Featured Application

This study can be applied in the petroleum and mining engineering and helps improve the efficiency of drilling, especially under the deep-hole condition.

Abstract

The self-resonating waterjet (SRWJ) has been applied in petroleum, natural gas, and mining engineering ever since its strong erosion ability in deep-hole drilling was recognized. Aiming at further improving the working efficiency of SRWJs, the effects of the exit angle of the organ-pipe nozzle on the axial pressure oscillations of the jet were experimentally studied. Six exit angles of θ = 0°, 30°, 45°, 60°, 75°, and 90° were employed in the experiment, and the axial pressure oscillation peak (Pmax) and amplitude (Pa) were used for characterizing the performance of SRWJs. It was found that the exit angle greatly affects the axial pressure oscillations, including the development trends against the standoff distance and the magnitudes of Pmax and Pa. Under testing with two inlet pressures, the exit angle of θ = 0° always resulted in the greatest Pmax and Pa within the range of the testing standoff distance. With the increase of standoff distance, both Pmax and Pa first increased and then decreased when the exit angle was 0°; while they kept decreasing when the exit angle was 30°, 45°, 60°, 75°, and 90°. Moreover, the exit angles of θ = 90° and 60°, corresponding to inlet pressures of Pi = 10 MPa and 20 MPa, led to both the minimum magnitudes of Pmax and Pa under the experimental conditions. The results also indicate that the exit angle affects the interactions between the nozzle lip and the jet and help provide information for improving the working efficiency of SRWJs in practical applications.

1. Introduction

When water is pressurized and flows through a tiny orifice, a high-speed waterjet possessing strong impact power is generated. It is claimed that a high-speed waterjet is able to disintegrate most existing materials by transmitting high energy to an extremely small area and is extremely suitable for cutting hard rocks [1]. Currently, waterjet technology is being widely used in the energy field as an efficiency operation assisting drilling [2]. For example, Liu et al. [3] studied the damage models of rock breaking assisted with a high-speed waterjet, in order to improve the life and working efficiency of conical cutters used in excavation. As waterjet technology has been efficiently used for slotting in coal mining of low permeability, Shen et al. [4] investigated the mechanism of pressure relief and permeability enhancement under the waterjet slotting process.

As the demand for energy is dramatically increasing year by year, improving the efficiency of energy exploitation is always a focus of researchers. In order to improve the working performance of waterjets used for rock breaking, several types of waterjet have been proposed. These are the cavitating waterjet, pulsed waterjet, self-resonating waterjet (SRWJ), and the abrasive waterjet. Each of these has much stronger impact power and higher working efficiency than the conventional plain waterjet under the same operating conditions [5,6,7]. The SRWJ has the advantages of both a cavitating waterjet and a pulsed waterjet, and thus has attracted the attention of a number of researchers [8,9].

To be more specific, the SRWJ was first proposed by Johnson et al. [10] in the early 1980s, based on the fact that the large-scale orderly patterns that existed in the noise producing region of a jet could be enhanced and controlled by a slight periodic surging imposed at the jet exit [11]. Generally, a SRWJ is generated by taking advantage of the passive acoustic resonance tuned to the preferred Strouhal number of the submerged jet to cause large-scale turbulent motions of the jet. Subsequently, Chahine and Johnson designed several nozzles that can generate a SRWJ, including the “pulser”, “laid-back pulser”, “pulser-fed”, and “organ-pipe” [12]. Then, by comparing the performance of these nozzles using experimental and numerical methods, it was demonstrated that the organ-pipe nozzle was the most promising due to its compact and simple structure. Moreover, by making use of the power generated by the collapse of the cavitation bubbles and the water hammer stress wave generated by the pulsations, the SRWJ showed significantly increased performance in its erosion capability and is used in a wide range of applications. For example, Li et al. [13] employed a SRWJ in petroleum engineering in China and found the penetration rate of deep-hole drilling could be improved by as much as 31.5%. They also demonstrated that the amplitudes of the pressure oscillation and the maximum impact pressure of the SRWJ could show improvements of 24% and 37%, respectively, compared with waterjets injected from a conventional cone-shaped nozzle [14]. Additionally, Ding et al. [15] used a SRWJ to impact aluminum alloy as a new peening method for improving its properties. They found that the hardness and residual stress after the waterjet peening process could be increased by 61.6% and 148%, respectively.

With the rapid development of SRWJs, not only is their application widening, but the demand for higher performance is also greatly increasing. Therefore, some researchers are focusing on clarifying the characteristics and properties of SRWJs rather than on applications. In more specific terms, Peng et al. [16] established a new mathematical model to describe the size variations of the cavitation bubbles, aiming at clarifying the process of bubble collapse. Liu et al. [17] analyzed the oscillation mechanism of a SRWJ, by both numerical and experimental methods, and found that the cavitation clouds dominate the oscillating frequency. Moreover, Fang et al. [18] numerically studied the characteristics of the flow field inside organ-pipe nozzles of different geometries, and experimentally investigated performance. Furthermore, Chahine and Genoux [19] mathematically studied the behavior of the collapse of a cavitating vortex ring within a SRWJ and claimed that the bubble ring collapse should be more erosive than that of an equivalent spherical bubble. Most recently, we studied the preferred Strouhal number used in SRWJs, and found that the optimum values are 0.315 and 0.278 respectively, corresponding to inlet pressures of 10 MPa and 20 MPa [20]. Furthermore, a series of experimental investigations on SRWJs have also been conducted, ranging from the effects of nozzle inner surface roughness to the influence of feeding pipe diameter [21,22,23,24,25,26,27,28,29]. These investigations on the mechanisms and principles of SRWJs have contributed to the understanding of the jet and improvement of the jet’s performance.

