Blistering Mechanism Analysis of Hydraulic Asphalt Concrete Facing

Abstract

Featured Application

Abstract

1. Introduction

2. Historic Review of Blister Defect in the Asphalt Impervious Facing Project

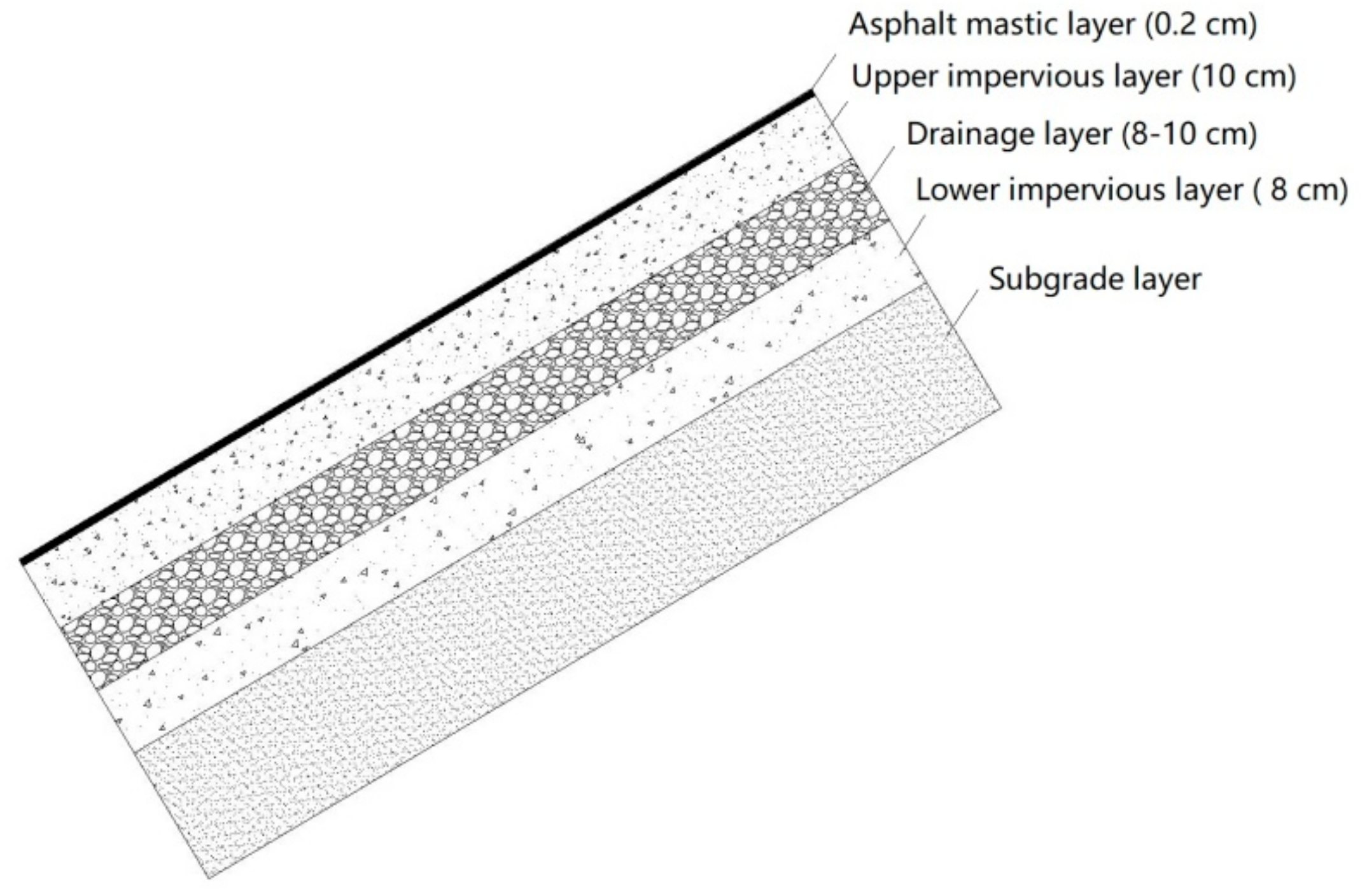

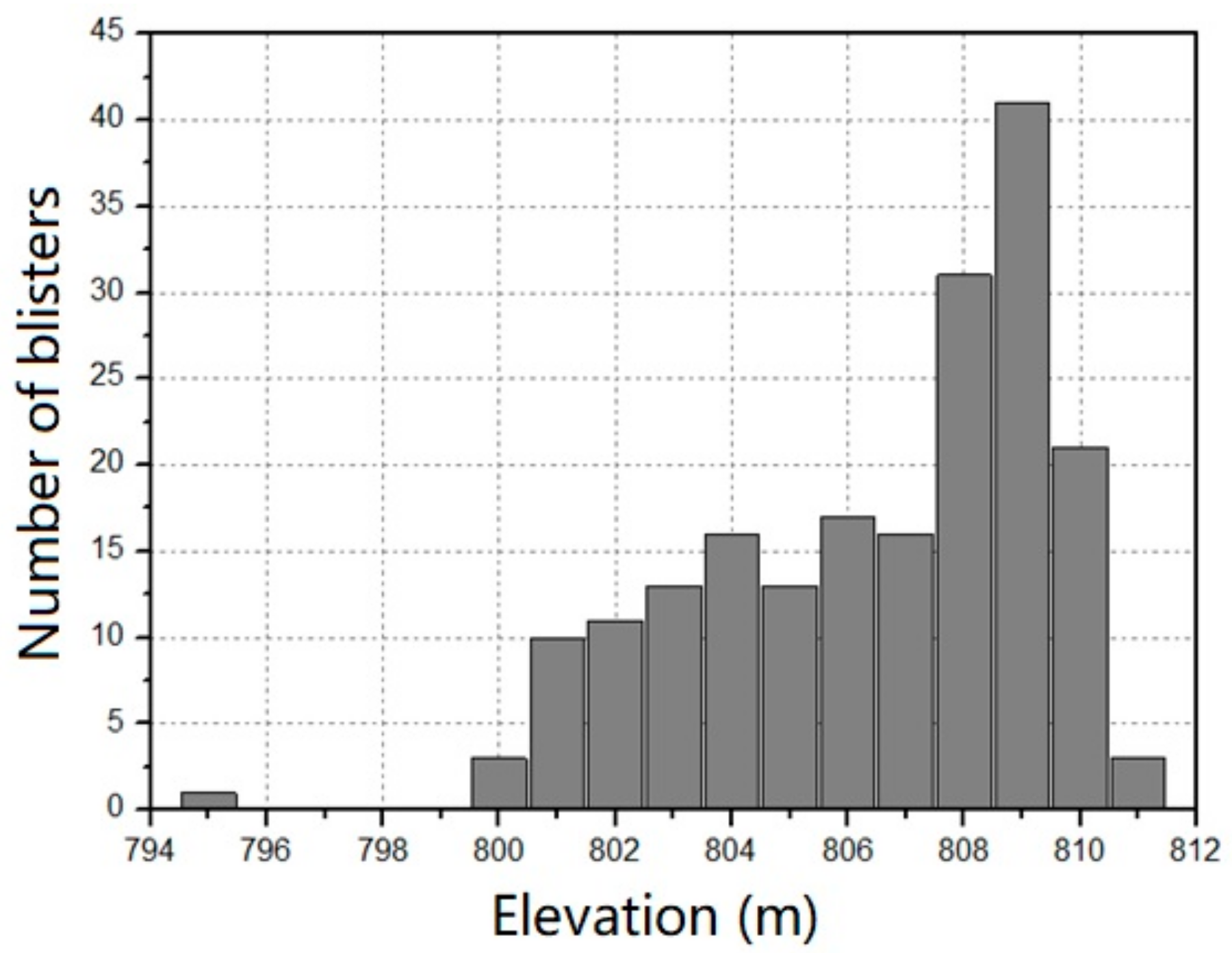

