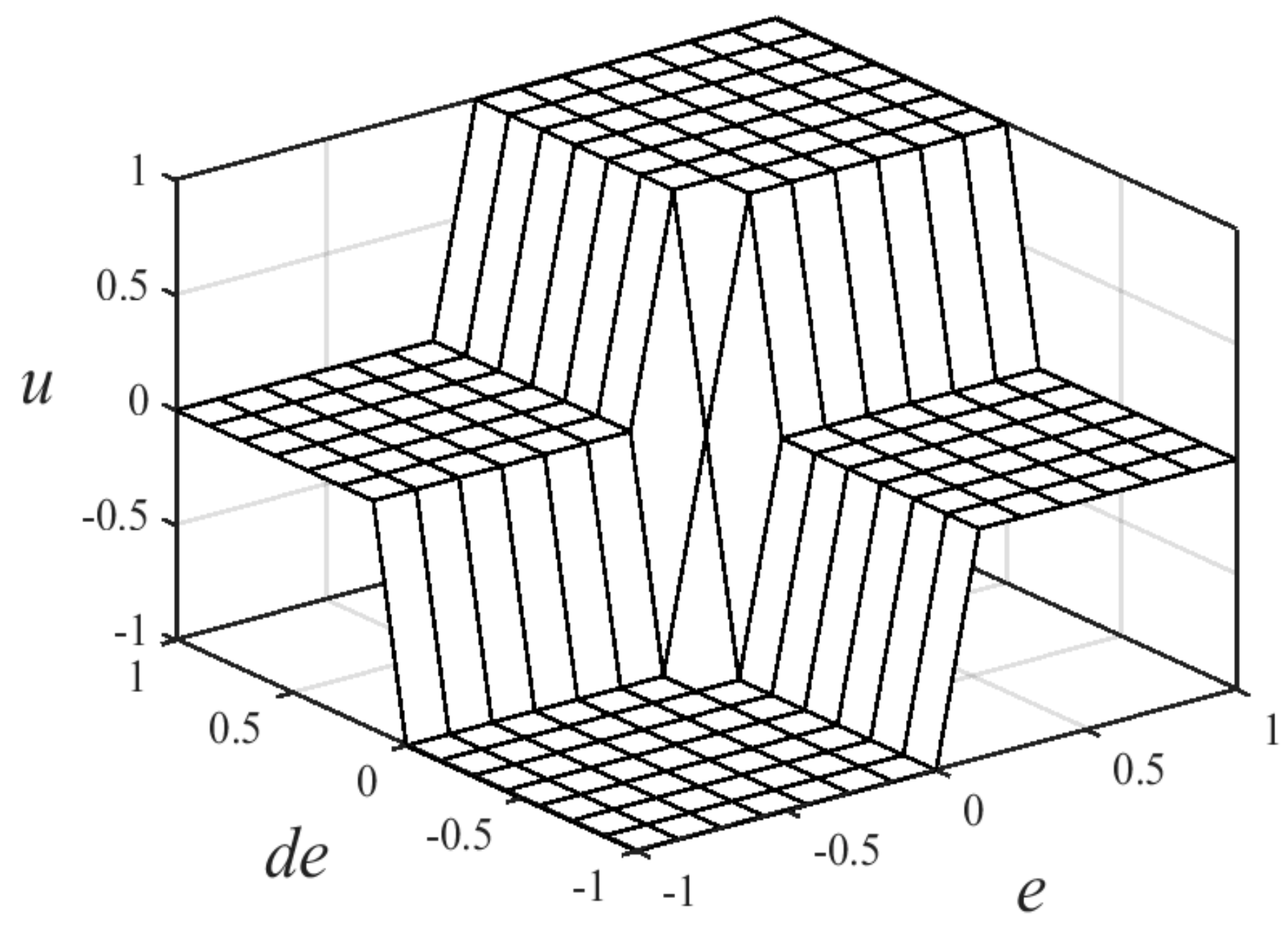

Finally, an advanced control strategy, such as a fuzzy logic controller, is an excellent alternative to deal with changing dynamics and non-linearities present in solar plants that traditional controllers cannot handle [