Another method for improving the performance of SRWJs commonly used in the field of waterjets is by optimizing the structure of the nozzle. For instance, Qu and Chen [30] conducted orthogonal experiments using a variety of geometric sizes of self-excited oscillation nozzles and found that the diameter of the suction nozzle was the most important factor and even determined the performance of the jet. Moreover, Arthurs and Ziada [31] performed a study using a series of nozzle thicknesses, to tryi to clarify the effect on the pattern of jet oscillation. They claimed that within the fluid-resonant regime, the acoustic tones are controlled by the impingement distance. In addition, Fan et al. [32] found that the frequency of SRWJs decreases with the increase of the length to diameter ratio of the chamber. Most recently, our research group experimentally studied the effects of the downstream contraction ratio of an organ-pipe nozzle on SRWJs and found that the development trends of the pressure oscillations against standoff distance were greatly affected [33]. Therefore, it can be concluded that the structural parameters play a significant and important role in improving the performance of SRWJs.

To the best of our knowledge, there is currently rather little literature focusing on the effects of the exit angle of the organ-pipe nozzle. Therefore, the present study intended to fill this gap by experimentally investigating the pressure characteristics of SRWJs issuing from organ-pipe nozzles of different exit angles, because the interaction between the shear layer of the jet and the nozzle lip is a predominant source of the pressure oscillations [12]. The axial pressure oscillation peaks and amplitudes were studied, and a non-dimensional analysis was performed, so as to figure out the effects of the exit angle. The research aimed to improve the performance of the SRWJ by offering better geometries for an organ-pipe nozzle.

2. Generation of SRWJs

When a turbulent air jet is excited with periodic acoustic signals by transducers or loudspeakers located at the upstream of the nozzle, the jet structure in the shear layer will organize into discrete ring vortices if the excitation frequency is equal to the predominant frequency of the non-excited jet [11]. The potential of this phenomenon for submerged waterjets was recognized and used to produce SRWJs under a critical Strouhal number of 0.3 [10]. The Strouhal number, Sd, is defined as [11]:

where fv is the structuring frequency of the jet, Dj is the jet diameter, and Uj is the jet velocity.

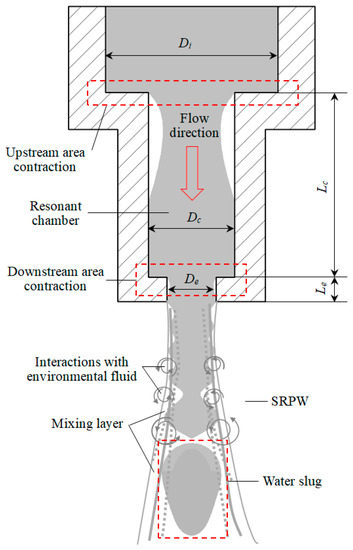

The passive excitation needed for successful generation of a SRWJ can be obtained by shaping the nozzle with a suitable acoustic chamber, so as to feed back the pressure waves which occur at the nozzle exit. The possible types of nozzle are, “pulser”, “organ-pipe”, “pulser-fed”, and “laid-back pulser”, as mentioned above [10]. Since the organ-pipe nozzle is the most promising self-resonating nozzle and has wide applications, it is used here to give a detailed description of the SRWJ generation process. The geometrical structure of the organ-pipe nozzle and the principles of the operation of SRWJs are schematically shown in Figure 1.

Figure 1.

Schematic diagram of an organ-pipe nozzle and the generation of a self-resonating waterjet (SRWJ).

An organ-pipe nozzle consists of two abrupt area contractions (the upstream one and the downstream one) and a resonant chamber. The upstream area contraction is characterized by (Di/Dc)2, and the downstream one is characterized by (Dc/De)2). Disturbances are triggered at the downstream contraction when the pressurized water is flowing through the nozzle, because of the abrupt change in the flow field. The disturbances propagate in the form of waves and the ones that propagate upwards are reflected at the upstream area contraction, due to the impedance change caused by the variation of the flow area. The reflected waves superpose the incident ones, and a standing wave appears if Lc satisfies the following equation:

where Di is the inlet diameter, De is the chamber diameter, De is the exit diameter, Lc is the chamber length, λ is the length of the standing wave, and n is the natural number.

For the pressure wave, we have:

where f0 is the frequency of the wave, and c is the local sound speed.

