Digital Image Correlation Applications in Composite Automated Manufacturing, Inspection, and Testing

Abstract

1. Introduction

2. Conventional Digital Image Correlation (DIC) Applications

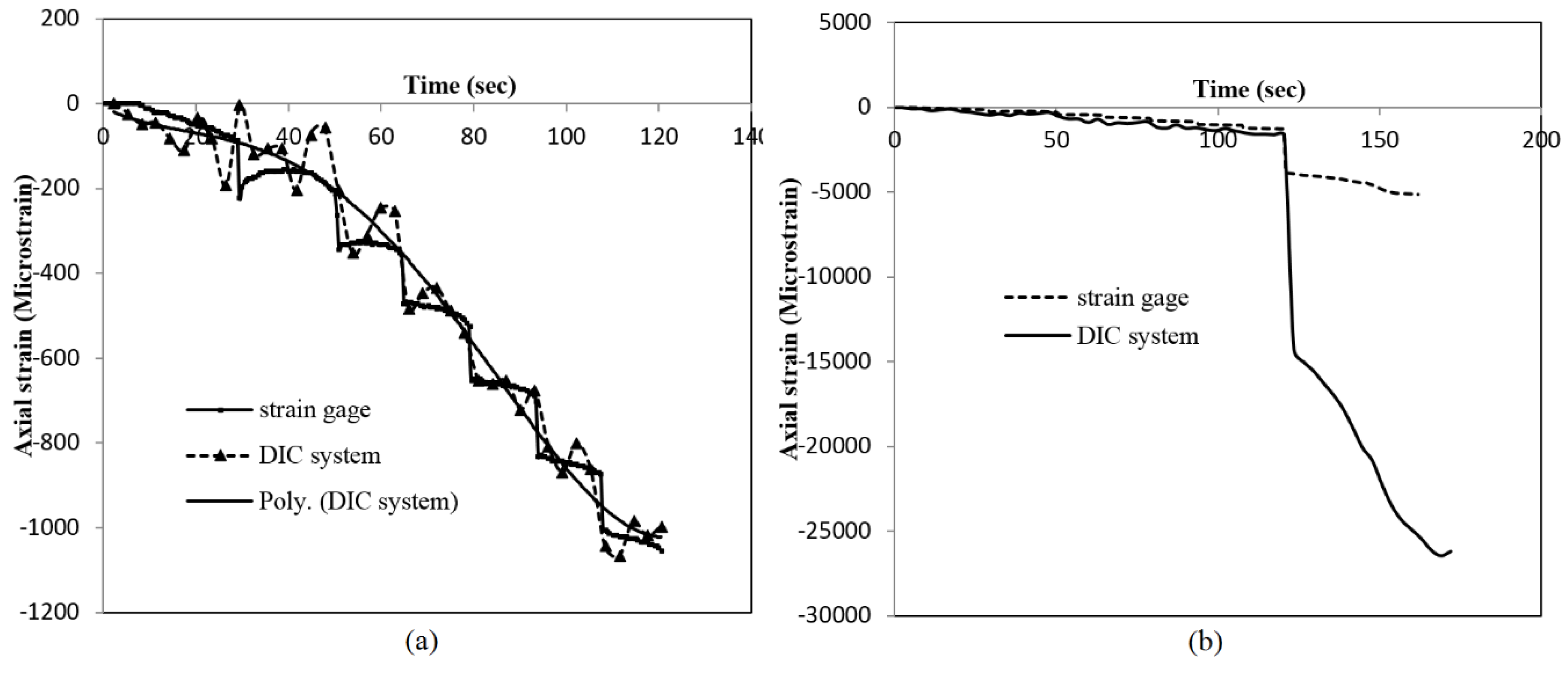

2.1. DIC- and Gage-Measured Strain Comparisons

