An Experimental Technology of Drying and Clean Combustion of Biomass Residues

Abstract

1. Introduction

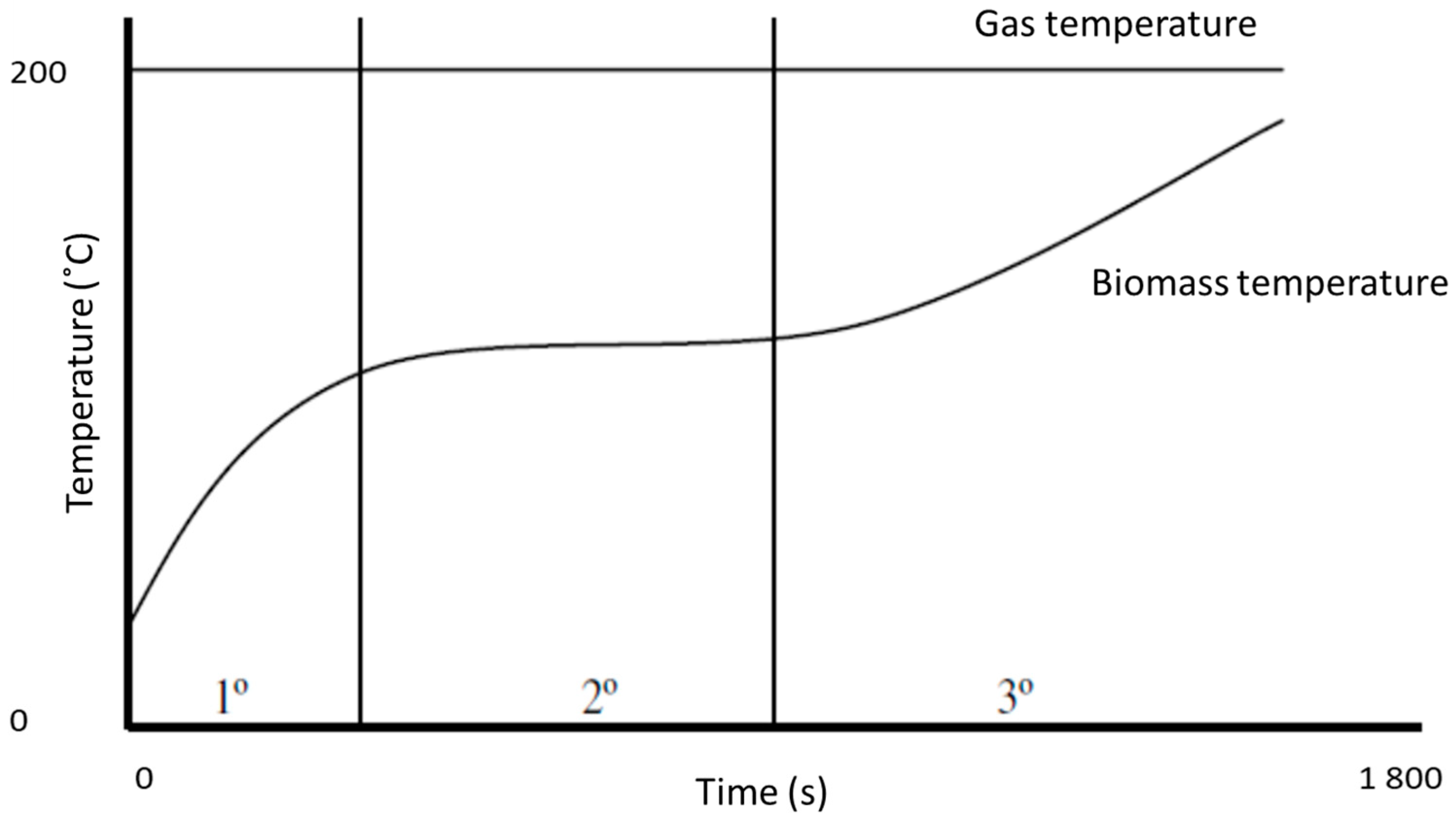

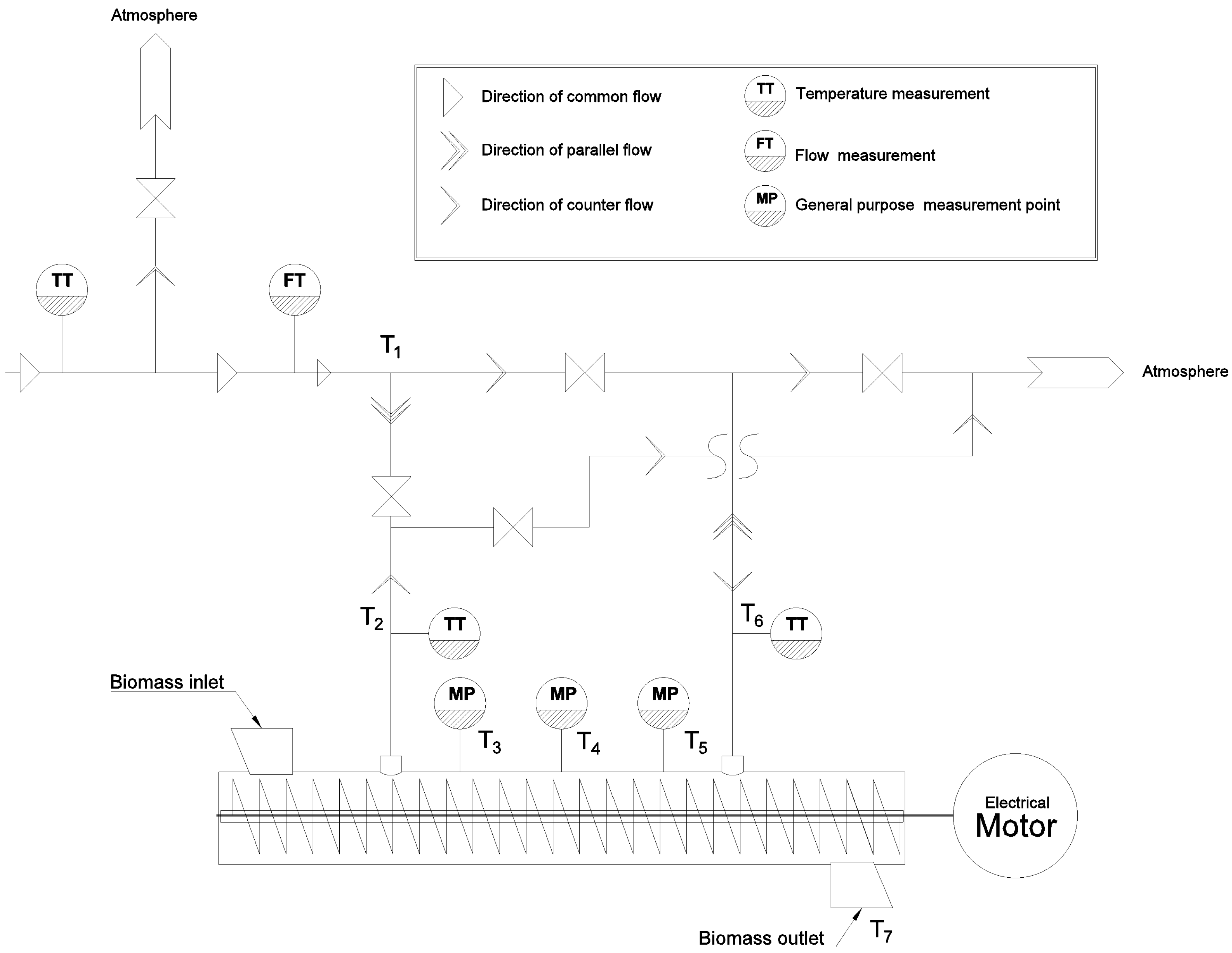

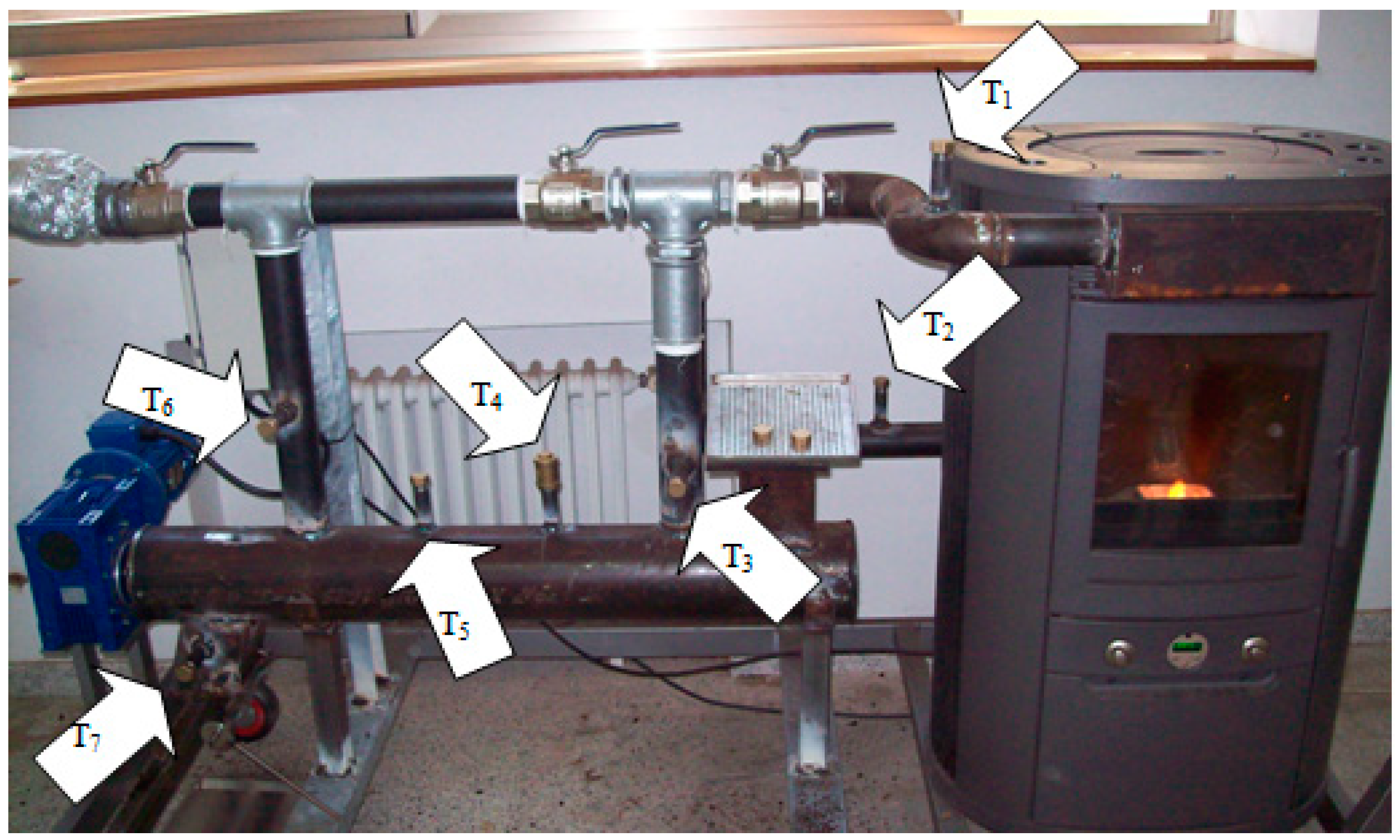

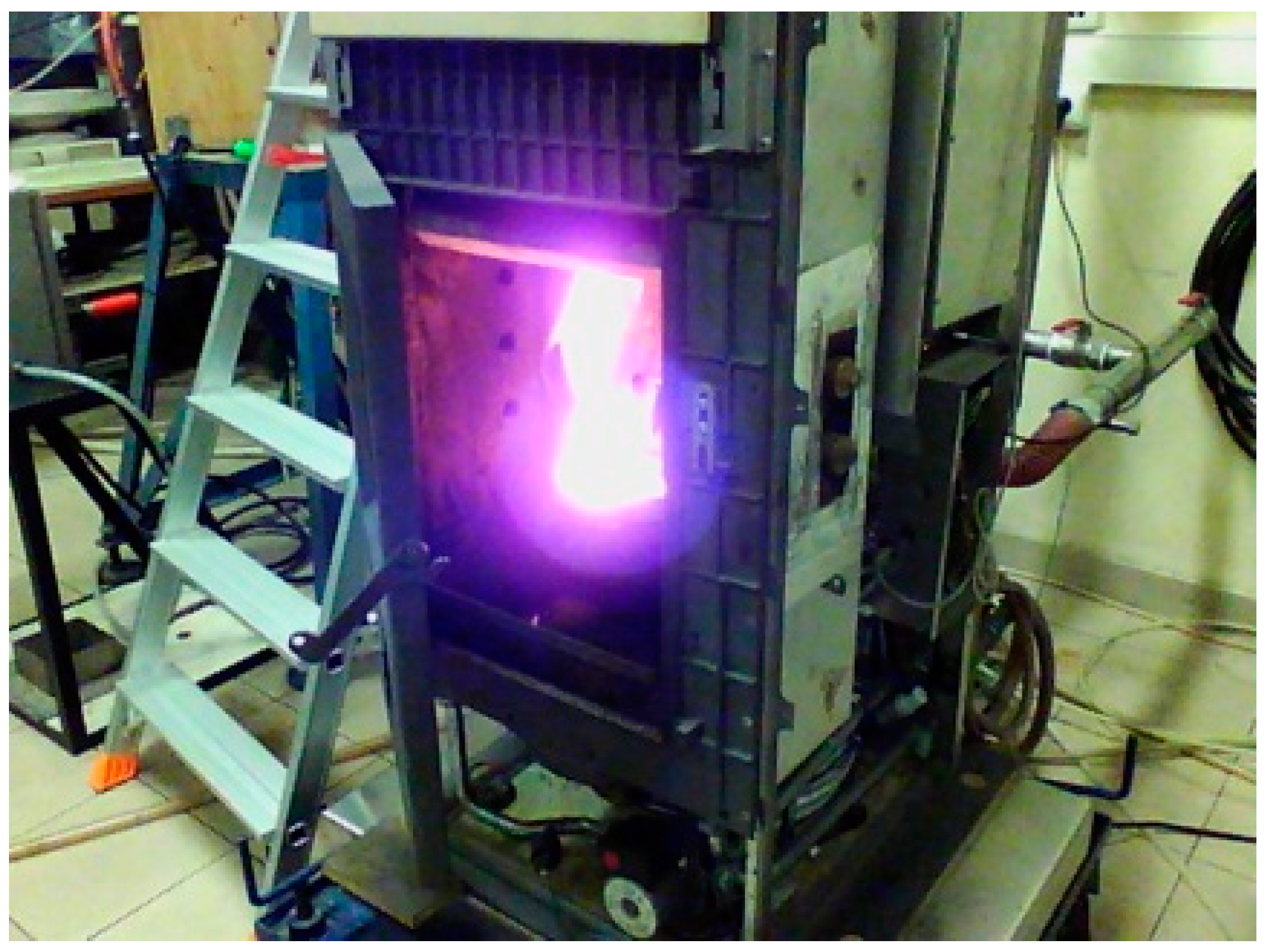

2. Materials and Methods

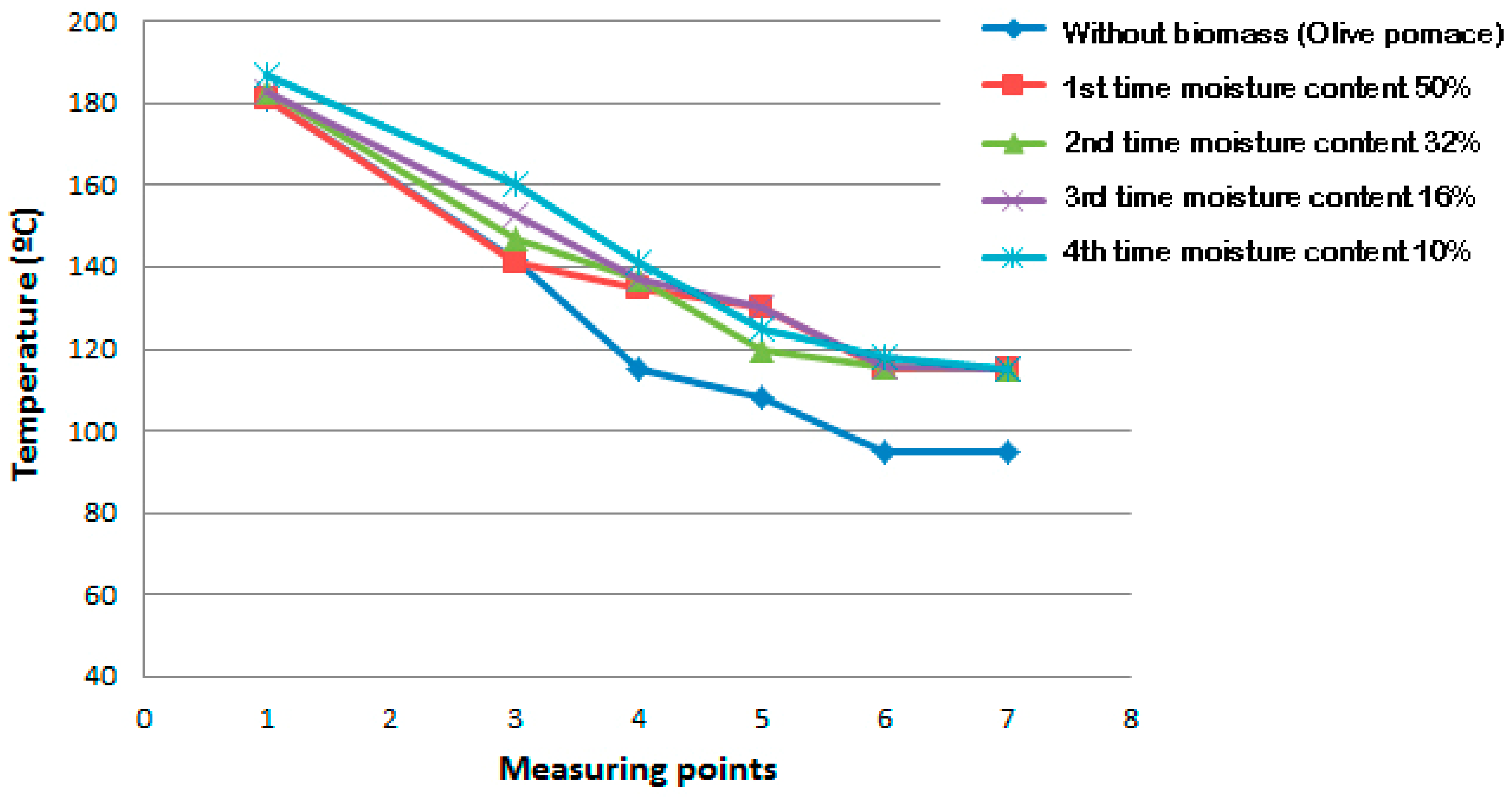

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Romero, S.R.; Santos, A.C.; Gil-Castro, M.A. EU plans