Furthermore, peak resonance caused by the standing wave will excite the shear layer of the jet to organize into large-scale structures if f0 is equal to, or is near, fv [12]. The large-scale structures then develop into vortex rings, whose volume fluctuations are another predominant source accounting for the generation of a SRWJ. Therefore, by equaling f0 and fv, the following relation between Lc and De can be obtained using Equations (1)–(3):

where Ma is the Mach number, and Kn is the mode number and is described as:

It should be noted that the jet diameter, Dj, has been approximated to the exit diameter of the nozzle, De, in Equation (4). As a result, a SRWJ can be successfully produced by an organ-pipe nozzle which meets the geometrical parameters in Equation (4). More detailed information can be found in the previous research [10,12,13,14].

3. Experimental Setup and Procedures

3.1. Facilities and Procedures

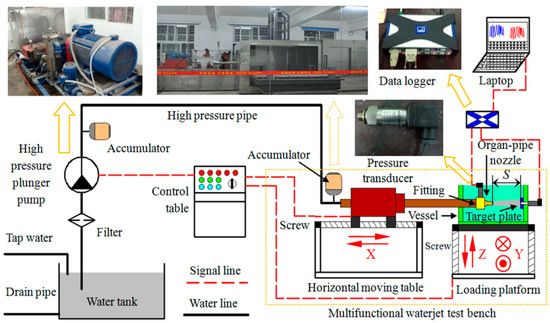

Since the intensity of the pressure oscillation is an important indicator used to evaluate the performance of SRWJs, experiments were carried out to obtain the axial pressure oscillation peaks and amplitudes of the jet. Figure 2 is a schematic diagram illustrating the experimental setup for acquiring the time-resolved axial pressures of the SRWJ. It should be noted that a series of experiments on SRWJs have previously been conducted using the same equipment and facilities, and the same pressure acquiring method. Figure 2 is thus the same as in our previous studies [20,23,25,26,33].

Figure 2.

Experimental setup of the axial pressure measurement [20,23,25,26,33].

The experiment was performed using a multifunctional waterjet test bench that has been applied in the previous investigations [15,17,18,20,21,22,23,24,25,26,27,28,29,33]. The test bench had a horizontal moving table with X directional motion and a loading platform that had Y and Z directional motions. The tested organ-pipe nozzle was mounted at the end of a hollow-rod fixed on the horizontal moving table, and a small tank filled with water was positioned on the loading platform. A target plate, which had a pressure tap of 1 mm diameter at its center, was fixed on the wall of the tank. The pressure tap was communicated with a dynamic pressure transducer (Model: XPM 10), which was connected with a data logger (Model: MX840B) used to collect the axial pressures of the SRWJ. The maximum and minimum pressures could be directly displayed on the laptop connected to the data logger. Furthermore, the pressure oscillation amplitude was defined as the difference of the two pressures, which is:

where Pa is the pressure oscillation amplitude, Pmax is the pressure oscillation peak, and Pmin is the minimum pressure.

The standoff distance, S, was defined as the distance from the nozzle exit to the surface of the target plate, and it was varied from S = 10 mm to S = 100 mm in increments of 10 mm during each group of tests. Before each measurement, the pressure tap on the target plate was made coaxial with the nozzle. The maximum working pressure and flow rate of the plunger pump were 60 MPa and 120 L/min, respectively. In addition, two bladder accumulators were used in the water line to reduce the disturbances generated by the pump, so as to improve the accuracy of the experimental results. More specifically, one accumulator was located near the pump and the other was close to the nozzle. Another pressure transducer (Model: DMK 331P) was used to monitor the inlet pressure, Pi, and inlet pressures of Pi = 10 MPa and 20 MPa were applied in the experiment. The duration time was 3 s for each measurement. The main parameters of the two pressure transducers are shown in Table 1 and Table 2, respectively.

Table 1.

Main parameters of the pressure transducer of DMK 331P.

Table 2.

Main parameters of the pressure transducer of XPM 10.

3.2. Design of Organ-Pipe Nozzles

To produce the tested organ-pipe nozzles, all the geometrical parameters shown in Figure 1 should first be acquired From Equation (4), it can be found that Uj should be obtained in order to get the value of Lc/De, because the values of Sd and c are already known as 0.3 and 1450 m/s, respectively. The inlet, chamber, and exit diameters can be determined as 13 mm, 5 mm, and 2 mm, respectively, based on the previous results [13,14]. The process for getting the values of Uj corresponding to the two inlet pressures is shown below.

Based on the Bernoulli equation, the relation between Pi and Uj can be obtained:

where ρ is water density, g is the acceleration of gravity, Po is the environment pressure (and here it can be neglected when compared with the inlet pressure), and hf and hj are the frictional and the local head losses, written as:

where η is the friction coefficient, l is the length of the flow channel (here it is the nozzle length), d is the channel diameter (here it is the nozzle diameter), u is the flow velocity, m/s, and k is the local resistance coefficient. For the case of a sudden area contraction, k is described as:

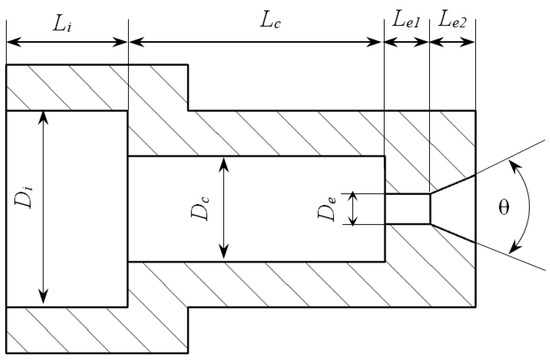

where A1 and A2 are the cross-section areas at the area contraction. A preliminary calculation indicated that the frictional head loss was rather small and could be ignored. Therefore, the chamber lengths could finally be obtained by combining Equations (4), (6), (8), and (9), and were Lc = 21 mm and 15 mm, respectively, corresponding to inlet pressures of Pi = 10 MPa and 20 MPa. Six exit angles were employed in the experiment, which were 0°, 30°, 45°, 60°, 75°, and 90°, respectively. The geometrical parameters of the tested organ-pipe nozzles are shown in Table 3, and the typical profile and pictures of the testing organ-pipe nozzles are displayed in Figure 3 and Figure 4, respectively.

Table 3.

Geometrical parameters of the tested organ-pipe nozzles.

Figure 3.

Profile of organ-pipe nozzle.

Figure 4.

Picture of the tested organ-pipe nozzles.

3.3. Experimental Uncertainties

As the axial pressure oscillation peak (Pmax) and amplitude (Pa) of the SRWJ were used to evaluate the effects of the nozzle exit angle, the experimental uncertainties were mainly determined by the accuracy and reliability of the pressure values obtained by the pressure transducer, XPM 10. Since the pressure oscillation peaks were directly acquired by the transducer, the experimental error of Pmax was less than 0.25% (shown in Table 2). With respect to the experimental error of the pressure oscillation amplitude, γ, it can be obtained from Equation (5) and Table 2, shown below:

Even the accuracy of the pressure transducer monitoring the inlet pressure and the linearity error of the data logger also contributed to the experimental uncertainties, they had very limited influence and could be neglected here.

4. Experimental Results and Discussion

4.1. Axial Pressure Oscillations

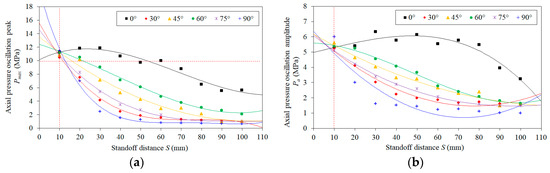

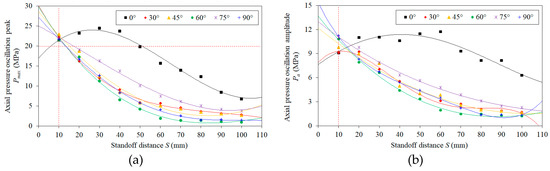

Pmax and Pa against S under different exit angles are plotted in Figure 5 and Figure 6, respectively, corresponding to the inlet pressures of Pi = 10 MPa and 20 MPa. More specifically, Figure 5a and Figure 6a show the development trends of Pmax against S, and Figure 5b and Figure 6b illustrate the trends of Pa along with S.

Figure 5.

Pmax (a) and Pa (b) as a function of S at Pi = 10 MPa.

Figure 6.

Pmax (a) and Pa (b) as a function of S at Pi = 20 MPa.

As illustrated in Figure 5 and Figure 6, the exit angle of the organ-pipe nozzle greatly influenced the axial pressure oscillations of the SRWJ, regardless of the inlet pressure. To be more specific, the exit angle of 0° resulted in the most violent pressure oscillations under the two inlet pressures, because the peaks and amplitudes were the maximum at almost all the standoff distances when compared with those under the other exit angles. Moreover, the development trends of Pmax and Pa against the standoff distance for the exit angle of θ = 0° were dramatically different from those for all the other exit angles. In more specific terms, for the case of 0°, both Pmax and Pa first increased and then decreased with the increase of S. If the typical features of the axial pressure oscillations of SRWJs are taken into consideration [20], it can be claimed that only the organ-pipe nozzle with an exit angle of 0° can generate successful SRWJs. That is to say, the exit angle of the organ-pipe nozzle can even determine the occurrence of SRWJs. This is also experimental proof of the conjecture proposed by Chahine et al. [12] that the interactions between the nozzle exit and the jet significantly affect the pressure oscillations of SRWJs.

Furthermore, the optimal standoff distance, which is defined as the distance where Pmax or Pa reaches the maximum, was approximately 30 mm for Pmax and approximately 60 mm for Pa when the exit angle was 0°. Therefore, the optimal standoff distances for the maximum Pmax and Pa were different, which is in good agreement with the previous experimental results [24,33]. Another interesting phenomenon observed is that the values of Pmax under different exit angles were very close to each other at a standoff distance of S = 10 mm, which was independent of the inlet pressure, and so were the values of Pa. This indicates that the influence of the exit angle on the axial pressure oscillations of the SRWJ was rather insignificant at this standoff distance, which is most likely due to the fact that the cavitation bubbles take some time to grow into large-scale vortex rings [13,14,27]. In other words, strong pressure oscillation starts to occur at a certain standoff distance, because the volume changes of the vortex-ring in the shear layer are a dominant source contributing to the pressure oscillations of SRWJs [12].