1]. Fuzzy logic controllers have been applied in order to control the orientation of a heliostat. Zeghoudi and Chermitti [

18] applied a speed control of a DC motor with an FLC for the orientation of a heliostat. Two FLC configurations were compared with a neural controller in Matlab software. The first configuration (FLC1) uses two inputs (error and derivate of the error), one output, and a rule base of ten rules, whereas second configuration (FLC2) uses only one input (error), one output, and a rule base three rules. The results demonstrated a better output response for the FLC compared with the neural controller, which presents some fluctuations that can be harmful to the DC motors. Zeghoudi et al. [

19] applied an adaptive fuzzy-proportional-integral (F-PI) controller in order to orient a heliostat by controlling a DC motor in Matlab software. The F-PI controller was compared with two FLC configurations (FLC1 and FLC2) and a conventional Proportional-Integral (PI) controller. The F-PI controller modifies the controller gains of a PI controller, by using two inputs (error and derivate of the error), two outputs (proportional gain and integral gain) and a rule base of thirty-five elements for each output. The results showed that the F-PI controller gives the best results compared to other methods. However, these works have only been presented in simulations.

Taking into account the developed works, this paper describes the design and construction of a heliostat control system based on a SCADA system with a stand-alone remote terminal unit and an embedded fuzzy logic controller on a low-cost microcontroller for the orientation control.

