Reliability Study on FRP Composites Exposed to Wet-Dry Cycles

Abstract

:1. Introduction

2. Materials and Methods

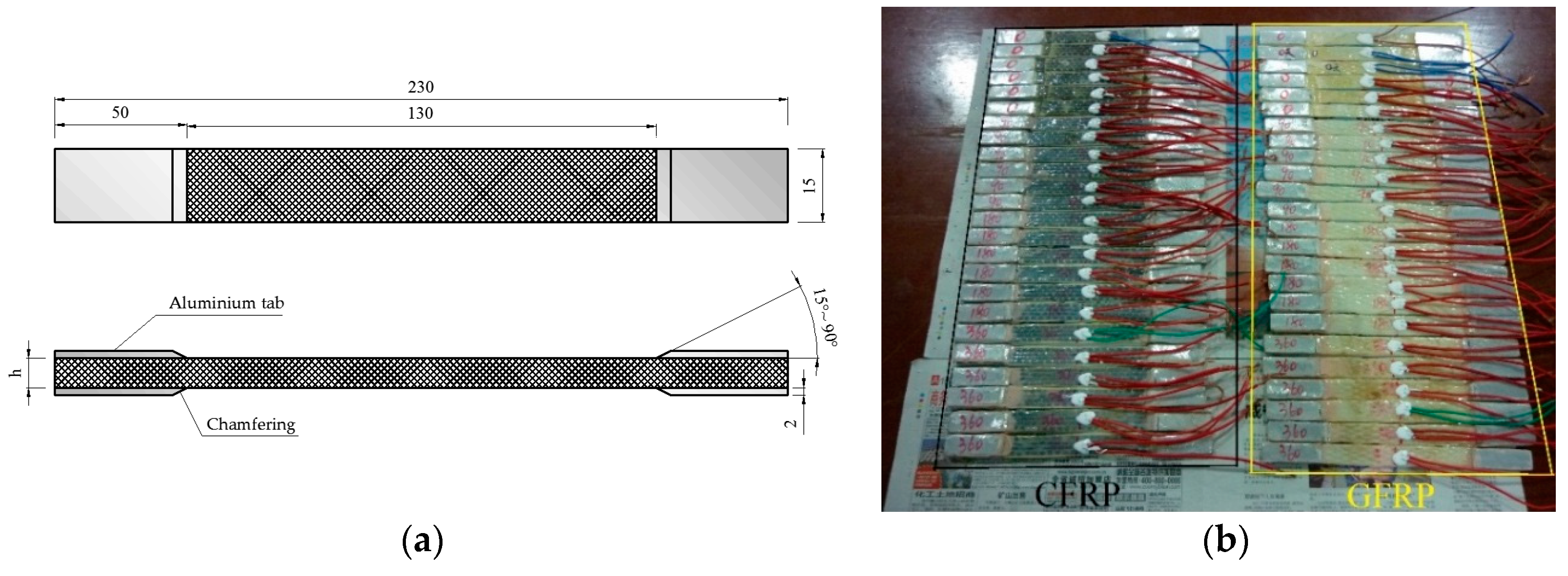

2.1. Specimen Preparation

2.2. Test Apparatus

3. Results

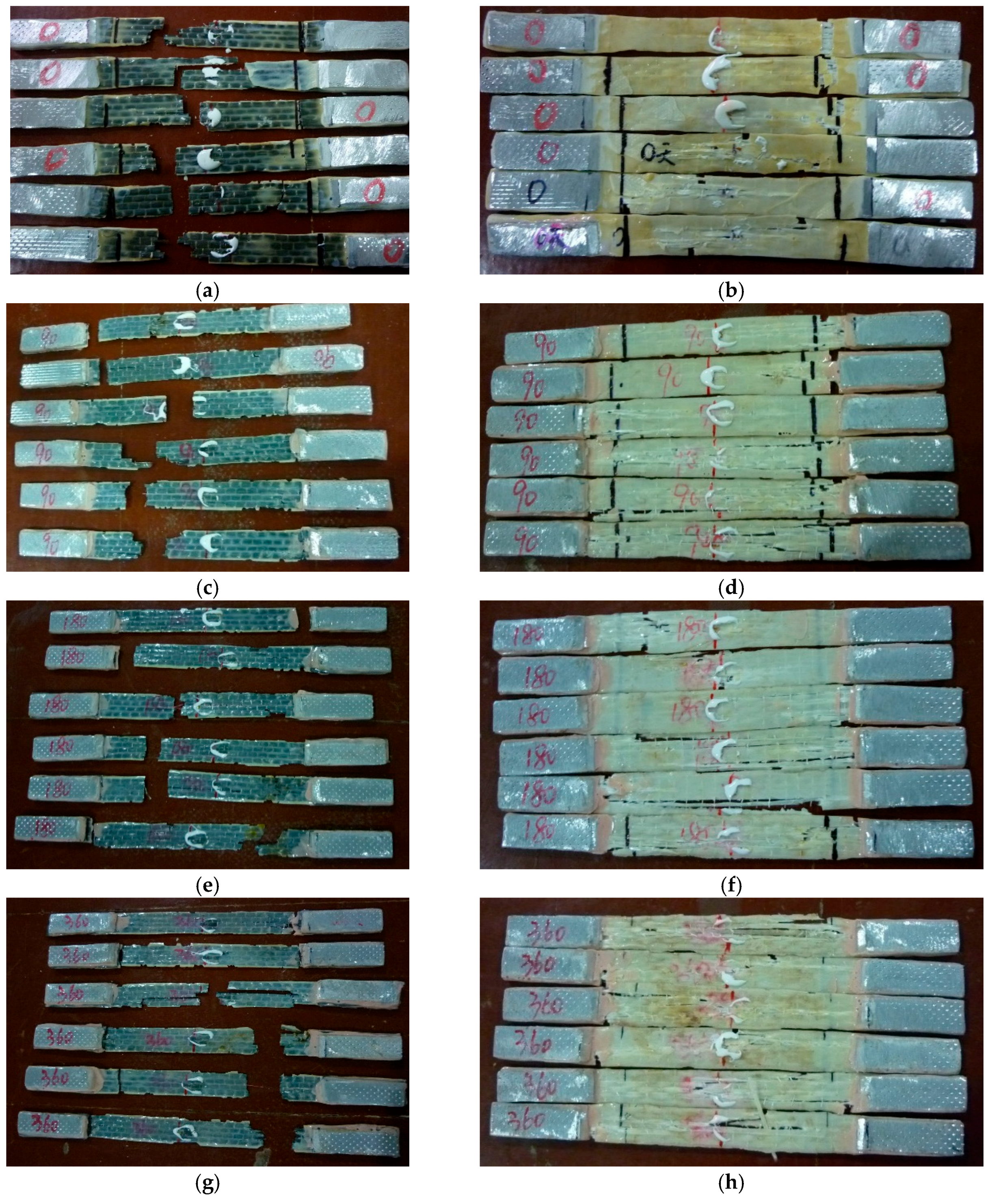

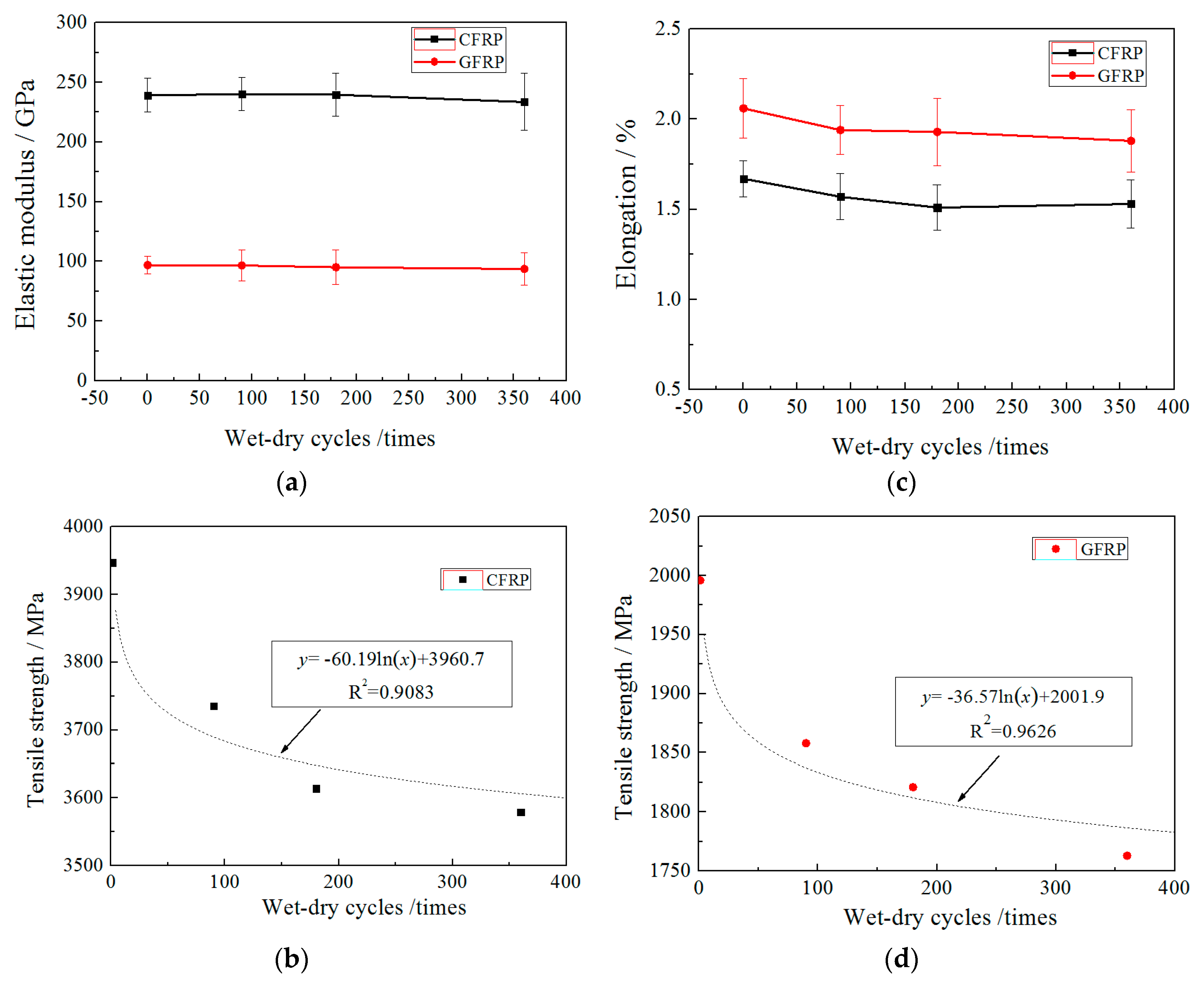

3.1. Experimental Results

3.2. Probability Distribution Type

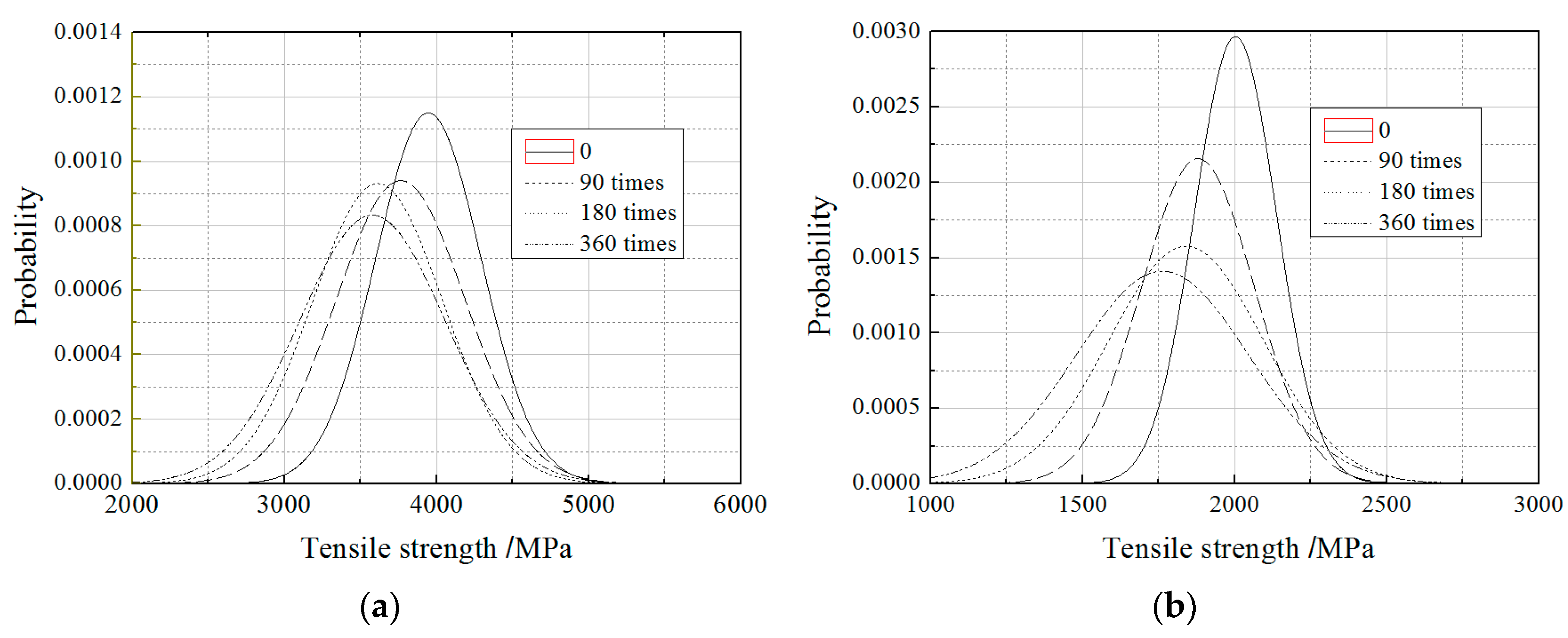

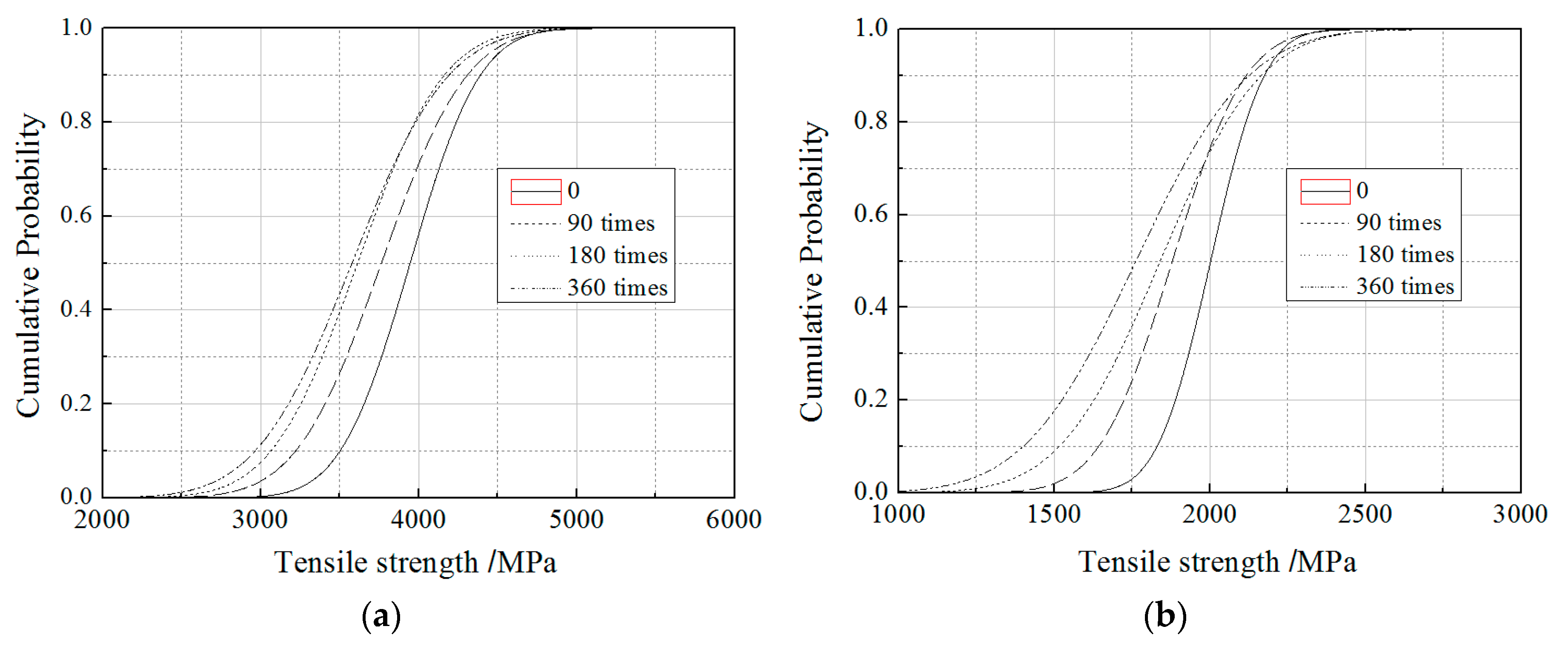

3.3. Probability Distribution

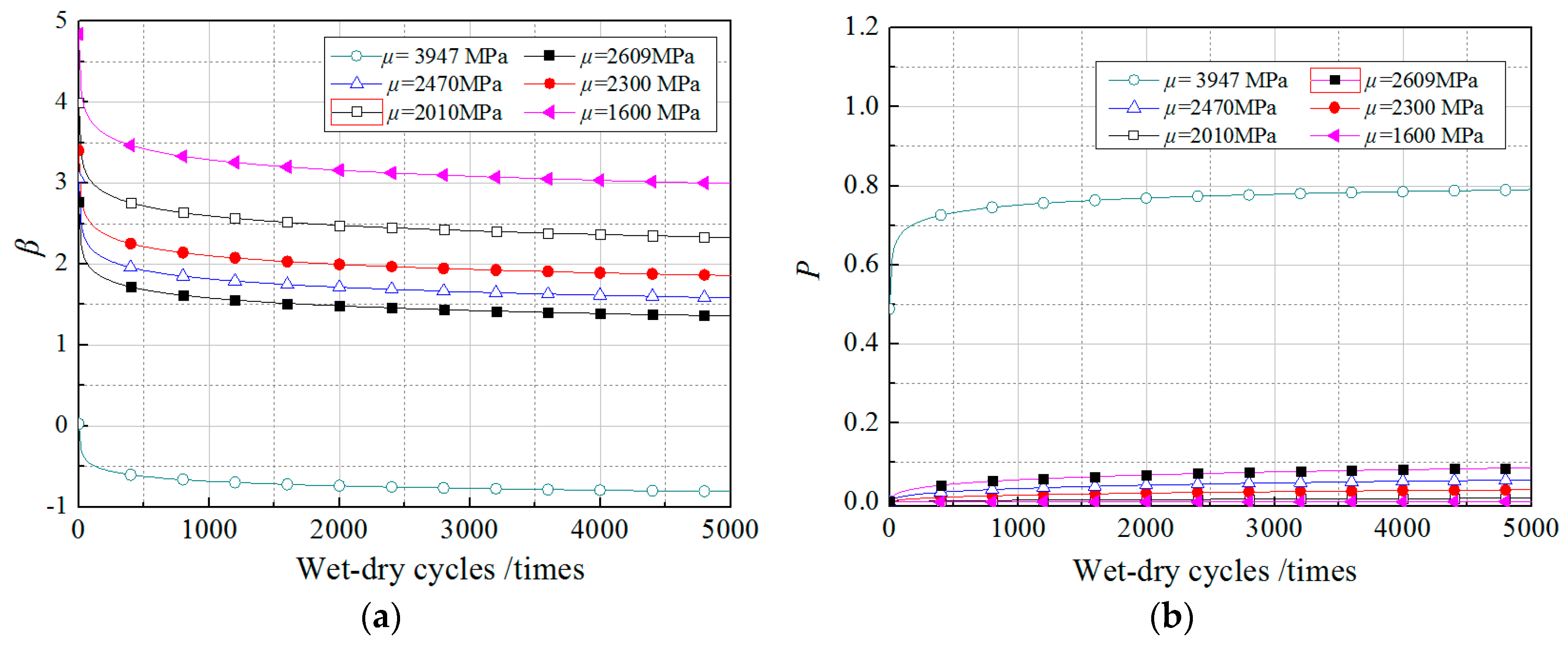

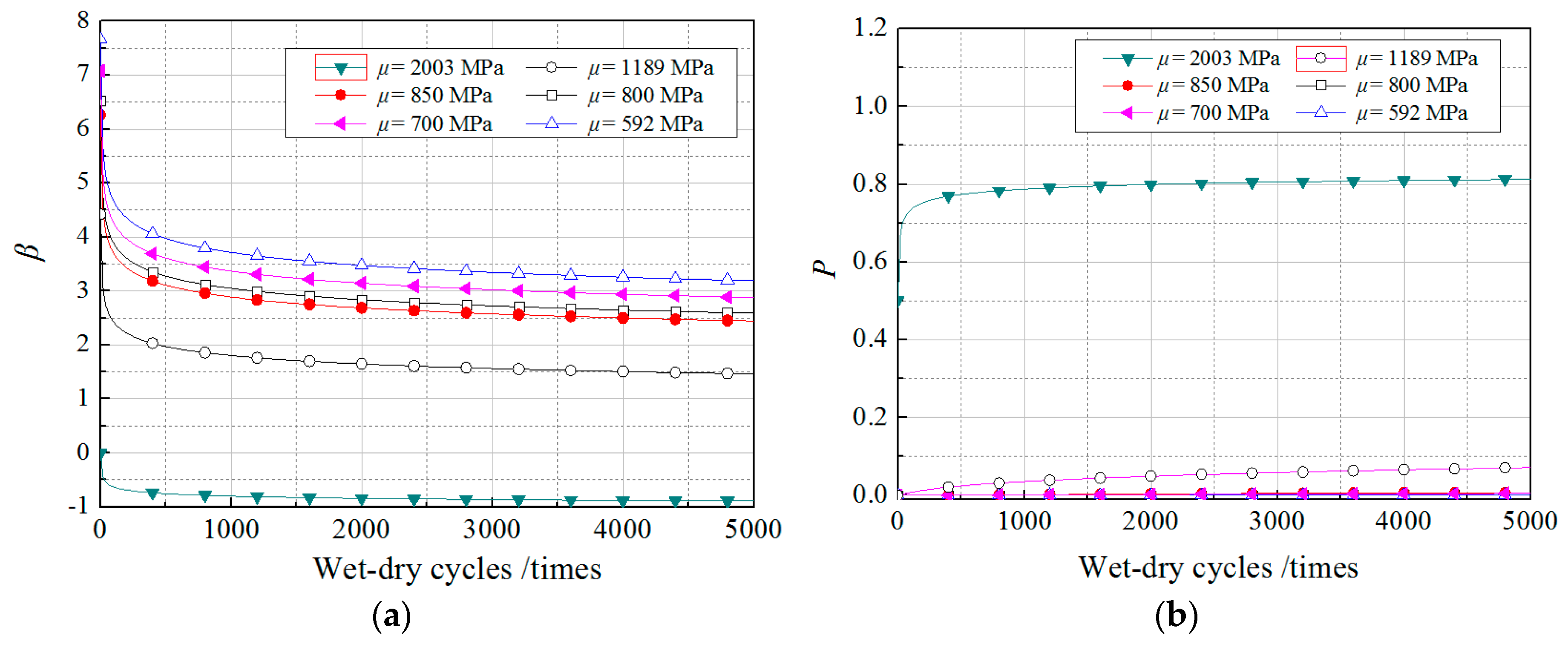