In more specific terms, at an inlet pressure of Pi = 10 MPa, the Pmax and Pa of SRWJs issuing from organ-pipe nozzles of the other five exit angles rapidly decreased with the increasing standoff distance, as shown in Figure 5. The development trends of Pmax against S were very similar to those of a regular submerged waterjet, indicating that the organ-pipe nozzles with exit angles larger than 0° could no longer generate effective SRWJs. In addition, it was observed that different exit angles led to clearly different values of Pmax at each standoff distance, and the order of the exit angles for obtaining greater peaks was 0°, 60°, 45°, 75°, 30°, and 90°, as depicted in Figure 5a. It is of great interest to find that the order of the exit angles for achieving larger amplitudes was the same as that for the peaks, which means the exit angle of the organ-pipe nozzle determines both Pmax and Pa at the same time.

When the inlet pressure was increased to 20 MPa, as shown in Figure 6, the development trends of Pmax and Pa also quickly decreased with the increase of the standoff distance, except for the case of the exit angle of 0°, which was the same as those at 10 MPa. Therefore, it can be demonstrated that Pi cannot change the development trends of the Pmax and Pa of a SRWJ if the organ-pipe nozzle is determined. Besides, at an inlet pressure of Pi = 20 MPa, the exit angle of 75° leads to the maximum peaks and amplitudes at each standoff distance, except for the case of 0°, while the exit angle of 60° always results in the minimum peaks and amplitudes. That is to say, the inlet pressure influences the relative magnitude of the peaks and amplitudes of the different exit angles, even though it cannot change the development trends of the pressure oscillations.

Moreover, according to Equation (11), the maximum experimental error for Pa under the two inlet pressures can be obtained, and were 0.92% and 0.97% for the exit angle of 90° at S = 20 mm and for the exit angle of 30° at S = 10 mm, respectively.

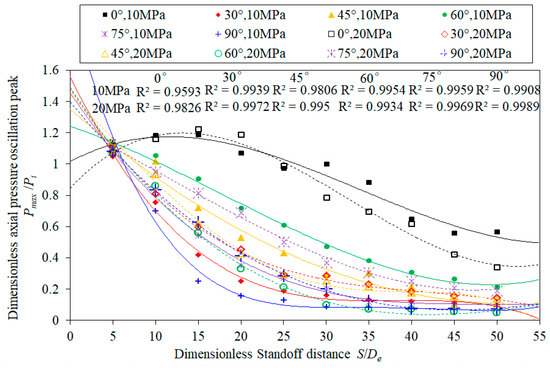

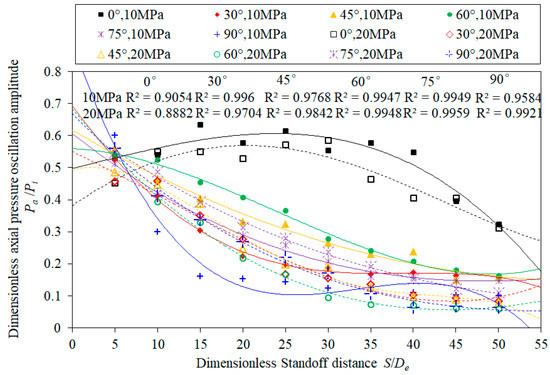

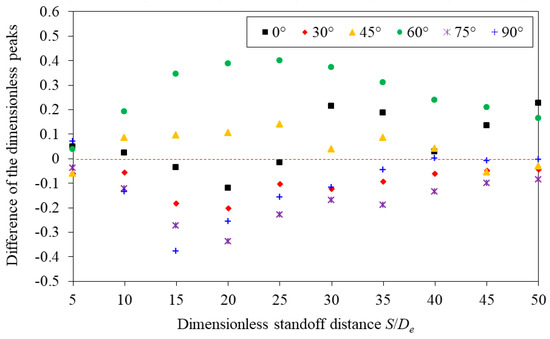

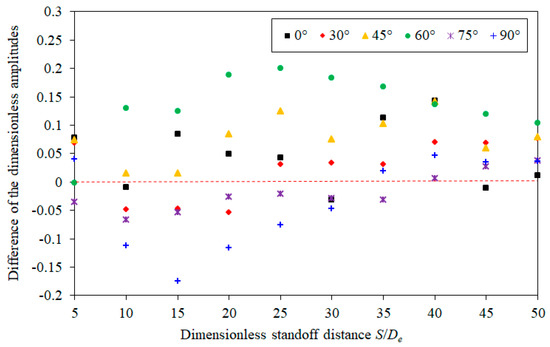

4.2. Preliminary Non-Dimensional Analysis

In order to provide further clarification on the pressure characteristics of SRWJs affected by the exit angle of the organ-pipe nozzle under different inlet pressures, a non-dimensional analysis of the Pmax and Pa was performed. Pmax and Pa were non-dimensionalized by Pi; and the standoff distance was non-dimensionalized by De, which has been defined as the characteristic parameter of the organ-pipe nozzle in the previous studies of SRWJs [10,12,20]. The dimensionless Pmax and Pa against the dimensionless S under the two inlet pressures are plotted in Figure 7 and Figure 8, respectively, and the correlation coefficients are also displayed. Moreover, for each exit angle, the differences in the dimensionless peaks and amplitudes under the two inlet pressures were calculated and plotted in Figure 9 and Figure 10, respectively.

