1. Introduction

The demand is increasing for Mini-Gliders that weigh less than 1 kg, are small in size and can also communicate with each other in order to achieve desired functionality while also being reliable, having low power usage and low cost [

1,

2]. In aviation, there are specialized systems that are capable of conducting field surveys by carrying multiple air vehicles such as rockets and dropping them on the target locations [

3,

4,

5,

6]. For such specialized systems, reducing the weight and size while also deploying the maximum amount of payload is crucial. Accordingly, selecting the suitable materials for the glider and finding the design parameters allow multiple gliders to be transported at the same time. For this reason, different methods such as wing-folding mechanisms have been successfully applied to reduce the volume of miniature air-vehicles in the former designs [

7,

8,

9,

10].

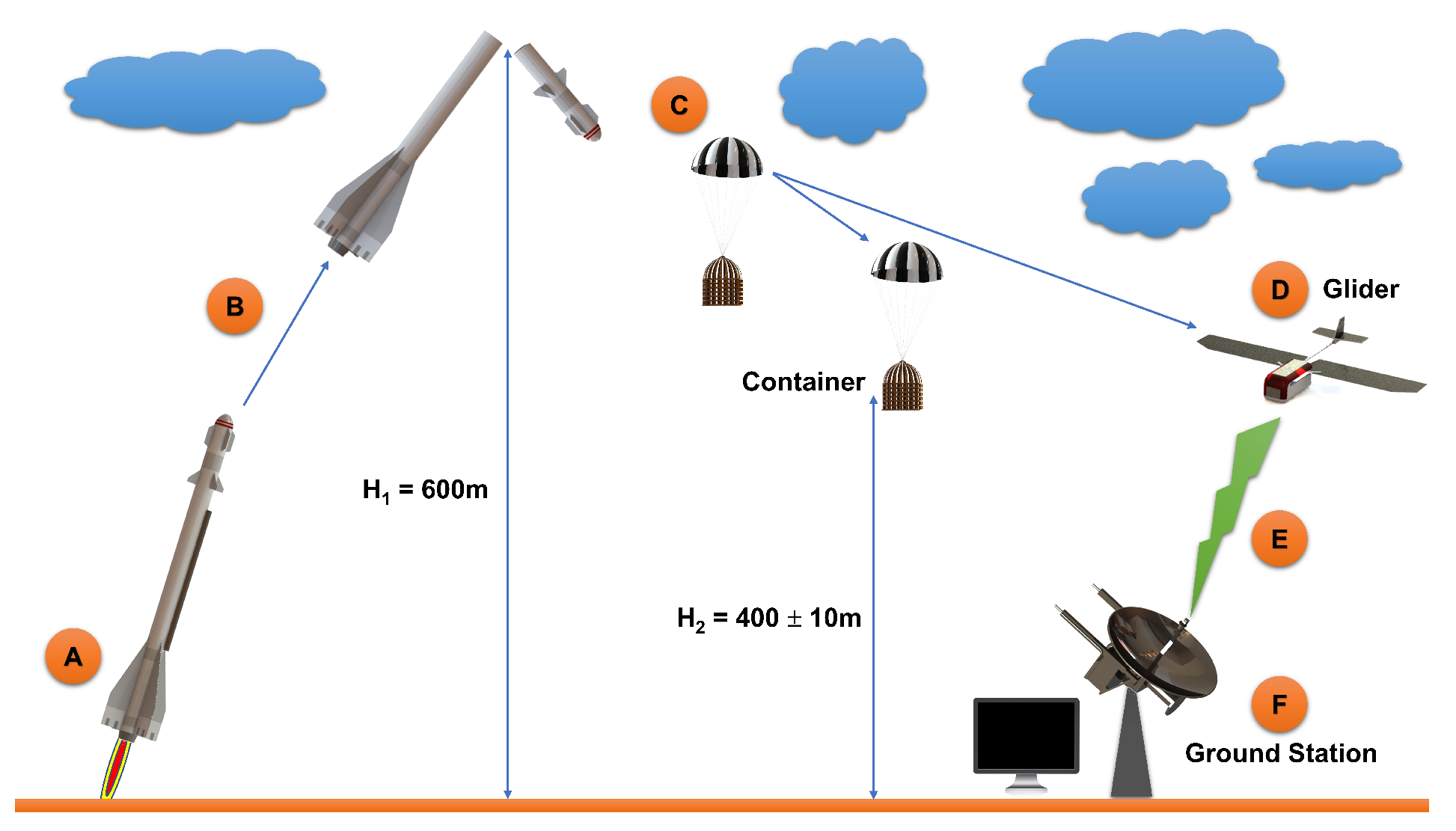

The international CanSat competition is a design–build–launch competition. The concept is somehow identical to a typical gun-launched air-vehicle system [

11]. The air-vehicles are required to meet predefined volume restrictions of a container that is built in a rocket launcher. The wing-folding structure of the air-vehicle allows it to be contained in a small volume, and thus to be placed in a protective fixed-size container [

12]. Recent research and industrial works related to gun-launched drones are principally focused on foldable fixed-wing configurations [

13,

14]. Our goal in this work is to ensure that the wing-folding mechanism is opened quickly and reliably immediately after separating from the rocket. It must fulfill its assigned tasks successfully according to the competition regulations [

15]. It is expected that the designed glider will descend from 400 m in helical orbit in around 120 s. For this purpose, the wing structure must have a fast deploying mechanism even in low air pressure and rough wind conditions and stabilize quickly.

There are many different wing models used in literature for fixed-wing aerial vehicles, and use of Eppler and National Advisory Committee for Aeronautics (NACA) type wing structures is relatively more common [

8,

16]. The Eppler-793 type wing structure appears to be fit for mini-gliders and speed-critical applications, where thickness, camber, and

(efficiency) ratio are crucial. Since the maximum

thickness ratio is in the 12–16% band, 2–5% camber is the best choice for desired operational speed [

17]. Eppler wing structure allows easy assembly and easy folding by virtue of not being excessively cambered. The other selection criteria to choose an Eppler wing is to have more linear behavior in the desired (previously found via simulations) alpha operational range AoA (angle of attack). In order to gather information about the atmosphere, there are fixed-wing and larger-sized heavier systems [

18] or measurements with different approaches [

19,

20] instead of foldable wing systems. As a matter of fact, in many control applications, in order to find an optimal solution for a stable glider flight, Proportional-Integral-Derivative (PID), Adaptive and Neural network are widely used. Our glider mechanism does not have any motors attached to it; therefore, the phugoid flight mode is a necessity [

21].