3. Results and Discussion

The heliostat and the RTU of the control system are shown in

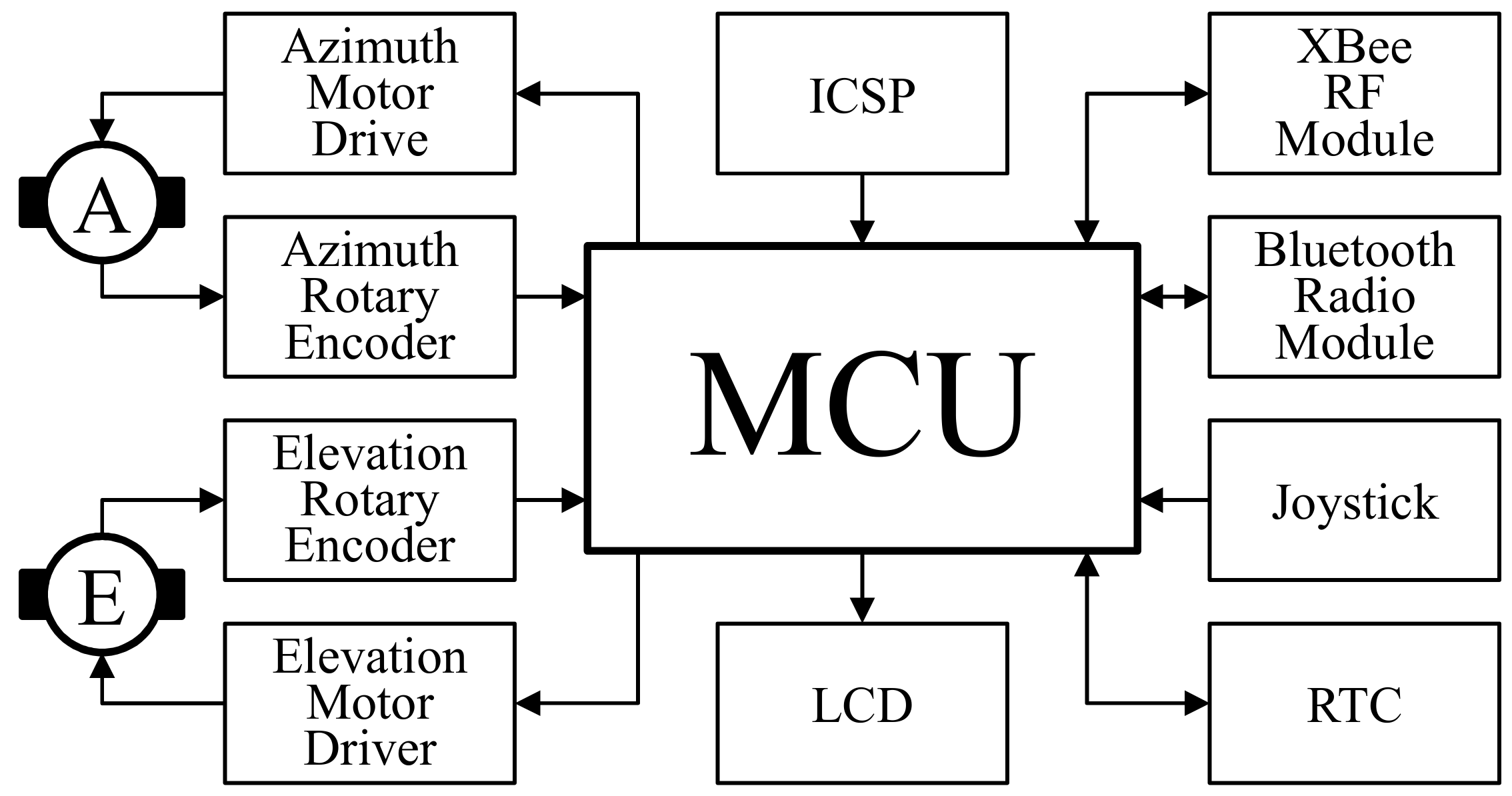

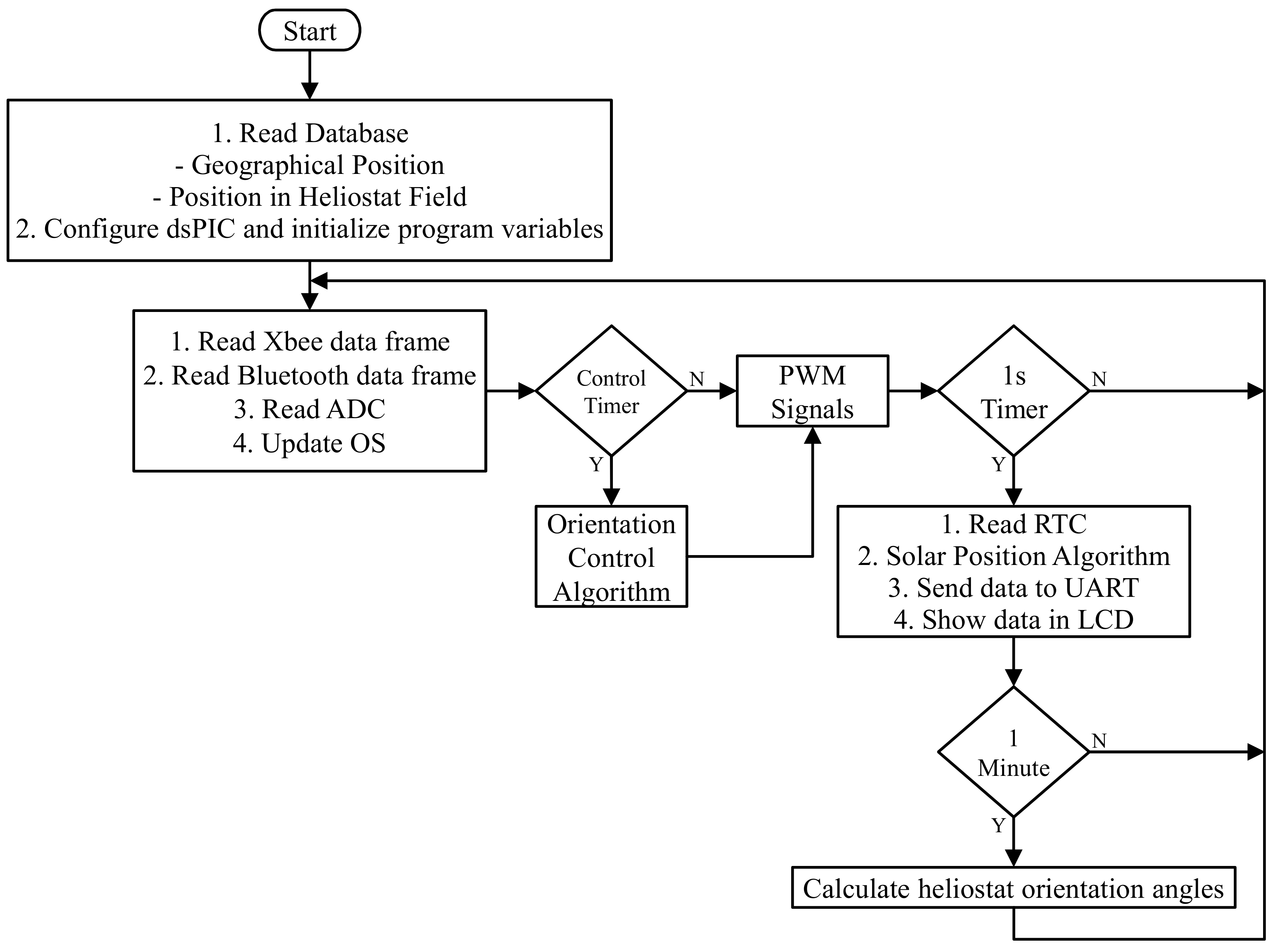

Figure 18 and

Figure 19. The RTU consists of the PCB (Printed Circuit Board) of the MCU and the PCBs of the motor driver circuits. It is powered by a 24 V power supply for the motor driver circuits, and it is regulated at 5 V and 3.3 V in order to provide the power to the RTU components.