Figure 7.

The dimensionless Pmax against dimensionless S.

Figure 8.

The dimensionless pressure oscillation amplitude against dimensionless standoff distance.

Figure 9.

The differences in the dimensionless Pmax against dimensionless S.

Figure 10.

The differences in dimensionless amplitudes against dimensionless standoff distance.

As shown in Figure 7, it is clear that the inlet pressure can hardly affect the development trends of Pmax, as the curves of the same color have the same shapes. More specifically, for the exit angle of θ = 0°, the development trends of Pmax can be described by a quadratic convex function, which is y = −4 × 10−4x2 + 2.89 × 10−3x + 1.163. For the other exit angles, the trends are fitted by quadratic concave functions. For example, when the exit angle was 30°, the trend of the Pmax fits the function of y = 7 × 10−4x2 − 0.059x + 1.3. Furthermore, when combined with Figure 9, it was found that the dimensionless values of Pmax at the two inlet pressures were very close when the exit angle was 0° or 45°, because the differences were the closest to the red dashed line of 0. In addition, it is of interest to find that the dimensionless values of Pmax at an inlet pressure of Pi = 10 MPa were always greater than those at an inlet pressure of Pi = 20 MPa under the exit angles of θ = 45° and 60°, and the greatest differences occurred when the exit angle was 60°. However, at the exit angles of θ = 30°, 75°, and 90°, the dimensionless peaks at Pi = 10 MPa were smaller than those at Pi = 20 MPa, and the exit angle of θ = 75° resulted in the greatest differences.

With respect to the dimensionless Pa shown in Figure 8, the development trends were almost the same as those of the dimensionless Pmax under the tested organ-pipe nozzles of different exit angles. That is to say, both Pmax and Pa have a convex quadratic relationship with the standoff distance for the exit angle of θ = 0° and have a concave quadratic relationship with the standoff distance for the exit angles of θ = 30°, 45°, 60°, 75°, and 90°. Moreover, the dimensionless values of Pa under the two inlet pressures were rather close at the testing standoff distances when the exit angle was 30° and 75°, as shown in Figure 10. In addition, the dimensionless pressure oscillation amplitudes at an inlet pressure of Pi = 10 MPa were always greater than those at Pi = 20 MPa when the exit angle was 45° and 60°, while at the other exit angles, the relative magnitudes of the amplitudes under the two inlet pressures fluctuated with the standoff distance.

However, it has to be emphasized that the analysis here is somewhat qualitative, due to the rather limited literature on this point. Further investigations focusing on the mathematical and theoretical aspects should be undertaken, in order to provide a deeper understanding of the influence mechanism of nozzle structure on the performance of SRWJs.

5. Conclusions

Aiming at improving the efficiency of deep-hole drilling, the pressure oscillations of SRWJs were experimentally studied with organ-pipe nozzles of various exit angles. The Pmax and Pa under the different exit angles were analyzed. It should be noted that we have not made sufficient progress to present a complete discussion on the influence mechanism of the exit angle on SRWJs, and further theoretical and mathematical investigations should be carried out. However, the present study still makes a contribution to an improved understanding of how the pressure characteristics are influenced by the exit angle. The main results are shown below:

- (1)

- The exit angle of the organ-pipe nozzle greatly affects the axial pressure oscillations of SRWJs, with different angles causing obviously different values of Pmax and Pa at standoff distances of S > 10 mm.

- (2)

- The exit angle of 0° always leads to the largest values of Pmax and Pa under the two inlet pressures, and makes the jet possess the typical pressure feature of a SRWJ; while for the other exit angles, both Pmax and Pa decrease rapidly with the increasing standoff distance.

- (3)

- At an inlet pressure of 10 MPa, the exit angle of 90° always results in the minimum values of Pmax and Pa at almost all the testing standoff distances, while at an inlet pressure of 20 MPa, the exit angle of 60° takes the place of 90°.

- (4)

- When the exit angle is 0°, both Pmax and Pa have a convex quadratic relationship with the standoff distance, while they have a concave quadratic relationship with the standoff distance when the exit angle is 30°, 45°, 60°, 75°, and 90°.

Author Contributions

Conceptualization, X.W.; investigation, Z.W., M.Y., and Q.F.; writing—review and editing, D.L.

Funding

This research was financially supported by the National Natural Science Foundation of China (No. 51805188), the China Postdoctoral Science Foundation Founded Project (No. 2017M620313), and the National Key Research and Development Program of China (No. 2018YFC0808401).

