Corrosion Behavior and Conductivity of TiNb and TiNbN Coated Steel for Metallic Bipolar Plates

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Coatings

2.2. Characterization of Coatings

3. Results and Discussion

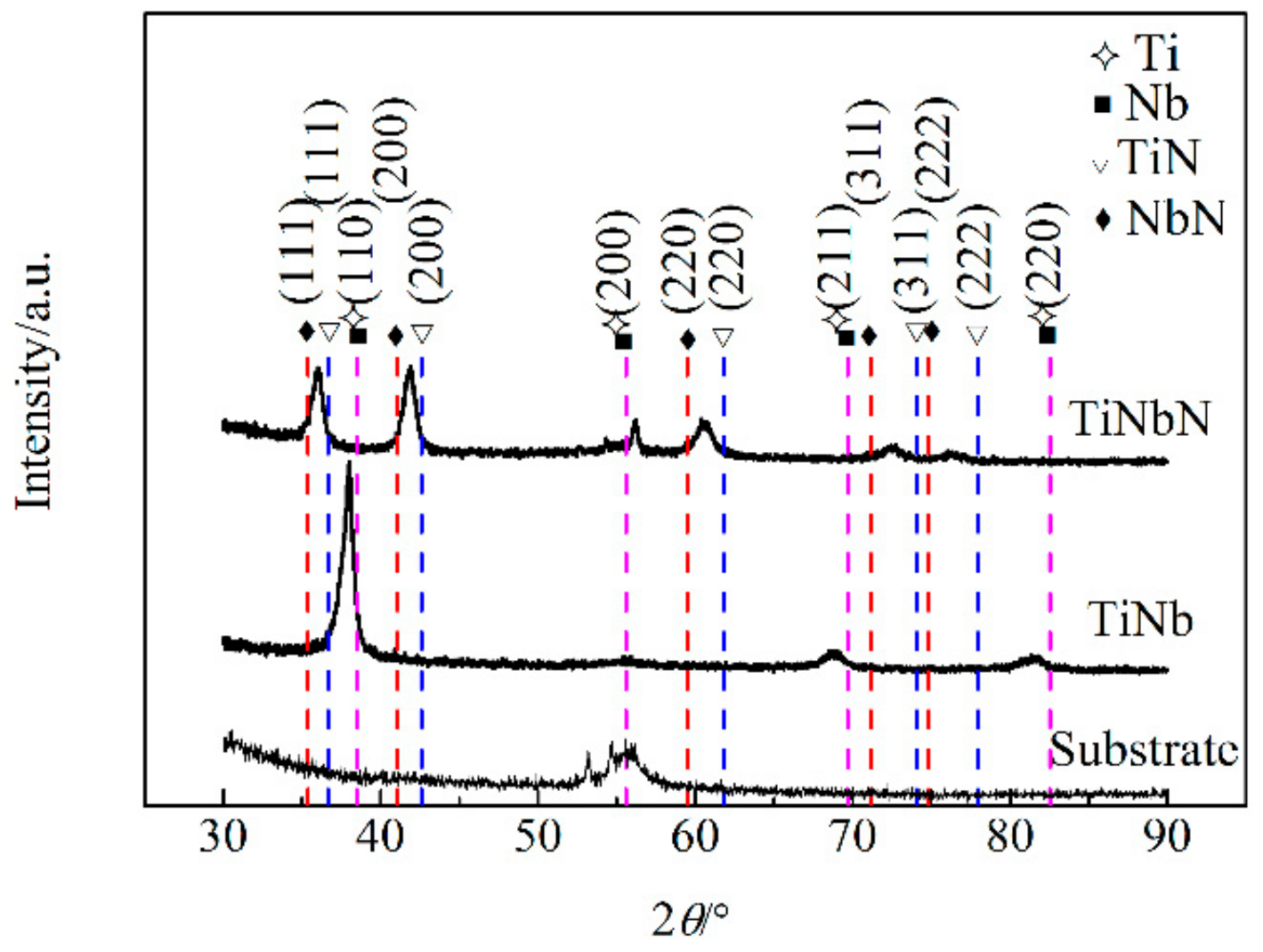

3.1. Structural Characterization

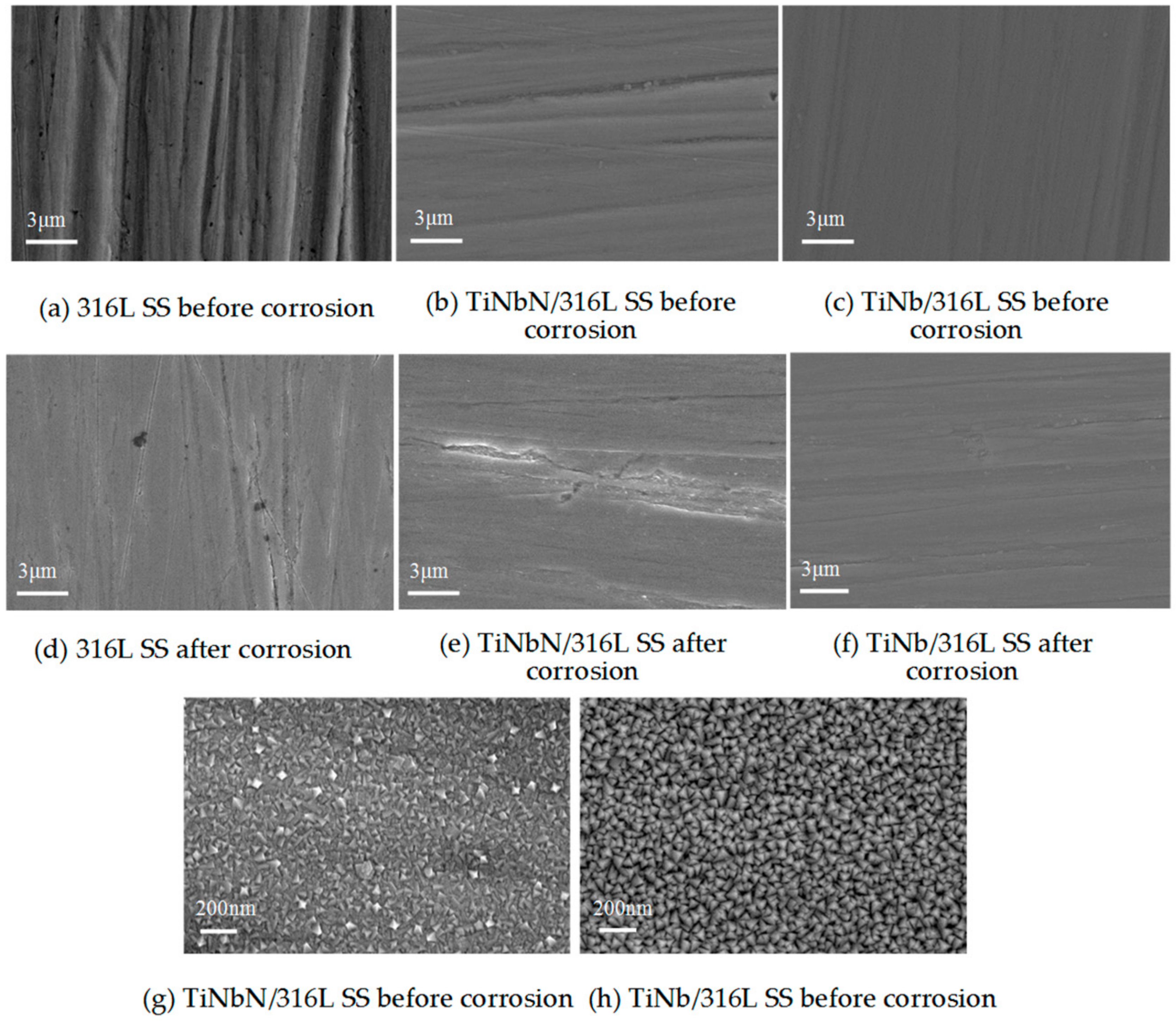

3.2. Surface Morphology

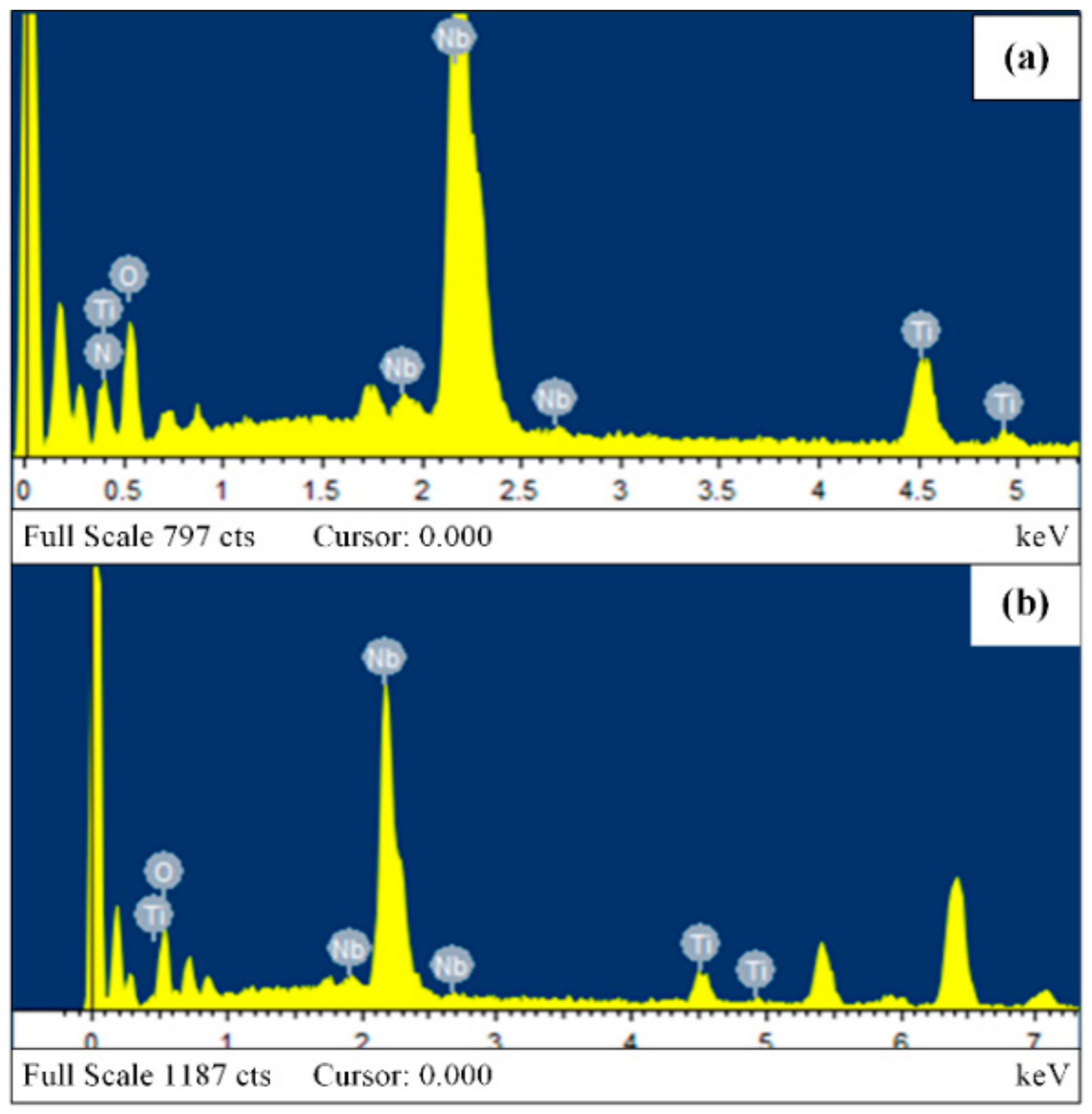

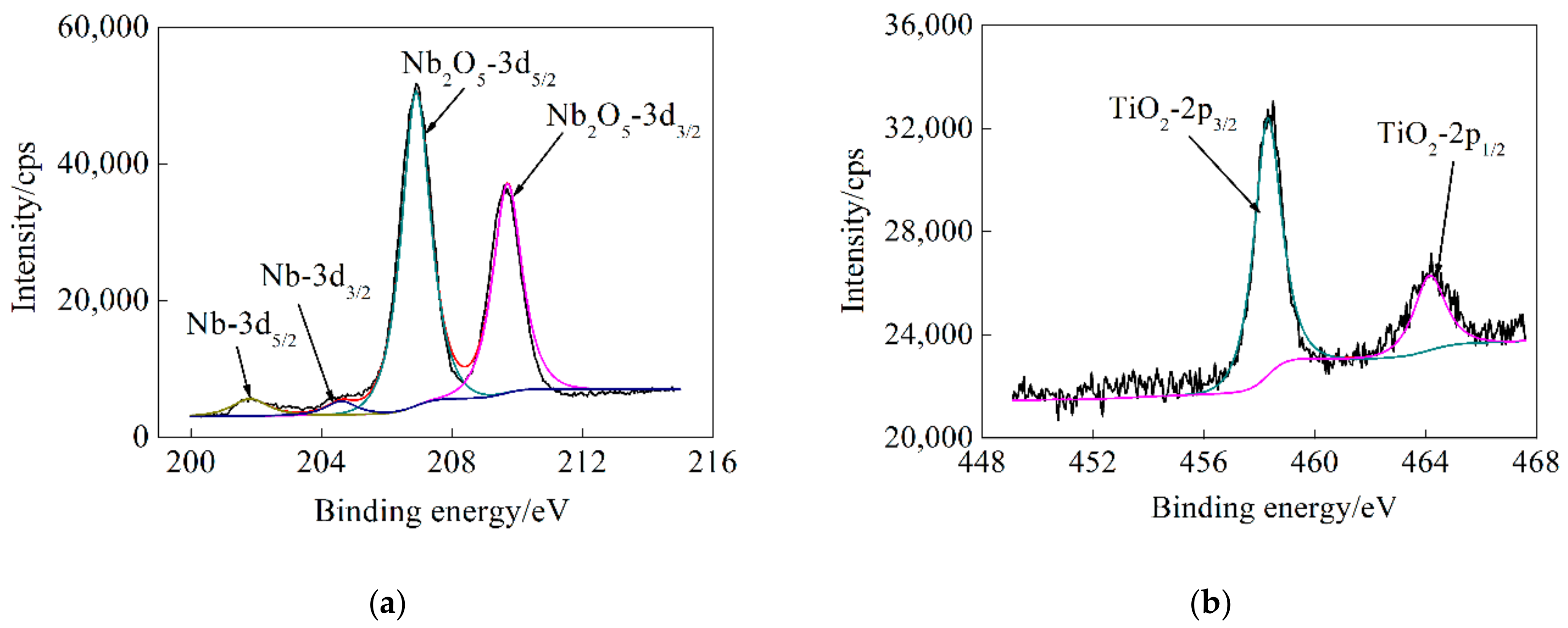

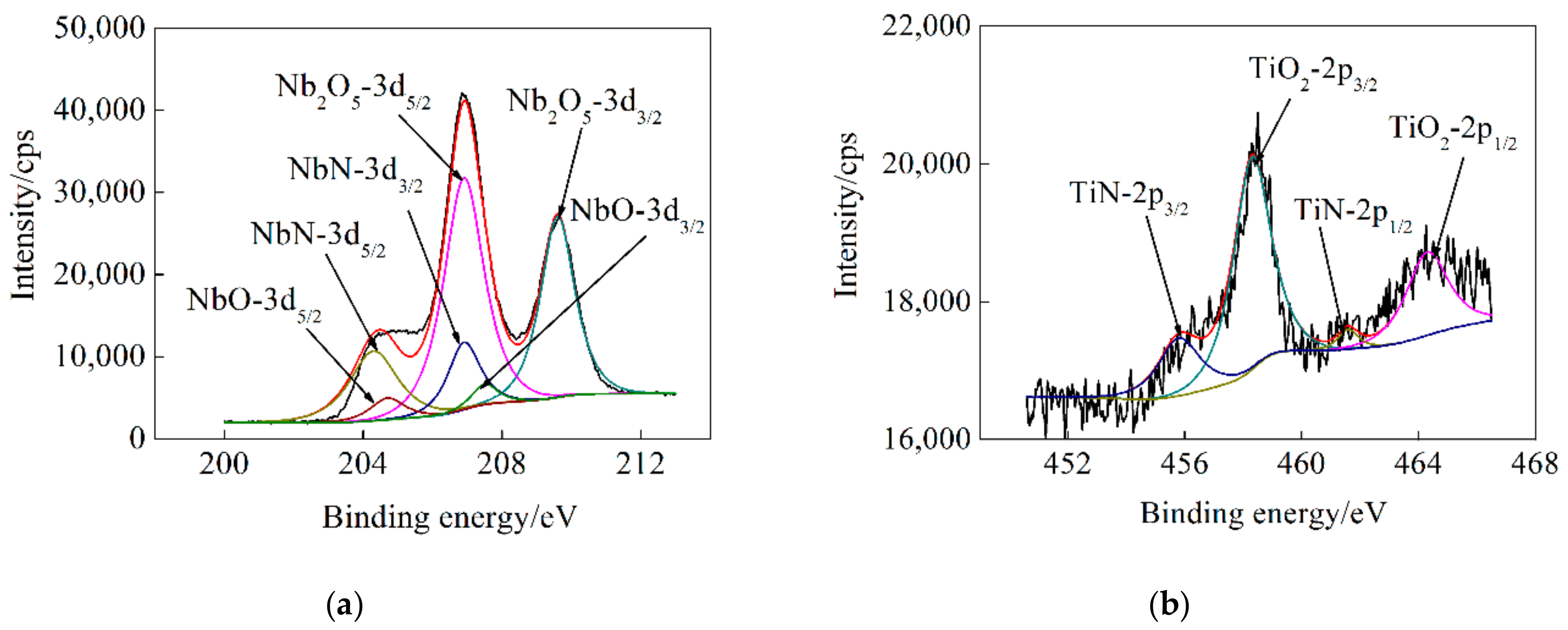

3.3. X-ray Photoelectron Spectroscopy Analysis