for renewable energy. An application to the Spanish case. Renew. Energy 2012, 43, 322–330. [Google Scholar] [CrossRef]

- Del Río González, P. Ten years of renewable electricity policies in Spain: An analysis of successive feed-in tariff reforms. Energy Policy 2008, 36, 2917–2929. [Google Scholar] [CrossRef]

- Moreno, B.; Lopez, A.J. The effect of renewable energy on employment. The case of Asturias (Spain). Renew. Sustain. Energy Rev. 2008, 12, 732–751. [Google Scholar] [CrossRef]

- Shinners, K.; Friede, J. Energy Requirements for Biomass Harvest and Densification. Energies 2018, 11, 780. [Google Scholar] [CrossRef]

- Kadiyala, A.; Kommalapati, R.; Huque, Z. Evaluation of the Life Cycle Greenhouse Gas Emissions from Different Biomass Feedstock Electricity Generation Systems. Sustainability 2016, 8, 1181. [Google Scholar] [CrossRef]

- Field, C.B.; Campbell, J.E.; Lobell, D.B. Biomass energy: The scale of the potential resource. Trends Ecol. Evol. 2008, 23, 65–72. [Google Scholar] [CrossRef] [PubMed]

- Demirbas, A. Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Al-Kassir, A.; Gañán, J.; Tinaut, F.V. Theoretical and experimental study of a direct contact thermal screw dryer for biomass residues. Appl. Therm. Eng. 2005, 25, 2816–2826. [Google Scholar] [CrossRef]

- Roos, C.J. Biomass Drying and Dewatering for Clean Heat & Power; Northwest CHP Application Center: Olympia, WA, USA, 2008. [Google Scholar]

- Zabaniotou, A.A. Simulation of forestry biomass drying in a rotary dryer. Dry. Technol. 2000, 18, 1415–1431. [Google Scholar] [CrossRef]

- Liu, Y.; Aziz, M.; Kansha, Y.; Bhattacharya, S.; Tsutsumi, A. Application of the self-heat recuperation technology for energy saving in biomass drying system. Fuel Process. Technol. 2014, 117, 66–74. [Google Scholar] [CrossRef]