2.2. Bending and Buckling Analyses of Composite Conical Shells for Helicopter Tail-Boom Applications

2.2.1. Synopsis

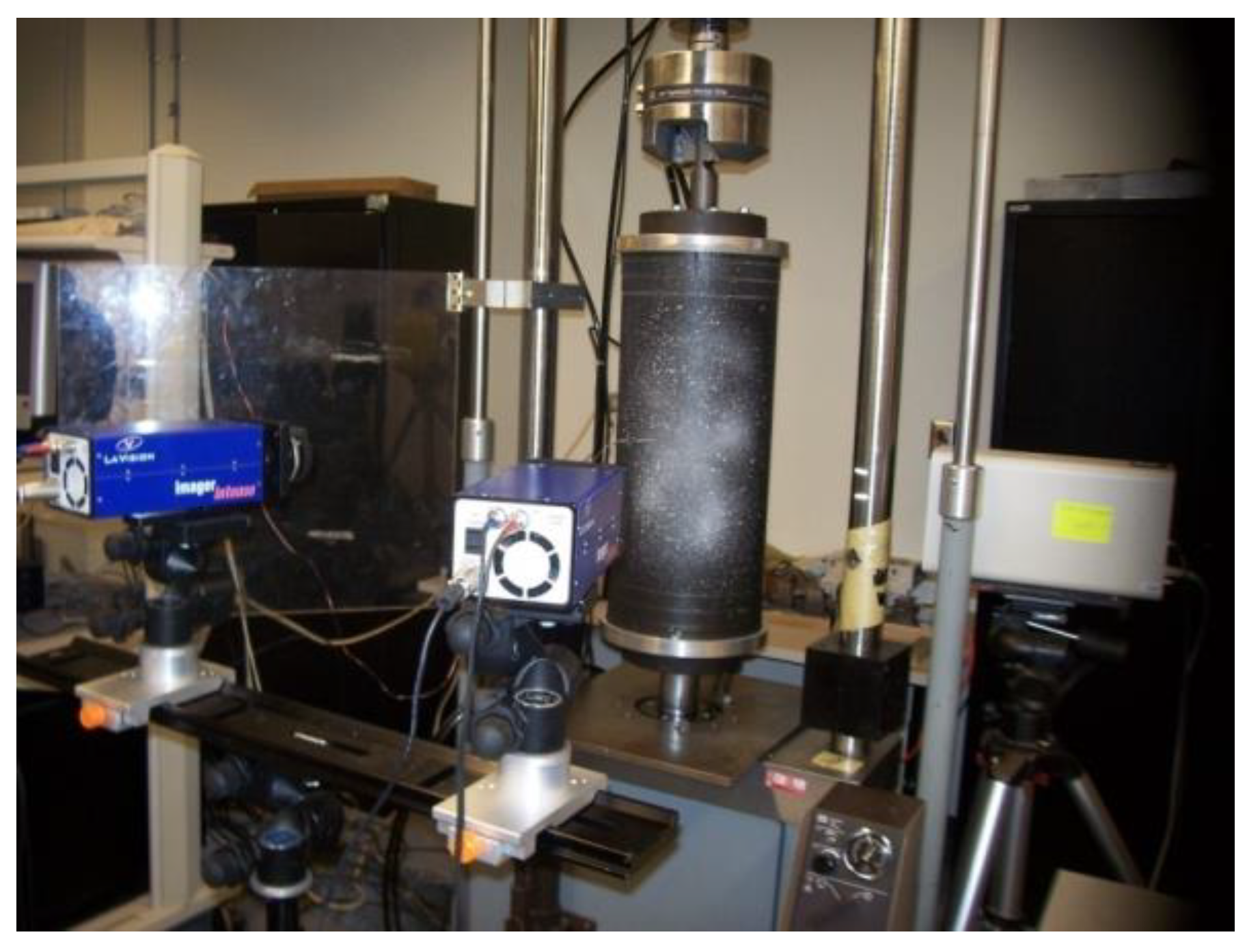

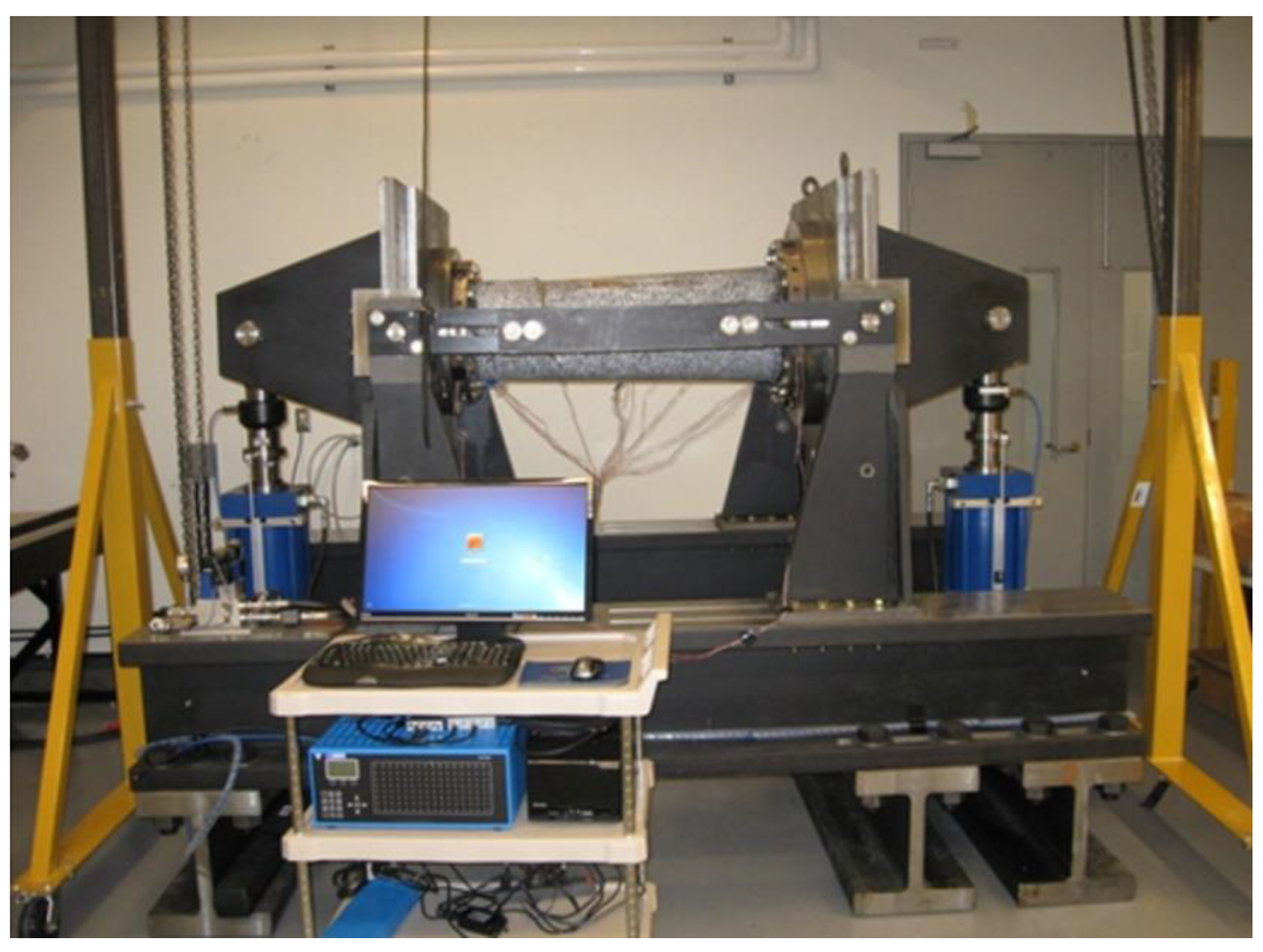

2.2.2. Experimental Work

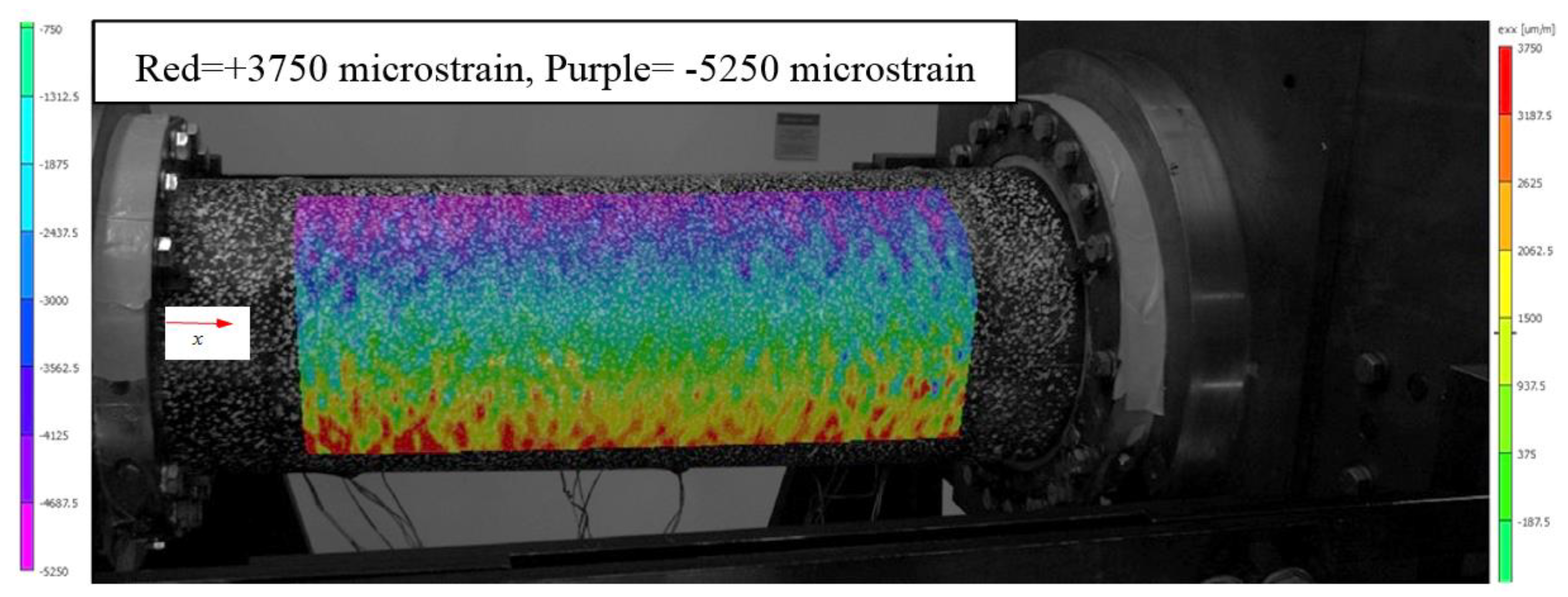