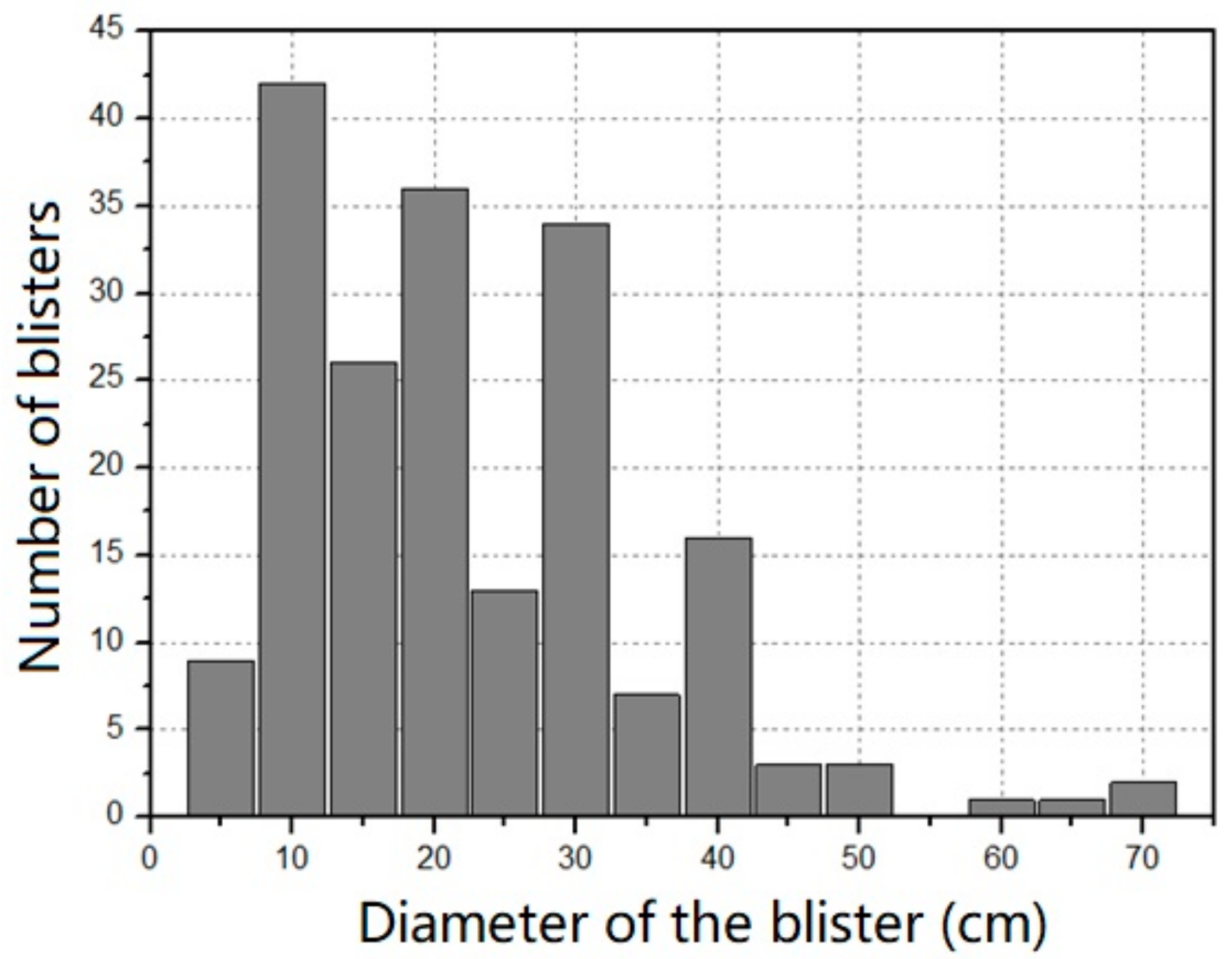

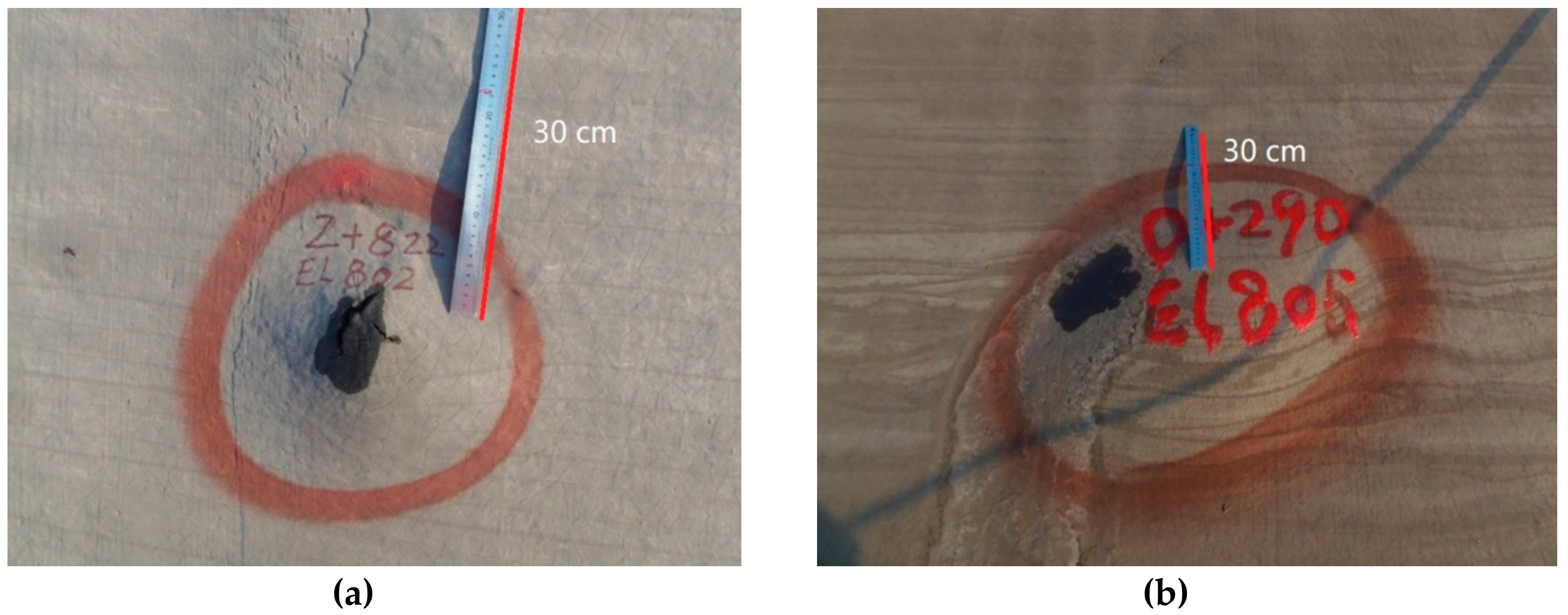

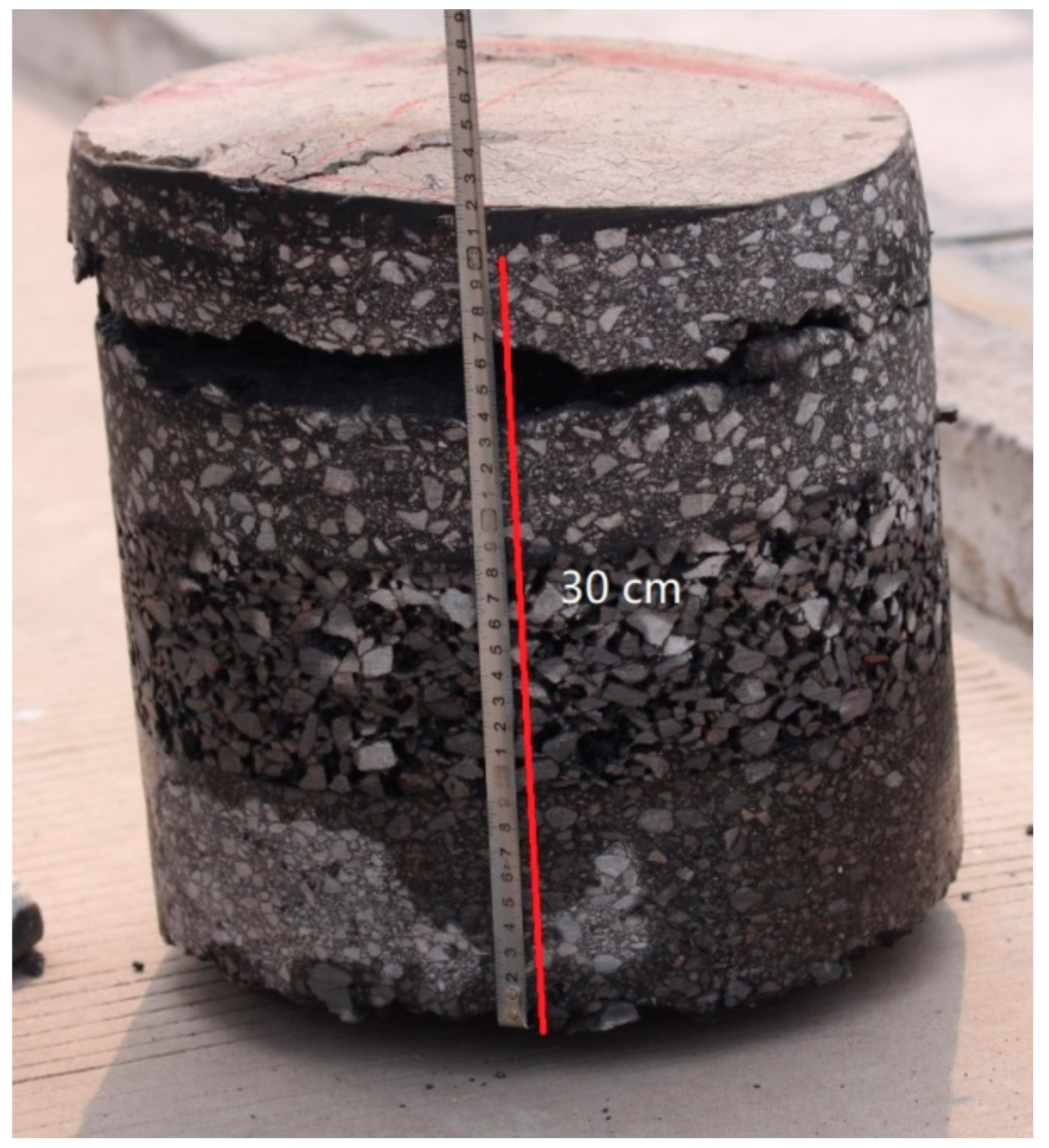

3. Blister Defect Characteristics of Zhanghewan Asphalt Concrete Facing

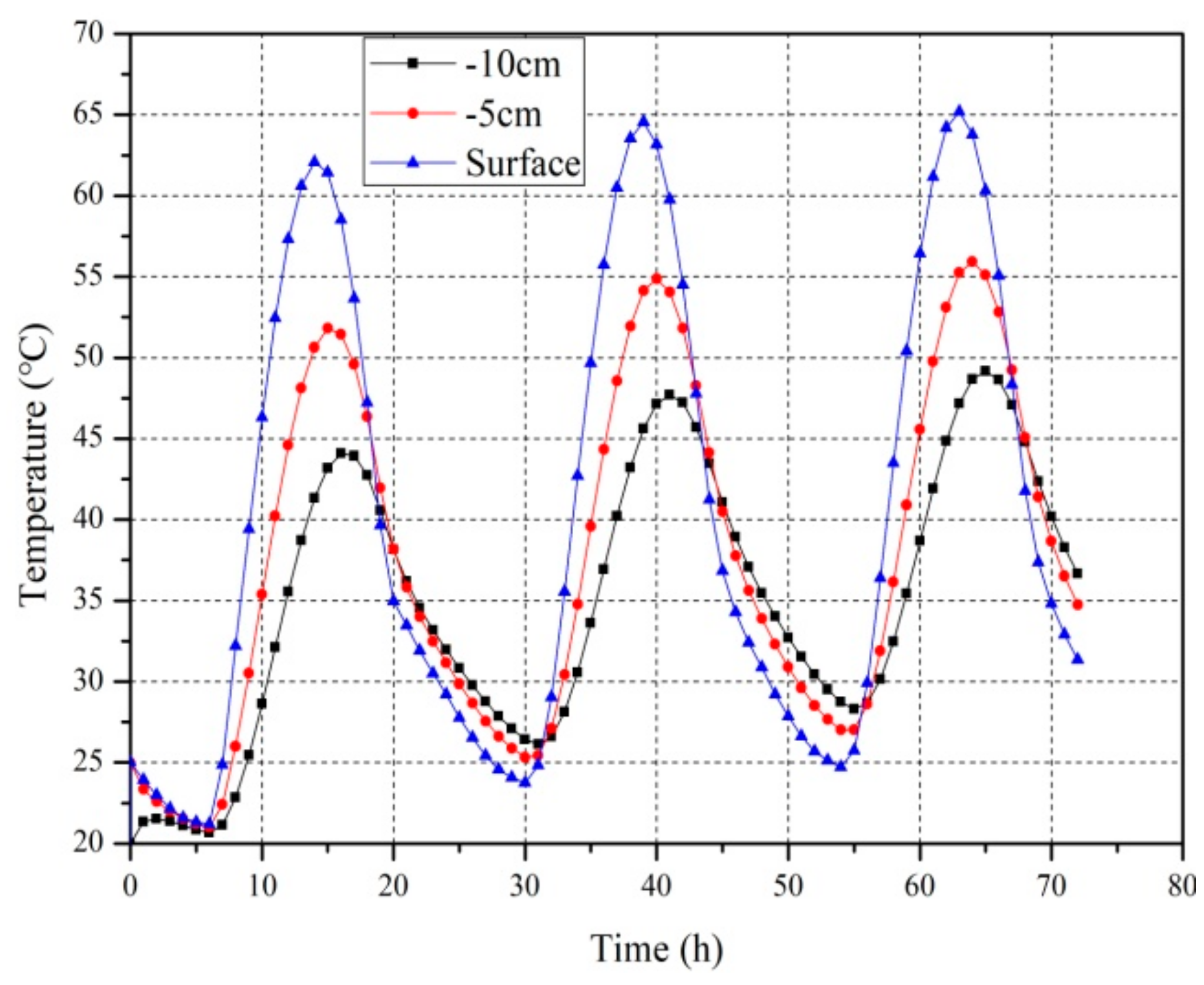

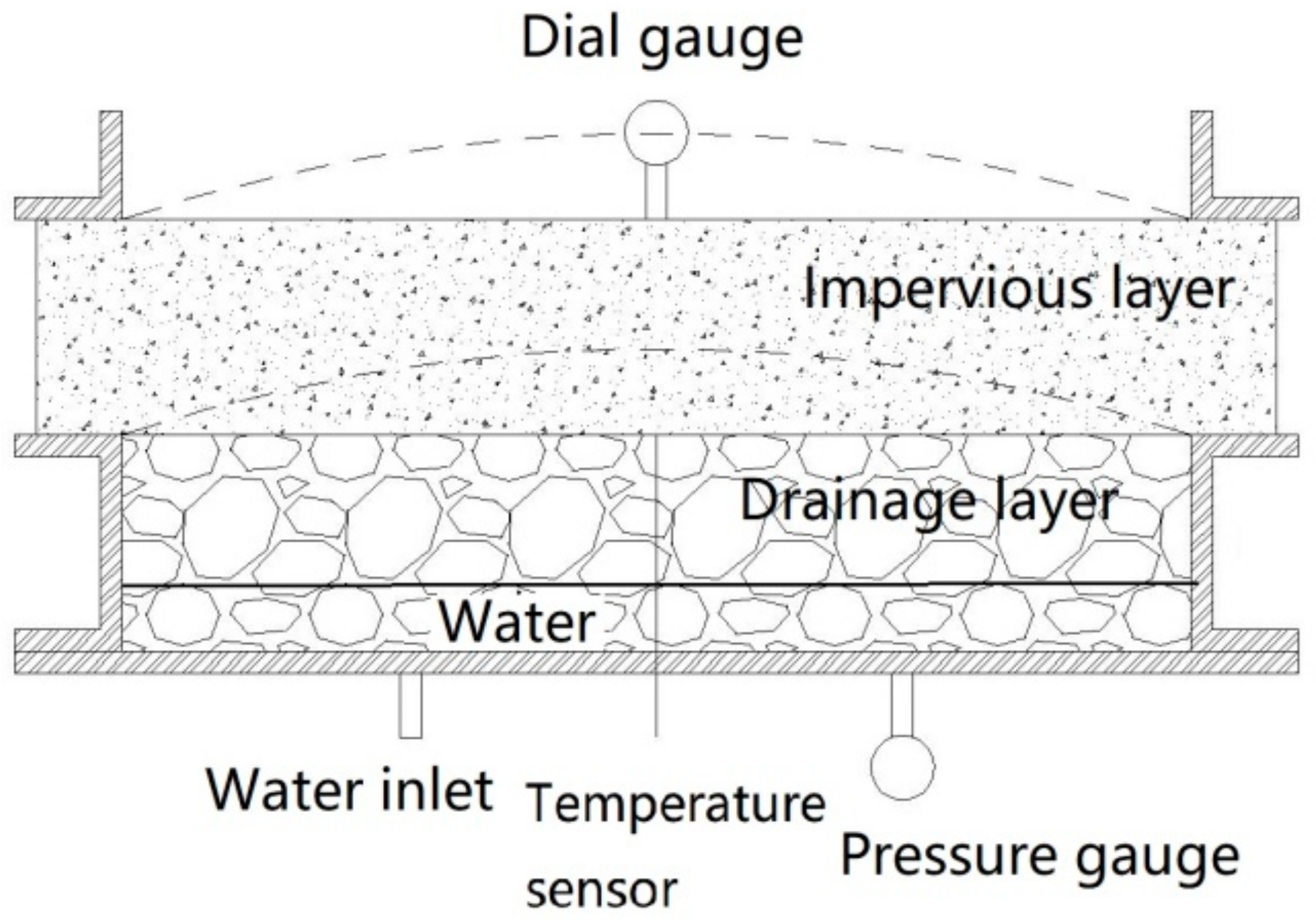