- Svoboda, K.; Martinec, J.; Pohorely, M.; Baxter, D. Integration of biomass drying with combustion/gasification technologies and minimization of emissions of organic compounds. Chem. Pap. 2009, 63, 15–25. [Google Scholar] [CrossRef]

- Waje, S.S.; Thorat, B.N.; Mujumdar, A.S. Study of residence time distribution in a pilot scale screw conveyor dryer. Dry. Technol. 2007, 25, 249–259. [Google Scholar] [CrossRef]

- Waje, S.S.; Thorat, B.N.; Mujumdar, A.S. Hydrodynamic characteristics of a pilot scale screw conveyor dryer. Dry. Technol. 2007, 25, 609–616. [Google Scholar] [CrossRef]

- Gimelli, A.; Luongo, A.; Amoresano, A. Experimental Data and Thermodynamic Analysis of Biomass Steam Power Plant with Two Different Configurations Plant. Int. Rev. Mech. Eng. 2012, 6, 1109–1116. [Google Scholar]

- Aziz, M.; Prawisudha, P.; Prabowo, B.; Budiman, B.A. Integration of energy-efficient empty fruit bunch drying with gasification/combined cycle systems. Appl. Energy 2015, 139, 188–195. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Zhou, Y.; Dong, R. The Influences of Various Testing Conditions on the Evaluation of Household Biomass Pellet Fuel Combustion. Energies 2018, 11, 1131. [Google Scholar] [CrossRef]

- Gimelli, A.; Luongo, A. Thermodynamic and experimental analysis of a biomass steam power plant: Critical issues and their possible solutions with CCGT systems. Energy Procedia 2014, 45, 227–236. [Google Scholar] [CrossRef]

- García-Sanz-Calcedo, J.; Cuadros, F.; López, F. Eficiencia de una caldera de biomasa en un centro hospitalario. Aprovechamiento de huesos de aceitunas triturados para producción de calor. Dyna 2011, 86, 343–349. [Google Scholar] [CrossRef]

- García-Sanz-Calcedo, J.; López-Rodríguez, F. Analysis on the Performance of a High Efficiency Administrative Building in Spain. Int. J. Green Energy 2017, 14, 55–62. [Google Scholar] [CrossRef]

- Soltero, V.M.; Chacartegui, R.; Ortiz, C.; Lizana, J.; Quirosa, G. Biomass District Heating Systems Based on Agriculture Residues. Appl. Sci. 2018, 8, 476. [Google Scholar] [CrossRef]

- Ståhl, M.; Granström, K.; Berghel, J.; Renström, R. Industrial processes for biomass drying and their effects on the quality properties of wood pellets. Biomass Bioenergy 2004, 27, 621–628. [Google Scholar] [CrossRef]

- Li, H.; Chen, Q.; Zhang, X.; Finney, K.N.; Sharifi, V.N.; Swithenbank, J. Evaluation of a biomass drying process using waste heat from process industries: A case study. Appl. Therm. Eng. 2012, 35, 71–80. [Google Scholar] [CrossRef]

- Madhlopa, A.; Ngwalo, G. Solar dryer with thermal storage and biomass-backup heater. Solar Energy 2007, 81, 449–462. [Google Scholar] [CrossRef]

- Tolga-Balta, M.; Dincer, I.; Hepbasli, A. Development of sustainable energy options for buildings in a sustainable society. Sustain. Cities Soc. 2011, 1, 72–80. [Google Scholar] [CrossRef]

- Faulkes, D.M. Modelling the optimum thermal store and biomass boiler size for a small communal heating scheme. Build. Serv. Eng. Res. Technol. 2015, 37, 136–147. [Google Scholar] [CrossRef]

- Damartzis, T.; Michailos, S.; Zabaniotou, A. Energetic assessment of a combined heat and power integrated biomass gasification-internal combustion engine system by using Aspen Plus. Fuel Process. Technol. 2012, 95, 37–44. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Renewable fuels and chemicals by thermal processing of biomass. Chem. Eng. J. 2003, 91, 87–102. [Google Scholar] [CrossRef]

- Panepinto, D.; Viggiano, F.; Genon, G. Analysis of the environmental impact of a biomass plant for the production of bioenergy. Renew. Sustain. Energy Rev. 2015, 51, 634–647. [Google Scholar]

