The Effect of Elevated Temperatures on the TRM-to-Masonry Bond: Comparison of Normal Weight and Lightweight Matrices

Abstract

1. Introduction

2. Materials, Specimens, and Experimental Program

2.1. Materials

2.1.1. Masonry

2.1.2. TRM

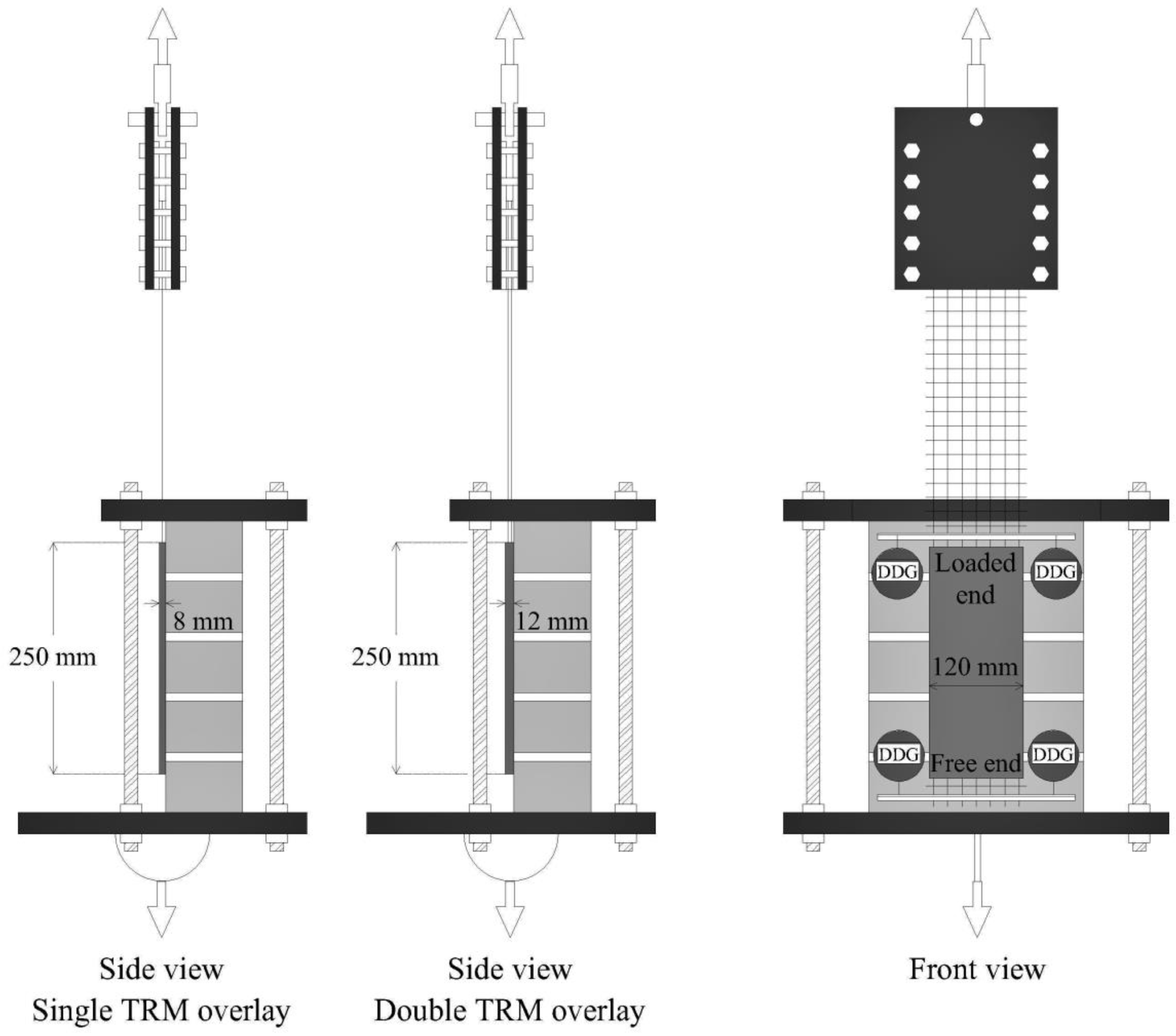

2.2. Specimens

2.3. Experimental Program

2.3.1. Test Plan

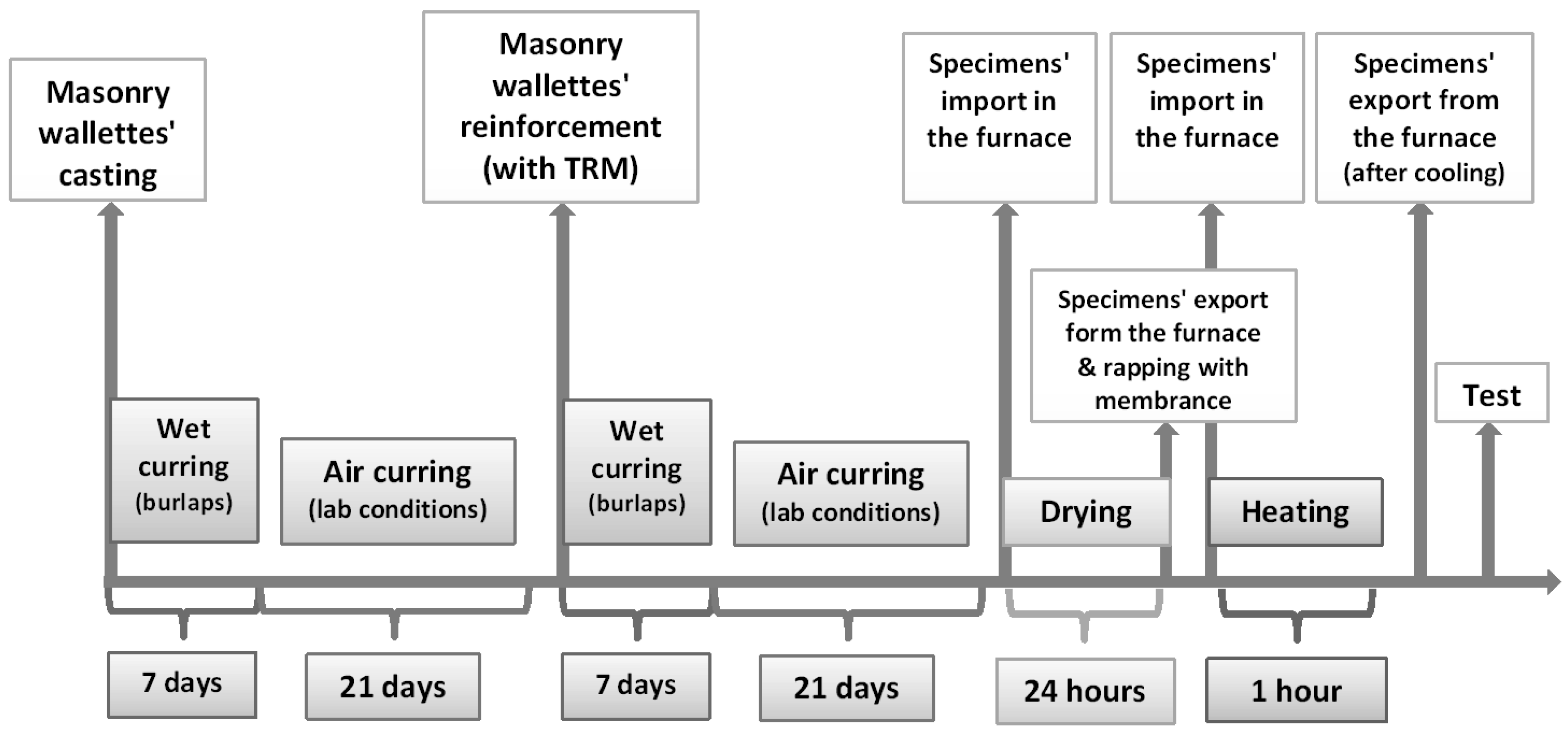

2.3.2. Pre-Heating Treatment and Heating Regime

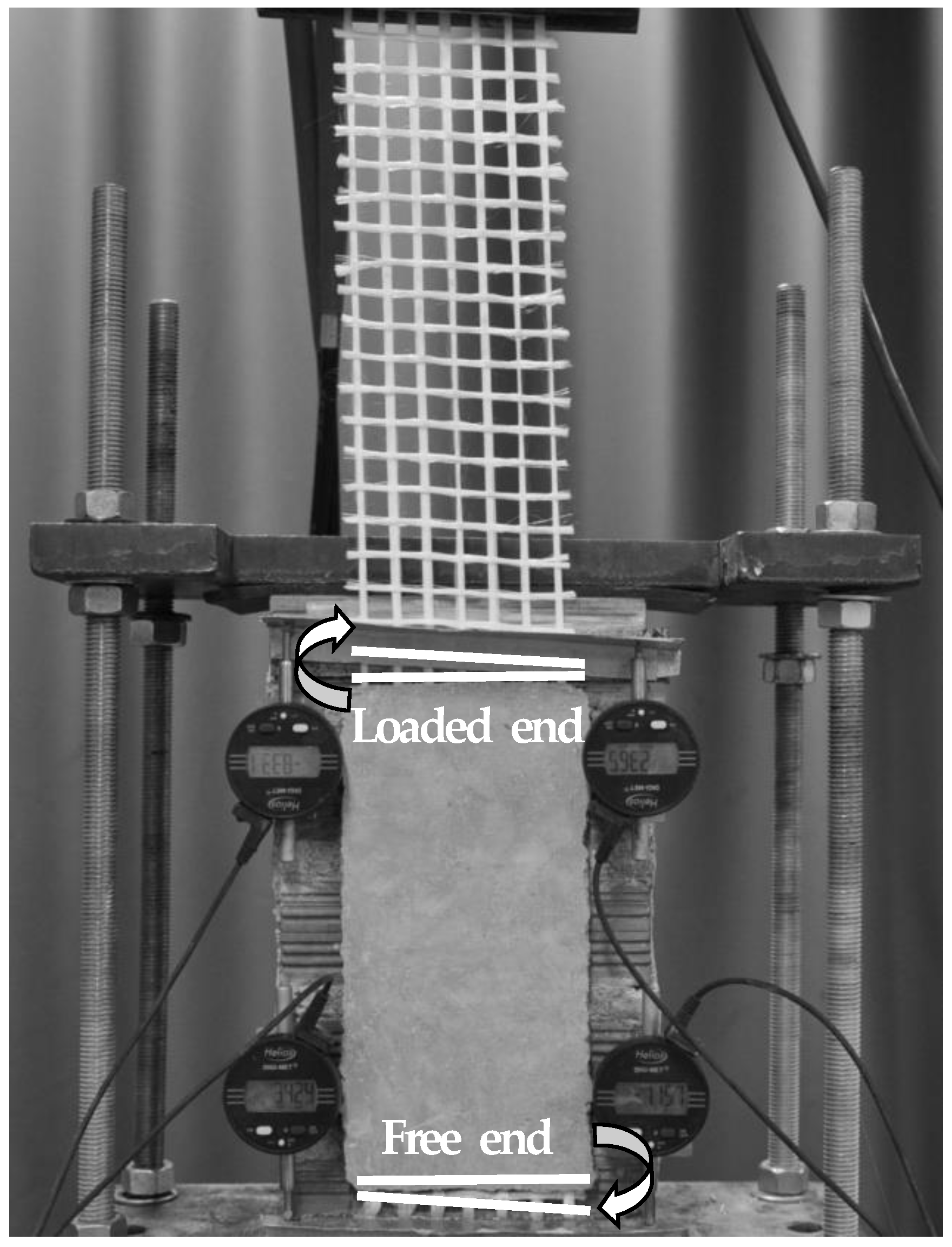

2.3.3. Shear Bond Tests Set-Up