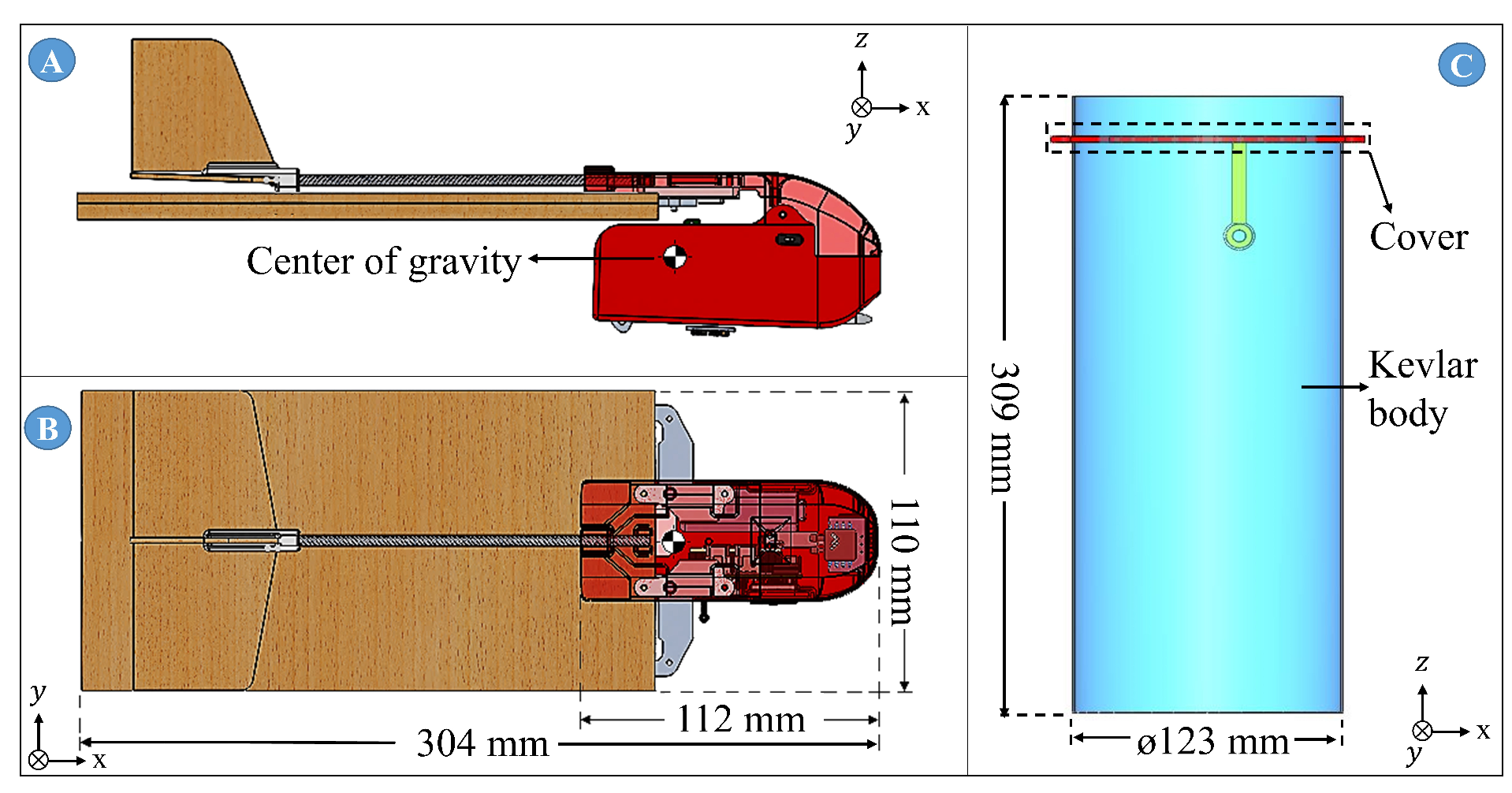

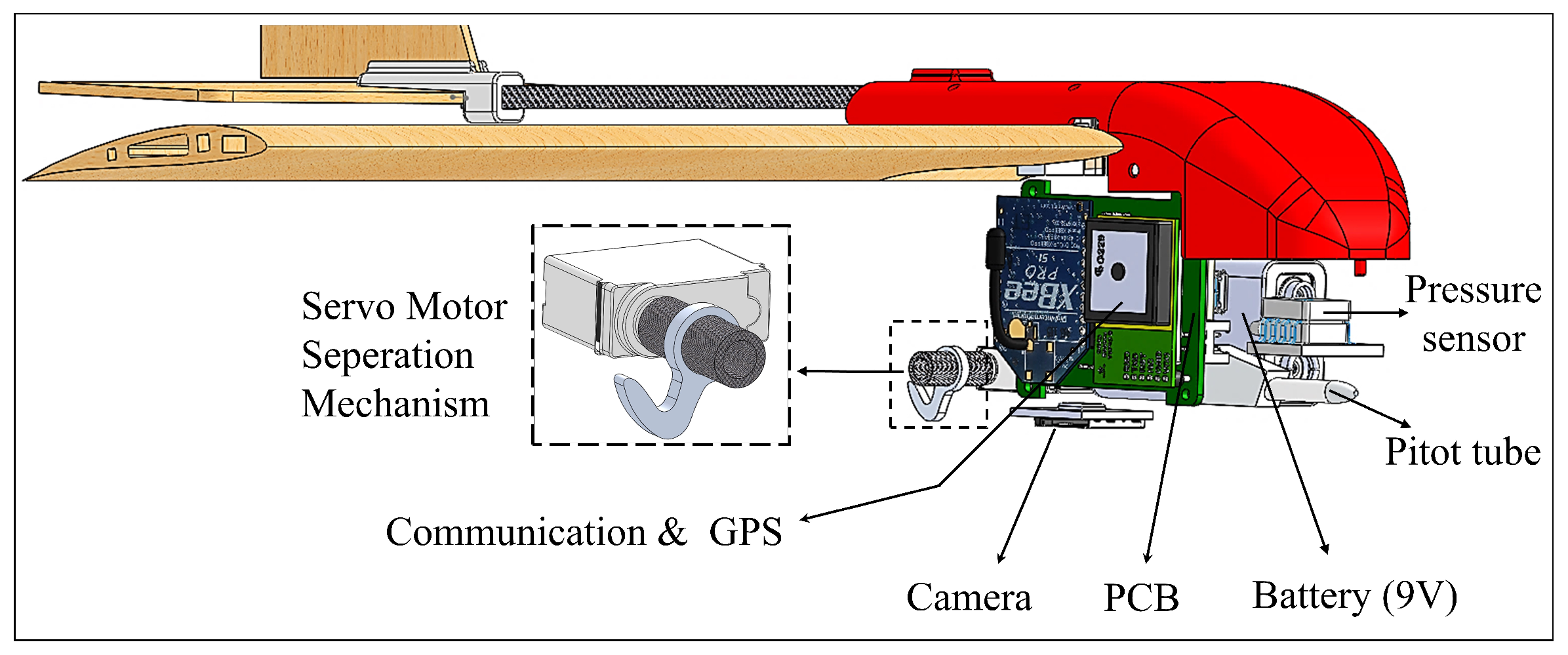

To achieve passive mechanical control, our aim is to combine all electronic equipment such as telemetry devices, communication devices, and sensors into a small PCB (Printed Circuit Board) while maintaining a light and compact design. According to research on related topics, our glider’s

is higher at the same mass while also being smaller [

19], and the wing-folding mechanism is also faster [

9]. Moreover, there are designs whose stowed configurations are better than our glider and occupy %75 less volume and %75 less width than their deployed form. However, our primary aim is not a only wing-folding mechanism; our designed glider, which is able to land in a controlled manner via phugoid mode, can also collect data during its descent. For different approaches in literature, although the same mechanical equipment is used, we can see that sensor data retrieval experiences mishaps during the launch process [

8,

9]. With this method, the amount of energy needed will be kept at a minimum, resulting in a light and compact structure. There are different autonomous studies that perform sudden dive to the target point [

22]. It is observed that the success at higher wind speeds (>3 m/s) and the pitch error (avg 33.29

) are considerably high, although diving with an average error of 1 m to the desired point is carried out with low altitude release (30–40 m). Although it can dive to the target point from a lower altitude than our study, autonomous separation and wing-folding mechanism have been not mentioned. In addition, despite having an open loop controller, the pitch error is quite high. There are also works related to the folding of the wings [

23]. Wing deploying and folding times, efficiency and stress analyses are not given and no real test results are available.

This work is a mini-glider that can be autonomously separated at a certain height and autonomously open its wings. To the best of our knowledge, the speed optimization of the wing-unfolding and mechanical analysis regarding its unfolding speed have never been studied. Moreover, as a contribution to literature, passive glider design and implementation under certain limitations are given with application details. What should be considered in a lightweight (<1 kg) of a glider and firm foldable structure of wings are reported. Such a work, which has a mechatronics approach, can influence other works done in miniature level in future. It is worth mentioning that this mini-glider design is not just for a competition, but also for use in the other areas by further improving the design. Some possible areas in which the designed can be implemented into are as follows: transportation of medical and surgery supplies, exploration of chemical and radioactive areas, search and rescue operations, communication systems, and agriculture. With its lightweight design and low power consumption, the glider can obtain relevant flight data from all sensors. Thus, aerodynamically, a more successful design has been made.

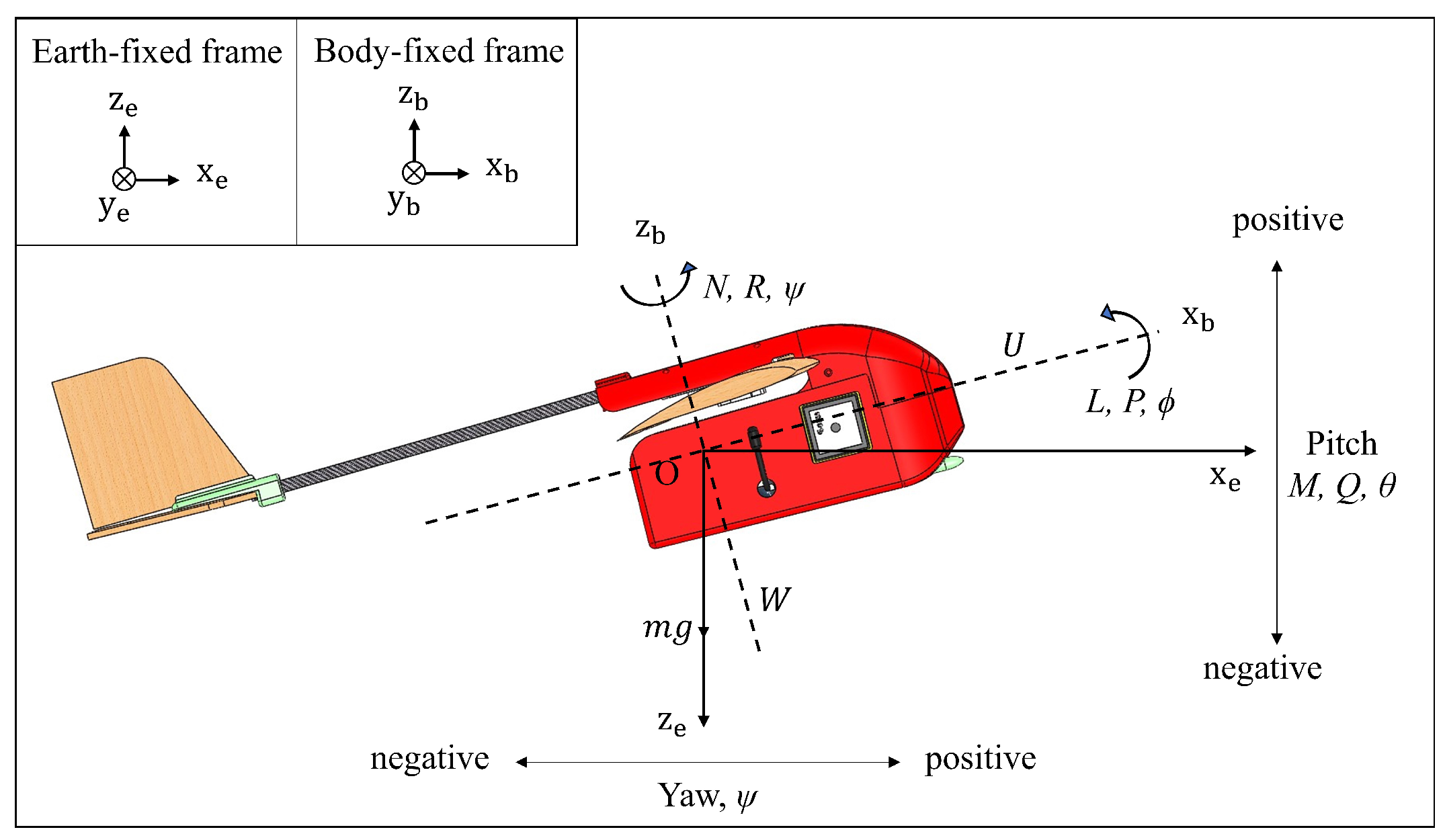

In our work, six-degree-of-freedom movement systems were first created and simulated in MATLAB/Simulink® (version R2015a, MathWorks Inc., Natick, MA, USA) Mechanical design and the analysis of the planer is made in the 3D Solidworks® (version 2015, Dassault Systèmes, Vélizy-Villacoublay, France) program. Electronic card design is made through the Proteus® (version 7.6, Labcenter Electronics Ltd., North Yorkshire, UK) program. While the ground station software required for communication structure is completed with Labview® and C♯ language, the microprocessor structure of the planner is made with Arduino IDE (version 1.6, Ivrea, Italy). In the second part of the work, measurement models used with satellite kinematic and dynamic equations are presented. In the third part, after the system analysis is made by COMSOL® (version 5.3, COMSOL Inc., Stockholm, Sweden) and the simulated studies, the fourth and last, the result section is discussed and evaluated.