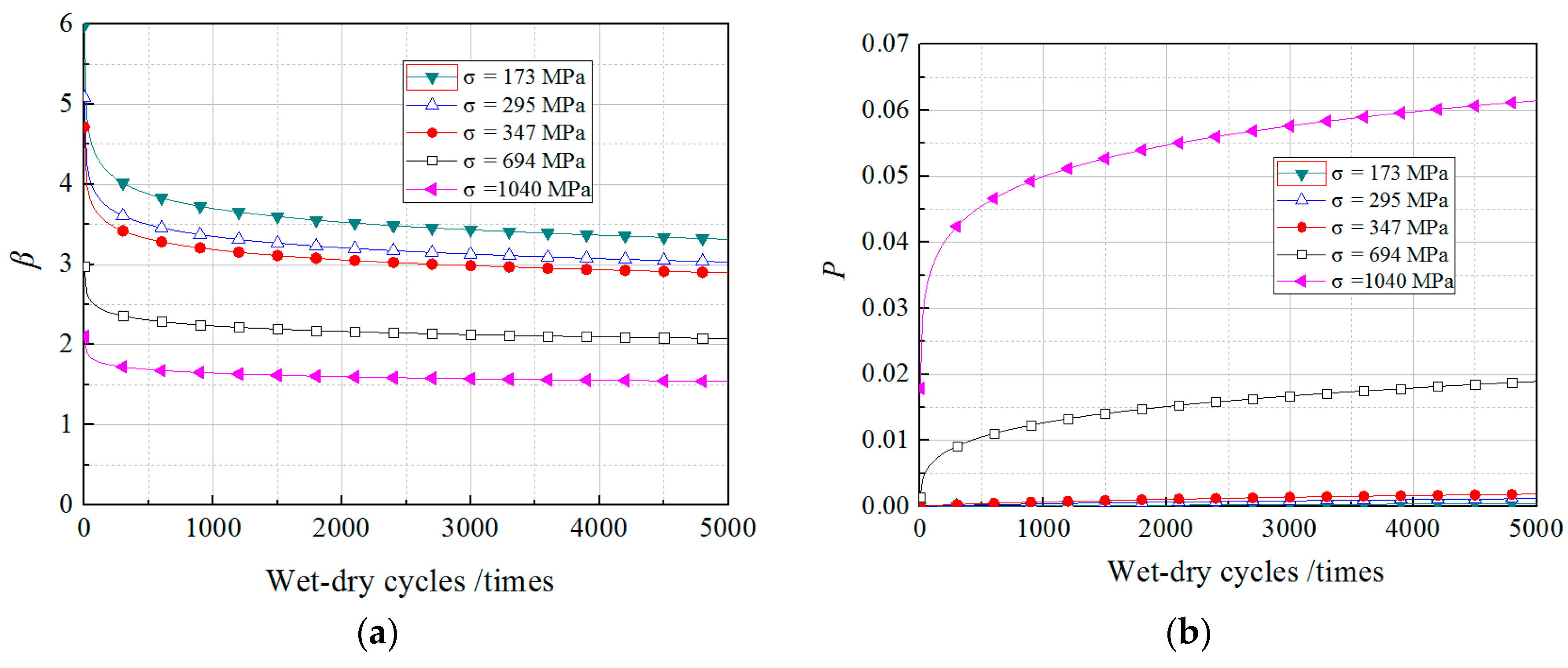

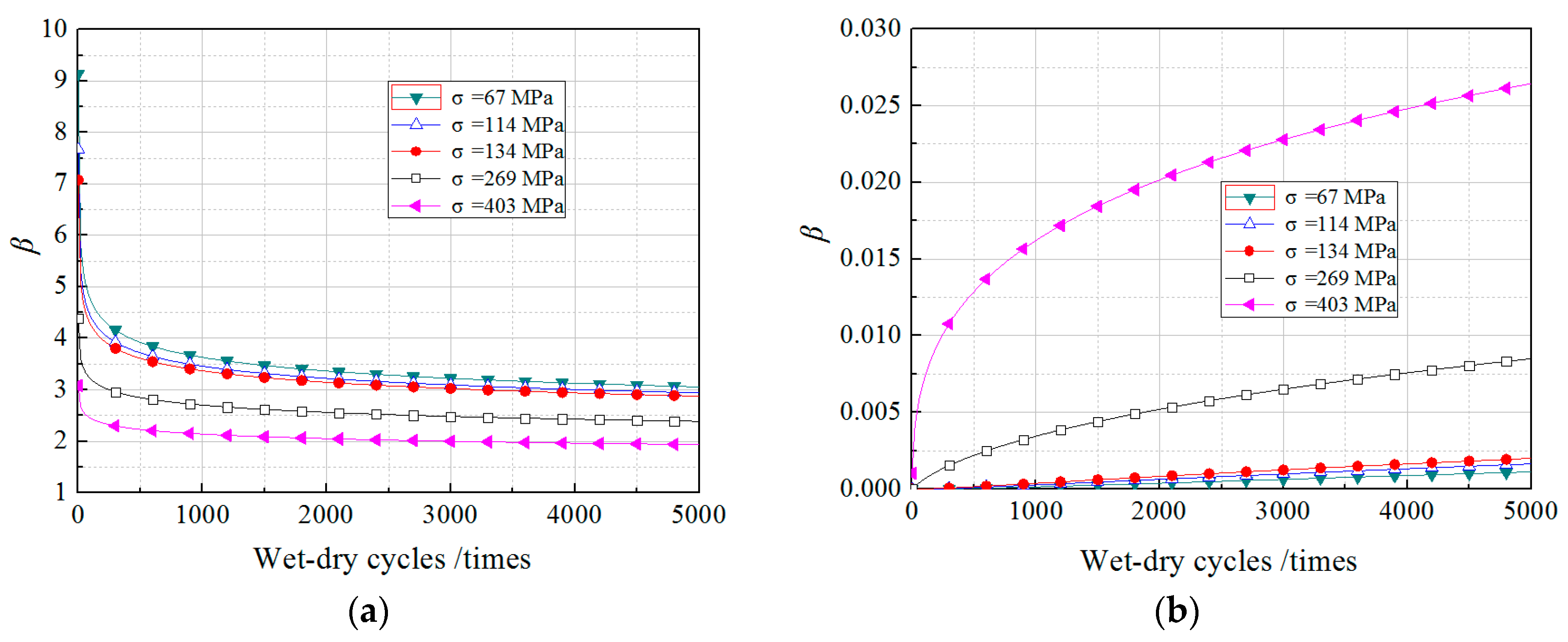

3.4. Reliability Analysis of FRP Strength

4. Discussion

4.1. The Safety Factors for FRP

4.2. The Effects of Mean Values of the Load

4.3. The Effects of Standard Deviations of the Load

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| R | resistance |

| S | load effect |

| Tn(N) | resistance after N times wet-dry cycles |

| Tc(N) | load effect after N times wet-dry cycles |

| mn(N) | mean of Tn(N) |

| σn(N) | standard deviation of Tn(N) |

| mc(N) | mean of Tc(N) |