2.2.3. DIC Measurements

2.3. Bending Behavior of Thick-Walled Composite Tubes

2.3.1. Synopsis

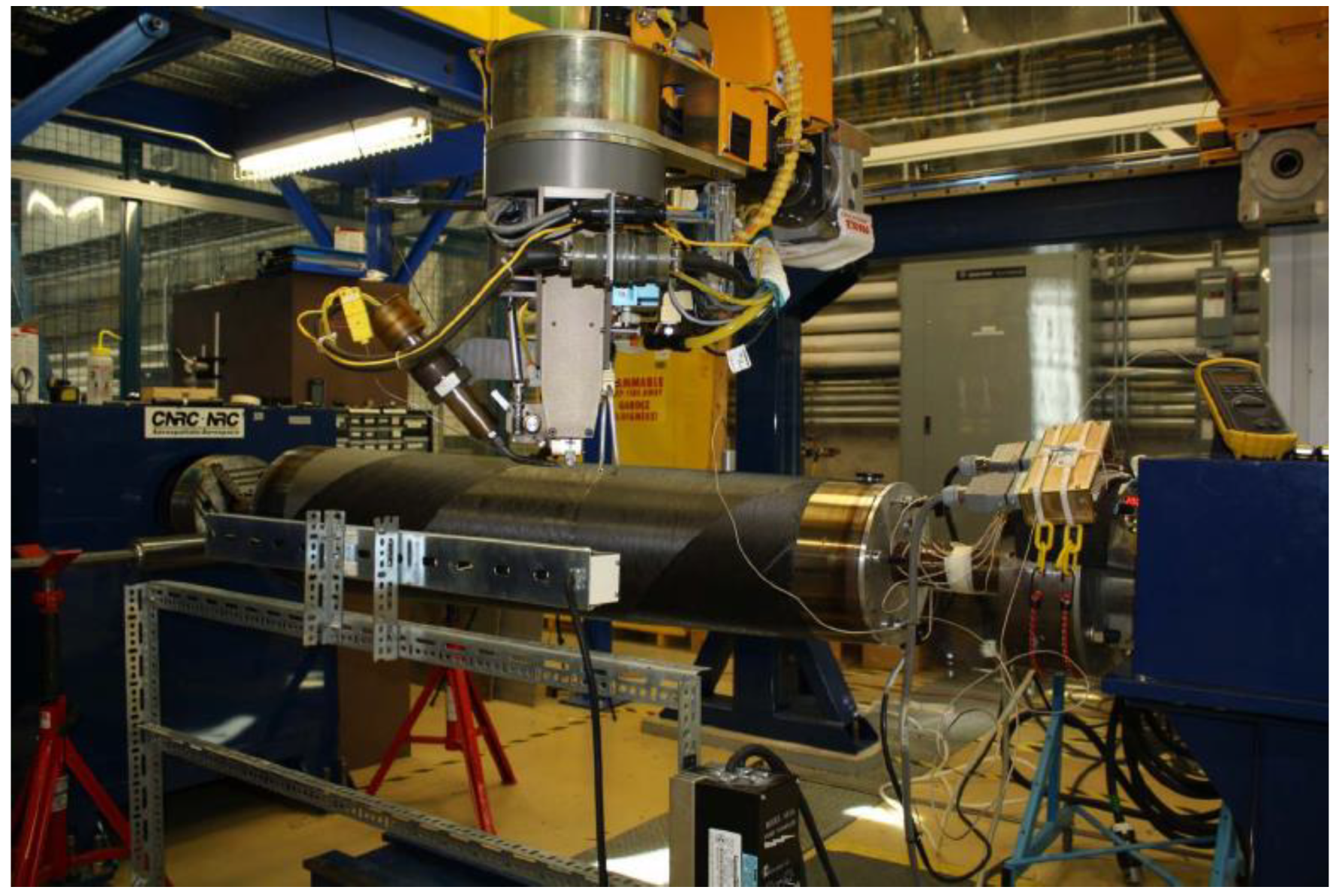

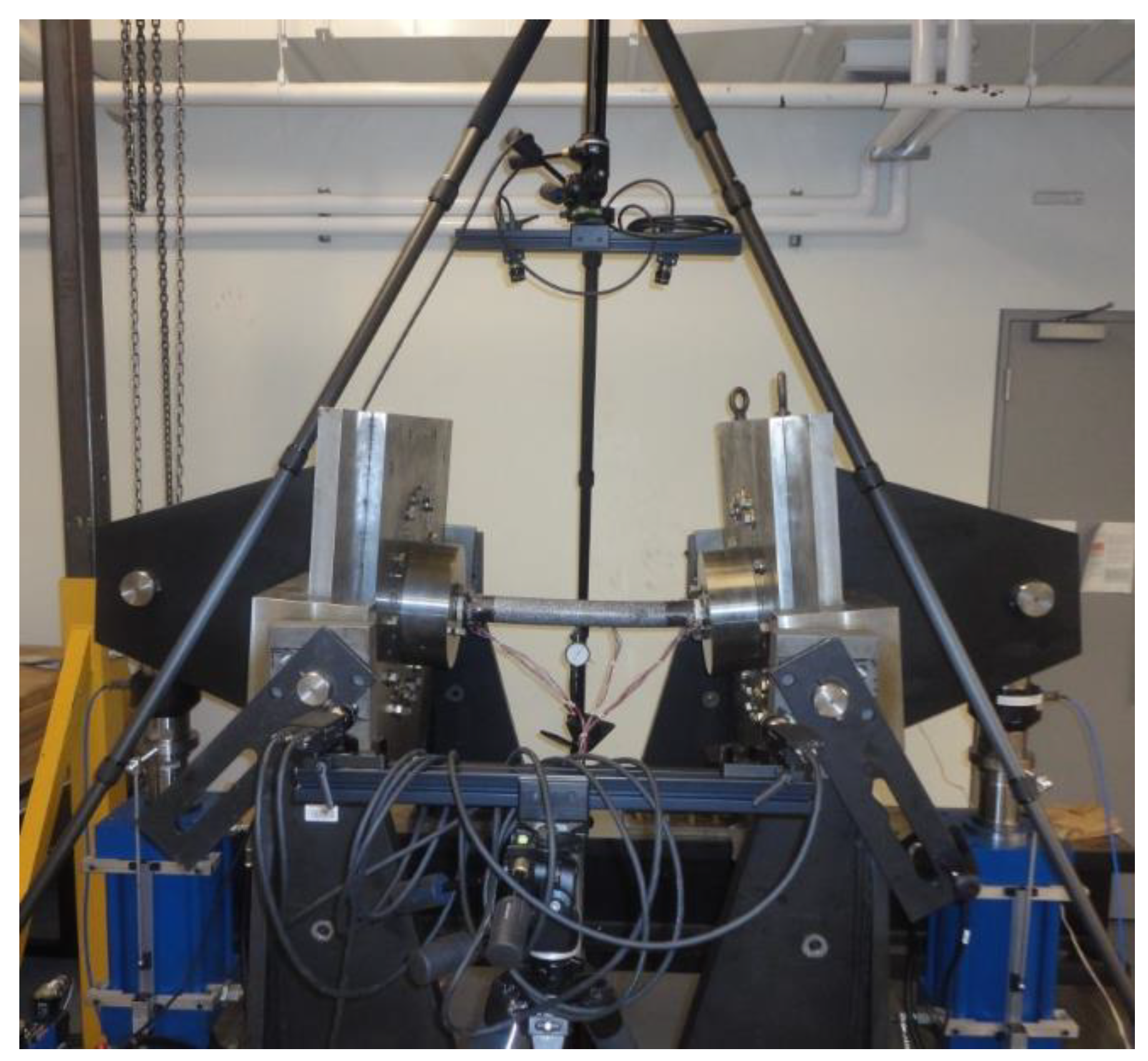

2.3.2. Experimental Work

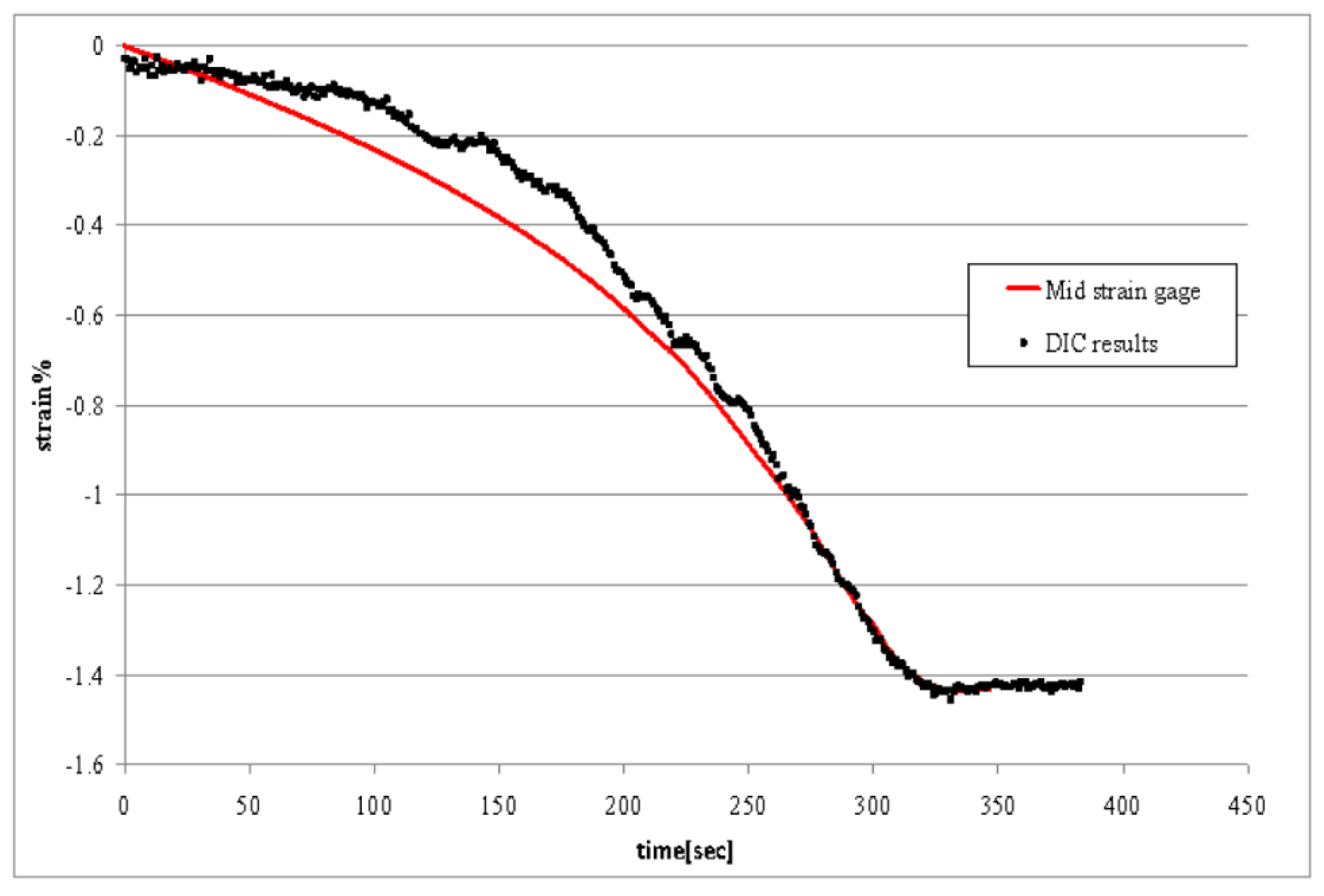