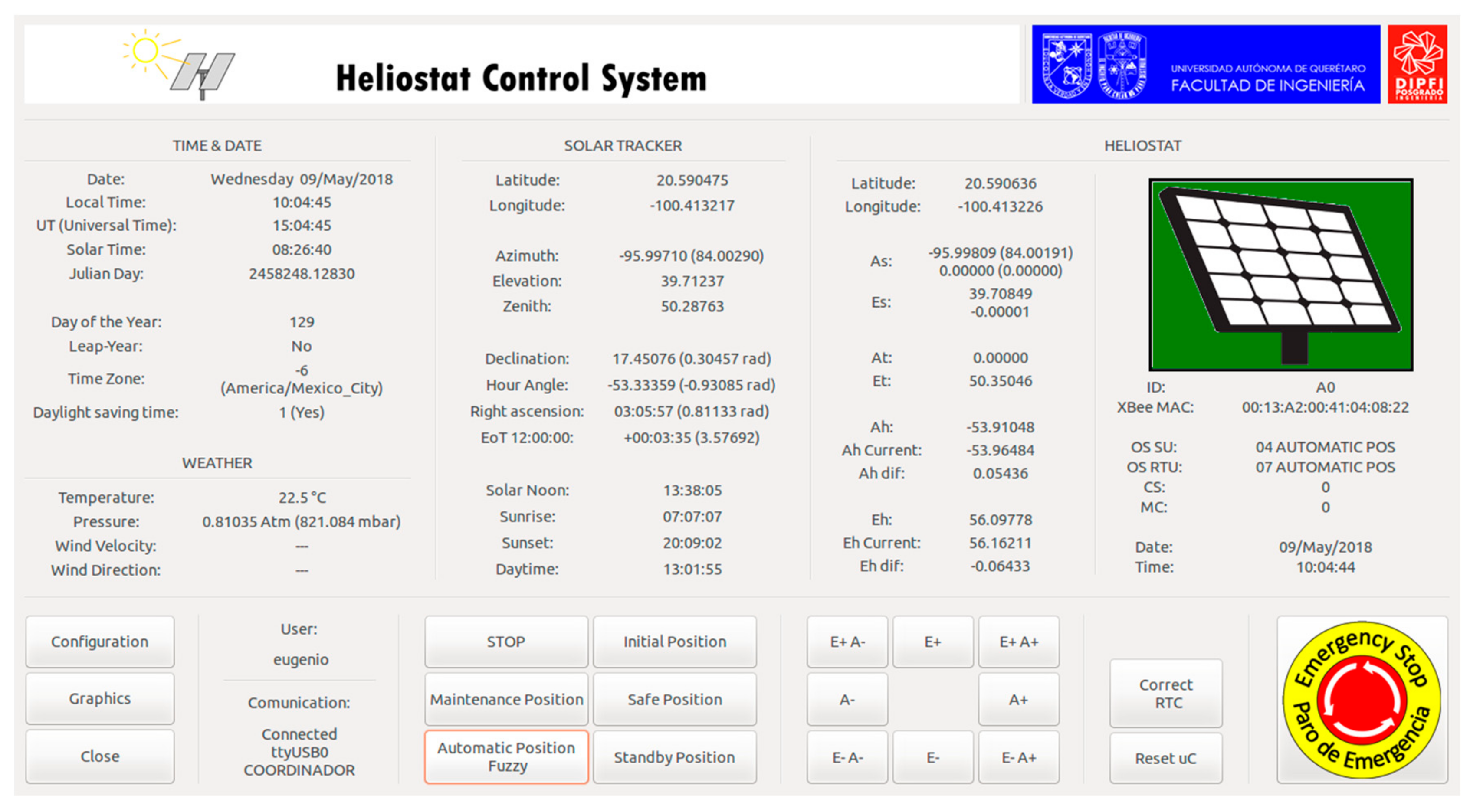

The developed GUI of the SU and the mobile App are shown in

Figure 20 and

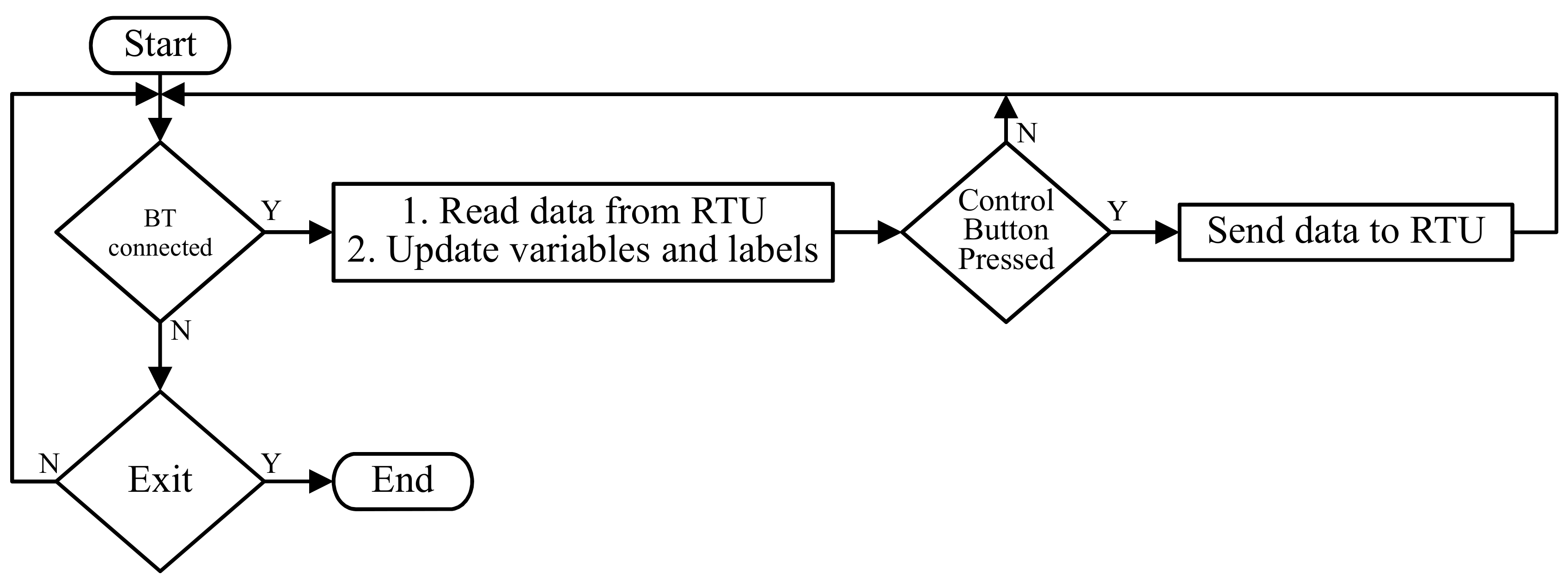

Figure 21. The GUI displays the values of time and date (date, local time, universal time, solar time, Julian day, day of the year, daylight saving time, and time zone), solar position (latitude and longitude, solar angles, declination, hour angle, right ascension, equation of time, dawn hour, sunset hour, solar noon, and daytime), heliostat data (latitude and longitude, heliostat angles, operation status, MAC address, an time and date), and the status of the communication with the RTU. There are also the control buttons and an image that shows the OS of the RTU. The mobile app consists of the buttons for the Bluetooth connection, labels that show the OS of the RTU, and the control buttons. The date and hour are colored in red if there is an error of one second in relation to the time of the device. Otherwise, the values are displayed in green. For both, the GUI and the mobile app, the control buttons are not activated until the communication with the RTU is established.

The HCS was tested with the parameters shown in

Table 5, first on the DC motors with no load and then on the heliostat. The experimental results of the orientation control are shown in

Figure 22 for the DC motors with no load and in

Figure 23 for the heliostat, whereas the values of the error of the orientation control are shown in

Figure 24.