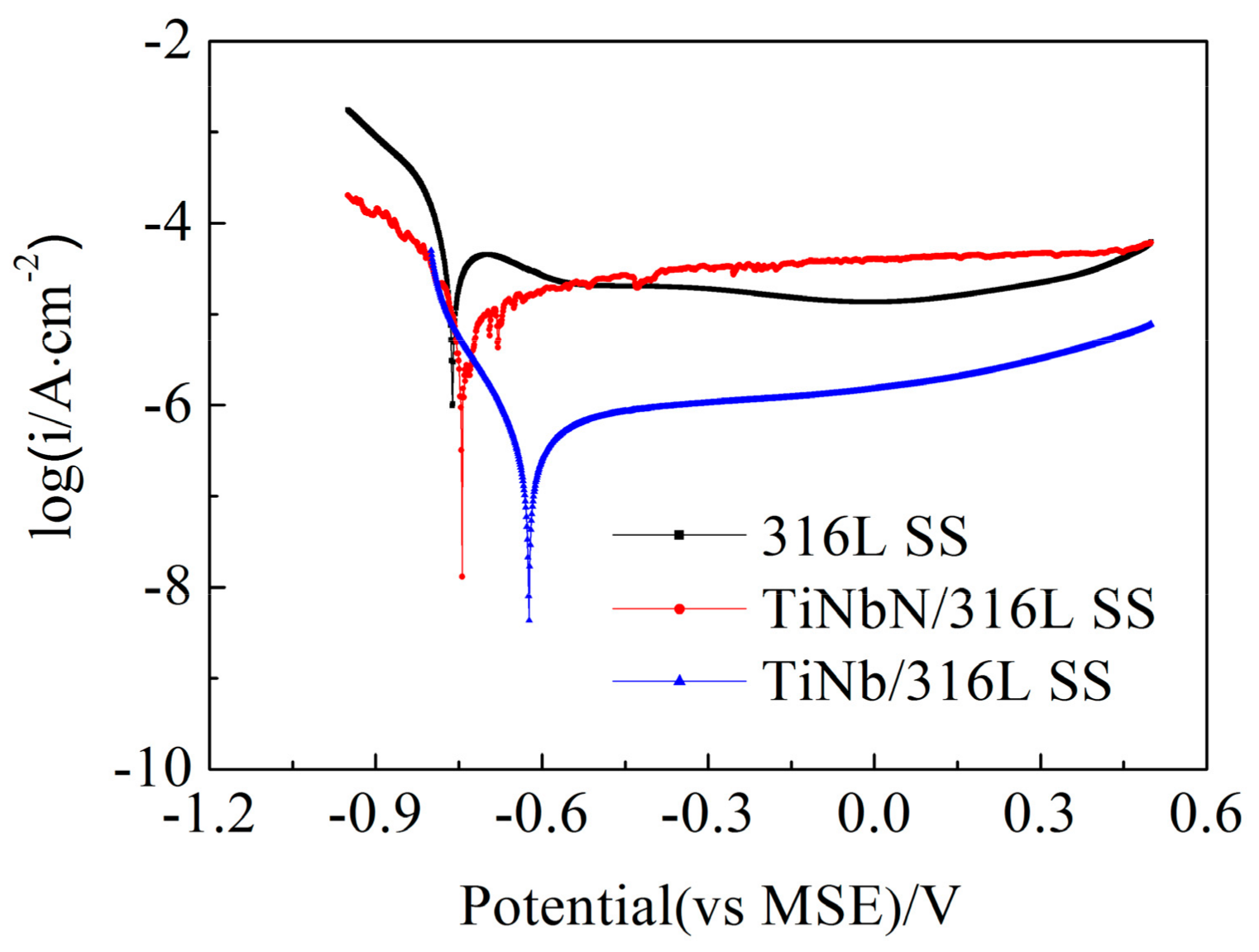

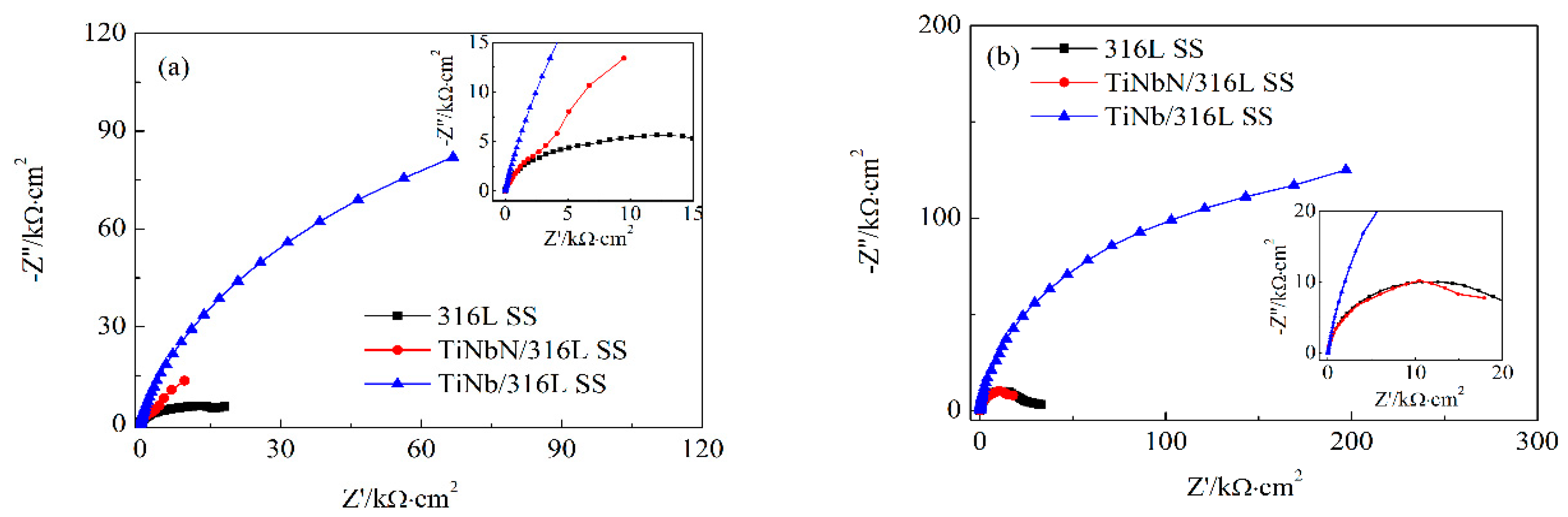

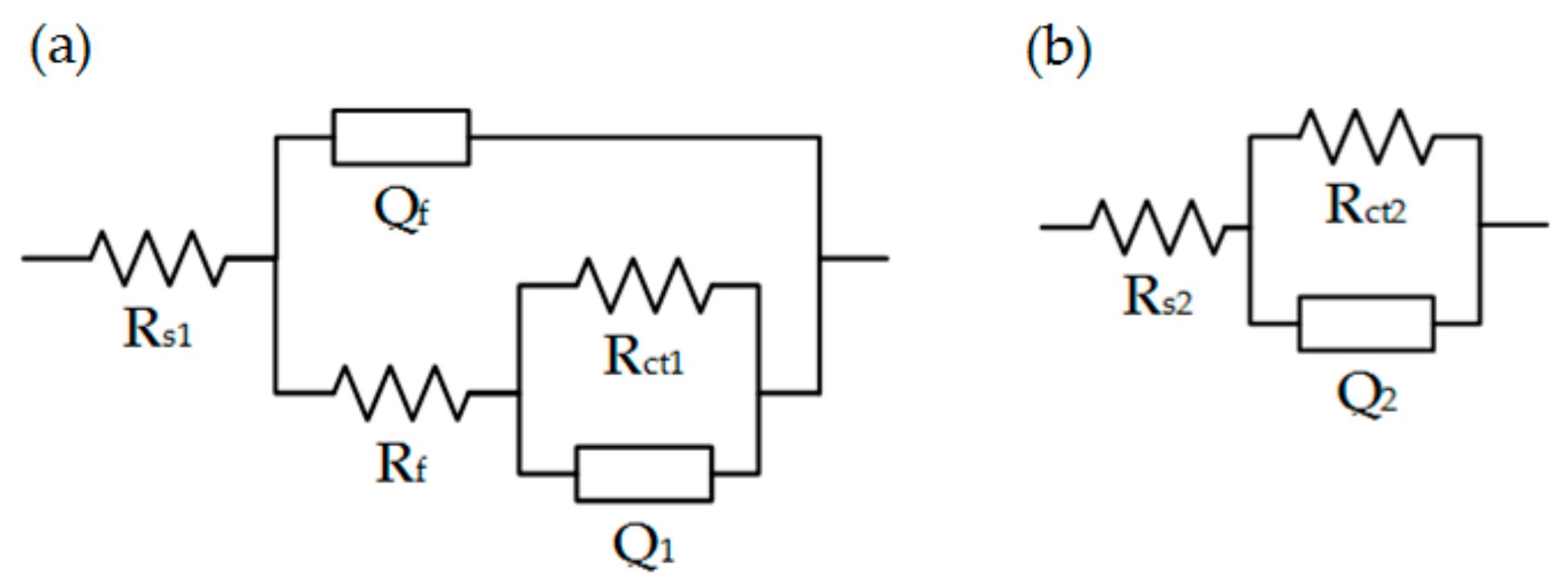

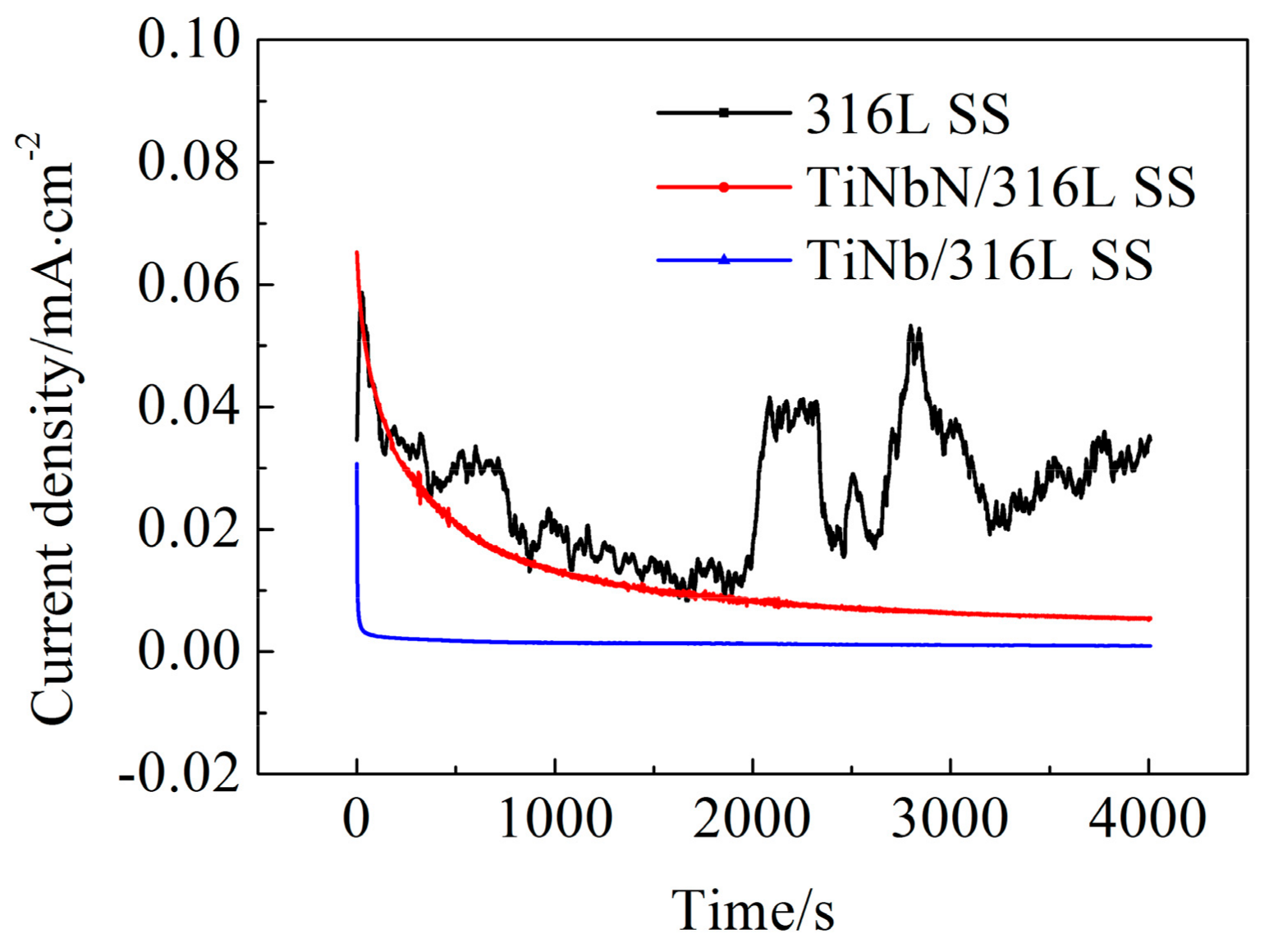

3.4. Corrosion Behavior

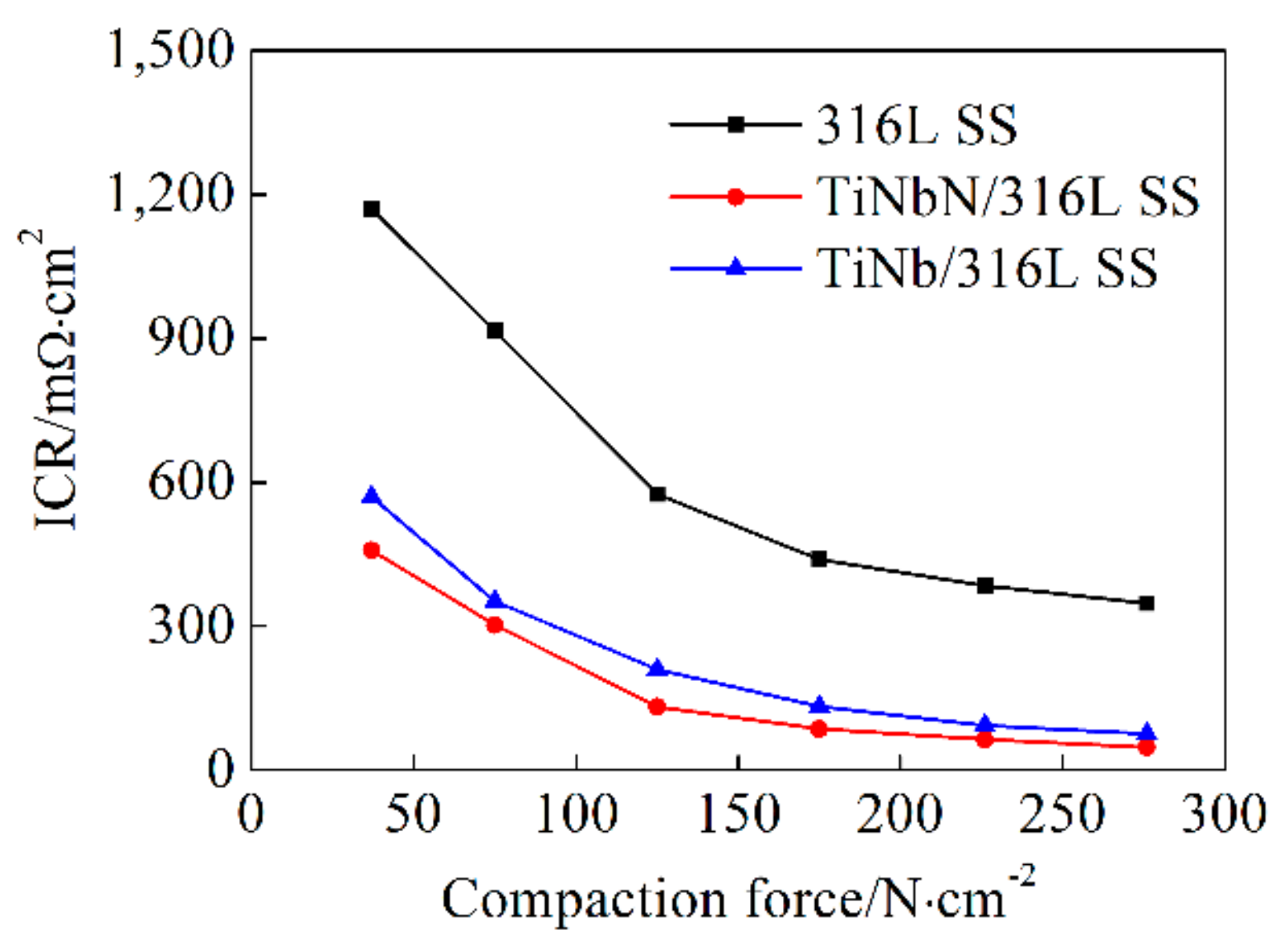

3.5. Interfacial Contact Resistance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wang, Y.; Chen, K.S.; Mishler, J.; Cho, S.C.; Adroher, X.C. A review of polymer electrolyte membrane fuel cells: Technology, applications, and needs on fundamental research. Appl. Energy 2011, 88, 981–1007. [Google Scholar] [CrossRef]