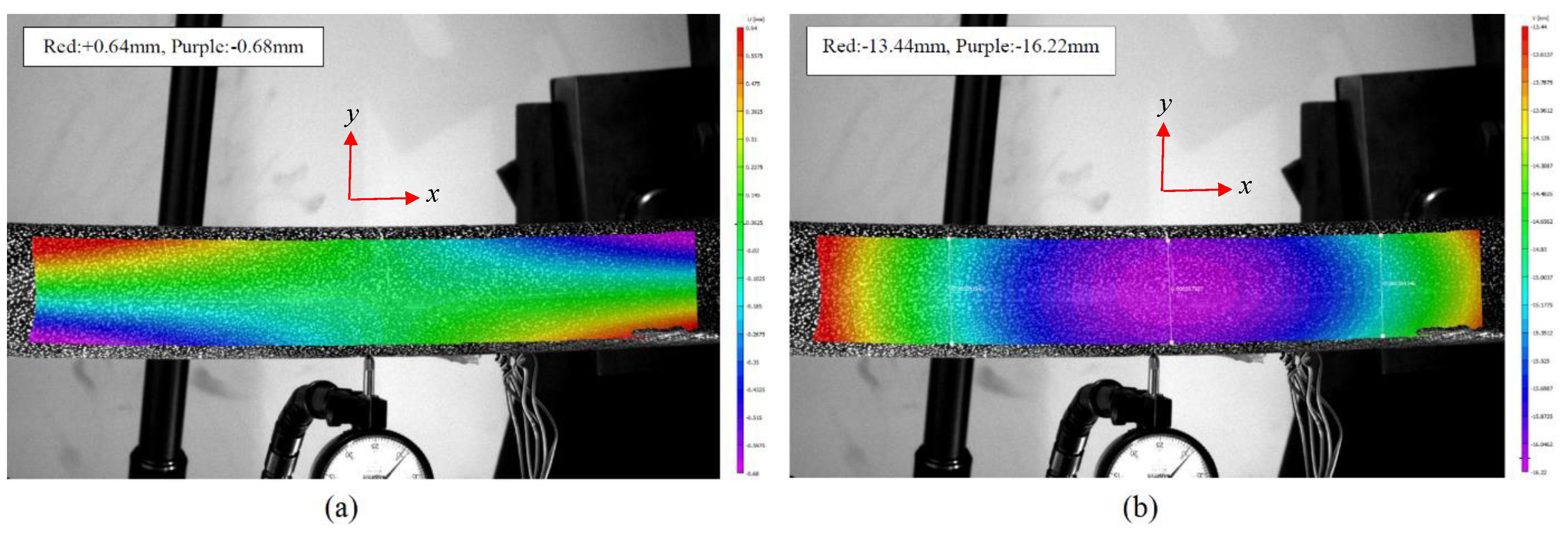

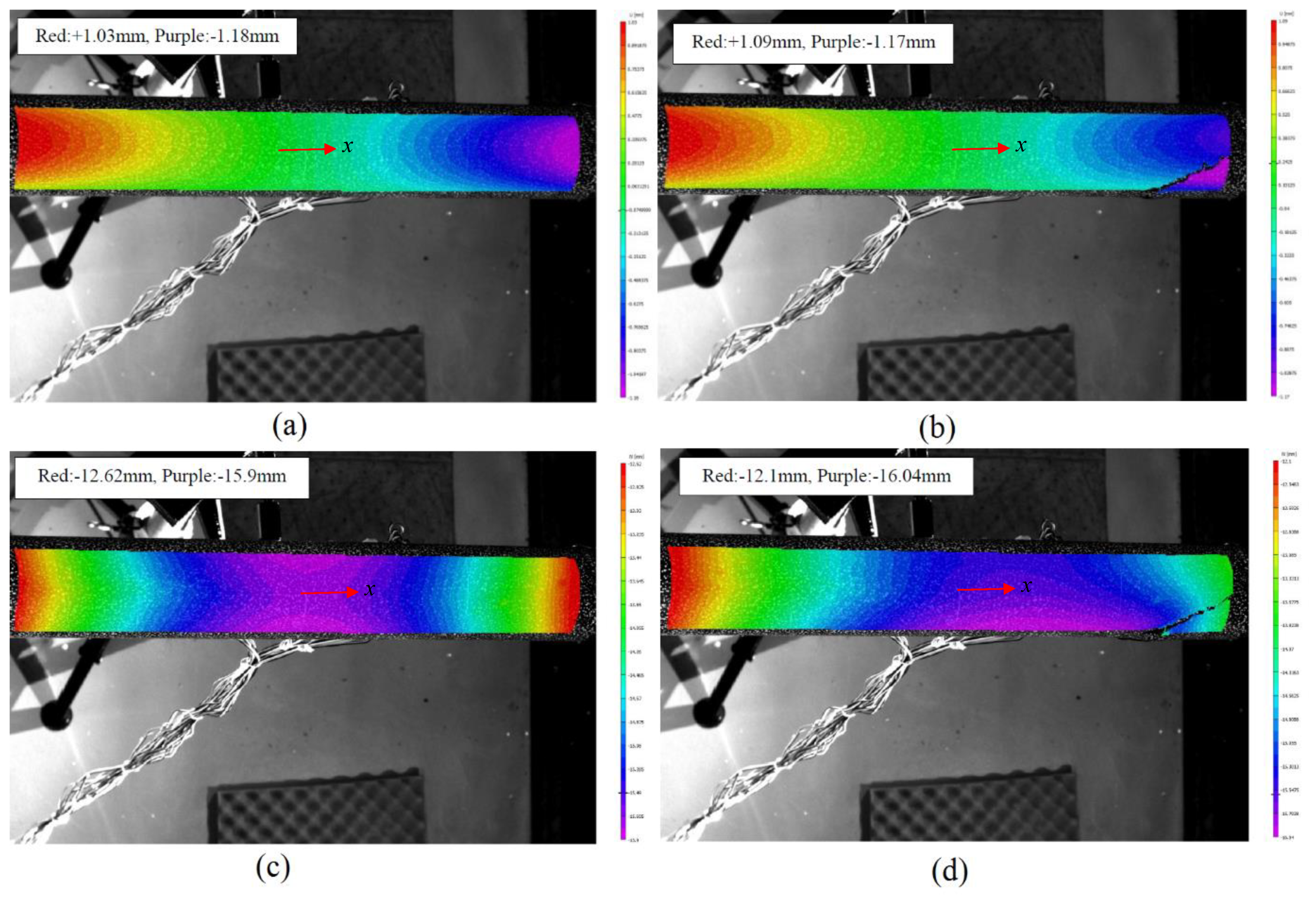

2.3.3. DIC Measurements

3. Development of New Applications for DIC

3.1. Strain and Deformation Measurements for In-situ Manufacturing of Thermoplastic Composites Using Automated Fiber Placement (AFP)