4. Model Test of the Blister

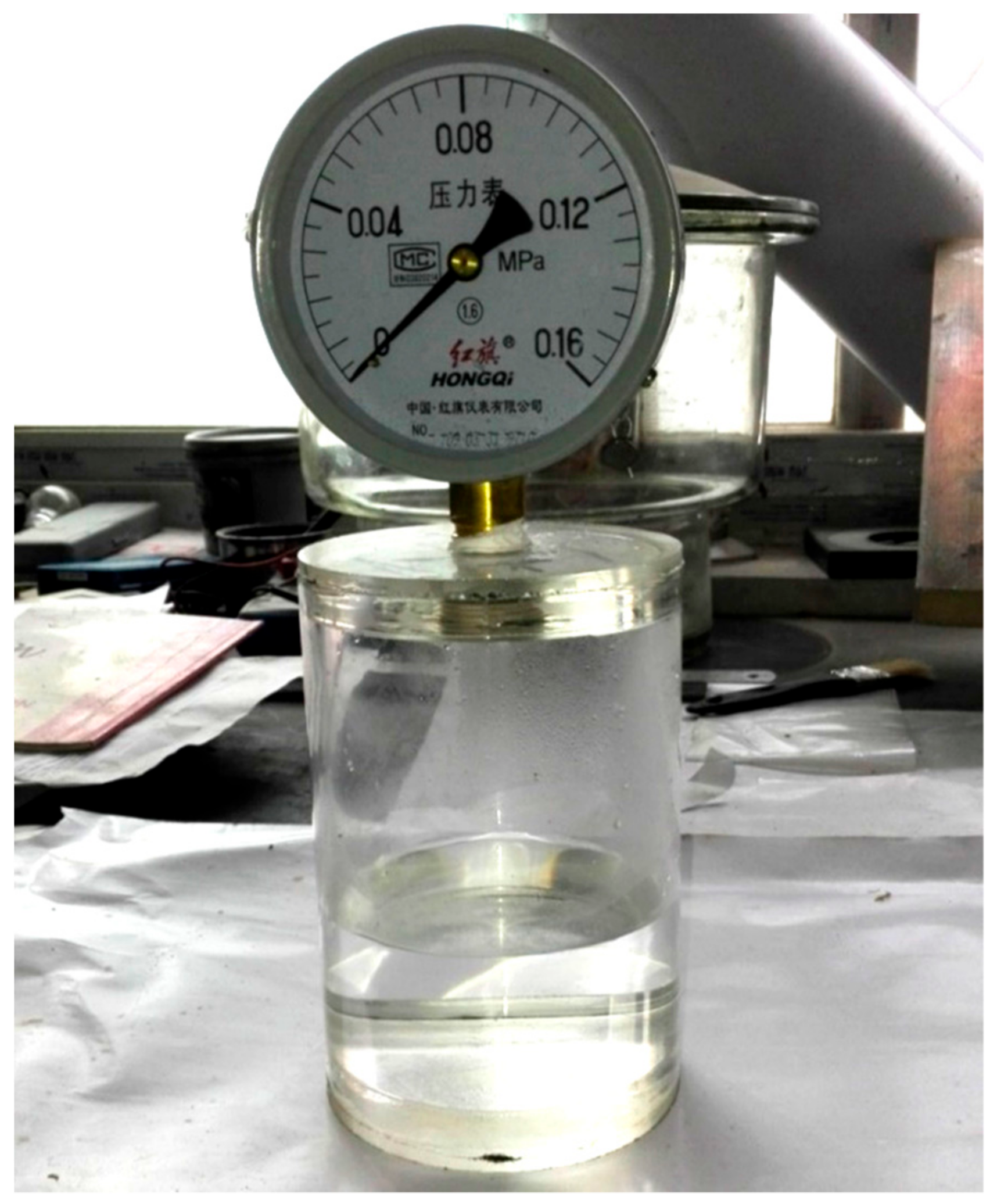

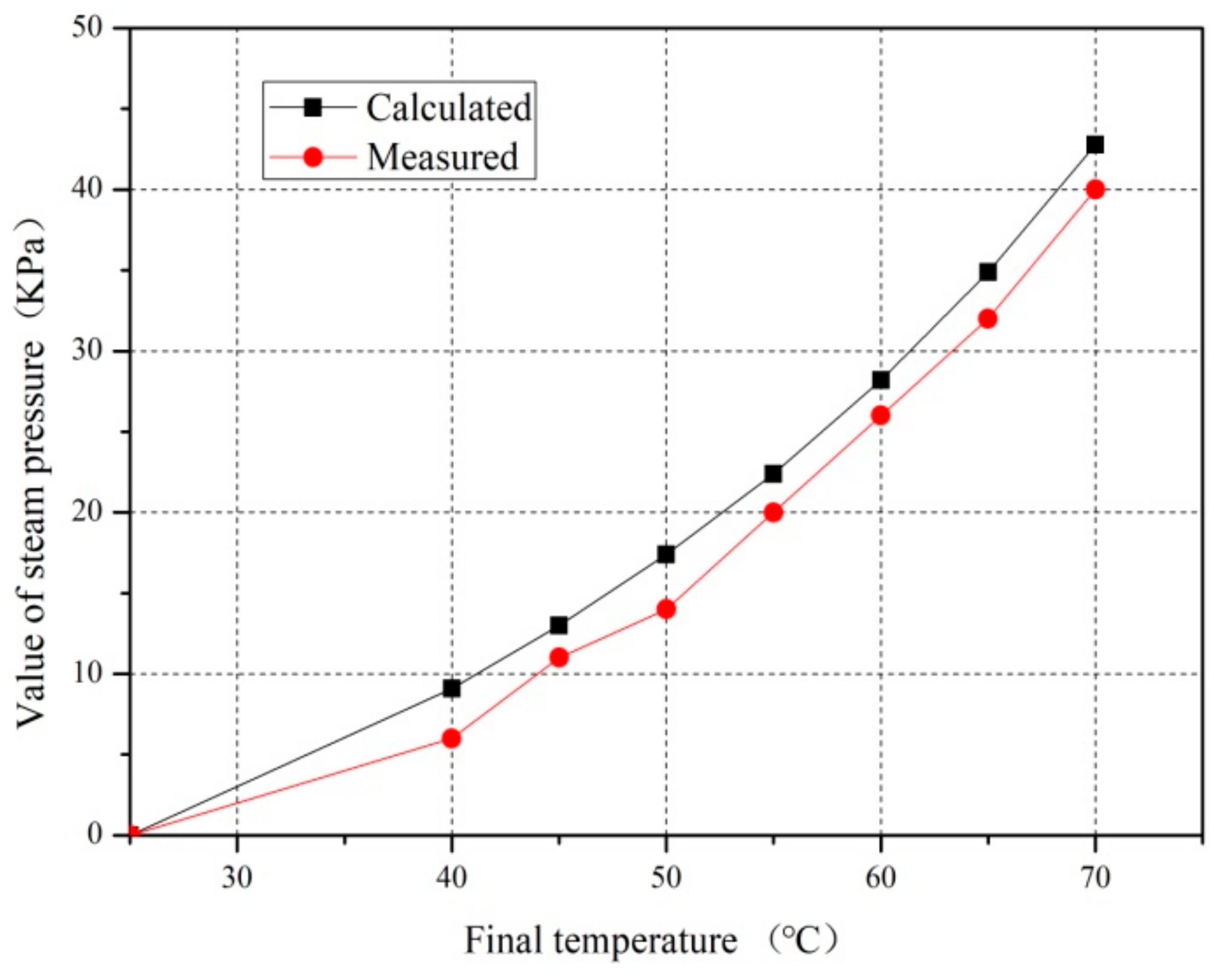

4.1. Estimation of Steam Pressure

4.2. Model Test

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jutao, H.; Cao, P.Y.; Liu, Z.H.; Wang, Z.X. Developingof a SBS polymer modified bitumen to avoid low temperature cracks in the asphalt facing of a reservoir in a harsh climate region. Constr. Build. Mater. 2017, 150, 105–113. [Google Scholar]

- Xia, S.F.; Lu, Y.H.; Wang, Z.X.; Zhang, F.C. Studies on the key technical problems ofasphalt concrete facing slabs in upper reservoir of Huhhot Pump Storage. In Proceedings of the 4th International Conference on Concrete Repair, Rehabilitation and Retrofitting, Leipzig, Germany, 17 September 2015; pp. 540–545. [Google Scholar]

- Wang, Z.; Hao, J.; Yang, J.; Cao, Y.; Li, X.; Liu, S. Experimental Study on Hydraulic Fracturing of High Asphalt Concrete Core Rock-Fill Dam. Appl. Sci. 2019, 9, 2285. [Google Scholar] [CrossRef]

- Embankment dams with bituminous concrete facing. In Proceedings of the Review and recommendations, Bulletin 114, ICOLD, Paris, France, 6 June 1999; p. 79.