- Antunes, R.A.; Oliveira, M.C.L.; Ett, G.; Ett, V. Corrosion of metal bipolar plates for PEM fuel cells: A review. Int. J. Hydrog. Energy 2010, 35, 3632–3647. [Google Scholar] [CrossRef]

- Wang, L.; Tao, Y.; Zhang, Z.; Wang, Y.; Feng, Q.; Wang, H.; Li, H. Molybdenum carbide coated 316L stainless steel for bipolar plates of proton exchange membrane fuel cells. Int. J. Hydrog. Energy 2019, 44, 4940–4950. [Google Scholar] [CrossRef]

- Kim, M.; Lim, J.W.; Lee, D.G. Electrical contact resistance between anode and cathode bipolar plates with respect to surface conditions. Compos. Struct. 2018, 189, 79–86. [Google Scholar] [CrossRef]

- Adloo, A.; Sadeghi, M.; Masoomi, M.; Pazhooh, H.N. High performance polymeric bipolar plate based on polypropylene/graphite/graphene/nano-carbon black composites for PEM fuel cells. Renew. Energy 2016, 99, 867–874. [Google Scholar] [CrossRef]

- Dhakate, S.R.; Sharma, S.; Chauhan, N.; Seth, R.K.; Mathur, R.B. CNTs nanostructuring effect on the properties of graphite composite bipolar plate. Int. J. Hydrog. Energy 2010, 35, 4195–4200. [Google Scholar] [CrossRef]