3. Simulation and Analysis

In this section, simulation studies are described for the glider whose design is completed according to the rules and theoretical calculations based on the developed mathematical model. According to the parameters that are determined by theoretical calculations, the dynamic behavior of the glider is repeated in the simulation environment. The analysis should be performed by using authentic equipment with their properties to see more realistic behaviour in the design model to further improve the glider design after simulation. The location of center of gravity, horizontal and vertical stabilizers’ size estimation, determining

to provide maximum lift, and so forth are obtained in the previous section. The simulation’s aim is to compare parametric verification of the results with the theoretical calculations. Firstly, there are five different natural modes to determine stability of an aircraft which are related with two longitudinal and three lateral axes should be investigated. They are phugoid mode and short period mode for longitudinal and the spiral mode, the roll damping mode and the dutch roll mode for the lateral axis. Short period mode eigenvalues are

and phugoid mode eigenvalues are

. All the roots are on the negative side of the Alpha axis. In this case, it represents that all the roots of the system are stable. For the roots with smaller values of the imaginary axis (beta), the damping ratio is lower. In such a case of phugoid oscillations, the change between kinetic energy (speed) and potential energy (height) is very slow, so that the glider can return to its horizontal flight position again. Phugoid mode response can be given in the form (Equation (

36)) for

and

,

where damping ratio is

and natural frequency is

. In the case of phugoid mode, the glider dynamic response according to the step input is

and

Hz. Stability and control coefficients are determined and showed that the glider can fly steadily depending on the eigenvalues.

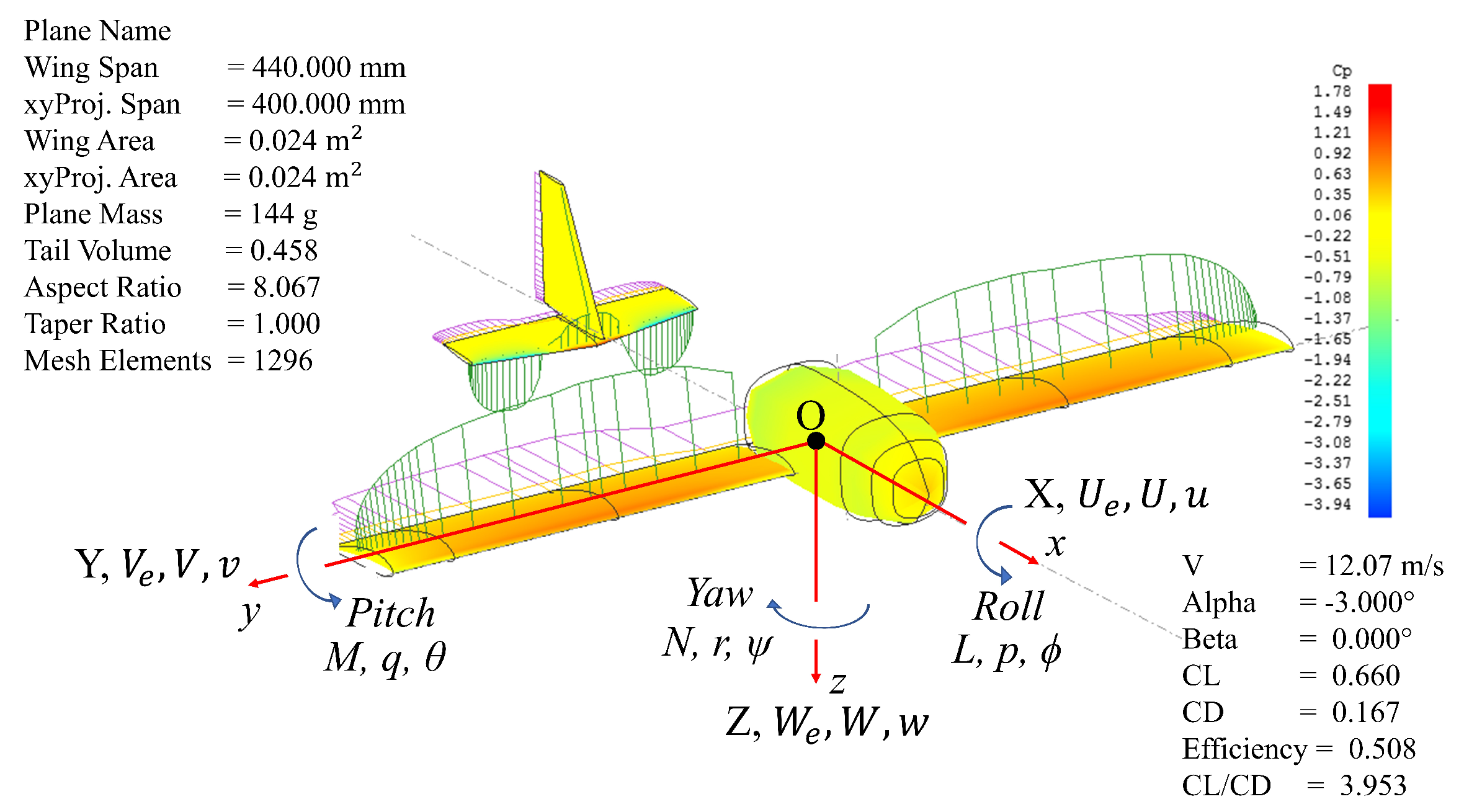

In addition, to obtain aerodynamic behaviour of the system, XFLR5

® is preferred since it has a more realistic approach through using VLM. To determine aerodynamic coefficients and efficiency, the range is selected from

to

and

to

in

Figure 5. In this figure, the pressure points on the glider’s wing can be seen with an orange-red colour. The pressure coefficient

varies between 0.66–1.11, which determines stability and axial moments, and it is more likely to be on the leading edge. Lift coefficient

, which is greater than

, which is mentioned in

Section 2.1.

Table 2 is found when the speed of glider is

(m/s) and AoA

. The pitching moment of the glider is determined as zero when AoA is selected as

.

graph shows that, mathematically, the design is stable if it has a negative gradient.