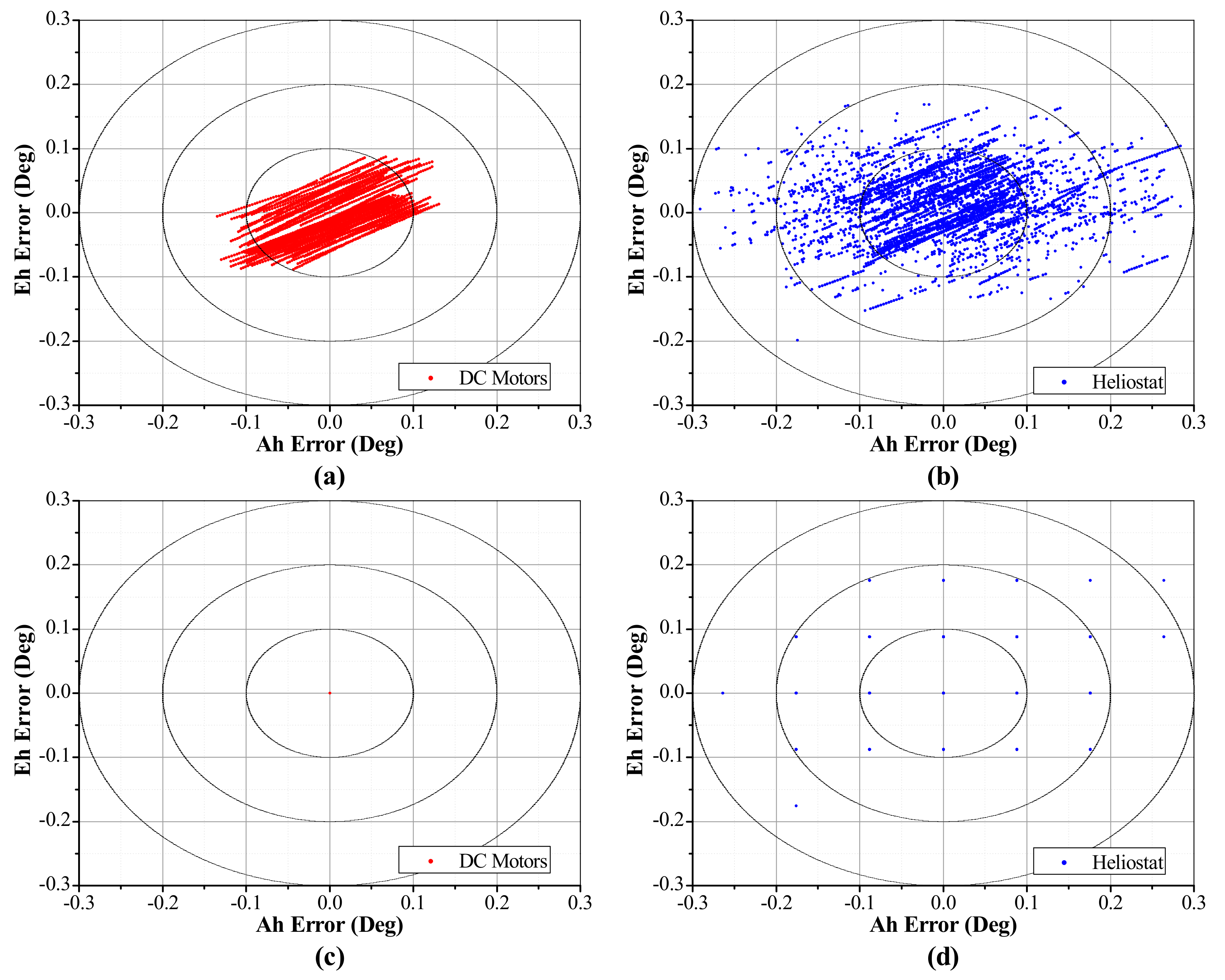

Table 6 shows the mean squared error (MSE) of the orientation control compared to the three reference values.

The results show an MSE of 0.05371° and 0.03761° between the DC motors with no load and the desired reference for the azimuth and elevation angles, respectively (

Figure 24a). Besides, there is an MSE of 0.0° between the final reference values and the angular position of the DC motors with no load (

Figure 24c), and an MSE of 0.02352° and 0.02730° between the position of the DC motors with no load and the discretized reference for the azimuth and elevation angles, respectively. Therefore, the error signal in the controller is equal to zero when the angular position reaches the final reference value. For the orientation control of the heliostat, the results show an MSE of 0.09577° and 0.05401° for the azimuth and elevation angles compared to the desired reference (

Figure 24b), which is less than 0.1° for both axes facing an average wind speed of 6 m/s over the mechanical structure. Finally, there is an MSE of 0.08236° for the azimuth axis and 0.05511° for the elevation axis compared to the final reference values (

Figure 24d), with a maximum error value of 0.26367° (3 encoder steps).

4. Conclusions

A heliostat control system based on a SCADA system was designed and implemented in order to monitor and control the orientation of an Azimuth-Elevation heliostat. The proposed system allows a single registered operator to visualize and control the operation status of the heliostat in order to detect any failure in its operation. The system consists of a supervisory unit with a graphical user interface, a remote terminal unit implemented in a low-cost microcontroller, a wireless communication network, and a mobile app. Besides, a fuzzy logic controller embedded in the remote terminal unit orients the heliostat to the desired position.

The stand-alone RTU performs all the calculations and tasks of the orientation control by only a control command sent by the supervisory unit. Therefore, this reduces the network traffic between the SU and the RTU. The experimental results show a similar behavior between the orientation control of the DC motors with no load and the heliostat, with an MSE less than 0.1° for the orientation control of the heliostat, despite the backlash in the axis mechanisms and the load of the wind over the mechanical structure. Therefore, the control algorithm with fuzzy logic can guide the heliostat to the desired angles using the same parameters of the position control of the DC motors with no load, and it is not necessary to tune the controller parameters if the dynamics of the system changes, as in the traditional PID controllers.

As future work, the system can be applied to control an entire heliostat field just by modifying the GUI in order to send the corresponding control command to each heliostat by using the broadcast model of the RF modules, and the same program code for each RTU, only by updating the data of the geographical position and the distance to the target of each heliostat. Besides, the FLC can orient all the heliostats by using the same control parameters, because it is robust in front of changes in the dynamics of the process. However, higher resolution encoders would be necessary for farthest heliostats from the central tower. The system can also be adapted in order to control other two-axis solar-tracking systems that only use the solar-tracking system, such as photovoltaic, parabolic trough, or solar dish systems.