| σc(N) | standard deviation of Tc(N) |

| f0 | tensile strength without environment exposure |

| f(N) | tensile strength at N times cycle |

| mnC(N) | mean of CFRP strength |

| σnC(N) | standard deviation of CFRP strength |

| mnG(N) | mean of GFRP strength |

| σnG(N) | standard deviation of GFRP strength |

| β | Reliability index |

| P | failure probability |

| γf | partial safety for materials type of GB 50608 |

| γe | partial safety for environment of GB 50608 |

| γmf | partial safety for environment of TR-55 |

| γmm | partial safety for manufacture of TR-55 |

| CE | environmental factor of ACI-440 |

| ffu | design tensile strength of ACI-440 |

| Reported strength of ACI-440 | |

| mean ultimate strength | |

| ffk | characteristic strength of TR-55 |

| ffd | design tensile strength of TR-55 |

| fd | design tensile strength of GB 50608 |

| fk | characteristic strength of GB 50608 |

| f13 | design tensile strength of GB 50367 |

References

- Mansouri, I.; Kisi, O.; Sadeghian, P. Prediction of Ultimate Strain and Strength of FRP-Confined Concrete Cylinders Using Soft Computing Methods. Appl. Sci. 2017, 7, 751. [Google Scholar] [CrossRef]