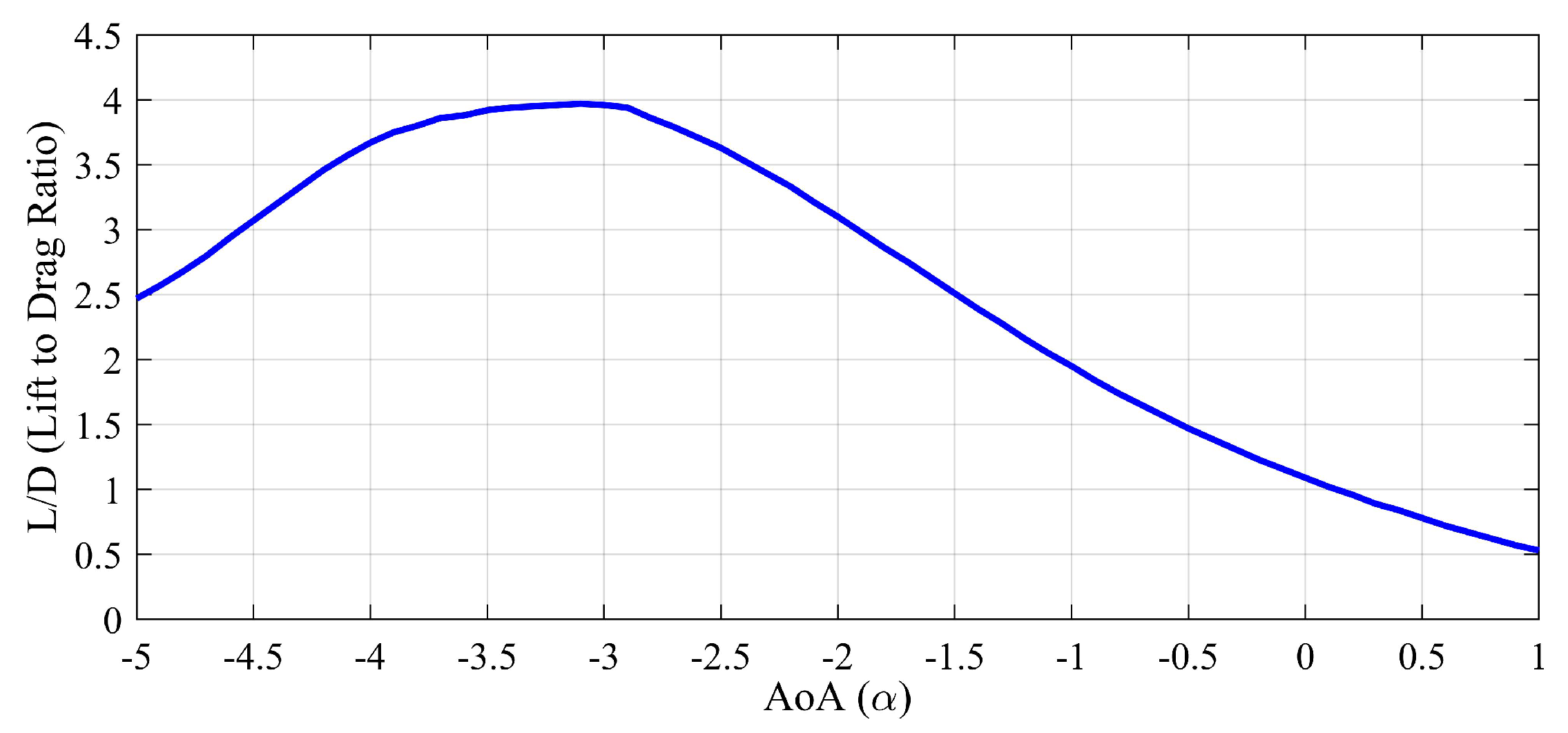

Furthermore, it is crucial to determine the lift to drag

ratio since a higher

is typically one of the major goals in aircraft design. Here,

is calculated as

. Accordingly, it has been observed that the glider can produce the lifting force greater than its own weight [

30]. In

Figure 6, lift to drag ratio with respect to AoA is presented. A Gaussian curve characteristic can be observed based on XLFR5 results, as expected. The AoA at the point where

is taken since it gives the maximum ratio of L/D.