3.1.1. Synopsis

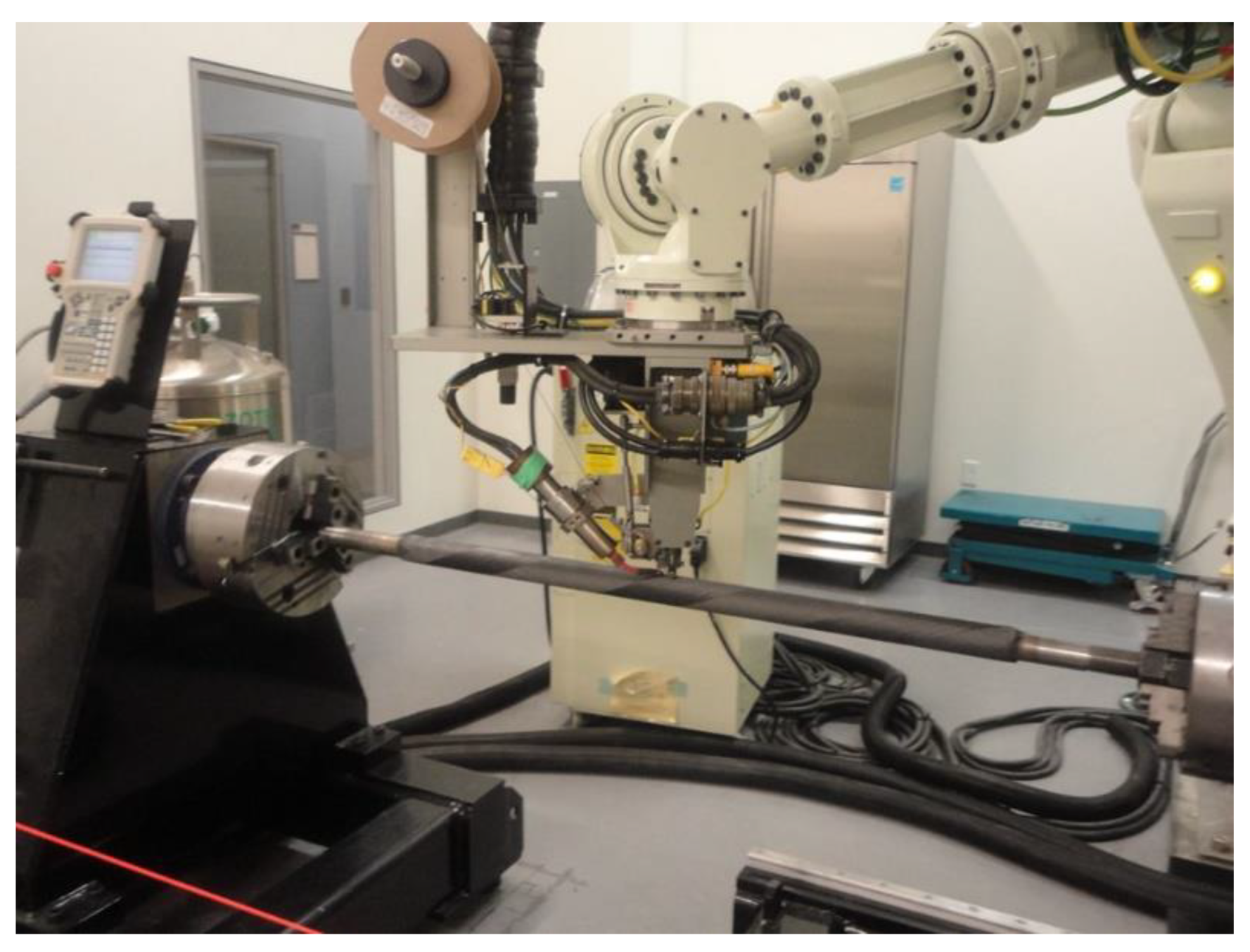

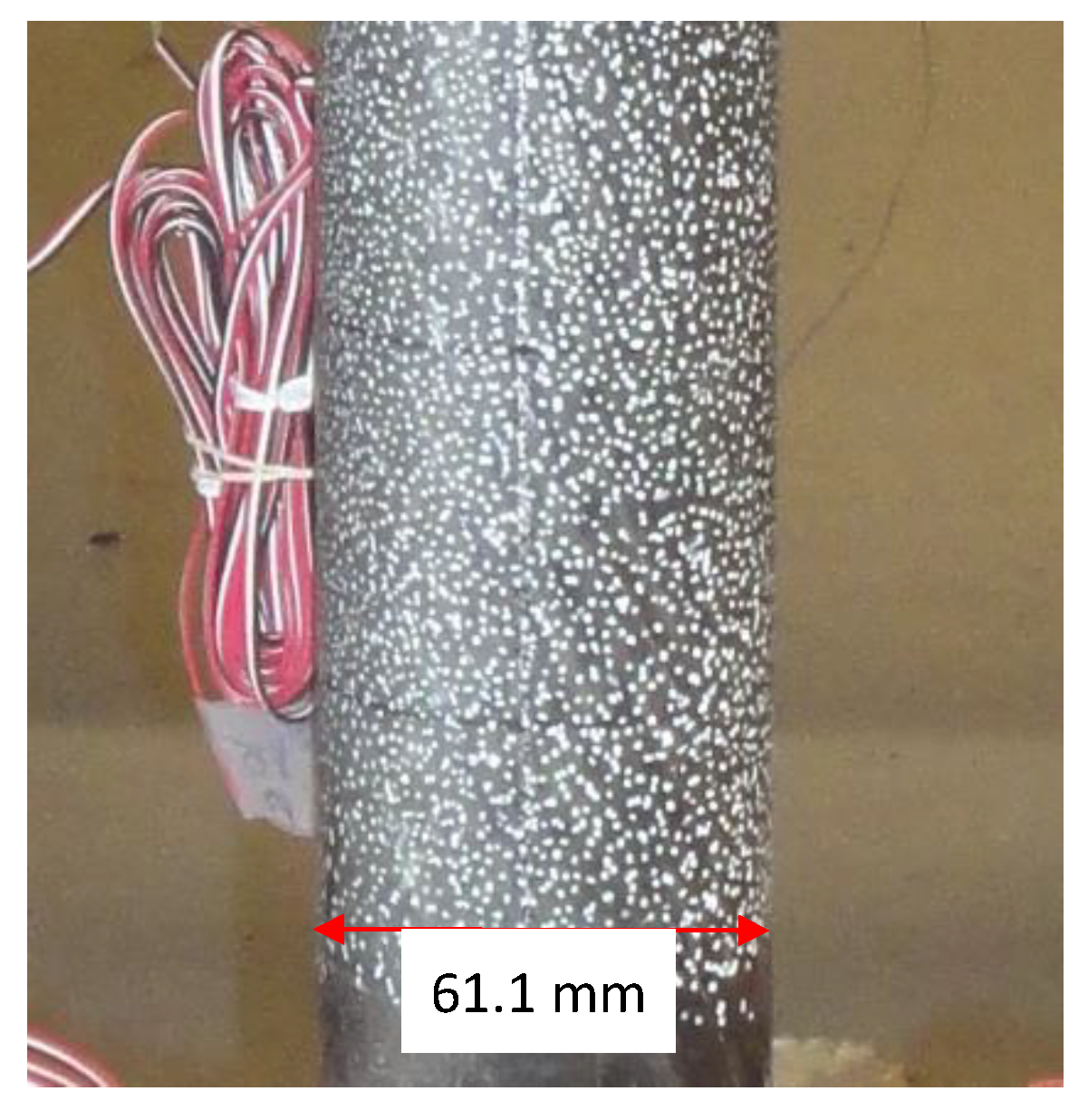

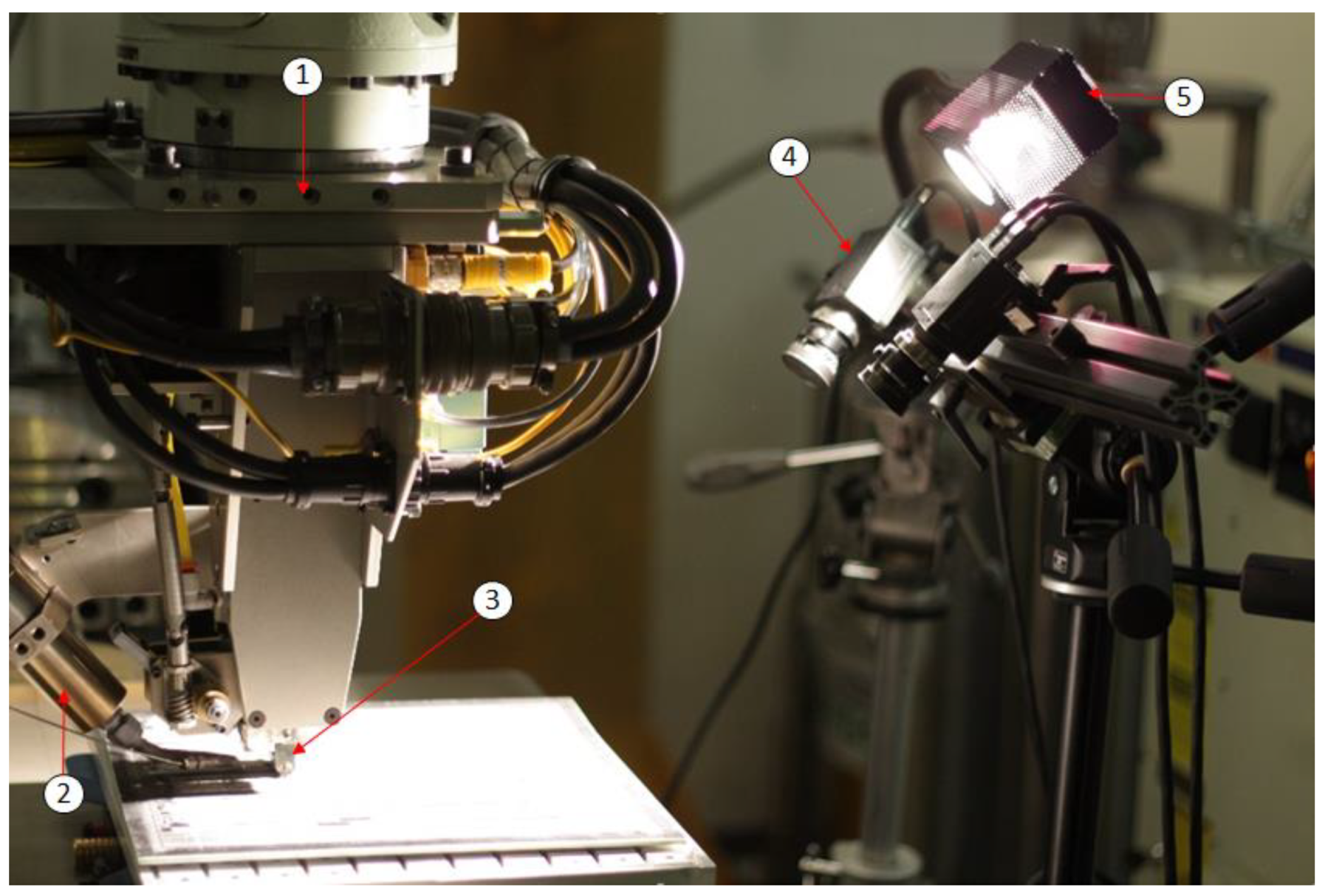

3.1.2. Experimental Work

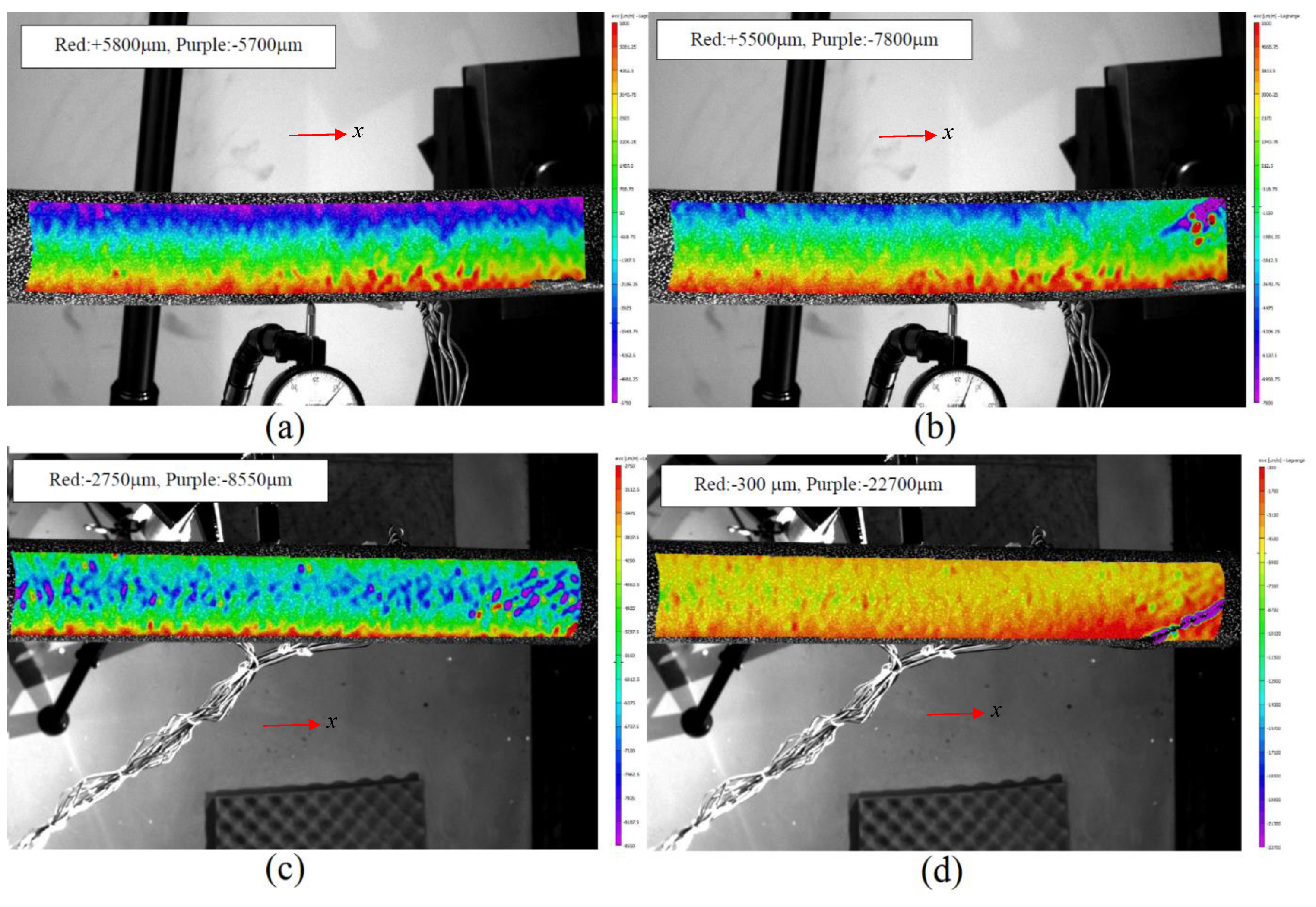

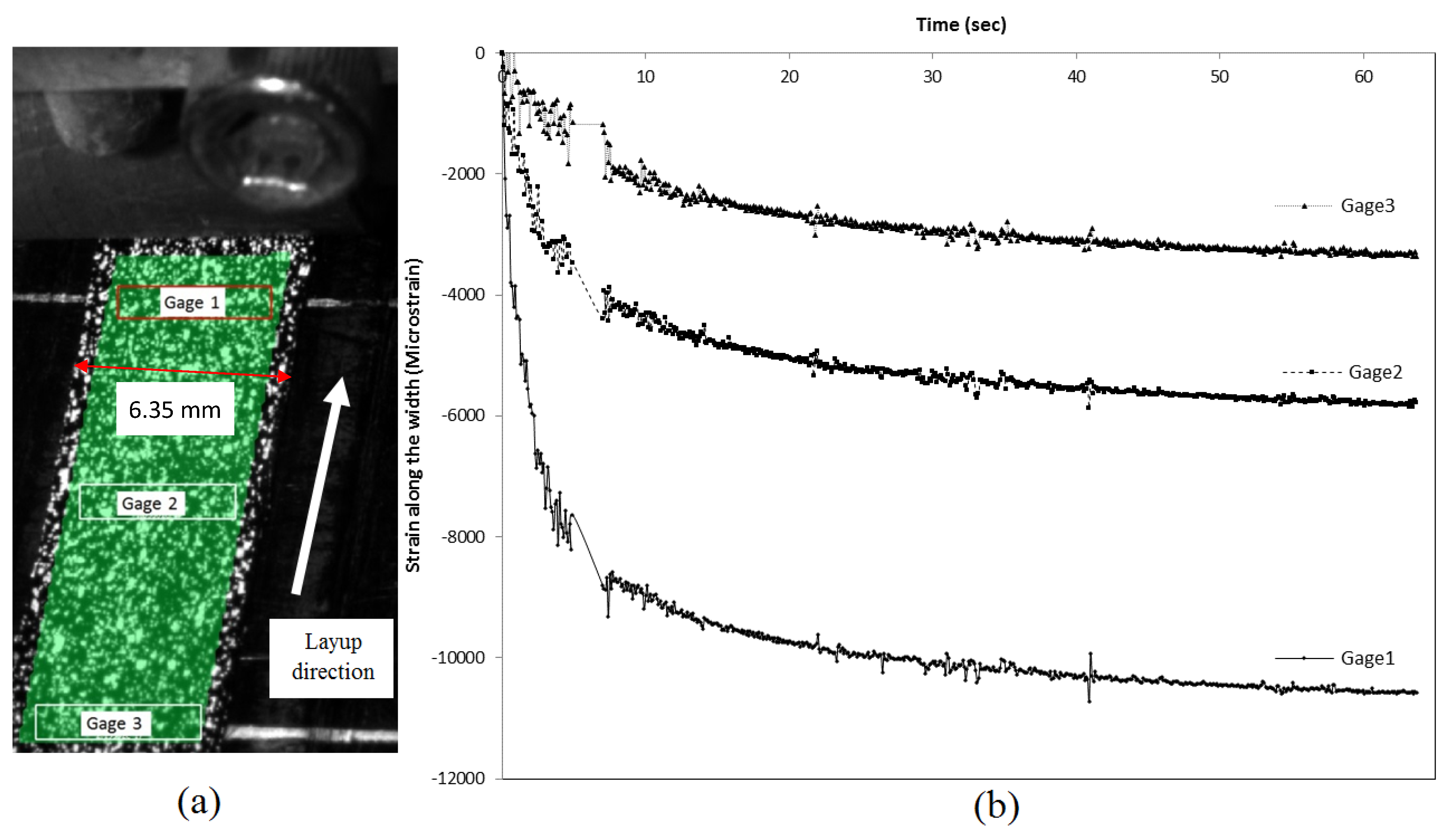

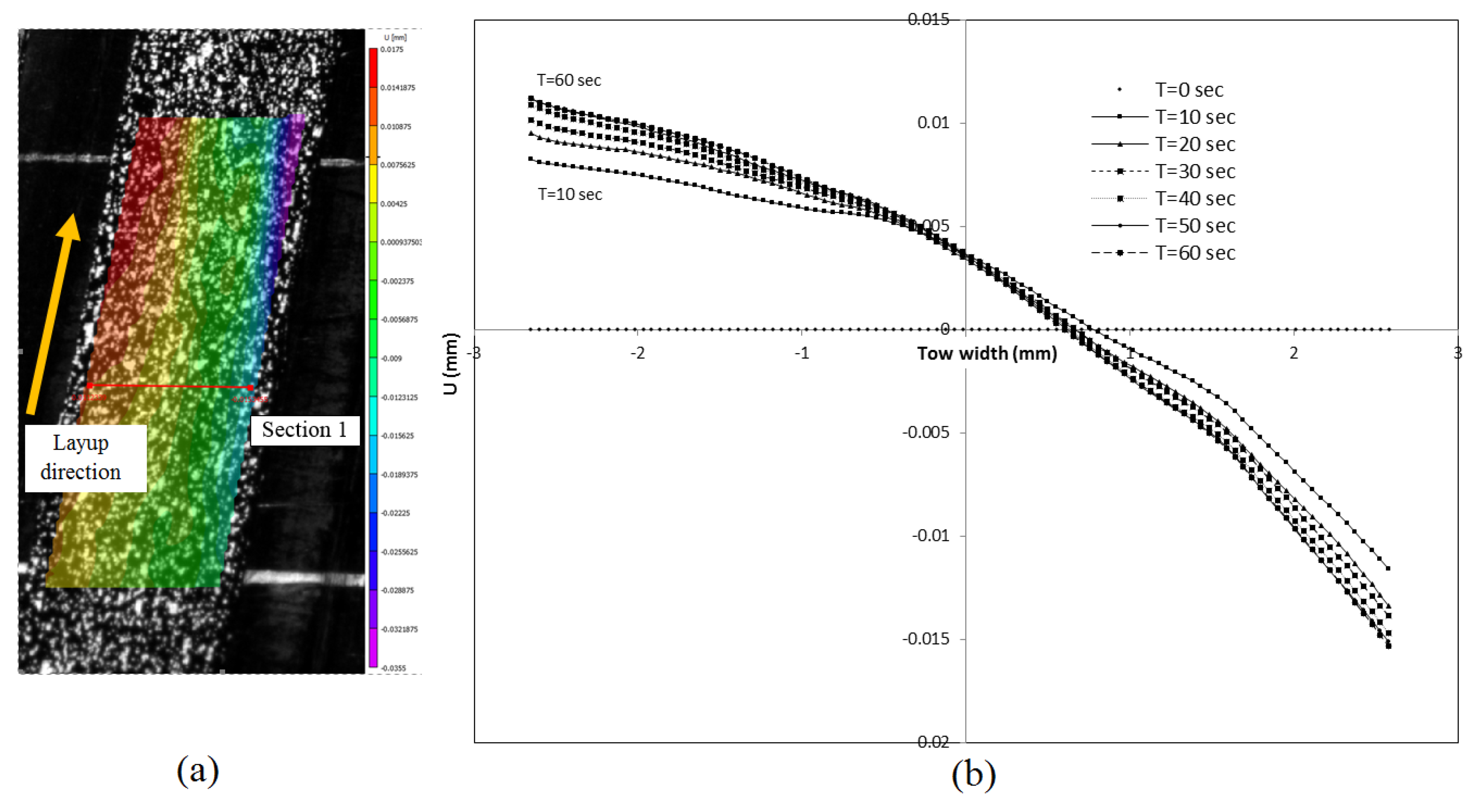

3.1.3. DIC Measurements

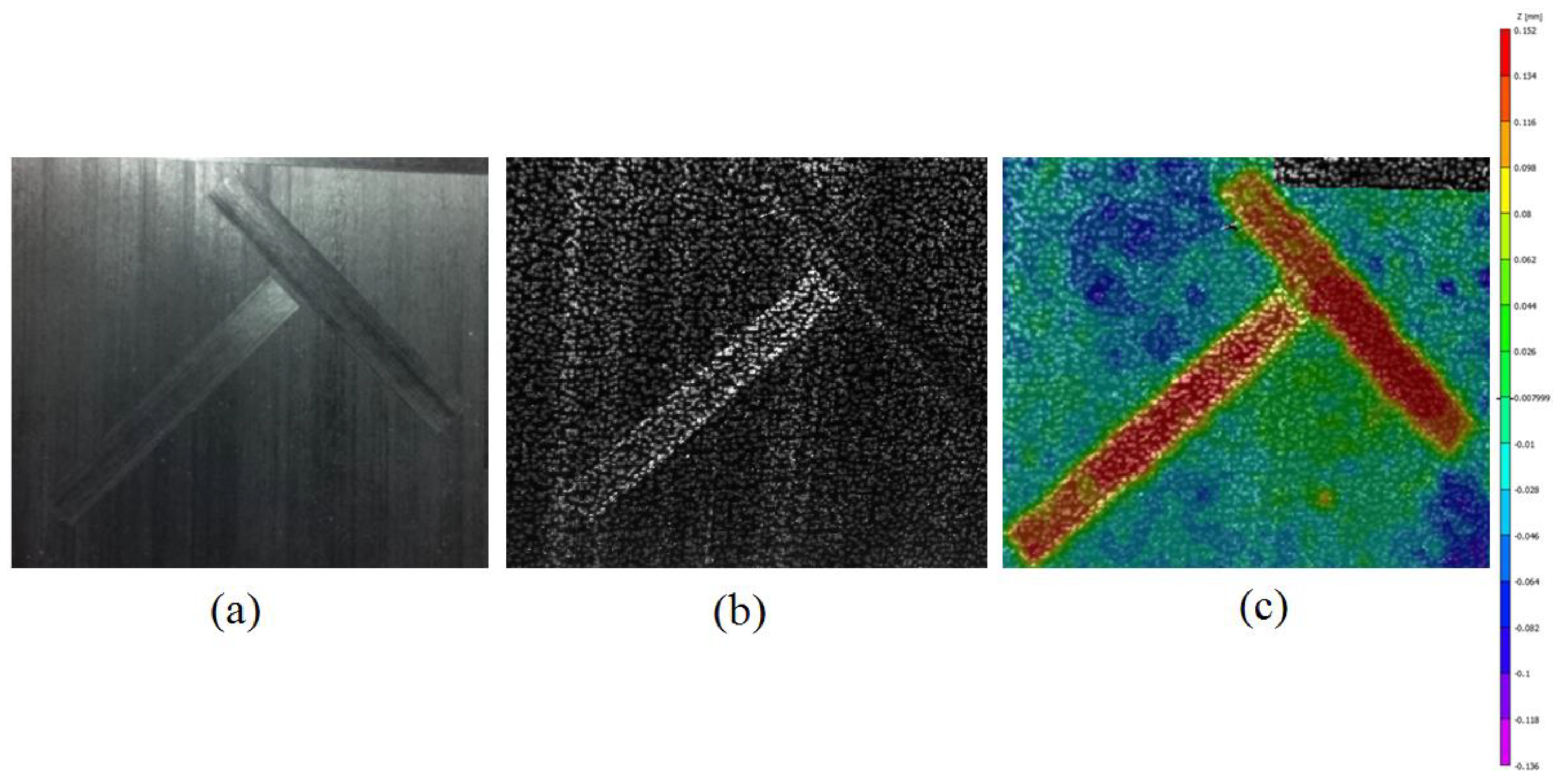

3.2. Inspection of the Automated Fiber Placement (AFP) Process

3.2.1. Synopsis

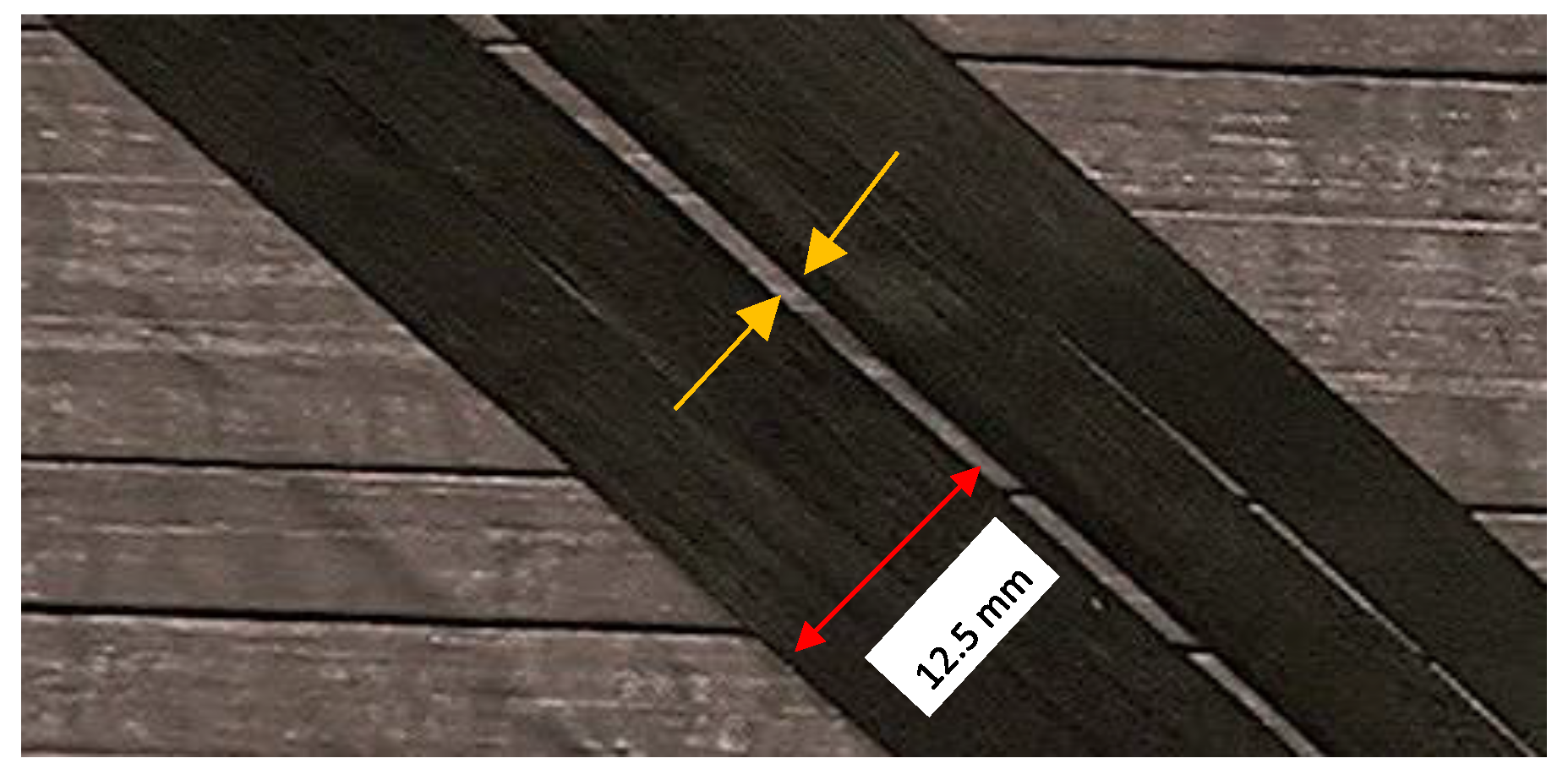

3.2.2. Proof of Concept

4. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Anuta, P.E. Spatial registration of multispectral and multitemporal digital imagery using fast fourier transform techniques. IEEE Trans. Geosci. Electron. 1970, 8, 353–368. [Google Scholar] [CrossRef]

- Keating, T.J.; Wolf, P.R.; Scarpace, F.L. An improved method of digital image correlation. Photogramm. Eng. Remote Sens. 1975, 41, 993–1002. [Google Scholar]

- Peters, W.H.; Ranson, W.F. Digital imaging techniques in experimental stress analysis. Opt. Eng. 1982, 21, 427. [Google Scholar] [CrossRef]

- Sutton, M.A.; Wolters, W.J.; Peters, W.H.; Ranson, W.F.; McNeill, S.R. Determination of displacements using an improved digital correlation method. Image Vision Comput. 1983, 1, 133. [Google Scholar] [CrossRef]

- Sutton, M.A.; Cheng, M.; Peters, W.H.; Chao, Y.J.; McNeill, S.R. Application of an optimized digital image correlation method to planar deformation analysis. Image Vision Comput. 1986, 4, 143–150. [Google Scholar] [CrossRef]

- Schreier, H.W.; Braasch, J.; Sutton, M.A. Systematic errors in digital image correlation caused by intensity interpolation. Opt. Eng. 2000, 39, 2915. [Google Scholar] [CrossRef]