- Mansouri, I.; Hu, J.; Kisi, O. Novel Predictive Model of the Debonding Strength for Masonry Members Retrofitted with FRP. Appl. Sci. 2016, 6, 337. [Google Scholar] [CrossRef]

- Zhang, D.W.; Shi, H.; Jin, W. Cover separation of CFRP strengthened beam-type cantilevers with steel bolt anchorage. Eng. Struct. 2017, 156, 224–234. [Google Scholar] [CrossRef]

- Zhou, Y.W.; Wu, Y.F.; Yun, Y.C. Analytical modeling of the bond-slip relationship at FRP-concrete interfaces for adhesively-bonded joints. Compos. Part B Eng. 2010, 41, 423–433. [Google Scholar] [CrossRef]

- Liang, H.J.; Li, S.; Lu, Y.Y.; Yang, T. The combined effects of wet–dry cycles and sustained load on the bond behaviour of FRP-concrete interface. Polym. Compos. 2018. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, W.W.; Harries, K.A. Bonding Behaviour of Wet-Bonded GFRP-Concrete Interface. J. Compos. Constr. 2015, 19, 1–14. [Google Scholar] [CrossRef]

- Li, S.; Hu, J.Y.; Ren, H.T. The combined effects of environmental conditioning and sustained load on mechanical properties of wet lay-up fiber reinforced polymer. Polymers 2017, 9, 244. [Google Scholar] [CrossRef]