- Li, W.; Jing, S.; Wang, S.; Wang, C.; Xie, X. Experimental investigation of expanded graphite/phenolic resin composite bipolar plate. Int. J. Hydrog. Energy 2016, 41, 16240–16246. [Google Scholar] [CrossRef]

- Taherian, R. A review of composite and metallic bipolar plates in proton exchange membrane fuel cell: Materials, fabrication, and material selection. J. Power Sources 2014, 265, 370–390. [Google Scholar] [CrossRef]

- Yu, H.; Yang, L.; Zhu, L.; Jian, X.; Wang, Z.; Jiang, L. Anticorrosion properties of Ta-coated 316L stainless steel as bipolar plate material in proton exchange membrane fuel cells. J. Power Sources 2009, 191, 495–500. [Google Scholar] [CrossRef]

- Mawdsley, J.R.; Carter, J.D.; Wang, X.; Niyogi, S.; Fan, C.Q.; Koc, R.; Osterhout, G. Composite-coated aluminum bipolar plates for PEM fuel cells. J. Power Sources 2013, 231, 106–112. [Google Scholar] [CrossRef]

- Bi, F.; Peng, L.; Yi, P.; Lai, X. Multilayered Zr–C/a-C film on stainless steel 316L as bipolar plates for proton exchange membrane fuel cells. J. Power Sources 2016, 314, 58–65. [Google Scholar] [CrossRef]