- Peter, T. Long time behavior of asphalt concrete lined reservoirs and dams and their foundation. In Proceedings of the 1st International Conference on Long Time Effects and Seepage Behavior of Dams, Nanjing, China, 2 June 2008. [Google Scholar]

- Teltayev, B.B.; Rossi, O.C.; Izmailova, G.G.; Amirbayev, E.D. Effect of Freeze-Thaw Cycles on Mechanical Characteristics of Bitumens and Stone Mastic Asphalts. Appl. Sci. 2019, 9, 458. [Google Scholar] [CrossRef]

- Özgan, E. Modelling the Stability of Asphalt Concrete with Fuzzy Logic and Statistical Methods for Various Freezing and Thawing Cycles. Math. Comput. Appl. 2010, 15, 176–186. [Google Scholar] [CrossRef]

- Yang, Q.M.; Sun, Z.T.; Ding, P.R. Asphalt concrete facing for rockfill dams built by directional blasting. In Proceedings of the ICOLD 16th Congress, San Francisco, CA, USA, 4–5 October 1988; pp. 1091–1103. [Google Scholar]

- Szling, Z.; Szymański, A. The origin of and prevention from damage to impervious facings. In Proceedings of the ICOLD 17th Congress, Vienna, Austria, 14–17 October 1991; pp. 95–102. [Google Scholar]

- Garcia-Gil, L.; Miró, R.; Pérez-Jiménez, F.E. Evaluating the Role of Aggregate Gradation on Cracking Performance of Asphalt Concrete for Thin Overlays. Appl. Sci. 2019, 9, 628. [Google Scholar] [CrossRef]

- Kong, D.; Chen, M.; Xie, J.; Zhao, M.; Yang, C. Geometric Characteristics of BOF Slag Coarse Aggregate and its Influence on Asphalt Concrete. Materials 2019, 12, 741. [Google Scholar] [CrossRef] [PubMed]

- Frohnauer, R. Special application of asphaltic concrete for dam water barrier construction. In Proceedings of the Waterpower Conference 1999, Las Vegas, NV, USA, 6–9 July 1999; pp. 1–10. [Google Scholar]

- Schönian, E. The Shell Bitumen Hydraulic Engineering Handbook; Shell International Petroleum Company Ltd.: The Hague, The Netherlands, 1999; p. 449. [Google Scholar]

- Li, X.L.; Hao, J.T.; Wang, Z.X. Experimental study on ground penetrating radar in quality inspection of asphalt concrete impervious facing of pumped storage power station. In IOP Conf. Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 423, p. 012020. [Google Scholar]

- Mallick, R.B.; Allen, C.J.L.; Teto, M.R. An Evaluation of Factors Affecting Permeability of Superpave Designed Pavements. In National Center for Asphalt Technology; Auburn University: Auburn, AL, USA, 2003. [Google Scholar]

- Sawada, T.; Nakazima, Y.; Tanaka, T. Emperical research and practical design of rockfill dams with asphalt facing. In Proceedings of the ICOLD 11th Congress, Madrid, Spain, 2–4 October 1973; pp. 281–313. [Google Scholar]

- Robert, G. Mortimer. In Physical Chemistry, 3rd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Ohe, S. A Prediction Method of Vapor Pressures by using boiling point data. Fluid Phase Equilibria 2019, in press. [Google Scholar] [CrossRef]

- Choe, G.; Kim, G.; Yoon, M.; Euichul, H.W.; Nam, J.S.; Nenad, N.G. Effect of moisture migration and water vapor pressure build-up with the heating rate on concrete spalling type. Cem. Concr. Res. 2019, 116, 1–10. [Google Scholar] [CrossRef]

- Dean, J.A. Lange’s Handbook of Chemistry, 2nd ed.; Science Press: Beijing, China, 2003. [Google Scholar]

- Chen, J.Q.; Wang, H.; Zhu, H.Z. Analytical approach for evaluating temperature field of thermal modified asphalt pavement and urban heat island effect. Appl. Therm. Eng. 2017, 113, 739–748. [Google Scholar] [CrossRef]

- Chen, J.Q.; Li, L.; Wang, H. Analytical prediction and field validation of transient temperature field in asphalt pavements. J. Cent. South Univ. 2015, 22, 4872–4881. [Google Scholar] [CrossRef]

- Teltayev, B.; Aitbayev, K. Modeling of Temperature Field in Flexible Pavement. Indian Geotech. J. 2015, 45, 371–377. [Google Scholar] [CrossRef]

- Wang, W.J. Calculation and Analysis Report on Temperature Field and Temperature Stress of Asphalt Concrete Anti-seepage Panel of Xilongchi Pumped Storage Power Station; Xi’an University of Technology: Xi’an, China, 2004. [Google Scholar]