- Lu, H.; Cary, P.D. Deformation measurements by digital image correlation: Implementation of a second-order displacement gradient. Exp. Mech. 2000, 40, 393–400, 2000. [Google Scholar] [CrossRef]

- Haddadi, H.; Belhabib, S. Use of rigid-body motion for the investigation and estimation of the measurement errors related to digital image correlation technique. Opt. Lasers Eng. 2008, 46, 185–196. [Google Scholar] [CrossRef]

- Tiwari, V.; Sutton, M.; McNeill, S.R. Assessment of high speed imaging systems for 2D and 3D deformation measurements: Methodology development and validation. Exp. Mech. 2007, 47, 561–579. [Google Scholar] [CrossRef]

- Sutton, M.A.; Yan, J.H.; Tiwari, V.; Schreier, H.W.; Orteu, J.J. The effect of out-of-plane motion on 2D and 3D digital image correlation measurements. Opt. Lasers Eng. 2008, 46, 746–757. [Google Scholar] [CrossRef]

- Luo, P.F.; Chao, Y.J.; Sutton, M.A.; Peter III, W.H. Accurate measurement of three-dimensional deformations in deformable and rigid bodies using computer vision. Exp. Mech. 1993, 33, 23–132. [Google Scholar] [CrossRef]

- Luo, P.F.; Chao, Y.J.; Sutton, M.A. Application of stereo vision to three-dimensional deformation analyses in fracture experiments. Opt. Eng. 1994, 33, 981. [Google Scholar] [CrossRef]

- Helm, J.D.; McNeill, S.R.; Sutton, M.A. Improved three-dimensional image correlation for surface displacement measurement. Opt. Eng. 1996, 35, 1911. [Google Scholar] [CrossRef]

- Herbst, C.; Splitthof, K. Basics of 3D Digital Image Correlation; T-Q-400-Basics-3DCORR-002a-EN; Dantec Dynamics GmbH: Ulm, Germany.