- Mani, S.P.; Rajendran, N. Corrosion and interfacial contact resistance behavior of electrochemically nitrided 316L SS bipolar plates for proton exchange membrane fuel cells. Energy 2017, 133, 1050–1062. [Google Scholar] [CrossRef]

- Asri, N.F.; Husaini, T.; Sulong, A.B.; Majlan, E.H.; Daud, W.R.W. Coating of stainless steel and titanium bipolar plates for anticorrosion in PEMFC: A review. Int. J. Hydrog. Energy 2017, 42, 9135–9148. [Google Scholar] [CrossRef]

- Wind, J.; Spah, R.; Kaiser, W.; Bohm, G. Metallic bipolar plates for PEM fuel cells. J. Power Sources 2002, 105, 256–260. [Google Scholar] [CrossRef]

- Tsai, S.Y.; Bai, C.Y.; Lin, C.H.; Shi, G.N.; Hou, K.H.; Liu, Y.M.; Ger, M.D. The characteristics and performance of electroless nickel and immersion Au plated aluminum alloy bipolar plates in polymer electrolyte membrane fuel cells. J. Power Sources 2012, 214, 51–58. [Google Scholar] [CrossRef]

- Wang, C.; Wang, S.; Peng, L.; Zhang, J.; Shao, Z.; Huang, J.; Sun, C.; Ouyang, M.; He, X. Recent progress on the key materials and components for proton exchange membrane fuel cells in vehicle applications. Energies 2016, 9, 603. [Google Scholar] [CrossRef]

- Wang, L.; Sun, J.; Li, P.; Jing, B.; Li, S.; Wen, Z.; Ji, S. Niobized AISI 304 stainless steel bipolar plate for proton exchange membrane fuel cell. J. Power Sources 2012, 208, 397–403. [Google Scholar] [CrossRef]

- Zhang, D.; Duan, L.; Guo, L.; Tuan, W.H. Corrosion behavior of TiN-coated stainless steel as bipolar plate for proton exchange membrane fuel cell. Int. J. Hydrog. Energy 2010, 35, 3721–3726. [Google Scholar] [CrossRef]

- Cha, B.C.; You, Y.Z.; Hong, S.T.; Kim, J.H.; Kim, D.W.; Lee, B.S.; Kim, S.K. Nitride films as protective layers for metallic bipolar plates of polymer electrolyte membrane fuel cell stacks. Int. J. Hydrog. Energy 2011, 36, 4565–4572. [Google Scholar] [CrossRef]

- Serro, A.P.; Completo, C.; Colaço, R.; dos Santos, F.; da Silva, C.L.; Cabral, J.M.S.; Araújo, H.; Pires, E.; Saramago, B. A comparative study of titanium nitrides, TiN, TiNbN and TiCN, as coatings for biomedical applications. Surf. Coat. Technol. 2009, 203, 3701–3707. [Google Scholar] [CrossRef]

- Gispert, M.P.; Serro, A.P.; Colaço, R.; Pires, E.; Saramago, B. Wear of ceramic coated metal-on-metal bearings used for hip replacement. Wear 2007, 263, 1060–1065. [Google Scholar] [CrossRef]

- Saud, S.N.; Hosseinian, R.; Bakhsheshi-Rad, H.R.; Yaghoubidoust, F.; Iqbal, N.; Hamzah, E.; Ooi, C.H.R. Corrosion and bioactivity performance of graphene oxide coating on Ti-Nb shape memory alloys in simulated body fluid. Mater. Sci. Eng. C Mater. Biol. Appl. 2016, 68, 687–694. [Google Scholar] [CrossRef] [PubMed]

- Aukland, N.; Boudina, A.; Eddy, D.S.; Mantese, J.V.; Thompson, M.P.; Wang, S.S. Alloys that form conductive and passivating oxides for proton exchange membrane fuel cell bipolar plates. J. Mater. Res. 2004, 19, 1723–1729. [Google Scholar] [CrossRef]

- Yi, P.; Zhu, L.; Dong, C.; Xiao, K. Corrosion and interfacial contact resistance of 316L stainless steel coated with magnetron sputtered ZrN and TiN in the simulated cathodic environment of a proton-exchange membrane fuel cell. Surf. Coat. Technol. 2019, 363, 198–202. [Google Scholar] [CrossRef]

- Wang, H.; Sweikart, M.A.; Turner, J.A. Stainless steel as bipolar plate material for polymer electrolyte membrane fuel cells. J. Power Sources 2003, 115, 243–251. [Google Scholar] [CrossRef]

- Xu, J.; Huang, H.J.; Li, Z.Y.; Xu, S.; Tao, H.; Munroe, P.; Xie, Z.H. Corrosion behavior of a ZrCN coated Ti alloy with potential application as a bipolar plate for proton exchange membrane fuel cell. J. Alloys Compd. 2016, 663, 718–730. [Google Scholar] [CrossRef]

- Gollapudi, S. Grain size distribution effects on the corrosion behaviour of materials. Corros. Sci. 2012, 62, 90–94. [Google Scholar] [CrossRef]

- National Institute of Standards and Technology. NIST X-ray Photoelectron Spectroscopy Database, NIST Standard Reference Database Number 20. Available online: https://srdata.nist.gov/xps/ (accessed on 15 April 2019).

- Bahl, M.K. ESCA studies of some niobium compounds. J. Phys. Chem. Solids 1975, 36, 485–491. [Google Scholar] [CrossRef]

- Nyholm, R.; Martensson, N. Core level binding energies for the elements Zr-Te (Z = 40–52). J. Phys. C Solid St. Phys. 1980, 13, L279–L284. [Google Scholar] [CrossRef]

- Nefedov, V.I.; Salyn, Y.V.; Chertkov, A.A.; Padurets, L.N. X-ray electron study of electron-density distribution in hydrides of transition-elements. Zh. Neorg. Khim. 1974, 19, 1443–1445. [Google Scholar]

- Latta, E.E.; Ronay, M. Catalytic-oxidation of niobium. Phys. Rev. Lett. 1984, 53, 948–951. [Google Scholar] [CrossRef]

- Blasco, T.; Camblor, M.A.; Corma, A.; Perez-Pariente, J. The state of Ti in titanoaluminosilicates isomorphous with zeolite β. J. Am. Chem. Soc. 1993, 115, 11806–11813. [Google Scholar] [CrossRef]