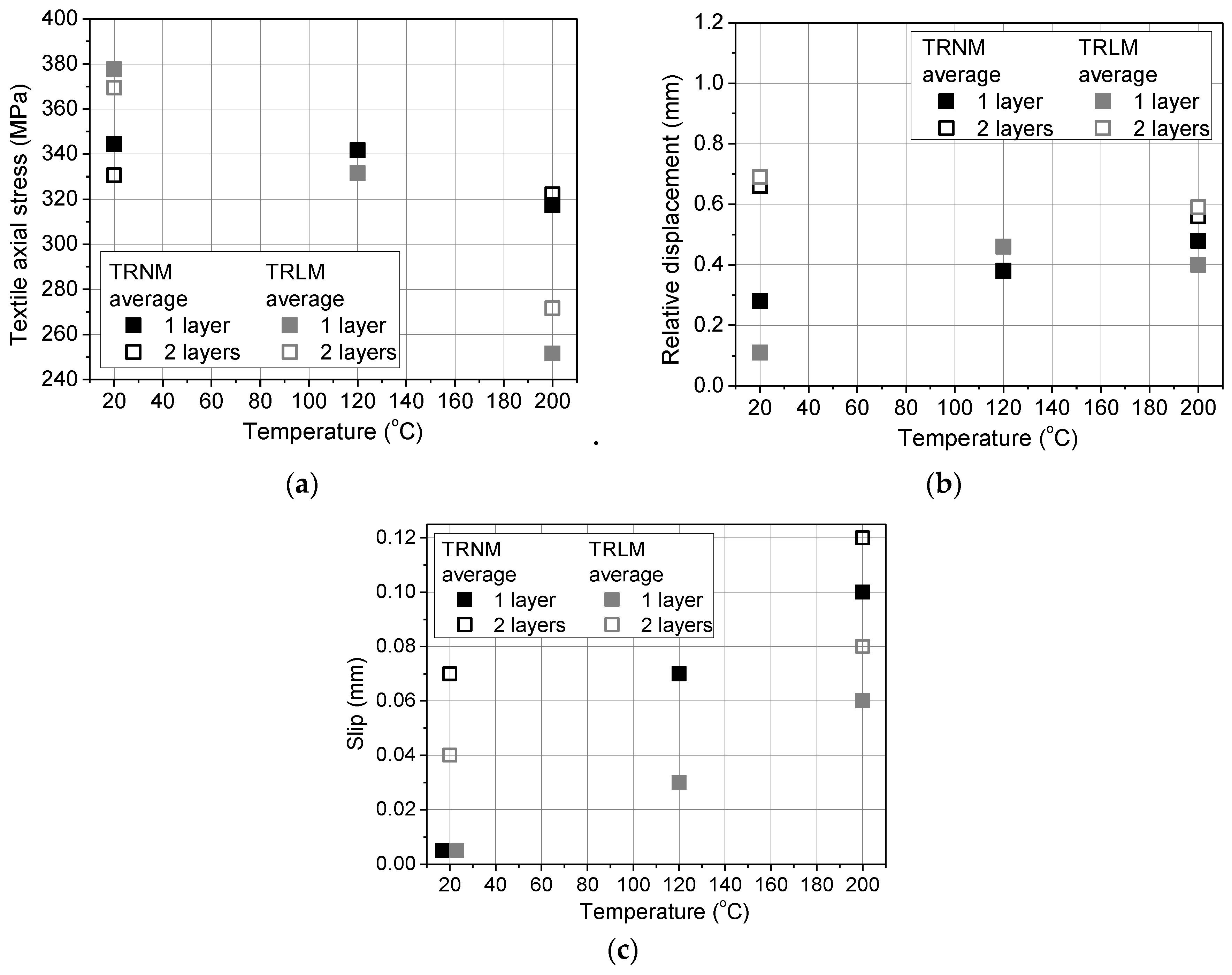

3. Results

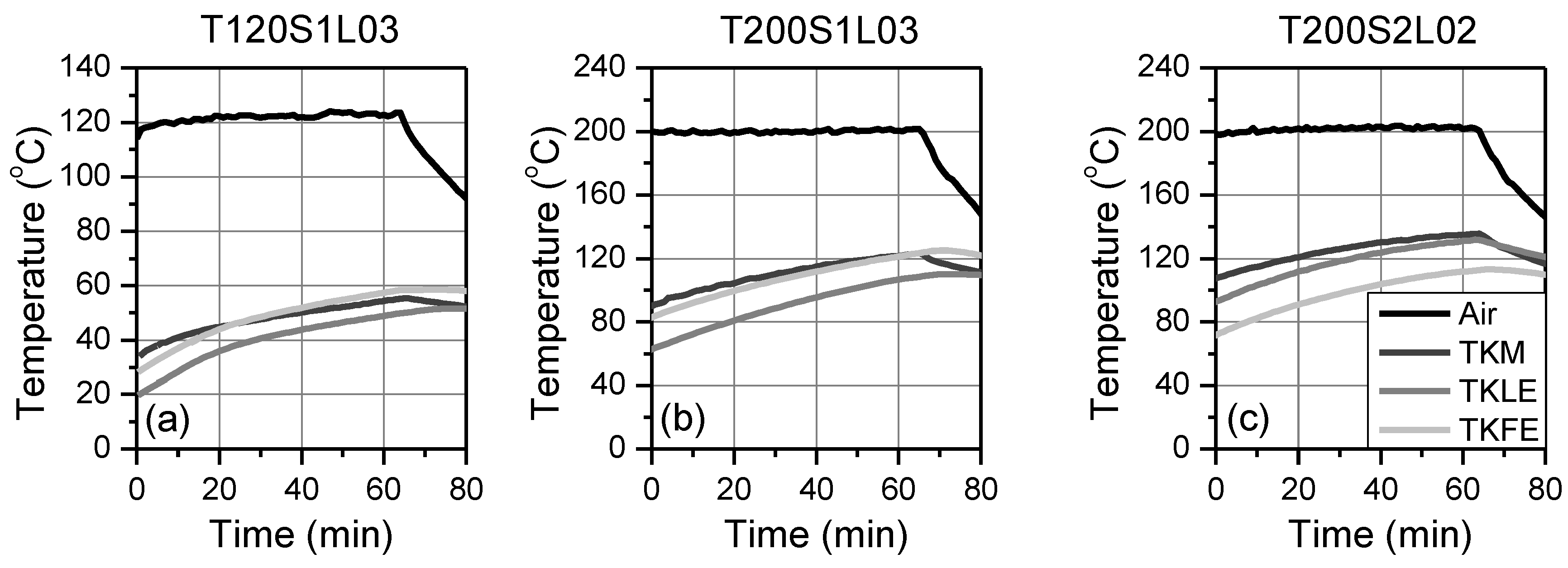

3.1. Heating Effect

3.2. Failure Mode

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Koutas, L.N.; Tetta, Z.; Bournas, D.A.; Triantafillou, T.C. Strengthening of Concrete Structures with Textile Reinforced Mortars: State-of-the-Art Review. J. Compos. Constr. 2019, 23, 03118001. [Google Scholar] [CrossRef]

- Kouris, L.A.S.; Triantafillou, T.C. State-of-the-art on strengthening of masonry structures with textile reinforced mortar (TRM). Constr. Build. Mater. 