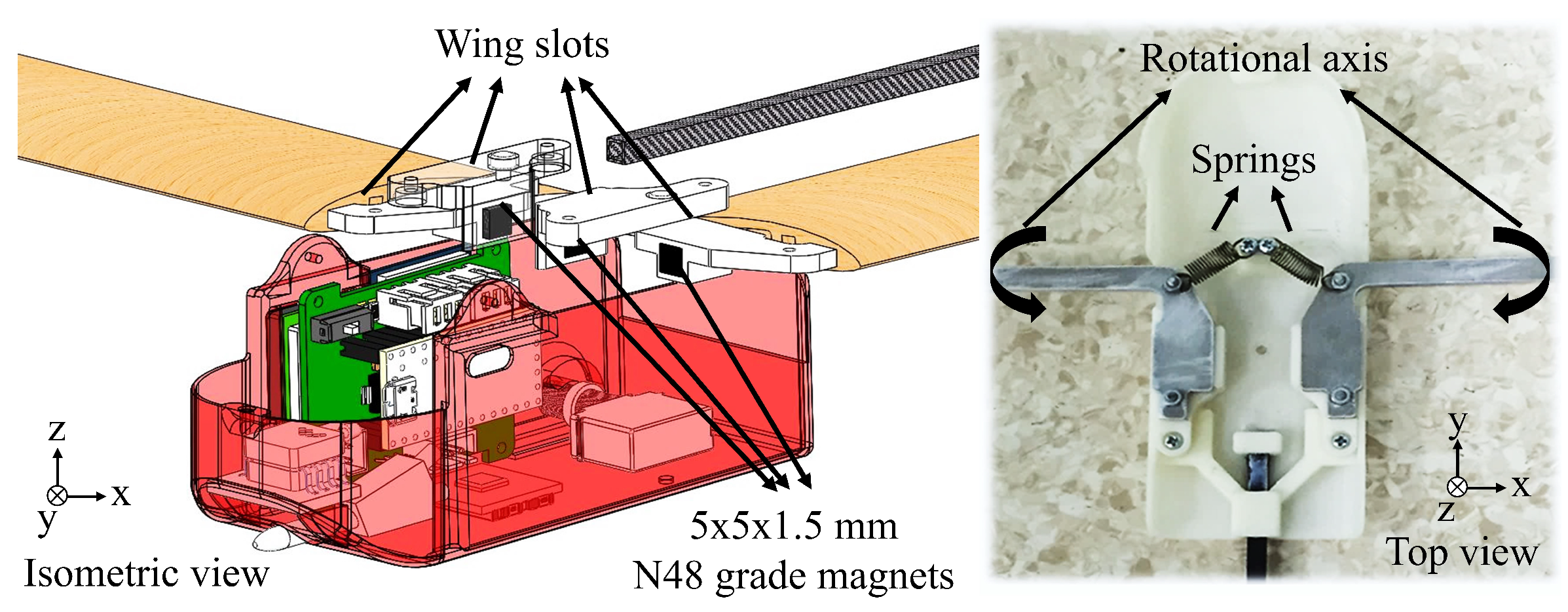

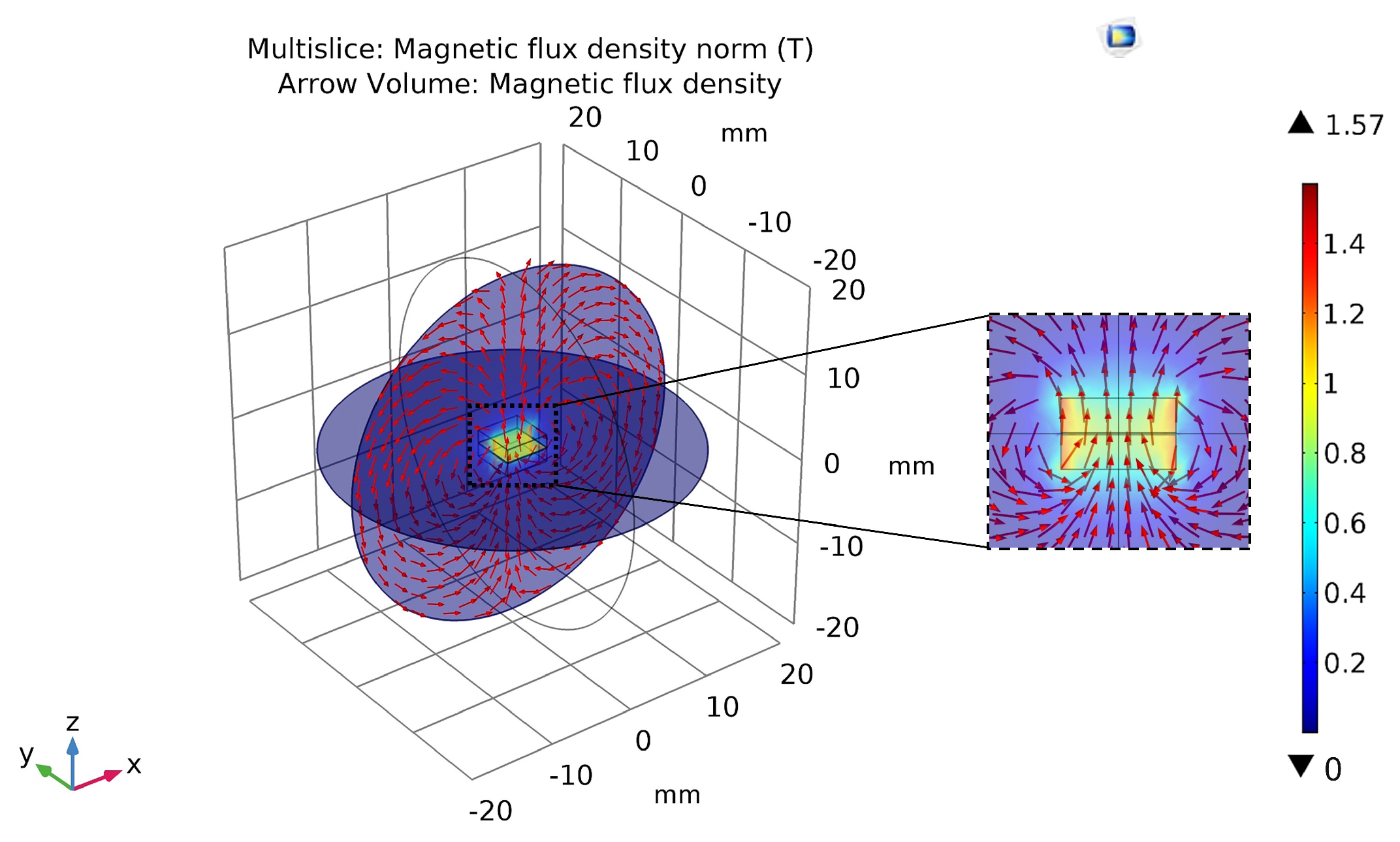

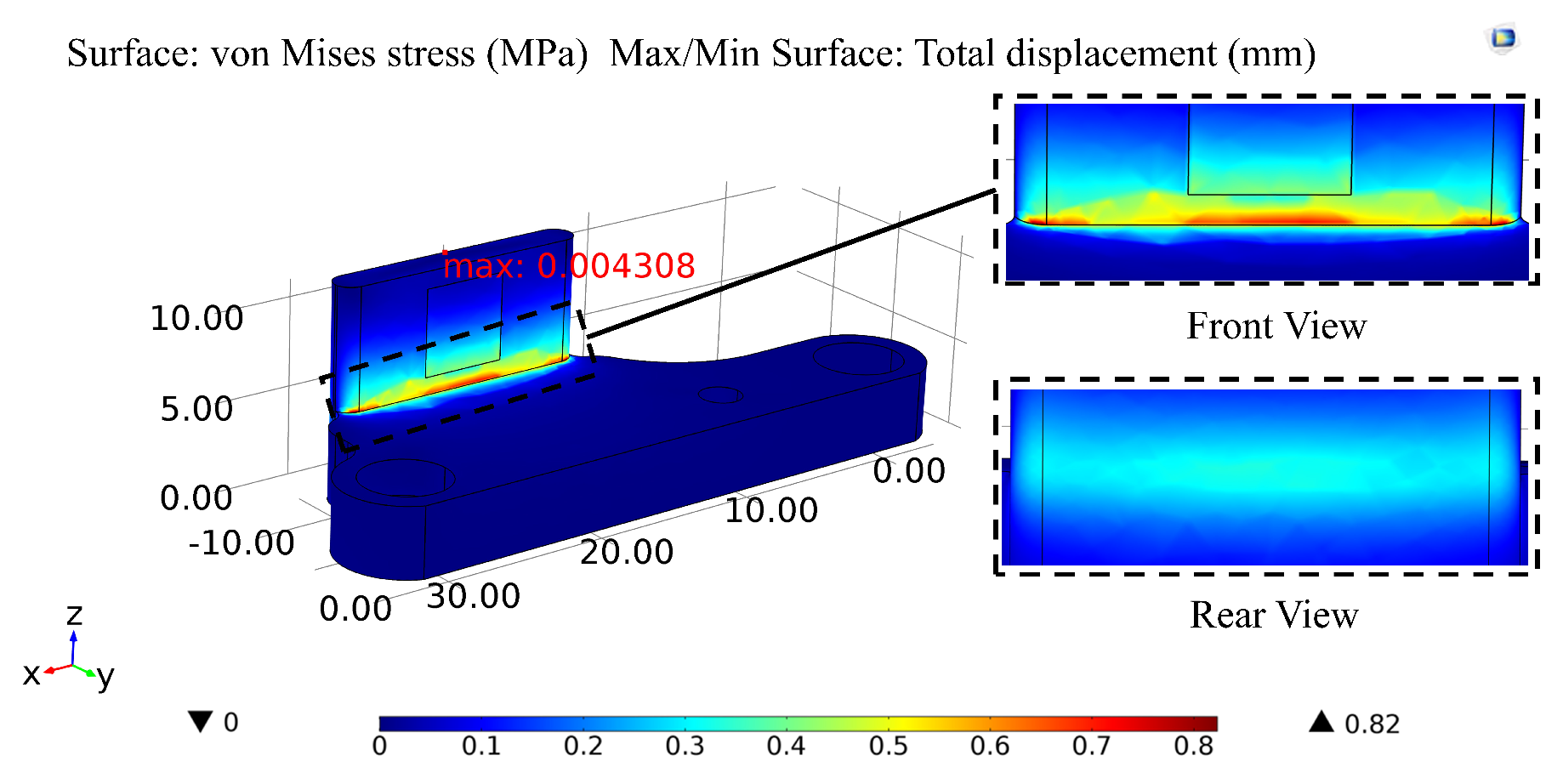

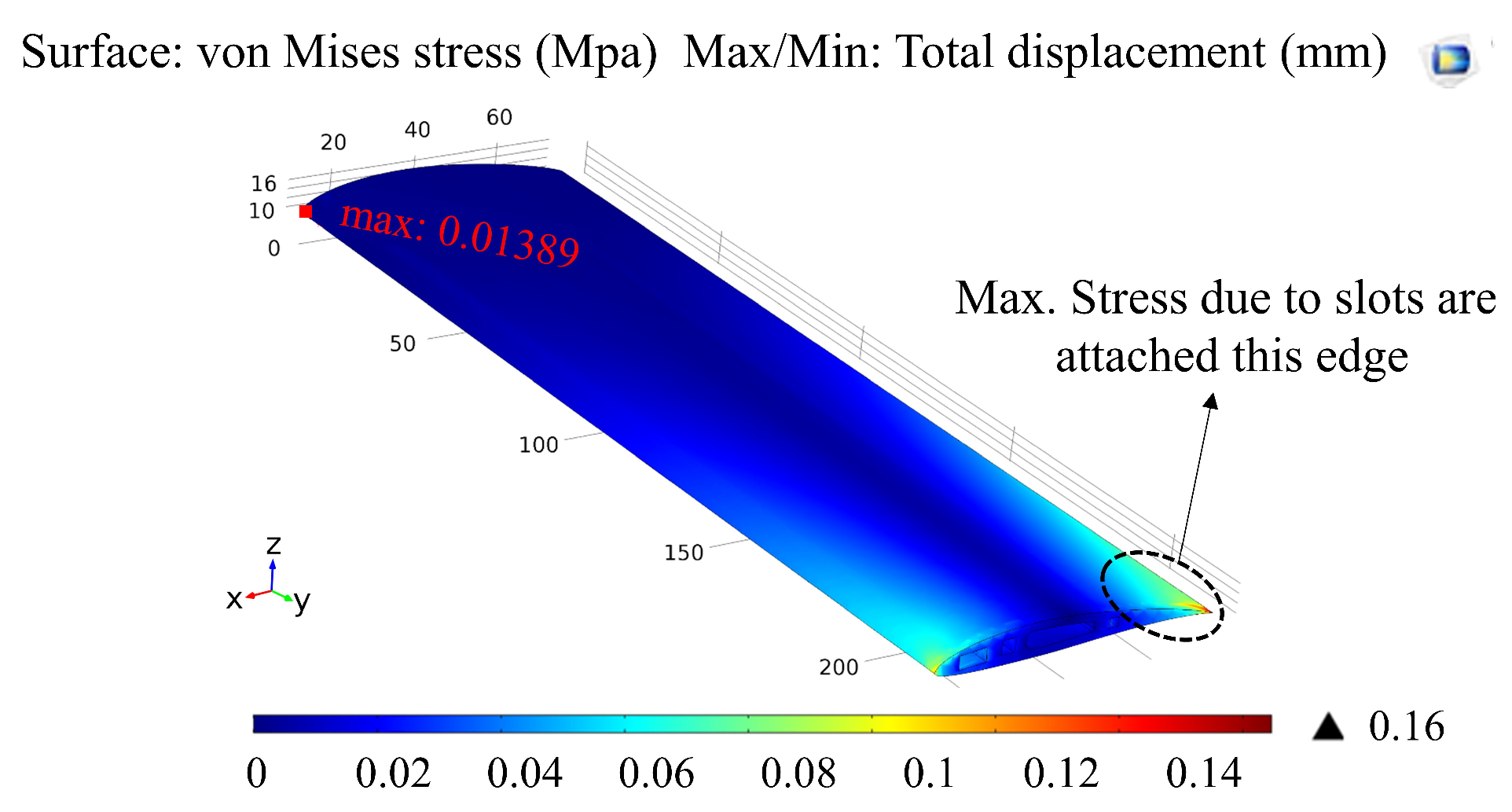

Aerodynamic coefficients match in both theoretical and simulation results. This is followed by the wing folding mechanism during separation of the glider from the container. Most folding theories are concerned with either speed of a stowed mechanism or its effect on the lift force. However, the strength of the wings and the folding mechanism should not be neglected. Deployment of the glider needs just a simple action from the user, since basic components are used, which are springs and magnets that are shown in

Figure 7. In this figure, wing slots and magnets are represented in isometric view and springs can be seen in the top view of the glider. In our first configuration, only a spring is used in the wing folding mechanism.

Folding mechanism and glider sizes are affected by the miniaturization of core technologies. However, the endurance of miniature drones’ wings are questionable when they are exposed to maximum force [

7,

8,

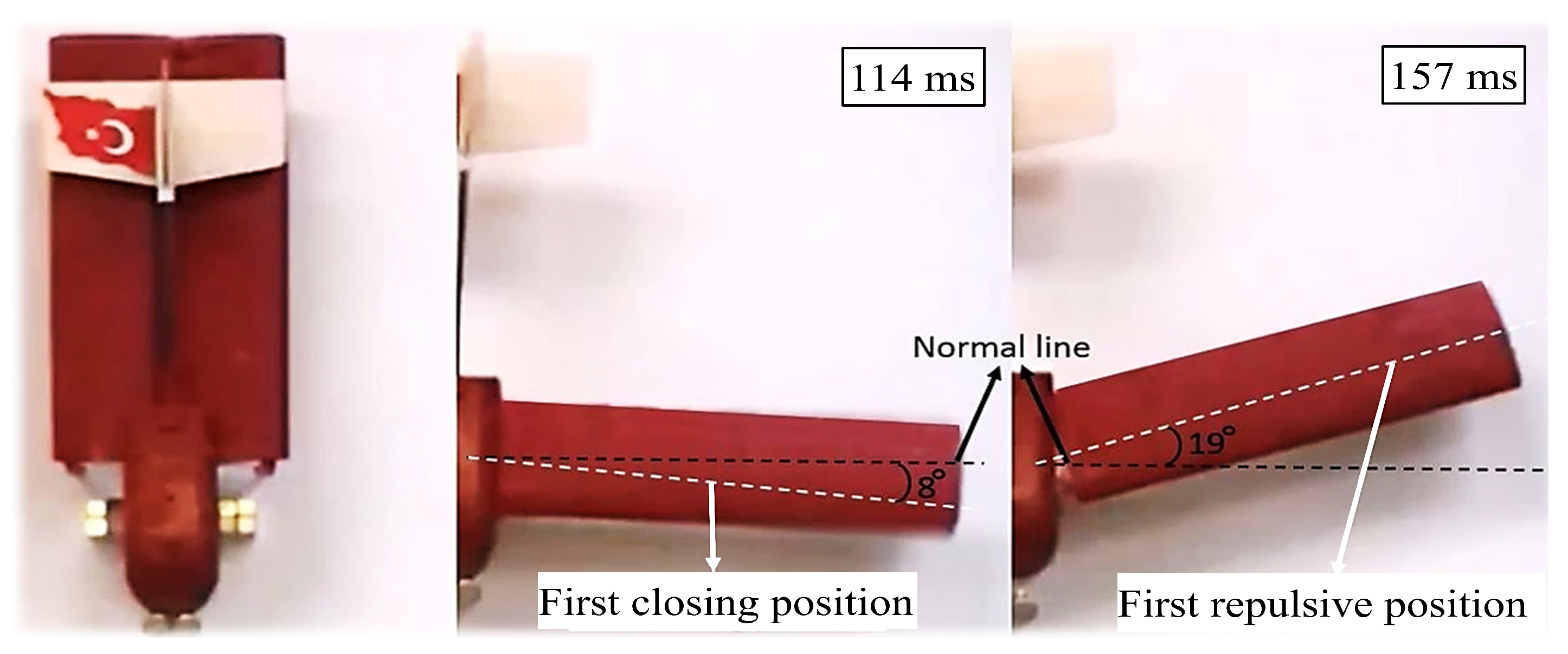

9]. The aim is to show that the wings are completely foldable even in unsuitable conditions. First, only a spring is used in the wing folding mechanism. This allows the mechanism to store potential energy. It would be desirable for the wing to be deployed parallel to the normal line, but the energy stored in the spring mechanism is designed to move the wing