- Lian, Z.W.; Wang, L. Analysis of two kinds of historical extreme high temperature genesis in Shijiazhuang in the summer of 2002. In Proceedings of the 2003 National Major Severe Weather Process Summary and Forecasting Technology Experience Seminar, Chongqing, China, 10 July 2003. [Google Scholar]

| Sheive Size | Passing Rate (%) | Bitumen Content | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | ||

| Impervious layer | 100 | 100 | 100 | 92.4 | 68.7 | 58.1 | 46.2 | 26.2 | 17.2 | 13.3 | 11.7 | 7.7 |

| Drainage layer | 100 | 98.2 | 48.2 | 32.8 | 16.4 | 12.0 | 10.6 | 8.1 | 5.8 | 4.0 | 3.0 | 3.5 |

| No. | Station Number | Elevation/m | Diameter of Blister/cm | Depth of Separation/cm | Drainage Layer | Void Content of Impermeable Layer % | |

|---|---|---|---|---|---|---|---|

| Void Content % | Permeability Coefficient cm/s | ||||||

| 1 | 1 + 713 | 809.0 | 30 | 2.7–5.8 | 20.4 | 0.114 | 2.85 |

| 2 | 1 + 627 | 810.0 | 40 | 7.4–9.1 | 17.2 | 0.206 | 2.90 |

| 3 | 2 + 356 | 809.0 | 30 | 6.1–8.9 | 17.3 | 0.085 | 2.47 |

| 4 | 2 + 349 | 806.5 | 40 | 5.2–7.3 | 20.2 | 0.137 | 2.89 |

| 5 | 2 + 390.5 | 809.0 | 40 | 5.3–7.6 | 16.0 | 0.267 | 2.68 |

| 6 | 2 + 741 | 809.0 | 20 | 7.3–8.5 | 18.3 | 0.098 | 2.75 |

| 7 | 2 + 769 | 809.0 | 40 | 2.2–3.3 | 19.4 | 0.103 | 2.67 |

| 8 | 0 + 56 | 806.5 | 40 | 2.6–9.3 | 20.1 | 0.115 | 2.95 |

| 9 | 0 + 127 | 808.0 | 30 | 3.1–4.5 | 20.5 | 0.201 | 2.82 |

| Temperature (°C) | Calculated Pressure (kPa) | Measured Pressure (kPa) | ||

|---|---|---|---|---|

| Saturated Vapor Pressure Pw | Air Pressure Pa | Pt-P0 | ||

| 25 | 3.1 | 98.2 | 0 | 0 |

| 40 | 7.3 | 103.1 | 9.1 | 6 |

| 45 | 9.5 | 104.8 | 13.0 | 11 |

| 50 | 12.3 | 106.4 | 17.4 | 14 |

| 55 | 15.7 | 108.1 | 22.4 | 20 |

| 60 | 19.8 | 109.7 | 28.2 | 26 |

| 65 | 24.9 | 111.4 | 34.9 | 32 |

| 70 | 31.1 | 113.0 | 42.8 | 40 |

| C J/(kg·K) | ρ kg/cm3 | λ J/(m·h·K) | β J/(m2·h·K) | ε | σ J/(h·m2·K4) | αs | |

|---|---|---|---|---|---|---|---|

| Impervious layer | 958 | 2450 | 6059 | 68400 | 0.81 | 2.041 × 10−4 | 0.9 |

| Leveling layer | 771 | 2250 | 5184 | - | - | - | - |

| Cushion layer | 691 | 2100 | 4752 | - | - | - | - |

| Time (h) | Temperature (°C) | Solar Radiation (J/h·m2) | Time (h) | Temperature (°C) | Solar Radiation (J/h·m2) |

|---|---|---|---|---|---|

| 0 | 25.8 | 0 | 12 | 34.4 | 4,680,000 |

| 1 | 24.7 | 0 | 13 | 35.3 | 4,544,008 |

| 2 | 23.7 | 0 | 14 | 35.6 | 4,143,934 |

| 3 | 23.1 | 0 | 15 | 35.3 | 3,503,030 |

| 4 | 22.8 | 0 | 16 | 34.7 | 2,658,543 |

| 5 | 23.1 | 0 | 17 | 33.7 | 1,659,551 |

| 6 | 24 | 0 | 18 | 32.6 | 564,111.7 |

| 7 | 25.4 | 1,659,551 | 19 | 31.5 | 0 |

| 8 | 27.2 | 2,658,543 | 20 | 30.3 | 0 |

| 9 | 29.2 | 3,503,030 | 21 | 29.2 | 0 |

| 10 | 31.2 | 4,143,934 | 22 | 28.1 | 0 |

| 11 | 33 | 4,544,008 | 23 | 26.9 | 0 |

| Thickness (cm) | Temperature (°C) | Pressure (kPa) | Deflection (mm) | Deflection Span Ratio | Remarks |

|---|---|---|---|---|---|

| 10 | 45 | 11 | 3 | 0.006 | No cracking, no leakage |

| 50 | 14 | 11 | 0.022 | No cracking, no leakage | |

| 55 | 20 | 28 | 0.056 | No cracking, no leakage | |

| 5 | 45 | 11 | 11 | 0.022 | No cracking, no leakage |

| 50 | 14 | 22 | 0.044 | No cracking, no leakage | |

| 55 | 20 | 58 | 0.116 | Cracked, leakage |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Hao, J.; Sun, Z.; Ma, B.; Xia, S.; Li, X. Blistering Mechanism Analysis of Hydraulic Asphalt Concrete Facing. Appl. Sci. 2019, 9, 2903. https://doi.org/10.3390/app9142903

Wang Z, Hao J, Sun Z, Ma B, Xia S, Li X. Blistering Mechanism Analysis of Hydraulic Asphalt Concrete Facing. Applied Sciences. 2019; 9(14):2903. https://doi.org/10.3390/app9142903

Chicago/Turabian StyleWang, Zhengxing, Jutao Hao, Zhiheng Sun, Baodong Ma, Shifa Xia, and Xiulin Li. 2019. "Blistering Mechanism Analysis of Hydraulic Asphalt Concrete Facing" Applied Sciences 9, no. 14: 2903. https://doi.org/10.3390/app9142903

APA StyleWang, Z., Hao, J., Sun, Z., Ma, B., Xia, S., & Li, X. (2019). Blistering Mechanism Analysis of Hydraulic Asphalt Concrete Facing. Applied Sciences, 9(14), 2903. https://doi.org/10.3390/app9142903