2018, 188, 1221–1233. [Google Scholar] [CrossRef]

- D’ Antino, T.; Sneed, L.H.; Carloni, C.; Pellegrino, C. Influence of the substrate characteristics on the bond behavior of PBO FRCM-concrete joints. Constr. Build. Mater. 2015, 101, 838–850. [Google Scholar] [CrossRef]

- Raoof, S.M.; Koutas, L.N.; Bournas, D.A. Bond between textile-reinforced mortar (TRM) and concrete substrates: Experimental investigation. Compos. B Eng. 2016, 98, 350–361. [Google Scholar] [CrossRef]

- Askouni, P.D.; Papanicolaou, C.G. Experimental investigation of bond between glass textile reinforced mortar overlays and masonry: The effect of bond length. Mater. Struct. 2017, 50, 164. [Google Scholar] [CrossRef]

- Askouni, P.D.; Papanicolaou, C.G. Textile Reinforced Mortar-to-masonry bond: Experimental investigation of bond-critical parameters. Constr. Build. Mater. 2019, 207, 535–547. [Google Scholar] [CrossRef]

- Maroudas, S.R.; Papanicolaou, C.G. Effect of High Temperatures on the TRM-to-Masonry Bond. Key Eng. Mater. 2017, 747, 533–541. [Google Scholar] [CrossRef]

- Ombres, L.; Iorfida, A.; Mazzuca, S.; Verre, S. Bond analysis of the thermally conditioned FRCM-masonry joints. Measurements 2018, 125, 509–515. [Google Scholar] [CrossRef]

- Donnini, J.; De Caso y Basalo, F.; Corinaldesi, V.; Lancioni, G.; Nanni, A. Fabric-reinforced cementitious matrix behavior at high-temperature: Experimental and numerical results. Compos. B Eng. 2017, 108, 108–121. [Google Scholar] [CrossRef]