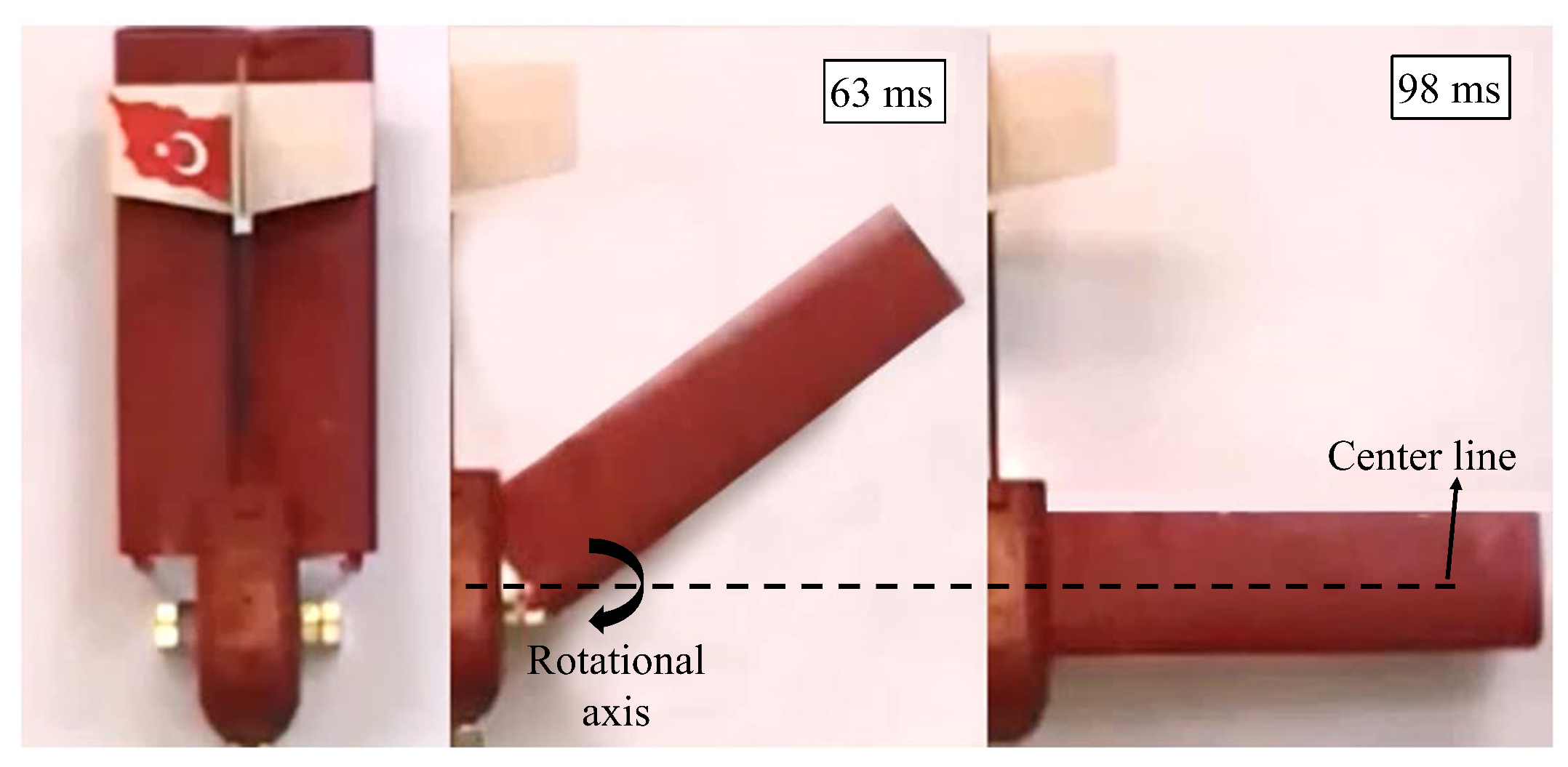

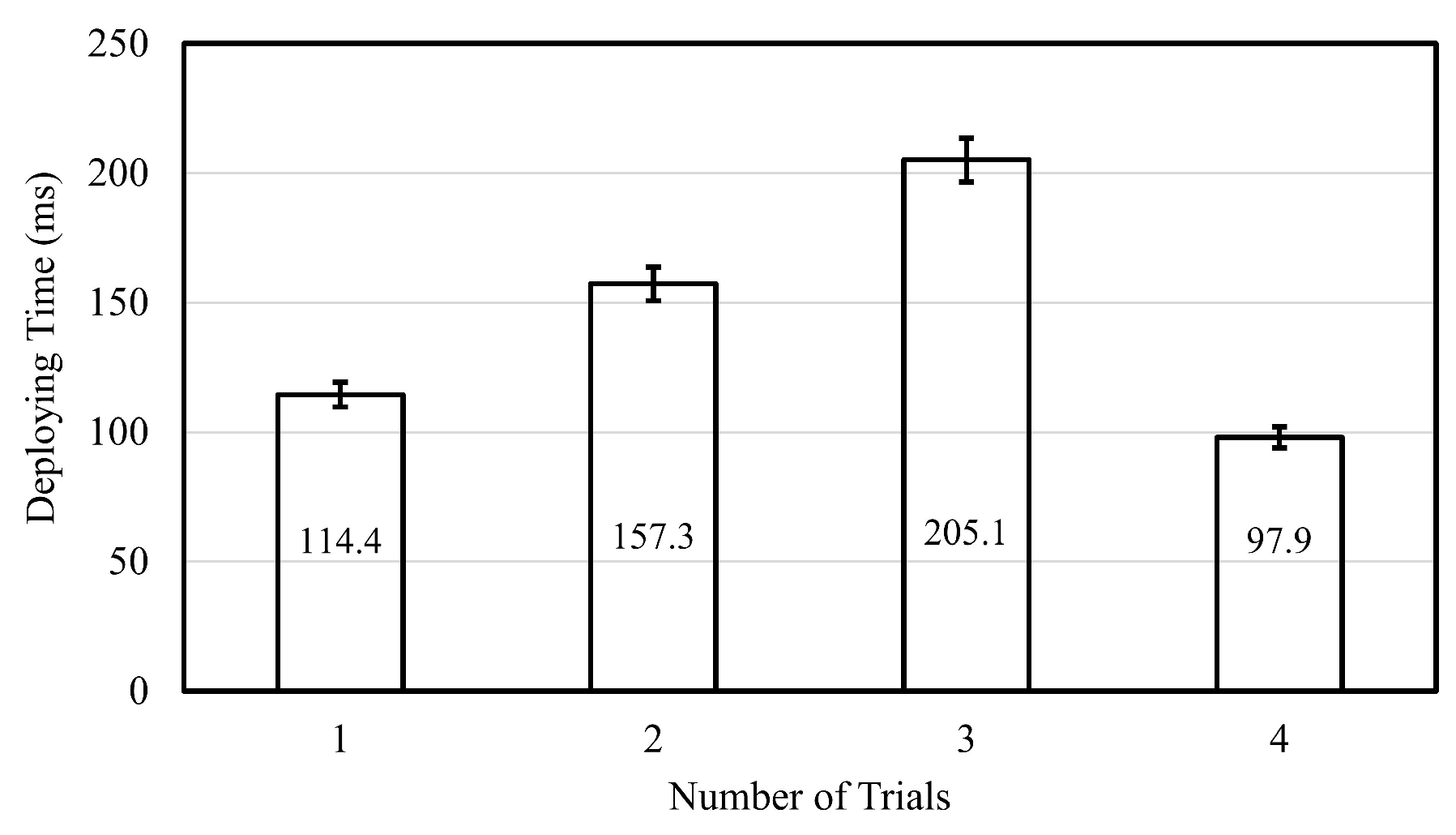

forwards in 114 ms in

Figure 8. However, after this movement of the wing, the wing moves back and falls short of the parallel wing position by 19

in 157 ms in an oscillating manner. When only a spring is used, it shows that the energy stored in the springs during the folding of the wings can not absorb the potential energy efficiently. For this reason, it was observed that the folding response of the wings has oscillations during their deployment and it is reported with the duration and angle.