- Lleida, J.P.M. La Madera y su Secado Industrial; OIKOS-TAU: Barcelona, Spain, 1991. [Google Scholar]

- Al-Kassir, A. Characterization and preparation of biomass residues. In Energy and Development, Summer International Course; SP-UEX: Caceres, Spain, 2001. [Google Scholar]

- Brammer, J.G.; Bridgwater, A.V. Drying technologies for an integrated gasification bio-energy plant. Renew. Sustain. Energy Rev. 1999, 3, 243–289. [Google Scholar] [CrossRef]

- Fagernäs, L.; Brammerb, J.; Wiléna, C.; Lauerc, M.; Verhoeffd, F. Drying of biomass for second generation synfuel production. Biomass Bioenergy 2010, 34, 1267–1277. [Google Scholar] [CrossRef]

- Norm EN 15407:2011. Combustibles Sólidos Recuperados. Métodos Para la Determinación del Contenido en Carbono (C), Hidrógeno (H) y Nitrógeno (N); AENOR: Madrid, Spain, 2011. [Google Scholar]

- Norm UNE 32019-84. Combustibles Minerales sólidos: Determinación del Contenido en Materias Volátiles; AENOR: Madrid, Spain, 1999. [Google Scholar]

- Norm UNE 32001-81. Hulla y Antracita: Determinación de la Humedad Total; AENOR: Madrid, Spain, 1999. [Google Scholar]

- Norm UNE 32004-84. Combustibles Minerales Sólidos: Determinación de Cenizas; AENOR: Madrid, Spain, 1999. [Google Scholar]

- Kassir Al-Karany, R. Characterization and Preparation of Biomass Residues with Experimental Thermal Drying & Non-Contaminant Combustion. Master’s Thesis, Polytechnic Institute of Portalegre, Portalegre, Portugal, 2013. [Google Scholar]

- Al-Kassir, A.; Gañán, J.; González, J.F.; Kassir Al-Karany, R. Thermal drying of biomass by-products to obtain efficient environmental solutions with higher heating value and combustion efficiency. Curr. Opin. Biotechnol. 2013, S44. [Google Scholar] [CrossRef]

- Al-Kassir, A.; Yusaf, T.; Kassir Al-Karany, R.; Hamawand, I. Determination of drying characteristics of biomass residues to be used as a renewable fuel. J. Biotechnol. 2015, 208, S15. [Google Scholar] [CrossRef]

- Gonzalez, J.F.; Ledesma, B.; Alkassir, A.; Gonzalez, J. Study of the influence of the composition of several biomass pellets on the drying process. Biomass Bioenergy 2011, 35, 4399–4406. [Google Scholar] [CrossRef]

| Type Pellet | O2 (% vol.) | CO2 (% vol.) | CO (ppm) | NOx (ppm) | HC (ppm) | Tf (°C) |

|---|---|---|---|---|---|---|

| Pine | 17.4 | 3.2 | 10.7 | 17.5 | 2.2 | 126.7 |

| Cork | 16.4 | 3.7 | 383.4 | 72.5 | 13.8 | 135.6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Kassir, A.; Coelho, P.; García-Sanz-Calcedo, J.; Moral, F.J.; Kassir Al-Karany, R.; Yusaf, T. An Experimental Technology of Drying and Clean Combustion of Biomass Residues. Appl. Sci. 2018, 8, 905. https://doi.org/10.3390/app8060905

Al-Kassir A, Coelho P, García-Sanz-Calcedo J, Moral FJ, Kassir Al-Karany R, Yusaf T. An Experimental Technology of Drying and Clean Combustion of Biomass Residues. Applied Sciences. 2018; 8(6):905. https://doi.org/10.3390/app8060905

Chicago/Turabian StyleAl-Kassir, Awf, Pedro Coelho, Justo García-Sanz-Calcedo, Francisco J. Moral, Raúl Kassir Al-Karany, and Talal Yusaf. 2018. "An Experimental Technology of Drying and Clean Combustion of Biomass Residues" Applied Sciences 8, no. 6: 905. https://doi.org/10.3390/app8060905

APA StyleAl-Kassir, A., Coelho, P., García-Sanz-Calcedo, J., Moral, F. J., Kassir Al-Karany, R., & Yusaf, T. (2018). An Experimental Technology of Drying and Clean Combustion of Biomass Residues. Applied Sciences, 8(6), 905. https://doi.org/10.3390/app8060905