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Dj | jet diameter (m) |

| Di | inlet diameter of organ-pipe nozzle (m) |

| Dc | chamber diameter of organ-pipe nozzle (m)] |

| De | exit diameter of organ-pipe nozzle (m) |

| Ma | Mach number, Uj/c |

| Kn | mode number |

| Lc | chamber length of organ-pipe nozzle (m) |

| Le1 | length of the straight part of the nozzle exit (m) |

| Le2 | length of the divergent part of the nozzle exit (m) |

| A1 | upstream cross-section area at the contraction (m2) |

| A2 | downstream cross-section area at the contraction (m2) |

| Sd | Strouhal number |

| Uj | jet velocity (m/s) |

| Pa | pressure oscillation amplitude (MPa) |

| Pmax | pressure oscillation peak (MPa) |

| Pmin | minimum pressure oscillation (MPa) |

| Pi | inlet pressure (MPa) |

| P0 | environment pressure (MPa) |

| S | standoff distance (m) |

| f0 | frequency of the pressure wave (Hz) |

| fv | structuring frequency of the jet (Hz) |

| λ | length of the standing wave (m) |

| c | local sound speed (m/s) |

| n | natural number |

| ρ | water density (kg/m3) |

| g | gravity acceleration (m/s2) |

| hf | frictional head loss (m) |

| hj | local head loss (m) |

| η | coefficient of the frictional head loss |

| k | coefficient of the local head loss |

| l | length of the flow channel (m) |

| u | flow velocity in the nozzle (m/s) |

| θ | exit angle of organ-pipe nozzle (°) |

| γ | experimental error of Pa |

References

- Zelenak, M.; Foldyna, J.; Scucka, J.; Hloch, S.; Riha, Z. Visualisation and measurement of high-speed pulsating and continuous water jets. Measurement 2015, 72, 1–8. [Google Scholar] [CrossRef]

- Karpuz, C. Energy Efficiency of Drilling Operations. In Energy Eff Miner Ind; Awuah-Offei, K., Ed.; Springer: Cham, Switzerland, 2018; pp. 71–86. ISBN 978-3-319-54198-3. [Google Scholar]

- Liu, S.; Liu, Z.; Cui, X.; Jiang, H. Rock breaking of conical cutter with assistance of front and rear water jet. Tunn. Undergr. Space Technol. 2014, 42, 78–86. [Google Scholar] [CrossRef]

- Shen, C.; Lin, B.; Sun, C.; Zhang, Q.; Li, Q. Analysis of the stress–permeability coupling property in water jet slotting coal and its impact on methane drainage. J. Pet. Sci. Eng. 2015, 126, 231–241. [Google Scholar] [CrossRef]

- Kang, C.; Liu, H.; Soyama, H. Estimation of aggressive intensity of a cavitating jet with multiple experimental methods. Wear 2018, 394, 176–186. [Google Scholar] [CrossRef]

- Schwartzentruber, J.; Spelt, J.; Papini, M. Prediction of surface roughness in abrasive waterjet trimming of fiber reinforced polymer composites. Int. J. Mach. Tool Manuf. 2017, 122, 1–17. [Google Scholar] [CrossRef]

- Liu, Y.; Wei, J.; Ren, T.; Lu, Z. Experimental study of flow field structure of interrupted pulsed water jet and breakage of hard rock. Int. J. Rock Mech. Min. Sci. 2015, 78, 253–261. [Google Scholar] [CrossRef]

- Huang, M.; Kang, Y.; Wang, X.; Hu, Y.; Li, D.; Cai, C.; Liu, Y. Experimental investigation on the impingement characteristics of a self-excited oscillation pulsed supercritical carbon dioxide jet. Exp. Therm. Fluid Sci. 2018, 94, 304–315. [Google Scholar] [CrossRef]

- Arthurs, D.; Ziada, S. Self-excited oscillations of a high-speed impinging planar jet. J. Fluid Struct. 2012, 34, 236–258. [Google Scholar] [CrossRef]

- Johnson, V.; Lindenmuth, W.; Conn, A.; Frederick, G. Feasibility Study of Tuned-Resonator, Pulsating Cavitating Water Jet for Deep-Hole Drilling; SAND-81-7126, Technical Report; Department of Energy Office of Scientific and Technical Information: Oak Ridge, TN, USA, 1981. Available online: https://www.osti.gov/biblio/6266875 (accessed on 24 April 2017).

- Crow, S.; Champagne, F. Orderly structure in jet turbulence. J. Fluid Mech. 1971, 48, 547–591. [Google Scholar] [CrossRef]

- Chahine, G.; Johnson, V. Mechanics and applications of self-resonating cavitating jets. Proc. Int. Symp. Jets Cav. ASME 1985, 15, 21–33. [Google Scholar]

- Li, G.; Shi, H.; Liao, H.; Shen, Z.; Niu, J.; Huang, Z.; Luo, H. Hydraulic pulsed cavitating jet-assisted drilling. Pet. Sci. Technol. 2009, 27, 197–207. [Google Scholar] [CrossRef]

- Li, G.; Shen, Z.; Zhou, C.; Zhang, D.; Chen, H. Investigation and application of self-resonating cavitating water jet in petroleum engineering. Pet. Sci. Technol. 2005, 23, 1–15. [Google Scholar]

- Ding, X.; Kang, Y.; Li, D.; Wang, X.; Zeng, D. Experimental Investigation on Surface Quality Processed by Self-Excited Oscillation Pulsed Waterjet Peening. Materials 2017, 10, 989. [Google Scholar] [CrossRef] [PubMed]