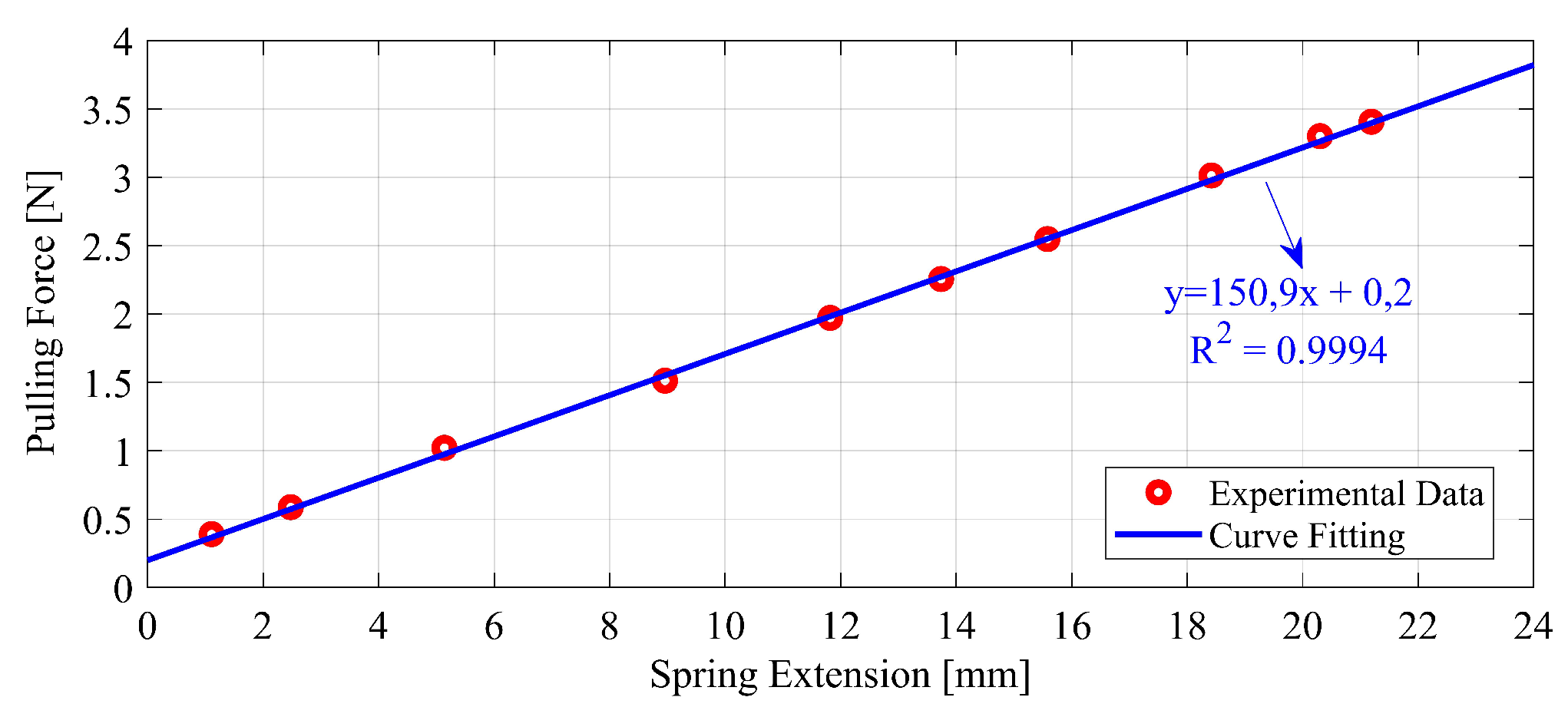

The recoil of

has to be damped with additional equipment on the glider. To find the damping force needed, spring coefficient, k, should be determined first to evaluate repulsive force. K can be obtained experimentally by measuring ten fixed different weights whose mass are determined with three decimal precision scales with 1 mg resolution. Experimental results of k are detailed in

Section 4. After that, neodymium magnets are used as a damping element and detailed in

Section 4 in the second configuration. All equipment is designed to be used to simulate flight trajectory in MATLAB SIMULINK

® by using equations that are mentioned in the mathematical modeling section. After finding all the necessary parameters and calculation results, the glider’s components’ mass can be expressed in

Table 4.

The system model could be done by designing the equipment the same as the results, including their mass. Glider force and moment stability could be achieved during 12 (m/s) flight speed and

. According to obtained speed and

;

x,

y, and

z positions of the glider, and the glide duration can be calculated. Glide duration and helical path can be controlled by two different control inputs that are elevator and rudder. The elevator, which is the aerodynamic control for pitch angle, can also affect efficient lift and AoA. It is positioned at the rear of the stabilizer that is attached to the fixed sections by hinges. Because the elevator can move, it varies the amount of force generated by the tail surface. The elevators work by changing the effective shape of the airfoil of the horizontal stabilizer. A helical path with a diameter of 85.03 m maximum could be maintained for 118.3 s until completion when the elevator

and rudder

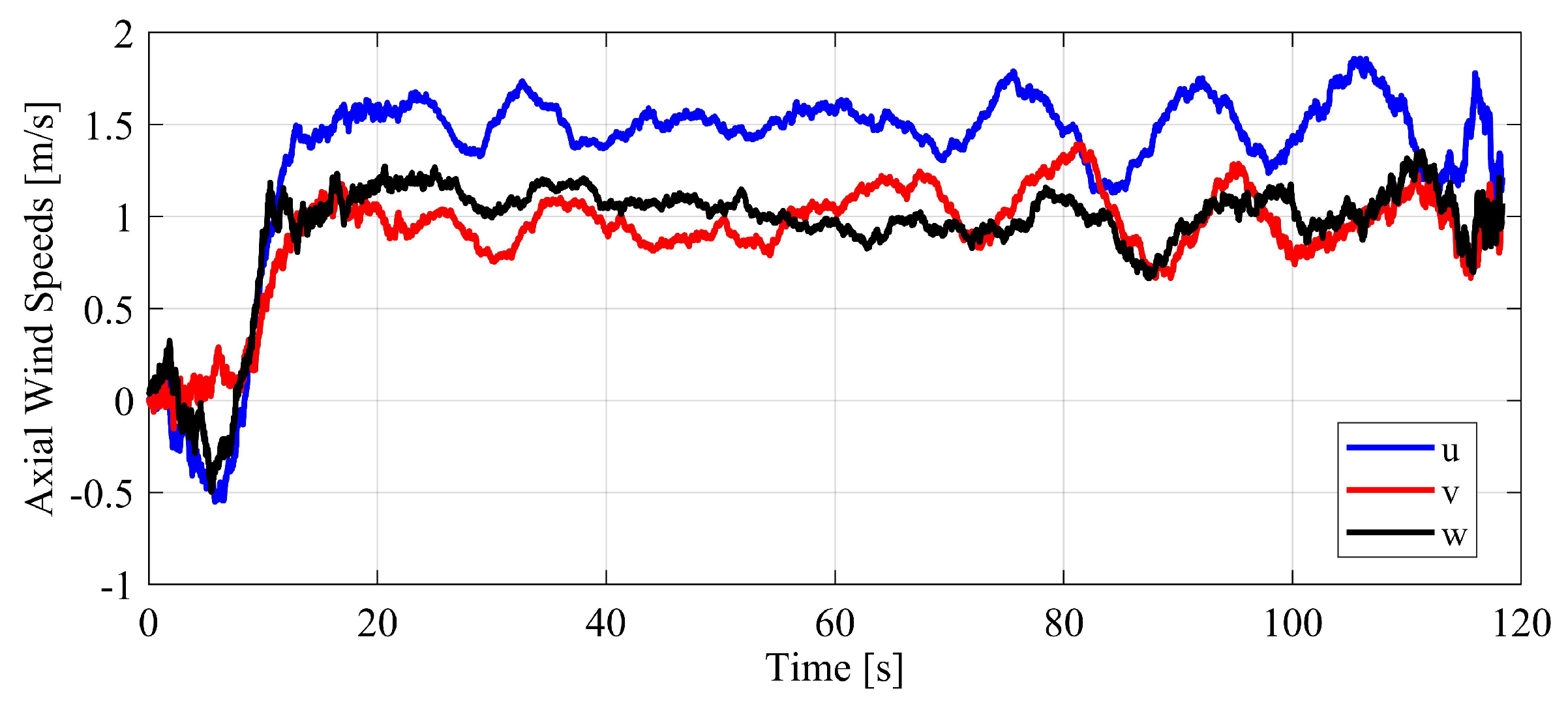

under axial wind disturbances. Atmospheric conditions and wind properties must be modeled due to the glider not being released in a controlled test environment. The wind pattern is set to be about 1.5 m/s for each axis. Wind speeds are denoted as

u,

v and

w, which are representing noise, and shown in the same axis set in

Figure 9. In this way, the glider is subjected to a more realistic test and the results are more accurate.