- Ombres, L. Analysis of the bond between Fabric Reinforced Cementitious Mortar (FRCM) strengthening systems and concrete. Compos. B Eng. 2015, 69, 418–426. [Google Scholar] [CrossRef]

- Raoof, S.M.; Bournas, D.A. Bond between TRM versus FRP composites and concrete at high temperatures. Compos. B Eng. 2017, 127, 150–165. [Google Scholar] [CrossRef]

- Pancar, E.B.; Akpınar, M.V. Temperature Reduction of Concrete Pavement Using Glass Bead Materials. Int. J. Concr. Struct. Mater. 2016, 10, 39. [Google Scholar] [CrossRef]

- Oxfall, M. Climatic Conditions Inside Nuclear Reactor Containments: Evaluation of Moisture Condition in the Concrete within Reactor Containments and Interaction with the Ambient Compartments. Ph.D. Thesis, Lund University, Lund, Sweden, 2016. [Google Scholar]

- CEN. EN 1996-1-1 Eurocode 6–Design of Masonry Structures–Part 1-1: General Rules for Reinforced and Unreinforced Masonry Structures; European Committee for Standarization: Brussels, Belgium, 2005.

- RILEM TC 76: Technical Recommendations for Testing and Use of Constructions Materials: LUMB1-Compressive Strength of Small Walls and Prisms; Chapman & Hall: London, UK, 1991.

- CEN. EN ISO 13934-1: Textiles-Tensile Properties of Fabrics–Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method; British Standard: Brussels, Belgium, 1999.

- CEN. EN 1015-11: Methods of Test for Mortar for Masonry–Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; European Committee for Standardization: Brussels, Belgium, 1993.

- AC434 ICC-ES: Masonry and Concrete Strengthening Using Fiber-Reinforced Cementitious Matrix (FRCM) Composite Systems; ICC-Evaluation Service: Whittier, CA, USA, 2013.

- De Felice, G.; Aiello, M.A.; Caggegi, C.; Ceroni, F.; De Santis, S.; Garbin, E.; Gattesco, N.; Hojdys, Ł.; Krajewski, P.; Kwiecień, A.; et al. Recommendation of RILEM Technical Committee 250-CSM: Test method for Textile Reinforced Mortar to substrate bond characterization. Mater. Struct. 2018, 51, 95. [Google Scholar] [CrossRef]

- Chandra, S.; Berntsson, L. Lightweight Aggregate Concrete, 1st ed.; William Andrew Publishing: William, CA, USA, 2003; pp. 291–319. [Google Scholar]

| Coupon’s Configuration | First Crack Stress | Tensile Strength | Axial Strain Corresponding to fTRM |

|---|---|---|---|

| fFCR | fTRM | εTRM | |

| (MPa) | (MPa) | (%) | |

| {CoV} | {CoV} | {CoV} | |

| TRNM 1 layer | 604 {17%} | 604 {17%} | 0.02 {19%} |

| TRNM 2 layers | 241 {12%} | 576 {7%} | 1.11 {13%} |

| TRLM 1 layer | 594 {13%} | 594 {13%} | 0.03 {20%} |

| TRLM 2 layers | 151 {17%} | 532 {6%} | 1.04 {9%} |

| Specimen | Temperature (°C) | Tex Strip # | TKLE (°C) {CoV} | TKFE (°C) {CoV} | TKM (°C) {CoV} | σmax (MPa) | σmax,average (MPa) {CoV} | dr,max (mm) | dr,max,average (mm) {CoV} | smax (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| T20S1N01 | 20 | 1 | - | - | - | 313.28 | 344.36 {11%} | 0.26 | 0.28 {29%} | 0.005 |