- Peng, K.; Tian, S.; Li, G.; Huang, Z.; Yang, R.; Guo, Z. Bubble dynamics characteristics and influencing factors on the cavitation collapse intensity for self-resonating cavitating jets. Pet. Explor. Dev. 2018, 45, 343–350. [Google Scholar] [CrossRef]

- Liu, W.; Kang, Y.; Zhang, M.; Zhou, Y.; Wang, X.; Li, D. Frequency Modulation and Erosion Performance of a Self-Resonating Jet. Appl. Sci. 2017, 7, 932. [Google Scholar]

- Fang, Z.; Kang, Y.; Wang, X.; Li, D.; Hu, Y.; Huang, M.; Wang, X. Numerical and experimental investigation on flow field characteristics of organ pipe nozzle. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Montreal, QC, Canada, 22–26 September 2014. [Google Scholar]

- Chahine, G.; Genoux, P. Collapse of a cavitating vortex ring. J. Fluid Eng. 1983, 105, 400–405. [Google Scholar] [CrossRef]

- Li, D.; Chen, Y.; Kang, Y.; Wang, Z.; Wang, X.; Fan, Q.; Yuan, M. Experimental investigation of the preferred Strouhal number used in self-resonating pulsed waterjet. J. Mech. Sci. Technol. 2018, 32, 4223–4229. [Google Scholar] [CrossRef]

- Li, D.; Li, X.; Kang, Y.; Wang, X.; Long, X.; Wu, S. Experimental investigation on the influence of internal surface roughness of organ pipe nozzle on the characteristics of high pressure jet. J. Mech. Eng. 2015, 51, 169–176. (In Chinese) [Google Scholar] [CrossRef]

- Li, D.; Kang, Y.; Ding, X.; Wang, X.; Fang, Z. Effects of Nozzle Inner Surface Roughness on the Performance of Self-Resonating Cavitating Waterjets under Different Ambient Pressures. Stroj. Vestn. J. Mech. Eng. 2017, 63, 92–102. [Google Scholar] [CrossRef]

- Li, D.; Kang, Y.; Ding, X.; Liu, W. Experimental study on the effects of feeding pipe diameter on the cavitation erosion performance of self-resonating cavitating waterjet. Exp. Therm. Fluid Sci. 2017, 82, 314–325. [Google Scholar] [CrossRef]

- Li, D.; Kang, Y.; Ding, X.; Wang, X.; Fang, Z. An experimental investigation on the pressure characteristics of high speed self-resonating pulsed waterjets influenced by feeding pipe diameter. J. Mech. Sci. Technol. 2016, 30, 4997–5007. [Google Scholar] [CrossRef]

- Li, D.; Kang, Y.; Ding, X.; Wang, X.; Fang, Z. Effects of area discontinuity at nozzle inlet on the characteristics of self-resonating cavitating waterjet. Chin. J. Mech. Eng. 2016, 29, 813–824. [Google Scholar] [CrossRef]

- Li, D.; Kang, Y.; Ding, X.; Liu, W. Effects of the geometry of impinging surface on the pressure oscillations of self-resonating pulsed waterjet. Adv. Mech. Eng. 2017, 9, 1687814017720081. [Google Scholar] [CrossRef]

- Li, D.; Kang, Y.; Wang, X.; Ding, X.; Fang, Z. Effects of nozzle inner surface roughness on the cavitation erosion characteristics of high speed submerged jets. Exp. Therm. Fluid Sci. 2016, 74, 444–452. [Google Scholar] [CrossRef]

- Li, D.; Kang, Y.; Ding, X.; Wang, X.; Fang, Z. Effects of area discontinuity at nozzle inlet on the characteristics of high speed self-excited oscillation pulsed waterjets. Exp. Therm. Fluid Sci. 2016, 79, 254–265. [Google Scholar] [CrossRef]

- Li, D.; Kang, Y.; Ding, X.; Wang, X.; Liu, W. Effects of feeding pipe diameter on the performance of a jet-driven Helmholtz oscillator generating pulsed waterjets. J. Mech. Sci. Technol. 2017, 31, 1203–1212. [Google Scholar] [CrossRef]

- Qu, Y.; Chen, S. Orthogonal experimental research on the structural parameters of a self-excited pulsed cavitation nozzle. Eur. J. Mech.-B/Fluid 2017, 65, 179–183. [Google Scholar] [CrossRef]

- Arthurs, D.; Ziada, S. Effect of nozzle thickness on the self-excited impinging planar jet. J. Fluid Struct. 2014, 44, 1–16. [Google Scholar] [CrossRef]

- Fan, J.; Wang, Z.; Chen, S. Self-excited oscillation frequency characteristics of a paralleled pulsed jet nozzle. Energy Proced. 2017, 141, 619–624. [Google Scholar]

- Wang, X.; Kang, Y.; Zhang, M.; Yuan, M.; Li, D. The Effects of the Downstream Contraction Ratio of Organ-Pipe Nozzle on the Pressure Oscillations of Self-Resonating Waterjets. Energies 2018, 11, 3137. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).