- Shadmehri, F. Buckling of Laminated Composite Conical Shells; Theory and Experiment. Ph.D. Thesis, Concordia University, Montreal, QC, Canada, September 2012. [Google Scholar]

- El-Geuchy, M.I. Bending Behavior of Thick-Walled Composite Tubes. Ph.D. Thesis, Concordia University, Montreal, QC, Canada, June 2013. [Google Scholar]

- Patel, J.; Peralta, P. Mechanisms for Kink Band Evolution in Polymer Matrix Composites: A Digital Image Correlation and Finite Element Study. In Proceeding of the ASME 2016 International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, November 11–17 2016; ASME: New York, NY, USA, 2016; Volume 9: Mechanics of Solids, Structures and Fluids; NDE, Diagnosis, and Prognosis, p. V009T12A055. [Google Scholar] [CrossRef]

- Nizolek, T.J.; Begley, M.R.; McCabe, R.J.; Avallone, J.T.; Mara, N.A.; Beyerlein, I.J.; Pollock, T.M. Strain fields induced by kink band propagation in cunb nanolaminate composites. Acta Mater. 2017, 133, 303–315. [Google Scholar] [CrossRef]

- Ghayoor, H.; Shadmehri, F.; Hoa, S.V. Development of experimental technique for measuring strain and deformation in manufacturing of thermoplastic composites using automated fiber placement (AFP). In Proceedings of the International SAMPE Technical Conference, Seattle, WA, USA, 2–5 June 2014. [Google Scholar]

- Hoa, S.V. Principles of the Manufacturing of Composite Materials, 2nd ed.; Destech Publications, Inc.: Lancaster, PA, USA, 2009. [Google Scholar]