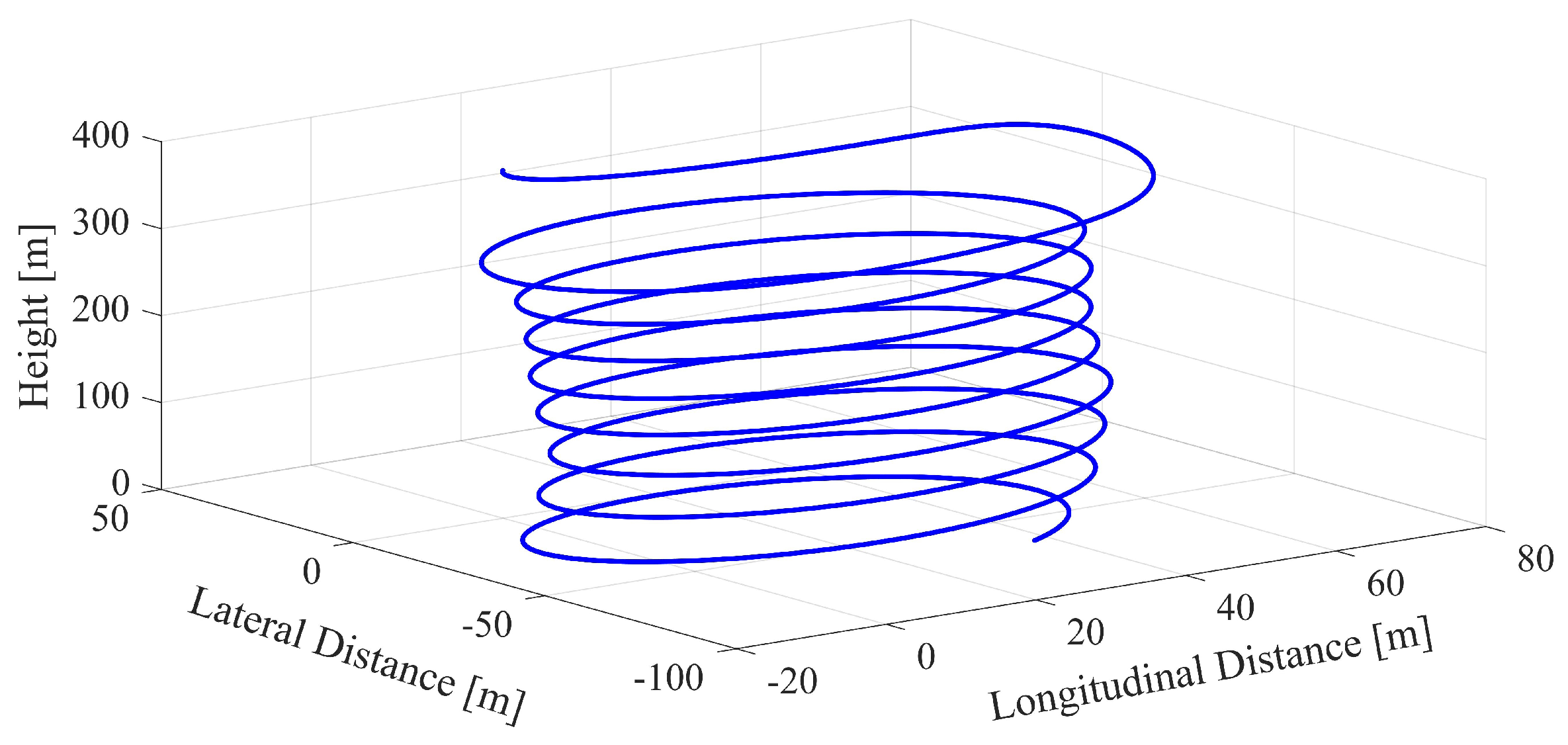

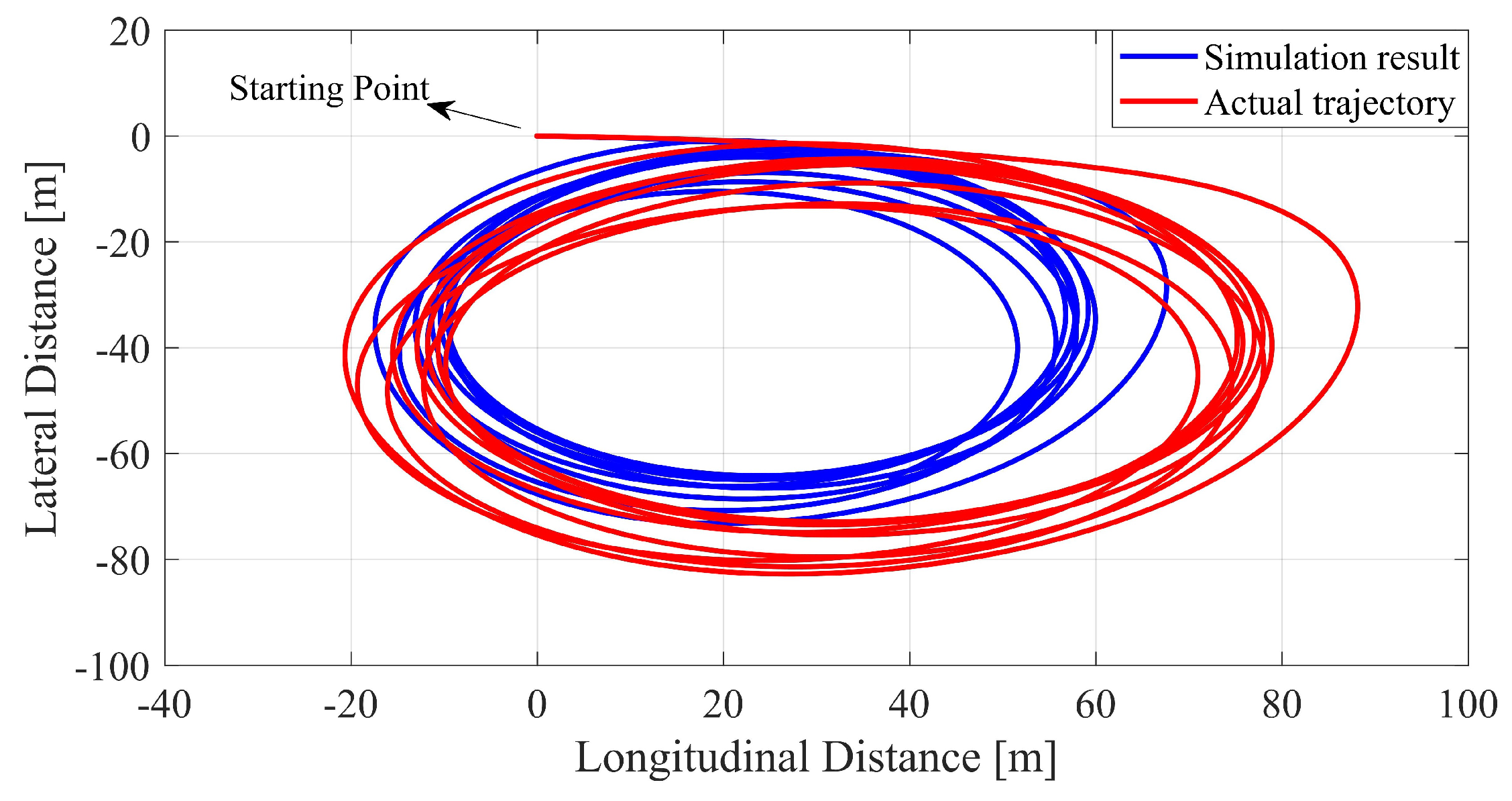

Under wind disturbances, a flight path can also be seen in

Figure 10. During descent, a 1.5 cycle, whose diameter is bigger than other helical cycles, could be seen at the beginning of the path due to the glider not reaching the speed limit, which is needed for the stability. However, when the glider is about 310 m in height, equal helixes are seen since the limit speed is reached. Moreover, the glider is separated from a container with initial speed 0 (m/s).

The graph of the helical path diameter derived from longitudinal distance and lateral distance with respect to time shows that the time required for stable flight is 23.7 s. As a result, the glider should be stable at about 310 m at 23.7 s. According to analysis and simulations in this section, it is shown that the wing-folding structure is safe and that the glider can fly and hover according to the rules.

5. Discussion

In this study, a foldable mini-glider design and implementation was described in detail while design constraints were defined based on CanSat competition rules. By mentioning the materials used in the design and the selection criteria, the glider’s mathematical model and system dynamics are presented. Flight limitations were also presented according to aerodynamic analyses, supported by design simulation results. A new method has been done and reported for more optimized operation by testing the wing deploying and folding times. Tests have been made for the reliability of the wing-folding mechanism, and a safe and easy to implement design has been done. Finally, experimental flight results were also reported to show a good match with theoretical results. Since the proposed glider has a passive flight structure and limited sensor capability due to regulations of CanSat Competition, the simulation parameters were verified by using actual experimental results via required path-following in the desired circular diameter and flight time.

Accordingly, as a contribution to the literature, an unmanned glider designed under certain rules and constraints is described. It has been shown what should be considered in a lightweight and foldable design of a glider. The lightweight glider was designed to have a higher and a lower coefficient than similar studies. According to similar studies of the same size, there was no problem in transmitting data from the sensors even when it is inside of the rocket, in the container or outside the container. The wing-folding of the glider was realized by a completely passive-autonomous mechanical mechanism and fulfilled the desired objectives without any initial condition at low altitude. The designed glider can receive telemetry data and also allows flight information to be sent to the ground station. With its lightweight design and low power consumption, the glider can obtain relevant flight data from all sensors. Thus, aerodynamically, a more successful design has been made.

In the experiments, the wings were opened successfully when glider separation from the container. If there is a delay or failure during wing deployment, the glider would not be able to fly in co-helical orbits and land. For this reason, a specialized wing-folding mechanism was presented. Simple equipments (springs-magnets) were utilized based on offered mechanism. It was also seen that it gave faster opening results compared to similar designs of the same size of folding mechanism. The deployment speed of the wings was tested with repetitive experiments (25 times) for the two different wing-folding configurations. Deployment duration was recorded by high speed camera and the strength of the mechanism was also reported.

The oscillation caused by the momentum generated during the opening and closing of the wings has also been examined. The results were shown by the analysis, and the experimental setups in which a mechanism with fast and reliable opening of the wings were obtained. Lastly, more stable flight is shown in experimental studies than in similar examples of glider without any motor and active controller. It has been observed that a successful phugoid motion has been captured. In this mode, a continuously descending flight orbit was observed. The glider system successfully opened its wings when it left the container, just like in the test results, and successfully completed the competition goals.