- Tatar, J.; Hamilton, H.R. Bond Durability Factor for Externally Bonded CFRP Systems in Concrete Structures. J. Compos. Constr. 2016, 20, 1–11. [Google Scholar] [CrossRef]

- Civil Engineering Research Foundation. Gap Analysis for Durability of Fiber Reinforced Polymer Composites in Civil Infrastructure; ASCE: Reston, VA, USA, 2001. [Google Scholar]

- Karbhari, V.M. Response of fiber reinforced polymer confined concrete exposed to freeze and freeze-thaw regimes. J. Compos. Constr. 2002, 6, 35–40. [Google Scholar] [CrossRef]

- Karhari, V.M.; Rivera, J.; Dutta, P.K. Effect of short-term freeze-thaw cycling on composite confined concrete. J. Compos. Constr. 2000, 4, 191–197. [Google Scholar] [CrossRef]

- Xie, J.H.; Lu, Z.Y.; Guo, Y.C.; Huang, Y.H. Durability of CFRP sheets and epoxy resin exposed to natural hygrothermal or cyclic wet-dry environment. Polym. Compos. 2017. [Google Scholar] [CrossRef]

- Akbar, S.; Zhang, T. Moisture diffusion in carbon/epoxy composite and the effect of cyclic hygrothermal fluctuations: Characterization by dynamic mechanical analysis (DMA) and interlaminar shear strength (ILSS). J. Adhes. 2008, 84, 585–600. [Google Scholar] [CrossRef]

- Nardone, F.; Ludovico, M.D.; Basalo, F.J.d.C.y.; Prota, A.; Nanni, A. Tensile behavior of epoxy based FRP composites under extreme service conditions. Compos. Part B Eng. 2012, 43, 1468–1474. [Google Scholar] [CrossRef]

- Rivera, J.; Karbhari, V.M. Characterization of sub-zero response of vinylester FRP in civil infrastructures renewal. In Proceedings of the 11th International Offshore and Polar Engineering Conference, Stavanger, Norway, 17–22 June 2001; pp. 124–130. [Google Scholar]

- Böer, P.; Holliday, L.; Kang, H.K. Independent environmental effects on durability of fiber-reinforced polymer wraps in civil applications: A review. Constr. Build. Mater. 2013, 48, 360–370. [Google Scholar] [CrossRef]

- Wan, B.L.; Petrou, M.F.; Harries, K.A. Effect of the Presence of Water on the Durability of Bond between CFRP and Concrete. J. Reinf. Plast. Compos. 2006, 25, 875–890. [Google Scholar] [CrossRef]

- Hulatt, J.; Hollaway, L.; Thorn, A. Preliminary investigations on the environmental effects on new heavyweight fabrics for use in civil engineering. Compos. Part B Eng. 2002, 33, 407–414. [Google Scholar] [CrossRef]

- Ascione, L.; Berardi, V.P.; Aponte, A. Creep phenomena in FRP materials. Mech. Res. Commun. 2012, 43, 15–21. [Google Scholar] [CrossRef]

- Helbling, C.; Abanilla, M.; Lee, L. Issues of variability and durability under synergistic exposure conditions related to advanced polymer composites in the civil infrastructure. Compos. Part A 2006, 37, 1102–1110. [Google Scholar] [CrossRef]

- Helbing, C.S.; Karbhari, V.M. Investigation of the sorption and tensile response to pultruded E-glass/vinylester composites subjected to hygrothermal exposure and sustained strain. J. Reinf. Plast. Compos. 2008, 27, 613–638. [Google Scholar] [CrossRef]

- TR-55. Design Guidance for Strengthening Concrete Structures Using Fibre Composite Materials; The Concrete Society: Blackwater, UK, 2000. [Google Scholar]

- Wang, N.; Ellingwood, B.R.; Zureick, A.H. Reliability-Based Evaluation of Flexural Members Strengthened with Externally Bonded Fiber-Reinforced Polymer Composites. J. Struct. Eng. 2010, 136, 1151–1160. [Google Scholar] [CrossRef]

- American Concrete Institute. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; ACI Committee 440, Report 440.2R-08; American Concrete Institute: Farmington Hills, MI, USA, 2008. [Google Scholar]

- GB 50608-2010. Technical Code for Infrastructure Application of FRP Composites; China Planning Press: Beijing, China, 2010. (In Chinese) [Google Scholar]

- GB 50367-2013. Design Code for Strengthening Concrete Structure; China Architecture & Building Press: Beijing, China, 2013. (In Chinese) [Google Scholar]

- GB 50728-2011. Safety Appraisal Code for Application of Engineering Structural Strengthening Materials; China Architecture & Building Press: Beijing, China, 2011. (In Chinese) [Google Scholar]

- Rana, D.; Sauvant, V.; Halary, J.L. Molecular analysis of yielding in pure and antiplasticized epoxy-amine thermosets. J. Mater. Sci. 2002, 37, 5267–5274. [Google Scholar] [CrossRef]

- Rana, D.; Mounach, H.; Halary, J.L.; Monnerie, L. Differences in mechanical behavior between alternating and random styrene-methyl methacrylate copolymers. J. Mater. Sci. 2005, 40, 943–953. [Google Scholar] [CrossRef]

- ASTM D3039/D 3039M. Standard TEST Method for Bearing Response of Polymer Matrix Composite Laminates; Society for testing and materials; West Conshohocken: Montgomery, PA, USA, 2008. [Google Scholar]

- Karbhari, V.M.; Abanilla, M.A. Design factors, reliability, and durability prediction of wet layup carbon/epoxy used in external strengthening. Compos. Part B Eng. 2007, 38, 10–23. [Google Scholar] [CrossRef]

- Karbhari, V.M. E-glass/vinylester composites in aqueous environments: Effects on short-beam shear strength. J. Compos. Constr. 2004, 8, 148–156. [Google Scholar] [CrossRef]

- Fib Bulletin 14, FIB TG 9.3 FRPEBR. Externally Bonded FRP Reinforcement for RC Structures; International Federation for Structural Concrete: Lausanne, Switzerland, 2001. [Google Scholar]

- CNR DT200R1. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures; National Research Council: Washington, DC, USA, 2013; Available online: https://www.cnr.it/en/node/2636 (accessed on 29 May 2018).