| T20S1N02 | 20 | 1 | 335.91 | 0.22 | ||||||

| T20S1N03 | 20 | 1 | 383.88 | 0.38 | ||||||

| T20S2N01 | 20 | 2 | - | - | - | 340.72 | 330.53 {7%} | 0.48 | 0.66 {32%} | 0.07 |

| T20S2N02 | 20 | 2 | 305.58 | 0.90 | ||||||

| T20S2N03 | 20 | 2 | 345.30 | 0.61 | ||||||

| T20S1L01 | 20 | 1 | - | - | - | 375.32 | 377.57 {6%} | 0.13 | 0.11 {17%} | 0.005 |

| T20S1L02 | 20 | 1 | 355.49 | 0.09 | ||||||

| T20S1L03 | 20 | 1 | 401.90 | 0.11 | ||||||

| T20S2L01 | 20 | 2 | - | - | - | 341.48 | 369.49 {7%} | 0.66 | 0.69 {18%} | 0.04 |

| T20S2L02 | 20 | 2 | 391.14 | 0.83 | ||||||

| T20S2L03 | 20 | 2 | 375.86 | 0.59 | ||||||

| T120S1N01 | 120 | 1 | 51 {8%} | 45 {9%} | 63 {20%} | 337.66 | 341.74 {2%} | 0.28 | 0.38 {27%} | 0.07 |

| T120S1N02 | 120 | 1 | 348.36 | 0.36 | ||||||

| T120S1N03 | 120 | 1 | 339.19 | 0.49 | ||||||

| T120S1L01 | 120 | 1 | 49 {1%} | 49 {17%} | 53 {11%} | 316.27 | 331.55 {6%} | 0.39 | 0.46 {22%} | 0.03 |

| T120S1L02 * | 120 | 1 | - | - | ||||||

| T120S1L03 | 120 | 1 | 346.83 | 0.54 | ||||||

| T200S1N01 | 200 | 1 | 110 {14%} | 99 {13%} | 109 {2%} | 345.30 | 317.29 {9%} | 0.49 | 0.48 {2%} | 0.10 |

| T200S1N02 | 200 | 1 | 319.33 | 0.47 | ||||||

| T200S1N03 | 200 | 1 | 287.24 | 0.48 | ||||||

| T200S2N01 | 200 | 2 | 121 {7%} | 102 {9%} | 118 {4%} | 300.23 | 322.13 {10%} | 0.74 | 0.56 {32%} | 0.12 |

| T200S2N02 | 200 | 2 | 306.34 | 0.57 | ||||||

| T200S2N03 | 200 | 2 | 359.82 | 0.38 | ||||||

| T200S1L01 | 200 | 1 | 117 {4%} | 105 {7%} | 118 {3%} | 238.35 | 251.59 {11%} | 0.49 | 0.40 {21%} | 0.06 |

| T200S1L02 | 200 | 1 | 282.66 | 0.37 | ||||||

| T200S1L03 | 200 | 1 | 233.77 | 0.33 | ||||||

| T200S2L01 | 200 | 2 | 125 {12%} | 111 {3%} | 133 {4%} | 233.00 | 271.63 {13%} | 0.79 | 0.59 {32%} | 0.08 |

| T200S2L02 | 200 | 2 | 276.30 | 0.55 | ||||||

| T200S2L03 | 200 | 2 | 305.58 | 0.42 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Askouni, P.D.; Papanicolaou, C.G.; Kaffetzakis, M.I. The Effect of Elevated Temperatures on the TRM-to-Masonry Bond: Comparison of Normal Weight and Lightweight Matrices. Appl. Sci. 2019, 9, 2156. https://doi.org/10.3390/app9102156

Askouni PD, Papanicolaou CG, Kaffetzakis MI. The Effect of Elevated Temperatures on the TRM-to-Masonry Bond: Comparison of Normal Weight and Lightweight Matrices. Applied Sciences. 2019; 9(10):2156. https://doi.org/10.3390/app9102156

Chicago/Turabian StyleAskouni, Paraskevi D., Catherine (Corina) G. Papanicolaou, and Michael I. Kaffetzakis. 2019. "The Effect of Elevated Temperatures on the TRM-to-Masonry Bond: Comparison of Normal Weight and Lightweight Matrices" Applied Sciences 9, no. 10: 2156. https://doi.org/10.3390/app9102156

APA StyleAskouni, P. D., Papanicolaou, C. G., & Kaffetzakis, M. I. (2019). The Effect of Elevated Temperatures on the TRM-to-Masonry Bond: Comparison of Normal Weight and Lightweight Matrices. Applied Sciences, 9(10), 2156. https://doi.org/10.3390/app9102156