- Sanjinés, R.; Tang, H.; Berger, H.; Gozzo, F.; Margaritondo, G.; Lévy, F. Electronic structure of anatase TiO2 oxide. J. Appl. Phys. 1994, 75, 2945–2951. [Google Scholar] [CrossRef]

- Zhang, L.; You, L.; Ying, L.; Peng, W.; Wang, Z. Characterization of surface oxidation layers on ultrathin NbTiN films. Phys. C Supercond. Appl. 2018, 545, 1–4. [Google Scholar] [CrossRef]

- Shulga, Y.M.; Troitskii, V.N.; Aivazov, M.I.; Borodko, Y.G. X-ray photoelectron-spectra of scandium, titanium, vanadium and chromium mononitrides. Zh. Neorg. Khim. 1976, 21, 2621–2624. [Google Scholar]

- Netterfield, R.P.; Martin, P.J.; Pacey, C.G.; Sainty, W.G.; McKenzie, D.R.; Auchterlonie, G. Ion-assisted deposition of mixed TiO2-SiO2 films. J. Appl. Phys. 1989, 66, 1805–1809. [Google Scholar] [CrossRef]

- Fierro, J.L.G.; Arrua, L.A.; Nieto, J.M.L.; Kremenic, G. Surface properties of co-precipitated V-Ti-O catalysts and their relation to the selective oxidation of isobutene. Appl. Catal. 1988, 37, 323–338. [Google Scholar] [CrossRef]

- Jeon, W.S.; Kim, J.G.; Kim, Y.J.; Han, J.G. Electrochemical properties of TiN coatings on 316L stainless steel separator for polymer electrolyte membrane fuel cell. Thin Solid Films 2008, 516, 3669–3672. [Google Scholar] [CrossRef]

- Cao, M.; Liu, L.; Yu, Z.; Fan, L.; Li, Y.; Wang, F. Electrochemical corrosion behavior of 2A02 Al alloy under an accelerated simulation marine atmospheric environment. J. Mater. Sci. Technol. 2019, 35, 651–659. [Google Scholar] [CrossRef]

- Kartsonakis, I.A.; Stanciu, S.G.; Matei, A.A.; Karaxi, E.K.; Hristu, R.; Karantonis, A.; Charitidis, C.A. Evaluation of the protective ability of typical corrosion inhibitors for magnesium alloys towards the Mg ZK30 variant. Corros. Sci. 2015, 100, 194–208. [Google Scholar] [CrossRef]

- Nam, N.D.; Jo, D.S.; Kim, J.G.; Yoon, D.H. Corrosion protection of CrN/TiN multi-coating for bipolar plate of polymer electrolyte membrane fuel cell. Thin Solid Films 2011, 519, 6787–6791. [Google Scholar] [CrossRef]

- Li, M.; Luo, S.; Zeng, C.; Shen, J.; Lin, H.; Cao, C. Corrosion behavior of TiN coated type 316 stainless steel in simulated PEMFC environments. Corros. Sci. 2004, 46, 1369–1380. [Google Scholar] [CrossRef]

- Kartsonakis, I.A.; Stanciu, S.G.; Matei, A.A.; Hristu, R.; Karantonis, A.; Charitidis, C.A. A comparative study of corrosion inhibitors on hot-dip galvanized steel. Corros. Sci. 2016, 112, 289–307. [Google Scholar] [CrossRef]

- Shen, S.; Zuo, Y.; Zhao, X. The effects of 8-hydroxyquinoline on corrosion performance of a Mg-rich coating on AZ91D magnesium alloy. Corros. Sci. 2013, 76, 275–283. [Google Scholar] [CrossRef]

- Xu, J.; Li, Z.Y.; Xu, S.; Munroe, P.; Xie, Z.H. A nanocrystalline zirconium carbide coating as a functional corrosion-resistant barrier for polymer electrolyte membrane fuel cell application. J. Power Sources 2015, 297, 359–369. [Google Scholar] [CrossRef]

- Feng, K.; Li, Z.; Sun, H.; Yu, L.; Cai, X.; Wu, Y.; Chu, P.K. C/CrN multilayer coating for polymer electrolyte membrane fuel cell metallic bipolar plates. J. Power Sources 2013, 222, 351–358. [Google Scholar] [CrossRef]

- Lee, E.K.; Kim, J.K.; Kim, T.J.; Song, H.; Kim, J.H.; Park, S.A.; Jeong, T.G.; Yun, S.W.; Lee, J.; Goo, J.; et al. Enhanced corrosion resistance and fuel cell performance of Al1050 bipolar plate coated with TiN/Ti double layer. Energy Convers. Manag. 2013, 75, 727–733. [Google Scholar] [CrossRef]

| Materials | 316L SS | TiNb/316L SS | TiNbN/316L SS |

|---|---|---|---|

| Rct @ OCP/ kΩ⋅cm2 | 16.2 | 198 | 21.13 |

| Rct @ 0.19 V vs MSE/ kΩ⋅cm2 | 26.74 | 229 | 23.52 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, K.; Li, X.; Zhao, Y.; Li, W.-W.; Wang, S.-B.; Xie, X.-F.; Yao, L.; Jensen, J.O.; Li, Q.-F. Corrosion Behavior and Conductivity of TiNb and TiNbN Coated Steel for Metallic Bipolar Plates. Appl. Sci. 2019, 9, 2568. https://doi.org/10.3390/app9122568

Shi K, Li X, Zhao Y, Li W-W, Wang S-B, Xie X-F, Yao L, Jensen JO, Li Q-F. Corrosion Behavior and Conductivity of TiNb and TiNbN Coated Steel for Metallic Bipolar Plates. Applied Sciences. 2019; 9(12):2568. https://doi.org/10.3390/app9122568

Chicago/Turabian StyleShi, Kun, Xue Li, Yang Zhao, Wei-Wei Li, Shu-Bo Wang, Xiao-Feng Xie, Li Yao, Jens Oluf Jensen, and Qing-Feng Li. 2019. "Corrosion Behavior and Conductivity of TiNb and TiNbN Coated Steel for Metallic Bipolar Plates" Applied Sciences 9, no. 12: 2568. https://doi.org/10.3390/app9122568

APA StyleShi, K., Li, X., Zhao, Y., Li, W.-W., Wang, S.-B., Xie, X.-F., Yao, L., Jensen, J. O., & Li, Q.-F. (2019). Corrosion Behavior and Conductivity of TiNb and TiNbN Coated Steel for Metallic Bipolar Plates. Applied Sciences, 9(12), 2568. https://doi.org/10.3390/app9122568