- GB 50068-2001. Unified Standard for Reliability Design of Building Structures; China Architecture & Building Press: Beijing, China, 2001. (In Chinese) [Google Scholar]

| Samples | Wet-Dry Cycles/days | Numbers | Nominal Thickness/mm | Ultimate Strength/MPa | Young’s Modulus/MPa | Elongation/% |

|---|---|---|---|---|---|---|

| CFRP-0 | 0 | 6 | 0.111 | 3947 | 2.36 × 105 | 1.67 |

| CFRP-90 | 90 | 6 | 0.111 | 3765 | 2.40 × 105 | 1.57 |

| CFRP-180 | 180 | 6 | 0.111 | 3614 | 2.40 × 105 | 1.51 |

| CFRP-360 | 360 | 6 | 0.111 | 3579 | 2.34 × 105 | 1.53 |

| GFRP-0 | 0 | 6 | 0.169 | 2003 | 9.71 × 104 | 2.06 |

| GFRP-90 | 90 | 6 | 0.169 | 1880 | 9.67 × 104 | 1.94 |

| GFRP-180 | 180 | 6 | 0.169 | 1841 | 9.52 × 104 | 1.93 |

| GFRP-360 | 360 | 6 | 0.169 | 1763 | 9.38 × 104 | 1.88 |

| Test Method | Equation |

|---|---|

| S-W test | in which, yi is the ith data when the sample is sorted from small to large, is the sample average, is the expected value of normal distribution according to the sample data, is the covariance matrix for the sample data. |

| K-S test | in which, is the assumed distribution function, is the cumulative frequency function of the sample. |

| C-M test | in which, n is the sample size, is the assumed distribution function. |

| A-D test | in which, is the assumed distribution function. |

| χ2 test | in which, Ai the actual frequency of the sample, Ti is the theoretical frequency of the assumed distribution. |

| Test Method | Normal | Lognormal | Weibull | Gamma |

|---|---|---|---|---|

| a. Goodness of fit for strength of CFRP without wet-dry cycles exposure. | ||||

| S-W test | 0.364 | 0.266 | - | - |

| K-S test | >0.150 | 0.119 | - | - |

| C-M test | 0.125 | 0.096 | 0.142 | - |

| A-D test | 0.166 | 0.124 | 0.219 | - |

| test | 0.326 | 0.271 | 0.407 | 0.274 |

| b. Goodness of fit for strength of GFRP without wet-dry cycles exposure. | ||||

| S-W test | 0.221 | 0.158 | - | - |

| K-S test | >0.150 | >0.150 | - | - |

| C-M test | >0.250 | 0.237 | >0.250 | - |

| A-D test | 0.243 | 0.183 | >0.250 | - |

| test | 0.098 | 0.087 | 0.084 | 0.071 |

| c. Goodness of fit for strength of CFRP with wet-dry cycles exposure. | ||||

| S-W test | 0.501 | 0.373 | - | - |

| K-S test | >0.150 | >0.150 | - | >0.250 |

| C-M test | >0.250 | >0.250 | >0.250 | >0.250 |

| A-D test | >0.250 | >0.250 | >0.250 | >0.250 |

| test | 0.244 | 0.152 | 0.319 | 0.148 |

| d. Goodness of fit for strength of GFRP with wet-dry cycles exposure. | ||||

| S-W test | 0.594 | 0.226 | - | - |

| K-S test | >0.150 | 0.103 | - | 0.167 |

| C-M test | >0.250 | 0.175 | >0.250 | >0.250 |

| A-D test | >0.250 | 0.204 | >0.250 | >0.250 |

| test | 0.114 | 0.062 | 0.220 | 0.073 |

| FRP Type | Mean Value (MPa) | Std. Dev. (MPa) | (MPa) | ffk(MPa) | fk(MPa) | Design Value (MPa) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ACI-440 (ffu) | TR-55 (ffd) | GB 50608-2010 (fd) | GB 50367-2013 (f13) | Fib Bulletin (ffd,fib) | Italian CNR (Xd) | ||||||

| CFRP | 3947 | 347 | 2906 | 3253 | 3376 | 2470 | 1660 | 2010 | 2300 | 2501 | 2609 |

| GFRP | 2003 | 134 | 1600 | 1734 | 1783 | 800 | 847 | 795 | 700 | 1189 | 810 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, H.; Li, S.; Lu, Y.; Yang, T. Reliability Study on FRP Composites Exposed to Wet-Dry Cycles. Appl. Sci. 2018, 8, 892. https://doi.org/10.3390/app8060892

Liang H, Li S, Lu Y, Yang T. Reliability Study on FRP Composites Exposed to Wet-Dry Cycles. Applied Sciences. 2018; 8(6):892. https://doi.org/10.3390/app8060892

Chicago/Turabian StyleLiang, Hongjun, Shan Li, Yiyan Lu, and Ting Yang. 2018. "Reliability Study on FRP Composites Exposed to Wet-Dry Cycles" Applied Sciences 8, no. 6: 892. https://doi.org/10.3390/app8060892

APA StyleLiang, H., Li, S., Lu, Y., & Yang, T. (2018). Reliability Study on FRP Composites Exposed to Wet-Dry Cycles. Applied Sciences, 8(6), 892. https://doi.org/10.3390/app8060892