- Shadmehri, F.; Ioachim, O.; Pahud, O.; Brunel, J.-E.; Landry, A.; Hoa, S.V.; Hojjati, M. Laser-Vision Inspection System for Automated Fiber Placement (AFP) Process. In Proceedings of the 20th International Conference on Composite Materials (ICCM20), Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Blom, A.W. Structural performance of fiber-placed, variable-stiffness composite conical and cylindrical shells. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, November 2010. [Google Scholar]

- Croft, K.; Lessard, L.; Pasini, D.; Hojjati, M.; Chen, J.; Yousefpour, A. Experimental study of the effect of automated fiber placement induced defects on performance of composite laminates. Composites Part A 2011, 42, 484–491. [Google Scholar] [CrossRef]

- Cai, X. Determination of Process Parameters for the Manufacturing of Thermoplastic Composite Cones using Automated Fiber Placement. Master’s Thesis, Concordia University, Montreal, QC, Canada, June 2012. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shadmehri, F.; Hoa, S.V. Digital Image Correlation Applications in Composite Automated Manufacturing, Inspection, and Testing. Appl. Sci. 2019, 9, 2719. https://doi.org/10.3390/app9132719

Shadmehri F, Hoa SV. Digital Image Correlation Applications in Composite Automated Manufacturing, Inspection, and Testing. Applied Sciences. 2019; 9(13):2719. https://doi.org/10.3390/app9132719

Chicago/Turabian StyleShadmehri, Farjad, and Suong Van Hoa. 2019. "Digital Image Correlation Applications in Composite Automated Manufacturing, Inspection, and Testing" Applied Sciences 9, no. 13: 2719. https://doi.org/10.3390/app9132719

APA StyleShadmehri, F., & Hoa, S. V. (2019). Digital Image Correlation Applications in Composite Automated Manufacturing, Inspection, and Testing. Applied Sciences, 9(13), 2719. https://doi.org/10.3390/app9132719